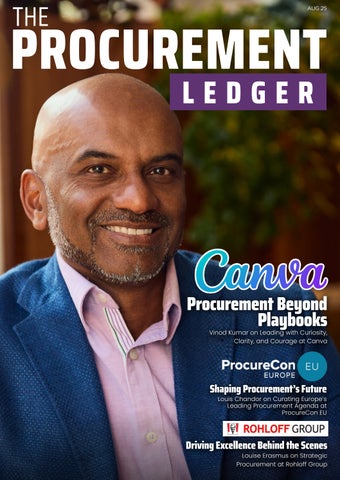

Vinod Kumar on Leading with Curiosity, Clarity, and Courage at Canva

Shaping Procurement’s

Louis Chandor on Curating Europe’s Leading Procurement Agenda at ProcureCon EU

Driving Excellence Behind the Scenes

Louise Erasmus on Strategic Procurement at Rohloff Group

Dear Readers,

Welcome to the latest edition of The Procurement Ledger, where we continue to spotlight the leaders redefining procurement as a driver of strategic value, innovation, and resilience.

Our front cover feature takes us inside Canva, where Technology Sourcing Lead Vinod Kumar shares how curiosity, clarity, and courage are powering procurement in one of the world’s most creative and fast-paced companies. His insights reveal how authentic relationships, smart vendor partnerships, and a future-focused approach are enabling scale and impact.

Iwan Kwak of Calix offers a masterclass in building a resilient, tech-enabled sourcing function, leveraging AI, risk intelligence, and collaboration to stay ahead in a rapidly changing broadband market. Philip Douglas of Compleat Software explores how intelligent automation and AI are transforming the procure-to-pay landscape, delivering efficiency and empowering finance teams.

Louis Chandor of ProcureCon EU takes us behind the scenes of one of Europe’s leading procurement events, while Welthungerhilfe Malawi’s Head of Procurement and Logistics, Evance Ziwa Kalepa shows how ethical, localised sourcing is driving impact in humanitarian operations. In hospitality, Sageer Patel shares how he delivered procurement excellence across the simultaneous openings of the Marriott Marquis Dubai Creek and Hilton Dubai Creek Residences.

This edition also features powerful industry perspectives. Sam Achampong of CIPS sets out a practical blueprint for embedding ESG and ethics into procurement. Angelos Gregoriades demonstrates how structured data, fit-for-purpose tools, and a commercially minded approach elevate procurement performance through transparency, supplier evaluation, risk mitigation, sustainability insights, and predictive analytics. Mohamed Berrechid of TAQA Morocco outlines how strategic procurement supports energy transition and operational resilience.

From Javad Mohamaddi at Mammut Group on cross-industry procurement leadership, to Louise Erasmus at Rohloff Group on enabling growth across one of Africa’s largest KFC franchise networks, and Mario Khalil at Anghami OSN+ on strategic procurement in the streaming sector, each story reflects the diverse challenges and opportunities shaping our profession today.

We also speak with Dirk Guinan of AVM Green Tape on empowering SMEs through inclusive digital procurement, Karthik Rama “The Procurement Doctor” on diagnosing and solving complex procurement challenges, and Erik Drown of Select Technology on building resilient supply chains through strategic sourcing and partnership.

As always, this edition is packed with actionable insights, bold ideas, and the voices of leaders who are shaping the future of procurement. Enjoy the read!

EDITOR

Christopher O’Connor

CREATIVE DIRECTOR

Martyn Oakley

DESIGN SUPPORT

James Pate

SOCIAL MEDIA MANAGER

Summer Buisson

PROJECT DIRECTORS

Phillip Forde

Denitra Price

Cisco Loevendie

PRODUCTION MANAGER

Ewa Piwoni

No.159, Field Maple Barns, Weston Green Road, Weston Longville, Norwich, Norfolk, NR9 5LA

ACCOUNTS

Emilio Vences

Joseph Heaton

MANAGING DIRECTOR

Stuart Irving

CHIEF OPERATING OFFICER

Fabian Stasiak

CHIEF EXECUTIVE OFFICER

Alex Barron

If you would like more information about ways in which The Procurement Ledger can promote your business please email | info@theprocurementledger.com

The Procurement does not accept responsibility for omissions or errors. The points of view expressed in articles by attributing writers and/or in advertisements included in this magazine do not necessarily represent those of the publisher. Any resemblance to real persons, living or dead is purely coincidental. Whilst every effort is made to ensure the accuracy of the information contained within this magazine, no legal responsibility will be accepted by the publishers for loss arising from use of information published. All rights reserved. No part of this publication may be reproduced or stored in a retrievable system or transmitted in any form or by any means without the prior written consent of the publisher.

Vinod Kumar on Leading with Curiosity, Clarity, and Courage at Canva

Iwan Kwak on Building a Resilient, Tech-Enabled Procurement Future at Calix

EXECUTIVE INSIGHT: ANGELOS GREGORIADES

From Insight to Impact: Angelos Gregoriades on Elevating Procurement Through Data and Analytics

Driving Financial Efficiency Through Innovation: A Conversation with Philip Douglas, CEO of Compleat

Shaping Procurement’s Future: Louis Chandor on Curating Europe’s Leading Procurement Agenda at ProcureCon EU

WELTHUNGERHILFE

Procurement for Impact: Building Ethical, Localised Supply Chains at Welthungerhilfe Malawi

JEWEL OF THE CREEK

Hospitality by Design: Sageer Patel on Delivering Procurement Excellence Across Dual Brand Openings

EXECUTIVE INSIGHT: SAM ACHAMPONG

Embedding Purpose into Procurement: Sam Achampong on ESG, Ethics, and Sustainable Leadership

ROHLOFF

(KFC)

Driving Excellence Behind the Scenes: Louise Erasmus on

Procurement at Rohloff Group

Driving Strategic Procurement Across Industries: Javad Mohammadi on Leading Transformation at Mammut Group

AFFNO VIRTUAL MARKETS (GREENTAPE)

Scaling Smart: Dirk Guinan on Leading Green Tape’s SME-Focused Procurement Transformation

