With nearly two decades of procurement experience, Leonardo Fanzini leads a critical mandate at GE Vernova: managing over $150 million in global sourcing for services that support the company’s gas-powered equipment portfolio. From advanced machining to on-site maintenance, his role touches every facet of supplier engagement from risk management and sustainability to innovation and resilience. In this in-depth interview, Fanzini shares how GE Vernova is transforming service sourcing into a strategic advantage, emphasising the importance of supplier partnerships, digitisation, and operational excellence. His insights highlight how sourcing professionals can drive long-term value by aligning quality, cost, and collaboration in an increasingly dynamic energy landscape.

Can you share your journey leading up to your current position as Global Sourcing - Services at GE Vernova? What are your primary responsibilities in this role?

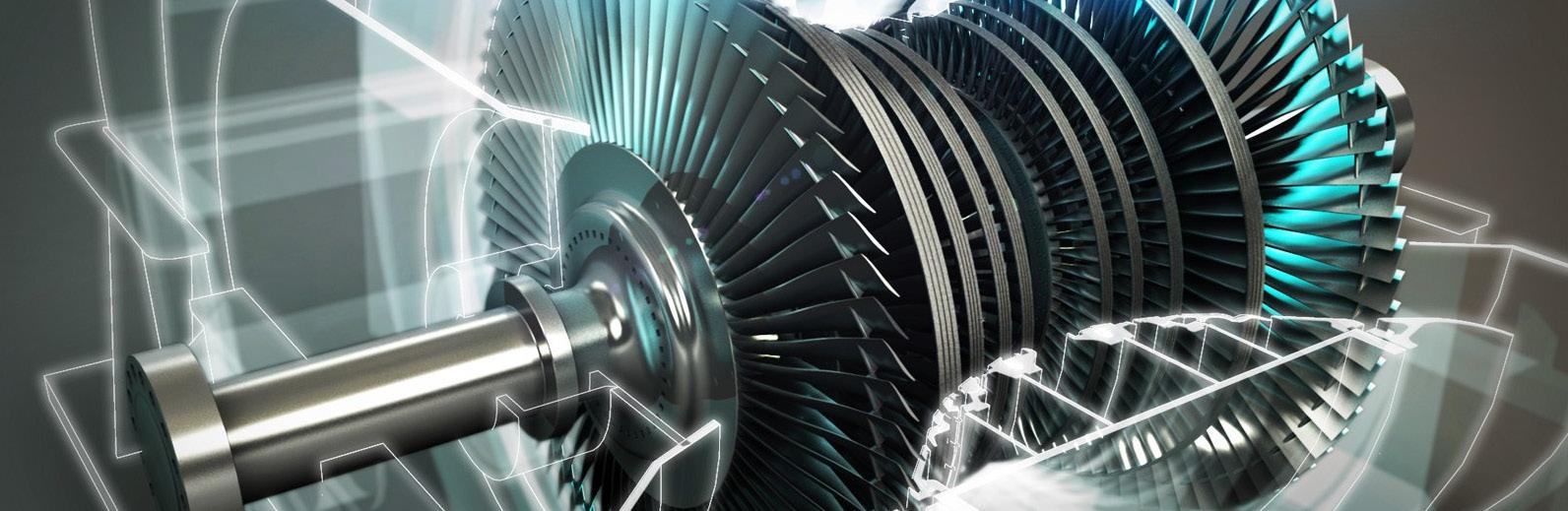

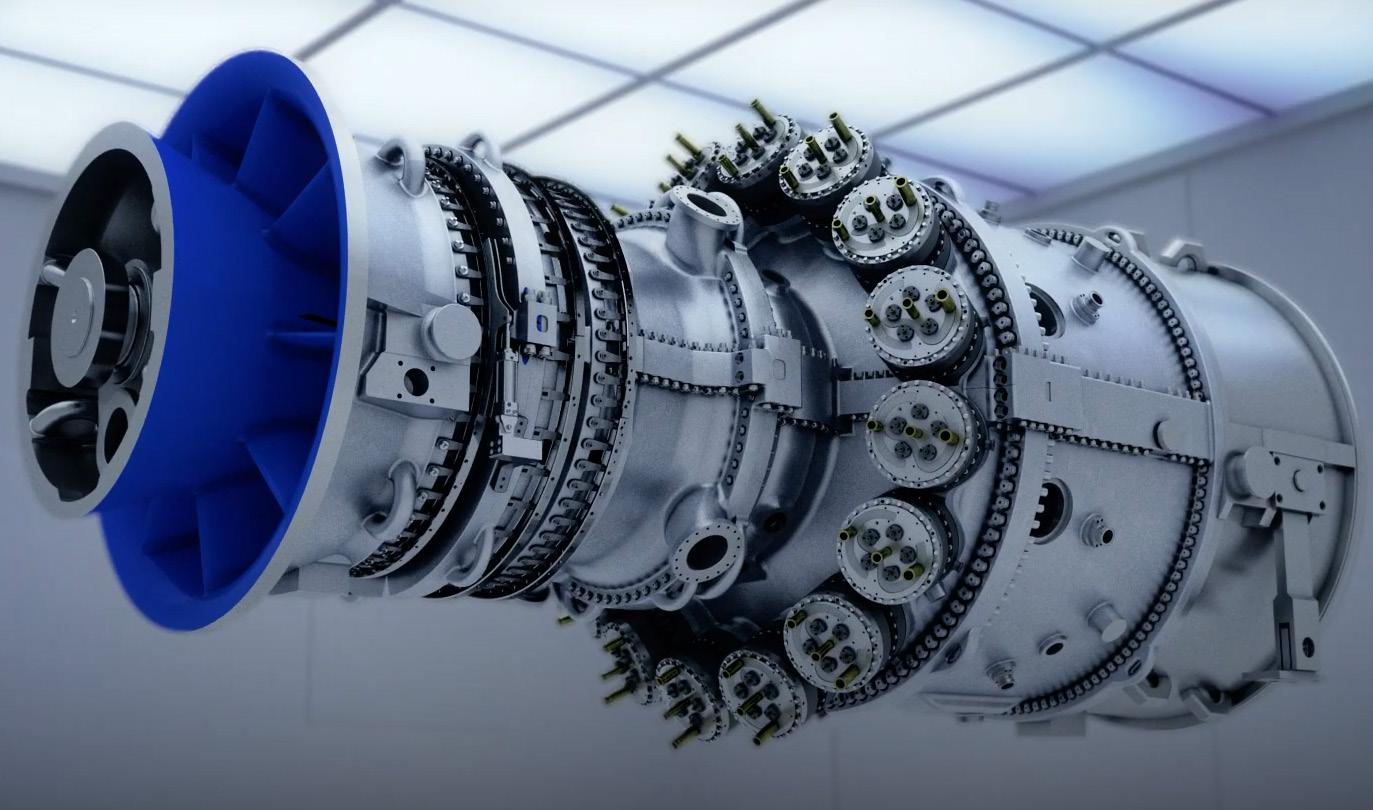

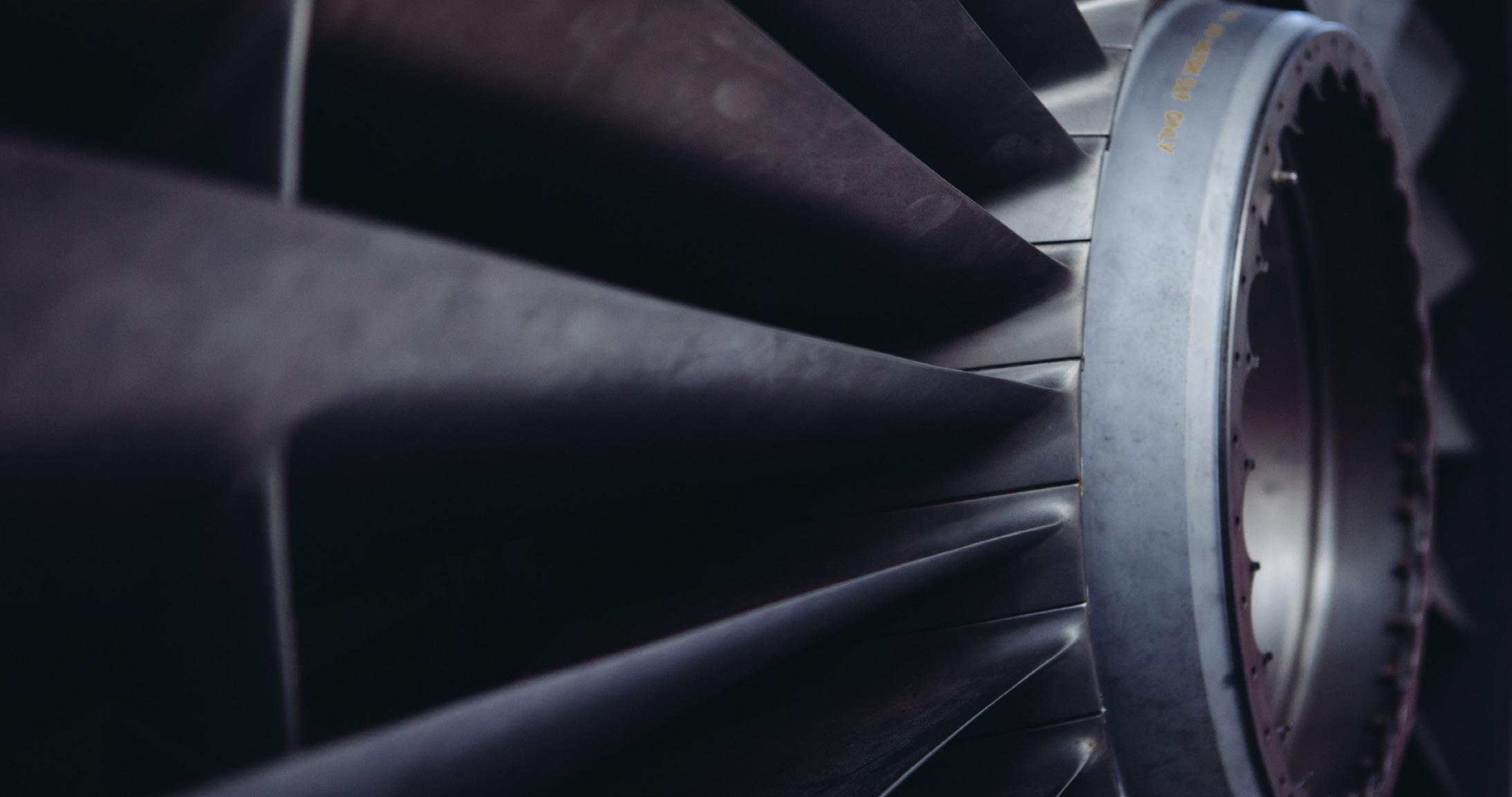

The role I am currently responsible for aims to achieve a strategic alignment of the global spend to third parties in maintenance services for Vernova gas powered equipment. Simplifying, it includes services such as rigging, scaffolding, other equipment rentals as well as highly specialized services such as mechanical repairs, electrical testing and various installation services.

The main goal is to have services strategically covered whether at a global or at a regional level. This task is shared with either strategic sourcing functions at HQ level or regional procurement teams.

Before taking over these responsibilities, I have always been engaged within GE’s power generation units’ maintenance activities in various procurement roles at a regional and global level. In my 17 years career journey I’ve been engaged in almost all the aspects of procurement and sourcing from buy-to-pay process management to commodity strategy development.

With over $150 million in annual spend under your purview, how do you approach developing and implementing global sourcing strategies for services?

The first step is to understand whether the category of spend can be approached from a global, regional or even country-level standpoint. At this stage, the total monetary value serves the purpose of ranking the various commodities but is not as relevant as other critical factors such the geographical application of the services, the regulatory environment, logistics and transportation costs, key suppliers’ footprint, etc.

After this initial analysis, global categories are separated from the local ones and two different approaches are implemented. Categories usually labeled as “global”, e.g., logistics, travel and living, etc. are analysed in synergy with the global indirect sourcing teams, whether at corporate or business unit level, while the “local” ones, e.g., on-site maintenance services, specialized craft labour, etc., deserve a dedicated analysis jointly developed with procurement and operations regional teams.

The typical sourcing analytical tools and templates (e.g., Kraljic portfolio analysis) are utilized in multiple stages to assess whether a partnership engagement (e.g., services which are critical to customers) rather than a leverage or transactional one (e.g., MRO, consumables) can give us the best potential outcome.

Different implementation actions (multi-year agreement, suppliers’ e-auctions) follow accordingly.

Our main campus in Savannah GA utilizes over 250,000 square feet of facilities and multiple satellite locations across the southeast. This enables us to offer the specialized machining services and on-site industrial contractor work they need.

