Hygienic and

sustainable solutions

Optimize maintenance and cleaning time

sustainable solutions

Optimize maintenance and cleaning time

Every progress starts with a wise decision based on in-depth understanding

At NGI, we’re about more than just parts.

We partner with food equipment OEMs to eliminate food safety risks during the design phase, before they impact performance.

With assistance from our engineering, you can build machines that:

Give you and your customers a competitive advantage

Increase yield and performance by maximizing runtime

Simplify food safety compliance with hygienic design

We have helped raise the standards of hygiene and ease of cleaning in large parts of the food industry for more than 50 years. Product development and hygienic design alone do not make the difference.

Innovation is also about the way we collaborate with customers, suppliers and others in our common value chain.

1. Bearing houses

Certified by EHEDG, 3-A and USDA

Protection class IP69K

Lubricated for life

Minimized risk of breakdowns

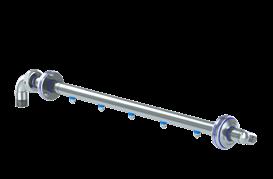

2. Plug & Play CIP Unit

Enhanced Food Safety

Hygiene-optimised design

Automation of the cleaning process for belting equipment

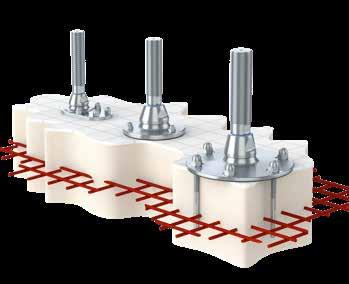

3. Adjustable legs

Plug & play assembly

Hygiene-optimised design

Flexible customisation on request

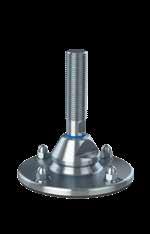

4. Levelling feet

Wide selection for every application

Various hygiene levels

Flexible customisation on request

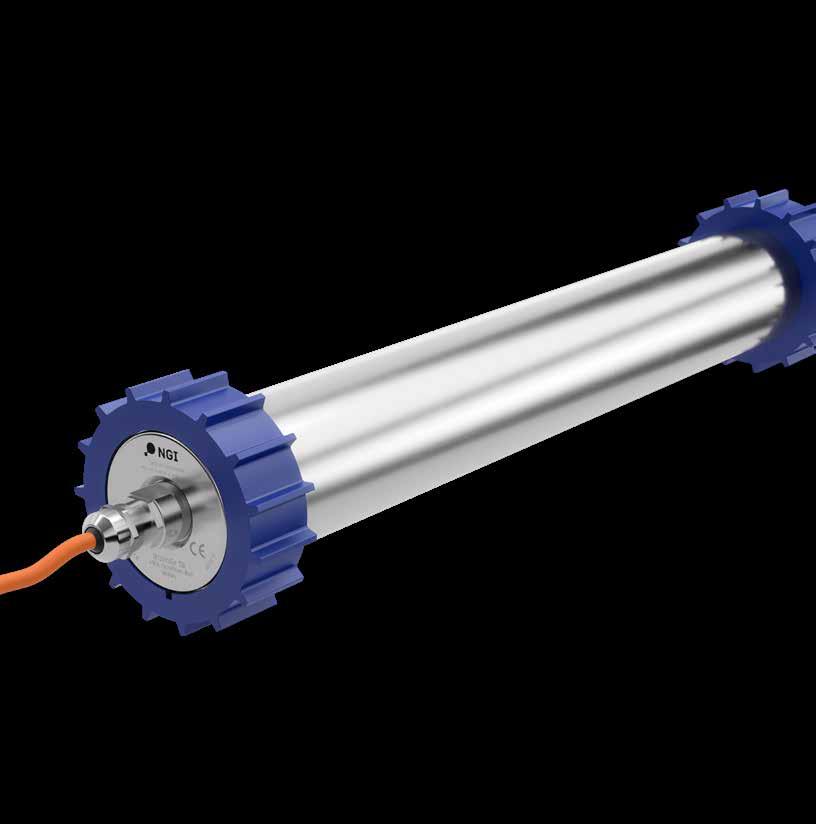

5. Synchronous drum motors

Oil free minimizing the risk of oil leaks

Lower energy consumption

Compact MTS82 Drum motor: Designed to fit. Built to perform.

New MTS62 Drum motor: Think BIG. Engineer small.

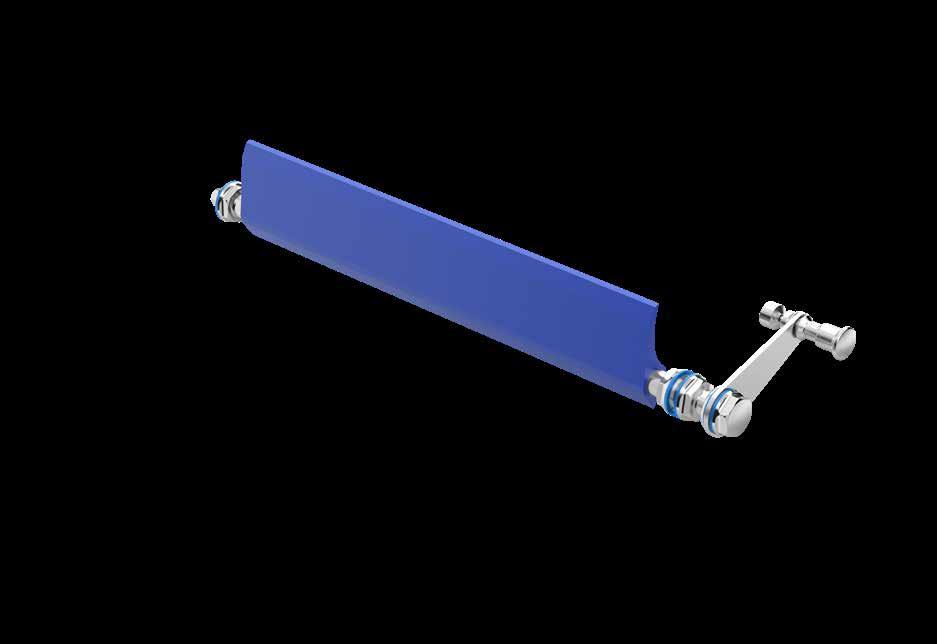

6. Belt Scraper

Fine-tune cleaning pressure in seconds.

Provides cleaning coverage across the belt surface, ensuring food safety

Quick release for effortless removal and maintenance, minimizing downtime.

7. Castors

Move with confidence, minimize cross contamination.

Powerful easy-clean design

Mechanics 100 % integrated

Minimisation of bacterial build-up

8. Hygienie-optimized accessories

Wide selection of plug & play accessories

Hygiene-certified design

Flexible customisation on request

Hygienic components are specifically designed to adhere to strict food safety standards, reducing the chances of contamination.

Contaminants like bacteria, mold, or foreign particles can jeopardize the safety of food items, posing health risks to consumers.

Furthermore, numerous countries have stringent regulations and guidelines concerning food processing hygiene. By employing hygienic components, businesses can ensure compliance with these regulations, thereby avoiding legal complications and penalties.

Our hygienic components are crafted from stainless steel to facilitate easy cleaning and disinfection. We are committed to adhering to design standards set by USDA, 3-A, and EHEDG.

Please note that you also can also find hygienic versions of our seismic and weighing levelling feet on page 52 - 59.

Certified and designed to meet the strictest standards of cleanliness and durability.

Ideal for industries such as food processing where hygiene is of utmost importance.

USDA, EHEDG, and 3-A certifications available for more variants.

AISI 304 or AISI 316 stainless steel with vulcanized FDA-approved rubber to prevent slippage and reduce vibration.

Rubber available in black, blue, white NBR, and black EPDM.

Self-draining surfaces and safety from exposed threads for easy cleaning and hygienically sealed movable parts with blue detectable sealings.

Wash-down test shows up to 28% savings vs fully-threaded feet; ROI calculator available online.

Our top-quality hygienic industrial machine levelling feet are certified and designed to meet the strictest standards of cleanliness and durability. They are ideal for industries such as food processing where hygiene is of utmost importance.

Constructed from stainless steel, these levelling feet are corrosion-resistant, effortless to clean and built to withstand rigorous cleaning agents. Furthermore, you can look forward to a 28% decrease in cleaning expenses with NGI hygienic

adjustable feet compared to fully threaded levelling feet, as cleaning becomes less resource-intensive (time, water, detergents etc.).

Our hygienic machine feet and their sturdy construction guarantee long-lasting performance and reliability, making them a cost-efficient option for ensuring optimal equipment functionality.

