HARDWOOD MATTERS

April 2023

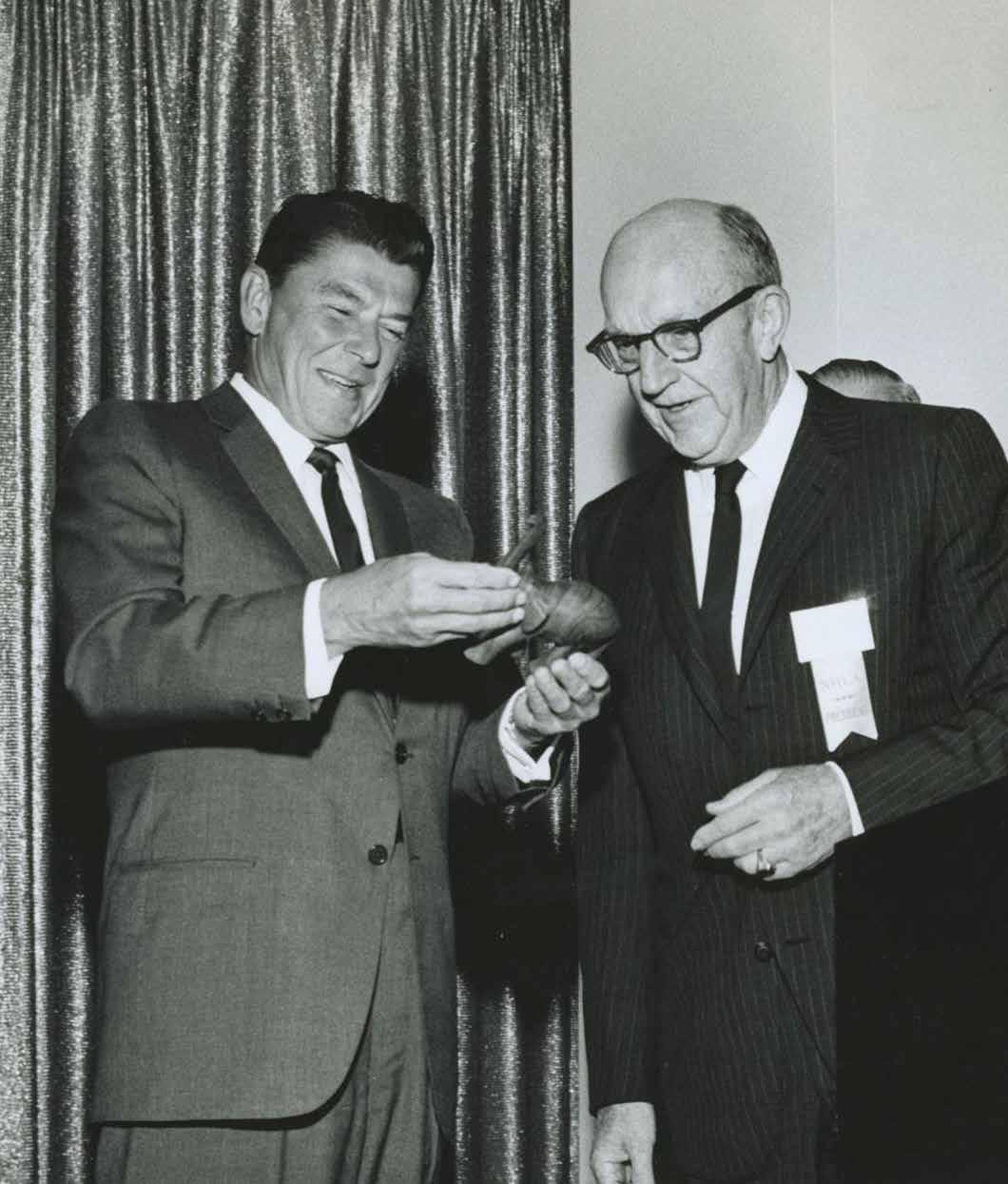

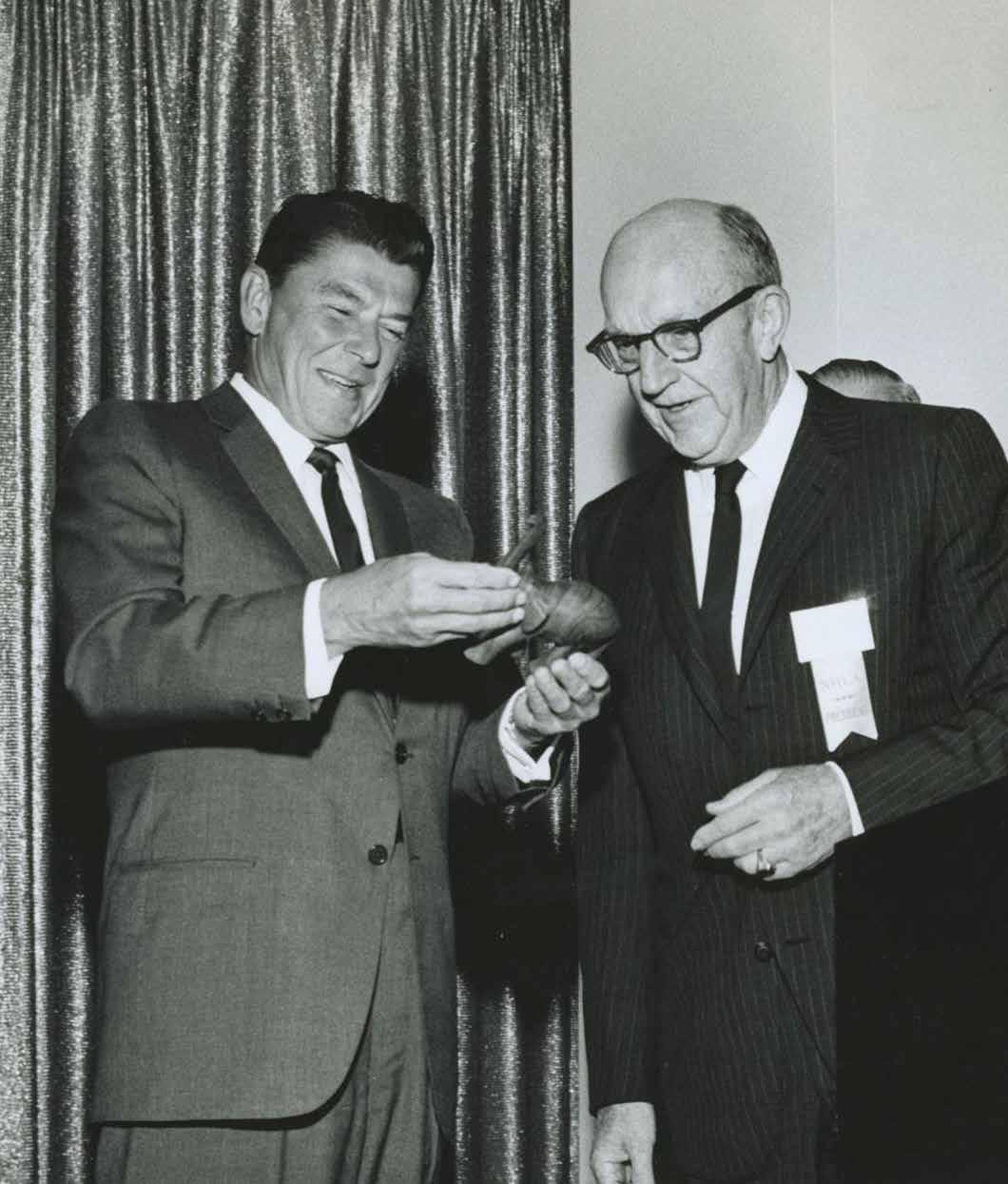

President Ronald Regan is presented a wooden elephant by sitting NHLA president L. D. Kellogg at the 71st NHLA Annual Convention

THE VOICE OF THE HARDWOOD INDUSTRY

VISIT DMSi.COM TO LEARN MORE

TIMBER, LOGGING & LUMBER Handheld & desktop software HARDWOOD END TALLIES Mobile app with A.I. DISTRIBUTION AND RETAIL Inventory and order management

ONE SOFTWARE PARTNER FROM TIMBER TO CONSUMER

EXECUTIVE COMMITTEE

Jon Syre, Chairman Cascade Hardwood, LLC

Bucky Pescaglia, Vice Chairman Missouri-Pacific Lumber Co., Inc.

Jeff Wirkkala, Past Chairman 2020-2022 Hardwood Industries, Inc.

MISSION LEADERS

Sam Glidden, Unique Services GMC Hardwoods, Inc.

Ray White, Rules Harold White Lumber Inc.

Joe Pryor, Industry Advocacy & Promotion Oaks Unlimited

Rich Solano, Structure Pike Lumber Company, Inc.

Stephanie VanDystadt, Membership & Networking DV Hardwoods, Inc.

COMMITTEE CHAIRS

Burt Craig, Membership Matson Lumber Company

Rob Cabral, Promotion & Advocacy Upper Canada Forest Products, Ltd.

Dennis Mann, Convention Baillie Lumber Co.

Tom Oiler, Inspection Services Cole Hardwood, Inc.

Brant Forcey, ITS/Continuing Education Forcey Lumber Company

George Swaner, Communications & Marketing Swaner Hardwood Co., Inc.