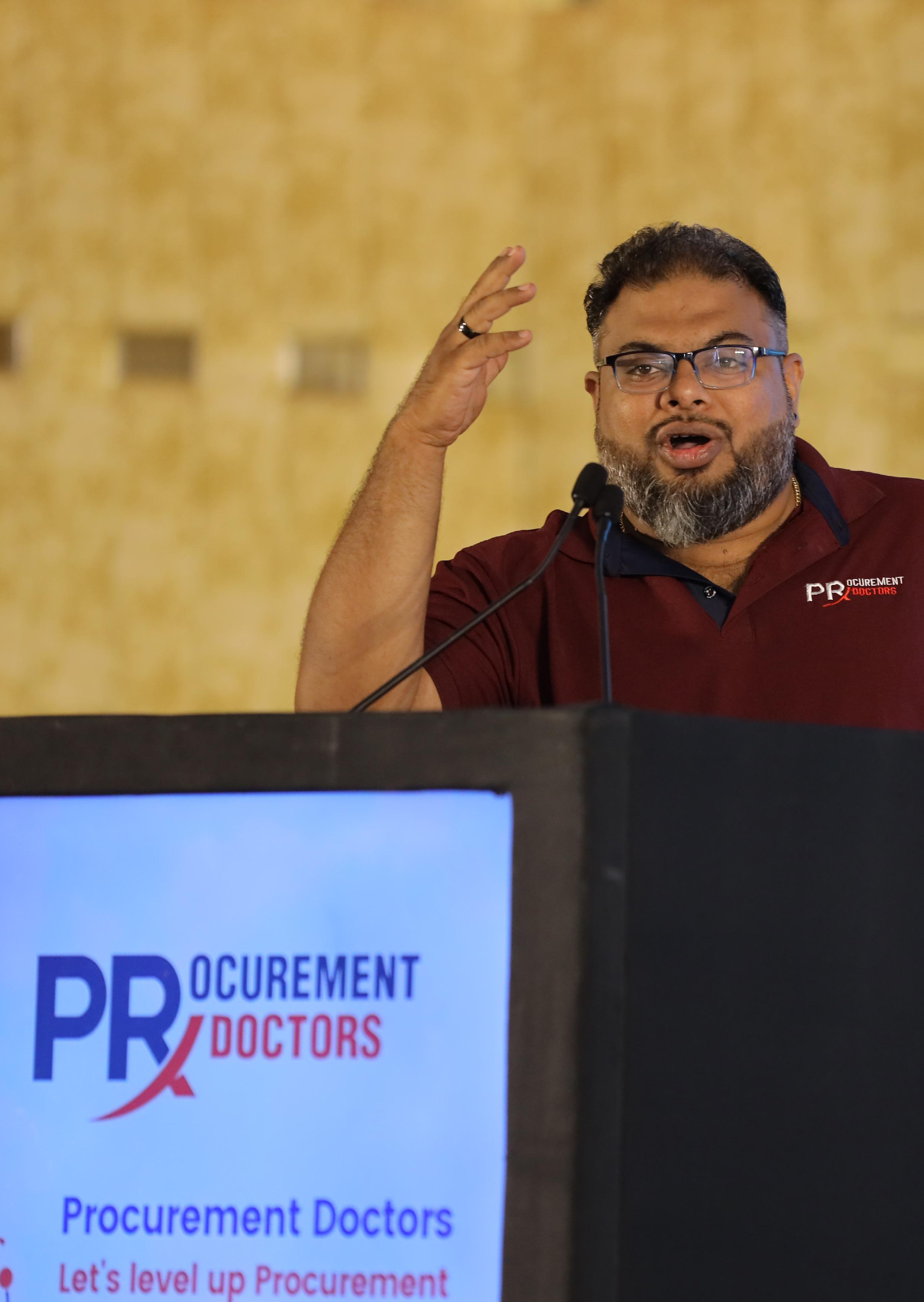

Diagnosing Procurement with Precision: Karthik Rama on Transformation, Technology, and Trust

ANGHAMI OSN+

Procurement with Purpose: Mario Khalil on Driving Strategic Value at Anghami OSN+

From the Field to the Frontline: Erik Drown on Strategic Sourcing, Resilience, and the Future of Supply Chains

Powering Procurement Excellence: Mohamed Berrechid on Strategic Sourcing Leadership at TAQA Morocco

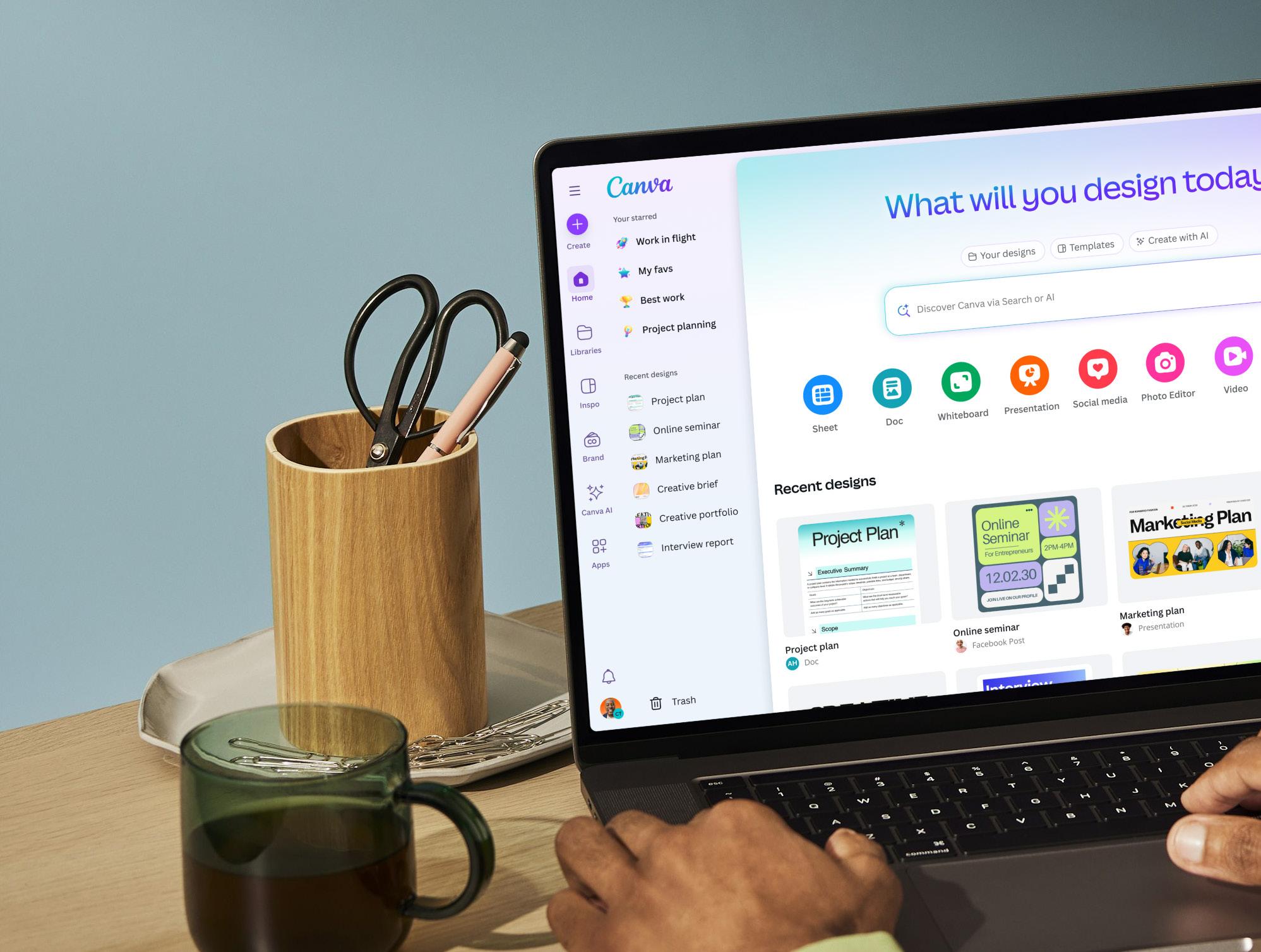

In a company where creativity and speed drive everything, from design to deployment, procurement must do more than keep up; it has to lead. As Technology Sourcing Lead at Canva, Vinod Kumar has embraced this challenge head on. With a background that spans luxury hospitality, banking, and tech, Vinod brings a rare mix of customer centricity, commercial insight, and operational sharpness to the world of technology procurement.

In this interview, he shares how Canva’s fast paced, collaborative culture shapes his sourcing strategy, how AI is already transforming the way procurement adds value, and why building authentic relationships across the business matters more than ever. From navigating SaaS complexities to enabling scale through smart vendor partnerships, Vinod offers a grounded yet future focused perspective on what it really takes to lead procurement in one of the world’s most dynamic tech companies.

Can you share your career path and what led you to your current role as Technology Sourcing Lead at Canva? What experiences have most influenced your approach to technology procurement?

I started my career in luxury hospitality, working across India, the Middle East, and on cruise lines, an experience that instilled in me a deep focus on customer centricity, cost consciousness, and operational excellence. After a decade, I moved to Australia with the goal of transitioning into the corporate world. I joined one of the country’s largest banks to help transform its Corporate Services team.

That role led me to manage an accelerated supplier consolidation program following a major M&A, and eventually into technology procurement after navigating a particularly challenging software audit. Since then, I’ve led complex negotiations with major software vendors, service integrators, and cloud providers, always with a focus on creating long term value.

Looking back, three key experiences have shaped my procurement approach. Hospitality taught me to always put the customer first. That principle now guides how I design procurement processes— building everything around what internal users truly need, while aligning with the company’s broader strategy. I’ve also learned that success in procurement isn’t about squeezing vendors; it’s about understanding usage patterns and unlocking real ROI. And finally, working at Canva has shown me how essential it is to stay tech savvy and market aware. In a fast growing tech company, procurement must enable innovation, not slow it down.

I wanted to join a company that moves fast, solves meaningful problems, and gives me the freedom to truly own my work. Canva delivered on all of that—and more.

The first thing that drew me in was the culture. It’s young, dynamic, and deeply collaborative. Everyone thinks like a founder—bold, curious, and unafraid to challenge the status quo. There’s no red tape and no sacred cows. We set a high bar, celebrate wins loudly, and always push for progress over perfection.

That mindset is matched by the scale of what we’re building. Over 2430 million people use Canva each month, with more than 35 billion designs created to date. We’re also one of the top AI design platforms globally—our AI tools have already been used over 18 billion times. As Canva expands into the Enterprise space—with customers like Salesforce, DocuSign, and eXp Realty embracing Canva Enterprise —we’re tackling even more complex and impactful challenges.

From a procurement perspective, that means operating at the intersection of velocity, innovation, and real impact. We’re not just ticking boxes—we’re helping shape the future of how people design, collaborate, and create. That’s what makes coming to work every day genuinely exciting.

