2

A New Beginning

Master of Architecture Tectonics is a new program at the Faculty of Architecture at CEPT University. It is founded on the promise of developing competencies in architectural detailing and expression. The curriculum is focused on creating a community of fellow students and tutors who can examine, envision, and resolve a building’s architecture.

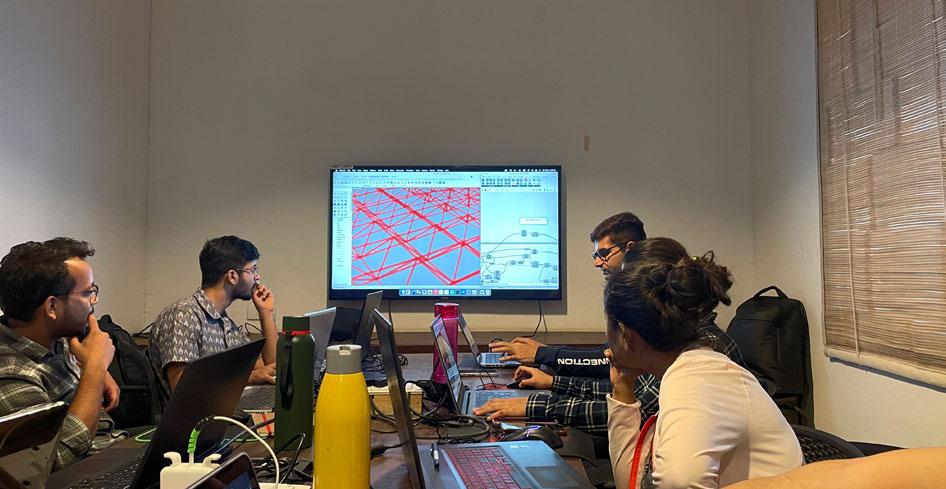

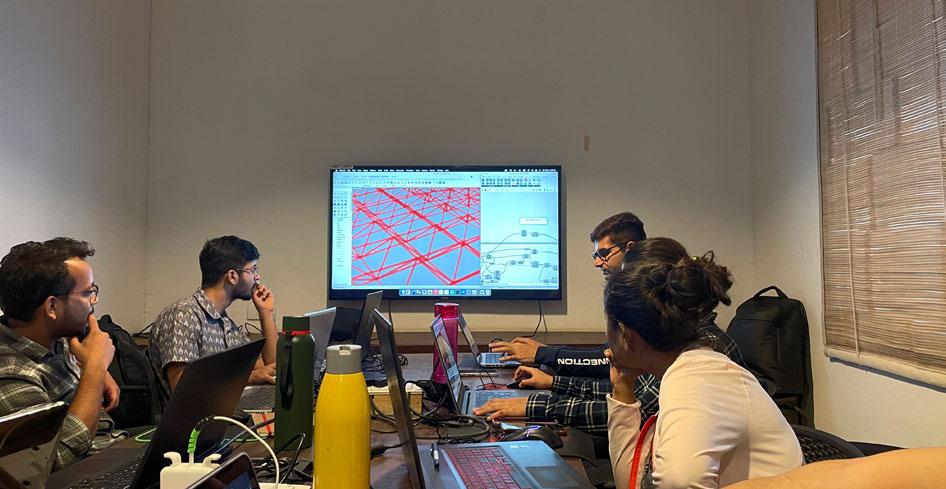

The MAT Foundation studio is a balancing act of four essentials of architectural tectonics. First, it teaches students how to make using analogy and digital workshop tools. The emphasis here is on tool handling, optimal posture while working, and the concentration required for general focus and safety. Second, it trains students to visualize structural stresses through modelling experiments. Students can express a detail based on structure and material properties. Third, it fosters agility in surveying available market items and products to employ them in detail or as a building element. Fourth, it prepares to discern between different sorts of drawings and create an appropriate drawing set to communicate an idea.

While grounded in the pedagogy around making as a basis, the studio never loses sight to be one of the prime movers of the future of architectural tectonics concerning India. An elaborate discussion on developing building language and aesthetics out of the coming together of industrial and natural material were taken at length to respond to some of our future environmental crises. In this sense, the foundation program is groundwork, reflexive yet with an eye set on the future for our students to lead with ideas when the time is right. We are very well answerable to a realistic present as much as to an imaginary future.

I acknowledge and express my deep gratitude to the students for having shown fortitude and taken a leap into the relentless demands of the foundation program. I am also thankful to my fellow teaching team Neel, Hemanshu, and Divya, for having supported me thoroughly and professionally during a tough academic time. We cannot fail in the beginning since we have failed so many times in the past. The studio remains incomplete without all of them. I wish to particularly thank Neel for having supported me in the studio throughout the last four years in a sustained way. I wish to thank CEPT workshop technicians Yatin bhai, Chirag bhai, Chhagan bhai and Amar bhai for training the students in the workshop. Maharshi bhai from FabLab ensured that the students learn 3D printing and laser cutting. Many thanks to him for his continuous support with modern tools. The studio also got immense support from Anjali Yagnik (Dean, Faculty of Architecture) in its inception, and colleagues of the Faculty of Architecture.

This booklet is inception to build a tradition of a compilation of studio work before the commencement of the CEPT exhibition. I am thankful to the entire student team to have made this possible.

Sankalpa

03 December, 2022

3

Foreword

4

Acknowledgement

The inception of MAT has been an exciting start of a journey towards a discrete vision in architectural practice that adds value through making, detailing, and meaning. The MAT Foundation studio successfully prompted us to reflect that a lot is yet to be explored, experienced, and experimented with. The studio inculcated knowledge in various areas allowing us to seek, analyse and reflect.

We thank Prof. Sankalpa and Neel Jain for opening our minds to a broader spectrum of skills and learnings. Our teaching associates, Hemanshu Dodiya, and Divya Solanki contributed significantly in adding value to the discussions and coordinating the studio. The studio framework helped us maneuver our thoughts into results through well-structured exercises and discussions. It was ensured that we became well versed with the workshop and sharpen our skills to understand the larger possibilities of making in Architecture. This inversion from making to drawing has made a difference in how we think now. We are grateful to Amar Kori, Chhagan Mahajan, Chirag Gajjar, Yatin Mistry, and the entire workshop team for their patience and guidance while training us at the workshop. Maharshi Solanki and Manish Patani guided us through the FAB-Lab and helped us explore digital fabrication technology.

During each exercise, the inputs from external mentors were insightful and needed at those crucial stages. We thank Anuj Anjaria, B.L. Manjunath and Shamik Desai for their valuable insights on mechanisms, building services, and structural systems.

Dinesh Sharma’s inputs on Fenestrations and Bhairav Patel and Aditya Patel on structural systems during midsemester reviews were valuable and thought-provoking.

We also thank our reviewers Mitul Desai, Pratik Soni, Saleem Bhatri, Saptak Patel, Sudhir Reddy, Smit Vyas, Surya Kakani, Vijay Arya and V. R. Shah for their valuable time and inputs on each of our projects. The conversations were interesting and provided a fresher perspective for thinking about a way forward in the program. Post-jury interactions with Bhavin Shukla and Kireet Patel opened avenues for discussions on varied topics. We thank you for initiating these valuable discussions.

Lastly, we would like to take this opportunity to thank every student who participates in the MAT Program. We all have been growing together through failure and success. Each of us is one of a kind and adds value and meaning to the journey ahead. We would continue to move forward with positivity and enthusiasm.

5

Khushi Daxini on behalf of MAT 2022 batch

6

Introduction

Course Description

The foundation studio aimed to set up a disciplinary impetus for the program with considerable emphasis on the method of design and making. The tectonic spatial form we see today is an expressive outcome of manipulating the geometrical logic, material,constructional, and structural ingenuities. The studio thus built the foundation of tectonics by ensuring students engage systematically in methods of investigation, derivation, and evaluation of form.

Four key considerations were accounted for while dealing with tectonics, namely:

1. Expression of detail as the articulation of structural forces

2. Expression of detail as the articulation of material and construction

3. Expression of the program as an articulation of detail

4. Expressive dimension of detail as expressed through prototypes, drawings, and models.

Coursework

The studio initiated familiarising students with the workshop, and building their ability to employ the various analogue and digital tools to produce specific building products. The developed skills were utilised through following exercises:

1. To make a mechanically controlled fenestration unit. The unit was aimed to be expandable, professionally deployable and technically innovative.

2. The second part dealt with the understanding of structural forces and their articulation in form. This is induced through active physical modelling by students using humble materials which mimic the properties of realworld construction materials. A spanning system was devised, tested and revised, to achieve an informed form.

3. The third and final part dealt with the consolidation of the above acquired skills, their resolution and their layering with a given design challenge. The skills were tested through three emerging typologies in a highrise, keeping in mind the future of resource crunch, land shortages and sustainability.

7

Making

Select one of the types of motion with material for the panel and the characteristics of the panel you wish to explore and attempt all the parts of the task given below.

Task

Design the climate control devices. Considering the dimension of frame to be 460 x 460mm.

Part A: To design a mechanism for the climate control device in a way that it can be operated through a mechanical input. Input force cannot directly be applied to the panel.

Part B: To design and make the panel for your climate control device. Preferably use more than one panel.

Part C: Do a market survey of hardware and fasteners that you would require in order to work out parts A, B and D. Make a matrix of those parts including detailed specifications and costs.

Part D: Design a locking system and a handle for the panel.

Learning outcome:

1. To detail out elements in two materials for a specific given function.

2. To identify and appropriately apply materials for a given task.

3. To design a mechanism to induce a type of selected motion in an opening. (4 weeks)

8 1.1

1.2

Opening assembly drawings

Create an assembly document for individual student’s fenestration in the sequence described:

1. A brief note of around 300 words describing each student’s object, its motion, materials, key highlights, and spaces where it can be used.

Modelling

Material:

Rigid Material: Board of max. dimensions 120 mm long, 20 mm wide, and 1 mm thick.

Flexible Material: Thin Printing Paper of max. dimensions 100 mm long, 100 mm wide, and lesser than 80 gsm,Flexible thread, thin transparent OHP sheet, pins, rubber-based adhesives

Task:

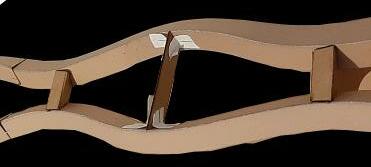

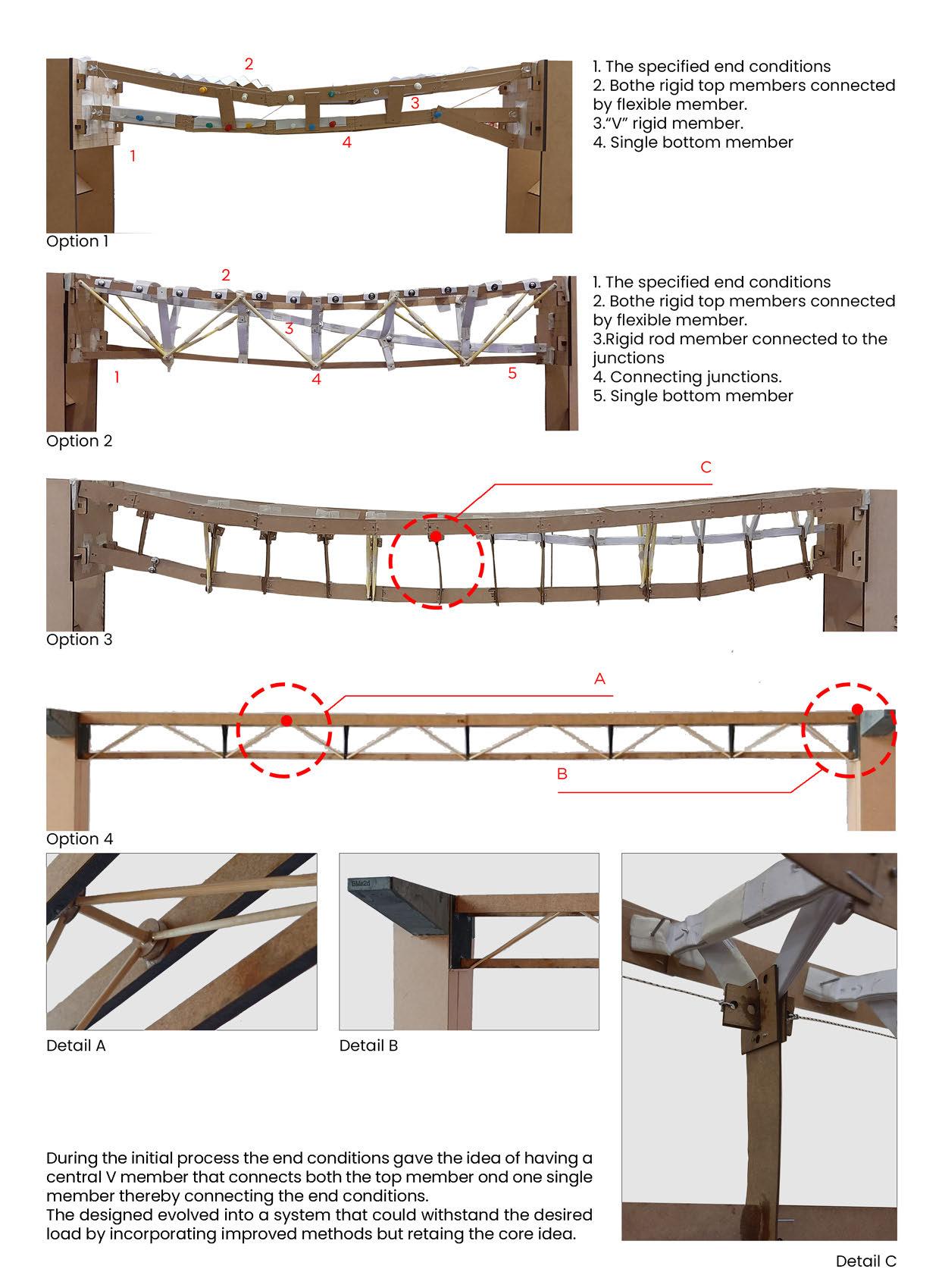

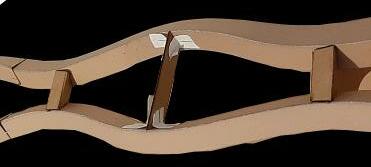

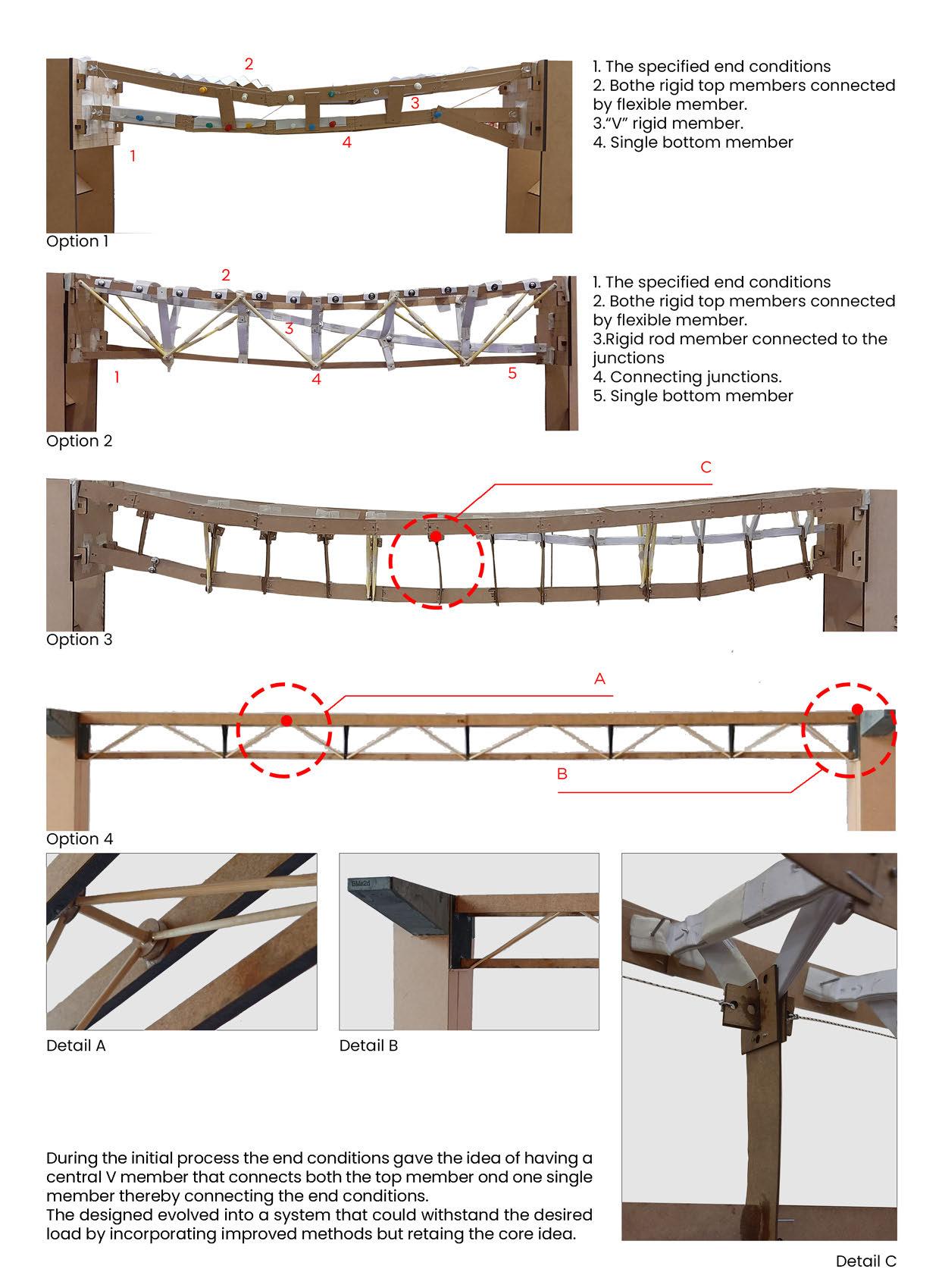

Students are required to pick a pair of end conditions from the options, and construct them1000 mm apart. Make a 1000 mm x 100 mm piece of OHP sheet and span it between the end conditions. The OHP should be broken into 3 or 5, or 7 and shall be placed in a horizontal plane. Stabilise this OHP sheet using the assigned materials.

While stabilising follow the following conditions: In stable conditions, the OHP sheet should not deflect more than 5 mm at the center under a 3kg uniform load over the entire spanning system. Material sizes should not exceed the specifications given. All connections have to be pin connections. Threads should be fixed at all connections and cannot slide. Distance between two parallel members should be 10 mm or more. Adhesives can only be used to connect your members at end conditions.

Tests:

The system should not deflect more than 5mm under uniform loading of 3 kg. The system should not break under 30 times its own self-weight or 10 kg load.

Learning Outcomes:

1. To derive a structural system that is able to resolve the intended load.

2. To physically realise the resolution of forces.

3. To recognise and articulate forces while addressing direction and magnitude.

4. To develop systems of joinery based on the behaviour of forces and mechanism of load transfer.

5. To develop modules that can repeat to form stable and complex assemblies. (3 weeks)

10 2.1

Identify materials for the spanning system and make a model at the end condition with the module next to it at the 1:5 scale.

(2 week)

11 2.2 Detailing and referencing

Input lecture and workshops

Mechanism, Gears and Systems : Prof.Anuj Anjaria Building services and application : Prof. Shramik Desai

Technicians guiding students

Metal Workshop : Amar Kori, Chaggan Mahajan

Wood Workshop : Chirag Gajjar, Yatin Mistry

Fablab Assistance : Maharshi Solanki, Manish Patani

12

13 Studio

M.A.T_Work

1. M.A.T Work becomes an attractive opportunity to access technology and equipment that an individual feels is essential and beneficial for one’s work but comes from a collaborative investment.

2. Workspace has a singular aim, to enable making accessible. These spaces are essentially open workshops that provide tools, spaces and even the know-how for individuals to create with. It aims to encourage a maker community where individuals with different interests and curiosities may come together to experiment, design and build, subsequently increasing the opportunities for creative problem solving and collaboration.

3. The spaces not only have access to equipment but also engage with other similarly motivated individuals and further diversifies collaboration opportunities.

Operation:

1. The makers can rent spaces on a weekly basis or quarterly basis.

2. Visitors can access public spaces freely, whereas studios only by invitation.

Design Objectives:

1. Function; allowing ease of making

2. Collaborate; spaces promoting creative collaborations, encourage involvement and interaction

3. Educate; space for individuals to learn from others and grow

4. Work and innovate; makers can customise their space for the nature of work

M.A.T_Learn

An individualised child-centric approach focused on creating a holistic upbringing of the child. A learning methodology that is satisfied through experiential learning by exploration and curiosity.

1. While the majoritarian view sees the learning spaces as a classroom, the new philosophy challenges the core pedagogical space and demands a new approach.

2. The foundation is seeking an architectural design where this pedagogical approach can be classified to rethink and reimagine school design beyond the perception of the typical classroom design.

3. It calls for an activity-based, hands-on learning school design based on this new learning philosophy. The complex understanding of children’s development and learning spaces can be brought into tangible architectural solutions.

Design objectives:

1. Design Flexibility; providing individual children to perform activities in their own way

2. Innovation; the design shall be challenging and innovative

3. Multifunctional spaces; able to carry out multiple functions efficiently.

M.A.T_Play

1. Sport centres are modern facilities which have to function extremely precisely and efficiently. In the Sports Centre, the inside and outside spaces are closely interlocked, creating harmony. As the exterior offers a place for the city to engage with along with the façade, the interior balances people’s emotions.

Design Objectives:

1. Inspiring and Integrating: To promote and encourage sports culture in the city.

2. Adaptability: to meet demands for flexible and differentiated sports facilities.

3. Efficient: Adhering to the international standards.

4. Educate: Space for individuals to learn from others and groW

14

15

M.A.T_WorkM.A.T_Work

M.A.T_Learn M.A.T_Play

02. Tessera

Rasika Lohar I Khushi Daxini

Selvin Varghese I Diksha Garg

05. Work links Hardik Arora

Interplay Manasvi Patil I Amrita Das

Hetansh Patel I Prateek Bansal

Vrushali Mali I Nishiki Varma

Mudit Tikmani I Miloni Patel 18 46 70 92 118 138 164 188 214 238 264

Content Foreword Acknowledgement

Introduction 01. Poly

06.

07. Vertical grounds Devashree Choudhari I Saurabh Narsikar 03. Four Gables

Harshal Kalantre I Hitprakash Mohanty 08. The Lacuna Alfiya Shaikh I Jyoti Mali 09. Learn High Aswin Sreekumar I Suriya Kumar 04. Built x autonomy

10. Tripple-Ripple

11. Frag-Play

The extensive 18 week Foundatio Studio did exactly what it intended to, it gave me a crisp introduction to what’s in store for this journey of architectural tectonics.

The studio followed a reverse pedagogy wherein we made to scale models right from the beginning and only produced the shop drawings once the final prototype was made. The idea was to better our understanding of materials and mechanisms through direct stimuli to our senses and get a more profound sense of “making.”

While the routes taken may have left me questioning the conventional methods of design, the uncertainty of a new process gave me an entirely new set of tools to work with, helped me build a stronger never die attitude and provided fresh avenues to interrogate.

At the beginning of the journey, one had an obvious question of “what” about the journey but the gradual process of taking one from an atomic to molecular stage has led one to question the “why” of it through critical understanding of the subject, in turn triggering a thought of its element and compound. The studio begun with a pragmatic approach of understanding mechanisms at a micro level and designing one at the node of functionality and aesthetics which later transformed into designing a spatial entity incorporated with the understanding of mechanisms done initially. This studio has induced a culture among us to look at any object’s design and functioning with a conscious effort of understanding it and knowing the purpose of its existence.

19

Mudit Tikmani Miloni Patel

PAT22206 PAT22197

ASSEMBLY:

Star Link is a climate control device that functions on a vertical pivot motion. The primary materials used are timber and mild steel (MS). The device combines a system to links to that of a mechanical system which enables movement without any direct input force.

ABOUT TOOLS AND FINISHES

Timber: Automatic Saw Router Hammer Chisel Band Saw Sanding Machine Mitre Saw Junior Saw File

Mild Steel (MS):

Cutting Machine Drilling Machine Sheet cutting Grinding Machine Buffing Machine Clamps Welding Spot Welding Metal Chisel Hammer Punch Right Angle Pliers

Drilling Machine Impact Drill Wood Marker Screw Driver L Angle Adhesive Acrylic Spray Paint (Black)

Stain (Blue) Base Coat Top Coat

PARTS LIBRARY

Angle Bracket x 8 75mmx75mm Ball Bearing x 1 19mm dia., 6mm bore

Bevel Gear x 1 OD.: 43mm ID.: 6mm Teeth: 16; Right-Angle

Bevel Gear x 1 OD.: 65mm ID.: 6mm Teeth: 32; RightAngle

Threaded Rod x 1ft. 6mm

Double Screw x 32 25mm; 4mm dia.

Nut x 8 6mm bore

Washer x 4 6mm bore

Screw x 4 19mm; 4mm dia.

Nut- Bolt x 8 25mm; 4mm dia.

Sleeve x 4 19mm; 9mm bore

Nut- Bolt x 5 12mm; 3mm dia.

D- Nut x 1 6mm bore

MATERIALS

All dimensions in mm.

90 90 90 90

x 75 x

15 15 30 30 x-15

20 y-80

2x+75 y 20

30 20 20 7 13 50

1. Assemble primary timber members.

172 20 50 45 25

210

335

12 12 35 85 85 85

210

335

172 20 50 45 25

Timber: X= 175; upto 350 Y= 400; upto 900 85 45 45

Mild Steel (MS): Acrylic: 85 45 45

2mm thick perforated sheet.

2mm thick solid sheet.

12 12 35 85 85 85

3mm thick clear sheet.

4. Integration of MS components.

20 STAR LINK

members.

2. Use L angles to fix members in postition.

3. Gear box assembly:

x 2

components.

5. Assemble the shutters and fixing of shutters onto the frame.

6. Final, closed condition.

21

fenestration by Mudit Tikmani

22

The plant-based turquoise stain can remind one of lights or the pol houses of Ahmedabad city

Linkages are connected to the shutters via clamps which provide the axis for pivot.

Perforated MS works well as the primary curtain wall element.

System of bevel gears connected to links.

of the northern city to the other.

Final, open condition. Opens upto 45 degrees.

23

fenestration by Mudit Tikmani

ABOUT

Phalanges is a climate control device that functions on a horizontal hinged motion. The primary materials used are wood and acrylic. The concept of the design was to imitate the movement of fingers which happens because of the hinge joints between two bones enabling the finger to move upward and downward.

The mechanical system of the device comprises of a pully connected with the worm drive. When the string of the pully is pulled it enables the worm drive to rotate enabling the cam follower mechanism to get into action because of which the fingers open and close.

The device is made with a combination of wood and acrylic. The expression of the window is fragile and graceful at the same time due to the used of acrylic. Also, the louvers made in transparent acrylic allows one to see the skeleton of the panel and provides a well-lit space even in the closed condition.

TOOLS

Automatic Saw Router Hammer Chisel Band Saw Sanding Machine Mitre Saw

PARTS LIBRARY

Drilling Machine Impact Drill Wood Marker Screw Driver L Angle Grinding Machine Lase cutting machine File

1. Assemble primary timber memebers of the frame.

Detail A : Step 1

3A. Assembly of the main members.

2. Gear box assembly.

4. Fixing the louvers on the main members.

5. Close condition of

24

MATERIALS

Screw Screw Nut

bolt

F

- F

-

Timber : Acrylic : PHALANGES Thread Rod

Nut boltNut boltNut

M -

pinM

pinM

F pin Pully Bearing Worm Wheel Washer L - Angle Worm

Detail A

3. Assembly of the main memebers with the cam follower system.

Detail A : Step 2

3B. Assembly of the main members with the cam follower mechanism.

Front view

Top view

the window. 6. Open condition of the window.

Side view

25

fenestration by Miloni Patel

Close

Semi-Open

Detail showing the connection between the cam follower mechanism and the arm of the screen with multiple hinge joints.

Detail showing the connection between the two separate arms of the screen by a serpentine element which allows the movement of both the memebers of screen in a synchronized manner.