These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression and tensile loads of up to 110.000N and 20.000N, respectively. These feet are both EHEDG and 3A certified and feature 2 mounting holes.

ZHJC variant: Base variant

ZHJS variant: Includes safety against exposed thread

ZHFVJ variant: Enables lower minimum adjustment with a high total adjustment

These machine feet are 3-A certified hygienic versions of our standard fully threaded levelling feet. They are available in sizes from 65mm to 150mm.

XH variant: The XH system allows for exceptionally easy adjustment during installation, with a weight capacity of up to 70,000N and builtin slope compensation of up to 10°.

XH-FIX variant: Includes floor fixing options and allowing up to 4,000N tensile load. Available in foot diameters 65, 80, 105 and 125mm.

XHG variant: These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression loads of up to 110.000N and can compensate for floor slopes of up to 9°.

XHJ variant: These feet have a high pull rating. Applications are great for robotics or anything that creates upward forces on the spindle (ie tensile). They support compression and tensile loads of up to 110.000N and 20.000N, respectively. The feet can compensate for floor slopes of up to 9°.

XHT variant: Comes with a separate spindle and footplate, ideal for indexing machines that need to be moved and placed back precisely. The rubber underside provides a suction cup effect, preventing movement. This variant can handle an additional 5°, resulting in up to 15° slope compensation.

These feet enable lower minimum adjustment with high total adjustment and are 3-A certified.

XHFV variant: The XH system allows for exceptionally easy adjustment during installation, with a weight capacity of up to 70,000N and builtin slope compensation of up to 10°.

XHFV-FIX variant: Includes floor fixing options and allowing up to 4,000N tensile load. Available in foot diameters 65, 80, 105 and 125mm.

• Material and Sizes: Our hygienic levelling feet are available in foot diameter sizes ranging from 65mm to 150mm. All feet can be made in AISI 304 or AISI 316 stainless-steel and are equipped with vulcanized FDA-approved rubber to prevent slippage and reduce vibration transmission. Rubbers are available in black, blue and white NBR and black EPDM.

• Construction Details: All feet are made from high-quality stainless steel, utilizing a formed stainless-steel plate with vulcanized rubber on the underside, providing corrosion resistance and longevity. These feet have excellent vibrationdamping properties

• Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a straightforward installation process.

XHFVG variant: These feet include a bolted connection for minimum play between the footplate and spindle. They support compression loads of up to 110.000N and can compensate for floor slopes of up to 9°.

XHFVJ variant: These feet include a bolted connection for minimum play between the footplate and spindle. They support compression and tensile loads of up to 110.000N and 20.000N, respectively. The feet can compensate for floor slopes of up to 9°.

XHFVJ variant: Comes with a separate spindle and footplate, ideal for indexing machines that need to be moved and placed back precisely. Flexible mounting with optional flanges or thread adaptor

Certified and designed to meet the strictest standards of cleanliness and durability.

Our bearings reduce the emission of grease spreading from the bearing to both wastewater and to other parts of the production environment.

Certified by EHEDG, 3-A, USDA standards, and IP69K-classified.

Two fastening types: locking collars and screws, with steel or ceramic balls.

Made of sturdy grilamid with co-molded FDA-approved TPS seals. Solid construction ensures long-lasting performance and cost efficiency.

Flexible mounting with patented seal system, waterproof at over 3° misalignment.

ROI calculator available online to calculate savings

Our top-quality hygienic bearing houses are certified and designed to meet the strictest standards of cleanliness and durability. They are ideal for industries such as food processing where hygiene is of utmost importance..

These bearing houses come with various types of open or closed covers. The house and covers are available in white and blue colors which can be combined on request.

In addition, they are available in an anti-static variant which is marked with “EC” after the product name.

XB2FC variant: installed parallel to the shaft direction, featuring two flanges.

Available with high-quality bearings in stainless steel or ceramic hybrid bearings.

XB3FC variant: installed parallel to the shaft direction, featuring three flanges.

Available with high-quality bearings in stainless steel or ceramic hybrid bearings.

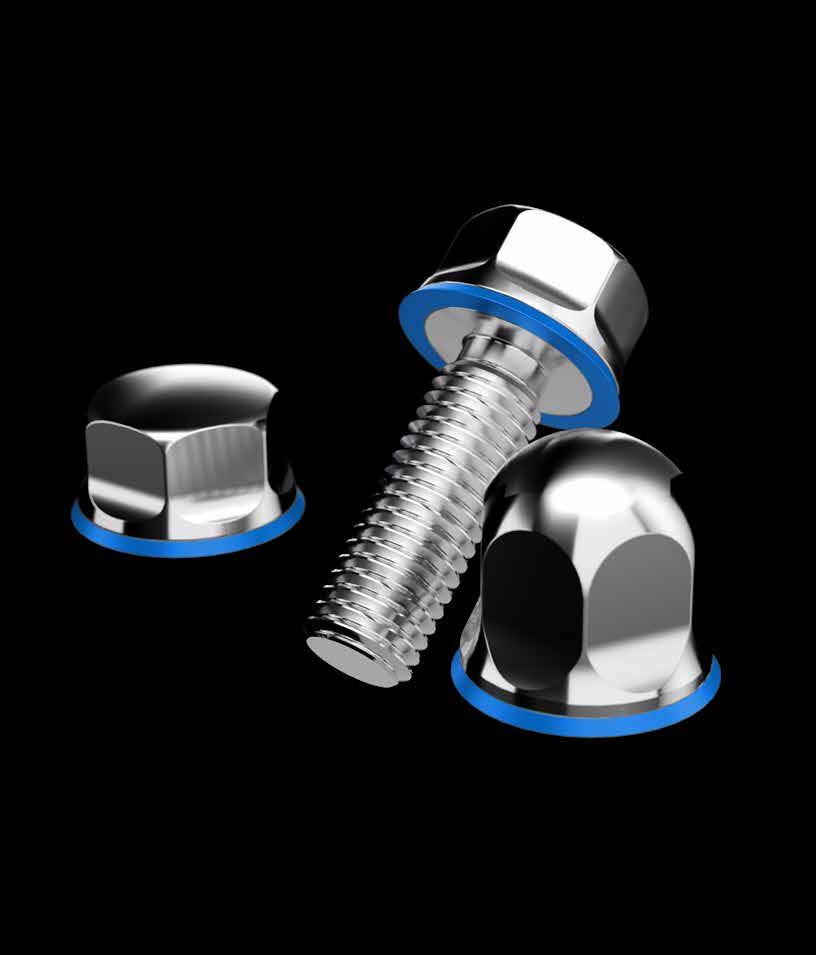

Furthermore, all models can be supplied with certified hygienic nuts and bolts for maximum hygienic safety. Our bolts and nuts are necessary for installation to guarantee compliance with EHEDG, 3-A, and USDA standards.

Additionally, the USDA certification mandates the inclusion of spacers in the assembly process.

• Material and Sizes: Our bearing houses come with 2 types of fastening, locking collars and screws. In addition, they are available with either steel or ceramic balls. They are available in sizes from 2040 mm and 3/4”-1 1/2”.

• Construction Details: Our bearing houses are constructed of sturdy grilamid with co-moulded FDA-approved TPS seals. Their solid construction

XB4FC variant: installed parallel to the shaft direction, featuring four flanges.

Available with high-quality bearings in stainless steel or ceramic hybrid bearings.

XBPBC variant: installed perpendicularly to the shaft direction.

Available with high-quality bearings in stainless steel or ceramic hybrid bearings.

guarantees long-lasting performance and reliability, making them a cost-efficient option for ensuring optimal equipment functionality.

• Ease of Installation: The mounting pattern is identical to the existing bearing houses on the market and a replacement is therefore easy while achieving a more hygienic solution on your equipment.

XBTBC variant: installed perpendicularly to the shaft direction and equipped with 2 threaded inserts.

Available with high-quality bearings in stainless steel or ceramic hybrid bearings.

Our stainless steel inserts bearings are of the highest quality. Seals are made from FDA blue NBR.

SSB bearing: Stainless steel bearing, stainless steel balls and AISI 440 rings

SSA bearing: Stainless steel bearing, stainless steel balls and AISI 440 rings with eccentric locking collar

Our ceramic hybrid high performance insert bearings are of the highest quality. Seals are made from FDA blue NBR.

CSA bearing: Ceramic Bearing, hybrid with ceramic balls and AISI 440 rings as well as eccentric locking collar.

CSB bearing: Ceramic Bearing, hybrid with ceramic balls and AISI 440 rings.

Designed in compliance with EHEDG, 3-A, and USDA standards. Our levelling castors provide the flexibility to adjust the height of your equipment according to your specific needs.

We can also offer plate fitting and single bolt hole fitting.