Joe Snyder, Rules Fitzpatrick & Weller, Inc.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 1 CONTENTS April 2023 • Issue 243 feature 14 NHLA: Celebrating 125 Years of Service to the Hardwood Lumber Industry by Amanda Boutwell Marketing Communications Manager departments 4 One Common Ground Proof that NHLA Improves Your Value by Dallin Brooks, Executive Director 6 Inside NHLA 7 Member of the Month 8 Accolades 9 Education Spotlight Congratulations to the Graduates of the 201st Class 10 Legislative Log Congress Gears Up for Farm Bill 2023 by Dana Cole Executive Director Hardwood Federation 12 Member Spotlight USNR 19 Rules Corner Making the Grade by Dana Spessert, Chief Inspector WHAT'S INSIDE Follow us 6 9 14 reader services 3 Chairman’s Message 20 Educational Calendar 21 NHLA Job Board 24 Market Trends

HARDWOOD MATTERS

THE VOICE OF THE HARDWOOD INDUSTRY

National Hardwood Lumber Association PO Box 34518 • Memphis, TN 38184-0518 901-377-1818 • 901-382-6419 (fax) info@nhla.com • www.nhla.com

THE MISSION OF NHLA

To serve NHLA Members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public/private policy issues; and providing a platform for networking opportunities.

NHLA STAFF

Dallin Brooks, Executive Director dallin@nhla.com

John Hester, Chief Development Officer j.hester@nhla.com

Renee Hornsby, Chief Operating Officer r.hornsby@nhla.com

Dana Spessert, Chief Inspector d.spessert@nhla.com

ACCOUNTING

Desiree Freeman, Controller d.freeman@nhla.com

Jens Lodholm, Data Administration Specialist j.lodholm@nhla.com

Amber Signaigo, Assistant Controller a.signaigo@nhla.com

INDUSTRY SERVICES

Mark Bear, National Inspector m.bear@nhla.com

Tom Byers, National Inspector t.byers@nhla.com

Mark Depp, National Inspector m.depp@nhla.com

Kevin Evilsizer, National Inspector k.evilsizer@nhla.com

For advertising contact: John Hester j.hester@nhla.com or 901-399-7558

Vicky Simms v.simms@nhla.com or 901-399-7557

“Whitson Lumber Company has been a member of NHLA for 104 years because of the multiple benefits that we receive. There are always new members to meet at the conventions. We like to send employees to the Inspector Training School and other classes. The marketing efforts that NHLA coordinates for our entire industry are something every lumberman should support - whether NHLA is educating the rest of the world about North American Hardwoods or telling our story to domestic architects, designers, and homeowners. It seems to me that NHLA is the flagship organization to do this”

Simon Larocque, National Inspector s.larocque@nha.com

Benji Richards, Industry Services Sales Manager b.richards@nhla.com

INSPECTOR TRAINING SCHOOL

Geoff Webb, Dean of the Inspector Training School g.webb@nhla.com

Roman Matyushchenko, Instructor of the Inspector Training School r.matyushchenko@nhla.com

MARKETING/COMMUNICATIONS

Amanda Boutwell, Marketing and Communications Manager a.boutwell@nhla.com

Melissa Ellis Smith, Art Director m.ellis@nhla.com

Rachel Spiers Blossman, Digital Media Specialist r.blossman@nhla.com

MEMBERSHIP

Julia Ganey, Member Relations Manager j.ganey@nhla.com

Vicky Quiñones Simms, Membership Development Manager v.simms@nhla.com

2 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

INDEX IFC DMSi/eLimbs/TallyExpress 5 King City Forwarding USA BC NWH IBC Pike Lumber Company, Inc. 23 U•C Coatings 11 Wood-Mizer

ADVERTISER

— Albert Whitson, Whitson Lumber Company | 104-year member

SOLVING THE MYSTERY OF YIELD

The art of the sale. If you Google that, it seems everyone has an opinion on what exactly defines the art of the sale. How to increase sales? How to make the buying decision go your way versus your competitor’s? How to make the first sale lead to the second?

Specifically, for the hardwood industry, and more specifically for the primary manufacturers in the hardwood industry, how do we make our products more appealing to our customers? Due to the competitive nature of our businesses, what can I do to make my offering stand out above the others?

I am willing to bet our customers want a consistently high-quality product at a fair price. Along with those attributes, our customers want a product that makes sales to their customers easier and more profitable. How can I make my customer’s job easier? If I can do that, I suspect additional sales will come.

In October 2018, then NHLA President Brent Stief wrote an article in Hardwood Matters that really resonated with me. He brought up the question of random widths versus standardized widths. His comments have stayed with me for several years. I have visited some of our customers and watched them process our random-width products. The customer must be highly skilled and strategic about each board and strive to get the highest yield solution for every board. How can I make this easier for them?

Some industry competitors, notably plywood, MDF, and plastic manufacturers, can provide the advantage of yield consistency. Customers will know what they can yield from each panel of MDF, for example. Our hardwood products have a superior environmental and durability story to tell, but the yield mystery can make the sale decision a bit more challenging.

What if we took a little of the randomness out of random width? Would that make the purchasing decision a little easier for your customer?

For example, in manufacturing cabinetry, a lot of manufacturers use a door rail or face frame material that is approximately 2-1/2” wide. Most generally rip a blank slightly over this width, then mold the blank before cutting to their length needs. So ideally, multiples of this 2-5/8” ripped blank can help maximize yields. Multiples help in our high-wage environment as one piece can make 2x rips, 3x rips, or even 4x rips (except in my mill, those of you familiar with Alder know we don’t get a lot of 12” wide lumber) while at the same time decreasing the number of pieces through the saw improving both yield and productivity.

The same holds true for furniture manufacturers. A lot of production furniture plants rely heavily on 3” wide parts. So here, the better width might be 7” or 10”, but still, there is a sweet spot that enhances yield and efficiency.

So, the challenge is multi-faceted for our industry. Are we adequately training salespeople to understand the manufacturing capabilities of their employer so that they can work hand-in-hand with the downstream manufacturer on optimized yield solutions? Do salespeople understand the manufacturing processes at the cabinet, furniture, molding, and millwork plants deeply enough to help steer their mill to optimized widths? Are operations people learning how our products are being used and looking at opportunities to tweak processes upstream to generate both margins and efficiency in hardwood-using manufactured products? We are a random width industry, but more and more of us are looking to offer rip solutions to our customers.

This is not a new idea. The strip flooring people have been sawing ties alongside low-grade Oak for years, optimizing the ripping of blanks to make 2-1/4” and 3-1/4” strip flooring. Ask the people you know that run both sawmills and flooring plants. Nearly all will share that they took the random out of random width long ago.

We train lumber inspectors; that is one of the primary missions of NHLA. That is why NHLA has been offering classes on yield at the sawmill level for several years. Maybe it’s time to expand our mission and start offering training options for the salespeople and mill operations people of tomorrow. Our resource is valuable yet underutilized. If we can work hand in hand with manufacturers to expand the use of hardwoods by making it easier and more profitable to do so, shouldn’t we look at what we can offer? Twenty-five years ago, North American hardwood lumber production was double or more than what it is today. Might this be one reason why?

Thank you for taking the time to read my letter. I hope it leads you to think about ways to improve yield. I also hope this letter increases your involvement in the NHLA by voicing your agreement or disagreement with the above thoughts and expressing your opinions on how we, as an industry, can recover market share. Best wishes to you, your families, and your business.

Jon Syre NHLA Chairman | Cascade Hardwood

WWW.NHLA.COM CHAIRMAN’S MESSAGE

PROOF THAT NHLA IMPROVES YOUR VALUE

By DALLIN BROOKS, Executive Director

The National Hardwood Lumber Association is 125 years old as of April 8, 2023. That is a great accomplishment because of what it proves. It proves that NHLA is needed. It proves that NHLA has value. It proves that NHLA improves your business.

How does NHLA improve your business? First and foremost, NHLA is the steward of the hardwood lumber grading Rules. Rules that have existed for 125 years. Rules that are reevaluated and changed every four years by the members of NHLA. Rules that are printed in 6 different languages. Rules that ensure you know what you are selling and ensure that your customers know what they are buying. Keeping the government out of your grading Rules improves your business value.

The second way NHLA improves your business is through the Inspector Training School and the Inspection Services Department. If you have hardwood lumber grading Rules, you need to ensure that people know them and that they are being followed. Over the last 20 years, NHLA Inspector Training School has trained almost 1,000 new inspectors. The Inspector Training School is also celebrating a milestone this year with its 75th Anniversary. While we struggle as an industry with a labor shortage, the School is critical to teaching the trades that inspect your grades and improves your business value.

There is a tie for third place between the NHLA Kiln Drying (KD) Certification and the Yield Recovery/Quality Control Services. The KD Certification achieves the same goals as the APHIS Phytosanitary Certificate for exports at a lower cost to your business. This program is underutilized and needs more members to participate for it to grow even more.

The Yield Recovery and Quality Control quality Services that NHLA offers mills improve operational efficiency. This program comes with high marks for success and even benefits members who already have a quality program in place. Production is the one area where even small improvements can have a big impact and prove the value of NHLA knowledge is worth it.

Outside of lumber services, NHLA improves your business with its support of Educational Services, especially promotion and advocacy efforts by the Real American Hardwood Coalition and the Hardwood Federation. These efforts are critical to growing your markets and keeping regulatory and legislative impacts minimal. NHLA is the biggest association contributing to these efforts and participates with them to ensure your voice is heard, so your business grows and adapts to the changing landscape. Working together, we can do more than working alone; that improves your business too.

