Mehmet Erengul on Innovation, Sustainability and Future Ready Juice Sourcing

Zoheb Shah on Procurement, Public Value, and the Future of Transport in Auckland

Transforming Luxury Procurement

Vishal Noronha on Innovation, Sustainability, and the Future of Retail Excellence

Innovation is at the heart of everything we do. The digital space changes on a daily basis, meaning we have to be agile and adapt to new ways of working. By partnering with us, you can rest assured that your business is at the forefront, and is driven by experienced individuals who are well connected into the digital landscape globally.

Welcome to the 2026 edition of The Procurement Ledger, a collection that showcases the leaders, organisations and ideas redefining procurement as a strategic engine for resilience, innovation and long term value.

We open with Coca Cola, where Mehmet Erengul provides a compelling look inside one of the world’s most geographically complex sourcing landscapes. His perspective on agricultural risk, supplier ecosystems and value creation sets a strong foundation for this edition.

From New Zealand, Auckland Transport’s Zoheb Shah reflects on how procurement can influence community outcomes, sustainability and award winning operational excellence. His detective like approach and upcoming book highlight the power of curiosity in shaping better decisions.

Across the Middle East, Vishal Noronha of Chalhoub Group shares how procurement supports luxury retail experiences and a bold three year maturity journey built on innovation, sustainability and operational excellence.

Technology enabled excellence continues at TP, where Gianfilippo Villa leads a unified procurement function across EMEA. From Saudi Arabia, features with Durrah Advanced Development Company and SANKYU Saudi Arabia explore resilience, supplier partnerships and national capability building.

We also examine the evolution of procurement across Pakistan’s energy landscape through Saad Khamisani of Cnergyico, before moving to ACE Hardware Philippines, where Arnel Gamboa details the transformation of a vast, fast paced retail distribution network.

Our final features explore two very different sectors: the marble industry with Markos Poulios at FHL Group, and community focused procurement leadership at RAAFA WA with Anthony Wayne.

Together, these stories capture a discipline that is advancing rapidly, expanding its influence and shaping outcomes across economies, industries and communities. I am pleased to present this issue and the exceptional leaders behind it.

EDITOR

Christopher O’Connor

CREATIVE DIRECTOR

Martyn Oakley

DESIGN SUPPORT

James Pate

SOCIAL MEDIA MANAGER

Summah Buisson

PROJECT DIRECTORS

Denitra Price

Cisco Loevendie

PRODUCTION MANAGER

Ewa Piwoni

No.159, Field Maple Barns, Weston Green Road, Weston Longville, Norwich, Norfolk, NR9 5LA

ACCOUNTS

Emilio Vences

Joseph Heaton

MANAGING DIRECTOR

Stuart Irving

CHIEF REVENUE OFFICER

Fabian Stasiak

CHIEF EXECUTIVE OFFICER

Alex Barron

If you would like more information about ways in which The Procurement Ledger can promote your business please email | info@theprocurementledger.com

The Procurement does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Strategic Procurement at Scale: Mehmet Erengul on Innovation, Sustainability and Future Ready Juice Sourcing

TRANSPORT

Solving Complexity with Clarity: Zoheb Shah on Procurement, Public Value, and the Future of Transport in Auckland

Transforming Luxury Procurement: Vishal Noronha on Innovation, Sustainability, and the Future of Retail Excellence

Driving Procurement Excellence at Dubai World Trade Centre: Zyad Khan on Governance, Innovation and Event-Ready Supply Chains

Elevating Procurement Excellence Across EMEA: Insights from Gianfilippo Villa at TP

ADVANCED DEVELOPMENT COMPANY

Procurement with Purpose: Mohamed Kheir on Resilience, Sustainability, and National Alignment

SANKYU SAUDI ARABIA

Building Resilient Supply Chains Through

CNERGYICO PK LIMITED

Powering Pakistan’s Energy Future: Saad Riaz Khamisanii on Strategic Procurement, Resilience, and Transformation

Operational Excellence Nationwide: Arnel Gamboa on Transforming Logistics at ACE Hardware Philippines

I. KIRIAKIDIS MARBLES Building on Tradition: Markos Poulios on Procurement Excellence and Innovation

Driving Strategic Procurement and Care Excellence: Insights at RAAFA WA from Anthony Wayne

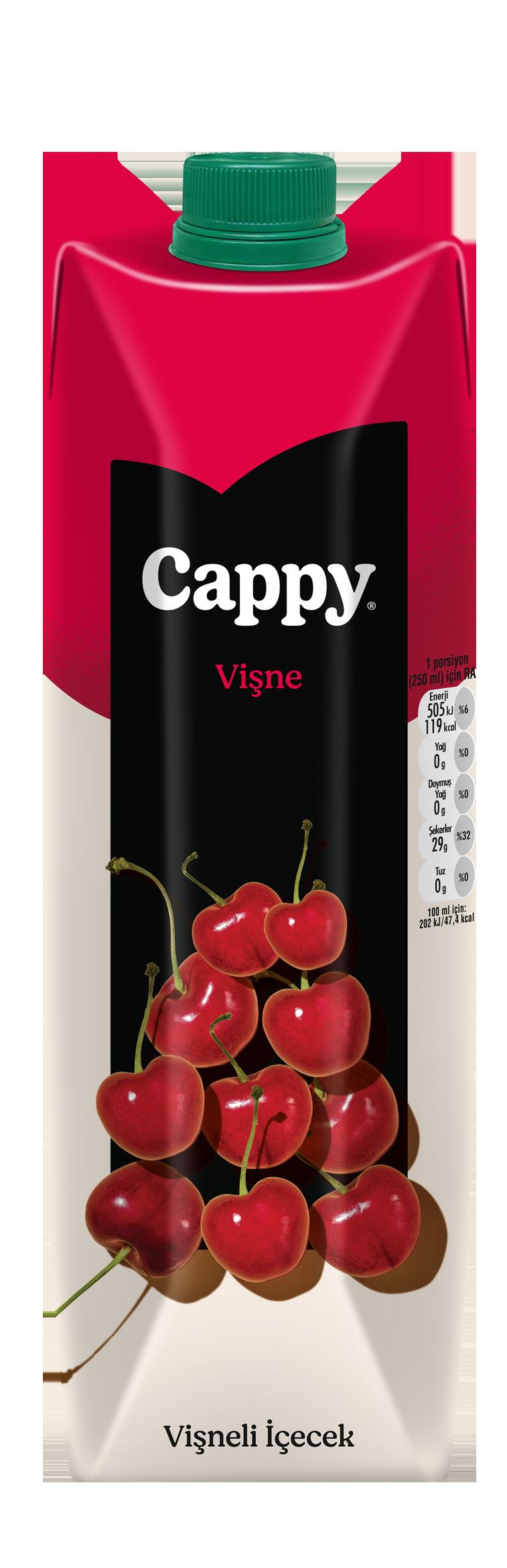

With one of the most geographically diverse portfolios in the business, the Juice category at Coca-Cola operates across a landscape shaped by agricultural risk, fluctuating markets, and shifting consumer expectations. Leading this complexity is Mehmet Erengul, Regional Juice Senior Procurement Director, whose remit spans Eurasia, the Middle East, India, Greater China, Japan, ASEAN and the South Pacific.

Built on a foundation of engineering, operational discipline and global supply insight, Mehmet’s career reflects a commitment to building resilient ecosystems rather than simply managing transactions. His leadership philosophy centres on value creation, supplier partnership, sustainability, and the use of technology to anticipate challenges rather than react to them. In this interview, he shares how global procurement is evolving, the future of agricultural sourcing, and the capabilities procurement leaders must develop to navigate a world defined by risk, innovation, and constant change.

Can you walk us through your career path and what led you to your current role as Regional Juice Senior Procurement Director at Coca-Cola, overseeing such a diverse and geographically complex region? What experiences have shaped your leadership in global procurement?