K Machine has built a reputation on trust and excellence in the U.S., Canada, and overseas. From providing 24/7 emergency repairs to manufacturing turbine components, our customers have come to know what true service means. Founded in 1993 as an independent company, K Machine’s team of engineers, machinists, technicians, and welders, has provided trusted industrial services and delivered exceptional value to our clients in the pulp and paper, oil and gas, and power generation industries.

Our collaboration with GE also extends to the Gas Turbine product line, where we’ve provided dedicated support within the exhaust systems segment. Our Exhaust Specialty Services team has engineered and manufactured a wide range of solutions, many of which are deployed during forced outages or unplanned service events. These solutions are developed in close coordination with GE teams and are often custom-built to meet specific turbine configurations and operating conditions.

Over the years, we’ve also supported GE in planned initiatives aimed at enhancing exhaust system durability and reducing operational risk. These include upgrades, retrofits, and proactive service work designed to extend component life and improve system performance. Our team provides both the labour and material support necessary to execute these scopes to the highest standard. Our field crews bring decades of OEM experience and are supported by a manufacturing team that understands GE’s expectations and consistently delivers on quality and schedule.

With over 25 years of OEM experience and 20 years of manufacturing support for OEM components, K Machine has built a trusted reputation. Our clients, including GE Vernova, rely on us to deliver solutions with speed, precision, and full accountability. Whether we are performing valve rebuilds in our Savannah shop or executing on-site gas turbine exhaust retrofits halfway around the world, our commitment to safety, quality, and technical excellence remains unwavering.

K Machine Industrial Services continues to grow by doing what we do best—solving complex mechanical challenges for our clients and supporting the long-term performance of critical power generation equipment. Our relationship with GE Vernova reflects our ability to consistently meet the high standards required to support one of the most demanding OEMs in the energy industry. We look forward to continuing this collaboration and providing worldclass service and support wherever it’s needed.

What key metrics and processes do you utilize to assess and manage supplier performance, ensuring alignment with GE Vernova’s standards?

In Vernova we are very focused on the application of a lean methodology. Since the time of GE’s Six Sigma approach, the elimination of waste and continuous improvement have become a companywide embedded “mantra”: daily management, standard work, bowler charts and kaizen events more than just tools are a “second skin” in our way of operating. They are applied in managing key partners and suppliers as well.

In terms of key performance indicators, we use the acronym SQDC, which stays for Safety, Quality, Delivery and Cost. Safety is our top priority, and we need our suppliers to consider it as such too: every meeting starts with reflections on incidents, hazards and safety-related topics and we consistently promote a “stop work” attitude, in case any of us finds out a potential safety risk.

Quality follows second with the ambitious goal of zero defects in ours and suppliers’ deliveries to customers. Delivery time is of the essence as our customers face millions in losses if we delay by just one day an outage execution. Finally, but nonetheless extremely important, is the focus on cost to ensure that we get the best prices available in the market.

How does GE Vernova integrate sustainability and environmental considerations into its sourcing and procurement decisions?