Building on the promotion collaboration is the importance of networking with allied associations and together as an industry at the NHLA Annual Convention and Exhibition Showcase. These interactions are critical to influencing all aspects of the hardwood industry and creating social and business relationships with customers and suppliers that improve your business.

Finally, NHLA is going to prove this year and for another 125 years that WE can help grow and stabilize the hardwood industry. If your livelihood and legacy are to build a hardwood business that lasts, then NHLA should think 125 years ahead too. Because, in futuristic movies - they don’t harvest the trees or use wood 125 years from now. What a misleading fact of life. Forests are always changing, and we need to prove to the world that hardwoods are for life and legacy beyond years and into centuries.

There is so much more that NHLA does that is not seen by you, yet you benefit from the NHLA being in business. To that end . . . Why Knot Prove that the NHLA Improves Your Value.

Dallin Brooks NHLA Executive Director dallin@nhla.com | 360-823-3898

4 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM ONE COMMON GROUND

YOU SAW IT, WE

SHIP IT.

CONTACT US TODAY FOR COMPETITIVE RATES AND UNPARALLELED SERVICE SINCE 1977!

USA: 1-855-682-1637

LLOVETT@KINGCITYUSA.COM

CANADA: 1-800-355-5394

PLOVETT@KINGCITYNORTHWAY.COM

TAKING THE REINS

As of February 12, 2023, James W. (Jim) Steen will step down as President of Pike Lumber Company in Akron, Indiana, handing the reins to Craig M. Brouyette (pictured left), who has served as Executive Vice President for the last eight years. Chris Herrell is promoted to Executive Vice President /Vice President of Operations.

Steen will take on a part-time role working on operational efficiencies and special projects while continuing to serve as a member of the Pike Lumber Company Board of Directors.

Craig Brouyette has worked for Pike Lumber Company since 2002. He graduated from Manchester College with a B.S. in Business Administration and began his Pike Lumber career in sales and has served as Sales Manager and Executive Vice President. He continues as a member of the Board of Directors. Craig is passionate about the hardwood industry and is finishing his term as President of the Indiana Hardwood Lumbermen’s Association. He has also served as IHLA Forestry Council President and will continue as a member of IHLA’s executive committee.

Chris Herrell has worked for Pike Lumber Company in different roles, starting in 2002. Before this, Chris graduated from Purdue University with a B.S. in Business Administration. Chris started his career as the Kiln Dried Processing Supervisor. He has served as the Akron Production Manager and Vice President of Operations.

Pike Lumber Company Inc is northern Indiana’s largest manufacturer and distributor of kiln-dried hardwood lumber. Established in 1904, Pike continues to provide area landowners with forest management services while marketing kiln-dried lumber worldwide

HAPPY BIRTHDAY IHLA!

NHLA attended the IHLA Annual Convention February 6-9 and it was an excellent opportunity for NHLA to network with our members and industry friends.

FIND NHLA AT THESE UPCOMING EVENTS

APRIL 30-MAY 3 | NHLA Spring Board Meeting | San Antonio, TX

MAY 15-19 | Ligna | Hannover, Germany

JUNE 9-10 | PA Timber Show | State College, PA

JUNE 13-15 | Fly-In | Washington D.C.

AUGUST 22-24 | Forest Products Expo | Atlanta, GA

“For over a century, the NHLA has helped us stay connected with our colleagues, customers, suppliers, and friends throughout the hardwood industry – especially at the Annual Convention. The Grade standards are quite literally the language of our business, and the Association’s support of critical initiatives is enormously valuable. As we look to the future, we see an ever-increasing need to promote hardwoods as an alternative to petrochemical and other non-renewable building products. As the industry’s most established and respected association, the NHLA is uniquely positioned to lead this promotion, which is of existential importance to all of us.”

— Garner Robinson, CEO Robinson Lumber Company | 104-year member

6 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM INSIDE NHLA

BUSKIRK LUMBER

Member Since 1902

Buskirk Lumber, in Freeport, MI, is the longest-running member of NHLA, signing up for membership 121 years ago. Buskirk employs over 80 individuals and produces over ten-million board feet of lumber a year. They are currently renovating to become one of the largest sawmills in Michigan. Having been in business for over 100 years, Buskirk is a company you can trust to be professional and transparent. NHLA is proud to recognize Buskirk Lumber as our Member of the Month! Thank you for 121 years of membership!

CAN’T MAKE IT TO THE OPEN HOUSE IN PERSON? We have you covered! NHLA will be live streaming our Anniversary festivities on our Facebook page. Make sure you are following us on Facebook (@nhlaofficial), so you receive the notification when we go live.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 7 MEMBER OF THE MONTH OPEN HOUSE NHLA 125th Anniversary Celebration Wednesday, April 12 10:00 am-2:00 pm Official Program & Rededication Ceremony 11:00 am-12:00 pm NHLA Headquarters in Memphis, TN Rsvp Please RSVP to 125years@nhla.com

Call Renee Hornsby 901-399-7560 or email r.hornsby@nhla.com

Questions?

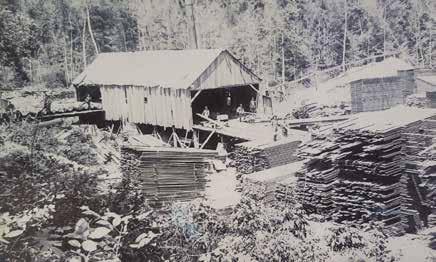

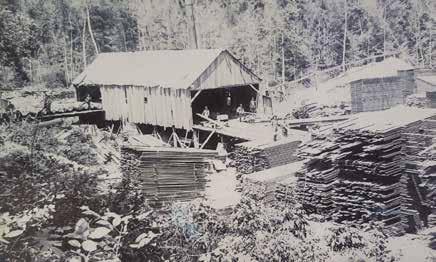

Left: Clarence Buskirk BeLow: Mill and Lumber yard on Cold Water Creek

ACCOLADES

Welcome

New Members

(November 2022 - February 2023)

ACTIVE MEMBERS

Brown Millwork, Sheridan, AR

Buck Run Lumber, Millersburg, OH

Cambiumex Inc., Sy Hillaire, QC

Douthit Tie & Lumber Co., Camden, AR

Fingerlakes Forest Products LLC, Auburn, NY

Henning Hardwoods, LLC, Henning, TN

Lincoln Hardwood Lumber, Hustonville, KY

M. T. Forest Products, Apple Creek, OH

Penn Forest Products Unlimited, LLC, Butler, PA

Phillips Forest Products, Dekalb, TX

SSPC Industries, LLC, Centerville, TN

ASSOCIATE MEMBER

Savage Paper Specialties LLC, Chandler, AZ

RESEARCH MEMBER

Kirtland Community College, Grayling, MI

SUSTAINING MEMBERS

Blue-vent USA, Rockford, IL

Northeast Mill Services LLC, Plymouth, NH

Tamarack Software, Bozeman, MT

Webster Industries, Tiffin, OH

Congratulations to these companies who are celebrating significant milestone anniversaries with NHLA.

5 YEARS

BEILER'S SAWMILL LLC

Active | January 2018

FR. MEYER'S SOHN NA LLC

Sustaining | February 2018

HASKO INDUSTRIES

Sustaining | March 2018

LAKESIDE LUMBER MILL LLC

Active | February 2018

STOLTZFUS FOREST PRODUCTS

Active | February 2018

10 YEARS

HANAWALT & SON LUMBER, LLC

Active | February2013

NELSON FOREST INDUSTRIES, INC.

Active | January 2013

25 YEARS

BEST HOME FURNISHINGS.

Associate | February 1998

MITCHELL FOREST PRODUCTS, INC.

Active | January 1998

NYLE DRY KILNS

Sustaining | January 1998

50 YEARS

DUNAWAY TIMBER CO., INC.

Active | January 1973

75 YEARS

COLLINS CORPORATE Active | February 1948

100 YEARS

J. T. SHANNON LUMBER CO. Active | March 1923

8 | APRIL 2023 HARDWOOD

WWW.NHLA.COM

MATTERS

Congratulations to the Graduates of the 201st Class of the NHLA Inspector Training School

The National Hardwood Lumber Association celebrated the graduation of the 201st class of the Inspector Training School on March 4, 2023. Five students completed the 8-week Program, and one completed the Online Training Program.

Instructor Roman Matyushchenko thanked the employers who supported the students during their time away and encouraged students to “give more than what is expected from you and be more than what you’re expected to be.”

Class President Gunnar Cook of Merrick Hardwoods spoke to his fellow students, saying, “Now that we have graduated, we can get one of the best jobs in one of the best industries in the dt ways here; I hope that you look back fondly on the experiences and the good times we all had at Inspector Training School.”

GRADUATES OF THE 201ST CLASS WERE:

• Gunnar Cook, Merrick Hardwoods, Inc.

• Alberto Distefano, Independent

• Nicolis Edoardo, Independent

• Parker Holmes, Superior Hardwoods

• Ethan Klein, Bennett Hardwoods, Inc.