26

Open

Detail showing the joinery of the transparent acrylic louvers with the arms of the screen. Notches in the arms hold the lovers in place which is further bolted using L-clamps. for stability.

Detail of junction of two hinge joints between: 1) two arms and 2) arms and serpentine members.

27

fenestration by Miloni Patel

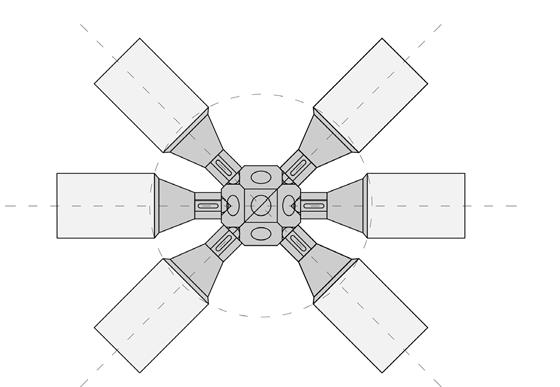

SPANNING 01:

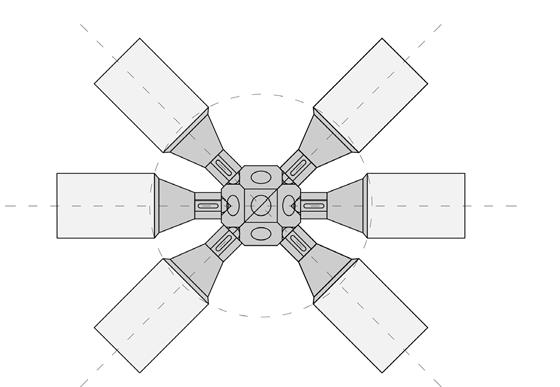

The spanning system is conceptualised to integrate idea of modular units to that of tensigrity to derive a system which provides beam like solutions for large spanning area.

Module 01 consisting of 3 arms at set angles produced by “lost wax casting.” C clamp composed of 5mm plates is fixed to the module using plates in U profile.

Module 02 consisting of 3 arms at set angles produced by “lost wax casting.” Clamp supported the tension cable is fixed to the bottom of the module.

28

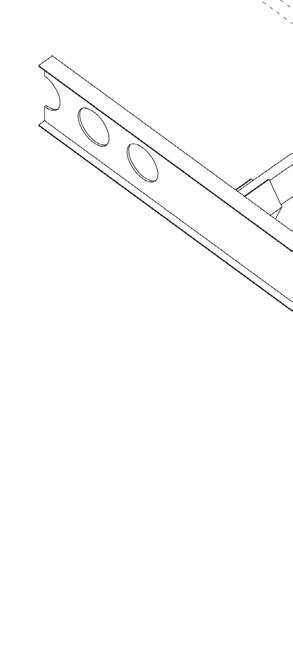

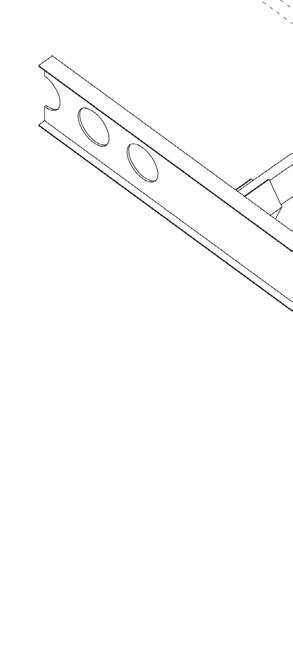

150x150x300mm C clamp composed of 5mm MS plate and anchored to the 38mm OD dia. rod using a 40mm ID dia. sleeve.

Turn buckle anchored to the bottom of the I-beam and used to keep the cables in tension.

150x150x300mm C clamp composed of 5mm MS plate and anchored to I-beam with brackets and 12mm bolts.

29

spanning by Mudit Tikmani

Top View

End Condition and Module 01.

Module 02 detail and tension cable.

Isometric View

The exercise focused on deriving a structural system that is able to span for 10 meters. Initially dummy materials like paper and pins were used to design modules to span horizontally while understanding the behaviour of forces acting on it. Further, the spanning had to be resolved for it to materialise in reality.

The idea here was to create a spanning system that has a delicate demeanour but takes load in actuality. To do so, the spanning system was created with bundled tubes running horizontally which was imagined to take certain load above it.

30

Weld SPANNING 02:

Mero Joint Detail

31

Steel tubular section Cover sleeve Rod anchor Locking ring Gusset plate Ring stiffner

Final model - Elevation

spanning by Miloni Patel

Final model - Isometric view

Location : Sabarmati Riverfront, Ahmedabad

Site Area : 6375 SQM.

Typology : Workspaces | MAT Work

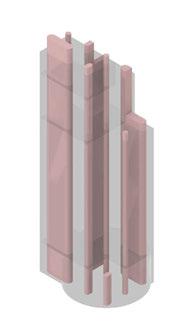

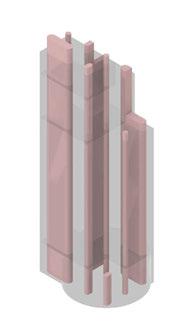

Poly which translates to “many” is built on the idea of bundled columns and split core system. Taking an unconvential route for both, structural and functional systems of a multi-storey structure, the intention is to blur the lines between primary and secondary spaces.

MASSING IN-PROCESS:

Singular mass and core.

Singular mass and split cores to enable greater internal permeability.

Split mass to increase exposed surface area to capture more views and sun.

Cores massing as imagined with typical functions.

Structure restrictricted to the core perphery to integrate functional to structural systems.

32

POLY

CORES: ZONING:

Vertical Circulation: Staircases

Service Cores

Wet Areas

Admin. an Vertical Circulation: Lifts

Service cores are distributed across the floor plate to better integrate them with the primary spaces.

Washroom/ Kitchen Core at the south-west can modulated on each floor as per requirement.

DEVELOPING AN EXPRESSION:

Admin. and Services

Public and Community Spaces Workshops Studio/ Lecture Halls/ Co-Working Spaces

Spaces with greater dead load stacked towards the bottom.

Fixed/Regular footfall areas placed towards the top.

System of bundled columns; 70 primary columns each of 150mm dia.

Columns wrapped around the critical core positioning to curtail south light.

16m tall circular podium defined by 150mm dia. columns.

Using metal curtain to act as primary external skin along with dry walls at certain locations to break monotony.

33

organization and planning_poly

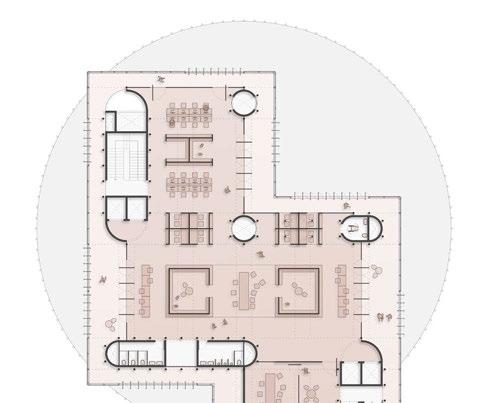

34 4 WHEELERPARKING 2 WHEELERPARKING

STP

05 10M UNORGANISED SETTLEMENTS TOWARDS SABARMATI RIVER RIVERFRONT

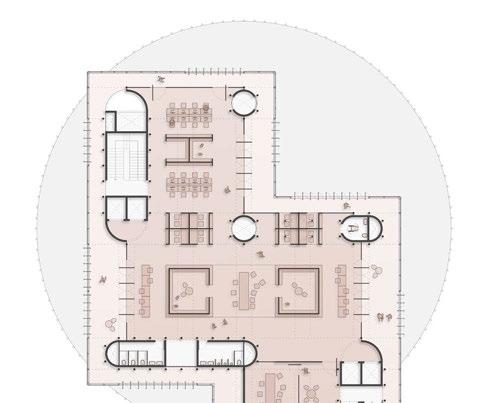

Ground Floor Plan

AMPHITHEATRE ALIGHTING AREA ENTRY EXIT

SECURITY TRANSFORMER POND RETAIL SPACES 1. 2. 7. 4. 6. 3. 5. 7. 8. 9. 11. 12. 12. 12. 1. 4. 6. 10. VEHICULAR ACCESS EXHIBITION AREA

RIVERFRONT ROAD TOWARDS AIRPORT

35 1. Staircase 2. Garbage Chute 3. HVAC Shaft 4. Fire Shaft 5. Electric and Server Shaft 6. Passenger Lift 7. Service Lift 8. Female Toilet 9. Male Toilet 10. Drinking Water 11. Accessible Toilet 12. Plumbing Shaft 13. Kitchen/ Pantry 14. Unisex Toilet 15. Storage LEGEND ground floor plan and typical floor plans_poly

Auditorium

Library Studios Lounge/ Day Care Centre Workshop

1. 2. 7. 4. 6. 3. 5. 7. 8.9. 11. 12. 12. 12. 1. 4. 6. 10. 1. 2. 7. 4. 6. 3. 5. 7. 8.9. 11. 12. 12. 12. 1. 4. 6. 10. 1. 2. 7. 4. 6. 3. 5. 7. 14.13. 11. 12. 12. 12. 1. 4. 6. 10. 1. 2. 7. 4. 6. 3. 5. 7. 8.9. 11. 12. 12. 12. 1. 4. 6. 10. 1. 2. 7. 4. 6. 3. 5. 7. 8.9. 11. 12. 12. 12. 1. 4. 6. 10. 15.

Top of overhead water tank.

+128m +120m

End of habitable/Service areas. +72m

Double Height 03: +32m

Top

Double Height 02: +16m

36 BUILDING SECTION: B2 B1 G 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 T 0 8 16M

Level Basement Below

of podium. +/-00m Double Height 01: Ground

Decking Sheet below VDF flooring.

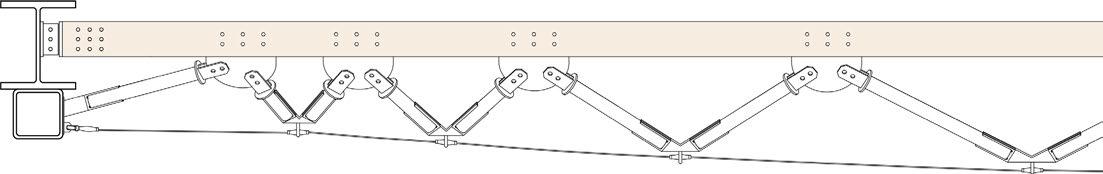

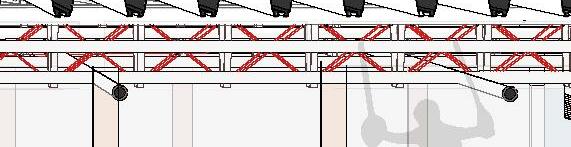

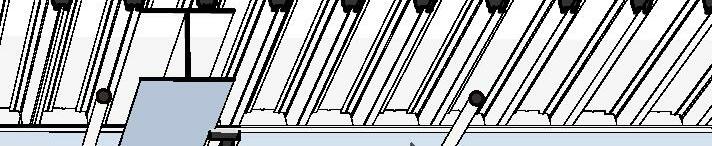

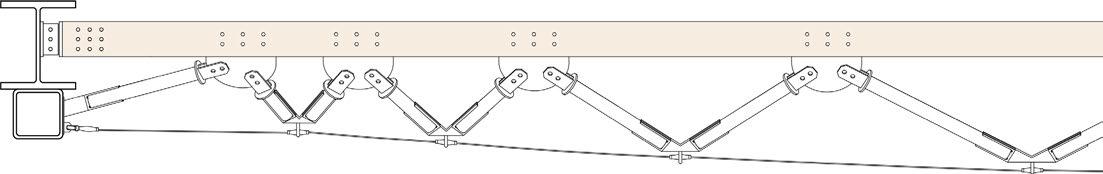

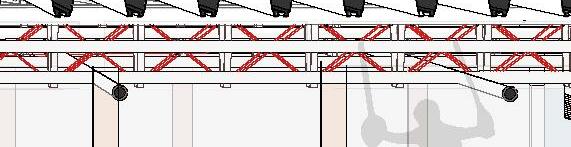

Spanning system across a 9m span supporting glulam members.

450mm deep cellular I-section.

Ring beam tieing the bundled columns together.

150mm dia. MS sections as the unit of bundled columns.

buidling section and structural system_poly

37

STRUCTURAL SYSTEM:

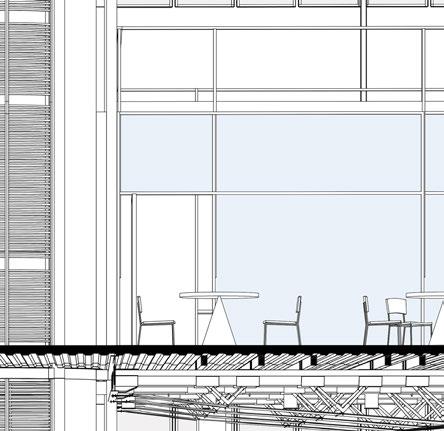

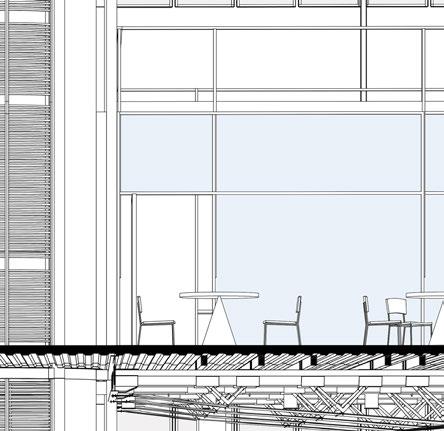

38 SECTIONAL PERSPECTIVE ACROSS FLOORS 12-14:

CAFE/ LOUNGE/ DAY CARE CENTRE

WORKSHOPS

STUDIO/ CO-WORKING SPACES

39

sectional perspective_poly

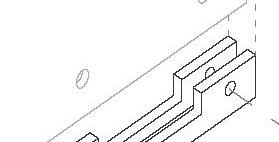

1. Fixing 50mm dia. MS section between two mullions as railing and adding C clamps along the I-beams.

Study Model

2. Assemblying the metal curtain by wrapping it around a frame made of 25x25mm MS box section and clamping with MS plates on all 4 sides.