My career in procurement began with a strong foundation in engineering and supply chain, but what truly shaped my path was the gradual progression from operational roles into broader, strategic responsibilities. Joining Coca-Cola more than a decade ago was a defining moment. It opened the door to leading sourcing initiatives across multiple regions, industries, and cultures, each one adding a new layer of insight and capability.

Today, as Regional Juice Senior Procurement Director, I oversee one of the company’s most dynamic and challenging categories. Juice procurement demands agility and resilience, shaped by the volatility of agriculture, evolving consumer preferences, and the need to balance global strategies with diverse local realities.

What has influenced my leadership most is working with cross-functional teams and guiding them through transformation. I’ve had the privilege of championing sustainable sourcing, strengthening supplier ecosystems, and building teams that are proactive rather than reactive. Over time, I’ve learned that procurement leadership goes far beyond cost, it’s about creativity, collaboration, and delivering value that extends well beyond the organisation itself.

Given your remit spans Eurasia, Middle East, India, Greater China, Japan, ASEAN, and the South Pacific, how do you tailor Juice sourcing strategies to account for varying regional supply risks, climate conditions, and market dynamics?

Sourcing juice across such a diverse footprint requires a strategy that is both globally aligned and locally intelligent. There is no single template that works everywhere. This is why I place enormous value on strong in-market teams, people who understand regional nuances better than anyone, from climate shifts and farming cycles to regulatory changes and consumer preferences.

Our sourcing model is built on adaptability. We continuously rebalance global and local sourcing depending on market needs, risk exposure, and supply availability. Strategic partnerships with both global and regional suppliers are a cornerstone of this approach. We work with partners who share a long-term mindset and a commitment to mutual growth.

Risk resilience is a major driver. We use multi-sourcing strategies across regions to avoid overdependence on any one geography. At the same time, we lean into common platform juices to reduce complexity and increase interchangeability across SKUs. Standardised specifications and global packaging harmonisation further allow us to unlock efficiency and scale.

Ultimately, our approach goes beyond securing supply. It’s about building a flexible, risk-resilient network that delivers consistent value to all markets, no matter the conditions.

What are some of the most unique challenges you face in sourcing juice across such a diverse region, and how does Coca-Cola address them to ensure competitiveness and reliability?

Across many of our regions, fruit markets are heavily influenced by merchants who supply both domestic consumers and export channels. Traditionally, industries such as juice, jam, and canning have served as stabilisers, absorbing surplus fruit when crops are abundant. However, in emerging markets where agriculture is highly fragmented and dominated by small farms, processors often depend on traders and brokers to secure fruit.

This structure creates intense competition among processors, especially during short harvests or poor crop seasons, which puts upward pressure on prices and increases overall market volatility. Compounding this is a broader structural issue: urbanisation and labour migration continue to shrink the farming population, weakening long-term supply resilience across several key origins.

To address these realities, we focus on building strong, long-term partnerships with our suppliers. Through multi-year agreements and collaborative frameworks, we encourage them to invest in farming infrastructure and capability. We also support structured farming programs that incentivise growers, promote responsible agriculture, and help stabilise supply for both processors and farmers. Our aim is clear: create a more predictable, competitive, and resilient sourcing ecosystem, one that benefits suppliers, growers, and ultimately the consumers we serve.

What systems and supplier governance practices do you put in place, especially for Juice suppliers to ensure consistent quality and traceability?

Consistent quality and full traceability are absolute priorities in our juice sourcing strategy. We enforce a robust supplier governance framework that includes regular audits, comprehensive performance scorecards, and strict compliance checks covering quality, service, sustainability, and traceability standards. Every supplier is required to document raw material origins, processing methods, and maintain transparent, end-to-end traceability systems that meet our global requirements.

Quality assurance extends well beyond documentation. Before any shipment is released, we require product samples to be tested in our designated laboratories. This independent verification ensures alignment on specifications, validates product integrity, and provides an additional safeguard against any variation or oversight.

Ultimately, our approach is built on long-term partnerships with suppliers who view quality and transparency not merely as obligations, but as core shared values. This shared mindset is what protects consistency, builds trust, and secures mutual success across all markets we serve.

How is technology, data analytics, digital traceability, or supplier performance dashboards, being used to improve visibility, decision-making, and responsiveness in global juice procurement?

Technology is playing a transformative role in how we manage global juice procurement. We’re leveraging digital platforms to increase transparency, enhance governance, and demonstrate the strategic value procurement brings to the business. With advanced contract management systems and sourcing analytics, we can track performance, value delivery, and compliance in real time, enabling faster, more informed decision-making.

Supplier performance dashboards have also become a powerful tool. By monitoring quality, service, sustainability, and compliance metrics, these dashboards create a shared view of performance and foster healthier, more transparent conversations with our partners. This data-driven clarity strengthens relationships and supports a culture of continuous improvement.

Looking ahead, we see significant potential in predictive technologies. Crop yield forecasting tools, for example, could revolutionise our ability to anticipate supply shifts and strengthen our sourcing strategies. While these technologies still need time to mature, particularly given the variability of global agricultural data, we are optimistic about their long-term value.

Ultimately, our goal is to evolve from reactive management to predictive, insight-driven sourcing. By embracing digital capability, we’re building a more agile, resilient, and future-ready procurement function.

How is procurement helping Coca-Cola stay ahead by securing innovative ingredients or working with suppliers to support product development?

Innovation is essential in a fast-evolving beverage landscape, and procurement plays a central role in helping the business stay ahead. We work closely with R&D and our supplier network to spot emerging trends early and secure breakthrough ingredients that reflect changing consumer preferences across our diverse markets.

This goes far beyond traditional sourcing. We actively invest in supplier development programs that strengthen capabilities, encourage experimentation, and support new ingredient or processing innovations. These collaborative partnerships enable rapid testing, scaling, and adaptation, ensuring a seamless bridge between concept and commercialisation.

At its core, procurement becomes a co-creator in innovation. By combining market intelligence, strong supplier ecosystems, and close alignment with R&D, we help keep the portfolio fresh, competitive, and futureready, no matter how quickly consumer expectations evolve.

How do you build long-term supplier relationships built on continuous improvement, innovation, and shared sustainability objectives, especially in emerging markets where infrastructure and supplier maturity may vary?

Long-term supplier relationships are essential to building a resilient and sustainable procurement ecosystem. At Coca-Cola, we focus on partnerships rather than transactions, working collaboratively with suppliers to drive continuous improvement, innovation, and shared sustainability outcomes.

In emerging markets where capabilities or infrastructure may vary, we prioritise development. Through regular business reviews, structured feedback, and open communication, we maintain a proactive dialogue that helps us identify challenges early, address gaps, and strengthen performance. This approach supports not just short-term fixes, but long-term capability building across the value chain.

Sustainability is a core pillar of these relationships. Whether it involves reducing environmental impact, improving agricultural practices, or advancing ethical sourcing, we work closely with partners to design solutions that are practical, scalable, and future-fit. These initiatives create meaningful progress while aligning global expectations with local market realities.

Ultimately, our strategy balances Coca-Cola’s global standards with the unique needs of each region, helping to elevate supplier maturity, strengthen reliability, and unlock innovation in every market we serve.

Considering geopolitical instability, crop variability, and inflationary pressures, how are you building resiliency into juice procurement through diversification, risk mapping, and alternative sourcing partnerships?

In a category as sensitive and climate-dependent as juice, resilience is not a supporting element, it is the core of our procurement strategy. The landscape is shaped by geopolitical shifts, crop volatility, and inflationary pressure, so our approach to risk management is both proactive and multi-layered.