• Fischer Wilkerson, Winston Hardwood Lumber

Roman Matyushchenko presented the individual achievement awards. Outstanding individual awards recipients were as follows:

• Alberto Distefano, ITS Educational Foundation Award for Highest Overall Average

• Ethan Klein, Howard Hanlon Award for Second Highest Overall Average

• Gunnar Cook, Westside Hardwood Club Award for Highest Board Run Average

• Fischer Wilkerson, NHLA Award for Best Attitude/Citizenship

• Gunnar Cook, The Lumbermen’s Club of Memphis Award for Most Improved

Enrollment is now open for the 202nd class in Oil City, PA, beginning on June 5, 2023. Enrollment is also open for class 203 in Antigo, WI, starting on June 5, 2023. To enroll or learn more about the Program, please visit www.nhla.com.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 9 EDUCATION SPOTLIGHT

Back Row L to R: FischeR wiLkeRson, ethan kLein | FRont Row L to R: aLBeRto DisteFano, GunnaR cook, eDoaRDo nicoLis, PaRkeR hoLmes

Congress Gears Up for Farm Bill 2023

By DANA COLE, Executive Director of the Hardwood Federation

As the 118th Congress kicks off its first session, lawmakers are beginning to roll up their sleeves on moving the Farm Bill, which is up for reauthorization in 2023. Although Congress will be operating under razor-thin margins, a factor that bodes well for fans of legislative gridlock, the Farm Bill has historically moved forward within the context of bipartisan cooperation. While the massive legislation covers a variety of multi-billion-dollar programs ranging from nutrition assistance to insurance programs for various crops, which could become the target of budget hawks and delay the legislative process, the Hardwood Federation will be laser-focused on priorities that directly impact the industry. Many of the sector’s priorities will be housed in the aptly named Forestry Title and reside in the Trade and Energy Titles. Provisions of interest include the following:

• Maintaining or increasing funding for export promotion programs administered by the U.S. Department of Agriculture.

• Improving the U.S. Forest Service’s capacity to manage federal lands, including meeting regional timber harvest objectives and funding state and local partnership programs.

• Maintaining or increasing funding for the Wood Innovation Grant programs, including specific hardwood projects.

• Including hardwood products in federal carbon accounting systems and programs.

• Proposing and advocating for funding to educate the public and consumers about the environmental and health benefits of hard wood products.

• Maintaining programs that promote biomass energy and the deployment of heating and power systems that rely on woodbased biomass fuel.

• Supporting programs that incentivize private woodland owners to keep forests as forests.

The legislative process begins with a series of hearings on Capitol Hill and at various locations nationwide, where lawmakers vet priorities from their constituents. On January 13, 2023, the first of these hearings was held in Harrisburg, PA. Matt Gabler, the Executive Director of Hardwood Federation association member Pennsylvania Wood Products Association, testified at the “field hearing” and delivered on-point messages on behalf of the industry, succinctly noting that the industry is “looking to this Farm Bill as an important opportunity to optimize the management of federal lands, improve the outreach and educational materials available to the public, and ensure that our commodities effectively reach domestic and foreign consumers.” The Hardwood Federation will certainly be delivering this message and looking for ways to engage our association executives and industry leaders to do the same.

While the Federation has conducted several meetings with members

“As a 6th generation hardwood producer, it is important to support our industry, and being a member of NHLA is one of the best avenues to do so. Contributing to this great Association has been a major benefit to Hartzell Hardwoods for over 100 years, and we plan to continue to support and contribute to the NHLA for another 100 years! The hard work the NHLA does to promote hardwood use is invaluable to us all. Throw in the standard grade regulations that give us a common language to trade our products around the world and the Annual Convention, and being a member is an easy decision.”

10 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM LEGISLATIVE LOG

— Tom Coble, Hartzell Hardwoods | 107-year member

of the House and Senate Agriculture Committees to tee up industry priorities, such as a new competitive grant program that will promote education about the benefits of hardwood products, we are also working in conjunction with the Forest in the Farm Bill (FIFB) coalition to leverage other messages. The FIFB is a group of trade associations representing makers of forest products and landowners to move provisions around which there are common interests, including robust funding of USDA export programs.

Both the Senate and House Agriculture Committees took some time to finalize their membership list. In both cases, the rosters look promising for Hardwood Federation outreach.

Fortunately, the industry keeps a roster of bipartisan allies. It can look forward to working with champions such as Rep. GT Thompson (RPA), chairman of the House Agriculture Committee as well as senior and influential Democrats on the panel, Ranking Member David Scott (D-GA), and Committee Members Jim Costa (D-CA) and Abigail Spanberger (D-VA). Other hardwood champions among the 51-panel members include Reps. Jim Baird (R-IN), Dusty Johnson (R-SD), Trent Kelly (R-MS), Chellie Pingree (D-ME), and David Rouzer (R-NC). The industry has also had talks with freshman Rep. Marie Gluesenkamp-Perez (D-WA), who demonstrates promising enthusiasm for industry issues.

The House Committee is a large one, and we have our work cut out for us, making sure we touch base with each and every office

ALL SYSTEMS

The industry is “looking to this Farm Bill as an important opportunity to optimize the management of federal lands, improve the outreach and educational materials available to the public, and ensure that our commodities effectively reach domestic and foreign consumers.”

throughout the Farm Bill process . . . but we have already made a start and will continue to reach out to them all.

On the Senate side, the Federation has enjoyed past partnerships with Ag panel leaders, Chair Debbie Stabenow (D-MI), who has announced her retirement in 2024, and Ranking Member John Boozman (R-AR). We look forward to continued good relations. Other key members of the Committee we have targeted for initial outreach include Mike Braun (R-IN), Sherrod Brown (D-OH), Joni Ernst (R-IA), Cindy Hyde-Smith (R-MS), Amy Klobuchar (D-MN), Mitch McConnell (R-KY), Tommy Tuberville (R-AL), Raphael Warnock (D-GA), and Peter Welch (D-VT).

As Farm Bill 2023 moves forward, stay tuned for updates from the Federation about how YOU can make your voice heard as part of these very important deliberations.

Be a participant in our upcoming Fly-In to D.C., June 13-15! To register, visit us at www.HardwoodFederation.com.

BRING YOUR GROWTH GOALS TO WOOD-MIZER AND OUR SAWMILL SYSTEM SPECIALISTS WILL GO TO WORK FOR YOU.

From economic narrowband sawmill systems to high-throughput commercial sawing lines, Wood-Mizer designs the ideal system to reduce labor costs, meet your requirements and achieve results.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 11

© 2023 Wood-Mizer LLC *Price and specifications subject to change without notice. 844.339.7815 | woodmizer.com

TV6000 TWIN VERTICAL SAW

MR6000 GANG SAW

MATERIAL HANDLING EQUIPMENT

G O ! STAND ALONE OR SYSTEM? WE CAN DO THAT .

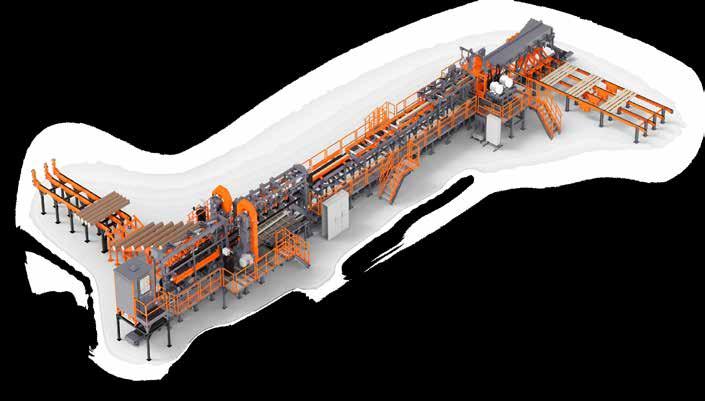

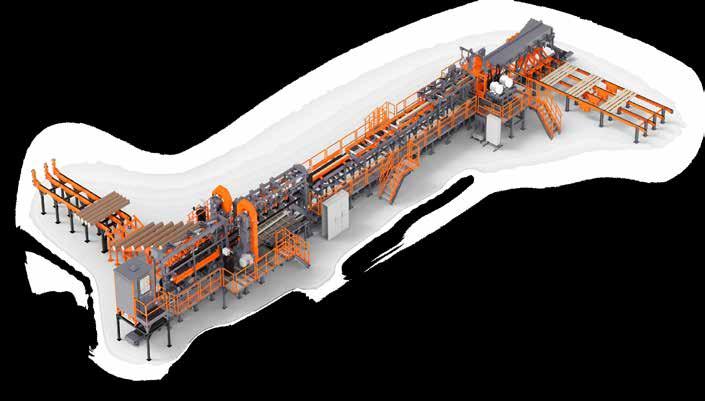

USNR’s THG hardwood grading system accurately grades hardwood lumber at high speeds with consistent results, improved efficiency, and increased yield, all with minimal grader oversight. For over 30 years, USNR has been a leader in providing scanning and optimization solutions to the hardwood industry.

USNR and the Evolution of Sawmill Technology

Sawmills have existed since the medieval period, and they have come a long way since then. Sawmill machinery and technology have advanced over the years, most notably in the 19th century, when steam power was introduced, and again in the 20th century, when electricity became commonplace. Sawmills took another giant leap forward in the 1980s with the advent of artificial intelligence and machine learning.

One of the world’s premier technology and equipment manufacturers, UNSR, played a vital role in the evolution of sawmills. They started in the 1850s as an equipment supplier, bringing the talents of well-respected innovators together with design and technology. By the mid-1980s, USNR had begun to see the importance of supplying the machinery AND the optimization and controls that accompany it. Now, in the 21st century, USNR has hundreds of patents to its credit and continues to push the hardwood industry forward through invention and investment.