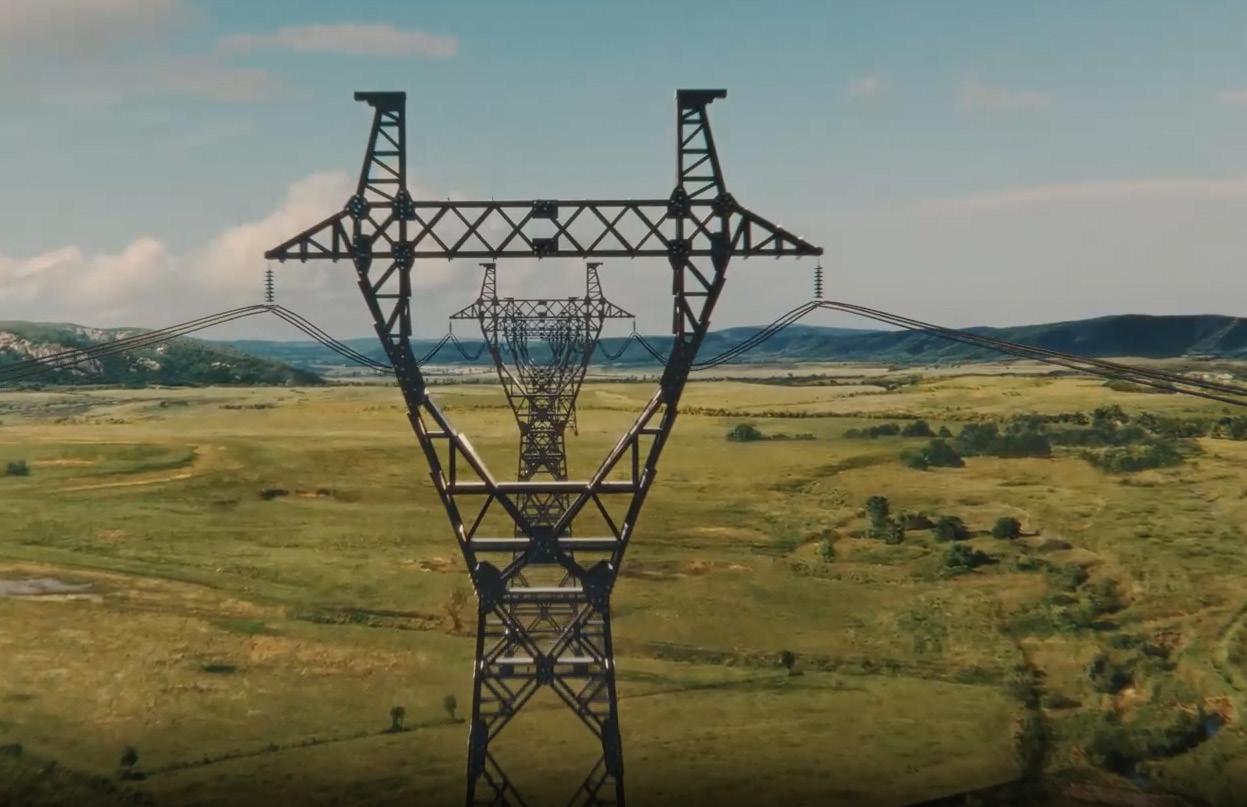

As a power equipment manufacturer with almost 25% of the world electricity generated with the support of our technology, Vernova is at the crossroad of critical decisions for the future of energy and environmental sustainability. Future energy demand mainly driven by additional needs from data centres and AI applications pushes us hard to increase capacity in the market. On the other hand, tight environmental regulations demand for a cleaner and more efficient way to cope with such an increase. This is why a core tenet of our sustainability strategy is” to electrify and decarbonize” the world, to be achieved through a diversified portfolio of solutions (Power, Renewables, Grid and Storage). Although maintenance services execution may be seen as less critical from an environmental impact standpoint, we are undertaking several initiatives to improve the sustainability of the procurement decisions, particularly in logistics and transportation with the key goal to reduce CO2 emissions from our logistics partners.

An important topic, which I am very keen about, is suppliers’ financial sustainability. We constantly monitor our key suppliers’ financial health and bankruptcy risk so to ensure them a healthy profitability as well business continuity in a mutually beneficial collaboration.

Whether you need to protect it, prove it, or improve it, ATS is ready to partner with you in quality, safety, and reliability. With expertise in Inspection, Testing, Calibration, and Consulting for a wide range of industries, our experts deliver insights that support client efforts to meet regulatory compliance, minimize the likelihood of unplanned outages, and ideally extend the life of critical assets.

ATS knows that every client’s needs are unique. Our team of specialists values your project, working closely with you to develop solutions tailored to meet your specific objectives. View our capabilities below to see how we help you predict, prevent, and perform.

Since 1967, Applied Technical Services (ATS) has built expertise in Power Generation—providing Inspection, Testing, Calibration, and Consulting Services to clients in Energy Production, Field Maintenance, and OEM Manufacturing. While quality and efficiency are engineered into the technologies that power the world, processes can break down, operational conditions can shift, and uptime demands continue to stretch the boundaries of safe operation. Our goal is to help clients enhance performance, enable predictive insights, and support preventative strategies that protect critical assets and extend operational life.

Our Purpose is to create a safe and reliable world.

Our Mission is to deliver assurance through precise technical and professional services.

ATS provides inspection services for large-scale assets and infrastructure within the power generation facility. This includes thorough assessments of turbines, boilers, pressure vessels, generators, heat exchangers, and structural systems to assess their condition and provide insights to evaluate continued serviceability. Inspections such as Fitness-for-Service (FFS) evaluations, corrosion mapping, and remaining life assessments help determine whether equipment can safely continue operation or requires repair or replacement. By leveraging advanced inspection methods—such as ultrasonic testing, digital radiography, and phased array— ATS delivers assessment insights that support client efforts to meet regulatory compliance, minimize the likelihood of unplanned outages, and ideally extend the life of critical assets.

Beyond asset protection, ATS plays a vital role in supporting power generation facilities by performing inspections on critical parts and components. Through a combination of non-destructive testing (NDT), material verification, dimensional analysis, and advanced failure analysis techniques, we gather critical data to help clients identify potential defects, irregularities, or early indications of degradation in key components such as valves, turbine blades, bearings, and electrical connectors. In cases of malfunction or unexpected wear, failure analysis can provide insights into likely root causes—which may include material fatigue, corrosion, stress fractures, or manufacturing inconsistencies. The data gathered by performing these techniques can aid in reducing recurring issues and supports clients in making informed decisions on maintenance schedules and part replacements.

Demonstrating our dedication to technical solutions and human connections, ATS proudly received the Excellence in Accountability award from GE Vernova— a global leader in power generation for over 130 years. This recognition, awarded to only a select group of top-performing partners by GE Vernova’s Gas Power One Field Services, underscores ATS’s partnership in delivering dependable, high-impact service across the power generation sector.

ATS Provides Insights You Can Count On

If you’re seeking a partner known for precision, accountability, and industry recognition, ATS is ready to deliver insights you can count on. We offer comprehensive Inspection, Testing, Calibration, and Consulting Services — each designed to address a wide range of technical and operational needs. Discover why industry leaders trust ATS. Contact us today to learn how we can support your next project with award-winning service.

Inspections

Dimensional Inspections – Computed Tomography, CMM, and 3D Laser Scanning

Non-Destructive Inspections – Borescope, Ultrasonic (Conventional, Shear Wave, PAUT), Eddy Current, Magnetic Particle, Penetrant, Visual Testing, and Radiography (Film & Digital)

Mechanical Integrity – Predictive Maintenance Programs, API Inspections (Tanks, Piping, and Pressure Vessels)

Reliability Inspections – Balancing and Alignment, Preventative Maintenance, Motor Testing, Vibration Analysis, Thermal Imaging, Ultrasonic Listening

Calibration

Cal Labs for Precision Equipment– Avionics, Electrical, Mechanical, Environmental, and Standards

On-site Services – Field Services and Embedded Labs

Equipment Maintenance and Sales – Repairs and Replacements

Specialty Flow – Gas, Liquid, Water, and Multiphase

Testing and Analysis

Materials – Mechanical, Metallurgy, Polymer Analysis, Chemistry, Material Identification, and Characterization

Environmental – Flammability, Ingress Protection, Weather, Corrosion, Vibration, Radiation Effects, Electrical, and EMI/EMC

Failure Analysis – Mechanical, metallurgical, Polymers, Dimensional, Component, and Forensic Consulting Services

Fall Protection – Design and Furnish Installation, Anchor Load Testing, Safety Compliance, Inspection and Certification

Special Access – Rope Access Inspections and Training, Drone Inspections, Remote Visual Inspections

Failure Analysis – Mechanical, metallurgical, Polymers, Dimensional, Component, and Forensic Structural Engineering – Post-Damage Assessment, Design and Renovation, and Vibration Analysis

Forensics – Accident Reconstruction, Fire Origin and Cause, Biomechanical, Expert Witness, Building Consulting, and Forensic Engineering

Could you discuss GE Vernova’s commitment to supplier diversity and how it influences your sourcing strategies?

Commitment to a diverse and inclusive value base is a critical part of GE Vernova’s Human Rights Statement of Principles. In full alignment with international standards of human rights, it offers clear guidelines for ethical and safe business practices which apply to our suppliers as well.

Our employees’ code of conduct, called “The Spirit and the Letter”, which outlines our policies in terms of fairness and respect for all our stakeholders, independently of their gender, race, religion, etc., is expected to be followed and adhered to by our partners as well. It is fully embedded in our Know Your Suppliers (KYS) due diligence process, a key component of which is our “Suppliers Integrity Guide”. This process focuses on suppliers’ practices such as labour policies, age and nature of workers among others. Suppliers’ input is then properly evaluated and eventually approved, if it is in line with our requirements and expectations.

We do not stop just here, though, as we continuously seek to elevate ours and our suppliers’ standards of behaviour: we utilize external third-party data for risk identification, analysis, mitigation, and remediation; we continuously refresh and update supplier training and provide with additional documents for risk assessment and mitigation plans.

In light of recent global disruptions, what strategies have you employed to maintain resilience and adaptability in GE Vernova’s supply chain?