3. Attaching the modular frame onto the I-sections with the help of the clamp.

4. Openable vertical pivot devices controlled through linkages. Infill made in same metal curatin. Final, open conditions.

40 FENESTRATION ASSEMBLY:

1. 100x110mm MS I-Section Mullions to mount the curatin wall.

2. 110x300mm MS I-Section on the periphery of each floor plate. 3. MS Floor Drain 4. Mezzanine Floor Parapet Composed Of 38x38mm MS Box Section. 5. 4mm Thk Metal Curtain wrapped over 38x38mm box section. 6. Mezzanine Floor 150x150mm MS Box Section. 7. 150x150mm MS Box Section Bundle Column Tie Member.

150mm Dia. Ms Section Bundle Column Member

13. 110x400mm MS I-Section Cellular beam as secondary spanning beam.

Opening system in vertical pivot motion. 15. 38mm dia. MS section between mullions as handrail.

41 WALL SECTION: fenestration

assembly and wall section_poly

9. VDF Flooring 10. Decking Sheet 11. Aluminium Flashing 12. Spanning System

LEGEND 4. 12. 6. 13. 14. 5. 15. 3. 11. 2. 8. 10. 9. 1. 0 0.51M

8.

14.

42

Exterior view as seen from north

north of the structure.

Workshop

Studios

Lounge/ Day Care Centre

Typical Space between the exterior and interior skin.

43

visualisation_poly

Process model expressing the verticality of the building.

Process model expressing the volumetric play in the building.

Process model showing the play of vertical service cores.

Modelling the fixed cores and structure composed of bundled columns and floor plates.

Fixing the facade panels on the structural skeleton and curtaining the podium with slender vertical facade mullions.

Facade panels placed completely on the whole building.

44

STUDY MODELS:

45 study models_poly

Writing a reflection for me is to look back at the learnings in terms of the journey and how far I’ve come through. A person isn’t static, and who am I right now is not as important unless we have the context of what I was before this studio. It has broadened my spectrum of questions whose answers are to be found. The studio has pushed my limits so much so that at this point, it feels content to have been survived through. The last 4 months really challenged me to realise my abilities as well as inabilities. These realisations were important so that it can be worked on with a positive attitude and enthusiasm. It was a journey of learnings, unlearnings, failures and success.

The Foundation Studio has boosted my sense of detailing. It has pushed me to get out of my comfort zone and explore myself to create something beyond my limits. The Process of making, fostering new technologies, critical thinking, failures, brainstorming, making mistakes, resolving, learning, translating ideas into details, the expression of forces, their articulation into spanning system, structural systems, materials, and details, all of it has encouraged me to learn from own mistakes and advance further based on the learnings.

47

PAT22167 PAT22278

Khushi Daxini Rasika Lohar

SWIVEL

Horizontal Pivot Window

Swivel is a Horizontal Pivot Window designed to simplify user experience by providing a single rotating handle for multiple horizontal pivot panels. The mechanism is based on connecting multiple panels with gears that are provided with motion through a single loop of timing belt on both sides of the window frame. The bevel gear setup at the base of the window frame change the direction of the motion, facilitating movement of the Timing belt.

48

Kit of Parts

01.

02.

03.

04.

05.

06.

07.

08.Timing

09.

10.

11.

12.

13.

14.

15.

LEGEND

MS Anchor for MDF Frame

Nut Bolts

MDF Frame for MS Panel

MDF Panel

L Angle

Acrylic Panel (MDF Substitute for visibility)

Gear

Belt

Ball Bearing

Washers

Bevel Gear

MS Rod for Bevel gear

MDF base panel

MS Panel

MDF Front frame

Align timing belt to the gear set in synchronization

Fix panels to the MS Anchors using nut bolts

Closed condition Open condition

49 fenestration

by Khushi Daxini

Assemble MDF Parts with interlocking system.Gear Assembly with MS Panel anchorsAssemble Bevel gear Assembly at the base

REPRISE

Vertical Sliding Shading Device

Reprise is a Vertically Sliding shading device designed in MDF and Bamboo as its primary material used for construction. This device translates rotational motion into linear motion. When the handle is rotated in anti-clockwise direction , the panel of opening moves upwards.

Tools Used

Bamboo saw Mallet Knife Hacksaw Planar Machine Sanding Machine Mitre Saw Junior Saw Right Angle

File Drilling Machine, Socket drill Chisel Hammer Wood marker Screw Driver Pliers Punch

Cutting Machine Laser cutting Machine Drilling Machine Sheet cutting Grinding Machine Buffing Machine Clamps Metal Chisel Hammer

1. Bottom Frame Assembly

2. Addition of Mechanism

Parts Library

Panel Assembly

3. Addition of Panel and Frame

50

Open Condition

51 fenestration

by Rasika Lohar 5. Frame Top Part Assembly

Closed Condition 4. Addition of Front and Back of Frame

The intention of this exersice was to understand the basics of forces, in terms of direction and magnitude. The learnings were taken forward to understand how pyramid as an accepted stable form can be incorporated into a force diagram to design a spanning system (10 m span). The process initially explored pyramid as surfaces and eventually was optimized into line diagram keeping in mind material utilization, joinery details and aesthetics.

This exersice also explored new means of technology for model making through 3D Printing.

52 SPANNING 1

Process Models

Final Model

1 2

3 4 5

10

Typical condition Detail 01 End condition detail 01

End condition Detail 02

7 6 8 1 3 LEGEND 01. Glulam member (120x180 mm) 02. MS Gusset Plate (5 mm thk.)

8 mm Dia Bolt 04. Hook for tension cable 05. MS Pipe (60.3 mm OD) 06. MS I section as beam

MS Box section 08. MS Plate for Glulam anchor (5 mm thk.)

MS Plate on Box section 10. Tension cable (8 mm thk.) Isometric View

Typical condition Detail 02

53

Elevation Plan

03.

07.

09.

spanning by Khushi

Daxini

The Spanning System exercise helped to understand the line diagram of forces and the translation of line diagram into a spanning system consisting of spanning members, as a stable form which was designed and explored using state of the art technologies such as 3D printers, which in this case helped to explore and convey material expression. The process also helped us understand the ways of material optimization, making and experimenting joinery details with respect to aesthetics and stability.

Process model of spanning system

Final model of spanning system

54 SPANNING 2

Plan of spanning system

Elevation of spanning system

1. 2 3 4 5 6 7 8

Spanning Assembly Drawing

1. 60 x 60 mm M.S angle

anchored In the precast member and M.S box section

2. 172 x 92 mm M.S box section that holds the precast spanning member

3. 450 mm depth M.S I section

4. 8 mm thk M.S base plate

5. 6mm thk gusset plate with Cylindrical y - end pin

6. 12mm dia tie rod in tension

7. 6 mm M.S plate anchored in precast member.

8. M.S rod end that holds 12mm tie rod tension member

3 4 5 6 7 7

Isometric view of assembled spanning system

2 2

1. 1.

8 8

Elevation of Spanning member

View of end condition and cable to spanning member detail

by Rasika Lohar

55 spanning

Inspire; inspire makers through design form and spaces, be an identity Function; allowing ease of making Collaborate; spaces promoting creative collaborations, encourage involvement and interaction.

Educate; space for individuals to learn from others and grow Work and innovate; makers can customise their space for the nature of work

LOCATION : SABARMATI RIVERFRONT, AHMEDABAD

SITE AREA : 6375 SQM. TYPOLOGY : WORKSHOPS

TESSERA

9m

1m 3m 0 Site Plan

Understanding site, context and movement

Understanding scale, orientation and built mass

Design Development

Seggregating core and program and developing the form to create sense of approach

Integrating ancillary activities as a linkage to primary activities and the service core.

12 m3 m9 m 7.5 m 9 m 7.5 m

Seggregating Work areas and Service core as a key to initiate design.

Re-orienting the service core block to allow sense of approach and accessibilty.

Integrating column-grid. Eccentric corridor provides varied spanned spaces, as an intention to divide primary and secondary spaces accordingly.

Integrating services, shear walls to understand the structural system wholistically.

Finalizing movement diagram with a focus on the importance of connecting transition space.

57 organization and planning_tessera

Concluding geometry, movement, spatial configuration and overall structural system. Form Development

58 Ground Floor Plan 01 02 03 04 10 11 12 01. Atrium 02. Wood Workshop 03. Administration 04. Machine Lab 05. Toilet (Male) 06. Toilet (Female) 07. Toilet for specially abled 08. AHU 09. Passenger Lobby 10. Foyer 11. Landscapes 12. Loading Unloading deck 1m 3m 0 9m 1m 3m 0 9m 0 m3m 9m 18m

Typical Floor Plan (Workshop + Studio )

8th Floor Plan ( Library + Archive )

Typical Floor Plan ( Discussion Rooms + Studio )

11th Floor Plan ( Cafeteria + Recreation )

59 organization and planning_tessera

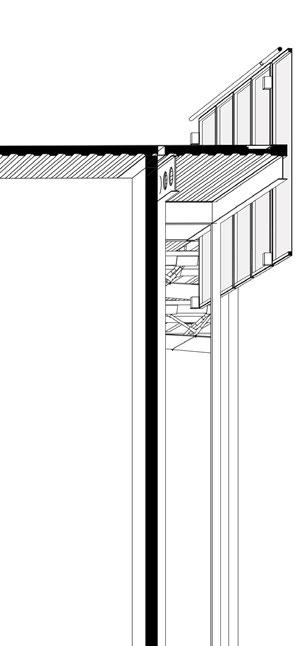

60 Section Basement Ground Floor Podium 8th Floor 3rd Floor 11th Floor 22nd Floor

Terrace Lvl OHT Level

LIBRARY

CAFETERIA WORKSHOPS and STUDIOS

WORKSHOPS and STUDIOS

1m 3m 0 9m 0 m4.2 m 9m 18m

AUDITORIUM Atrium

Decking Sheet

Joists along 9m span to support MS Section

Spanning system adding structural stability in larger volumes

Castellated beams along corridor for ease of services

Shear Wall ( Passenger elevators )

Castellated beams along corridor for ease of services

RCC+I-section composite columns

Flooring 450 mm deep I-Sections

Structural System

61 building section and structural system_tessera

62

63 sectional perspective_tessera

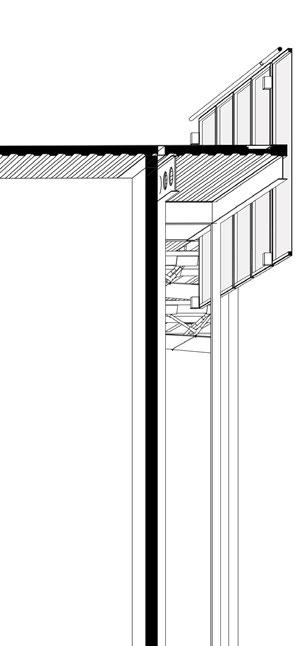

64 Wall Section Detail at Floor Junction A 1 2 3 4 5 6 7 8 9 10 Perforated sheets composed for varied light and ventilation requirements of the space M S Framework For Facade exo-skeleton acting as a layer to modulate porosity 1. M S I section 450 MM Depth 2. M.S 100 X 100 MM Box Section 3.Perforated Metal sheet 4. Vertical cross bracing cables 5. Spandrel panel 6. Double glazed inner facade 7. Horizontal extrusion for upper unit 7. Vertical extrusion for upper unit 8. Horizontal pivot shading device 9. Precast spanning members 10. 172 x 92 MM Box section holding precast members B C D

The IDEA

Detail showing integration of primary structure, spanning and glazing layer

B

Aluminium grating detail

A C D

Fenestration Details

65 fenestration and wall section_tessera

‘Porosity as a derivative of spatial Organization’

Process Models

66

67 process_tessera

68

69 model and renders_tessera

F O U R G A B L E S

F O U R G A B L E S

Understanding the significance of the process of creation and then realising the end product as a result of the process was the most important takeaway from this section of the program for me. Paying close attention to the origin of any detail and how it ultimately works in relation to the material and constructional approach used. In terms of course pedagogy, the studio allows students to investigate the structure of an idea and how to make it a reality by actually constructing it, accompanied by a seamless workshop making experience. This helped me acquire confidence in my ability to create, ultimately validating my concepts..

True learning in architecture can only be absorbed by intimating oneself with real material. That’s what I have understood from this part of the masters program. A rigorous process of visualisation as well as experiential structural systems both in digital and physical has widened my vision of looking into micro levels of architecture. Moreover, the intensity of the foundation program helped me stretch my limitations to it’s extremes and overcome them.

71

Harshal Kalantre

PAT22136

Hitprakash Mohanty

PAT22130

Vertical folding and rolling Window

The rolling and folding window is made out of Timber frame and MDF panels where the whole framing system is strengthen by tongue and groove joints. The window has a singular function of folding up and down which is controlled by the rotation in both direction of the knob below.The function run in simple concept of pulling and releasing.