Scott Norton, a Vice President at USNR, was one of the early authors of hardwood edger optimization and has been with the company for 30 years. He says, “Our push into artificial intelligence (AI), vision tools, and deep learning is something from which all our customers can benefit. There is value in the technology that we have developed. It’s a paradigm shift in solution accuracy that achieves a new level of defect detection, making grading solutions more accurate and more profitable.”

12 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

USNR

MEMBER SPOTLIGHT

Scott Norton is a Vice President at USNR and one of the early authors of USNR’s hardwood edger optimization software.

Typically, when you think about a sawmill, you think about multiple machine centers that are like islands of automation. We are actively advancing those systems’ ability to work together by gathering information from each one and using it to improve productivity, reduce downtime, and identify potential maintenance issues before they become problems. USNR’s Self-Adjusting Machine (SAM) technology closes the loop between operators, optimizers, and control systems to adjust machines in real-time.

Relationships are one of the top values at USNR. Norton explains, “From the beginning, USNR has understood the importance of close customer relationships. We get to know our customers to understand their needs and requirements. We don’t just drop an optimization or scanning package and say, ‘Okay, here it is; you’re on your own.’ We take the time to help set it up and ensure their operation works.

USNR views its employees as one of the keys to its success, with Norton saying, “Our greatest strength is our employees, who are willing to learn, be creative, and consider new concepts and ideas. They listen to thoughts and frustrations from a broad range of people and identify the key concepts that USNR can provide our customers that will give them the most value. We’re a company with over 2,000 employees working on various products. The expertise and creativity they bring to the table make USNR a stronger company.”

The Covid-19 pandemic and the ensuing supply chain crisis were difficult for all businesses in the technology sector. USNR was not immune, with Norton crediting good relationships with their suppliers, who kept their shelves stocked for the company. The company was also able to navigate the situation thanks to the foresight of its leadership team. Norton continues, “We also purchased a lot of inventory

in advance to deal with supply-chain problems. This allowed our customers to have access to parts they needed without having to shut down as they waited for a part. We have stayed ahead of the crisis thanks to our fantastic purchasing group and our management team, who recognized what was happening early on and knew it would be an issue, so they took quick action. There are still challenges with the supply chain today, but we deal with them as they come.”

USNR has been a member of NHLA for 49 years, and Norton says they wouldn’t have it any other way, revealing, “The most important thing about our membership with NHLA is the connections they give us. The networking opportunities that NHLA creates are a huge benefit for us. Going to the annual Convention is a great way for us to interact with customers and get to know what they need and how we can provide it.

We also appreciate that NHLA maintains the standard for grading hardwood lumber -- particularly from an optimization standpoint. The Rules and processes that form an industry-wide standard are beneficial because they help us understand how we need to design our systems to benefit our customers. For example, we have applied deep learning AI to hardwood sawmill edgers and trimmers and achieved a proven increase in finished grade accuracy, recovery, and total value.”

Mills have reported improved grading accuracy and an increase in higher-grade finished products. In the future, USNR expects to bring more integration and data collection in sawmills along with the expanded use of AI and machine learning. They cannot wait to discover what the next innovation will bring.

Find USNR online at www.usnr.com or call them at 1-800-289-8767.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 13

“From the beginning, USNR has understood the importance of close customer relationships. We get to know our customers to understand their needs and requirements. We don’t just drop an optimization or scanning package and say, ‘Okay, here it is; you’re on your own.’ We take the time to help set it up and ensure their operation works.”

USNR’s MillGenius edger optimizer is able to recover high grade boards from a mixed grade flitch according to NHLA grade rules based on yield and value.

Inspectors and yard workers at J.W. Black Lumber Company, 1953. Mr. Black is on the far right.

ANNI SARY VER 125 th

NHLA: Celebrating 125 Years of Service to the Hardwood Lumber Industry

By AMANDA BOUTWELL, Marketing Communications Manager

Axes, machetes and two-man saws were used to fell and buck this large white oak.

14 | APRIL 2023 HARDWOOD MATTERS

As the National Hardwood Lumber Association celebrates its 125th anniversary this month, consider what the hardwood industry looked like 125 years ago. In April of 1898, most sawmills were steam-powered, and while electricity had been invented, it was not widely used until the 1900s. New machines were being developed, but oxen and horses were still widely used. The world was different as well. William McKinley was the president of the United States. Aspirin hadn’t been invented yet. Railroads had expanded significantly, bringing remote areas of North America into a national market economy.

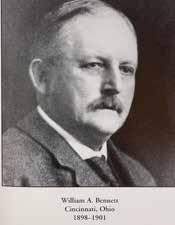

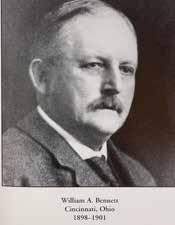

It was against this backdrop that approximately 40 men met in the cramped, dimly lit office of the Chicago Hardwood Lumber Exchange in Illinois to establish “uniformity of inspecting hardwood lumber.” The result was the formation of the National Hardwood Lumber Association. William A. Bennett of the Bennett and Witte Company served as the first president of NHLA, and his first order of business was to form a committee to draft rules for hardwood lumber inspection. The NHLA Rules Book the committee created was much more than just a list of

rules. The Rules stabilized the industry by acting as the basis of values. Without the Rules, prices were senseless. The Rules turned chaos into something meaningful.

The industry’s respect for the NHLA Rules continues to this day. Tom Oilar with Cole Hardwood (a member of NHLA for 117 years) said, “Cole Hardwood continues to be a member of NHLA because we use the NHLA grade standards every day. We take advantage of the grading school and the grading short courses and participate in the grade certification program. We use these to keep our inspectors in check and on par with NHLA standards.”

It isn’t just sawmills that benefit from the NHLA Rules. Scott Norton, Vice President at USNR (a machinery and technology company), echoes his gratefulness for the Rules, stating, “We appreciate that NHLA maintains the standard for grading hardwood lumber — particularly from an optimization standpoint. Those rules, those processes, that sort of standardization of a baseline across the industry, is beneficial to us because it helps us understand how we need to design our systems so that our customers benefit.”

After NHLA created the Rules for the Measurement and Inspection of Hardwood Lumber, it quickly became apparent that the Association needed a way to ensure the uniform application of the Rules. Thus, the birth of the National Inspector, a position that is greatly valued and respected by all in the hardwood industry to this day. National Inspectors are called upon to act as impartial experts to settle disputes, and they can step in as a company’s lumber inspector when requested. They also provide indispensable insight into mill operations and how to yield the highest profit.

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 15

Left: William A. Bennett of the Bennett and Witte Company served as the first president of NHLA.

The fifteenth class of the NHLA Inspection School conducts a board run at the NHLA school, Memphis, TN, 1955.

“The most important thing about our membership with the NHLA is the relationships that we have been able to cultivate over the years. It’s the people who matter the most! As we do in our business, the NHLA continues to evolve and stay relevant to what is important to its members. We take advantage of the NHLA Production Yield Analysis, Inspector Training School, and various webinars. These tools help improve our employee’s knowledge and proficiency, which directly impacts my bottom line.”

16 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

— Mike Powers – President & COO of Maley & Wertz | 117-year member

ABove Left to right: Lillard C. Nicely describes the characteristic of a board to students, Lumber for government use in 1919, and Tigerton Lumber. BeLow Left to right: Dedication of the new NHLA building, Benji Richards National Inspector and Chief Inspector Dana Spessert with students from the 191st class.

By the 1940s, the demand for lumber inspectors became so great that NHLA established a school to train people to enter the profession. What began as a temporary experiment to measure support rapidly transformed into a vital trade school. At the time, Memphis, Tennessee, was known as the “hardwood capital of the world,” so it made sense to situate the Inspector Training School in Memphis. A Memphis business, Nickey Brother Lumber Company, generously donated land to build a school. In 1948 classes were held at another location while the new school was constructed. The new building was designed to teach hardwood lumber grading, so it came equipped with a large classroom, an area for lumber storage, and facilities to practice grading lumber. The Inspector Training School celebrates its 75th anniversary this month as well.

Lillard Nicely served as the school director from its beginning through 1956. At the time, the NHLA Inspector Training School was a 20-week (5 months) program held twice a year. In 1971, the program was shortened to 12 weeks (three months) thanks to the introduction of visual aids and improved study material. This was again changed in 2020 when modern technology allowed the class to be shortened to eight weeks (two months).

Between the 1940s and 1970s, space at the School was limited, so there was a waiting list for students who wanted to attend. In an emergency effort to relieve the backlog of students, in 1979, the School began to operate on a “double shift” basis, with a morning session and an afternoon session. Working in this manner was not sustainable for staff or students. But in 1980, the problem was solved by moving the classroom to an even larger building at the newly built NHLA headquarters in Memphis. The move increased student capacity from 50 to 70, precisely what was needed to meet the demand for attendance. The new school was considerably larger, with areas for instruction, a lounge, a lumber grading facility (with lumber storage), ample parking, and sections for recreation.

Since its inception, the NHLA Inspector Training School has provided a wealth of new inspectors as well as mill operators, owners, sales executives, and more. The value of attending the Inspector Training School cannot be overstated, as it has served as a launching pad for careers throughout the industry. Phillip Pierce, President of Holt & Bugbee Co. (an NHLA member for 116 years), explains, “Both my brother and I started off our hardwood lumber careers over 40 years ago by attending the NHLA Inspector Training School in Memphis. It jump-started our knowledge of species identification and the basic principles of kiln drying. It also gave us a solid understanding of the grading Rules. Since then, many of our co-workers have taken advantage of the short courses, and it has helped Holt & Bugbee Co. strengthen our team.”