Wheel made from white polyamide with blue polyurethane tread and sealings made with FDA-approved TPE and available in wheel dimension Ø100, made from stainless steel.

One-sided fork body design for easy cleaning and enhanced hygiene and durable, corrosionresistant stainless-steel construction.

Equipped with two high-quality stainless steel ball bearings.

Compliant with DS/EN 12532:1999 and DS/EN 12527:1999 standards.

Wash down test shows up to 32% savings compared to standard castors.

Our hygienically optimized castors are designed to meet the highest standards of cleanliness and functionality in production environments.

With a wide range of mounting options and a load capacity of up to 200kg, we are equipped to address your specific challenges and ensure smooth, efficient operations.

Our new castors have been tested against standard castors by FORCE Technology - the Danish Research and Technology

Organization of Hygienic Design. These tests highlight the significant savings in resources and the enhanced food safety provided by our castors. Find the video online showing the test.

Online you can also find a video showing our castors in operation. These tests illustrated the quantity of debris that castors accumulate from the production floor while in use. The results were evident! – the hygienic design of our castors ensures that dirt does not accumulate and therefore minimizes the risks of cross-contamination between production zones.

These adjustable castors come in both metric and imperial sizes, ranging from M24 to M36 (1” & 1 ¼”). Available in both long and short variants, they feature a sleeve that covers the threads to meet stringent hygiene requirements.

XSC variant: The hygienic castor with levelling spindle of customers choice with swivel, but without brake.

XSCB Series: The hygienic castor with levelling spindle of customers choice - Similar to the XSC but includes a wheel and swivel lock.

XC Series: The hygienic castor with levelling spindle of customers choice - Similar to the XSC but with a rigid swivel

• Material and Sizes: The wheel of the castor is crafted from white polyamide, and the blue tread is made from polyurethane. All sealings are made with FDA-approved TPE. These castors are available in wheel dimension Ø100 and are constructed from high-quality stainless steel AISI 304/A2 (1.4301).

• Construction Details: Our castors are designed with a one-sided fork body that facilitates easy cleaning, thereby enhancing hygiene in

production environments. Constructed from durable and corrosion-resistant stainless steel, the body is built to last. Each castor is equipped with two high-quality stainless steel ball bearings for smooth operation. Moreover, these castors comply with DS/EN 12532:1999 & DS/EN 12527:1999 standards, ensuring they meet industry regulations and deliver high-quality performance.

• Ease of Installation: With a wide range of mounting possibilities the castors are designed to fit your needs.

These hygienic castors come with single bolt fitting.

XSCR Series: Hygienic Swivel Castor Round - Features a round flange with a central thread for direct screw-in to the frame or machine. Available in both metric and imperial sizes, ranging from M16 to M36 (5/8” to 1 ¼”).

XSCRB Series: Hygienic Swivel Castor Round Brake - Similar to the XSCR but includes a wheel and swivel lock.

XCR Series: Hygienic Castor Round - Similar to the XSCR but with a rigid swivel

These hygienic castors come with plate fitting.

XSCS Series: Hygienic Swivel Castor Square - This model comes with a square flange, allowing for direct mounting to the machine.

XSCSB Series: Hygienic Swivel Castor Square Brake - Identical to XSCS, with the addition of a wheel and swivel lock.

XSC Series: Hygienic Castor Square - Similar to the XSCS but with a rigid swivel

Watch our online video to see how castors collect debris during real production. The results speak for themselves: NGI’s hygienic design prevents dirt build-up, minimizing the risk of cross-contamination between production zones.

Watch the videos at ngi-global.com

When we are 120% satisfied with the solution– we launch!

Our products are specifically designed for hygienic optimization and optimal food saftey. Most of our components are certified in accordance wth 3-A, EHEDG and USDA standards. We offer:

Consultancy and development of customized solutions

ROI calculations for hygienic design

Hygiene and sustainable optimization

Sustainable product development and documentation

Securing the future via patents, design protection and certifications

Our hygienic accessories are specifically designed to adhere to strict food safety standards, reducing the chances of contamination.

Contaminants like bacteria, mold, or foreign particles can jeopardize the safety of food items, posing health risks to consumers.

By employing hygienic accessories, you can ensure compliance with these regulations, thereby avoiding legal complications and penalties.

Our hygienic accessories are crafted from stainless steel to facilitate easy cleaning and disinfection. We are committed to adhering to design standards set by USDA, 3-A, and EHEDG.

By using our hygienic accessories and by following proper cleaning and sanitation protocols, you can effectively reduce the risk of cross-contamination between various food items or batches, ultimately minimizing the likelihood of foodborne illnesses.

Discover our extensive range of various accessories, including bolts and nuts, flanges, plungers, handles, latches, knobs, spacers, adapters, top covers, and cable glands.

Our assortment is constantly growing, with an increasing number of component types and sizes.

Our efficient production process guarantees fast turnaround times and competitive pricing.

Additionally, we are pleased to provide customized models and sizes to meet your specific requirements.

We offer a range of EHEDG-certified hygienic bolts designed to enhance sanitation and efficiency in production environments. Our bolts are tailored to reduce cleaning time and resource consumption, ensuring a cost-effective and hygienic solution.

BXH: Bolt Certified Hygienic, available either partially or fully threaded.

BFXH: Bolt Fit Certified Hygienic, with a wide shank, ideal for applications requiring precise alignment.

BRXH: Bolt Reduced shank Certified Hygienic, also known as a captive screw. This bolt is designed to stay attached to one part (like a machine cover) when disassembled, preventing loss.

CBXH: Carriage Bolt Certified Hygienic, fully compatible with DIN 603. This bolt is suitable for applications that don’t have clearance for a traditional bolt head, however, this requires a square hole instead of a traditional round hole.

STBXH: Self-tapping bolt Certified Hygienic, is designed specifically for fastening steel to nylon without a threaded insert.

Our EHEDG-certified hygienic nuts with blue sealing provide a secure solution for machinery in wash-down environments by blocking out water and bacteria. The design matches standard nuts, simplifying the upgrade process.

NDXH: Nut Domed Certified Hygienic, also known as an acorn nut.

NLXH: Nut Low Certified Hygienic, a shorter variant of NDXH.

Our hygienic stainless steel SLX latches are meticulously designed to prevent bacterial accumulation and meet stringent hygiene standards for food machinery.

SLX Hygienic Latch: Ensures a secure closure through a maximum 90° rotation, positioning it securely behind the frame when locked.

We offer hygienic knobs with threaded pin or internal thread options. These knobs are designed to meet the highest standards of hygiene and functionality, ensuring optimal performance in various environments.

XK Series: Round hygienic knob.

XKG Series: Round knob with divots for improved grip.

XK3W Series: Hygienic knob with three wings for enhanced handling.

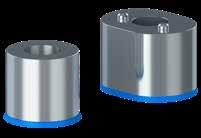

Our hygienic spacers are designed with a high focus on hygienic design to ensure that equipment can be easily cleaned behind and around all components.

SRXH variant: Standard spacer with an internal clearance hole

SRTXH variant: Spacer with internal thread either partly or fully threaded

SRTFXH variant: Spacer with internal and external thread

Hygienic spacers that comply with the USDA-recommended distance from machines and equipment. Use the spacers for hygienic installation of our bearing houses according to USDA regulations.

Spacer Round

Spacer Oval

Discover our extensive range of various accessories, including bolts and nuts, flanges, plungers, handles, latches, knobs, spacers, adapters, top covers, and cable glands.

Our assortment is constantly growing, with an increasing number of component types and sizes.

Our efficient production process guarantees fast turnaround times and competitive pricing.

Additionally, we are pleased to provide customized models and sizes to meet your specific requirements.

NGI offers a range of hygienic handles designed to enhance cleanliness and functionality in food production and other sanitary environments.

UHX Series: U-shaped hygienic handle.

The HSK Hygienic cable gland is meticulously designed to prevent the accumulation of microorganisms and dirt in industries such as pharmaceuticals, food, chemicals, biotechnology, and clean room technology.

Certified with IP66, IP68, and IP69K ratings, these cable glands are suitable for use in even the most demanding environments.

HSK Series: Hygienic cable glands.

• Material and Sizes: Our hygienic accessories are constructed from AISI 316 stainless steel, ensuring both hygiene and durability. Most of our accessories knobs feature seals available in blue, black, and white colors, crafted from NBR, HNBR, EPDM, FKP, and silicone materials. They are offered in both standard and customized measurements to meet diverse requirements.

• Construction Details: Our hygienic accessories feature blue sealings for easy detection by scanning systems. Their self-draining design minimizes cleaning efforts, making them ideal for sanitary applications.