We strengthen resilience by diversifying sourcing origins and technical specifications. Relying too heavily on one geography, one crop condition, or one specification exposes the business to unnecessary risk. By spreading our sourcing footprint and broadening specifications where feasible, we increase flexibility and maintain supply continuity during challenging seasons.

Robust risk mapping tools give us upstream and downstream visibility, allowing us to assess vulnerabilities from farm to production and logistics. Scenario planning is another key element, helping us anticipate the potential impacts of economic shifts, climatic events, or supply disruptions before they occur.

We are also expanding alternative sourcing options, including regional and local supply partners, to create more agility and reduce dependency on any single market. Alongside our strategic suppliers, we are investing in sustainable agricultural practices and long-term agreements that strengthen resilience for all parties involved.

Ultimately, our goal is to build a procurement model that is agile, transparent, and future-ready, one capable of navigating today’s uncertainties while preparing for the dynamic challenges of tomorrow’s global agricultural landscape.

How do you see the role of Procurement leaders evolving in shaping the future of sustainable and resilient supply chains, particularly in the Food and Beverages Industry?

I strongly believe the role of Procurement is evolving far beyond transactional buying, it’s becoming about shaping resilient ecosystems rather than simply managing efficient pipelines. In the Food and Beverages industry, where agricultural volatility, climate risks, and shifting consumer expectations converge, procurement leaders must think more broadly and act more proactively. Procurement is no longer a back-office support function; it is emerging as a front-line driver of long-term value and positive impact. This means enabling local sourcing ecosystems, developing supplier capabilities, embedding sustainability into every decision, and fostering deep collaboration across the value chain.

Technology is accelerating this shift. AI-enabled forecasting, data-driven risk modelling, and end-to-end digital visibility are helping us become more predictive, agile, and transparent. These tools support better decisions and give us the foresight needed to navigate complexity. Looking ahead, the real future of procurement lies in connecting global ambition with local action, creating supply systems that are cost-effective, sustainable, inclusive, and prepared for future disruptions. Procurement leaders have a unique opportunity, and responsibility, to help shape the future of the Food and Beverages industry in a way that benefits businesses, communities, and the planet.

What advice would you offer to procurement professionals aspiring to take on regional or global roles in strategic sourcing? What leadership qualities and capabilities do you consider essential?

For procurement professionals aiming to step into regional or global roles, my strongest advice is to cultivate a strategic mindset and expand your perspective beyond local priorities. At a global level, success is not only about cost, it’s about creating value, anticipating risk, driving innovation, and shaping a resilient ecosystem with your suppliers.

Looking ahead, the real future of procurement lies in connecting global ambition with local action

Cultural intelligence becomes crucial when operating across multiple regions. Each market has its own business rhythms, communication styles, and expectations, and the ability to adapt while building trust makes a significant difference. Strong, genuine relationships, built on respect and understanding, become one of your greatest assets.

Leadership in procurement today extends well beyond technical excellence. Emotional intelligence, adaptability, and the ability to inspire and guide cross-functional, multinational teams are essential capabilities. Equally important is the ability to influence, aligning stakeholders across geographies, functions, and priorities often becomes the real differentiator in global roles.

Finally, stay curious. Be proactive in learning about emerging technologies, new business models, and the macro trends reshaping global supply chains. The most impactful leaders are those who continue to evolve, challenge assumptions, and turn complexity into opportunity.

Coca-Cola is the world’s leading total-beverage company, producing and marketing a portfolio of iconic brands across soft drinks, water, sports drinks, juices, coffee and more. Operating in more than 200 countries and territories, the company works with a vast global network of bottling partners to deliver over 2 billion servings every day. Coca-Cola is committed to responsible growth, sustainability and innovation across its products and supply chain.

Zoheb Shah on Procurement, Public Value, and the Future of Transport in Auckland

With a career spanning defence, telecommunications, and now public transport, Zoheb Shah has built a reputation as one of the region’s most forward-thinking procurement leaders. As Senior Manager, Procurement at Auckland Transport, his work sits at the intersection of commercial strategy, community outcomes, and operational excellence. From leading award-winning procurement programmes, including the Bus Services Re-Tender, recognised as Public Procurement Project of the Year at the CIPS ANZ Excellence Award, to shaping technology partnerships, sustainability frameworks, and digital transformation initiatives, Zoheb brings a detective-like curiosity to every challenge.

In this feature, he reflects on his career journey, the critical role procurement plays in delivering reliable and sustainable transport, and the innovative mindset behind his upcoming book, The Procurement Detective.

Can you share your career journey and what led you to your role as Senior Manager, Procurement at Auckland Transport? Which experiences have most shaped your approach to procurement leadership within public transport?

After working in the Justice sector, I unexpectedly found my way into procurement, a profession that felt part detective work, part strategist. My career has since spanned an energising mix of private and public sectors, including defence, telecommunications, and now transport. Each role strengthened my understanding of procurement as a strategic value driver rather than a compliance function. In defence, I learned the importance of resilience, risk management, and tightly managed supplier partnerships across everything from catering services to critical systems. At Spark, I led one of Australasia’s most complex B2B relationships, balancing commercial outcomes with long-term partnership. At Vodafone, I supported a transformation that repositioned procurement as a digitalfirst enabler of business performance.

These experiences shape the lens I bring to Auckland Transport (AT), where public transport requires a balance of commercial acumen and community focus. At AT, I’ve had the privilege of leading award-winning procurement initiatives that modernised processes, embedded sustainability, and delivered meaningful impact for Aucklanders.

How does procurement contribute to delivering resilient, sustainable, and reliable transport services and projects at Auckland Transport?

Procurement underpins AT’s ability to deliver an effective, efficient, and safe land transport system for Auckland. Our role is to create the conditions for success by building strong supplier partnerships, ensuring transparency, and embedding resilience into every commercial arrangement. In complex service areas such as bus and ferry operations, this means bringing together commercial, operational, financial, and sustainability teams so that projects progress cohesively and deliver as one organisation.

Sustainability is a core priority, with low-emission fleets, greener infrastructure, and social outcomes integrated directly into our procurement frameworks. But procurement’s impact goes beyond process efficiency, it’s about scanning the market, anticipating risks, and providing strategic insight so the organisation can adapt early and confidently.

Ultimately, our focus is on public value. Reliability, safety, and service continuity are what Aucklanders experience every day, whether they are driving, walking, cycling, or using public transport.

Procurement’s role is to safeguard that experience by ensuring our suppliers, contracts, and commercial strategies are aligned with AT’s mission to keep transport accessible, dependable, and trusted.

Auckland Transport continued their engagement with Ansarada in 2023 at a pivotal moment in the evolution of its procurement function as the organisation prepared for a multi-tranche bus contracting programme. The project demanded strong governance, transparency, and consistency across a wide range of internal and external stakeholders.

From the outset, the relationship developed as a true partnership rather than a transactional supplier engagement. Open communication, mutual trust, and a shared commitment to collaboration shaped the way both teams worked together. Ansarada’s account and support teams were consistently accessible and hands-on, providing guidance, responding quickly to evolving requirements, and working closely with Auckland Transport to align the platform to its governance standards and operational expectations.

Being invited into regular internal meetings further strengthened this relationship. It allowed Ansarada to gain a deeper understanding of Auckland Transport’s procurement objectives, internal processes, and accountability requirements. This close alignment ensured the platform was configured in a way that supported not only compliance and structure, but also the practical realities of large-scale public sector procurement.

Auckland Transport required more than a software solution. It needed a platform capable of bringing structure, transparency, and confidence to complex and highly visible procurement activity. Ansarada delivered a comprehensive digital environment designed to support repeatable, auditable, and well-governed procurement processes.

Key capabilities were deployed to create a single, reliable source of truth for all procurement documentation. Structured document management replaced fragmented shared drives, significantly reducing version control issues and improving accessibility for internal teams and external stakeholders. Secure, role-based access controls ensured sensitive information was only available to authorised users, supporting probity requirements and strengthening risk management.