With the Snowflake Platform and AI Data Cloud

Canva has come a long way from its humble beginnings in Perth, Western Australia. Since its launch in 2013, Canva has established itself as the leading visual communication platform now serving more than 240 million monthly active users and generating more than USD$3 billion in annualised revenue.

Central to this success is a strong culture of data-informed decision-making.

Data is integral to smart decision-making across the organisation, from individual feature launches to executive strategy and development.

However, Canva’s data architecture wasn’t always optimised to support rapid growth. In its early stages, analytics and AI/ML workloads often required switching between multiple platforms to complete tasks, making the process complex and time-consuming. By leveraging Snowflake’s ML capabilities, it has been able to reduce this complexity and streamline certain workflows.

To achieve its mission of empowering the world to design, Canva needed to consolidate data management and utilisation into a single, highly scalable solution.

Through an evaluation, Canva determined the Snowflake platform and AI Data Cloud delivered reliability, flexibility and functionality. It was also easy to use and could grow to support Canva’s flourishing business.

The Snowflake product roadmap also incorporated a range of AI-powered features that could help Canva maximise the value of data to marketing and other functions across the business.

Having quickly built trust internally in the Snowflake platform and AI Data Cloud, Canva now uses a range of Snowflake features to accelerate global growth and product velocity. These include Snowpipe for real-time data ingestion and Cortex AI for business-to-business lead routing.

With Snowflake, Canva established a scalable data architecture that supported the business’s appetite for innovation. The platform and AI Data Cloud enabled Canva to continue making sense of data as it increased in volume and complexity. At the same time, the business was able to maintain the efficiency and performance of its systems.

Canva is now poised to push the boundaries of AI and analytics with the Snowflake platform and AI Data Cloud. This means using Snowflake to tackle bigger questions at a lower cost, address more complex problems faster, and answer questions with greater certainty.

To meet these challenges, Canva is testing a range of Snowflake AI capabilities, including Cortex Analyst, a managed, LLM-powered Snowflake Cortex feature that enables organisations to create applications that answer questions based on structured data in the Snowflake platform.

Canva is particularly excited about the opportunities presented by Cortex AISQL to use natural language in SQL queries. With the AI_CLASSIFY function, the business can understand core messages, classify calls to action and identify how visually engaging an ad is, all in a few lines of SQL. According to Canva team members, early signs are that the business can understand and scale thousands of ads faster.

These innovations build on a range of rich use cases enabled by the Snowflake platform and AI Data Cloud at Canva. For example, the business is using Snowflake to optimise B2B sales and marketing activities, including lead routing, scoring and attribution. With this robust data foundation, the business has expanded from serving primarily individual creators to delivering an enterprise-grade solution, Canva Enterprise, that services companies such as Salesforce, HP Inc. and Expedia.

The Snowflake platform and AI Data Cloud also enable Canva to validate development at scale, accelerating the delivery of features and enhancements to its hundreds of millions of users. This data-driven approach powers an extensive roadmap for the development of products such as the recently launched Canva Sheets, a visual-first spreadsheet.

Data flowing through Snowflake from Google Analytics and other sources provides rich insights into user behaviour and preferences that inform Canva’s product development process.

Meanwhile, the unified view of user data provided by Snowflake provides Canva with a better understanding of individual preferences, enabling the development of powerful personalisation features. These include AI-powered design style recommendations that suggest colours, fonts and layouts based on users’ previous behaviours and design preferences.

In addition, the Snowflake platform and AI Data Cloud empower Canva to maximise marketing return on investment by optimising marketing spend across a range of channels. With these analytics capabilities, Canva can access the insights to reach, engage and adapt campaigns and assets for local markets.

Further, analysing user data with Snowflake through AI and integrations with Claude, Llama and OpenAI enable more granular customer segmentation. With this enhanced understanding, Canva can deliver more relevant and personalised experiences to business customers.

A reliable, AI-powered data foundation is crucial for Canva to understand its users and make informed decisions about adding new capabilities to its visual communication platform.

As the Technology Sourcing Lead, how do you align Canva’s technology procurement strategies with the company’s mission to empower everyone to design?

Canva’s mission is to empower everyone to design and that means technology procurement can’t become a roadblock to innovation.

Our strategy is straightforward: be a trusted partner, understand what teams actually need, and then step back, while keeping the right guardrails in place.

We take a growth-first approach. We’re not just negotiating for today; we’re planning for the millions more people who will use Canva tomorrow. That means building flexible, scalable agreements that won’t hold us back as we grow.

Second, we aim to make procurement as seamless as possible. While some friction is inevitable in a fast-moving environment, our goal is to eliminate unnecessary hurdles. We’ve simplified approvals and created frameworks that empower teams to make swift, sound decisions.

Finally, we prioritise real partnerships not just vendor relationships. We look for partners who share our values and vision. In some cases, we’ve even invested in these partnerships because we believe in their long-term potential.

At Canva, procurement is a catalyst, not a blocker. My role is to ensure our teams have what they need to keep pushing forward—so anyone, anywhere, can design with ease.

Given Canva’s extensive use of SaaS solutions, what are the primary challenges you face in SaaS procurement, and how do you address them to ensure optimal value and compliance?

As a born-in-the-cloud company, SaaS has always powered the way we work—giving our teams instant scalability and access to world-class tools. But after a decade of rapid growth, we’ve also learned that the convenience of SaaS comes with its own set of challenges, particularly around cost visibility and control.

AI-driven and usage-based pricing models make forecasting difficult. SaaS and cloud costs are becoming increasingly intertwined. And with every team able to spin up their own tools, fragmentation and security risks begin to scale quickly.

We’ve addressed this by focusing on volume right-sizing, buying only what we need, when we need it—and by building a strong Cloud FinOps capability that helps us surface the true cost of our technology decisions.

Our engineering culture is also a major strength. We know what good looks like and use that expertise to negotiate better deals. On the compliance side, we work closely with our Security-Trust and Legal teams, using automation and proactive risk assessments to stay ahead of potential issues. SaaS isn’t going anywhere but getting the most out of it means treating it like a strategic investment, not just a convenience.

Canva has come a long way from its humble beginnings in Perth, Western Australia. Since its launch in 2013, Canva has established itself as the leading visual communication platform now serving more than 240 million monthly active users and generating more than USD$3 billion in annualised revenue.

Central to this success is a strong culture of data-informed decision-making.

Data is integral to smart decision-making across the organisation, from individual feature launches to executive strategy and development.

However, Canva’s data architecture wasn’t always optimised to support rapid growth. In its early stages, analytics and AI/ML workloads often required switching between multiple platforms to complete tasks, making the process complex and time-consuming. By leveraging Snowflake’s ML capabilities, it has been able to reduce this complexity and streamline certain workflows.

To achieve its mission of empowering the world to design, Canva needed to consolidate data management and utilisation into a single, highly scalable solution.

Through an evaluation, Canva determined the Snowflake platform and AI Data Cloud delivered reliability, flexibility and functionality. It was also easy to use and could grow to support Canva’s flourishing business.

The Snowflake product roadmap also incorporated a range of AI-powered features that could help Canva maximise the value of data to marketing and other functions across the business.

Having quickly built trust internally in the Snowflake platform and AI Data Cloud, Canva now uses a range of Snowflake features to accelerate global growth and product velocity. These include Snowpipe for real-time data ingestion and Cortex AI for business-to-business lead routing.

With Snowflake, Canva established a scalable data architecture that supported the business’s appetite for innovation. The platform and AI Data Cloud enabled Canva to continue making sense of data as it increased in volume and complexity. At the same time, the business was able to maintain the efficiency and performance of its systems.

Canva is now poised to push the boundaries of AI and analytics with the Snowflake platform and AI Data Cloud. This means using Snowflake to tackle bigger questions at a lower cost, address more complex problems faster, and answer questions with greater certainty.

To meet these challenges, Canva is testing a range of Snowflake AI capabilities, including Cortex Analyst, a managed, LLM-powered Snowflake Cortex feature that enables organisations to create applications that answer questions based on structured data in the Snowflake platform.

Scale thousands of ads faster with Snowflake

Canva is particularly excited about the opportunities presented by Cortex AISQL to use natural language in SQL queries. With the AI_CLASSIFY function, the business can understand core messages, classify calls to action and identify how visually engaging an ad is, all in a few lines of SQL. According to Canva team members, early signs are that the business can understand and scale thousands of ads faster.

These innovations build on a range of rich use cases enabled by the Snowflake platform and AI Data Cloud at Canva. For example, the business is using Snowflake to optimise B2B sales and marketing activities, including lead routing, scoring and attribution. With this robust data foundation, the business has expanded from serving primarily individual creators to delivering an enterprise-grade solution, Canva Enterprise, that services companies such as Salesforce, HP Inc. and Expedia.