72 ZIG-ZAG

Mechanical functioning of Window:

Outer frame parts are fixed in all grooves created

Parts Library:

Mechanism is fixed to the frame and its panel 5mm MDF panels are fixed in perpendicular to each other as shown in the above diagram

Timing Belt 40mm dia gear

Nut & bolt

Window opening motion images:

73

fenestration by Hitprakash Mohanty

60mm dia gear6mm threaded rod MS cleat

Construction timber

4mm folded gusset plate

2mm M.S. Plate 5mm thk. M.S. Plate

2mm thk. M.S. bend plate

8mm thk. tension cable

Detail A : Support Module

Detail B : End Condition

Cable Holder 6mm thk. M.S. Plate

Metal cable holder

3mm triangular MS plate is welded to maintain its form

4mm gusset plate to fix decking sheet 4mm gusset plate

50mm thk. const. timber

Detail D : Triangular plate

Detail C : Joinery

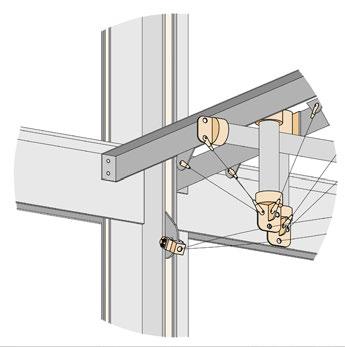

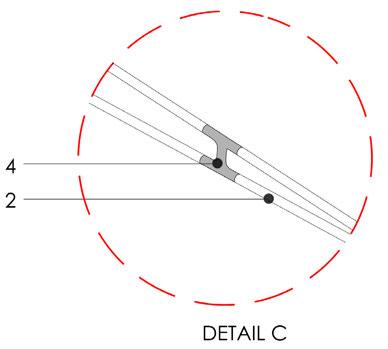

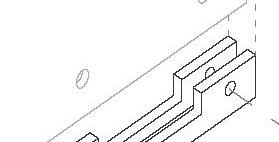

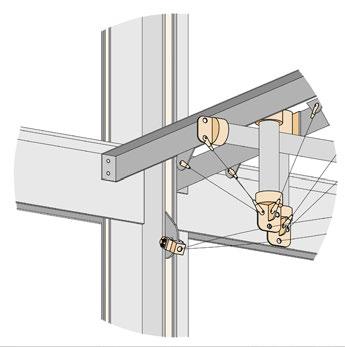

76 SPANNING SYSTEM:

This spanning system is a type of beam that can span up to 10-15m between beams or columns. This system, in particular, reacts differently to forces that come from above. As a result, while designing, a few factors were taken into account, such as the joinery of both the end conditions and the nature of the material, because different situations react differently to the forces applied to them. The majority of the spanning material in this system is flexible, which can be built of MS folded plates and is supported by additional stiff members to avoid torsion. A tension cable is supported beneath the system to prevent it from buckling or bending.

77

spanning by Hitprakash Mohanty

Model Images:

Process models:

78 SPANNING SYSTEM

79 spanning by Harshal Kalantre

LOCATION : SABARMATI RIVERFRONT, AHMEDABAD

SITE AREA : 6375 SQM.

TYPOLOGY : vWORKSHOP SPACES

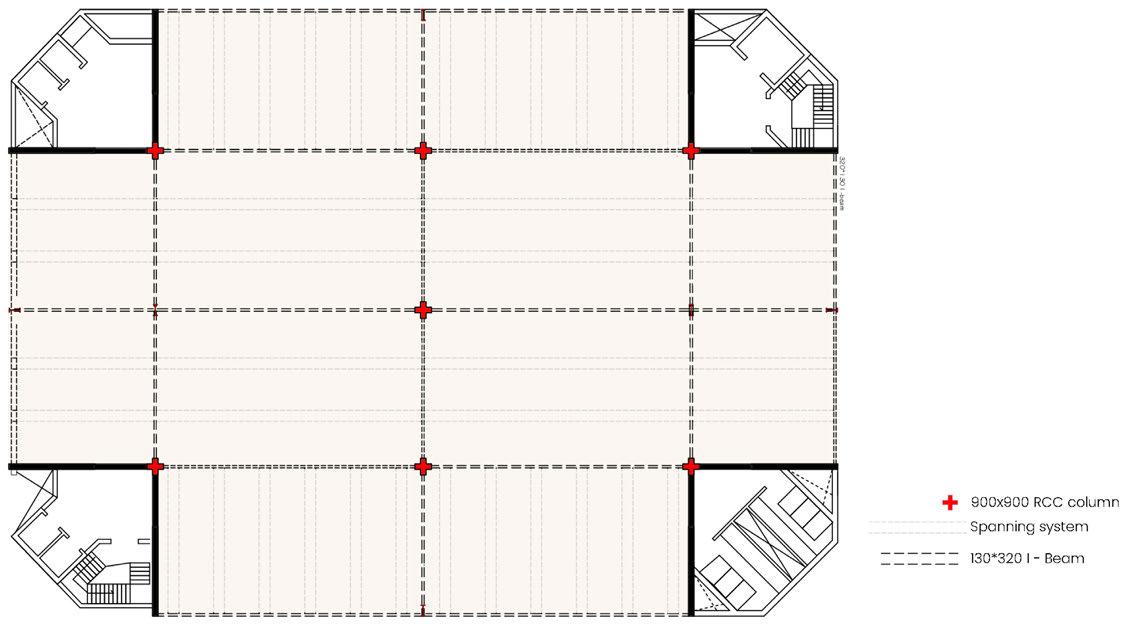

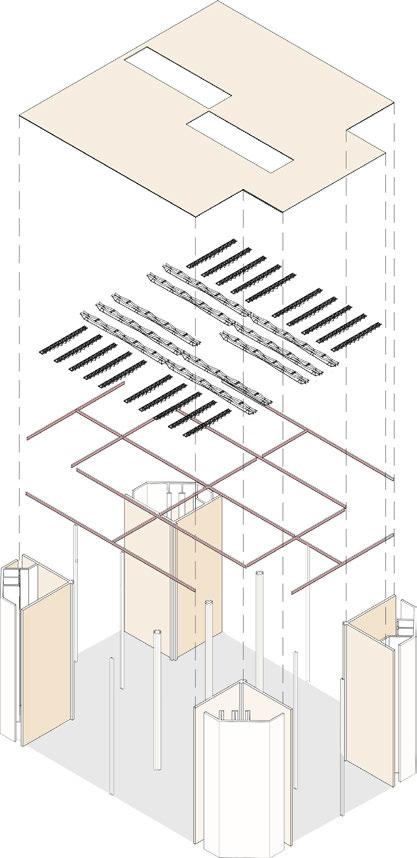

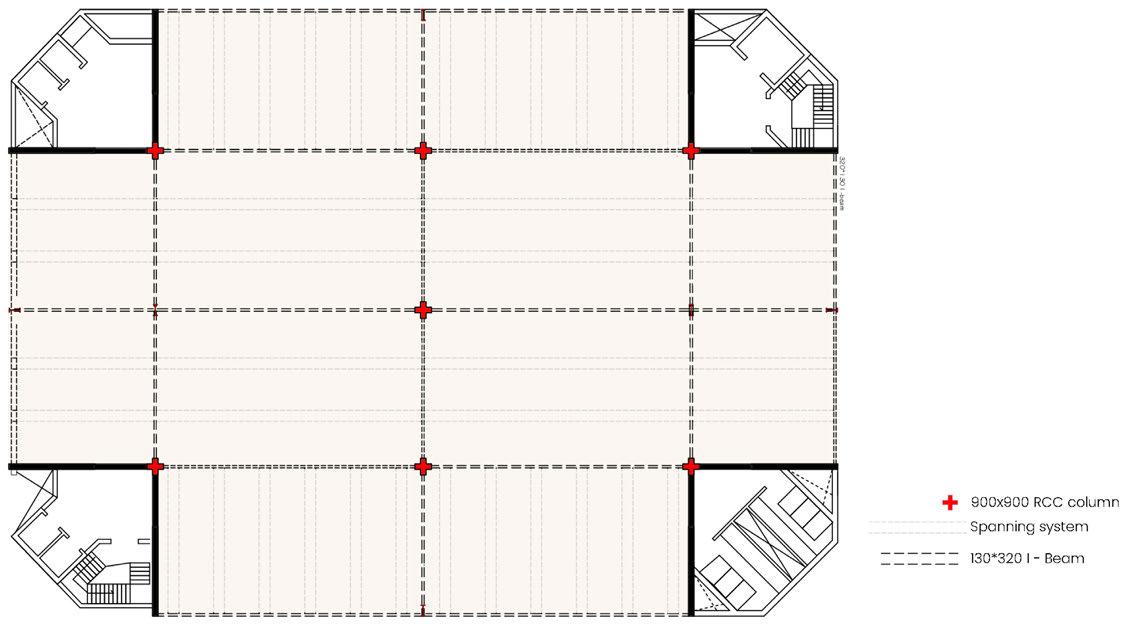

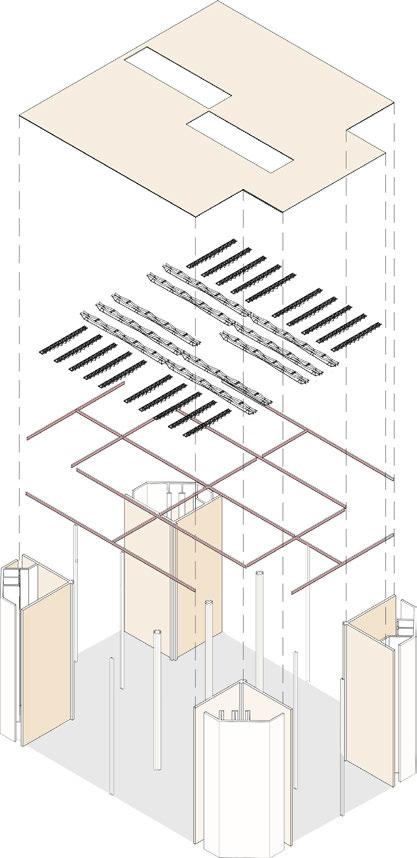

Four Gables is a multi-use commercial high rise tower comprising of workshop spaces, studio spaces, a multi-floor library and an auditorium with a capacity of about 200 persons. The design was developed to create multi-level spaces establishing an internal visual connectivity between floors in a high rise building.

80

FOUR GABLES

The basic idea was to design the structural system of the high rise such that the activity could take up as much floor area as possible. By locating the service cores on the four corners, we free up floor space from columns and shear walls.

With the service circulation now oriented along the exterior face, the circulation areas in the centre are limited. Therby allowing more volumnar variation in spaces with the provision of double heights and mezzanines.

The buidling mass is also raised to allow barrier free user movement throughout the plinth

81

Diagrams & Models :

Conceptual

Service cores are placed on all four corners

Volumnar mass raised to provide public space

organization and planning_Four Gables

Volumetric recessions on west and south facade to optimise daylighting and thermal heating

82 BUILDING ORGANISATION

Workshop floor plan

83 organization and planning_Four Gables

Site Layout

11.

12.

Auditorium floor plan Legends: 1.Auditorium 2.Open air theatre 3.Electrical shaft 4.HVAC shaft 5.HVAC Shaft 6.Plumbing Shaft 7.Electrical shaft 8.Fire shaft 9. Workshop seating 10.Tool rack