Most of the services’ supply chain is regionalized or even localized and close to customers’ locations. Therefore, most recent global disruptions either had very limited impact or had been addressed by switching from global to regional/local service providers. The exact opposite approach is used when unexpected changes at local level (e.g., social unrest, force majeure due to environmental disruptions) make the local sources unavailable: in such a situation, we switch providers sourcing them from the nearest area unaffected by the change.

To facilitate us in predicting areas of risk and to tailor mitigating strategies, we use suppliers’ scorecards based on their financial records and their past behaviour in terms of service level. Where we see a low score indicating that the evaluated supplier will likely default on its commitments, we approach available alternatives or new sources e.g., switching from a single source to a dual source strategy.

More generally, and without limiting ourselves to services, we adopt different risk mitigation strategies, depending on the risk involved: from the “unknown-unknowns”, where we cannot quantify the likelihood of occurrence to the “known-unknowns”, at the opposite side of the spectrum. To this second category belongs the case of suppliers’ scorecard, previously discussed.

How is GE Vernova leveraging digital tools and technologies to enhance procurement efficiency and transparency?

Although we are still in the early stages of our procurement digitisation journey, at Vernova we take very seriously the opportunities offered by the latest digital technologies. Our aim is to cover the full range of applications from purely descriptive to prescriptive, including predictive analysis tools. We already use, or are in the process of testing, different application software in the areas outlined above.

For the simple collection and visualisation of historical data, we create a data warehouse to segment suppliers or cluster procured services. These are visualised through real-time dashboards using some of the most popular software available on the market.

To predict future demand and commodity prices, for example, we have developed strong partnerships with global providers and make extensive use of regression analysis tools. The goal, however, is to leverage machine learning to build a prediction model trained on data from descriptive analysis, which can then be used as an input for the prescriptive phase.

The final phase will ideally consist of digitising purchasing decisions—such as quantities and timing of purchases, supplier selection, negotiation strategies, and smart contracting through the development of a decision model using advanced analytics tools such as NLP, AI, and blockchain.

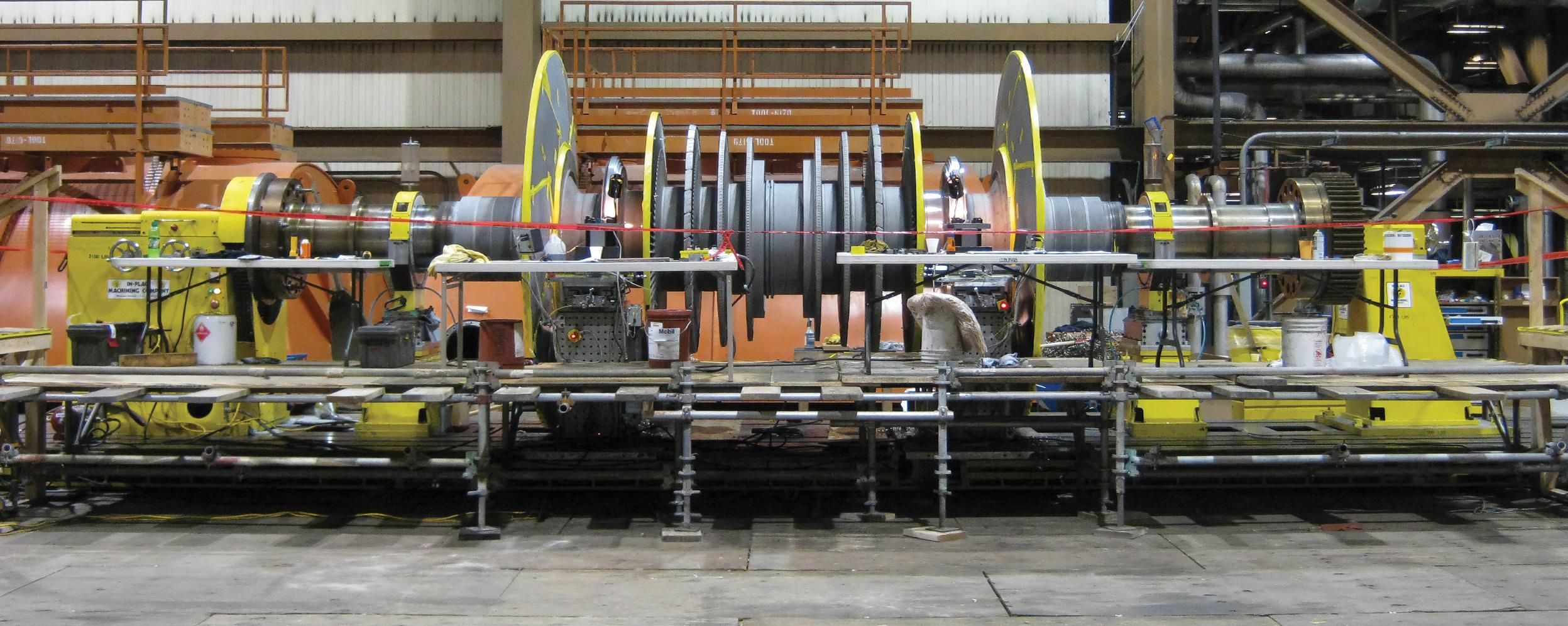

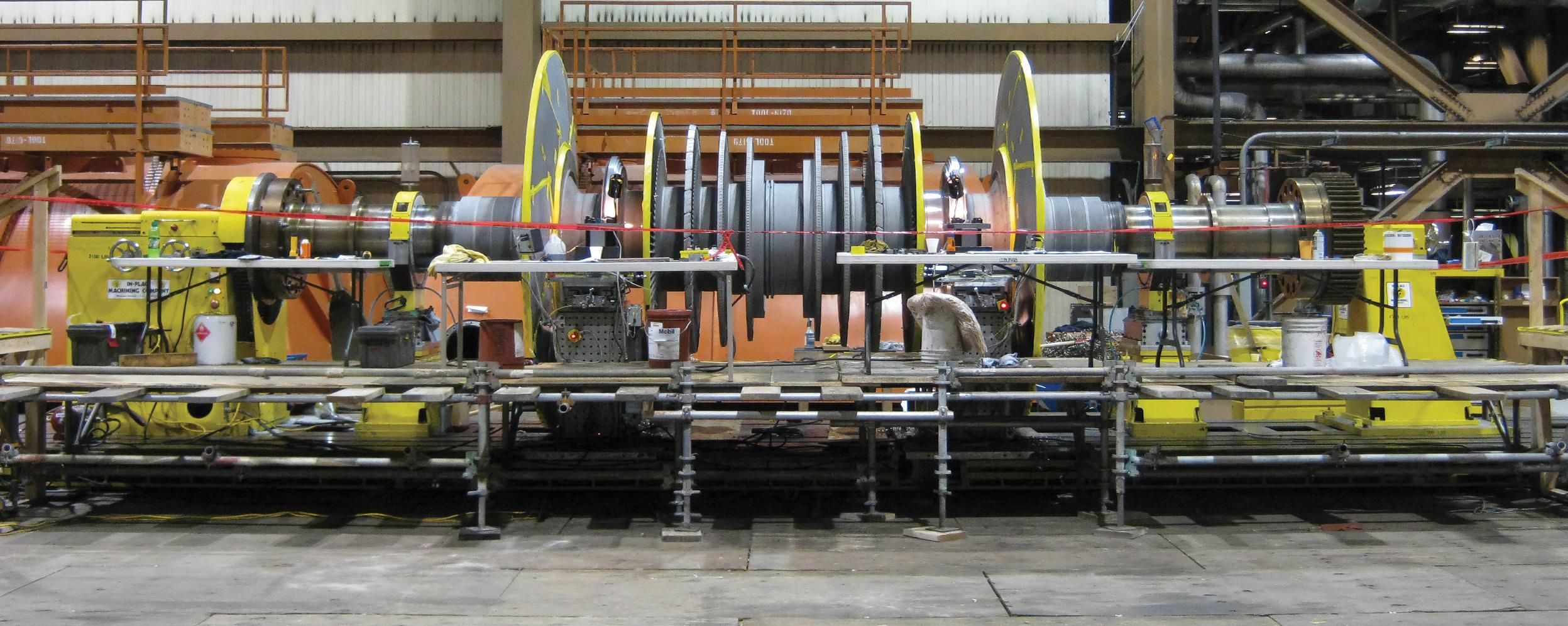

Our long-standing partnership with GE Vernova speaks volumes. At In-Place Machining Company (IPM), we operate as an extension of your team—fully aligned with your goals, timelines, and performance expectations. With industry-leading equipment, deep expertise in critical repairs, and teams with technical mastery you can trust, IPM is built to support GE Vernova’s mission and Power Generation Service Strategy—from planned outages to emergent repairs—when it matters most.

