CONNECTED BY PASSION

DRIVING SMART LOGISTICS

Peter Spalt on Automation, Resilience, and Sustainable Growth at Hirschmann Automotive

With operations spanning nine plants across seven countries, Hirschmann Automotive has built a reputation for precision, innovation, and reliability within the global automotive supply chain. Behind this success lies a forward-thinking logistics strategy led by Peter Spalt, Director of Logistics, whose decadelong leadership has steered the company through a transformative era of automation, digitalisation, and sustainable growth.

From introducing fully automated intralogistics and AI-enabled systems to strengthening global resilience and decarbonising transport, Spalt and his team are shaping a logistics network built for flexibility and the future. In this feature, he discusses Hirschmann Automotive’s journey toward a smarter, more connected, and sustainable supply chain, one where technology, people, and partnerships work in perfect sync.

Professional Journey

Peter, could you walk us through your career path and the key experiences that have shaped your journey to becoming Director of Logistics at Hirschmann Automotive?

After completing my studies in Business Project and Process Management at the University of Applied Sciences in Vorarlberg / Austria, I began my professional career at ThyssenKrupp Presta in Liechtenstein, working in the field of logistics. Over the following years, I gained deep insights into the business, further enriched by an MBA in Supply Chain Management from ETH Zürich and several months abroad at Presta’s plants in China.

As part of the core team responsible for introducing lean manufacturing, I developed a strong appreciation for continuous improvement principles, which later inspired me to join Hilti’s Austrian plant to establish a lean management and manufacturing organisation. My time there, combined with additional years in production and logistics, helped me build a solid operational foundation and a deep understanding of lean-driven processes.

My return to the automotive sector marked a new chapter, I joined Hirschmann Automotive as Head of Logistics and, just six months later, assumed the position of Director of Logistics. For over a decade now, I have been responsible for operational supply chain planning and execution across Hirschmann Automotive’s global network, driving efficiency, innovation, and excellence throughout our logistics operations.

Strategic Role of Logistics

How does the logistics function at Hirschmann Automotive support the company’s broader goals, such as innovation, sustainability, and global expansion, particularly considering its presence in plants across Austria, the Czech Republic, Morocco, China, Mexico, and beyond?

The function of logistics at Hirschmann Automotive is broad and strategically vital. It involves continuously adapting the external network, both inbound and outbound, to align with company and customer requirements in an environment of sustained growth, marked by multiple new plants and plant expansions.

In parallel, logistics plays a central role in driving operational innovation and sustainability. This includes the introduction of fully automated intralogistics systems in two plants, which enhance efficiency, reduce resource consumption, and support Hirschmann Automotive’s long-term commitment to technological advancement and environmentally responsible operations.

Since 1978, your family business has specialized in conveyor system closures and their control technology.

Conveyor system closures

We deliver fire protection closures as part of railway based conveyor systems for all conveyor systems as well as for pneumatic conveyor systems. Our product portfolio includes conveyor system closures for wall and ceiling installations of sliding and lifting gates, revolving doors and flaps up to swivel sliding gates.

We look forward to your inquiry! Fon +49 6131 5803 51 Sales@abs-brandschutz.de

Smart Factory Intralogistics

At your Rankweil site, you’ve implemented a fully automated intralogistics system, including transport robots integrated with ERP and the Servus ARC5 system. Could you explain how these technologies have enhanced flexibility, performance, and cost efficiency in your internal material flows?