Working Table

Workshop machinery

84 SECTION

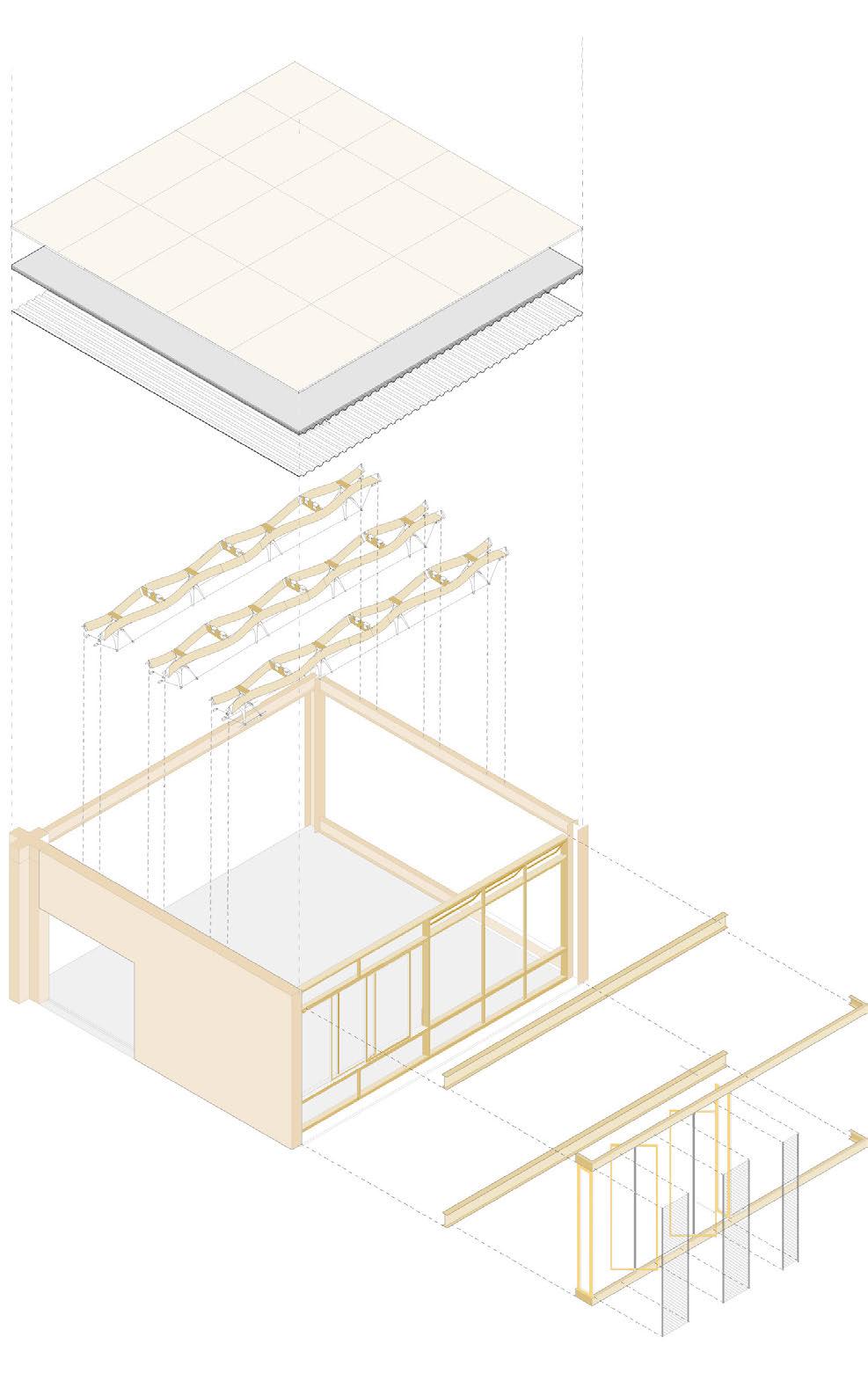

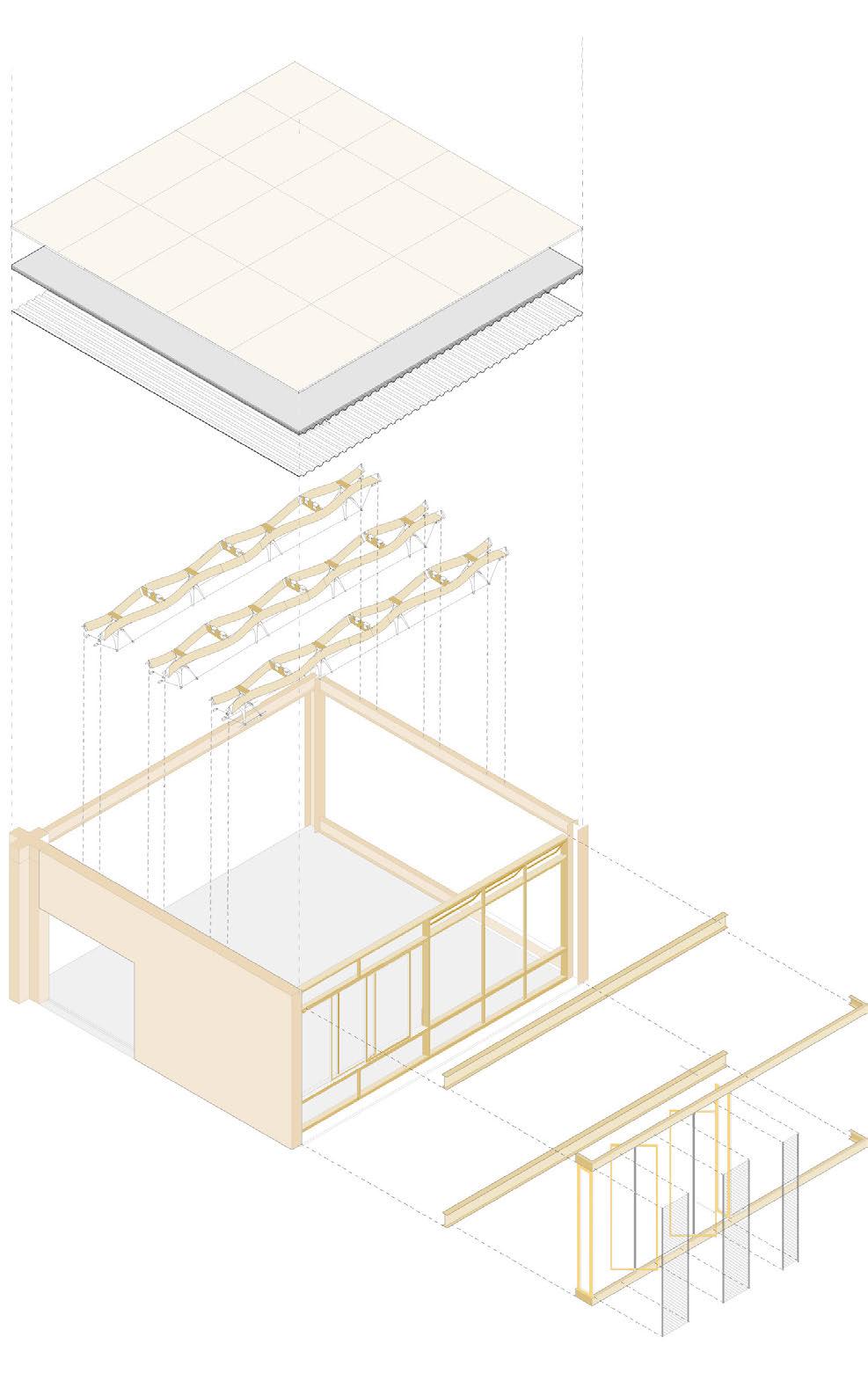

Structural Layout Exploded View :Structural System

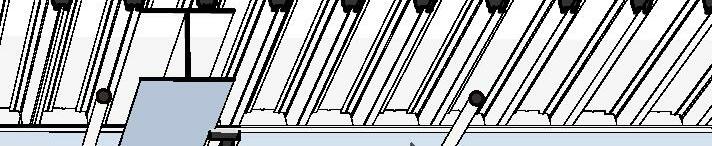

100mm RCC on 2mm decking sheet

Spanning system 1 & 2

Decking sheet to I-section (beam) joinery

130*320mm I-section Beam

I-section(beam) to shear wall joinery

Four cores consisting L- shaped shear wall

I-section(beam) to H-Section column joinery

85

STRUCTURAL SYSTEM

Building section and structural system_Four Gables

86 SECTIONAL PERSPECTIVE

87 sectional perspective_Four Gables

50mm flooring 100mm RCC Slab on decking sheet

2mm decking sheet

Spanning system

300*300mm H - section column

60*60mm Box section framing 130*320mm I - section as beam

C- section as Support of vertical louver

Vertical louver with metal porforated panel

88 FENESTRATION DRAWINGS

89 fenestration and details_Four Gables

Handle Vertical Louver detail:

gear

MS Rod

box section Aluminium

thk. MS Plate

bearing

Fenestration model image: Fixed glass detail: Bevel

10mm

60x60mm

casing C-Shaped Aluminium frame Double glass 2mm

Ball

C-Section(Bottom) C-Section(Top) Ball bearing

90

91 physical model_Four Gables

My approach towards an architectural intervention has always been through understanding of a mass, where detailing somehow was a recurrent thought to the overall built. Through this semester, I developed an outlook towards detailing as an integral part of a whole. I have realised how even an opening design is tied to the expression on a city wide scale.

The studio began with the fundamental question of starting a design from a part rather than the complete and progressed to the integration of details in the final exercise. The concept centered around creating a narrative about the relationship between spatial experience and the processes that generate expression. As a result, the overwhelming process of employing tools in the workshop and understanding dynamics leading to design in a construction system was fulfilling. Working with scales that are rarely used, such as 1:1, 1:10, and 1:50, as well as having hands-on experience with manufacturing, helped build a grasp of materials and their behaviour, as well as the art of construction.

93

Selvin Varghese

Diksha Garg

PAT22312

PAT22100

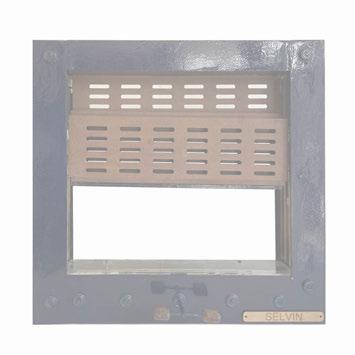

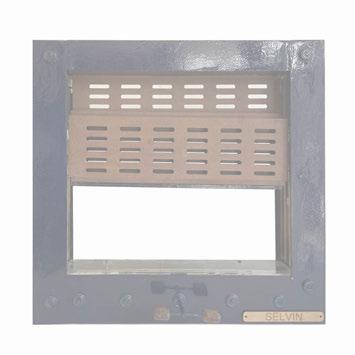

LATTICE

vertical sliding opening

‘The lattice’ is envisioned as modular based system for vertical sliding opening. The system devised tries to achieve opening using rack and pinion system and transferring the motion through a pulley mechanism into a timer belt attached to spur gear and the panel.

The distance travelled by the rack is equally proportionate to the movement of panel upwards.

MECHANICAL

94

SYSTEM_COMPONENTS

Rack Timing belt Acrylic washer Acrylic washer

PROTOTYPE_CLOSED AND OPEN CONDITION

Spur gear Ball bearing M.S rod

Roller wheel

95 W-110 50 W-135 65 W 65 W-110 80 11 H H-135 55 65 1. M.S. main frame components + assembly_parts 3. Side

assembly 5. Panel assembly_parts 6. Closed and open

assembly 2. M.S.

components + assembly_ welded 4. Bottom

frame

condition_final

main frame

frame assembly

fenestration by Selvin Varghese

96

97 fenestration by Diksha Garg

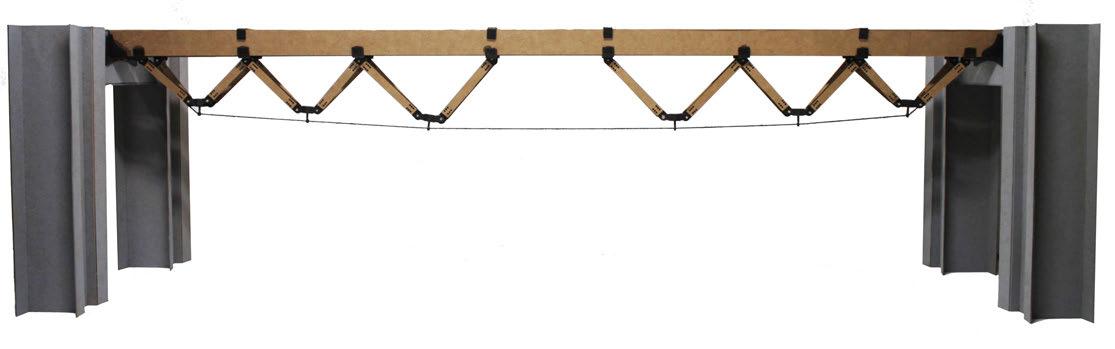

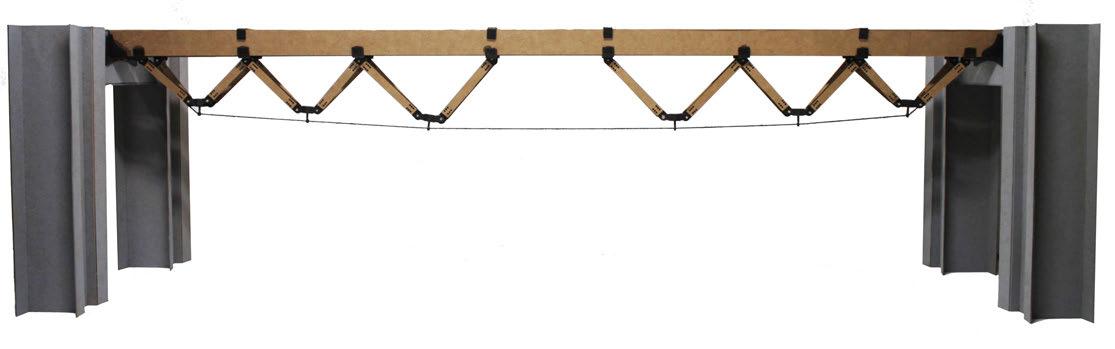

A structural system is derived that is able to resolve the intended load, using 120mm long, 20mm wide and 1mm thick board, 80 gsm paper and flexible thread. Support members were used under the following conditions: rigidity 60%, flexibility 10% and threads 30%. The spanning uses Glulam top-chord connected to the structural member and the spanning members are composite of glulam and M.S members adhering to compressive and tensile stresses. Steel cables are further used for further tensioning of the members .

B

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

150 x 150 Glulam spanning member

10mm thk MS plate

150 x 150 Glulam

10mm thk MS Connector

10mm thk MS strut

5mm thk Gusset Plate

5mm thk Gusset Plate with hook for tension cable

8mm thk tension cable

8mm dia bolt

10mm dia Bolt

98 SPANNING 1

A

Detail at ‘A’

Detail at ‘B’

7 3

1 2 3 4 5

9 9 2 4 5

3 8

6 10 8 spanning by Selvin Varghese

99

Detail at ‘C’

100 SPANNING 2

101 spanning by Diksha Garg

Our spaces’ needs and requirements are always evolving. Today’s urban environments demand ongoing expansion and change. Buildings are often created with the goal of serving specific roles and user groups and not undergoing major modification over its lifetime.

Functions may change over time, but form is what remains.

SITE PLAN

Way to Basement

10m Wide Road Loading and Unloading Bay Parking

Entrance 0 20

102 Built x autonomy

Urban Plaza Exhibition Area Play Area

Workspaces

Socio-interaction spaces

Studios

Urban farm Workshops Multifunctional hall Library Lecture hall Auditorium Offices

Retail and urban plaza

CLIMATE CONSIDERATIONS

103 organization and planning_built x autonomy

Site Program Distribution Program Distribution

and roof open spaces BUILDING ORGANIZATION

Existing

Mass on Site Elevating the ground form Ground

SYSTEM Permeable floor plate to allow cross ventilation Provision of informal double height volumes along north and east and service core along south to prevent heat gain Permeable floor plate to allow cross ventilation Provision of informal double height volumes along north and east and service core along south to prevent heat gain

STRUCTURAL

Inner and outer columns Service CoreCross Ventilation Double height volumes across northern facade

Break

Workshop zone 1 Workshop zone 2

Staff lockers and storage

Service storage/ Multi purpose room

Common Workspace

TYPICAL WORKSHOP PLAN

seen below

TYPICAL STUDIO PLAN

104

out space Workshop

1 23 4 5 6 7 10 9 11 9 12 13 14 8 1 1 23 4 5 6 7 10 9 11 9 12 13 14 8 1 10 0 10 0

105 organization and planning_built x autonomy 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. Staircase HVAC Indoor Unit HVAC Shaft Dust Collection Area

Break out space Planter box seen below

Storage/

Ramp Up 1 23 4 5 6 7 10 9 11 9 12 13 14 8 1

PLAN Studio 1 Studio 2 STUDIO/

PLAN 1 23 4 5 6 7 10 9 11 9 12 13 14 8 1 10 0 10 0

Service Lift Female Toilet Male Toilet Plumbing Shaft Passenger Lift Drinking Water Service Storage Garbage Chute Fire Shaft Electric and Server Shaft

Discussion Area

Control Room Green Room

AUDITORIUM

LECTURE ROOM

Urban farm Workshop and studios Library Auditorium and lecture hall Reception

SECTION

1 2

7 8 8 9

6

3 4 5

10

11 12

1.150 x 200 Glulam spanning member 2.550 x 550 ISMB and RCC composite column 3. 130 mm thk. steel deck slab and VDF flooring 4.450 x 220 I section beam 5.65 mm thk. FRP grated flooring 6.Vertical sliding folding partitions

7. 250 x 110 M.S. C-Channel 8.75 x 75 SHS column 9.Vertical hinge opening 10.Horizontal pivot opening 11. U-PVC louvers 12.Chicken mesh

building section and structural system_built

107

x autonomy STRUCTURAL SYSTEM

108 SECTIONAL PERSPECTIVE

109 sectional perspective_built x autonomy

110 FENESTRATION DRAWINGS 2 1 A D B C 1 detail at ‘A’ detail at ‘B’ detail at ‘C’ detail at ‘D’ 2 1 2 5 6 111 1 12 14 4 6 8 9 3 3 10 7 1 3 1.75 x 75 SHS Column 2.40 x 40 SHS 3.12 mm MS Tie rod 4.Clevis and Yoke 5.MS angle runner 6. Steel sheet panel 7. MS angle cleat 8. Vertical panel joint 9. Horizontal panel joint 10. Turnbuckle connection

mesh

Gear

11. 250 x 110 M.S. C-Channel 12.M.S. Chicken

13.M.S. Rod for connection 14.M.S. Flat 4MM thk 15.S.S. Bevel Gear 16.S.S. Spur

1. 75 x 75 x 10 M.S Box section 2. 25 x 25 x 3 M.S Box section 3. 65 mm thk. M.S grated flooring 4. 75 x 75 x 10 M.S L-angle 5. 75 x 75 x 8 M.S Box section 6. 130 mm thk. steel deck slab 7. VDF flooring 8. 25mm thk industrial flooring

9. M.S sheet 10. 40 x 40 x 5 M.S box section 11. 8mm thk toughened glass 12. 40 x 25 x 4 R.H.S 13. M.S wire 14. 40 x 40 x 5 M.S box section 15. 450 x 220 x 18 I-section 16. 25 x 15 x 5 L-angle

17. M.S wire mesh 18. U-PVC louvres 19. 100 x 100 x 12 M.S Box section 20. 40 x 25 x 4 R.H.S 21. 5MM thk M.S flat 22. 5MM thk M.S expanded mesh

111 fenestration

x autonomy WALL SECTION

and wall section_built

_ 1 : 250 expression model

112

_ 1 : 250 conceptual model

113 process models_built x autonomy

115 renders_built x autonomy

116 _ 1 : 50 detailed model

117 physical model_built x autonomy

Moving away from a set approach to design, into a pedagogy as that of the foundation studio of Architectural Tectonics, it was indeed an enthralling experience.