In the 1970s, NHLA made the monumental decision to move its headquarters from Chicago to Memphis, and the Lumbermen’s Club of Memphis played a big part in that decision. The Lumbermen’s Club of Memphis went to the NHLA board and encouraged them to move the headquarters to Memphis. They agreed – if

NHLA MEMBERS

121 YEARS

Buskirk Lumber Co. (Kamps Hardwoods)

120 YEARS

Thomas & Proetz Lumber Co.

118 YEARS

Anderson-Tully Lumber Co.

117 YEARS

Cole Hardwood, Inc.

117 YEARS

Heidler Hardwood Lumber Co.

117 YEARS

Maley & Wertz, Inc.

116 YEARS

Alan McIlvain Co.

116 YEARS Holt & Bugbee Co.

116 YEARS

Frank E. Wilson Lumber Co.

109 YEARS

J.M. Jones Lumber Company

108 YEARS

Tigerton Lumber Co.

107 YEARS

Hartzell Hardwoods

104 YEARS

Holmes & Co.

104 YEARS

Robinson Lumber Company

104 YEARS

Whitson Lumber Company

NHLA didn’t have to spend any money for the move. It was the hard work of the Lumbermen’s Club of Memphis and the generosity of NHLA members that made the move to Memphis possible. The Club managed to get everything needed for the new headquarters donated by members, from the purchase of the land to the office and School buildings. Today, the Lumbermen’s Club of Memphis is one of the oldest and most respected industry organizations in the region and remains active in networking, education, and charitable causes in the Memphis community.

In 1979, a groundbreaking ceremony was held to begin the construction of a new building with 8,500 square feet of office space and an additional 10,000+ square feet to build the new Inspector Training School. The building was expanded in the 1990s to accommodate more office space. These new buildings present a beautiful showcase of various species of hardwood lumber. Each office is paneled in a different species, from soft maple to walnut, with hardwood floors and paneling throughout both buildings.

NHLA has been present for some remarkable points in history. The Association provided exceptional service to the United States and Allied Nations during the first World War when NHLA created a War Service Bureau to oversee the procurement of the large quantities of lumber needed for the war effort. NHLA also aided the government during World War II, developing rules for the

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 17

HOW LONG HAS NHLA BEEN AROUND?

• When NHLA was founded, England was ruled by Queen Victoria

• NHLA is older than aspirin, which was patented by Bayer in 1899.

• NHLA was around long before Pablo Picasso held his first art exhibition in 1901.

• NHLA was 5 years old when the Wright Brothers had their first flight in 1903.

• NHLA is older than the Modern Olympic Games, which began in St. Louis, MO, on July 1, 1904

• When NHLA was founded, fingerprints weren’t used in investigations. That didn’t start until 1904.

• NHLA is older than cartoons! The world’s first animated cartoon, “Humorous Phases of Funny Faces,” wasn’t filmed until 1906.

• NHLA was 10 years old when the first Ford Model T automobile was produced in 1908.

construction and materials used in training camps, housing, and production plants.

Today, NHLA provides a variety of benefits to its members, including the Inspector Training School and a wide berth of Inspection Services. NHLA is at the frontline of efforts to advocate for its members’ interests and promote the use of hardwood lumber. NHLA also hosts an Annual Convention that serves as the largest gathering of the hardwood community in the world. It is said you can see more industry leaders at the Convention in just three days than you could if you traveled for six months.

Sean Briscoe, the Assistant Vice President of Pennsylvania Lumbermens Mutual Insurance Company, says they are a “proud member of NHLA because we recognize the tremendous value the Association has brought both to our business and to our customers. NHLA provides the hardwood community with a united voice, advocating for the future of our industry. As the hardwood business continues to change rapidly, we’re grateful for NHLA’s continued success in bringing our community together to discuss the core issues our businesses face and to come up with solutions designed to meet the needs of our customers.”

Buskirk Lumber (now Kamps Lumber) is the longestparticipating member of NHLA. Their membership goes back 121 years. Tyler Kamps appreciates their membership, saying, “The most valuable thing about our membership with NHLA is the credibility that comes with it. When someone sees we are an NHLA member by spotting the NHLA logo on our website or brochures, there is instant credibility gained. We also find that the staff at NHLA promotes their members, and we are on the receiving end of many phone calls and emails with potential customers and suppliers who were told about our company by one of the NHLA staff members.”

NHLA has seen almost everything over the last 125 years and has the experience to weather any storm its members face. From conflicts like World Wars to economic downturns like the Great Depression and multiple recessions, NHLA has been there to guide its members through the dark. Most recently, NHLA has been at the forefront of working through trade tariffs by advocating the hardwood community’s interests, guiding companies through global pandemics, and promoting the use of hardwood lumber against replacement products. More importantly, NHLA will continue to be here for the next 125 years, ready to face whatever the world throws our way with the same steadfastness and grace as in the past.

18 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

125th NHLA Annual Convention

65th NHLA Annual Convention

MAKING THE GRADE

By DANA SPESSERT, Chief Inspector

Over the past few years, there has been an increased demand for hardwood building materials, specifically in larger timbers. These timbers must make a certain grade to meet the designer’s strength ratings requirements. NHLA has grading Rules that meet or exceed the requirements of many of the design values necessary for projects, and many of these projects are replacements of older timbers for restoration.

This month I want to describe the first of these Rules, Select Dimension - Select Car Stock (Boxed Hearts & Planking), or as I like to call it, “The FAS of Timbers.” On page 65 of the NHLA Rules Book, under the heading “Select Dimension – Select Car Stock,” you can find the entire Rule. For the purpose of this article, I will summarize the Rule.

1. Square Edges, except:

a. Wane not over ¼ width of surface it appears on, on one corner or amount divided and show on more than one corner

b. Pieces 5” and less thick, wane admitted (no more than 20% of shipment).

i. 1/3 width

ii. 1/3 thickness

iii. 1/3 length in the aggregate.

4. Sound Knots Limitations:

a. Not exceeding ½ the width of the surface, minimum of 6’ apart.

b. Less than ½ to 1/6 the width of the surface in average diameter, minimum of 12” apart.

c. Less than 1/6 the width of the surface, unlimited.

5. Unsound Knots and/or Holes Limitations:

a. Minimum 6’ apart.

i. Less than 6” thick - ½” average diameter.

ii. 6” to 10” thick - 3/4” average diameter.

iii. 11” and thicker - 1 ¼” average diameter.

6. Pith Limitation:

a. Boxed pith admitted without limit.

b. Exposed firm pith admitted 1/3 the length on one face.

7. End Shake Limitation:

a. Not over two annual growth rings, confined within end.

b. Maximum length = 1/4 circumference of shake ring.

c. Cannot extend to two faces.

8. Surface Shake Limitation:

a. 1/12 of the length of the piece in the aggregate.

2. Size:

a. 10% may be ¼” scant in thickness and/or width.

b. 100% may be up to 1” over in thickness and/or width.

c. No more than 3” overlength.

3. Will admit stain, ordinary season checks, bird pecks, pin worm holes, spot and shot wormholes.

9. Split Limitation:

a. Shall not exceed 12” in length in either end of the piece of Standard or specified length.

If you have any questions please reach out to me at d.spessert@nhla.com or 901-399-7551.

“The most valuable thing about our membership with NHLA is the credibility that comes with it. When someone sees we are an NHLA member by spotting the NHLA logo on our website or brochures, there is instant credibility gained. We also find that the staff at NHLA promotes their members, and we are on the receiving end of many phone calls and emails with potential customers and suppliers who were told about our company by one of the NHLA staff members.”

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 19

— Tyler Kamps, Kamps Lumber | 121-year member | NHLA’s Oldest Member Company

RULES CORNER

NHLA PROVIDES EDUCATION AND TRAINING TO IMPROVE YOUR BOTTOM LINE

APR

April 24-26

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

APR

April 24-27

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: WV Wood Technology Center Location: Elkins, WV

Instructor: Mark Depp, National Inspector

JUNE

June 5- July 28

Inspector Training School

202nd Class

Traditional 8-week hands-on training to achieve the certificate of completion in Hardwood Lumber Inspection.

Venue: Venango Technology Center

Location: Oil City, PA www.nhla.com/PAsummer

JUNE

June 5- July 28

Inspector Training School

203rd Class

Traditional 8-week hands-on training to achieve the certificate of completion in Hardwood Lumber Inspection.

Venue: Northcentral Technical College

Location: Antigo, WI www.nhla.com/WIsummer

AUG

Aug. 21- Sept. 1

Inspector Training School Online Training Program

MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks hands-on training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, ITS Instructor

SEPT

Sept. 6-8

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

Sept. 25- Nov. 17

Inspector Training School

204th Class

Traditional 8-week hands-on training to achieve the certificate of completion in Hardwood Lumber Inspection.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

OCT

Oct. 23-27

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: Wood-Mizer, LLC

Location: Indianapolis, IN

Instructor: Kevin Evilsizer, National Inspector

20 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM Register for classes at www.nhla.com/Education.

ITS CALENDAR

NHLA JOB BOARD

Here you will find our current job listings. To see more details or to post a job, visit www.nhla.com/industry-services/job-board.

HARDWOOD LUMBER INSPECTOR BANKS HARDWOODS

Banks Hardwoods is in search of lumber inspectors who have graduated from the NHLA Inspection School. We have position openings at both our White Pigeon, MI, and Menomonie, WI, locations. Banks Hardwoods is known for consistent, excellent quality lumber and a safe, pleasant employee-oriented work environment.