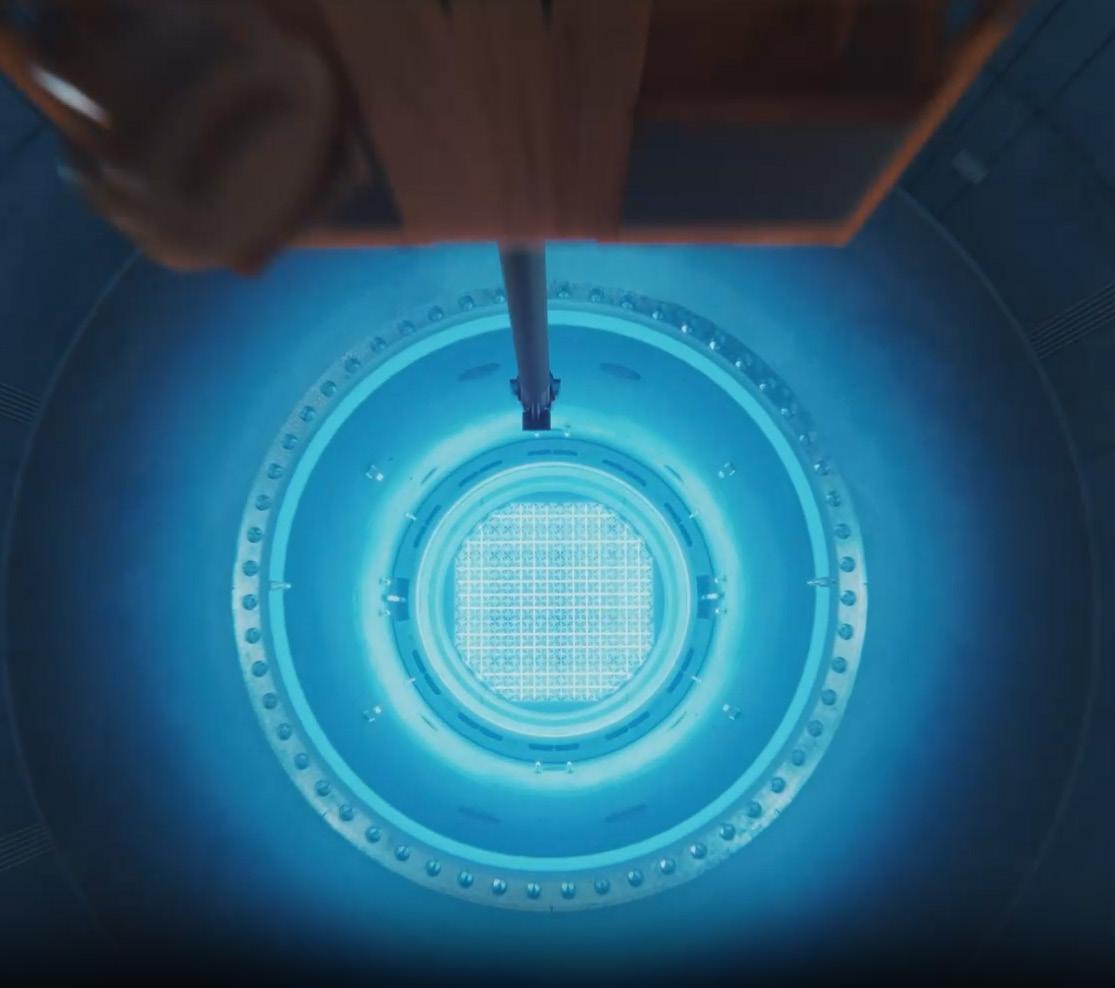

Ensuring gas, steam, nuclear, and renewable energy systems stay at peak performance under the toughest conditions.

The world’s largest team of full-time, high-acuity Field Service Engineers and Technicians—trusted to solve what others can’t.

With 18 service hubs strategically located across North America, including over 240,000 sq. ft. of specialized machine shop facilities, we mobilize fast—when every second counts. Whether it’s emergency repairs, equipment refurbishments, or full-scale outage support, our team is ready to meet your most complex challenges.

Our in-house team of engineering experts and technicians design, build, and customize solutions for quick mobilization, efficiency, safety, and first-time right results.

As North America’s leader in alignment and metrology, we deliver high-accuracy measurements, 3D scanning and modeling, reverse engineering, and precision alignment for turbines, shafts, generators, and more. With the expertise and metrology instruments to get it right the first time, we ensure flawless installations and peak performance across your most critical power generation assets.

Bringing unmatched technical depth and innovative problem-solving to every high-stakes power generation challenge, ensuring results when failure isn’t an option

How do you ensure effective collaboration between the sourcing department and other divisions within GE Vernova to achieve cohesive business objectives?

In addition to collaboration tools provided by the latest networking technologies, clear and effective communication remains essential to ensuring full alignment of goals and objectives both at the company level and within each function. This is especially true in a matrix-operating organisation like Vernova.

Sourcing annual priorities are set jointly with other divisions, usually cascaded down from the most senior levels, but always incorporating the bottom-up inputs gathered at critical touchpoints throughout the year.

Operationally, short-term goals between collaborating departments do not always align. To avoid unnecessary and counterproductive discussions such as prolonged negotiations or escalations to functional leaders it is best practice to involve all key functions, including procurement, from the very early stages. This applies whether we are talking about a maintenance project or an ERP rollout. The outcomes are significantly better when procurement is part of the planning phase, rather than being asked to optimize decisions already made at the engineering or operational execution level.

At the same time, selecting strategic partners is not the exclusive domain of sourcing. Involvement from other functions is critical to achieving success.

• Automatic and Manual Welding

• Laser Tracking and Alignment

• Stationary Journal Machining

• Portable Lathe with 225 Ton Capacity

• Rotor Bore Services

• Boring / Milling

• Stud Removal

• Portable Machine Shops

• 100,000 sq ft Machine & Welding Shop

• Tooling Design and Manufacturing

• CNC Milling and Turning Services

• OEM Part Manufacturing

• 50 Ton Lift Capacity

• Project Management

• Pumps: Boiler Feed / Recirc / Reactor Feed / Circulating and many more

• Valve: Main Steam Stop Valves / Control Valves / Check Valves / Throttle Valves Wye Globe Valves / Gate Valves and many more

GE Vernova and RapidRatings delivers deep, objective insights into supplier financial health—turning risk into resilience.

Our financial health ratings reveal risks that others’ don’t

Continental Field Systems (CFS)’s mission is to be the forefront leader in the industries we serve by setting high standards for machining and welding, through continuous improvement, and by meeting the expectations of our customers, employees, suppliers, and owner. The safety and health of our employees, contractors and suppliers continues to be the first consideration in the operation of this business. At CFS, the quality of our products and services are key to meeting and succeeding our high standards for machining and welding.

RapidRatings equips procurement teams in global organizations with accurate data-driven insights to assess supplier risk and make confident, informed business decisions.

CFS offers a wide range of services to the oil & gas, combined cycle, nuclear, and traditional energy industry as well as other heavy industrial groups. Among the range of services we provide include, valve, pump, turbine repair, portable lathe turning, stud removal, flange facing, portable shop machining, line boring, milling, metal disintegration, on-site laser tracking & alignment, automatic & manual welding, quality control, assurance & inspection.

CFS’s quality assurance programs are compliant with the National Board Inspection Code (NBIC) and the American Society of Mechanical Engineers (ASME). We maintain the following Certificates of Repair: NBIC NR & R and ASME U, S, & PP. Our nuclear quality program meets the requirements of 10 CFR Part 50, Appendix B, 10 CFR Part 21, and ASME NQA-1 and are audited triennially by the Nuclear Procurement Issues Corporation (NUPIC). The partnership between GE Vernova and CFS focuses on delivering high quality services in a safe, qualityminded professional manner. This partnership enhances CFS’s capabilities and market reach and allows us to leverage GE’s expertise and resources thereby ensuring that both companies remain at the forefront of our industry.

Peer comparisons

0.81 EMR safety rating

6 continents reached

35 countries ser ved Boots on the ground within 48 hrs (US) / 72 hrs (globally)

SG Energy Solutions provides end-to-end support to power plants and utilities worldwide through comprehensive engineering services:

Mechanical & Electrical Engineering utilizing cuttingedge technology

Electrical Infrastructure for complete industrial installations

Instrumentation & Controls featuring advanced troubleshooting capabilities

Learn more about our capabilities

sgenergysolutions.com info@sgenergysolutions.com (248) 281-1868

In the context of global sourcing for services, how do you strike a balance between cost optimisation and maintaining high-quality standards?

As explained regarding suppliers’ performance, cost is a critical factor alongside safety, quality, and delivery. In sourcing services, these priorities often conflict with one another: a supplier offering the fastest lead time may achieve it by cutting corners or inflating prices through expediting fees; conversely, we may receive the highest-quality service but not within the required timeframe or at the most competitive price.