One of the most impactful improvements came through the introduction of structured question and answer workflows. Previously, hundreds of supplier queries were managed through email and spreadsheets, often resulting in delays, duplication, and inconsistent responses. By moving this process into a controlled digital workflow, Auckland Transport achieved faster response times, clearer communication, and greater consistency across bidder interactions.

To support successful adoption, Ansarada invested heavily in onboarding, training, and ongoing user support. Workshops, guidance materials, and direct assistance helped teams transition from manual processes to a more disciplined and transparent digital framework. This focus on user readiness was critical in embedding the platform across multiple tranches and procurement teams.

Operating within a public sector environment brings significant pressure around timelines, accountability, and stakeholder scrutiny. Auckland Transport regularly manages large bid volumes, concurrent users, and tight delivery schedules. Ansarada provided a stable and scalable platform capable of supporting these demands without disruption.

Beyond the technical requirements, cultural change was a key consideration. Moving to a structured and auditable system required a shift in mindset. This was addressed collaboratively by aligning the platform to existing templates, evaluation frameworks, and governance processes, ensuring it felt intuitive and practical rather than restrictive.

Time pressure was another important factor. Procurement activity often extends beyond standard working hours, particularly during major evaluation phases. By reducing manual effort, simplifying document retrieval, and improving overall visibility, the platform helped teams manage workloads more effectively and work in a more sustainable way.

Introducing a fully digital and transparent procurement platform also represented a step change within New Zealand’s infrastructure sector, where manual processes have historically been common. The platform now supports Auckland Transport’s longer-term ambition to modernise procurement through analytics, digital tools, and future integration of advanced capabilities.

The outcomes of the partnership have been significant. The platform’s successful deployment during Tranche Two contributed to Auckland Transport receiving the CIPS Public Procurement Project of the Year award, recognising the strength of governance, structure, and execution achieved through the programme.

Operationally, the move to a single source of truth has reduced duplicated effort, improved document accuracy, and strengthened communication with suppliers. Bidders, including international proponents, have highlighted the transparency and reliability of the procurement environment, reinforcing confidence in Auckland Transport’s processes.

The platform’s scalability has allowed consistent standards of governance to be maintained across multiple tranches and major procurement packages. It is now regarded as a core component of Auckland Transport’s procurement ecosystem, supporting both current delivery and future growth.

What distinguishes Auckland Transport’s approach is its understanding that innovation extends beyond technology alone. The organisation has actively challenged traditional procurement practices while maintaining a strong focus on people, efficiency, and long-term readiness. Rather than adopting a platform in isolation, Auckland Transport worked closely with Ansarada to refine workflows, improve usability, and ensure the system genuinely supported how teams operate.

This balanced approach reflects a commitment to work life sustainability, operational discipline, and continuous improvement. By combining structured governance with a people-focused mindset, Auckland Transport has built a procurement environment that is modern, resilient, and fit for the future.

Together, Auckland Transport and Ansarada have established a transparent and scalable procurement framework that sets a strong benchmark for public sector procurement in New Zealand.

Congratulations on Auckland Transport’s Bus Services Re-Tender winning Public Procurement Project of the Year at the CIPS ANZ Excellence in Procurement Awards. Could you tell us more about the scale and impact of this project, and why the “whole-of-business movement” was so important to its success?

The Bus Services Re-Tender was one of Auckland Transport’s largest and most complex commercial undertakings, covering a multi-billion-dollar service portfolio. Winning Public Procurement Project of the Year at the CIPS ANZ Awards recognised not only the scale of the work but the way it was delivered. This was never a routine procurement exercise, it became a true whole-of-business movement involving finance, operations, commercial, sustainability, and procurement working as one integrated team. At its height, it felt less like a project and more like an ecosystem: dozens of interdependent workstreams, each critical to achieving the right outcome.

We developed evaluation criteria that balanced price, quality, sustainability, and social outcomes, rewarding operators that demonstrated proven reliability and a commitment to community value. Internally, we redesigned our processes to remove duplication, strengthen governance, and create clear evaluation templates that suppliers and evaluators could trust.

A project of this magnitude will always carry complexity. The goal is not to eliminate that complexity, but to harness it, to govern it, structure it, and turn it into transparent and defensible outcomes. This award reflects what is possible when collaboration, discipline, and purpose sit at the centre of public procurement, setting a new benchmark for the sector.

“Sustainability is a core priority, with low-emission fleets, greener infrastructure, and social outcomes integrated directly into our procurement frameworks”

How does procurement balance cost management with the need to maintain quality and continuity across priority projects and services?

Balancing cost management with service continuity is one of the core challenges in public procurement. For us, it extends far beyond securing the lowest price, our focus is on maximising public value. Every dollar spent must ultimately contribute to outcomes Aucklanders experience daily: a transport system that is convenient, well-connected, accessible, and reliable.

To achieve this, we apply holistic evaluation methods that consider more than cost alone. A key mechanism is the Price Quality Methodology (PQM), which places a notional price on quality. This approach creates a quality premium, recognising that suppliers with stronger performance capabilities often deliver greater long-term value, particularly where reliability, sustainability, and social impact are critical.

At the same time, we understand that numbers alone cannot capture the full picture. That’s why we rely on experienced subject-matter experts across disciplines to interpret context, assess risk, and apply informed judgement. Procurement therefore becomes the balancing mechanism, safeguarding financial stewardship while ensuring the operational and community outcomes Auckland depends on remain uncompromised.

How are you leveraging digital tools and procurement strategies to improve resilience, efficiency, and transparency for customers and stakeholders?

Digital tools only create value when they are orchestrated to serve customers and stakeholders. Procurement’s role is to ensure technology investments are not just “shiny objects” avoiding the shiny object syndrome, or a collection of disconnected systems creating the Frankenstein effect. In transport, digital transformation must translate into real public value: reliable disruption alerts, smoother journeys, clearer information, and greater trust in the network.

At Auckland Transport, we are continuing to build the orchestration required to fully connect our digital tools, platforms, and data flows. With AI, machine learning, and automation opening new possibilities, from predictive fleet maintenance to enhanced customer information systems, the priority is to ensure these technologies integrate seamlessly rather than operate in isolation. Procurement plays a critical role in scanning the market, filtering out noise, shaping commercial models, and securing supplier partnerships that add resilience rather than complexity.

A good example is our collaboration with Ansarada. Their secure data room platform has supported several of our major procurement programmes, including the Bus and Ferry RFPs, making evaluation more efficient, auditable, and collaborative. Combined with the rollout of a new contract management system, these digital partnerships are helping us create a more connected, transparent, and trusted procurement environment across AT.

Alongside this, I’ve been developing the C.O.R.E. Framework, designed to reimagine procurement’s role in digital transformation. C.O.R.E. stands for Collaboration, Orchestration, Resilience and Enablement, positioning procurement as the integrator of people, processes, and data. It acts as a control-tower lens, enabling organisations to make decisions that are coherent, future-focused, and genuinely value-creating.

Lite Civil is a locally grounded, values led civil construction partner helping shape communities through reliable infrastructure delivery. We work across public infrastructure, subdivision, and commercial projects, supporting small, medium, and large scale works in stakeholder led environments where trust, planning, and accountability are essential.

Our team delivers roading, drainage, earthworks, concrete, and siteworks with a practical, hands on approach and a focus on doing things right. As a 100 percent Māori owned business, Lite Civil is committed to supplier diversity and positive social outcomes, working as an approachable, dependable partner from project inception through to completion.

From integrated ticketing systems to new digital platforms, how does procurement support the successful implementation of technology while managing supplier relationships and risks?