The Snowflake platform and AI Data Cloud also enable Canva to validate development at scale, accelerating the delivery of features and enhancements to its hundreds of millions of users. This data-driven approach powers an extensive roadmap for the development of products such as the recently launched Canva Sheets, a visual-first spreadsheet.

What criteria do you prioritise when selecting technology vendors to partner with Canva, and how do you ensure these partnerships support the company’s growth and innovation goals?

There’s a saying: “Give me six hours to chop down a tree, and I’ll spend the first four sharpening the axe.” That mindset shapes how we approach vendor selection—the upfront work helps avoid downstream surprises.

The cheapest tool rarely delivers the best value, especially at our scale. We prioritise scalability without the drama, no surprise usage caps, rigid licenses, or inflexible terms that can’t adapt as we grow. A solution that works at 500 people needs to perform just as well at 5,000 and beyond.

We also look for a strong technical fit and a genuine partner mindset. Our engineering teams move quickly, so we need vendors who can keep pace and ideally grow with us. That often leads us to emerging tech companies where we’re among the first major customers. The shared ambition usually results in deeper collaboration than we typically see with larger, more rigid providers.

Security and compliance are table stakes, especially as we expand our AI capabilities. We also value cost transparency, seamless integration, and longterm alignment. But above all, we look for partners who make our teams more effective—not just better equipped.

Organizations across industries face growing complexity in procuring and managing software, data, and professional services. A new study from Forrester reveals how organizations achieved significant time and cost savings through AWS Marketplace.

The Forrester Total Economic Impact™ of AWS Marketplace study provides data to show the time and cost savings achieved when organizations use AWS Marketplace to find, try, buy, deploy and manage cloud solutions. From Forrester, “The purpose of this study is to provide readers with a framework to evaluate the potential economic impact of AWS Marketplace on their organizations.”

To develop this framework, Forrester interviewed decision-makers at global enterprises and surveyed small to medium-sized business (SMB) and public sector respondents across global regions and industries who had experience using AWS Marketplace. Forrester aggregated the experiences of the interviewees and combined the results into a single composite organization that is an enterprise organization with 10,000 employees and revenue of multiple billions per year.

Key findings based on the composite organization include:

• 377 percent return on investment (ROI), with payback within 6 months

• 70 percent reduction in solution discovery time

• 60 percent faster procurement processes

• 30 percent acceleration in time-to-market with deployment efficiencies

Beyond process improvements, organizations reported cost savings through spending in AWS Marketplace, which was enabled through promotional offers, free trials, and pay-as-you-go pricing. These benefits might scale based on the number and size of transactions when using AWS Marketplace.

Alongside the benefits highlighted from the composite organization, this study surveyed 419 SMBs and public sector organizations across the globe. The survey found that these organizations also reported shorter pre-purchase time, faster procurement cycles, and cost savings.

Based on interviews with six representatives from six organizations and a survey of 419 decision-makers, Forrester created a composite organization and concluded that AWS Marketplace provides buyers the following financial impact over a three-year period.

“AWS Marketplace improves the productivity of various teams because it provides a single pane of glass view into questions about our current vendors such as our contract terms and conditions and payment schedules. It provides us with financial controls because we know that every purchase has to go through a well-defined process centered around AWS Marketplace.”

“We needed one operational role to ensure we were timely with our renewals, so we saved at least one senior headcount with AWS Marketplace ”

“Because we’re buying development tools through AWS Marketplace, they are already there and installed. Time to market is faster by between 20% and 30%. I would also say we saved internal headcount costs ”

with AWS Marketplace.

Can you share insights into your approach to negotiating technology contracts? What strategies have you found effective in achieving favorable terms for Canva?

Honestly, the best negotiations start long before you’re in the room. It’s less about being tough at the table and more about doing your homework—understanding your goals, the market, and the other side’s levers.

I begin by getting clear on our business priorities, growth plans, and deal-breakers. Then I dive into the market—what’s available, what the tech actually delivers, and what likely drives the vendor’s costs. That context helps me understand where there’s room to move.

Before any meeting, I align internally and get sign-off on what I can and can’t agree to. That allows me to make real-time decisions rather than deferring with a “let me get back to you.”

I’m a firm believer in “don’t ask, don’t get,” but I’m also ready to make smart concessions. The best deals aren’t one-sided. When both sides walk away feeling like they’ve won, that’s when you build real, long-term partnerships.

And ultimately, the strongest leverage comes from being willing to walk away, because you’ve already mapped out your limits.

How do you collaborate with other departments within Canva, such as IT, Legal, and Finance, to ensure a cohesive and efficient technology procurement process?

One of the biggest misconceptions in procurement is thinking we’re the decision-makers. We’re not, we’re facilitators, helping smart people make better decisions together.

At Canva, cross-functional collaboration comes naturally. Our culture is agile, fast-moving, and focused on progress over perfection. We use visual docs (made in Canva, of course) to align on ideas, decisions, and outcomes. Everyone contributes, Legal, IT, Finance, Security & Trust—so we’re drawing on collective wisdom, not just one perspective.

Our purchase workflow functions like a town square. All teams review requests through their expert lens in a transparent flow. If something stalls, it’s never a mystery, anyone can see what’s needed to keep things moving.

For larger purchases, we create dedicated channels with all stakeholders. Everything—questions, decisions, trade-offs—happens in one place. And when the deal’s done, we celebrate. A little recognition goes a long way in keeping people energised for the next big project.

The secret? Respect everyone’s expertise, make collaboration seamless, and always share the wins. That’s what keeps the engine running.

What measures do you implement to manage risks associated with technology sourcing, particularly concerning data security, compliance, and vendor reliability?

Risk management in tech sourcing isn’t about eliminating risk, it’s about understanding it and making smart trade-offs. With millions of users trusting us, we can’t afford to get this wrong. We’ve embedded risk assessment into our procurement workflow—not as a blocker, but as a way to move faster with confidence. Vendors are classified based on the type of data they’ll access. A design tool that interacts with user content is very different from a backend productivity app, and we treat those risks accordingly.

With AI vendors, we pay particular attention to privacy and data ownership. We want to be crystal clear: user content should never end up training someone else’s model. On the security front, we work closely with our Security & Trust team. Instead of overwhelming vendors with endless questionnaires, we focus on what matters most, encryption standards, data residency, incident response protocols. For cloud-native tools, we dig deeper into multi-tenancy models and data isolation.

Vendor reliability is about future-proofing. We evaluate financial stability, operational resilience, and how vendors have handled past outages or service disruptions. We know perfect security doesn’t exist—but transparency builds trust. We’d rather work with vendors who are honest about their limitations than those who overpromise.

Most risks aren’t technical, they’re communication failures in disguise. So we focus on clarity, alignment, and open dialogue from day one.

With the rise of AI and machine learning, how do you see these technologies influencing the future of procurement at Canva? Are there specific AI-driven tools or processes you are considering adopting?

AI is already beginning to reshape how we work in procurement, and at Canva, we’re genuinely excited about the potential it holds. We’re still early in the journey, but adoption has been fast and surprisingly smooth. We’re already using AI to review contracts more efficiently, boost team productivity, and gather sharper market insights. It handles much of the repetitive work, which frees us to focus on strategy, relationships, and better decision-making.

Looking ahead, one area we’re particularly excited about is agentic AI, tools that don’t just assist but act. We’re testing ways it could support smaller tasks, such as triaging purchase requests, comparing vendors, or kicking off low-risk renewals. These processes still involve human oversight, but the goal is to have AI handle more of the heavy lifting. We’re also exploring how AI can help us stay ahead of vendor risk, streamline documentation, and eliminate busywork throughout the sourcing lifecycle.

AI won’t replace the human side of procurement but it’s already making us sharper and more proactive. For us, it’s not about whether we’ll use AI, but how far we can take it responsibly and how quickly we can unlock real value.

What advice would you offer to professionals aspiring to lead technology sourcing in dynamic and fast-growing companies like Canva?

If you want to lead tech sourcing in a fast-growing company, get comfortable being uncomfortable. You’ll face problems with no playbook—and honestly, that’s the fun part. Start by getting curious about technology. You don’t need to know how to code, but you do need to understand how things work and why they matter. Spend time with engineers—they love talking about what they’re building, and those conversations will teach you more than any course ever could.