• Ease of Installation: Designed for easy integration, our hygienic accessories fit seamlessly into your existing systems, ensuring straightforward installation without the need for additional adjustments.

Our hygienic indexing plungers are designed to meet the highest standards of cleanliness and functionality, offering numerous benefits for various applications, particularly in food sanitation.

PXH6: Hygienic indexing plunger, size 6.

I

PXH8: Hygienic indexing plunger, size 8.

Our hygienic flanges are designed for the installation of XHFV and ZHFVJ levelling feet into machinery or equipment. These flanges offer versatile mounting options and are available in a variety of sizes to meet different requirements.

WFRX Series: Welding flange round hygienic, can be welded to the frame or machine.

MFQX Series: Mounting flange square hygienic can be welded to the frame or machine.

Our hygienic top cover is designed to provide sanitary protection in scenarios where the upper part of the thread is exposed, potentially compromising the hygiene standards and certification of the levelling foot. By employing the top cover, the exposed thread becomes hygienically sealed.

THOX Series: Hygienic top cover designed for robust performance and hygiene.

The thread adaptor is an add-on for the XHFV & ZHFVJ system. It converts the size and type of the thread and extends the sleeve.

AX Adaptor: Adaptor for XHFV & ZHFVJ system.

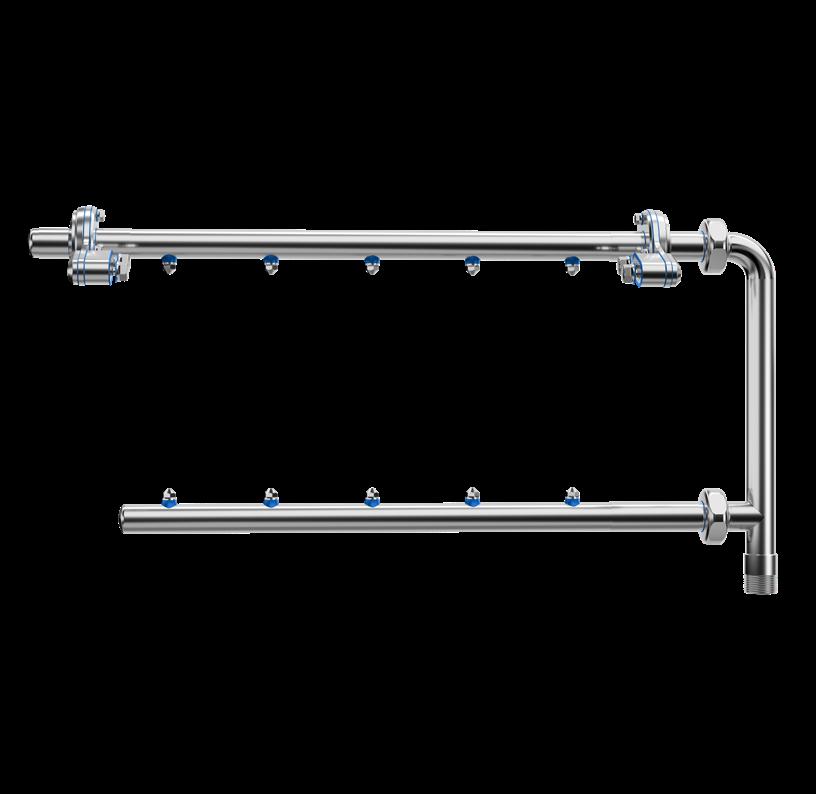

Optimize your belt cleaning sustainably and elevate your hygiene levels with our CIP Unit (spray bar).

Nozzles are mounted on the bar and spray the back and the front of the conveyor belt between production batches. It is easy to install as it is compatible with all standard conveyor belts.

Made from AISI 316 stainless steel with an electro-polished finish for durability and hygiene.

Features angular adjustability of both bars for flexible cleaning options.

Minimizes contamination and microbial growth, enhancing food production hygiene.

Complies with EHEDG, 3-A, and USDA design principles for top cleanliness standards.

Wash down test by Force Technology confirms efficient cleaning for conveyor belts.

CIP Unit – a Plug & Play unit for the belting equipment in the food industry that makes cleaning both easier, more effective and more environmentally friendly.

The CIP unit is a simple but efficient solution, where nozzles are mounted on the bar and spray the back and the front of the conveyor belt between production batches.

Our CIP Unit is easy to install as it is compatible with all standard conveyor belts. We have three different mounting fasteners all depending on whether the CIP unit is to be mounted on a square, a square angled, or a round tube.

When installed, you minimize contamination and microbial growth and increase your hygiene level. The CIP Unit has angular adjustability of both bars.

Also see a brief video at our websiteshowcasing our CIP Unit in operation, demonstrating the efficiency with which it cleans a conveyor belt.

Additionally, we have conducted tests on our CIP Unit at the Center for Hygienic Design (CHD) at FORCE Technology, yielding compelling results. Download the wash test online to obtain further information.

Optimize your belt cleaning sustainably and elevate your hygiene levels with our CIP Unit (spray bar). We have many different versions and both single spray bar or double spray bar. Contact us to learn more or explore the models at our website.

Single or double spray bar

No of nozzles: 6 - 16

Belt width: 10/12” - 30/32”

• Material and Sizes: Constructed from AISI 316 stainless steel with an electro-polished finish, the CIP unit ensures durability and hygiene.

• Construction Details: Our CIP Unit is compatible with all standard conveyor belts and offers four different mounting fasteners to suit various conveyor types: square, square-angled, round tubes, and flat-sided conveyors.

The unit features angular adjustability of both bars, providing flexible cleaning options.

• Ease of Installation: Designed for easy assembly, our CIP Unit integrates seamlessly into existing systems with multiple mounting options, ensuring a quick and hassle-free setup.

Stop carryback before it becomes a risk and keep your production line cleaner, safer, and more efficient.

Our hygienic scraper is designed for quick access and easy maintenance - helping you maintain top hygiene standards with minimal downtime.

Quick-release mechanism for fast belt access and easy installation/removal.

Adjustable pressure system for precise, consistent cleaning.

Fits belts up to 180 cm and integrates with new or existing conveyor systems.

AISI 316 stainless steel construction for durability and hygiene.

Complies with EHEDG and 3-A standards for food safety.

Blue Cast-PU scraper blade for excellent wear resistance and food safety.

Our Hygienic Belt Scraper is purpose-built for food-processing environments, combining advanced hygienic design with effortless maintenance to keep your production line running smoothly.

Each scraper is equipped with a high-performance Blue PUR blade, chosen for its excellent wear resistance, low friction, and food-safe properties - delivering reliable cleaning and minimizing the risk of carryback and contamination.

The innovative quick-release mechanism allows for fast belt access, while the adjustable pressure system ensures you can fine-tune cleaning performance for consistent, optimal results.

With six distinct configurations available, we tailor each scraper setup to your specific conveyor - taking into account belt width, tension, load, and wear conditions - so you get a solution that fits perfectly and performs from day one.

Our hygienic belt scraper range includes six specialized models, each designed for seamless integration and optimal cleaning performance in food-processing environments:

Model 1 - SBNX: Simple manual release with adjustable pressure. Best for straightforward applications where manual release and easy pressure adjustment are sufficient.

Model 2 - SBIX: Angle-adjustable manual release with adjustable pressure.

Ideal for belts requiring precise cleaning with angle adjustment.

• Material and Sizes: Constructed from AISI 316 stainless steel with an electro-polished finish for maximum durability and hygiene. Each scraper is equipped with a high-performance scraper blade made from Blue PUR, ensuring excellent wear resistance and food safety. The system supports belt widths up to 180 cm for broad application flexibility.

• Construction Details: Our belt scraper range includes six versatile models, each designed for

seamless integration with both new and existing conveyor systems. All models provide flexible cleaning options and consistent performance. The Blue PUR blade material is specifically chosen for its low friction, detectability, and suitability for hygienic environments.

• Ease of Installation: Engineered for straightforward assembly, the belt scraper comes with mounting fittings included and is designed for fast installation and effortless removal, minimizing downtime and simplifying maintenance.

Model 3 - SBOX: Angle-adjustable manual release with external adjustable pressure.

Perfect for systems needing both angle adjustment and external pressure control.

Model 4 - SBCX: Scraper with angle- and pressure-adjustable weight arm (external).

Recommended for applications needing consistent cleaning force with an external weight arm.

Model 5 - SBPX: Adjustable pressure with quick pressure release. Optimal for fast maintenance with a quick-release mechanism.

Watch our step-by-step installation videos for SBPX-Q, SBPX-B, and SBPX-C models on our website.

Model 6 - SBAPX: Adjustable pressure with multiple fixed intervals and pressure release.