For organisations with traditionally cautious approaches to risk, procurement’s role is shifting from transactional buying to architecting connected, future-ready digital ecosystems. A foundational step is benchmarking global best practice. For example, I’ve been engaging with Dubai’s RTA to understand how their digital twin pilot, developed collaboratively with industry partners, accelerated innovation while reducing implementation risk. These insights are valuable as we consider targeted local pilots in Auckland.

Today, success isn’t just about mitigating supplier risk; it is about enabling co-innovation. Procurement must champion commercial frameworks that evolve beyond static SLAs, promoting data transparency and interoperability through open data platforms. This shift transforms supplier relationships from opaque, “black box” arrangements into transparent, accountable, and innovationdriven partnerships.

To progress safely and strategically, we use these partnerships to test and validate new technologies through controlled pilots, for example, developing a digital twin of a key transport corridor. These structured trials allow us to learn quickly, refine collaboratively, and prove value before scaling across the network.

This approach ensures that procurement not only manages risk but actively enables the innovation that will shape Auckland’s transport future.

With growing demand for green and climate-resilient transport, how does procurement help embed environmental and sustainability outcomes in supplier selection, contracts, and performance frameworks?

Procurement is one of the strongest levers we have to deliver climate action, social impact, and community value. At Auckland Transport, sustainability is embedded into every major sourcing activity through our Sustainable Procurement Action Plan, which guides how procurement contributes to Auckland’s transition toward a regenerative, low-carbon economy.

In bus services, for example, contracts require operators to accelerate the shift toward low- and zeroemission fleets, directly supporting AT’s target of reducing emissions by 50% by 2031. We also embed waste-diversion KPIs, typically 65–75%, and require adherence to AT’s Supplier Code of Conduct and Sedex membership to uphold ethical, responsible business practices across supply chains.

Sustainability is also people-centred. Through the Kake Mai supplier diversity programme, we support Māori- and Pasifika-owned emerging suppliers by facilitating partnerships with head contractors on our Physical Works Supplier Panel. This creates genuine opportunities for capability building, participation, and long-term economic impact.

By setting clear criteria, deeply interrogating supplier responses, and monitoring delivery through the AT Sustainability Data Portal, procurement ensures that environmental and social outcomes are delivered alongside cost, quality, and reliability, strengthening Auckland’s transport system for the future.

What role does procurement play in embedding risk management and resilience into Auckland’s transport projects and supplier partnerships?

Risk management sits at the heart of procurement’s contribution to infrastructure and service delivery at Auckland Transport, and it begins long before a contract is awarded. Early market engagement allows us to surface potential vulnerabilities, from supplier capacity constraints and market volatility to cost escalation and delivery risks, so mitigation strategies can be built into project design from the outset.

A core mechanism is our Value Risk Assessment (VRA), which evaluates projects on value, complexity, and risk, categorising them from low to very high. The VRA determines the level of governance required, including cross-functional sign-offs from procurement, finance, safety, and probity. This ensures that risks are formally identified, assessed, and endorsed before any sourcing activity begins.

We then carry these controls through the contracting phase by embedding clear performance measures, KPIs, and monitoring frameworks, while designing contracts with enough flexibility to adapt as conditions evolve. Procurement’s role is to make risk visible, governable, and actionable, strengthening resilience across supplier partnerships and giving AT the confidence to deliver essential transport outcomes for Aucklanders, even in complex or unpredictable environments.

How does procurement at AT work with operators and industry partners to design contracts and partnerships that encourage accountability, innovation, and service quality?

Strong partnerships form the backbone of effective public transport delivery, and procurement’s role extends far beyond enforcing contract terms. At Auckland Transport, we focus on creating structured, value-driven relationships that incentivise accountability, foster innovation, and elevate service quality across the network.

Our aim is to position AT as a true ‘customer of choice’. To achieve this, we embed Supplier Relationship Management (SRM) practices aligned with the Ministry of Business, Innovation and Employment (MBIE) frameworks, strengthened through collaboration with State of Flux. Supplier segmentation enables us to identify our most strategic operators and partners, and for these priority suppliers, we are preparing to roll out Joint Business Plans (JBPs). These JBPs establish shared objectives, define governance mechanisms, and set clear metrics for performance, risk, and value creation.

Governance forums, performance scorecards, and ongoing dialogue ensure transparency and accountability for both AT and its partners. In specific contexts, open-book arrangements help deepen trust and reinforce joint responsibility for outcomes.

By balancing commercial discipline with collaboration, procurement acts as the connector between AT’s strategic objectives and supplier capability. The result is a partnership ecosystem designed to deliver reliable, safe, and sustainable services that Aucklanders can depend on every day.

What advice would you give to professionals looking to build a career in public-sector procurement, especially in complex, multi-stakeholder environments like transport?

Public-sector procurement is both demanding and deeply meaningful, and my biggest encouragement is this: be relentlessly curious. Curiosity keeps you learning, about markets, suppliers, risk, technology, and the broader forces shaping public services. In a world where digital tools evolve at speed, professionals need to understand not just what a technology is, but how it strengthens the category they are procuring. Depth of understanding will always outperform trend-chasing.

Secondly, avoid narrowing your experience too early. The strongest procurement leaders are shaped by breadth just as much as depth. My own career has spanned defence, telecommunications, and transport, across both direct and indirect categories, and that diversity has been invaluable. In environments defined by volatility, uncertainty, complexity, and ambiguity (VUCA), adaptability becomes one of your greatest assets.

Lastly, remember that public procurement is fundamentally purpose-driven. It’s not only about contracts and commercial outcomes, it’s about delivering value to communities. Lead with integrity, balance commercial discipline with empathy, and keep sight of the fact that procurement, when done well, improves lives. That sense of purpose is what will sustain you, guide your decisions, and shape you into a leader who lifts both the profession and the communities you serve.

You’re also writing a book, The Procurement Detective. Can you tell us about the concept behind it, and how it reflects your approach to procurement leadership and problem-solving?

I’ve always been a writer at heart, poetry, short stories, even a feature-length film script at school. Writing was my way of finding rhythm and narrative in complexity. When I discovered procurement, I realised it had the same creative DNA: intrigue, evidence, patterns, puzzles. It never felt like a linear process to me, it felt like a mystery waiting to be solved.

Public-sector procurement is both demanding and deeply meaningful, and my biggest encouragement is this: be relentlessly curious.

One of my earliest mentors in the Defence Force had previously worked as a private investigator. His method of dissecting problems, following unconventional leads, and piecing together evidence sparked something in me, the ‘procurement detective’ mindset. From then on, I saw procurement through a noir lens: part investigation, part strategy, part storytelling.

The Procurement Detective brings those worlds together. It blends practical tools with narrative, using classic detective archetypes, Sherlock Holmes included, to make procurement engaging, human, and accessible. It isn’t a theoretical manual, but a practitioner’s guide written with curiosity, clarity, and a touch of intrigue.

My goal is simple: to bring procurement alive on the page, practical, memorable, and genuinely useful for anyone leading, learning, or transforming in this profession.

Auckland Transport is the council-controlled organisation responsible for planning, funding and operating the transport network in the Auckland region of New Zealand. It delivers integrated services across roads, footpaths, cycling networks, parking, public transport and more, enabling the city to move efficiently, safely and sustainably.

With a career spanning global giants such as Halliburton and Unilever through to transformational leadership roles across MEERAS, ESAG, and Gargash Group, Vishal Noronha has built a reputation as a procurement leader who drives evolution, not maintenance. Now Vice President Procurement at Chalhoub Group, one of the Middle East’s most influential luxury retail organisations, he is steering a bold three-year maturity journey focused on innovation, sustainability, and operational excellence. In this interview, Vishal shares the philosophy behind his leadership, the role of procurement in delivering luxury experiences, and the trends shaping the future of retail supply chains across the region.

Can you share your career journey and what led you to your role as Vice President of Group Procurement at Chalhoub Group? What experiences have most influenced your leadership style in procurement and strategic sourcing?