Build strong relationships across the business. Some of the best insights come from casual conversations. People are usually happy to share what they know if you show genuine interest. Always remember, you’re not just negotiating; you’re solving business problems. Be honest about what you don’t know. I’ve learned the most by asking questions, not by pretending to have all the answers.

And finally, invest in your people skills. Procurement is all about relationships. Great leaders know when to push, when to pause, and when to partner.

If you love variety, solving puzzles, and making a real impact, this is the role for you.

Canva is a trailblasing online design platform (launched 2013) offering intuitive, drag-and-drop tools for creating social media content, presentations, videos, and more. With a global user base surpassing 220 million and support for 100+ languages, Canva powers creativity for individuals, teams, and enterprises with both free and AI-enhanced premium offerings .

In an era where supply chain agility and innovation are more critical than ever, Iwan Kwak is leading the charge at Calix by reimagining what sourcing can and should look like. As AVP of Sourcing, he brings a career shaped by global operational expertise and a passion for continuous improvement. Under his leadership, the sourcing function has become a strategic enabler, supporting Calix’s mission to help broadband service providers simplify, innovate, and grow communities.

In this interview, Iwan shares how his team is leveraging AI, risk intelligence platforms, and cross functional collaboration to drive greater value, compliance, and sustainability. From proactive supplier risk mitigation to long term partner development and future focused investments in generative AI, he offers a clear eyed view of what it takes to stay ahead in a fast moving, highly technical procurement landscape.

Can you share your career path and what led you to your current role as AVP of Sourcing at Calix?

I began my career in Customer Care with Lucent Technologies, followed by operational roles in supply chain, sales operations, material planning, fulfillment, and program management.

While most roles in the supply chain can be very gratifying, I gravitated early on toward Sourcing. It requires a person to gain expertise in multiple business areas and to build strong partnerships both cross functionally and with external third parties. My first sourcing role came in 2004, when Avaya centralised international procurement in the UK. In 2007, I relocated to the US and managed Avaya’s Contract Manufacturing business, followed by roles overseeing OEMs, raw materials, and NPI program management.

In 2016, I joined an embedded computing company in Oregon, leading the supply chain organisation. This was a great opportunity to put into practice everything I had learned throughout my career to date.

Talking to procurement leaders at cross industry events, I’ve come to really appreciate having landed in the technology sector. The constantly changing environment allows for continuous learning. For my next move, I knew I wanted to stay in tech but I was looking for a company with a growth mindset and the right culture. Calix checked all these boxes, and I was fortunate to have the opportunity in 2020 to lead Sourcing and Procurement Operations.

Calix supports a wide range of broadband providers from traditional BSPs like WWZ in Switzerland, to wholesale operators such as CityFibre in the UK, Eurofiber in Germany, to over the top experience providers like LitFibre. We work with municipal networks, tribal operators, and rural cooperatives. That variety means we must be globally scalable, regionally agile, and capable of supporting providers at very different stages of growth and complexity.

How does the Sourcing function at Calix support the company’s mission to help broadband service providers innovate to deliver experiences and grow value for the communities they serve?

The Calix mission is to enable broadband service providers (BSPs) of all sizes to simplify their operations, innovate for their subscribers, and grow value for themselves and their communities. Sourcing plays a pivotal role in aligning our suppliers to that mission. We help foster the right partnerships, ensuring that innovative technologies are delivered in a timely and cost competitive manner, while maintaining a strong focus on sustainability and efficiency across our supply chains.

We ensure access to forward looking solutions that BSPs can leverage to deliver differentiated value. These technologies support experiences across residential, business, and community markets, enabling smaller, rural communities to thrive. Many of our customers began as electric cooperatives. While they’ve evolved to deliver broadband connectivity, their core mission remains the same: to do good for their communities.

Sourcing at Calix identifies, evaluates, and collaborates with Product Line Leadership and Engineering to adopt innovative components and systems. With the right technologies and well developed partner relationships, we deliver impactful solutions that empower our BSP customers to simplify, innovate, and grow.

We also recognise the importance of sustainability for the communities we support. By prioritising environmentally responsible suppliers and materials, the Sourcing function helps our BSPs reduce their carbon footprint and promote green initiatives.

With Calix’s emphasis on empowering smart communities, what sustainable procurement practices have you implemented that align with broader environmental and social goals?

As part of our commitment to society and our people, Calix appointed Martha Galley as our Chief Sustainability Officer. Martha is a pioneer in broadband, known for her expert leadership in driving customer engagement through data driven strategies and a strong focus on the broadband experience. She brings strategic vision to ensure that sustainability is not only part of Procurement but embedded in everything we do at Calix.

Sustainability is a core element of our supplier onboarding process. Most Calix suppliers not only participate in EcoVadis self assessments but also receive recognition for completing training through the EcoVadis Academy. By partnering with EcoVadis, the world’s most trusted provider of sustainability ratings, we create transparency within our supplier network and work toward a more sustainable future for all.

We’ve made clear commitments across three focus areas. First, through leadership and compliance, Calix audits suppliers to ensure alignment with our Code of Conduct. Second, sustainability is embedded into every step of the supply chain, from onboarding to continuous performance reviews, fostering a culture of ongoing improvement. And third, our supply chain and sourcing managers are trained in sustainability and are empowered to innovate and improve products and processes.

We also provide our suppliers with access to the EcoVadis Academy and actively encourage them to use these tools to drive continuous improvement, focusing on areas such as environmental practices, labour and human rights, ethics, and sustainable procurement.

What strategies do you use to build and maintain long-term, value-driven relationships with suppliers in a highly technical and competitive landscape?

Building long term, value driven relationships is critical to maintaining a resilient supply chain. It begins with selecting the right suppliers, a task that is often more complex than it seems.

While the fundamentals like technical capabilities, quality, certifications, footprint, and financial stability are essential, once those appliances are checked, it ultimately comes down to relationship building. And like all meaningful relationships, it takes time, honesty, clear expectations, trust (with some degree of “trust but verify”), and frequent, open feedback.

We focus on maximising the time we spend with our suppliers. We want them to feel like an extension of our team because our success is their success. By sharing more about why we do what we do, we enable suppliers to suggest solutions we may not have otherwise considered, and to reframe discussions around cost reductions. For example, reducing costs enables us to sell more appliances, which ultimately results in more appliances for them to manufacture.

We’ve also designed our business performance scorecard to make it easier for suppliers to understand how they’re being evaluated. It allows them to see exactly where they stand and how they rank against others. This level of transparency has increased competition, boosted performance, and strengthened trust.

In the end, collaboration, clear communication, and mutual investment are key to fostering trust and achieving shared goals. These partnerships must be nurtured because when done right, they become a powerful source of competitive advantage and long term success.

How do you assess and mitigate supply chain risks, especially in the context of geopolitical tensions, component shortages, or regulatory changes?

Supply chain challenges are inevitable in today’s dynamic environment, but we manage them through proactive assessment, strategic mitigation efforts, and strong supplier collaboration. Continuous communication with our suppliers, who are upstream and often closer to potentially impactful events—ensures that we receive timely information to inform our Supplier Risk Management (SRM) strategies and address material shortages effectively.

Proactive risk management is part of our DNA. We’ve developed a dashboard that provides visibility into all risk areas critical to our operations. We also leverage tools from industry leading partners for business continuity planning, cybersecurity, ESG monitoring, and financial health, such as Rapid Ratings for financial analysis and Resilinc’s Resiliency Risk Score for operational insights. These tools proactively push risk data to our supplier managers so they can act quickly and with precision.

In 2021, we implemented Resilinc, a global leader in supply chain risk intelligence. Their autonomous AI driven solution helps predict disruptions, evaluate their impact, suggest response strategies, and support execution. With this platform, we often notify our manufacturers of potential risks to their operations before they’re even aware of them.

Alongside technology, we use traditional methods like product and raw material buffers, and have started expanding regional manufacturing. For Calix, supply chain risk management is not just an operational necessity, it is a strategic advantage in a volatile world.

How has Calix integrated digital tools or platforms into its sourcing and procurement processes to improve efficiency, visibility, and compliance?

Process compliance is a critical component of procurement at Calix, and we’ve implemented a range of digital tools and third party services to automate compliance checks, ensuring that all sourcing and procurement activities meet our internal standards and ethical guidelines.

We leverage the Supply Chain Management module within our ERP software suite to simplify and accelerate supplier onboarding and procurement compliance. This system works in tandem with our Supplier Risk Management platform, allowing us to evaluate suppliers before they are approved for purchasing. Together, these tools not only ensure process compliance but also provide the visibility needed to identify opportunities for cost savings and process improvements.