To ensure that the required levels of safety, quality, and delivery are consistently met by our service supply base, we apply a variety of methodologies and approaches, which are continuously monitored and refined as suppliers perform on our behalf.

For safety assessment, we work with preferred partners who independently evaluate suppliers based on their EHS (Environment, Health, and Safety) performance in accordance with our specified requirements.

For quality, a dedicated team of engineers qualifies and audits suppliers against Vernova’s specifications.

We use On-Time Delivery (OTD) metrics to evaluate service suppliers based on their ability to deploy at customer locations and complete services within the requested timeframe.

Once the providers meet these set targets, we are in a strong position to competitively bid or negotiate pricing using market data, historical benchmarks, and projected inflation to ensure optimal value.

What emerging trends do you foresee in global sourcing, and how is GE Vernova positioning itself to stay ahead in the evolving energy sector?

I see two diverging trends emerging in today’s procurement world.

On the one hand, more transactional activities ranging from purchase order requisition to invoice reconciliation, and including so-called “desktop procurement” tasks (e.g., price bargaining, competitive bidding analysis and evaluation, contract preparation) are expected to be increasingly automated and digitised, requiring less and less human involvement and interaction.

Conversely, purely cost-centred procurement, while still relevant as external purchases make up a significant portion of a firm’s total cost, is now viewed as only one aspect of the value procurement can offer.

With early supplier engagement and closer ties to critical-to-customer partners, sourcing can significantly enhance revenue and market share for companies that effectively leverage it.

This requires a significant shift in the typical sourcing department’s mindset and leadership approach: a collaborative and results-oriented engagement with partners, rather than an exclusive focus on cost-cutting, is key to successfully positioning the sourcing function within the broader organisation. A tangible and foreseeable consequence of this shift would be the replacement of the current “commodity management” model with a more strategic “supplier management” approach.

On-Site Consultations & Detailed 3D Lift Planning

65+ Years of Innovative Safety Education

Sophisticated Technology

Best Availability of Reliable Rental Cranes

NO MATTER THE SIZE OF THE JOB WE HAVE THE CRANE FOR YOUR PROJECT

Founded in 1959, Sims Crane & Equipment Co. has been a leader in the crane and rigging service industry for over 60 years, providing innovative solutions and exceptional service for all of your heavy lifting needs. With a commitment to safety, quality, and customer satisfaction, Sims Crane & Equipment Co. is the go-to choice for companies in need of reliable and efficient lifting solutions.

Our extensive fleet of cranes, ranging from 8 to 800 tons, is equipped to handle any project, no matter the size or complexity. Our team of highly trained and experienced operators ensures that every lift is executed with precision and safety, minimizing downtime and maximizing productivity.

At Sims Crane & Equipment Co., we understand the critical role that utility companies play in our communities. That’s why we offer 24/7 support and rapid response times to ensure that your projects stay on schedule. Our state-of-the-art equipment and cutting-edge technology, including 3D and P.E. Stamped lift plans provide the highest level of service and reliability.

Choose Sims Crane & Equipment Co. for your next Power Generation Project and experience the difference that our expertise and dedication can make. With our headquarters in Tampa, FL, and multiple branch locations throughout the Southeast, we are ready to serve your lifting needs. Trust Sims Crane & Equipment Co. to deliver the best in crane rental and rigging services for the power generating industry.

GE Vernova and RapidRatings delivers deep, objective insights into supplier financial health—turning risk into resilience.

Only RapidRatings analyzes the financials statements of your private and public suppliers to reveal the whole picture.

Our financial health ratings reveal risks that others’ don’t

RapidRatings equips procurement teams in global organizations with accurate data-driven insights to assess supplier risk and make confident, informed business decisions.

GE Vernova partners with a diverse range of service providers. How do you identify which partners are best suited for complex and mission-critical scopes? Can you share an example where collaboration with a trusted partner made a measurable impact?

Collaboration, particularly for services on complex and highly specialised equipment like Vernova’s— develops through several years of interaction at different levels, but most of it happens during real-time execution at customer sites. In addition to screening, evaluating, and approving basic mandatory requirements conveyed through Know Your Supplier (KYS) documentation, we look for providers with multi-year experience on gas-powered turbines who consistently perform at a high level across a range of situations (e.g., scheduled planned maintenance, unplanned and forced outages).

Our team of quality engineers follows selected partners throughout the various stages of the relationship, from simple tasks and operations all the way through to complex machining and assembly processes. The highly developed skills our partners have nurtured particularly in training selected professionals cannot be easily transferred internally as a commodity, nor are they readily available in the broader market.

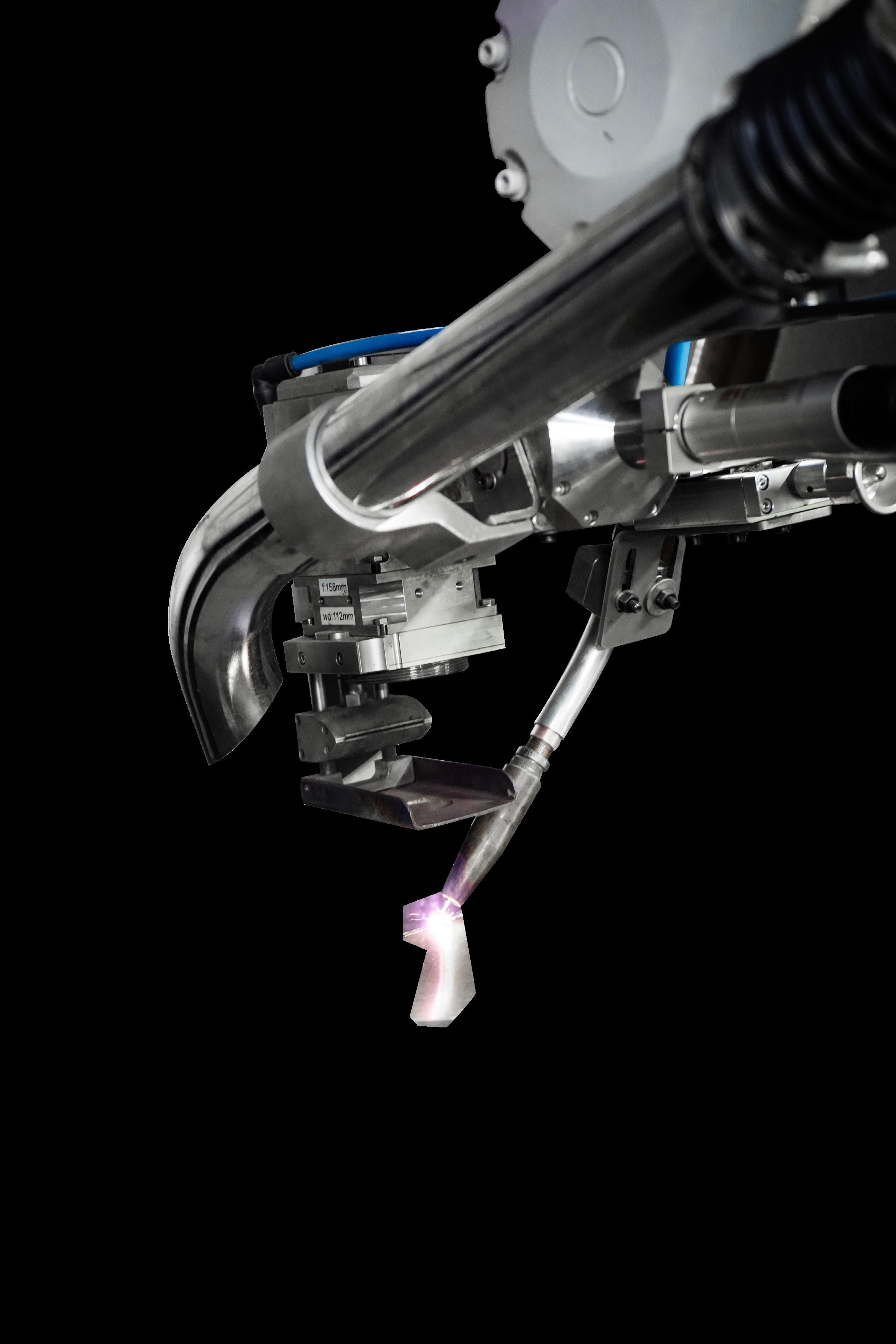

In-Place Machining Company is a best-in-class example of such collaboration. Their long-tenured expert machinists have enabled Vernova to complete critical work promptly, reduce the impact on scheduled activities, eliminate freight costs, and achieve zero rework in complex operations such as erosion ring machining, on-site weld repairs, and alignment of turbine casings.