My career has been shaped by a belief that procurement is far more than a commercial function, it is a catalyst for transformation. I began at Halliburton, where I learned the importance of operational resilience and strategic partnerships in a fast-paced, high-risk environment. My time at Unilever strengthened this foundation, demonstrating the impact of innovation, sustainability, and purposeled procurement on business performance.

I later moved into transformational leadership roles at MEERAS, ESAG, and GARGASH GROUP, where I rebuilt procurement functions, introduced digital capabilities, and championed value creation across diversified, complex organisations. These experiences deepened my conviction that procurement must evolve continuously and courageously.

Every organisation operates within a unique maturity lifecycle, and effective leadership lies in guiding that evolution. Today at Chalhoub Group, we are on an ambitious three-year maturity journey, one centred on innovation, sustainable impact, and operational excellence. This is the lens through which I lead.

Chalhoub Group is a leading luxury retailer and distributor in the Middle East. How does your procurement team support the Group’s commitment to excellence across retail, distribution, and beauty sectors?

Luxury retail is an experience, an emotion, and procurement is one of the quiet forces enabling it. Whether it is a new store opening, a digital innovation project, a marketing activation, or a logistics initiative, procurement ensures that every operational touchpoint behind the scenes aligns with the Group’s promise of luxury excellence.

Through the Group Transform Program, we are elevating the way we operate, bringing more agility, transparency, and strategic value to the functions we support. The goal is simple: to empower teams to deliver exceptional experiences while ensuring the Group operates responsibly, sustainably, and efficiently.

Sustainability is a key focus for Chalhoub Group, particularly through initiatives like the Chalhoub Impact program. How is procurement driving sustainability across your supply chain, and what recent initiatives have shown the most promise?

Sustainability is no longer an aspiration; it is a responsibility. At Chalhoub Group, our procurement agenda is closely aligned with our broader sustainability ambitions through the Chalhoub Impact program.

From greener store-construction materials to lower-carbon logistics solutions and more responsible sourcing frameworks, procurement is uniquely positioned to shape a more ethical and resilient ecosystem. The initiatives that excite me most are those that shift mindsets, where suppliers innovate with us, where sustainability becomes a selection criterion, and where long-term impact outweighs short-term cost.

This is how we redefine responsible luxury.

Turn every approved invoice into a workingcapital opportunity

Faster procurement, stronger supplier partnerships, and smarter cash flow with Mastercard.

Insight-led: We start with AP analytics to find where value is hiding.

Right-rail SCF: We route invoices to the best lever (VCN for tail/services, classic SCF for strategic suppliers, discounting where it fits).

Embedded + automated: Delivered inside existing ERP/P2P, with straightthrough supplier reconciliation.

In our recent work with Chalhoub Group, we showcased how Mastercard helps one of the Middle East’s leading luxury players streamline the full buy-to-pay journey across a complex portfolio of brands and thousands of suppliers. What was once fragmented across multiple systems, payment types, and approval flows becomes a single, datadriven experience that supports both top-line growth and disciplined cost control.

The transformation starts with AP analytics. We analyze invoice and supplier data to surface friction points, highlight early-payment opportunities, and segment spend by value, frequency, and supplier type. This intelligence lets procurement match every invoice to the optimal working-capital lever: corporate card payments for long-tail and services spend, conventional supply chain finance for strategic suppliers and larger invoices.

For buyers, this means improved DPO, better use of card limits and credit lines, richer data for negotiations, and tighter control over who gets paid, how, and when — all without adding manual workload to already-stretched AP and procurement teams. For suppliers, it means faster, more predictable cash flow, fewer payment disputes, lower collection costs, and a simpler path to accepting digital card payments through their existing banking relationships.

Execution is then embedded directly into existing ERP and P2P workflows. Once an invoice is approved, a controlled Virtual Card Number (VCN) can be issued automatically, paying suppliers instantly while allowing the buyer to settle later on card terms — extending DPO without compromising supplier relationships or financial control. Granular controls on amount, merchant category, currency, and validity window help reduce fraud risk and out-of-policy spend.

Finally, Mastercard Receivables Manager automates supplier acceptance and reconciliation, turning what used to be manual card capture into straight-through matching and faster month-end close. Suppliers receive clear remittance information, finance teams gain line-level visibility, and both sides benefit from fewer queries and cleaner books.

For luxury retailers, the outcome is a procurement function that is faster, more secure, more data-rich, and more cash-efficient — freeing teams to focus on brand growth instead of back-office complexity, while giving suppliers the confidence and liquidity they need to keep shelves full and customers inspired.

Speak to your bank or your Mastercard Corporate Solutions representative.

Given Chalhoub Group’s extensive portfolio of luxury brands, what strategies do you use to create strong, transparent supplier relationships while maintaining the high-quality standards required in the luxury retail space?

Luxury requires precision, consistency, and trust. Our approach to supplier partnerships reflects those same principles. We prioritise long-term relationships, shared values, and genuine collaboration, not just transactional engagement.

By establishing transparent governance and inviting partners to co-create solutions, we elevate the quality and innovation behind our operations. When suppliers grow with us, our brands and customers ultimately benefit.

The future of procurement is intelligent, predictive, and seamlessly integrated with technology. Through the Group Transform Program, we are embedding advanced analytics, AI-driven insights, digital contracting, and automation across our operating model.

AI is especially powerful, it enables procurement to anticipate opportunities, forecast risks, and uncover insights that were previously invisible. This shift allows our teams to spend less time on manual activities and more time shaping strategy, nurturing supplier-led innovation, and driving sustainable long-term value.

We are not simply digitising procurement; we are fundamentally reimagining what it can achieve.

As a major player with global operations, how does Chalhoub Group manage supply chain risks to ensure continuity and resilience, especially in light of recent geopolitical and logistical challenges?

Resilience has become one of the most defining differentiators in today’s global supply landscape. Whether dealing with geopolitical shifts, material shortages, logistics volatility, or sudden market disruptions, our responsibility is to anticipate risks early and engineer ecosystems that can adapt at speed.

At Chalhoub Group, we are strengthening our risk intelligence capabilities, diversifying our supplier base, enhancing governance frameworks, and leveraging digital monitoring tools to achieve realtime visibility across critical categories. The goal is clear: protect continuity, maintain agility, and ensure the business stays responsive, stable, and future-ready.

In an industry where customer demand can shift rapidly, how does your team approach inventory management and demand forecasting to balance product availability and cost efficiency?

In a fast-moving luxury retail environment, the operational rhythm must stay tightly aligned with business demand. Our focus is on building predictive visibility across the Group, anticipating retail activations, technology deployments, store development plans, and marketing initiatives before they materialise.

we are strengthening our risk intelligence capabilities, diversifying our supplier base, enhancing governance frameworks

Through data-driven forecasting tools and close collaboration with stakeholders, we ensure that capacity, budgets, and supplier readiness are fully synchronised in advance. This combination of foresight and flexibility allows us to support the Group’s ambitions while acting as responsible stewards of resources.

What are some of the unique procurement challenges faced in the luxury retail sector, and how does Chalhoub Group navigate these to maintain competitive advantage and brand integrity?

Luxury retail demands operational excellence at every touchpoint, with no margin for error. Timelines are tight, expectations are uncompromising, and every element, from store ambience to technology infrastructure, must embody the brand’s identity.

We meet these challenges through close collaboration, agile supplier ecosystems, and a continuous improvement mindset driven by our maturity roadmap. Rather than viewing challenges as obstacles, we see them as opportunities to innovate, elevate, and differentiate the luxury experience we deliver.

What trends do you see shaping the future of procurement in luxury retail, and how is Chalhoub Group positioning itself to adapt to these changes?