Suited for operations requiring repeatable pressure settings and quick release.

We can help you find the right solution

Country-specific key account consultants with local lanuage skills

High involvement in our customer’s businesses and needs

Consulting, sparring and knowledge-sharing

We take pride in offering only the highest quality components that are designed to be long-lasting. Each product undergoes thorough testing to ensure it meets our strict standards.

Our extensive assortment features a wide range of standard components to cater to all your requirements.

In this section you can also find seismic and weighing levelling feet - both fully threaded and hygienic versions.

Our diverse selection guarantees that you will find the perfect component for your equipment.

We have a growing variety of components and various types and sizes.

Our streamlined manufacturing process ensures quick turnaround times and competitive prices.

Crafted from stainless steel. These levelling feet are ideal for machinery and equipment in medium-weight production settings, offering excellent value.

Available in AISI 304 or AISI 316 stainless steel utilizing a formed stainless-steel plate with vulcanized rubber on the underside

Excellent vibration-damping properties and corrosion resistance.

Self-draining surfaces for enhanced hygiene on many models.

Wide variety in footplate design and functionality and unlimited customized height variations.

Thousands of variations in weight load, height adjustment, and flexible mounting.

We provide an extensive range of standard fully threaded levelling feet crafted from stainless steel.

These levelling feet are ideal for machinery and equipment in medium-weight production settings, offering excellent value with many models featuring self-draining surfaces. The dependability of the fully-threaded leveling feet has been recognized by customers globally for over five decades, and the existing product range reflects a sustained commitment to innovation and responsiveness to market input.

Features a self-draining footplate in diameters from 65mm to 150mm with black, blue, or white rubber.

HX Variant: Base variant. Allows for effortless adjustment during installation, with a weight capacity of up to 70,000N and built-in slope compensation of up to 10°.

HX-FIX Variant: Includes floor fixing options, available in sizes from 65mm to 125mm, allowing up to 4,000N tensile load.

HXT Variant: Comes with a separate spindle and footplate, ideal for indexing machines that need to be moved and placed back precisely. The rubber underside provides a suction cup effect, preventing movement. This variant can handle an additional 5°, resulting in up to 15° slope compensation.

Available in footplate sizes from 40mm to 180mm, with a load capacity of up to 50,000N and slope compensation of 5°.

M Variant: Base variant.

The M-FIX Variant: The M-series in sizes 75mm and 100mm are available with one or two floor fixing points, with a tensile capacity of up to 3,500N.

• Material and Sizes: Our stainless-steel levelling feet are available in various sizes to suit different applications and come in either AISI 304 or AISI 316, ensuring robust performance and durability for any environment.

• Construction Details: All feet are made from high-quality stainless steel, utilizing a formed stainless-steel plate with vulcanized rubber on

the underside, providing corrosion resistance and longevity. These feet have excellent vibrationdamping properties. Many models also feature self-draining surfaces for enhanced hygiene and maintenance.

• Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a smooth and trouble-free installation process.

Made from stainless steel. Ideal for heavy machinery and equipment, providing a sturdy and durable solution.

Made in AISI 304 or AISI 316 stainless steel and designed for high load and high pull applications.

Foot diameters range from 40mm to 150mm; other sizes available on request.

Optional FDA-approved vulcanized rubber (black, blue, white NBR, and black EPDM) for anti-slip and vibration reduction.

Wide variety in footplate design and functionality and unlimited customized height variations.

Thousands of variations in weight load, height adjustment, and flexible mounting.

We offer a wide selection of solid fully threaded levelling feet made from stainless steel. Our solid levelling feet are ideal for heavy machinery and equipment, providing a sturdy and durable solution.

The reliability of the solid fully-threaded levelling feet has been appreciated by customers world-wide for more than 50 years and the current product portfolio is a result of a continuous innovative approach and market feedback.

Bolts, nuts, washers, welding plates and plastic bushings can be supplied

These feet feature a solid construction and support compression loads of up to 120.000N, while they can compensate for floor slopes of up to 8°.

KG/KG-AS variant: Base variant without mounting holes

KJ/KJ-AS variant: Includes mounting holes and supports tensile loads of up to 8.000N

KT/KT-AS variant: Separated spindle and footplate for easily removing and placing the machine at the same location again. Compensate for floor slopes of up to 20°.

KCF/KCF-AS variant: Includes a decentred spindle and mounting hole and supports tensile loads of up to 12.000N

These feet include a bolted connection for minimum play between the footplate and spindle (except HXGT/HXGT-AS). They support compression loads of up to 110.000N. Compensate for floor slopes of up to 9°.

HXG/HXG-AS variant: Base variant without mounting holes

HXJ/HXJ-AS variant: Includes mounting holes and supports tensile loads of up to 20.000N

HXGT/HXGT-AS variant: Separated spindle and footplate for easily removing and placing the machine at the same location again. Compensate for floor slopes of up to 15°.

These feet are ideal for installation on flat surfaces as the slope of the spindle is limited to 1°. These feet support compression loads of up to 120.000N.

G/G-AS variant: Base variant without mounting holes

J/J-AS variant: Includes mounting holes and supports tensile loads of up to 12.250N

CF/CF-AS variant: Includes a decentred spindle and mounting hole and supports tensile loads of up to 12.000N

• Material and Sizes: Our solid fully threaded levelling feet are available in foot diameter sizes ranging from 40mm to 150mm (other sizes available upon request). All feet can be made in AISI 304 or AISI 316 stainless steel. Each version can be optionally equipped with vulcanized FDA-approved rubber to prevent slippage and reduce vibration transmission (marked with “AS”). Rubbers are available in black, blue and white NBR and black EPDM.

• Construction Details: All feet are made from high-quality stainless steel. Each version can be optionally equipped with vulcanized rubber on the underside, providing corrosion resistance and longevity. Our robust levelling feet are perfect for heavy machinery and equipment.

• Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a straightforward installation process.

Designed for light- to middleweight load capacities across various industries including manufacturing, electronics, and furniture.

Available in diameters from 40mm to 125mm, with fixing for sizes 80mm+.

Footplate made from black PA6 with AISI 304 or AISI 316 stainless steel spindles.

Footplate made from reinforced polyamide.

Unlimited customized height variations and optional floor fastening with sealed mounting holes.

Various options in weight load, height adjustment, and flexible mounting parts.

We offer a diverse range of plastic fully threaded levelling feet, designed for light- to middleweight load capacities across various industries including manufacturing, electronics, and furniture.

Each version can be optionally equipped with a rubbercoated underside to prevent slippage and reduce vibration

transmission. They can compensate for floor slopes up to 10°. These feet are tailored to meet specific needs, providing a cost-effective solution.

These feet lack a plastic cover for floor anchors and support loads up to 45,000N and up to 300N tension.

With a self-draining plastic cap, they support loads up to 22,000N and 300N in tension.

HPG-AS Variant: Includes a rubber-coated underside.

HPR-AS Variant: Upgraded with stainless steel cap and added rubber coating on the underside.

• Material and Sizes: Our plastic levelling feet are available in foot diameter sizes ranging from 40mm to 125mm, with sizes 80mm and up being available with fixing.

• All feet feature a footplate made from PA6 in black, with options for AISI 304 or AISI 316 stainless-steel spindles. The HPA-FIX variant in size 125 is also available in blue PA6.

HPA-FIX: Features two marked holes for floor fixing, available in size 80mm and up.

HPA-AS: Identical to HPA with an added rubber underside.

HPA-FIXAS: Similar to HPA-FIX, includes a rubber underside.

• Construction Details: All feet are made from highquality stainless steel with plastic footplates, providing corrosion resistance and longevity. Many models include self-draining surfaces for enhanced hygiene and maintenance.

• Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a straightforward installation process

Available with load cell ranges from 30-2000 kg per foot. Constructed from stainless steel AISI 304 (1.4301) with optional AISI 316 (1.4401) for enhanced durability and corrosion resistance.

Optimized for PR 6251 PanCake load cells for top weighing performance.

One-point impact between load cell and spindle guarantees force transfer.

Ideal for supporting and weighing machinery, tanks, and vessels.

Plug-and-play, height-adjustable design for easy installation.

Hygienically sealed movable parts with blue detectable sealings.

Our weighing levelling feet are available with load cell ranges from 30-2000 kg per foot. Constructed from stainless steel AISI 304 (1.4301) with optional AISI 316 (1.4401) for enhanced durability and corrosion resistance.

All movable parts are 100% hygienically sealed even if the load on the foot is removed, and all sealings are blue and detectable by scanning systems.

Solid steel footplate with a rubber strip for a hygienic seal to the floor, with higher accuracy than the vulcanized series.

HXJW: Fully threaded spindle with holes for floor fixing.