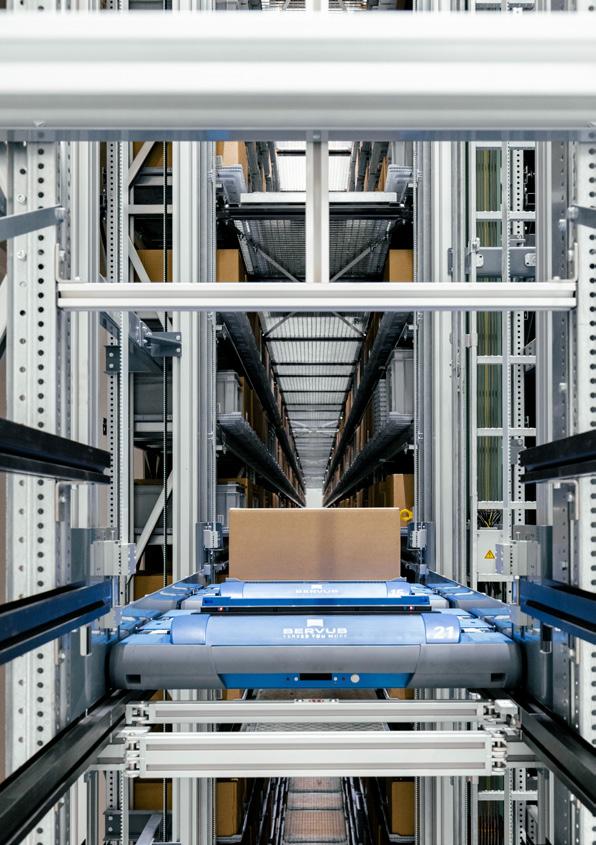

At our Rankweil site, we have implemented a fully automated intralogistics system based on Servus ARC5 transport robots, fully integrated with our ERP environment. This setup has significantly enhanced flexibility, performance, and cost efficiency across all internal material flows.

Using a brownfield approach in a 24/7 operational environment, we established a highly scalable and fully automated intralogistics concept that ensures continuous and seamless material flow. Produced goods, process-based waste (such as sprues from injection moulding), and packaging supplies are transported automatically by the ARC5 robots without manual intervention. Our high-speed assembly area is supplied directly from the automated small-parts warehouse, complemented by automation solutions for carton building, box shaking, closing, and labelling.

This end-to-end flow minimises in-process stock, shortens lead times, and enhances transparency and efficiency, a major step toward lean, digitalised operations. The seamless connection between production and logistics enables agile adjustments to demand, reduces process costs, and marks a significant milestone on Hirschmann Automotive’s journey toward a fully digital and flexible Smart Factory.

Partnerships in Smart Intralogistics

Hirschmann Automotive partnered with Servus Intralogistics to implement a fully automated, modular intralogistics system, enhancing flexibility and efficiency at your plants. From your perspective as Logistics Director, what has been the impact of this collaboration on operational performance, and how do you see such partnerships shaping the future of smart logistics at Hirschmann Automotive?

The collaboration with Servus Intralogistics, a regional partner, has been a key success factor in implementing our Smart Intralogistics strategy. Working with a local company allowed for short communication channels, close alignment, and hands-on collaboration throughout the entire project lifecycle.

From day one, Servus was actively involved in the design and concept phase. Together, we conducted multiple joint workshops to shape the vision of a true Smart Factory, always focused on achieving the optimal state of our internal operational processes.

This partnership resulted in the establishment of a highly efficient, modular system perfectly tailored to our operational needs. It has significantly enhanced transparency, reliability, and responsiveness across all material flows. Moving forward, we view such strategic partnerships as essential enablers of innovation, allowing us to continuously refine and optimise our logistics and production performance at Hirschmann Automotive.

Sustainability Targets

Hirschmann Automotive aims to achieve net-zero emissions (Scope 1 & 2) by 2030 and across all scopes by 2039, with all plants powered by green energy by the end of 2025. How is your logistics organisation aligning operations, such as transport management and supplier engagement, to support these sustainability objectives?

At Hirschmann Automotive, the logistics organisation plays a crucial role in delivering on the company’s ambitious sustainability goals: net-zero emissions (Scope 1 & 2) by 2030 and full valuechain neutrality by 2039. Both transport management and supplier engagement strategies are being aligned to actively support these objectives.

We are conducting a group-wide mapping project to ensure full compliance with the EU Packaging and Packaging Waste Regulation (PPWR). This initiative focuses on increasing the use of recycled materials and reducing waste across logistics processes.

“Moving forward, we view such strategic partnerships as essential enablers of innovation, allowing us to continuously refine and optimise our logistics and production performance at Hirschmann Automotive”

In transport operations, covering intercompany, inbound, and outbound flows, we optimise routes, consolidate shipments, and collaborate with long-term logistics partners who operate green fleets and invest in alternative-drive technologies. For outbound transport, where we maintain about 30 per cent direct responsibility, these partnerships are essential to lowering CO2 emissions and improving overall efficiency.

Close collaboration with our supply base is vital to strengthening transparency and resilience. Hirschmann Automotive is an active member of the Catena-X network, which enables continuous data exchange and harmonised sustainability reporting across the entire value chain.

We also use NQC/SAQ assessments to evaluate suppliers’ ESG performance and are implementing Green Purchasing Standards to further embed sustainability criteria in sourcing decisions. Our Business Partner Code of Conduct and CSRD Sustainability Assessment ensure that all partners align with our ethical, environmental, and social expectations, while continuous dialogue fosters improvement over time.