The future of procurement will be defined by AI, digital transparency, sustainability imperatives, and highly predictive supply ecosystems. Over the next decade, procurement will evolve from a value enabler to a true value architect, shaping strategy, driving innovation, and influencing long-term business outcomes far beyond cost optimisation.

At Chalhoub Group, we are preparing for this shift through a clear and deliberate roadmap, one that integrates advanced technology with human capability, blends sustainability with operational excellence, and positions innovation as a catalyst for enduring value creation across the organisation.

As a procurement leader in one of the region’s most prominent retail groups, and some one with a clear passion for procurement transformations, what advice would you offer to aspiring professionals aiming to grow their careers in procurement and supply chain, particularly within the retail and luxury sectors?

Procurement today is a space for innovators, problem-solvers, and purpose-driven thinkers. My advice is to stay curious, embrace continuous learning, and seek roles that challenge and expand your capabilities. Master the fundamentals, but also develop the confidence to question established norms, because transformation is not a one-off initiative, it is a mindset.

The most impactful leaders combine passion with humility and recognise their ability to influence entire ecosystems through the decisions they make. If you approach procurement with intention, courage, and a desire to create meaningful value, you won’t just advance your career, you will help shape the future of the profession.

Chalhoub Group is the leading partner and retailer for luxury brands in the Middle East, operating across 14 countries with a portfolio of more than 300 global brands in fashion, beauty and lifestyle. Established in 1955, the Group blends regional expertise with world-class retail, distribution and brandbuilding capabilities, delivering exceptional customer experiences across its stores and omnichannel platforms.

As Associate Director -Procurement, Contracts & ESG at Dubai World Trade Centre (DWTC), Zyad Khan plays a central role in enabling one of the world’s most high-profile events and venue organisations to operate with speed, integrity, and strategic foresight. With a career shaped across aviation, government, retail, private office operations, and more than a decade at DWTC, his leadership brings together deep governance, ethical procurement, complex category management, and an acute understanding of the operational pressures unique to the global events and MICE sector.

Khan today oversees procurement for major exhibitions, venue expansions, and internationally recognised mega-events, including Expo 2020 and COP28. Under his leadership, DWTC has strengthened its ethical and responsible sourcing framework through CIPS Ethical Procurement certification, embedded sustainability into contracting, and advanced digital transformation across the procurement function.

His approach reflects DWTC’s broader ambition to elevate procurement from a transactional function to a strategic enabler of resilience, innovation, and ESGaligned value creation. Through supplier development, localisation initiatives, digitalised governance, and a strong focus on stakeholder trust, Khan continues to shape a procurement organisation built for speed, transparency, and long-term impact across one of the region’s most dynamic event ecosystems.

You’ve risen through Procurement & Contracts into leadership at DWTC. Can you walk us through your path, what drew you into this role, and which experiences have shaped the way you lead procurement at a high-profile events & venue organisation?

My career journey has been defined by resilience and reinvention. What began as a shift from professional cricket due to injury accidentally led me into procurement where my curiosity for how things work behind the scenes found a fresh purpose. Early roles in retail and aviation at Emirates expanded my exposure to global supply networks, risk management through contracts and compliance-heavy considerations. At the Private Office of the Ruler, I had to maintain a fine balance between procurement success and sensitivity, speed and trust.

Over the last decade at DWTC, leading procurement for mega-events like Expo 2020 and COP28 has reinforced procurement as a strategic enabler of resilience and innovation and not just a support function (especially when category ring-fencing is a challenge due to content/spend diversity). My leadership style has been shaped by adaptability, foresight and a strong belief in mentorship and stakeholder trust. Stakeholders/relationships create the bridge that complements your competence and experience to deliver high impact outcomes.

DWTC’s procurement & contracts team was certified by CIPS for Ethical Procurement, with all members holding the CIPS Ethics Certificate and Kitemark. How has that certification influenced supplier selection, contract negotiations, and operational practices?

Achieving the CIPS Ethical Procurement certification with the Kitemark elevated how we approach procurement at DWTC. It gave us a common ethical framework and CIPS-backed credibility. Our supplier selection prioritises transparency and integrity, filtering out risks tied to unethical practices (extending into maximum supply chain tiers/visibility). In negotiations, the certificate strengthens our stance on responsible business conduct, making clear that compliance, fairness and accountability are non-negotiables backed by a grievance committee to reassure vendors on process integrity. Operationally, it fosters a culture where the team actively challenges shortcuts, insists on supplier due diligence and promotes responsible sourcing. This is a great foundation which will enable us to continue building strategic partnerships as we work to new ESG mandates. .

This certification is not just a badge; it’s a mindset shift that underpins every decision we make ensuring procurement remains a driver of trust, accountability and sustainable partnerships. Hopefully in coming years, ESG will be embedded into the CIPS excellence program .

Taaza Healthy has quickly become one of the UAE’s most respected and trusted food distributors, known for its uncompromising dedication to quality, freshness, and customer satisfaction. From humble beginnings, the company has evolved into a leading multi-category supplier, serving retail, hospitality, and foodservice partners across the region.

With a mission to deliver farm-fresh products from source to shelf, Taaza Healthy has built a robust portfolio that includes dairy, eggs, fresh produce, frozen items, dry goods, and health & wellness products. By working closely with both international and local producers, the company ensures the highest standards of safety, transparency, and traceability across every step of the supply chain.

At the heart of Taaza’s success is its commitment to sustainability and innovation. From adopting ecofriendly packaging solutions to streamlining logistics for reduced environmental impact, the company is actively reimagining how food reaches the end consumer. It continues to invest in digital transformation and modern cold chain infrastructure, ensuring temperature-controlled delivery and real-time tracking, both critical in the UAE’s demanding climate.

Taaza Healthy also takes pride in its ability to respond to evolving consumer expectations. As demand grows for health-conscious, clean-label, and functional food items, Taaza has expanded its offering to include an ever-wider range of organic, gluten-free, and nutritionally rich products. This agility, coupled with a strong sourcing network, positions the company as a vital partner for brands and retailers aiming to meet the needs of modern consumers.

A people-first culture underpins every aspect of Taaza’s operations. The company fosters strong relationships not only with customers but also with suppliers and employees, creating a trusted ecosystem built on collaboration, integrity, and shared goals. Training, upskilling, and a focus on food safety are prioritised across the team, supporting growth from within while reinforcing the company’s quality-driven mindset.

Today, Taaza Healthy is more than a distributor; it is a food solutions partner. With a future-forward outlook, the business is expanding into new categories and channels, leveraging data insights and market feedback to stay ahead of trends. Whether it’s helping a hotel source premium ingredients or guiding a retailer in the launch of a new product line, Taaza approaches each challenge with the same passion for excellence. As the region continues to evolve, Taaza Healthy remains firmly committed to delivering the best, with freshness, health, and trust at the core of everything it does.

With DWTC’s strong sustainability pillars and Green Globe / LEED certifications (especially for the Dubai Exhibition Centre), how is your procurement strategy adapting to source more sustainable materials, local suppliers, and reduce carbon/waste? What challenges do you face balancing cost, scale, and sustainability in event supply chains?

Sustainability is central to DWTC’s strategy reflected in Green Globe, GBAC Star and LEED certifications at our designated venues across Dubai.

Procurement plays a pivotal role to work alongside specifications that embed circular economy principles to reduce waste. We actively partner with suppliers who share these values, aligning sourcing practices with the UAE’s sustainability agenda. The challenge is balancing sustainability with cost and scalability especially given the fast-paced, short span and high-volume (foot fall) nature of events. For example, single-use plastics reduction requires supplier innovation while maintaining affordability and it took some time for bottled water companies to make Recyclable-Pet (rPet) as an affordable alternate to single use PET bottles. The path isn’t without trade-offs and requires patience, however, economies of scale (to counter cost risk) shall prevail when ESG mandates will gradually transform cultures, mindsets and operating models. Embedding sustainability KPIs into contracts ensures suppliers co-own this journey which is a key review/negotiation element to identify your longterm partners (Remember, there is a customer at the other end where their choices have evolved and they do look out for green/responsible options).