XHJW: Hygienic spindle with sleeve.

The standard range with a vulcanized rubber footplate.

HXW: Standard fully threaded spindle.

XHW: Same footplate as HXW, featuring a fully hygienic spindle with sleeve.

HXTW: Standard footplate with a separate spindle.

XHTW: Standard footplate with a separate spindle, featuring a fully hygienic spindle with sleeve.

Solid steel footplate with a rubber strip for a hygienic seal to the floor, with higher accuracy than the vulcanized series.

HXGW: Fully threaded spindle

XHGW: Hygienic spindle with sleeve

HXGTW: With a separate fully threaded spindle.

XHGTW: With a separate spindle, featuring a fully hygienic spindle with sleeve.

• Construction Details: The one-point impact between the load cell and spindle ensures direct and friction-free transfer of force. The plug and play, height-adjustable compact design facilitates easy installation and integration into existing systems.

• Ease of Installation: Designed for straightforward installation, our weighing levelling feet ensure easy integration into your equipment, providing reliable and stable support.

Engineered for stability and compliance with California and New Zealand seismic regulations (NZS 4219:2009).

Capable of handling tension loads of up to 126,000N, compression loads up to 432,000N, and simultaneous horizontal loads of 58,000N.

Available in AISI 304 and AISI 316 stainless steel, with footplate sizes from 150mm to 400mm.

Hygienic versions with a sleeve optimize lowresource cleaning.

Accommodates up to a 10° floor slope with a locking mechanism for stiffness.

Fast installation with height-adjustable compact design. Movable set-up, no concrete molding, and seismic stability via bolted fastening and patented locking mechanism.

Our seismic levelling feet are engineered for stability and compliance with California and New Zealand seismic regulations (NZS 4219:2009).

These are our most robust levelling feet, capable of handling tension loads of up to 126,000N, compression loads up to 432,000N, and simultaneous horizontal loads of 58,000N. Developed and rigorously tested using the Finite Element Method (FEM), our seismic levelling feet ensure optimal performance during earthquakes. We can also supply nuts and anchors etc. for installation

Provide maximum adjustment interval, allowing for low-profile installations.

HXJE Variant: Features a round footplate for maximal strength and rigidity. This version includes a gasket to prevent dirt and bacteria from getting under the footplate.

HXJCFE Variant: Features an elongated footplate to facilitate easier installation.

Include a protective sleeve to prevent dirt from entering the threads, reducing dirt accumulation and allowing for ease of cleaning.

XHJSE Variant: Features a round footplate for maximal strength and rigidity. This version also includes a gasket to prevent dirt and bacteria from getting under the footplate.

XHJCFE Variant: Features an elongated footplate to facilitate easier installation.

• Material and Sizes: Our seismic levelling feet are available in both AISI 304 and AISI 316 stainless steel, with footplate sizes ranging from 150mm to 400mm in diameter, ensuring robust performance and durability for various environments. The round footplates provide optimal support and stability.

• Construction Details: All feet are made from highquality stainless steel, offering corrosion-

resistance and longevity. The hygienic versions feature a sleeve, optimizing the foot for lowresource cleaning. These machine feet can accommodate up to a 10° floor slope and include a locking mechanism to ensure the required stiffness once mounted and adjusted.

• Ease of Installation: Designed for easy adjustment and stability, our levelling feet ensure a smooth and trouble-free installation process.

Hilti’s seismic research includes detailed investigation of product performance under simulated seismic conditions and full-scale system testing.

Designed for durability and performance in heavy-duty applications with corrosion-resistant construction.

Fork housing made from corrosion-resistant stainless steel and white polyamide castor rim with blue polyurethane tread for traction and stability.

Wheel dimensions range from Ø80 to Ø200 for various industrial needs and equipped with stainless steel roller bearings for smooth movement.

Wheel axle secured with a nut for heavy-duty use.

Certified for load capacity according to EN 12527:1998 and EN 12532:1998 standards.

Cost-efficient models available with or without swivel or brake functionalities, along with choices for a hygienic or fully threaded spindle.

Our standard levelling castors are designed for durability and performance in heavy-duty applications with corrosionresistant construction.

The product group consists of three hygienic-oriented types of castors: A castor with a plate fitting, a castor with levelling spindles and a single bolt hole Ø13.

The castor type with hygienic levelling spindles makes it possible to level your machinery and equipment while maintaining an acceptable hygienic design.

Castor Square with a square mounting plate, without any braking or swivel function. Supports loads up to 4000N.

Swivel Castor Round, capable of swiveling with or without braking function. Supports loads up to 1500N.

SCR-HX Variant (formerly LCHX): Includes a fully threaded spindle. Capable of swiveling but without a braking function.

SCR-XH Variant (formerly LCXH): Features a hygienic spindle with a sleeve. Capable of swiveling but without a braking function.

SCRB-HX Variant (formerly LCHXB): Includes a fully threaded spindle. Swivel Castor Round with Brake.

SCRB-XH Variant (formerly LCXHB): Features a hygienic spindle with a sleeve. Swivel Castor Round with Brake.

• Material and Sizes: The robust fork housing is made from stainless steel AISI 304/A2 (1.4301), ensuring corrosion resistance. The white castor rim is crafted from high-quality polyamide, while the blue tread is made from resilient polyurethane, offering excellent traction and stability. We offer a range of wheel dimensions from Ø80 to Ø200 to meet various industrial needs.

• Construction Details: Each castor is equipped with stainless steel roller bearings, guaranteeing

smooth and efficient movement. The wheel axle is secured with a nut, providing a strong foundation for heavy-duty use. Our castors have been rigorously tested and certified for load capacity according to EN 12527:1998 and EN 12532:1998 standards.

• Ease of Installation: Designed for easy adjustment and stability, our levelling castors ensure a straightforward installation process.

Swivel Castor Square, capable of swiveling without any braking functionality. Supports loads up to 4000N.

Swivel Castor Square with Brake, includes a swivel function and a locking brake for both the wheel and swivel. Supports loads up to 4000N.

Can be combined with a fully threaded or hyginic spindle.

Swivel Castor with single bolt hole Ø13 capable of swiveling without any braking functionality. Supports loads up to 4000N. Can be combined with a fully threaded or hyginic spindle.

Swivel Castor with single bolt hole Ø13 and with Brake, includes a swivel function and a locking brake for both the wheel and swivel. Supports loads up to 1500N.

Can be combined with a fully threaded or hyginic spindle.

Designed to provide robust support and ensure hygienic standards across various production environments and ideal for tanks, vessels, and heavy machinery.

Crafted from high-quality materials with a fixed blue sealing ring detectable by scanning systems.

Made from AISI 304 or AISI 316 stainless steel for corrosion resistance and longevity.

Hygienic versions include a sleeve for easy cleaning and reduced contamination.

Weld mounts (adjustable ball feet) available in various sizes, customizable for different pipe dimensions.

Designed to handle significant weight loads and floor inclines for stability.

We offer a range of tank support bolts and weld mounts designed to provide robust support and ensure hygienic standards across various production environments. Each product is tailored to minimize cleaning effort and enhance stability, making them ideal for demanding applications.

Choose our tank support bolts to secure your heavy machinery with a hygienic design. Our solutions provide unmatched reliability, safety, and cleanliness in demanding production environments.

Our tank support bolts are crafted to manage substantial weight loads and are well-suited for tanks, vessels, and heavy machinery.

SBX Model: Supports loads up to 493,600 N without a footplate. It can handle inclines of up to 20° and fits inside the machine leg.

KTSBX Model: Features a separated footplate, support bolt, and welding connector. The centrally located depression in the footplate secures the support bolt. This model supports a maximum weight of 200,000 N and can handle inclines of up to 20°.

KTSBX AS Model: Similar to the KTSBX model but includes antivibration, anti-slip rubber underneath the footplate. Maximum weight of 30,000 N. This model can also handle inclines of up to 20°.

Our BTX weld mounts, also known as adjustable ball feet or bullet feet, are ideal for food processing machinery, offering improved hygiene, stability, and space utilization.

BTX Model: Supports up to 112,000 N and is designed to weld externally at the bottom of the machine.

• Material and Sizes: Our tank support bolts are crafted from high-quality materials, with models featuring a fixed blue sealing ring detectable by scanning systems. The weld mounts, also known as adjustable ball feet or bullet feet, are available in various sizes and can be customized to accommodate different pipe dimensions.

• Construction Details: All tank support bolts and weld mounts are made from high-grade stainless steel either AISI 304 or AISI 316, providing

exceptional corrosion resistance and longevity. The hygienic versions feature a sleeve to optimize for easy cleaning and reduce contamination risks. These components are designed to handle significant weight loads and floor inclines, ensuring stability and safety.