Driven by the experience of hands-on learning, moving from a detail onto a project like the high rise, there were countless learnings developed through the ‘process’, which were realised when being conscious about every step.

119

Hardik Arora PAT22128

Horizontal Pivot Window

Paradox is an opening device pivoting on horizontal axes. It is named after the impression which the device paints in a viewer’s mind, it is an attempt at combining contradictory forms of expressions of design. Facing this paradox as it is operated by the user, the intent is to slowly build as a part of the viewer’s daily use.

The idea of the opening started with conceptualizing the design as a statement intended to break the usual association of an opening. The design started with assembling the panel and then going towards the mechanism.

Across four designed iterations of mechanisms achieving a pivot on horizontal axes, this was chosen based on its simplicity, ease of assembly, possible scaling and workmanship ease. Strengthened by the process of making, this design intends to open new possibilities of explorations of expression in elements of architecture. Furthermore, the design can be explored through different material combinations, rendering the product in varied ways as desired by the user.

Tools

Measuring Tape

Battery drill

Screwdriver

Hammer Chisel

Drill bit 1.5, 3, 6, 12 mm Jig saw Band Saw Machine Adhesive

Sandpaper 150 grit Miter Saw Right Angle Wood Marker Router

Mild Steel (MS):

Cutting Machine Drilling Machine Sheet cutting Grinding Machine Buffing Machine Welding

Spot Welding Metal Chisel Hammer Punch

Right Angle Pliers

120 PARADOX

Mechanism Installation

Mechanism Installation

Step 1 : Bearing into Acrylic Parts

Step 1 : Bearing into Acrylic Parts

Step 2 : Fix pully 1 and 2 on MDF

Step 2 : Fix pully 1 and 2 on MDF

Step 3 : Add rod with Gear and Pully into Bearing on one side

Step 3 : Add rod with Gear and Pully into Bearing on one side

Step 4 : Add 2nd Gear into handle Rod and fix spacer as per timing belt placement.

Step 4 : Add 2nd Gear into handle Rod and fix spacer as per timing belt placement.

Step 5 : Fix Outer Panel with Bearing

Step 5 : Fix Outer Panel with Bearing

121 5 Frame Assembly Acrylic 1 2 Note: Leave the fixing of Part 1 and Part 2 until last step. 6

Panel Assembly

Panel Top into Frame 6

Fix

Closed Condition Open Condition 1 1. Assemble Primary MDF members. Leave Part 1 and 2 Acrylic 2. Install Mechanism 3. Panel Assembly MDF: Y X-2T-4A A A A A A A A A A A A A A Z Z X-2Z A X-2Z X 2AY A X-2A +T A X-Z 10 T X/3 X/3 X2 X X2 Materials Y X+2T-B T T 2A-2T X-B X-B Y-2T A X-B X2 X2 Dim as per Pulley Component 1 All dimensions in mm. X= Length Y= Width A= Y/4 B=Width (Acrylic) T= Thickness Total = B A A A A A A A A A A A A A Z Z X-2Z X2 Z Z Z X-2Z Acrylic : Assembly : Open Condition 2 Fenestration by Hardik Arora

The spanning system designed, constitutes of two members running in a combination of compression and tension forces. ISMB 300 is used for the peripheral beam with the members composed of 50x50 I and cross sections of varying length.

The spanning is designed based on the given end conditions.The brief aims to achieve a design that takes up a load ten times the weight of the spanning. This spanning system is used as a part of the program as a primary structural member, amalgamating with the expression of the overall program.

122 SPANNING

Final Spanning Model 1:10

A work space, with its sole purpose to create innovation, demands innovative thought. Intuitive or process derived, this thought is of prime importance as a driving force throughout the design.

A new idea is generated through its manner of structure and expression. The design started with a different idea, slowly developing into an outcome of 3 parts demarcated by their expression, structure, opacity and relationship to one another. These three parts involve a difference of material which enhances the intended idea. This resulting idea, birthed out of an amalgamation of material, details, structure and the expression which kept on developing towards the final result.

The idea became clearer, through a series of sketches and models, rendering its related iterations as they were made. The expression models and sketches translated the brief in their individual manner, with the whole portraying the idea differently.

124

Concept Model 1 Concept Model 2 WORK LINK

Mass from FootprintPodium Base Subtracting in Site Response Setting Tower onto Podium

Adjusting mass on Podium as per site

125

building

and planning_work link

Adjusting massing of Podium Dividing Mass by Opacity Adding Circulation Cores Adding/Subtracting Volume of Mass Adding Lattice Exhibition Process Model 1:500 Process Model 1:250

organization

LEGEND

Site Plan / Ground

A.Entrance Plaza

B.Block Entrance

C.Fire Control Room

D.Staircase 1

E.Exhibition Hall

F.Staircase 2

G.Electrical Room

H.AHU Room

I.Toilet F

J.Toilet M

K.Fire Lift

L.Lift Lobby 1

M.Reception

N. Admin Head Office

O. Admin Offices

P.Lift Lobby 2

Q.Lecture Hall

R.Double Height Exhibition

S.Entrance 2

T.Staircase 3

U.Staircase 4

V.Conference Hall

W.Lawn

X.Central Atrium

2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

23

1

22

24

building organization and planning_work link

Exhibition Bridges Lattice Framework

Rooftop Plaza Private Studios Workshops Group Studios 2 Library Group Studios 1 Workshops Studios Offices Workshops

Retail Lecture Halls

Public Library Exhibition Halls

The structural design of the program was detailed out keeping in mind the intended expression of 3 typologies of mass throughout.

Uptil Floor 13, the structure constitutes of RCC columns (600x600), with a network of Spanning systems at 3m Distance and RCC beams (250x 500) as horizontal members.

From Floor 14, steel sections columns(500x500) with spanning and Steel I Section beams (250x500) are present continuing to lattice.

18 mm Flooring

140 mm Concrete Slab

2 mm Decking sheet bolted to Spanning Members

Spanning Members

I Section Beam 250 x 500

(C Section X 2 ) Column (500x500)

I Section Beam RCC Columns Steel Columns

system_work link

building section and structural

130 SECTIONAL PERSPECTIVE

Spanning System

18 mm Flooring

Library LVL 2 Library Floor 14 Workshop Floor 13

140 mm Thick Concrete Slab Workshop Floor 14

131

sectional perspective_work link

132 FENESTRATION DRAWINGS RCC COLUMN 600 X 600 INSULATION FOR STONE TO WINDOW SLIDING WINDOW MULLIONS 75 X 150 TRANSOM 75 X 75 SUPPORT FROM WINDOW FRAME

133 WALL SECTION

detail_work link

wall section and fenestration

134

135

Podium Southwest View

Credits Podium developed on concept by Habitat Architects

136 Southwest View Model 1:50

137 physical model_work link

Looking at architecture through the lens of tectonics opened up new avenues for exploration- starting from a micro scale, diving into an explorative study of mechanisms to understand their working and science, so that it can become a part of the design process, progressing to spanning and then further expanding the scale to a high rise. For me, this studio was a space for exploring the process and allowed me to grow with it. Resources such as workshop equipments, consultants and technicians enabled me to explore material and see it as something beyond what is read in case studies and lines drawn on a computer screen.

MAT is an atypical course which provided the knowledge of existing and emerging methods of architectural design, which was quite a unique experience. While working on various scales, from micro level to macro, I have learned that the resolution of forces is what ensures how a design functions. The studio instilled a new perspective, through a keen understanding of material, its effect on forces and its construction. The exploration of different materials was enriching along with the hands on work, as it introduced me to craftsmanship. The whole curriculum required a certain consistency. It was tough but the outcome was worthwhile.

139

Manasvi Patil

PAT22033

Amrita

Das PAT22186

Horizontal Sliding Folding Window

Wave is a Sliding Folding window which uses bamboo and MS as the primary material for construction. It works on a mechanism which allows it to be operated from an indirect mechanical input. Bevel gears connected to gears attached to a timing belt allow the horizontal motion of the panels of the sliding folding device.

The panel uses half cut bamboo attached together in a wave form to create a screening device. It is an attempt to use bamboo as a material in different ways. The slats look and function very similar to timber. Whereas, the half cut bamboos maintain the cylindrical character of bamboo and exhibit its natural beauty.

WAVE

Vertical Blinds

Click is a material-based design for Vertical Blind windows. The major aim is to get the window open to function without exerting any effort directly on the blinds. The materials used for the construction of the window is Timber and Bamboo. The lead screw is the main mechanism through which the horizontal movement of the panels takes place. The linkages are also used for the rotatory movement of the panels. The whole mechanism works through the electricity, which offers simple installation, accessibility and usability.

Adding wood and bamboo joinery

Model images

Adding the mechanism in place

142 CLICK

Panel Assembly

Addition of 5mm groove in the vertical frame

Attaching the pannel members and other pivot members

Clamping the frames

Connecting the pannels

143 fenestration

Amrita Das

by

Span - 10m

Material - Mild Steel

The spanning system was designed through an exploration of various kinds of forces acting upon a horizontally spanning member. This spanning assembly is a combination of systems put together to allow covering long spans.

End

Condition

Spanning Model - Scale 1:10

SPANNING 1

LEGEND

1. 100mm x 150mm M S Hollow Box Section

2. 50mm x 75mm MS Box Section Bracing 3. 50mm dia MS Hollow member 4. 8mm thk Gusset Plate 5. 22mm dia. Bolt 6. 30mm dia MS Member 7. 6mm dia Tension Cable 8. 10mm thk MS Hook for Turnbuckle 9. Turn buckle 10. 10mm thk MS L Plate 11. 6mm thk MS Plate 12. 275x 600 x 20 I- Section Column 13. 10mm thk MS Plate

Span - 10m

Material - Bamboo and Mild Steel

The spanning system was designed through experimenting on module formation. Each bamboo modules provides various support in a longer span.

End Condition

Spanning Model - Scale 1:10

Spanning Model in Elevation

146

2

SPANNING

LEGEND

1. 20 mm thk M.S Member 2. 20 mm M.S bracing members 3. 75 mm Hollow Bamboo 4. 45mm Solid Bamboo 5. 40mm Solid Connecting Bamboo 6. 20mm MS Saddle 7. 15mm Bolt 8. 6mm dia Tension Cable 9. 4mm thk MS Gusset Plate 10. Turn buckle 11. 10mm thk MS L Member 12. 8mm thk MS Tube 13. 600 x 275 X 20 I- Section Beam 14. 20mm thk Stiffeners 15. 10mm thk MS Angle Member

Location - Thaltej, Ahmedabad

Site Area - 6984 sq.m

Typology - Educational Institution

Interplay is a high rise educational institution with the capacity to accomodate 880 students and 80 teaching and non-teaching staff. Pockets of informal interaction spaces are interspersed between formal classroom spaces vertically, to allow a balance between work and play. The formal learning spaces do not follow a typical classroom layout, but incorporate spaces essential to the development of students within the formal area itself.

Terrace Class XI & XII Library Class IX, X & Laboratory Art Area

Class IV-VIII Indoor Games & Canteen

Class I - III

Dance & Drama Auditorium & Conference Exhibition Area Administration Block Assembly Area Reception

148

INTERPLAY

Site Context Building OrientationSegregation of spacesVolumetric ArticulationCore Position Zoning Diagram Formal Spaces SITE

Area RailwayTrack

Residential

Sardar Patel Ring Road

Informal Spaces

Core at South

149 organization and planning_interplay

Section Formal Block CLimate Response Vertical Sun Angle - 55 Light Shelf Thermally Insulating Wall Assembly LEGEND 1. Vehicular

2. Pedestrian

3. Bus

4. STP 5. Substation 6. Ground

7. Badminton

8.