Additionally, we use an AI supported contract lifecycle management platform for contract negotiations. This system streamlines document control, e-signatures, and secure digital contracts, while also offering analytics and automated alerts for both Procurement and Legal teams.

Can you discuss how Calix engages with strategic partners and suppliers to co-innovate or drive joint value creation in product development or supply chain initiatives?

Strategic collaborations thrive when built with a long term mindset. This level of commitment fosters deeper integration, greater innovation, and the ability to overcome challenges collaboratively.

By sharing our current product lifecycle, long term roadmap vision, and software ecosystem requirements with our ODM and silicon partners, we enable them to adjust development schedules and prioritise design features that align with our market and customer needs. This collaborative approach drives value in the form of increased customer retention and market competitiveness, while also ensuring meaningful value generation for our partners.

Our investments in risk mitigation tools such as Resilinc’s EventWatch also provide significant advantages to our contract manufacturers by alerting them to potential disruptions within their supply chains. These proactive insights allow all parties to respond quickly and efficiently, strengthening our collective resilience and agility.

How does your sourcing team stay agile and resilient in response to rapid market shifts, such as changes in telecom infrastructure needs or global logistics disruptions?

We continuously monitor changes in market dynamics to anticipate and respond effectively to new challenges. With limited resources, we rely on multiple digital platforms to push critical information to the right stakeholders, enabling faster reaction times to supply chain disruptions, geopolitical risks, and environmental impacts.

Business continuity planning is part of our annual planning cycle not just a check the box exercise. We conduct simulations to test our preparedness, and we expect the same from our suppliers. We don’t just ask for documented processes, we verify and test them to ensure real world effectiveness.

In today’s volatile global environment, scenario planning is a top priority. We proactively explore potential disruptions and build contingency plans in advance. Our digital platforms provide rapid alerts, so we make sure mitigation strategies are ready to activate as needed.

A well trained team is key to our resilience. Calix provides ongoing training in areas such as emerging technologies, negotiation techniques, and risk management, ensuring our sourcing professionals are equipped to handle complex challenges with confidence.

In 2024, Calix was ranked 16th out of 140,000 companies in the electronics, telecom, and semiconductor industries for supply chain excellence by Resilinc, a global leader in supply chain risk intelligence. This recognition reflects our proactive and holistic approach to building a resilient and agile supply chain.

We continuously monitor changes in market dynamics to anticipate and respond effectively to new challenges.

What initiatives do you have in place to ensure continuous learning, upskilling, and collaboration within your sourcing and procurement teams?

At Calix, we are committed to ensuring that employees continuously learn and grow throughout their careers. We recognise that skill development can take many forms, including formal education, hands on experience, feedback, and coaching.

We provide team members with a wide range of learning resources and subscriptions to help deepen their knowledge whether it relates to their current scope of responsibility or supports a desire to grow into new areas of the business.

Within the Sourcing and Procurement function, our entire Supply Chain organisation is provided with membership to the Association for Supply Chain Management (ASCM). This membership offers access to certifications and credentials that can be achieved through online courses and certificate programmes, supporting both professional development and industry best practice.

Looking ahead, what are your key priorities for evolving the sourcing function at Calix, particularly in areas like sustainability, digital transformation, or supplier collaboration?

I’m particularly interested in solutions that make greater use of artificial intelligence to process data and deliver insights, or even actions, in real time or near real time.

Accelerating supplier onboarding and controlling off contract spend are important goals. An AI driven solution that can integrate data sources and establish relationships across databases would provide much deeper insight into supplier disruptions, geopolitical risks, supply constraints, cost reduction opportunities, value engineering initiatives, and design input to support greater manufacturing automation and potential nearshoring strategies.

Generative AI has the potential to transform how we work. It can help automate tasks, analyse vast datasets, and support better decision making ultimately driving efficiency, cost savings, and risk reduction. I envision this capability enabling sourcing teams to conduct rapid should-cost analysis, perform early design iterations based on high level requirements, improve BOM grading for lifecycle and multi source resilience, and evaluate regulatory risks more effectively.

These are exciting times for sourcing, and with the increased flow of data and intelligence comes a new challenge: deciding how to harness that information and turn it into value generating actions for the business.

Calix is a cloud, platform, and managed services company helping broadband providers simplify operations, engage subscribers, and drive growth. Its end-to-end solutions empower providers of all sizes to leverage data, deliver exceptional experiences, and transform communities, supporting continuous innovation through a collaborative ecosystem focused on long-term success and value.

In today’s increasingly complex procurement landscape, data has evolved from a support function into a true strategic enabler. Drawing on his experience leading procurement analytics and operational excellence across multiple markets, Angelos Gregoriades, former Head of Procurement Excellence & Compliance at Coca-Cola Hellenic Bottling Company, shares how structured data, fit for purpose tools, and a commercially minded approach can drive meaningful value. From spend transparency and supplier evaluation to risk mitigation, sustainability insights, and early stage predictive analytics, Angelos reflects on how embedding analytics into core procurement activities enhances decision making, strengthens operational performance, and supports long term strategic alignment.

Advanced analytics played a critical role in optimising procurement decisions by enhancing spend visibility, monitoring supplier performance, and identifying cost saving opportunities.

With the implementation of SAP Ariba, we leveraged its capabilities to structure and enrich procurement spend data, making it more actionable. By applying predefined rules for data cleansing and consolidation, we extracted key insights that improved visibility and revealed opportunities for cost optimisation and supply base consolidation. Additionally, we developed Power BI solutions to visualise spending and procurement KPIs, enabling senior management to better understand trends, monitor progress, and take informed action.

Beyond Ariba, custom built analytics tools supported a wide range of strategic procurement decisions. Excel based solutions provided flexible and user-friendly insights for managers handling complex tenders, while additional dashboards supported areas such as savings tracking, RM&P cost planning, sustainability analytics, and performance monitoring.

During the COVID period, procurement teams were tasked with renegotiating high value contracts. My team developed tools to analyse, track, and report the resulting savings, delivering tangible value and contributing to company profitability.

By integrating multiple data sources and maintaining a strong focus on data accuracy, we elevated procurement’s role in decision making, cost efficiency, and overall business effectiveness.

Supplier performance evaluation was a structured, data driven process focused on strategic and critical suppliers. Key performance areas included sustainability, quality of service and products, supplier agility, joint business planning, delivery performance, price competitiveness, reliability, and technical capabilities. Each area was weighted based on category specific priorities and procurement’s strategic goals.

We conducted annual internal evaluations involving both procurement and key business stakeholders, complemented by external sources such as sustainability assessments, financial risk data, and third party evaluations. A dedicated evaluation platform enabled structured assessments through digital questionnaires, automated scoring, and progress tracking dashboards.

This process helped identify underperforming suppliers and trigger corrective actions, such as renegotiations, supplier capability building, or transitioning to alternative suppliers. Evaluation results also informed future sourcing strategies, reinforcing continuous improvement.

Beyond the annual exercise, insights from supplier performance evaluation supported broader procurement initiatives such as supplier segmentation, compliance monitoring, contingency planning, and supply risk mitigation. By combining internal and external data, we ensured that supplier partnerships aligned with business needs, ESG priorities, and long term performance expectations.

How has data analytics helped you mitigate risks in your supply chain?

Data analytics played a vital role in identifying and mitigating supply chain risks by providing transparency across supplier performance, financial stability, and operational reliability. Although we did not have a dedicated risk management system in place, my team developed custom built tools to support risk identification and monitoring, while collaborating with IT to explore longer term digital solutions.

We relied on a combination of internal risk assessments and external intelligence, such as financial ratings and sustainability data, to flag suppliers with potential vulnerabilities. These efforts were supplemented by periodic reviews, including category level risk mapping conducted by strategic procurement managers.

A critical focus area was ensuring supply continuity and preventing disruptions. Procurement maintained clear KPIs related to business continuity, and we implemented contingency plans for high risk categories. This included identifying secondary suppliers, developing backup sourcing options, and collaborating with stakeholders to assess feasibility and potential exposure.

By combining structured risk monitoring with practical mitigation planning, we strengthened our ability to anticipate and manage disruptions, enhancing procurement’s contribution to business resilience and agility.

Ensuring data accuracy and reliability in procurement was a top priority, given its direct impact on reporting quality, spend visibility, and strategic decision making. Our core data sources were SAP (ERP) and SAP Ariba, from which we retrieved and validated procurement data, including spend details, purchase orders, payment terms, contract status, and supplier hierarchies.

To enhance consistency, my team developed internal validation processes and leveraged external databases to structure supplier groupings, ensuring accurate classification. Month end data controls refined the information before it was published in dashboards and reports. We also implemented automated enrichment rules for spend categorisation, reducing manual corrections and improving reporting quality.