• Ease of Installation: Designed for straightforward installation and easy adjustment, our tank support bolts and weld mounts ensure a smooth setup process. The support bolts can handle inclines of up to 20°, and the weld mounts can be adjusted internally for optimal fit and stability.

Can assist you in reducing engineering hours, enhancing your design processes through standardization, and lowering your production expenses.

Made from high-quality AISI 304 stainless steel and compatible with XH footplates, with or without fixing.

Standard adjustment ranges: 50mm, 100mm, 150mm, 200mm, 250mm, 400mm.

Outer diameters: 38mm and 51mm; minimum length varies by range and brackets.

51mm diameter tube for added stiffness in demanding applications.

Multiple configurations and top-sealing options available and offers robust support for conveyors, tables, and machinery.

NGI offers a highly flexible and adjustable support system which easily and effectively can be adapted to your machinery and conveyors.

Our adjustable support system will help you save engineering hours, optimize your design processes through standardization and minimize your production costs.

XL1: Singular straight leg with any foot or castor mounted to the end.

XL2: U-shaped set of legs with any feet or castors mounted to the bottom.

XLH: H-shaped set of legs with any feet or castors mounted to the bottom.

Custom: Multi-leg or half-leg variations are available upon request.

Larger diameter tube for improved stiffness. All 38mm versions are also available in the larger 51mm size and can be customized with your required brackets and to a length of your specification.

leg

U-shaped legs

U-shaped legs mounted with brackets

• Material and Sizes: Constructed from high-quality AISI 304 stainless-steel, our adjustable legs are available in standard adjustment ranges of 50mm, 100mm, 150mm, 200mm, 250mm, and 400mm. The minimum length of the leg depends on the range of adjustment and the required brackets. Available in outer diameter 38mm and 51mm. Please contact us for detailed information.

• Construction Details: Typically used with XH footplates, with or without fixing, our adjustable legs offer unparalleled stability and customization options. The 51mm diameter tube provides improved stiffness for more demanding applications.

• Ease of Installation: Designed for straightforward installation, our adjustable legs can be fitted with various brackets and customized top fittings to ensure a seamless connection between the legs and your machinery.

Our extensive assortment features a wide range of standard accessories to cater to all your requirements. Whether you need nuts, bipod support, tripod support, bushings, standard flanges, weldable spacers, and welding plates, we have it all.

Our competitive pricing strategy ensures that you receive the best value for your investment. Enjoy top-notch products at prices that are budget-friendly.

Our knowledgeable and approachable sales team is always available to assist you. Whether you require guidance in selecting the right accessories or have inquiries about your order, our experts are here to offer you personalized support and advice.

We understand the importance of timely delivery. Our efficient logistics team ensures that your orders are processed swiftly and delivered promptly.

We recognize the significance of cost-effectiveness while maintaining quality.

Our competitive pricing strategy ensures that you receive the best value for your investment. Enjoy top-notch products at prices that are budget-friendly.

Our standard bipod and tripod plastic bases are designed to provide robust support for various applications, accommodating five different standard tube sizes ranging from Ø38.1 to Ø60.3.

Bipod: Two supporting legs

Tripod: Three supporting legs

Our standard bushings are designed to provide durable and reliable support, featuring black PA6 material with brass threads. These bushings are available in a range of thread sizes, ensuring versatility for various applications.

PTIQ Series: Plastic Threaded Insert Square, available in sizes from 20x20mm to 60x60mm. Rectangular options are also available, such as 100x50mm.

PTIR Series: Plastic Threaded Insert Round, available in diameters from 30mm to 60.3mm.

• Material and Sizes: The robust fork housing is made from stainless steel AISI 304/A2 (1.4301), ensuring corrosion resistance. The white castor rim is crafted from high-quality polyamide, while the blue tread is made from resilient polyurethane, offering excellent traction and stability. We offer a range of wheel dimensions from Ø80 to Ø200 to meet various industrial needs.

• Construction Details: Each castor is equipped with stainless steel roller bearings, guaranteeing

Our standard welding plates are designed to provide complete sealing of tubes after welding, ensuring robust and reliable connections for various applications.

WPR: Welding Plate Round.

WPQ: Welding Plate Square.

Our standard flanges and threaded inserts are designed to meet the diverse mounting needs of machinery and equipment. These components come in various shapes and sizes, ensuring versatility and reliability for different applications.

TIRC Series: Threaded Insert Round Clearance - Features a nonthreaded portion inside the flange for compatibility with hygienic spindle setups.

TIR Series: Threaded Insert Round - A round threaded insert with threading all the way through.

WFQ Series: Welding Flange Square - A square flange with a full thread for secure welding installations.

WFR Series: Welding Flange Rond - A round flange with a full thread for secure welding installations.

smooth and efficient movement. The wheel axle is secured with a nut, providing a strong foundation for heavy-duty use. Our castors have been rigorously tested and certified for load capacity according to EN 12527:1998 and EN 12532:1998 standards.

• Ease of Installation: Designed for easy adjustment and stability, our levelling castors ensure a straightforward installation process.

Our weldable spacers are designed to provide robust and hygienic integration solutions for food processing facilities. Constructed from high-quality stainless steel, these spacers are built to withstand rigorous cleaning processes and harsh conditions, ensuring long-lasting performance and sanitation.

SR: Spacer Round with a through hole.

SRT: Spacer Round Threaded.

Offer higher motor efficiency, less power loss, increased reliability, reduced operating costs, simplified integration, and guaranteed higher food safety

Oil-free design reduces contamination risks and maintenance.

Superior speed and torque control for precision tasks.

Space-saving and easy to integrate design.

Torque from 2.1Nm to 180Nm, speeds from 19600 rpm.

Lengths from 193mm to 1500mm; options with or without encoder.

Technology enclosed within the drum for a compact, reliable solution.

Our synchronous drum motors offer higher motor efficiency, less power loss, increased reliability, reduced operating costs, simplified integration, and guaranteed higher food safety.

Ideal for mixing, conveying, and sorting in food processing, our synchronous motors provide precise control over speed and torque, essential for efficient operations.

Our NGI DriveTech devision is dedicated to handle our drum motors. Below, we present a selection from our product range; however, we also possess specialized catalog materials specifically for our drum motors.

MTS Series: Standard synchronous oil-free drum motors designed for general food processing applications. They offer high peak torque, suitable for various conveyor systems. Our MTS Series are all UL certified.

MTS62: Slim 61 mm drum motor with gear ratios from 8–80, torque up to 19 Nm, speeds up to 563 RPM, and minimum shell length from 237 mm. Ideal for space-saving conveyor solutions and light-duty applications.

MTS82-0.19 Compact: Compact 81 mm motor, gear ratios 5–40, torque up to 23 Nm, speeds up to 600 RPM, and minimum shell length from 193 mm. Best for compact conveyors requiring higher speeds in tight spaces.

MTS82: Versatile 81 mm drum motor, gear ratios 5–160, torque up to 44 Nm, speeds up to 600 RPM, and minimum shell length from 260 mm. Suitable for a wide range of standard conveyor applications.

MTS113: Robust 112 mm motor, gear ratios 8–160, torque up to 44 Nm, speeds up to 375 RPM, and minimum shell length from 260 mm. Great for medium-duty conveyors needing reliable performance.

MTS115: High-torque 112 mm drum motor, gear ratios 10–160, torque up to 120 Nm, speeds up to 300 RPM, and minimum shell length from 320 mm. Designed for heavy loads and demanding conveyor tasks.

• Material and Sizes: Our drum motors are available in sizes ranging from 81mm to 136mm, with motor sizes between 0.19kW and 1.50kW. Torque and maximum speeds range from 2.9Nm to 180Nm and 19-600 rpm, respectively. Lengths are available from 288mm to 1500mm. Options with or without an encoder are available to suit your needs.

• Construction Details: The synchronous oil-free design ensures all technology is enclosed within

the drum, providing a compact and reliable solution. This design enhances food safety by eliminating the need for oil, thus reducing contamination risks.

• Ease of Installation: Our drum motors are designed for straightforward integration into existing systems, providing a versatile solution that can operate various belt types and designs.

MTD Series: Synchronous oil-free drum motors designed for heavy-duty applications requiring high continuous power and precision. Ideal for demanding tasks in food processing that require enhanced performance.

MTD138: 136 mm drum motor, gear ratios 10–32, torque up to 120 Nm, speeds up to 300 RPM, and minimum shell length from 350 mm. Optimized for higher speed and load requirements in larger systems.