We serve our customers with excellence from the paper work to our quality rebuilds. We will promptly respond to your questions or needs. ServoCon® ALPHA rebuilds are known for exceptionally long service life that why major steam turbine OEM’s, such as General Electric, use ServoCon® ALPHA to repair their customers servovalves, cylinders and control pacs.

With ServoCon® ALPHA there are no distributors that you have to go through, you simply send your component directly to us. We will give you the true facts about your hydraulic components. Since we specialize in the entire hydraulic system, we will make sound recommendation to prevent future component failure. We are experts and we want to share that expertise with you. Why settle for “good enough” when you can have the best. Rely only.

ServoCon Associates Inc.

167 Expo Road Fishersville Virginia 22939

Phone: (540) 337-4900

Toll Free: (800) 447-7747

Fax: (540) 337-4901

E-mail: servoconalpha@servoconalpha.com

Servocon Alpha and GE Vernova: A Proven Partnership in Turbine Excellence

For over four decades, Servocon Alpha has been a trusted name in the rebuilding and refurbishment of gas and steam turbine components. Founded in 1979, the company has earned its place as a leader in precision engineering by delivering consistent quality, reliability, and innovation to industrial partners around the world.

Today, that legacy is further enhanced through a collaborative partnership with GE Vernova, a global force in energy innovation. This partnership bridges Servocon Alpha’s deep expertise with GE Vernova’s forward-looking approach to cleaner and more efficient power generation, creating a synergy that supports a more sustainable energy future.

“Every turbine component tells a story of power, precision, and performance—and we make sure that story continues,” says GM-Matthew Ramey at Servocon Alpha.

At the core of Servocon Alpha’s service is a hands-on, detail-driven process: complete disassembly, rigorous inspection, expert reverse engineering, and meticulous rebuilding. From aging legacy systems to state-of-theart turbines, the company’s certified technicians and engineering teams deliver results that restore function and extend operational life—without compromising OEM standards.

Working closely with GE Vernova, Servocon Alpha ensures that customers benefit from both legacy craftsmanship and modern technological alignment. This powerful alliance allows plant operators to reduce downtime, cut costs, and gain peace of mind with every rebuilt component.

Several partners have supported GE Vernova with innovative approaches — such as robotic inspections or advanced machining solutions. How important is innovation in your supplier relationships, and how do you foster it?

Innovation is becoming increasingly critical, even in a non-product environment such as heavy-duty repair services. Vernova likely has one of the strongest internal engineering capabilities in designing and manufacturing industrial machines for the energy sector, but in several cases, these resources are in short supply during the maintenance phase of our equipment.

For this reason, continuously improving our service performance relies heavily on the solutions developed and tested by our selected partners through years of industrial application. Our suppliers constantly monitored and audited by our team of sourcing quality engineers are required to adhere to the highest industry standards and are certified in nearly all areas in which they operate.

I must highlight the case of K-Machine Industrial Services, which, in addition to supporting complex scopes, consistently delivers high-quality services and responds rapidly to emergent needs involving the repair, welding, and machining of our casings, diaphragms, and nozzles. They have also demonstrated innovative capabilities, such as using robotic devices to inspect the lower bowl of control valves in a safer and more cost-effective way.

Such innovative solutions become especially critical in supporting our internal repair network when it comes under pressure from intensifying customer demand.

During high-pressure outages, speed and precision are essential. How do you ensure your partners can deliver under tight timelines, and are there any standout examples from recent projects you’d like to share?

We try in every possible way to integrate key suppliers into all preparation phases of planned maintenance. This is extremely important to ensure that the right people and tools are available precisely when needed. Once deployed, it is also critical that the supplier’s resources effectively cooperate with Vernova’s crew to minimise the impact of any last-minute changes in the scheduled activities.

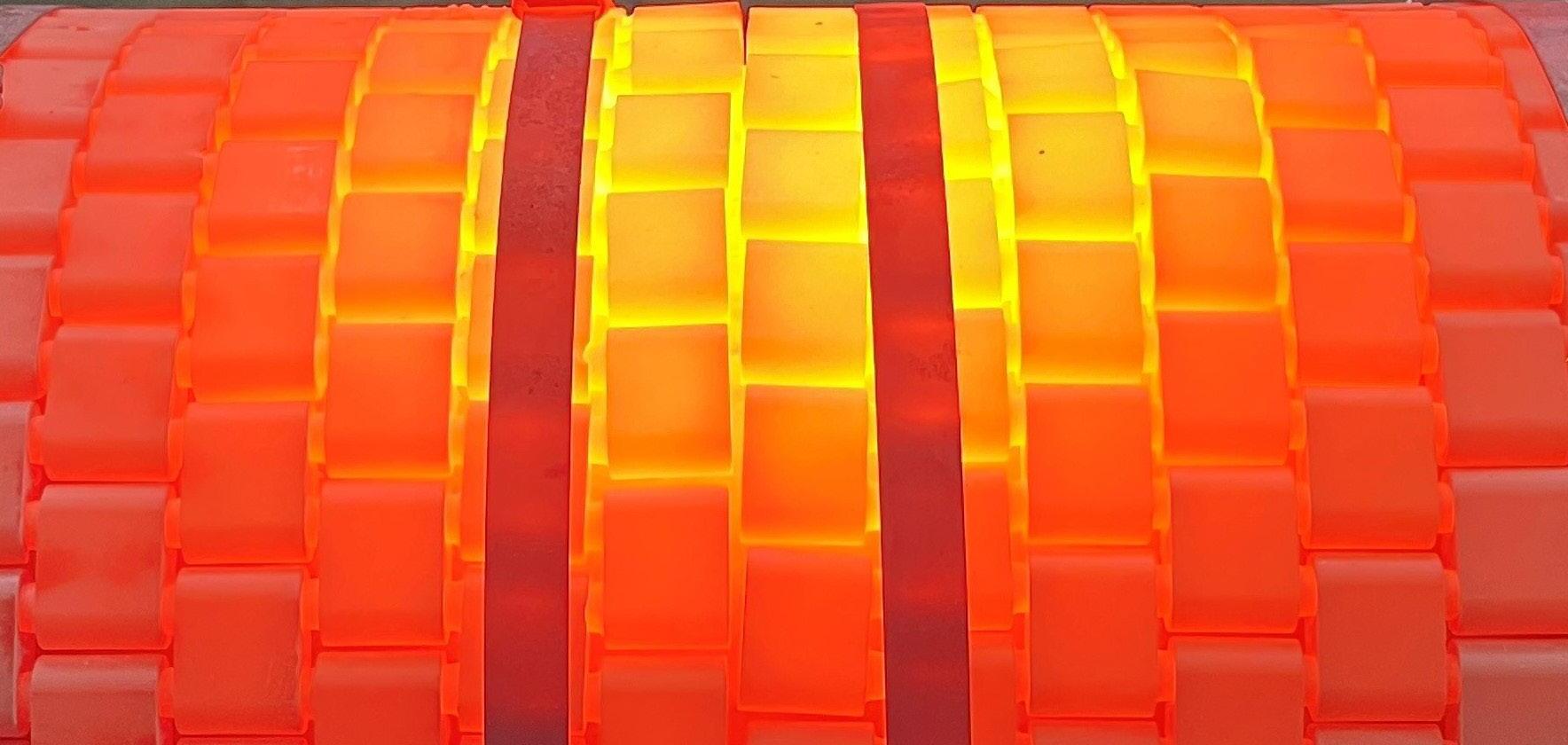

Of course, this isn’t always feasible or possible to execute in a structured way particularly during unplanned outages. Continental Field Systems, a key partner for high-quality onsite machining services such as boring bar machining and ovalised grinding, clearly showcased how critical supplier responsiveness is when they acted as a turnkey provider for more than 30 days, managing complex scopes both planned and unplanned at the Hanging Rock power plant in Ohio.

Another excellent example is Sims Crane and Equipment, a provider of critical enablers such as rented cranes and their operators. They consistently perform in a timely, highly responsive, and supportive manner. Their involvement allowed Vernova to meet customer expectations and deliver 100% on-time performance, as demonstrated at the Fort Myers power plant in Florida.

At Wärtsilä’s Bearing Centre, we bring 50 years of expertise in bearing solutions across sectors. Our 100BOND® white metal laser technology enhances bonding strength, extends equipment lifespan, and reduces downtime. Our solutions also help optimize power generation capacity and promote second life-sustainability through remanufacturing and advanced material technologies - supporting decarbonization and up to 90% GHGs reduction. With predictive behavior capabilities, we anticipate performance needs, while our continuous R&D enables tailor-made design for each application.

This drive for innovation is further strengthened by strategic partnerships, such as with GE Vernova. As a world-class supplier, we are proud to support their energy transition strategy by contributing to highperformance and reliable operations in power generation.