Skills & Experience Required

Potential Candidates must be able to demonstrate the following traits:

• Attendance – Dependable employee that is here every day and ready to have their department running at the start of each shift.

• Promote and apply our “Quality Everything” motto. Must be a leader on the line and by example to other employees.

• Must get along with others in a respectful manner ~ keeping morale high makes for a better work environment. Perform with high ethics and moral compass.

• Ability to be a good communicator and team player. Including the ability to communicate with employees, purchasing, sales, and management.

• Able to troubleshoot issues, whether it’s lumber, machinery, or employees.

• Able to apply NHLA grading rules and apply basic math skills.

• Understand production orders and our customer base.

• Adhere to all safety and operational procedures and policies.

Salary & Benefits

• Competitive pay

• Medical, Dental, Vision, and Disability Insurance available after 90 da •

• Paid Vacation

• 401K Plan available after 1 year and includes Annual Company Match

• Relocation assistance, if necessary

Our Mission Statement and a list of our company core values are available upon request. We also encourage you to call and speak to our Quality Control Manager, Dave Sieggreen, to discuss this career opportunity in detail.

How to Apply

Send your resume to: jennifer@bankshardwoods.com

Banks Hardwoods

69937 M 103 | White Pigeon, MI 49099 269-483-2323

HARDWOOD LUMBER INSPECTOR HARTZELL HARDWOODS

Basic Function: Inspects incoming and outgoing lumber according to NHLA rules at the assigned grading deck. The grading deck sits on the Lumber Handling Machine.

Responsibilities and Duties:

• Reports to Lumber Operations Supervisor and receives written and/ or verbal orders/specifications. It is the Lumber Inspector/Trainee’s responsibility to maintain the highest standards of grading when receiving or shipping lumber.

• Visually inspects lumber according to specie, grade, and dimension.

• Uses NHLA lumber grading rules to inspect lumber.

• The Lumber Trainee will grade offline or with an experienced grader until they are qualified to grade at the accuracy and speed determined by Hartzell standards.

• All inspectors may be required to switch off with another lumber inspector. Lumber inspectors are required to work in another assigned position when they are not grading lumber.

• During down times, other functions will be required. (e.g., clean-up, maintenance, stacking, etc.)

• Follows all safety practices.

Skills & Experience Required

• Previous experience in grading walnut lumber along with other hardwood species is desired.

• NHLA schooling is preferred but not mandatory.

• Long periods of standing.

• Flips boards weighing between 5 lbs. to over 60 lbs. using hands.

• Familiar with lumber grading rules, calculator, tally book, pencil, lumber crayon stick, grad console, and board turner is a plus.

Salary & Benefits

• Pay Range: $25+ Depending on Experience

• Medical, Dental, Vision, and Life Insurance

• 401k Match

• Discretionary Bonus

• Paid Vacation and Holidays

• Personal Time Off

• 100% Paid Training

How to Apply

Send your resume to: larling@hartzell.com

Hartzell Hardwoods

1025 S Roosevelt Ave | Piqua, OH 45356 937-615-1924

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 21

NHLA JOB BOARD

Here you will find our current job listings. To see more details or to post a job, visit www.nhla.com/industry-services/job-board.

WOOD SCIENCE INSTRUCTOR (FACULTY) NORTHCENTRAL TECHNICAL COLLEGE

• Facilitate learning through classroom activities, distance learning experiences, workforce development, out-of-classroom activities, and the mentoring of students and peers.

• Support and maintain collaborative relationships with business & industry, community-based organizations, and K-16 partners.

• Assess and evaluate student performance in alignment with the College assessment plan in a timely manner.

• Conduct assigned classes for the scheduled length of time.

• Submit final grades by the scheduled due date identified on the academic calendar.

• Post and maintain office hours.

• Maintain accurate records of student attendance and achievement for up to one semester after the semester end unless requested for a longer period of time.

• Furnish written evaluations as requested by students.

• Coordinate instructional support services to meet individual student accommodation and modification needs.

Please visit the posting on our careers page to view an extended list of job duties and responsibilities: https://www.schooljobs.com/careers/ ntc/jobs/3682249/faculty-wood-science-instructor?pagetype=jobOpportunitiesJobs

Skills & Experience Required

• Must have a minimum of two years (4,000 hours) full-time or equivalent demonstrated relevant wood industry occupational experience, one of which must be within the last five years.

• Bachelor’s degree in Wood Science and Technology or related field, or an Associate’s degree with the agreement to obtain a Bachelor’s degree upon hire.

• Willing/able to meet Wisconsin Technical College System (WTCS and Higher Learning Commission (HLC) requirements, accreditation standards, and/or licensing standards where applicable.

• Experience in teaching and working with diverse populations is preferred.

Salary & Benefits

• Depends on qualifications

• Our Comprehensive benefits package includes the following:

• Health and Dental Insurance

• Vision Insurance

• Life and Long-Term Disability Insurance

• Short Term Disability (voluntary)

• Wisconsin Retirement System

• 403(b) Pre-Tax Retirement Savings

• 457 Deferred Compensation Plan (Pre-tax & Roth Option)

• 529 Plan

• Accident & Critical Illness (voluntary)

• Paid Holidays & Sick Leave

• Professional Development

How to Apply

Send your resume to: hr@ntc.edu

Northcentral Technical College

312 Forest Ave. | Antigo, WI 715-803-1483

HARDWOOD LUMBER SALES

BENNETT HARDWOODS INC.

Bennett Hardwoods Inc. is seeking someone for hardwood lumber sales to work with customers to fill their needs. Responsibilities would include answering customer inquiries and providing outstanding customer service, as well as attempting to locate new customers.

Skills & Experience Required

The salesperson would need experience in sales within the lumber industry. A successful candidate will have strong communication skills and a strong technical knowledge of hardwood lumber.

Salary & Benefits

Salary will be based on experience. Excellent benefits package including Life, Health, Dental & Vision insurance. Paid time off. Simple IRA with employee match.

How to Apply

Send your resume to: Bennetthardwoods@aol.com

Bennett Hardwoods, Inc. 725 S 84th Ave | Wausau, WI 54401 715-845-9663

22 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

DAY SHIFT SUPERVISOR ALLEGHENY WOOD PRODUCTS

Allegheny Wood Products, a leading Appalachian hardwood lumber manufacturer, is looking for a highly motivated candidate for a day shift Supervisor position. This position is located in Kingwood, WV. The primary job functions include (but are not limited to)

• Overseeing day shift operations within guidelines established by the Plant Manager and company

• Enforcing safety rules and regulations, maintaining the cleanliness and appearance of the facility, and collaborating with maintenance staff to troubleshoot issues and plan approval projects.

• Coach and evaluate employees to help with career growth and talent development in the workplace and work with staff to help resolve workplace disputes.

• Develop strategic improvement plans with company executive leaders and work with contract labor agencies to help fill vacant positions.

• The ideal candidate should have previous supervisory experience, be hands-on, have experience working in an industrial environment, can work on a team, and is eager to learn and grow with our company.

Skills & Experience Required

• The ideal candidate has strong leadership skills, is very hands-on, and can work on a team.

• 3-5 years of supervisory experience preferred.

Salary & Benefits

Benefits include a competitive salary, 401(k) program, health insurance, dental and vision insurance, paid vacation, flexible spending account, short-term disability, and long-term disability.

How to Apply

NHLA JOB BOARD Here you will find our current job listings. To see more details or to post a job, visit www.nhla.com/industry-services/job-board.

Send your resume to: hr@alleghenywood.com Allegheny Wood Products 342 Mill Road | Kingwood, WV 26537 304-329-2097 WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 23 716-833-9366 toll free: 1-888-363-2628 uccoatings.com Buffalo | Portland | Seattle W O OD P R OT E C TI ON P R O DU C T S XL SAPSTAIN CONTROL Without SOL-BRITE® E With SOL-BRITE® E UCC_38723_IHLA 7.25” w x 4.125”h" Ad_No badge_v1.indd 1 2/15/23 6:34 PM

HARDWOOD MARKETS MATTER

Hardwood Markets Matter and it is important for NHLA to share market details of the entire Hardwood Industry. We appreciate the support of allied associations and publishers in gathering and sharing this important market information that can help you understand the complete hardwood industry picture. www.hardwoodreview.com

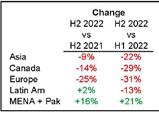

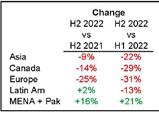

U.S. hardwood lumber exports rose 1% in 2022, but only because first-half shipments were so strong. Second-half shipments fell sharply to Canada and every major market region except the Middle East & North Africa, clearly contributing to the sharp declines in lumber prices after July. Q4 shipments to China were 62% lower than the record Q2 2018 volumes, and the second-lowest since the onset of the U.S.-China trade war. From the 1980s through the 2000s, second-half shipments to Europe were consistently lower than first-half shipments, as they were in 8 of the 13 years since, so second-half slowing is rather typical. However, the 31% drop in second-half shipments in 2022 was the largest in 33 years. Likewise, the 30% drop in second-half shipments to Canada in 2022 was 50% larger than any second-half decline in three decades. Despite a 15% year-over-year gain for the year, secondhalf shipments to Latin America fell 13%; the result of record-setting shipments to Mexico in January, March and May, followed by slower July, November and December shipments.