Procurement is evolving from cost control to impact creation by delivering experiences that are not only spectacular, but responsible too.

DWTC recently overhauled its digital infrastructure . How is digitisation reshaping your procurement/ contracting process, contract tracking, supplier performance, automation, etc.?

Digitisation has reshaped procurement at DWTC by embedding agility, visibility and accountability into every process. With IoT-driven building energy systems and a headless CMS powering our digital infrastructure, Procurement now integrates seamlessly into the wider organisational transformation. In the coming few months, we plan to introduce automation in contract lifecycle management (including template standardisation/AI drafting abilities) improving accuracy, timelines and compliance monitoring (diligence applied off Policy manual). Digitisation isn’t replacing procurement judgment, instead it is enhancing decision-making with actionable data. Ultimately, technology has helped procurement shift from reactive to proactive, making us more resilient and responsive in supporting DWTC’s global event portfolio which carries sourcing/availability challenges (in high season) against tight timelines and an expectation of “close to perfect” commercial decisions.

Transaction/approval and delivery tracking has also become data-driven, moving beyond anecdotal feedback to real-time dashboards and eased out workflows. This allows us to anticipate risks, measure performance and hold suppliers accountable with clarity, which in turn helps to shape the right governance frameworks under formal contracts.

Given DWTC’s scale, especially with mega-events like GITEX, how do you build trust and capability in local suppliers and integrate them into high-performance contracts typically dominated by global vendors?

DWTC’s scale demands a balance of suppliers with global expertise and local capability, especially when it comes to time challenges. There’s a need for building stronger local/supply networks to accelerate the economy, strengthen the UAE’s supplier ecosystem and reduce over-reliance on international players.

For mega-events like GITEX, the key is to treat local vendors not as backup but as strategic partners, aligning them with global standards while retaining their agility. It’s about localisation with ambition to develop capacity that can eventually compete globally, hence one area of our recent focus/inputs has been data-backed projections/committed spend threshold (Local produce farming/yields - Farm to Fork). This enables local vendors to plan and improve their respective supply chain deliverables, which eventually builds into the cost/quality performance of the eventual show.

A transparent support system for SMEs/local vendors is mapped through transparent contracting, capability-building workshops, including open briefs on what is expected from supply chain partners (including ESG-related aspects). Local suppliers are often agile and collaborative but may lack the scale/ and innovation of global vendors, which is why integrating them into structured frameworks, phased contracts and performance benchmarks helps them to mature and succeed.

EIS Technologies is a leading system integrator in the UAE, supporting enterprise organisations with secure, high-performance networking solutions.

Through our partnership with HPE, we design and implement resilient, AI-driven enterprise networks that span campus, branch, and edgeto-cloud environments.

Discover how EIS Technologies can support your enterprise network.

Events are often unpredictable.What procurement & contract clauses or practices do you insist on to ensure reliability, safety, contingency planning, and quality in large-scale events and construction/ venue buildouts?

Events do carry inherent unpredictability, to manage these, we embed robust contractual safeguards that include contingency planning, penalty-linked SLAs, safety compliance mandates and mandatory insurance. We insist on supplier readiness through redundancy plans, emergency logistics and multivendor sourcing where critical.

Contracts now extend beyond cost and delivery timelines to include resilience metrics such as crisis response, health & safety protocols and ESG compliance. At DWTC, procurement’s role in resilience is clear: anticipate disruptions, build flexibility into agreements and ensure suppliers are not just delivering a service but are also taking co-ownership for safety, quality and continuity at scale ).

The most satisfying aspect of the above is that no two days are the same in our industry. The procurement domain keeps challenging you and monotony doesn’t creep in.

Can you share examples of how DWTC has innovated in its contract terms (e.g. sustainability KPIs, value-based criteria, ethical clauses, local content, green supply chain requirements) to align with UAE government policy and DWTC’s strategic goals?

Contracts at DWTC have evolved into tools for transformation and execution and not just compliance. We embed performance and sustainability KPIs covering waste reduction, carbon footprint and local sourcing targets (indirect inclusion of SME’s) into agreements ensuring accountability and a visible metric to persist with a culture of continuous improvement. Ethical clauses/Vendor Code of Conduct/ Grievance Committee mandate anti-bribery, staff welfare standards and transparency aligned with the UAE’s broader guidelines and policy mandates. Value-based evaluation criteria reward innovation not just against the lowest cost but with long-term benefit (clean/green future) over short-term savings.

We also integrate local content requirements to stimulate the UAE economy, while clauses on green supply chain practices accelerate alignment with global ESG trends. Governance frameworks ensure these terms are monitored, enforced and responsibly reported by making contracts strategic levers for resilience, sustainability and competitive differentiation.

We will vet contracts further with the introduction of independent supply chain rating agencies (from due diligence/surveys to findings for client). This will create visibility and access to reporting elements that are instrumental for stakeholders to identify areas of focus/enforced measures and remain aligned towards the relevant frameworks.

During high-velocity periods (e.g. ahead of major events like GITEX), how does your team forecast demand, manage inventory of services/materials, and ensure cost discipline without compromising speed or quality?

In high-velocity cycles such as the one in the lead up to GITEX, procurement must balance agility with commercial discipline which is why the SRM element is so crucial in events industry.

DWTC’s history of delivering events and exhibitions has a great track record of holding events and completing build-up as per calendar timelines. We are expected to achieve this through predictive forecasting using historical event data, supplier insights and digital demand planning tools but these have all been greatly complemented by the category teams and their strategic partnerships with key vendors.

This combination allows us to scale at speed while protecting budgets and maintaining quality with a transparent framework of order/deliveries/ratification and post-event reconciliation to address any significant spikes.

Procurement becomes a conductor orchestrating multiple moving parts into a seamless yet costeffective delivery medium, which as a core competence is the most valued element in the events industry and amongst wider stakeholders. Even if we “fail to prepare” at times due to last-minute urgencies, the team is always ahead of the curve to manage and mitigate associated risks and are able to execute plans without compromising standards and timelines.

For those looking to lead procurement in large-scale event / venue operations, what skills, mindset, and exposure do you believe are essential, especially in areas like sustainability, ethics, digital capabilities, and supplier development?

Leading procurement in the events sector demands a unique blend of skills which are not very difficult to adopt. Agility is key as events operate on compressed timelines where adaptability outweighs rigid processes. Building trusted supplier relationships and mentoring teams for resilience is equally critical.

Exposure to a diverse supply base helps broaden perspective as procurement in events touches every domain from temporary build to catering and tech activations. My own personal growth has had a lot to do with the fact that I have never said no or been too busy to meet or network with any supplier .

It’s also important to focus on purpose, not just process or knowledge. View procurement as a value creator, and not as a cost centre, as we have demonstrated cross-selling revenues (adverts/ sponsorships/visibility-based airtime/barters, etc) in the past which has transformed our identity as a strategic powerhouse.

The leaders who thrive will be those who combine strategic foresight with empathy, collaboration and the courage to innovate under pressure. Commitment to excellence and knowing there is indefinite value on offer (not just a transaction to close) is something to be mindful of everyday to keep abreast of the momentum and the unique learnings at the end of every event cycle.

Dubai World Trade Centre is a premier global venue and events hub, hosting major trade shows, exhibitions, conferences, and business events across diverse industries. Known for world-class facilities, strategic location in Dubai, and a commitment to supporting business growth and international trade, DWTC enables organisations to connect, showcase innovation, and expand their global reach. The centre plays a vital role in facilitating commerce, commerce-driven networking and knowledge-exchange on a regional and global scale.