Aligned with internal control protocols, we used SAP BW reports to validate procurement data shared in external communications and corporate disclosures, maintaining complete audit records to support compliance. My team played a key role in ensuring this data was accurate and aligned with governance standards.

Beyond validation, my focus was on transforming data into insight. I encouraged my team not only to deliver reliable reports but to highlight key messages, prepare executive summaries, and consistently challenge the data to ensure it drives action. This approach positioned procurement analytics as a strategic enabler of business impact.

Can you share examples of how predictive analytics has improved procurement outcomes?

While predictive analytics was not yet fully implemented, we actively explored its potential to enhance procurement decision making. One promising area was the use of AI and RPA to automate PO classification, improving the accuracy of spend categorisation and reducing manual effort. Although full scale deployment was still in progress, the business case for such tools was clear.

In the meantime, we relied on historical spend patterns, supplier performance trends, and forward looking scenarios to anticipate risks and guide sourcing decisions. These insights supported more effective supplier negotiations, savings planning, and proactive alignment with business needs.

Looking ahead, predictive analytics holds significant promise. By combining machine learning with real time data, procurement functions can shift from reactive problem solving to proactive opportunity creation. My vision was to embed these capabilities into procurement strategy, enabling a more agile, resilient, and insight driven approach to supplier management, risk mitigation, and cost optimisation.

Our early efforts in this space, paired with strong analytics foundations, ensured that procurement was well positioned to embrace future digital transformation and continue delivering value to the business.

With over two decades of leadership across the technology and SaaS sectors, Philip Douglas brings a unique blend of financial expertise and tech driven vision to the forefront of digital transformation. As CEO of Compleat Software, he has built a platform that empowers businesses to streamline procurement and finance operations through intelligent automation, seamless integration, and user friendly design. In this interview, Philip shares the inspiration behind Compleat’s founding, explores the impact of AI on the procure to pay (P2P) landscape, and offers valuable insights on future trends, client success, and advice for the next generation of fintech innovators.

What inspired you to establish Compleat Software, and what key challenges in the financial and procurement sectors were you aiming to address?

I have been a small to mid market software senior executive for over 20 years, working in technology and SaaS across the UK, Europe, and North America.

As a qualified accountant, software engineer, and overall tech enthusiast, I have an eye for market needs, as well as the proven experience to grow revenue, develop new products, create new lines of business, and build the marketing strategies needed to take these to market.

During my many previous senior finance roles, I witnessed firsthand the inefficiencies within buying and finance functions and the lack of tools provided by most accounting software solutions. As a former FD, owner of a small ERP consulting practice, and technology founder with a previous exit, I gained a deep understanding of overall business processes, ranging from sales strategies and development cycles to implementation, service and support. I’ve also focused on building engaged and enthusiastic teams while implementing processes and solutions to ensure optimum departmental performance.

Throughout this journey, I’ve continued to champion a learning culture through strong facilitation, communication, and coaching skills. As a leader, there is no greater satisfaction than helping people grow, flourish, and succeed.

Compleat Software provides solutions like Invoice Capture, AP Automation, Purchase Order Automation, and Purchase-to-Pay (P2P). Could you elaborate on how these products integrate to streamline financial processes for businesses?

Absolutely. At Compleat, our solutions are designed to work seamlessly together. Invoice Capture uses AI to automatically extract and process invoice data, which then feeds directly into AP Automation for smooth approvals and accurate matching. Our Purchase Order Automation ensures that spending is controlled and monitored right from the start, while Purchase to Pay (P2P) ties everything together, giving businesses complete visibility and control.

It’s all about eliminating manual intervention, improving accuracy, and delivering meaningful insights into financial operations.

How does Compleat ensure that its automated solutions remain user-friendly, especially for employees who may not be tech-savvy?

Ease of use is one of our top priorities. We recognise that technology must serve the user—not the other way around. Our platform features intuitive dashboards, a simple workflow editor, and a clean, minimal design to ensure navigation is straightforward. Even employees with limited tech experience can quickly adopt the system, which ultimately increases engagement and accelerates implementation.

Your platform integrates with various accounting solutions like Xero, QuickBooks, Sage 50, Sage 200, and Sage Intacct. How does this flexibility benefit your clients?

Flexibility is critical. Businesses invest heavily in their financial systems, and they need solutions that complement—not replace—them. Our integrations allow customers to extend the capabilities of their existing accounting platforms without the need for disruptive migrations. This seamless synchronisation reduces errors, minimises manual work, and provides a unified view of financial health across both procurement and finance teams.

AI is everywhere—how has this impacted the P2P process?

AI allows us to automate data capture, flag anomalies, detect fraud patterns, and predict spending trends. We embed AI at the core of our offerings, not as a gimmick, but as a genuine driver of efficiency, accuracy, and insight. It’s about giving finance and procurement teams the tools to be proactive, not just reactive.

With operations in the UK and US, how does Compleat Software tailor its solutions to meet the diverse needs of businesses across these regions?

Our global footprint gives us a rich perspective on regional differences. We design our solutions with localisation in mind, supporting multiple currencies, tax codes, and compliance regulations. Beyond technical requirements, we adapt workflows and configurations to reflect how businesses operate in different regions. It’s about striking a balance between maintaining a global standard and offering the flexibility for local customisation.

What industry trends are you seeing around supplier relationship management?

Supplier relationships are more strategic than ever. We’re seeing a shift toward digital collaboration, enhanced communication, shared data, and mutual visibility into performance. There’s also a growing focus on risk management, not just cost savings. Organisations want to work with suppliers who are reliable, compliant, and aligned with their values, including sustainability. Our Compleat Ecosystem is designed to foster that level of partnership by connecting procurement, finance, and supplier networks into a single, transparent platform.

Can you share any notable examples of how Compleat’s solutions have significantly improved operational efficiency for your clients?

Certainly. Milton Abbey School implemented Compleat Education, gaining visibility on spend before it’s made. This allowed them to automate their purchasing and AP processes, saving time and money while gaining full oversight of all spend within the institution. Their accountant, Terry Harding, noted: “I would happily recommend iCompleat to any finance team in the education sector who is looking to digitise and take charge of their P2P processes.”

Another standout success story is with East Cheshire Hospice, a UK based healthcare provider offering palliative care services. They needed a solution that would improve their finance processes without adding complexity for staff. By implementing Compleat, they were able to automate their purchasing workflows, integrate seamlessly with their existing Sage 50 accounting system, and take advantage of our integration with Amazon Business for efficient online ordering.

Their Head of IT shared that Compleat is “very user friendly and efficient to use,” highlighting the ease of raising orders and the value of the Amazon Business integration.

What do you see as the future of strategic sourcing?

Honestly, strategic sourcing is getting a lot smarter, and a lot faster. It’s becoming increasingly data driven and automated. Businesses will be able to predict what they need, when they need it, and make better buying decisions as a result.

Sustainability is no longer just a “nice to have”, it’s becoming a core part of how companies choose their suppliers, with ESG (Environmental, Social, and Governance) factors playing a significant role.

At Compleat, we see integrated online buying as a major part of that future, giving users instant access to item comparisons from multiple supplier catalogues, with real time pricing and the ability to buy smarter without ever leaving their financial system, all driven by AI. That’s why we built the Compleat Ecosystem—to bring procurement, finance, and suppliers together in one connected, easy to use platform that helps businesses move faster, spend smarter, and stay ahead.

We’re seeing a shift toward digital collaboration, enhanced communication, shared data, and mutual visibility into performance.

What guidance would you offer to individuals looking to innovate in the financial technology sector?

Understand your market, knowing the needs and pain points of your target audience is essential. Embrace agility, as the market moves quickly, and be prepared to adapt your solutions based on feedback and change. Focus on user experience by designing user friendly, accessible platforms. Prioritise compliance and security. And lastly, build strategic partnerships to expand your reach and capabilities.

Compleat Software delivers cloud-based procurement and invoice automation solutions designed to simplify purchasing and payables processes for organisations of all sizes. By streamlining requisitions, approvals, and vendor management, Compleat enables efficient, transparent, and cost-effective financial workflows—boosting compliance, control, and operational efficiency.

As Content Director of ProcureCon EU, Louis Chandor plays a pivotal role in shaping one of Europe’s most influential procurement events. With a background in producing high impact conferences across the UK, Europe and the US, Louis combines analytical insight with a passion for connection to deliver programmes that reflect the evolving needs of procurement leaders. In this Q&A, he shares the strategy behind building an agenda grounded in research, the growing role of AI and IT procurement, and how ProcureCon continues to foster meaningful partnerships, sustainability and resilience across the procurement ecosystem.