MTD139: Heavy-duty 136 mm motor, gear ratios 32–40, torque up to 180 Nm, speeds up to 94 RPM, and minimum shell length from 410 mm. Perfect for the most demanding conveyor systems requiring maximum torque

We configure our drum motors precisely to your setup - taking into account tension, load, and usage patterns - so you save time, avoid costly errors, and receive a drive solution tailored to your needs.

Our comprehensive support services are designed to help you overcome challenges quickly and efficiently.

We’re committed to providing expert advice and are always ready to discuss your requirements in person - anytime, anywhere in the world.

Don’t hesitate to contact us to learn more. We take pride in delivering high-quality customer service and practical solutions that keep your operations running smoothly.

We have compared our synchronous drum motor with asynchronous

Learn about the advantages by using synchronous drum motors in regard to both food safety, efficiency and lower energy consumption!

Asynchronous drum motor

The asynchronous motor requires oil to cool down the motor which requires maintenance and can result in an oil leakage. In most cases, the leak is not identified until the engine stops running due to overheating caused by lack of oil. This means that the oil has been transferred into the food, undetected.

Asynchronous drum motors must work in oil bath to dissipate the heat generated by the motor inside. Leakage can be caused by excessive belt tensioning: this is a common problem with belting as belts tends to loosen with time and operators are required to increase the tension and it is easy to exceed.

The heat inside asynchronous motors is caused from losses: Iron losses, copper losses & mechanical losses Which results in low efficiency of the motor!

When using asynchronous motors, you will have no or very limited possibility to control the speed of the motor. When changing the rated speed on an asynchronous motor you will decrease the torque provided and therefore will not be able to convey the load.

An asynchronous motor has no torque available at low frequencies.

Our synchronous motors do not require oil. No oil equals no oil leakage, resulting in a cleaner and safer operation and higher food safety. Oil contamination of conveyed goods is therefore impossible – a perfect match for the food industry.

Our synchronous drum motors means high efficiency as they do not generate excess heat due to a very high efficiency (almost 95% of the energy we provide is turned into motion, and only 5% is lost as heat).

Synchronous drum motor

Our synchronous motors have a higher efficiency and up to 9 times lower power consumption than asynchronous drum motors due to minimized losses!

Our synchronous drum motors can convey very slowly or very fast – with continued high torque. This results in many new fields of applications – including quick starts and stops in packaging processes.

NGI constantly work to optimize the hygienic behaviour in the many companies using our certified hygienic components.

Our task goes far beyond just our products. We ensure responsible behavior through collaboration, insight and knowledge sharing accross industries and country borders.

Using NGI’s hygienic components significantly improves food safety, optimizes and reduces the use of cleaning ressources with minimum 28%.

Our customer service ensures prompt and professional assistance.

Our team consists of skilled professionals who manage and execute all orders with the utmost professionalism.

Offers multiple ways to contact support, such as phone, email, or chat.

Provides timely assistance for issues or questions.

Understands individual needs and offers tailored solutions.

Clarifies doubts about products, services, or policies.

Handles orders and questions in an effictive manner

Need components fast? Our upgraded webshop makes it easy:

Instant Solid STEP file downloads – No waiting, download directly from product pages.

Quick reordering – Find and repurchase previous orders in seconds.

Live lead times – See delivery estimates based on your selections.

24/7 access – Browse, plan, and order anytime.

From levelling feet to bearing houses and accessories, most items are in stock and ready to ship globally within days.

Explore the new features at ngi-global.com or contact us at ngi@ngi.dk | +45 98174500 to acquire username and password.

Line Knowledge-sharing

Improving hygiene and food safety doesn’t have to be difficult…

It is often just a matter of using the correct systematic and methods approach to solve specific issues. NGI’s brand owner partnership programme is a range of initiatives to ensure collaboration, insight, knowledge sharing, documentation and standardisation.

The NGI brand owner partnership programme consists of 5 concrete initiatives, which can improve food safety, hygiene and cleanability in your production environments.

The programme is a scalable set of tools, that can be adapted to the individual brand owners needs and wishes.

Get to know more about BOPP by NGI ngi-global.com/our-philosophy/bopp-partnership-programme/

Hygienic components. Delivered fast. Proven reliable

We design certified hygienic components that protect yield, shorten cleaning cycles, and simplify audits - so you can deliver machines with higher uptime and lower lifecycle costs.

IWorldwide delivery: 1–4 days (Scandinavia), 4–6 days (RoW)

Express delivery (next day) + Track & Trace

No minimum order quantities

Max. 12-hour response & 24-hour order confirmation

Orders shipped the same day (incoming)

Local language support via key account consultants

Only manufacturer of certified hygienic leveling feet

All types of high-quality leveling feet at competitive prices

We have partners and customers all over the world. Meet six of them here.

”NGI is a very interesting partner for us since their innovation within hygienic design allows us as a brand owner to specify hygienic EHEDG-certified levelling systems, thereby assuring that NGI will assist the OEM in implementing the most hygienic possible systems to our final gain.”

Hugo Durado & Sebastien Ducatteeuw, Mechanical engineer & Project manager, Barry Callebaut

”Being part of BOPP (NGI’s Brand Owner Partnership Programme) will allow us to offer our customers hygienic design advise about how to solve specific issues in their production regarding hygienic design and of course correctly combined with Ecolab cleaning procedures.”

Michael Stavad, European Application Specialist Food, Ecolab

”Hygienic design is extremely important to us. These drum motors are powerful, have low-self-heating, and are dry and robust. In addition, they reduce the individual components of a machine which makes construction easier.”

Andri Sveinsson, Project Manager for Innovation at Marel

”After having tested NGI’s hygienic bearing houses for almost two months in our production, we could conclude that they were the perfect solution as they require low maintenance. The bearings are lubrication-free when running, which results in significant resource savings.”

Mykola DubovykEquipment Maintenance Engineer, Trostyanets’ chocolate factory; Mondelez

”As part of Arla Maintenance it is crucial that the machines are up and running all the time. If we need to have extra downtime it will be a problem.”

Per Kaster Nielsen Maintenance, Arla

”The bearing houses from NGI increases the safety of our production environment as they are lubrication free when running and no grease can fall onto products or the production floor”

Preben Smith Korgaard, Technical Manager, Danpo A/S - a part of Scandi Standard

Discover how leading food manufacturers and OEMs are raising the bar for hygiene and efficiency with NGI.

Our online case stories and testimonials share honest feedback and practical results from customers across the globe - covering everything from streamlined cleaning to improved uptime and food safety.

See how companies like Arla, Amanda Seafoods, Bonduelle, Marel, and Uptimiz have optimized their production lines with NGI’s certified hygienic components.

Explore the challenge, solution, and effect in each storystraight from the people who use our products every day.

Watch video interviews and read in-depth case stories to learn why customers choose NGI as their partner in innovation.

Get inspired by real-world results and see what’s possible.

Find all our customer stories and testimonials at ngi-global.com.

BehindCleanLines is your go-to podcast for practical insights on hygienic manufacturing and design.

We explore a new topic aimed at professionals in food processing who want to enhance food safety.

We invite guests with relevant expertise - with guests like Dr. Thomas Buehler (Ecolab), Bill Marler (foodborne-illness attorney featured in Netflix’s Poisoned), Jennifer Crandall (CEO, Safe Food En Route), Debra Smith (Global Hygiene Specialist, Vikan), Steve Voelzke (Robroy Industries), and Nate Harrison (Phoenix Innovations).

Hear real-world lessons on design choices, strategic drivers, and the mindset that moves the food & beverage industry forward.

Listen on our website or your favorite platform.

Hygienic design is more than certified components - it’s about building equipment that reduces risk across the entire production process. Design flaws can lead to contamination, downtime, and compliance issues. For machine builders, this means creating systems that protect food safety while improving efficiency.

Updating equipment with hygienic design isn’t just about meeting standards - it’s about staying competitive and giving customers confidence. Hidden hygiene risks can cause cross-contamination and costly stops. Integrating hygienic principles from the start helps prevent these problems.

Our components are engineered for optimal hygiene and many meet strict 3-A, EHEDG, and USDA standards. True hygiene requires a holistic approach: evaluating the full production environment to eliminate vulnerabilities. When you design with hygienic components, you can:

Increase yield & efficiency

Maximize runtime & streamline cleaning

Enhance food safety & simplify compliance

Gain a competitive edge & boost customer confidence

Hygienic design is not an option - it’s a necessity for sustainable, safe, and high-performing production.

See the risk. Solve the risk. Eliminate food safety threats

At NGI, we’ve been developing hygienic solutions for over 50 years. Our focus is on fostering open dialogue and shared knowledge among key players in the food and machinery industries, recognizing that collaboration across the hygienic chain is essential for improving standards.

We measure our success by how well we enable and inspire our partners to make informed and wise decisions at every level.