On a species basis, exports of Red Oak, Ash, Birch and Cherry held up the best in the second half of 2022, dropping “only” 4%, 9%, 13% and 15% from first-half volumes, respectively. By comparison, White Oak, Poplar

Quarterly Hardwood Lumber Exports

and Walnut exports fell 28-29% in the second half; Hard Maple and Alder slowed by one-third; and Soft Maple shipments dropped 43%. That said, December shipments of Red Oak, White Oak, Poplar, Walnut, Ash, Cherry and Hard Maple held steady or rose from November lows— as did December shipments to China, Mexico, Vietnam, the UK, Japan and Spain. Contacts indicate Chinese buyers have come back somewhat aggressively since the first of the year, and, with December volumes turning up slightly to a number of major markets, Q1 2023 shipments should easily reverse the two-quarter decline, even if they fall well short of Q1 2022 volumes.

24 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM MARKET TRENDS

0 30 60 90 120 150 180 210 Asia Canada Europe Latin Am MENA + Pak Million Board Feet

Q1 2021 Q2 2021 Q3 2021 Q4 2021 Q1 2022 Q2 2022 Q3 2022 Q4 2022

“Nearshoring” Markets for US Hardwoods

• SE Asia and India for Asian Manufacturing

• Mexico for N. America

• Turkey, Estonia, Morocco for Europe

2022: Highest Export Values Ever

www.ahec.org

"NEARSHORING" HAVING STRONG EFFECT ON HARDWOOD EXPORT DESTINATIONS

By Tripp Pryor, AHEC International Program Manager

“Nearshoring” is pretty simple in theory: make stuff close to where the consumers are. But in practice, how can we actually move so much production out of China and diversify across the rest of the world? In response to a global focus on “nearshoring” we’ve seen a steady rise in our exports of hardwoods across Asia, Europe, and Latin America.

As we learned with China, political tensions can lead to real economic costs. More than just “nearshoring”, or shortening the supply chain, it’s important to consider the impact of trade policies. This is where we see the rise of “friendshoring”, or outsourcing manufacturing to countries with favorable political and trade relationships to the destination country. An example of this has been Apple manufacturing more of their iPhones in India and Vietnam to diversify their supply chain.

We’ve seen the impact of these global trends in our hardwood exports as well. In 2022, we saw record export values across “nearshoring” and “friendshoring” markets like Vietnam, Thailand, and India for Asian manufacturing, Mexico for North American demand, and Turkey, Estonia, and Morocco for European demand.

These countries are all attractive manufacturing centers with a combination of low labor rates, friendly political ties with the EU and US, and free trade agreements.

Southeast Asia remains a re-export market for the US, Europe, and even China, and while India is also a major exporter it is beginning to see a rise in domestic demand among the world’s largest population.

US hardwood lumber exports to Mexico have grown 68% since 2020, and the market is poised to grow even more in the next few years as more manufacturing from foreign investment comes online. Thanks to proximity to the US and the USMCA trade agreement, getting hardwoods into Mexico is easy and inexpensive. Labor in Mexico is also cheaper than in China, and with a relatively young median population age of 28 (median age in the US and China are both 38), the labor force in Mexico is expected to continue to grow.

Turkey, Estonia, and Morocco all imported record totals of US hardwood lumber in 2022, and the vast majority of their production went elsewhere in the EU. Estonia joined the European Union in 2004, and Turkey and Morocco both have free trade agreements with the EU, meaning they can provide goods across Europe without additional costs. In fact, Morocco is one of the few countries that has free trade agreements with both the EU and USA, allowing them to import hardwoods and export furniture at competitive prices. Turkey and Estonia have had strong thermal modification industries for years but are beginning to develop more in the furniture and flooring sectors for European markets.

All of these markets had record years in 2022 and are poised to continue this growth in the future. AHEC’s goal is to be an advocate for American hardwood products throughout the world and to connect you to interested buyers. For more information on international markets and AHEC events, please contact me at tpryor@ahec.org

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 25

$$25 $50 $75 $100 $125 $150 $175 $200 $225 $250 Vietnam Mexico Thailand Turkey Estonia India Morocco Millions ($USD) 2019 2020 2021 2022

Source: USDA GATS

AMERICA RUNS ON TIES, WOOD TIES

By Nate Irby, Railway Tie Association, and Petr Ledvina, Economist

The demand for wood crossties will remain strong in 2023 due to (current) insufficient railroad crosstie inventories, sawmill operator marginalized production (for a variety of reasons), and ongoing supply chain/ equipment shortages coupled with labor inconsistencies. Further, the demand for pallet lumber is easing and the price of cants has equilibrated. The decline in residential housing construction manifested itself in the decline of lumber, wood products and building material shipments. Slowing consumer demand resulted in lower intermodal shipments across railroad networks. Railroad intermodal traffic declined from its peak in

June by 4.3% compared to December 2022. During the second half of 2022, container shipments also declined by 3.5% from the first half (see Business Trends, Crossties Magazine, rta.org). Also, there are some mills that finally caught up with back orders for pallet lumber (Hardwood Market Report 1/20/2023 issue). Going forward, the demand for pallet/ consumer lumber could further soften as consumer demand declines further due to the economic slowdown.

Railroad intermodal headwinds were partially offset by shipments of automobiles, grain and food products as well as coal and fracking sand, as natural gas prices were well above average (various Class I Q4 earnings conference calls; AAR weekly reports). Despite lower shipments, the railroads managed to increase earnings through favorable pricing and cost savings measures. As a result, the aggregate railroads’ CapEx should be somewhat higher in 2023 and give precedence to re-invigorating crosstie inventories through aggressive tie purchases.

In conjunction with slow demand for board roads/mats and the aforementioned consumer-type lumber products, crosstie production is at the forefront of many sawing solutions. The crosstie inventory-to-sales ratio has been depressed for many months, mainly because of low tie inventories (see Tie Statistics & Trends, Crossties magazine, rta.org), and will bolster the need for continued crosstie production for the foreseeable. With wood ties and timbers still 90%+ of railroad track infrastructure in North America today, our railroads depend on sawmills to keep freight moving safely and reliably.

WHAT IS YOUR VIEW OF CROSSTIE COMPETITIVE POSITION RELATIVE TO OTHER HARDWOOD PRODUCTS?

REGARDING YOUR ABOVE ANSWER, PLEASE PROVIDE CONTEXT FOR MARKET, WEATHER OR OTHER CONDITIONS.

EASTERN US

LAKE STATES

Minnesota, Iowa, Wisconsin, Michigan, N Indiana, N Illinois: Logging conditions are poor. Heavy snows followed by rain have made conditions extremely difficult for loggers. Pallet Cant prices and production are low. One of the larger sawmills in the area was lost to fire this month. Grade lumber and in particularly H. Maple and S. maple are very hard to move at this time.

ATLANTIC

Virginia: Log inventories remain low due to bad weather conditions and market prices for some products. Pallet prices and demand remain low.

North & South Carolina: Cross tie prices are still high, and very competitive, with everything else in the industry

West Virginia: Hardwood production has been cut back, some weather related and some market driven.

(Continued at top of next page)

26 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

www.rta.org

NEW ENGLAND

New England 1: Log inventories are still low. Mud season is approaching which will further slow logging production. Pallet prices and demand continue to drop. Lumber prices are still low, but demand is starting to trend upwards on some items.

Pennsylvania: Brief freeze up have allowed some logging. Ties are pretty much the only thing keeping mills running at this time.

MIDSOUTH

E Texas, NW Louisiana: Crosstie's is holding up great to the mills if we can get a early logging season and production catches up some we can maybe see daylight ,we just need a dry spring.

SOUTHEAST

Mississippi: Tie markets remain stable. Winter weather is impacting log inventory.

www.hmr.com

The HMR Demand Index (HDI) is a feature in HMR Executive® that illustrates monthly trends in reported demand from 10 major domestic markets for hardwood lumber. Components of the index are color coded with various shades of blue when demand is slow, they transition to gray when demand is fair, and then to light red and deep red when demand moves from good to strong.

Index for February which is published the first week of March.

Cabinets

Residential Flrg.

Truck Trailer Flrg.

Upholst. Furniture

Wood Furniture

Moulding/Millwork

Wood Components

Board Road

Pallets

Railroad Ties

WWW.NHLA.COM APRIL 2023 HARDWOOD MATTERS | 27

Feb-21 Mar-21 Apr-21 May-21 Jun-21 Jul-21 Aug-21 Sep-21 Oct-21 Nov-21 Dec-21 Jan-22 Feb-22 Mar-22 Apr-22 May-22 Jun-22 Jul-22 Aug-22 Sep-22 Oct-22 Nov-22 Dec-22 Jan-23 Feb-23

Quite Slow Slow Fair/Steady Good Quite Good

www.nwfa.org

The NWFA/Hardwood Floors magazine’s 2023 Industry Outlook found that just over 73 percent of survey respondents reported difficulty finding adequate skilled labor in 2022, up 23 percentage points from last year’s survey when just about half had the same challenge. Referrals remain a top strategy to find labor, but NWFA members also have succeeded with classifieds/online job postings, social media, and working through channel partners.

28 | APRIL 2023 HARDWOOD MATTERS WWW.NHLA.COM

Simple – we handle all the complexities that go into hardwoods to make life easier for you. Natural – we manufacture and supply only sustainable, high-quality products that breathe life into your work. Hardwoods – from harvest to delivery, we set the standard for what the hardwoods experience should be.

nwh.com