Can you walk us through your career journey, what pivotal roles and experiences led you to your current position at ProcureCon EU and WBR?

After graduating with a history degree from the University of Bristol, I transitioned from archives to agendas and dove headfirst into the world of event production! Over the past three years, I’ve produced 54 events across the UK, Europe and the US, ranging from intimate roundtables to multi day conferences buzzing with ideas (and coffee).

Along the way, I’ve had the privilege of working with some remarkable leaders, from Blackstone’s Managing Director, who led a $70 billion data centre investment into Europe, to the Head of European Real Estate at Norges Bank, the world’s largest sovereign wealth fund.

Outside of work, I’ve always valued platforms for exchange, writing for the local newspaper, debating for the Model UN at the UN headquarters, and attending academic conferences. These experiences underpin my passion for building spaces where ideas and people come together.As Content Director for ProcureCon, I get to interview senior executives from companies like Ferrari and Novo Nordisk to uncover their biggest challenges and opportunities. I love turning these insights into impactful agendas that inspire connection, reflection and forward thinking, and at WBR, I’ve been lucky to do just that.

What do you see as the unique value that ProcureCon EU brings to procurement leaders across Europe, especially in comparison to other flagship procurement events?

ProcureCon Europe is the only event that brings together CPOs and their entire senior leadership teams across multiple categories. This means you’ll gain access to the most senior strategic thinkers in procurement, all in one place. ProcureCon Europe attracts key representatives from the largest organisations across Europe. It’s not just a meeting, it’s a gathering of the biggest and most influential players in the procurement industry.

The event’s content is meticulously crafted, drawing on more than 65 in depth interviews with senior procurement professionals across Europe, and over 90 total research calls with procurement leaders. As a result, ProcureCon Europe addresses the real, pressing issues and offers actionable solutions that drive value now.

ProcureCon Europe 2024 emphasised navigating geopolitical pressures, sustainability, automation and analytics. Which of these will carry into 2025, and are there any new priority topics for this year’s event?

The advancement of Artificial Intelligence is unprecedented, moving from theory and buzzword status to real world application in 2025. It’s arguably the greatest invention since the internet, unlocking time savings and driving value across all industries, with trillions of dollars’ worth of investment from both public and private sectors.

Instability, whether inflation, fears of recession, supply chain bottlenecks or tariffs, continues to plague the global economy, with daily price and supply chain shocks. This is causing economies to become increasingly fragmented, putting procurement teams on high alert as they work to mitigate both existing and potential disruptions.

Sustainability has been a top priority for almost all multinational, publicly listed companies over the past decade. However, it’s now being scrutinised through a new lens, considering changing political climates and shifting public perceptions. It’s essential to assess whether the real time benefits of sustainability efforts remain justifiable amid rising costs and continued pressure to drive profitability in today’s macroeconomic environment.

All of the above are mission critical topics, and procurement professionals must ensure they aren’t left behind, implementing the necessary changes to thrive by benchmarking with their peers. As digitisation and software implementation have become essential for all Fortune 500 businesses, ProcureCon is putting a spotlight on technology procurement in 2025 with the launch of our dedicated ProcureCon IT stream. Co located alongside ProcureCon Europe, ProcureCon IT is designed to empower IT procurement professionals to cut costs, manage risk and fuel digital growth.

ProcureCon EU involves numerous sponsors and strategic partners. How do you work with core partners to shape the conference agenda, and what criteria do you use when selecting those collaborators?

Connecting and exchanging ideas with our advisory board is a central part of the agenda development process. After conducting more than 90 interviews, we bring our research to this group to ensure the programme remains relevant, honest and market leading. Working with advisory board members, made up of CPOs and senior procurement professionals from the likes of Asahi, Unilever and CSL Behring, is not only a real pleasure, but truly invaluable in ensuring our agenda retains both relevance and integrity.

We also work closely with partners who genuinely bring value. Whether it’s global players like VISA or GEP, or start ups like Denova and ProcureVue, we prioritise those who have a story to tell, not a sales pitch to deliver. The aim is always the same: thought leadership that informs and engages.

The speaker lineup features CPOs from Unilever, Tata Steel, Keurig Dr Pepper and others. How do you identify and secure these voices, and what impact do their insights have on the event’s outcomes?

I have the honour of working with some of the industry’s heavyweights. Their insights, case studies, mistakes, successes, challenges and learnings are all crucial to delivering meaningful thought leadership to our audience of over 650 procurement professionals.

We give these leaders a platform to share their experiences, and in turn, they help raise the bar for the entire community. The opportunity to benchmark with peers at this level is truly invaluable.

With strong interest in automation and data analytics highlighted previously, how do you ensure ProcureCon showcases the most cutting edge technological solutions for procurement teams?

ProcureCon Europe stays at the forefront of procurement technology and innovation by curating sessions and partnering with tech providers that offer hands on insights.

This year’s event will open with a compelling case study from Unilever’s newly appointed CPO, who will share how they’ve successfully embedded AI into procurement, turning theoretical buzz into practical value.

Over the following three days, numerous procurement professionals will deliver deep dives into how they are integrating new technologies to help resolve some of the key challenges the community is facing.

Sustainable procurement continues to gain traction. How do you build sustainability into the DNA of ProcureCon (e.g., through session selection, speaker criteria, or content collaboration)?

Sustainability is firmly in the spotlight due to shifting political landscapes, evolving public sentiment and new policy developments. Many of our speakers, those responsible for purchasing goods and services, recognise sustainability as a real value add in contracts and negotiations. When weighing the benefits and costs, we prioritise bringing speakers to the stage who have heavily invested in this space, with a story to tell and tangible ROI to share.

ProcureCon EU has also partnered with One Tree Planted to support global reforestation. Each delegate’s registration triggers a £1 donation, contributing to our goal of planting over 9,000 trees. Beyond donations, we embed sustainability into the event experience itself, from choosing eco friendly venues and using paperless apps, to encouraging reusable materials and promoting public transport.

I’d encourage all our attendees to visit our website to find out more: https://procureconeu.wbresearch.com/one-tree-planted

Conferences emphasise networking and fostering supplier partnerships. How does ProcureCon facilitate genuine supplier–buyer engagement or ecosystem building during the event?

Alongside all the thought leadership and opportunities for in depth learning, ProcureCon Europe is also about expanding your network. Facilitating an ecosystem of exchange is a key aim, with over 15 hours of networking built into the agenda across breakfasts, lunches and evening drinks, attendees have ample opportunity to shake hands and share ideas.

The exhibition hall offers a unique chance to discover the “who’s who” in the procurement space. With a number of exciting and interactive stands planned, we’re confident every attendee will leave with a buzz.

Interactive formats such as roundtables, workshops and boardroom sessions create space for more intimate exchanges, allowing attendees to focus on core topics and drive conversations around the key challenges the industry is facing.

Sustainability is firmly in the spotlight due to shifting political landscapes, evolving public sentiment and new policy developments.

Given ongoing supply chain disruptions, from inflation to geopolitical shifts, what concrete strategies or case studies will ProcureCon spotlight to help procurement leaders build resilience?

ProcureCon Europe is laser focused on helping procurement leaders build stability in an unstable world by bringing together industry experts to share their experiences and showcase actionable strategies.

I’m especially excited about our keynote presentation from the CPO of Siemens Energy on navigating volatility. This session will offer a bold, in depth look at how enhanced visibility and agility have enabled companies to thrive amid shifting tariffs and trade policies.

Throughout the three day event, we’ll focus on providing end to end visibility, governance frameworks and adaptive strategies, all designed to empower procurement teams not just to respond to crises, but to build lasting resilience.

As ProcureCon EU approaches its next editions, what long term objectives or evolutions do you envision for the event to enhance its impact on the procurement community in Europe?

Our long term vision is to keep reflecting the real world of procurement, its challenges, opportunities and constant evolution. By anchoring our agenda in research interviews with procurement professionals, we ensure every session speaks directly to our audience’s needs and priorities.

Even with 30 percent year on year growth in attendance*, we’re committed to keeping the event personal and focused. We know attendees are taking time out of busy schedules, and it’s our responsibility to ensure they leave with more than they expected, whether that’s new ideas, meaningful connections or both.

Looking ahead, we’re expanding further into the DACH region and introducing new content areas such as IT procurement. However, our goal remains the same; to make ProcureCon the essential gathering point for Europe’s most influential procurement leaders.