9. Tennis

10. Childrens

11. Outdoor

12. Ramp

1 2 9 6 7 5 8 11 10 12 3 4

North Facade Glass Envelope Shading Device Wider Projection for West Direction West Facade

entrance

entrance

parking

with track

court

Basketball court

court

play ground

learing space

to basement

Formal Block Typical Floor Plan -1

Formal Block Typical Floor Plan -2

Exhibition Area

Administration Block

Assembly Area and Administration Block

Reception

Ground Floor Plan

150

151 organization and planning_interplay Formal Block Typical Floor Plan Formal Block Typical Floor Plan -1 Service Lift 2.4 x 2.0 m Service Lift 2.4 x 2.0 m Garbage chute Garbage chute Classroom 9.0 x 11.3 m 1.8 m wide Balcony Staff room 5.0 x 5.5 m Reading room 5.0 x 5.8 m Staircase 6.0 x 3.3 m Staircase 6.0 x 3.3 m Staircase 6.0 x 3.3 m Staircase 6.0 x 3.3 m Male Toilet 5.6 x 2.1 m Male Toilet 5.6 x 2.1 m Female Toilet 3.5 x 2.3 m Female Toilet 3.5 x 2.3 m D Toilet 1.6 x 2.3 m D Toilet 1.6 x 2.3 m Multipurpose space 20.5 x 11.3 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Lift 2.4 x 2.0 m Ac Ac FHC FHC LV LV ELV ELV Assembly Area and Administration Block N

152 SECTION

153 building section and structural system_interplay

SYSTEM LEGEND 1. IPS Flooring 2. Comflor Decking Sheet 3.Spanning Systen 1 4. Spanning System 2 5. False Ceiling 6. 275 X 600 I Section 7. Glass North Facade 8. Dry Wall 9. Light Shelf 10. MS Support Framework 11. Vertically Sliding Windows 12. Sunshading Devices

STRUCTURAL

154 SECTIONAL PERSPECTIVE

155 sectional perspective_interplay

F E

Exploded

View

of

Facade

156 FENESTRATION DRAWINGS

Detail A Detail B Detail C

Isometric Section

157 fenestration and wall section_interplay WALL SECTION

Detail D Detail E Detail F D

158 Visualization

159 render_interplay Multipurpose Activity Space Formal Classroom

160 1:50 Scale Model

Sunshading projections conceptualization Segragation of Formal and Informal

Combination of Concepts and further exploration of facade

1:500 1:500 1:250 1:500 1:250

Response to the ground

162

Formal Classroom Block Views

Informal Area Views

163 physical model_interplay

The foundation studio provided me with an opportunity to question and disrupt the design process followed in practice. The real challange was to build a narrative based on parts of a system for establishing architectural character. The gradual scaling of modelsfrom 1:1 for an element of building, to 1:10 for a system of the building, to finally 1:50 for the complete building added rigour and ambiguity to the studio.

Apart from the intended learning outcomes, the journey provided with lot of intangible learnings. From dealing with uncertainties of working on someone else’s design to working with a partner, the semester has been truly fun-filled and enriching.

After a long period of covid, moving out of the home town brought back the same feeling when I was heading for bachelors. Through my journey in this semester, I understood that the overall approach towards work was different from the process known to me. The assignments were designed in a way that we got a knowledge of working with actual material, dealing with a long span, and understanding of scale. The course helped me develop the curiousity for detailing. The urge to see the end product helped us to complete work consistently. Very thankful to the tutors and TA’s for guiding us through out the semester.

165

Devashree Choudhari

PAT22092

PAT22308

Saurabh Narsikar

The cross is a parallel motion window which operates using the mechanism of the lead screw. It consists of two frames with the outer frame moving linearly outwards. The outer frame is cladded with a series of interlaced bamboo slats to form the panel.

In the mechanism, there are 3 lead screws that control the motion with two in the vertical axes and one in the horizontal axis. Bevel gears have been used in the mechanism to facilitate the motion transfer between the axes. A system of cross linkages on the vertical sides are attached to the lead screw to allow the window to slide outwards from the frame. The linkages are connected to the panel via nuts which move up and down the lead screw to allow elongation and compression.

The window uses timber and bamboo as it’s primary materials with timber being used in the outer frame while the inner frame is framed in bamboo section and cladded in a mesh of bamboo slats.

166 CROSS

Parallel motion window

h

d Mechanism assembly Indoor elevation Outdoor elevation Frame and Panel assembly

w

LEGEND

1a38mm Timber frame horizontal member

1b38mm Timber frame vertical member

2a90mm Timber frame base horizontal member

2b90mm Timber frame base vertical member

3a12mm dia lead screw

3b6mm dia lead screw

4a12mm inner dia ball bearing

4b6mm inner dia ball bearing

4c5mm inner dia ball bearing

5Bevel gear

6Bamboo frame

712mm dia bolt with anchors (Custom made)

8150mm acrylic linkages

925mm timber vertical member for panel

167 fenestration by Devashree Choudhari

Isometric view

Closed position Open position 1a 1a 1a 1a 2a 2a 2b 2b 1b 1b 6 8 9 9 4c 7 7 7 7 1b 1b 4a 4a 3a 5 5 3a 3b 4b

Kit of Parts Linkage detail

Vertically Hinged window

The aim is to create a product in a way that the direct force application needs to be completely nullified, and the operation needs to be carried out with the mechanisms. This was done with the help of bevel gears, spur gears, and timing belts. The bevel gear assembly converts the force applied to the handle, to the gears functioning the opening and closing of the window.

The primary material used is the MDF and bamboo. MDF houses the entire mechanism, i.e. spur gears, washers, timing belt, ball bearings. The bamboo works as the vertical member of the frame. The panel has a frame of timber, with a laser cut MDF.

This window uses 4 38mm dia spur gears, 2 15mm dia spur gears, 13 6mm ball bearing, 2 6mm Washer, 2 metals linkages welded with SS rod, 2 20mm dia bevel gears, timing belt and 6mm SS rod.

The assembly of mechanism

The assembly of bamboo and MDF for the window frame

168

SWING

Model views - Closed, Open Conditions

The exploded view of the frame assembly

Panel assembly

169

fenestration by Saurabh Narsikar

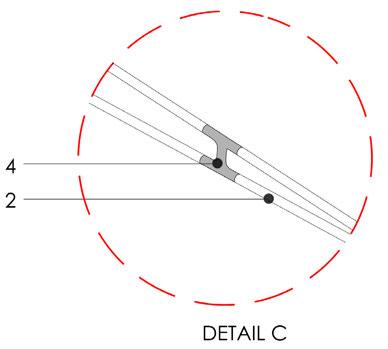

The key idea of the spanning beam was to express semi-tensigrity using flexibile and rigid materials. The alternating arrangement so formed was thus modulated to cater to torsion produced by vertical parallel members that are in tensigrity by the meanes of cables.

A B C

Isometric view of the spanning beam

Detail C Detail B Detail A

170 SPANNING 1

Process model: Iteration in articulating forces through paper and checking for loading.

Expression and detailing of iteration mentioned above through 1:10 model.

171 spanning by Devashree Choudhari

The spanning system is designed for a span of 10m. It uses 60mm dia steel pipe as supporting member. The top supporting member is a 180 x 100mm Glulam.

172 SPANNING 2

1. 180 x 100 mm Glulam member 2. 60 dia steel pipe 3. 6mm Gusset Plates 4. Custom made MS pipe connectors

1:10 Structural and Fenestration Model

173 spanning by Saurabh Narsikar

Steel pipes to Glulam connectionColumn - Beam Connection at first end

Column - Beam Connection at second endWW

174 VERTICAL GROUNDS

2

3

4

5

6

1 7 8 9 3 5 2 4 6 Exploration 1 Exploration 2 Exploration 3 Building

1:500

Building

7 Extra curricular zone: sports + recreation 8 Academic zone: Learning areas 9 Admin zone: Office and ancilliary areas Middle and high school Primary school Pre-primary school 1 Site context

Basic massing w.r.t. byelaws

Breaking the form for ventilation

response to sun: Insertion of core and adding porosity

Vertical grounds

Structural grid: RCC + Steel frame structure

Organisation

Model

evolution

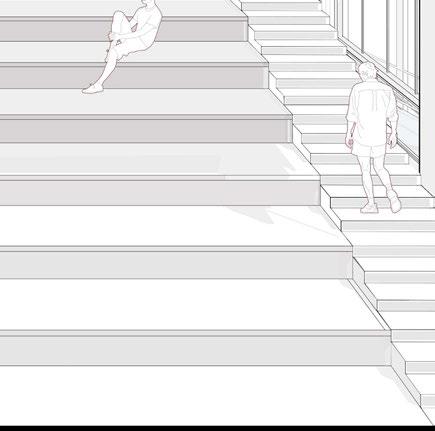

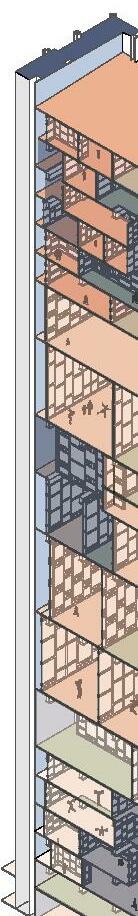

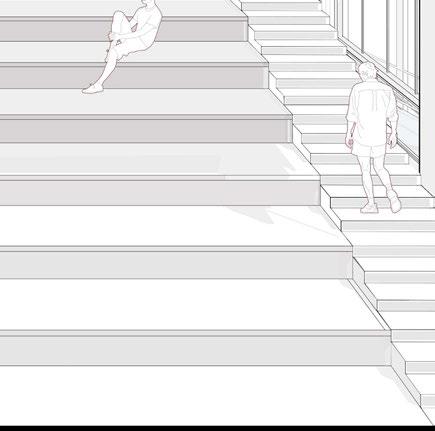

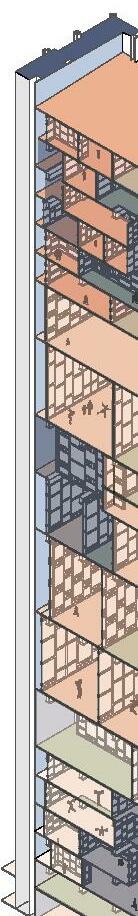

Imagining a school as a high-rise building could be the need of the hour, but it loses the scale and the touch of ground that is necessary for holistic learning. The question is- how to integrate this idea and make spaces with the point of view of a child?

Vertical grounds is thus a formal exploration of this idea. The program is divided such that it creates a schools within school expression, where cantilevered grounds act as datum for activity and interaction. The articulation of learning spaces is based on the age-group of the primary usersthe children.

175 organization and planning_vertical grounds

1 3 4 5 6

8 9 2

LEGEND 1Entry 2Watchman cabin 3Building 4Open air theatre 5Fire tank, Underground water tank and treated water tank 6Electrical substation 7STP 8Bus Parking 9Exit

7

Site Plan N

Typical plan: Pre-primary & Primary (arrangement 1)

1 2 3 3

Typical plan : Pre-primary & Primary (arrangement 2)

LEGEND

1Formal Learning

2Informal Learning

3Collective learning

4Double height court

5Co-curricular activities

6Admin Office

7Records Room

8Entrance Verandah

9Staff Room

10Spill out Space

11Vice-principal

12Principal chamber

13Meeting room

14Core

Typical Admin & Staff room Plan

176

5 5 4 4 2 2 2 1 1 6 7 8 10 11 12 14 14 14 14 14 14 13 9 1

Typical plan Secondary School (arrangement 1)

Typical plan :Secondary School (arrangement 2)

Typical plan: Vertical Grounds

177 organization and planning_vertical grounds

1 1 1 6 7 9 10 10 11 12 13 1४ 1४ 1४ 1४ 1४ 1४ 8 2 2 4 5 1 2 2 4 5

1Formal

2Informal

3Collective

4Double

5Co-curricular

6Badminton

7Amphi

8Board

9Table

10Canteen

11Serving

12Kitchen 13Store 14Core

LEGEND

Learning

Learning

learning

height court

activities

court

seating

game zone

tennis zone

seating

counter

Building section highlighting the volumetric play across the program

178 SECTION

179 building

grounds

SYSTEM

section and structural system_vertical

STRUCTURAL

LEGEND 1IPS flooring 2Framework for IPS flooring 3Precast hollowcore slab 4Spanning system across 10m 5350x350 cruciform column

180 SECTIONAL PERSPECTIVE

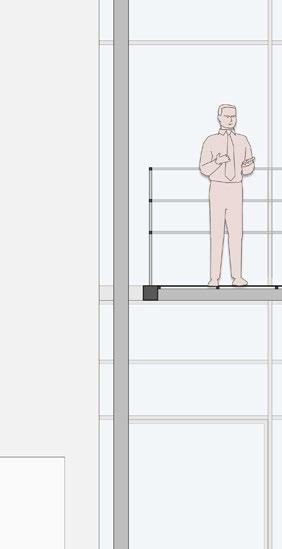

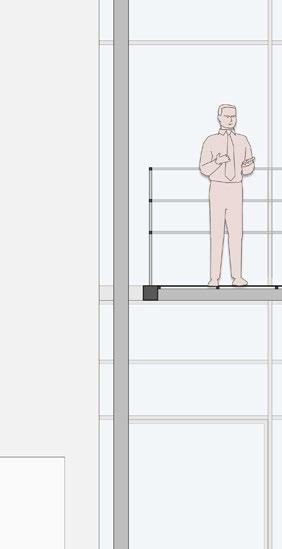

Sectional perspective showing the various activities and volumetric play in spaces.

181 sectional perspective_vertical grounds

LEGEND

1ISMC 150 Vertical mullion

2Built-in seating with back rest railing

3Planter box made in 18mm MS plate

4ISMC 150 Horizontal member

510mm MS plate

6Spanning beam

7150x75x10 Unequal angle section beams

8350x350 cruciform columns

9Railing for standing balcony

10Precast hollocore slab

11100dia Drain pipe for planter

182 FENESTRATION DRAWINGS

1 2 3 4 5 6 7 8 9 10 11

LEGEND

1Precast hollocore slab

2ISMC250 as end plate

318mm MS Plate as planater with 100dia drainage pipe

410mm MS Plate

5ISMC150 Vertical mullions

6ISMC150 horizontal member

183 fenestration

section_vertical grounds WALL SECTION

and wall

2 3 4 5 6

Fenestration & spanning detail model (1:10) 1

Exterior render showing North-east elevation

184

Render showing the spatial expanse of the vertical ground

Render showing Food court area

185 renders_vertical grounds

Building model Scale: 1:50

186

Facade detail

Connecting bridges

187 physical model_vertical grounds

This monsoon semester foundation Studio, has been a lot more challenging than I had expected it to be. The foundation studio has broadened my view beyond the typical nature of architecture, going beyond the basics and coming up with new ways to explore design and construction. The assignments starting from basic fenestration design and going up to high-rise expressions have helped widen our horizon on the subject by dealing with design and structure issues simultaneously. The experience of working relentelessly through out the semester and continuously been pushed to the edge of productive capacity has taught me a lot, and will always be a great yet a different learning experience.