In short, our logistics strategy is built on compliance, collaboration, and innovation, ensuring that operational excellence directly contributes to Hirschmann Automotive’s progress toward a sustainable and resilient global supply chain.

Resilience & Risk Management

With global operations across multiple locations, how do you ensure resilience and agility in your logistics networks? How do you identify and mitigate emerging risks, such as supply-chain disruptions or regulatory shifts?

Hirschmann Automotive operates nine plants across seven countries worldwide, each directly serving customers with highly specific, often customised products. Our customer portfolio spans the full supply chain spectrum, from OEMs to Tier 3 suppliers, and in many cases, identical products are produced in multiple plants, and even on different continents, to support localisation strategies.

For example, our core products, such as connectors, are manufactured in two highly automated facilities in Europe, as well as in our plants in China and Mexico. This multi-location approach provides significant flexibility: with minimal effort, we can shift production capacity between sites, as most customer approvals are already in place.

A similar philosophy applies to our supply chain. Core raw materials, such as resins, are sourced from multiple suppliers across several regions, ensuring low disruption risk. However, given the high level of product specification and the need for validation and approval, certain components and materials are necessarily single-sourced. These suppliers are selected through a strategic sourcing process that prioritises risk mitigation as a core criterion.

When disruptions occur, whether caused by global events such as the COVID-19 pandemic, floods, the Suez Canal blockage, or semiconductor shortages, our success lies in rapid, coordinated response. Cross-functional collaboration between development, purchasing, logistics, and external partners ensures we can act with agility and precision across our global network. This proactive and integrated approach enables Hirschmann Automotive to maintain operational continuity, protect customer deliveries, and strengthen overall supply chain resilience even in the face of unforeseen challenges.

Traceability & End-to-End Automation

The company emphasises full traceability and intelligent automation across product development, supply chain management, and quality control. How are digital tools integrated across these stages to enhance visibility, reduce errors, and optimise logistics workflows?

In our plants equipped with fully automated intralogistics, we achieve an exceptionally high level of tracking and tracing across all operational stages. The core systems interacting in this ecosystem include our ERP system with its integrated warehouse management module, an external material flow control system, and particularly at the interface with production, a self-developed Manufacturing Execution System (MES).

This integration enables seamless data flow between logistics and production, ensuring full visibility of materials, real-time inventory accuracy, and process reliability. Every product movement, from raw material intake to finished goods dispatch, is digitally tracked, supporting error reduction, quality assurance, and performance transparency.

Our strategic focus remains digitalisation on demand, implemented when it brings clear operational or quality advantages. Digital tools are deployed both in response to customer requirements and as part of our internal continuous improvement initiatives, such as quality and risk management. This pragmatic, purpose-driven approach ensures that technology supports our goals of efficiency, traceability, and reliability across the entire value chain.

Team Development & Skills Strategy

As logistics become increasingly digitised, with smart robotics, augmented reality, and ERP integrations, how do you ensure your logistics teams are prepared and upskilled to manage these sophisticated systems effectively? What initiatives support evolving capabilities within your workforce?

In today’s environment, where the competition for talent is intense and the boundaries between IT and logistics are increasingly blurred, our focus is on attracting young, motivated individuals with strong logistics foundations and a genuine interest in digitalisation.

The scope of potential applications is vast, from the upcoming SAP S/4HANA transition to the growing integration of automation in hardware and software across daily operations, and, in the ahead future, the deployment of AI-driven tools. To prepare our teams for this evolution, we apply several complementary approaches.

One key strategy is close cooperation with consultants and technology partners, embedding them directly within our logistics teams. This hands-on collaboration allows our employees to learn rapidly through real-world implementation, developing both technical competence and strategic understanding. Additionally, structured internal and external training programmes, covering digital tools, process optimisation, and leadership, play a central role in advancing capability.

We also place strong emphasis on dual education programmes, which combine theoretical knowledge with practical experience. This model ensures that young professionals gain a comprehensive understanding of both logistics processes and the digital systems that enable them.

Through these initiatives, we are building a workforce that is adaptable, digitally fluent, and ready to lead Hirschmann Automotive’s logistics operations into the next generation of smart, connected, and data-driven supply chain management.

Hirschmann Automotive is a global automotive-supplier specialising in connectors, cable-assemblies, sensor systems and customised connectivity solutions for all vehicle types and drive technologies. With over 60 years of experience, the company supports automotive OEMs and micromobility manufacturers by delivering robust, reliable components engineered for the most demanding environments.

Peter Spalt Director Logistics