With strict technical specifications in place, how do your partners contribute to ensuring the highest quality standards, especially in areas like inspection, machining, and bearing repairs?

The support of our partners is vital to ensure that Vernova’s highest quality standards are properly transferred to our customers. A good example is provided by the repairs of components not originally manufactured by us, such as bearings and auxiliary equipment (e.g., valves).

In Europe, it took several years to set up a highly qualified supply base in the above-mentioned services. Finally, after careful selection and a lot of hard work from Vernova’s sourcing quality engineers, we came up with two strategic partners whom we rely upon for quality, as well as for high responsiveness and cost-effectiveness.

Wärtsilä Ibérica is our preferred regional supplier for off-site bearing repairs. They provide qualified services at their repair centers for various types of bearings (e.g., journal bearings, generator bearings, etc.), all fully compliant with Vernova’s technical specifications, in an efficient and timely manner.

Similarly, for valve repairs, Reman Europe is a critical supplier for all valve repair needs in Europe. They have become, over the years, the center of reference to reduce lead times to end customers by offering a wide array of solutions in a cost-effective way.

“We try in every possible way to integrate key suppliers into all preparation phases of planned maintenance”

GE Vernova places strong emphasis on financial sustainability. How does partnering with providers like RapidRatings help you manage supplier risk and maintain continuity in critical operations?

We always operate with the highest financial rigor to ensure that our commitments to shareholders are fulfilled and, whenever possible, exceeded. This flows through in every aspect of our activities, and we ask the same level of attention to financial performance from our key suppliers as well. This is extremely important in maintaining a healthy supply base and in avoiding the risk of disruptions or discontinuities in our service to customers.

As most of our partners are privately owned companies, it is a very difficult and labor-intensive effort to achieve a satisfactory level of visibility to monitor such risks. To help us in tracking the potential risk of supplier bankruptcies, RapidRatings provides us with a wide suite of products specifically designed for that purpose.

For example, their Financial Health Rating (FHR)® effectively maps and ranks suppliers’ default risk, as well as their medium-term sustainability index, measured through operational indicators. Particularly useful for procurement professionals with no formal training in accounting and finance is the Financial Dialogue Report, a concise summary that guides us in articulating discussions with suppliers regarding their plans to address and improve any highlighted shortcomings.

With over 75 years of combined experience, SWA is a leading technical staffing provider specializing in identifying, mobilizing, and supporting skilled trades professionals across various industries to support our clients.

SWA focuses on specific industries, which allows us to specialize our services to best fit your business needs.

Contract Hire:

Providing clients with temporary staffing solutions, allowing them to access specialized skills for specific projects or periods of increased workload.

Mobilization & Demobilization:

Handling the logistics of deploying and withdrawing personnel for projects, ensuring a smooth transition and efficient use of resources.

Direct Hire:

Facilitating the permanent placement of qualified candidates, ensuring a long- term fit for both the client and the candidate.

Payroll Services:

Managing the payroll process for temporary or contract workers, relieving clients of administrative burdens and ensuring timely and accurate compensation.

Safety & Training Compliance:

Prioritizing the safety of personnel by offering training programs and ensuring compliance with industry standards and regulations, promoting a secure working environment.

SWA, operating under the Sidewinders LLC contract, has become the first call for generator labor support, both across the US and internationally. While others operate as recruiters, SWA stands apart as a generator service provider that specializes in delivering highly trained, safety-certified skilled trades professionals, known across the industry as “winders.”

With deep roots in generator field services and a steadfast commitment to compliance, SWA brings much more than manpower. Every technician deployed is backed by GE EHS training and full approval through ComplyWorks. Whether supporting a planned outage or responding to an emergency, SWA can mobilize crews globally within 24 hours, equipped with the tools, knowledge, and experience to integrate seamlessly with GE’s internal and partner teams.

What truly differentiates SWA is its investment in quality. Through in-house training programs, SWA ensures every winder arrives on site fully prepared to contribute effectively and safely. Recently, SWA invested in over $100,000 in on-site training covering generator fundamentals, basic electrical testing, and hands-on brazing certification. Additionally, the company conducts thorough assessments of each technician’s qualifications and experience, ensuring that every outage team is equipped with a balanced mix of skills and expertise. This approach helps ensure repair scopes are completed on time and within budget.

This approach, aligned with GE’s core values of safety, accountability, and reliability, has earned SWA a strong reputation for consistent, high-standard service delivery across multiple regions, further supporting GE Vernova in meeting it’s global energy commitments.

For more information on SWA and its capabilities, visit www.swastaffing.com.

Several of your partners have mobilised globally, especially during peak outage seasons. How critical is global scalability in your sourcing strategy, and what does it take to ensure partners are ready for such demand?

High-quality support is not always available at the local or regional level especially during peak seasonal demand. We highly benefit from those partners who are willing to support not only in their usual geographical areas of operation but also overseas, and with the needed flexibility. Of course, their deployment in remote locations has consequences both in terms of timeliness in delivery and additional costs.

We reduce or mitigate such negative impacts by carefully integrating critical suppliers’ resources during the planning phase and by crafting commercial conditions that are both sustainable for suppliers and do not jeopardise our service competitiveness at the local level.

Sidewinders, a provider of generator repair services headquartered in Utah, is a best-in-class example—servicing our operations globally by mobilising highly skilled technicians across all regions. In other cases, where the needed capabilities are neither in-house nor with our partners, we rely on collaboration with specialised temporary labour agencies such as Deena Energy Services. These partners offer deeper knowledge of local markets and are able to identify the best available resources to match our needs while offering competitive solutions.

Some of your partners have been recognised at the GE Vernova Americas Suppliers Conference. What qualities do you look for when honoring suppliers, and how do these recognitions shape long-term partnerships?

To reward those suppliers who exceeded our expectations and differentiated themselves from others, we use Vernova’s Principles of Excellence: act as one team, put a relentless focus on the customer, operate with a lean mindset, drive innovative approaches, and be accountable to promises and commitments.

We have seen over several years that awarding suppliers not just with contracts and purchase orders but also symbolically by showing that we value their business and the behaviours we most appreciate has significantly strengthened relationships.

Last January, in Houston, we focused our attention on providers of testing services (e.g., borescope inspections and non-destructive testing). These types of services are usually peripheral to the core of the maintenance activity. Nevertheless, they have a significant impact on our customers because their results influence the go/no-go decision for resuming plant operations.

Applied Technical Services was awarded for their high level of accountability, which resulted in very positive customer feedback. The NDT division of Integrity Assessment Group (IAG) was also recognised for their innovative approaches to inspection solutions, tested and implemented across more than one hundred outages.

Supporting GE Vernova and the Industrial Gas Turbine Fleet for the servicing & upgrades of gas turbine accessory components globally.

Products Include:

• Gas Control Valves SRV/GCV

• Combined Gas/Stop Speed Ratio Valve

• Inlet Bleed Heat Valves

• Admission Stop & Control Valves

• Inlet Guide Vane Actuators & Controllers

• Hydraulic Ratchet & Sequencing Valves

• Liquid Fuel Stop & Bypass Valves

• Liquid Fuel Flow Dividers

• Liquid Fuel 3 Way Purge Valves sales@reman-europe.com www.reman-europe.com

From new suppliers to long-standing collaborators, how do you balance onboarding fresh expertise with deepening established relationships for long-term value creation?

Vernova is always looking to continuously improve its performance for customers. We usually achieve the needed incremental change from the existing supply base, but this is not always possible when we need to radically improve along different dimensions. In such circumstances, we are compelled to search for alternative sources of value in areas we are not fully familiar with. This effort takes considerable time, and often the chosen path results in a dead end.

Once the new source has been identified, we usually don’t proceed with a full-blown approach; we start small in a key area of focus, delve deeper into it, and later extend the relationship to neighbouring applications. The development is almost never linear or straightforward, there are often ups and downs in implementation, sometimes followed by failures that require additional efforts to get back on track.

A good example of a new partnership currently in development is ServoCon, a Virginia-based provider of hydraulic systems and controls. We are sourcing cost-efficient hydraulic system solutions from them, including services, and implementing an exchange program of dedicated solutions aimed at decreasing our lead time to customers by 90%.

Remote Visual Inspection (RVI) employs the use of borescopes, video probes, tube cameras, robotic crawlers, pan tilt zoom cameras, drones and submersibles to yield detailed assessments of critical plant systems, components, and assets.

RVI often reduces the time and effort of component disassembly necessary to support inspection activities. The work scope reduction helps to streamline unit outage or turnaround timetables and schedules. Additionally, the inspection data is immediately shareable eliminating bottlenecks and empowering timely decision making.

(989) 772-8888

RVI enables high quality data capture, clear and concise with discernable locations and orientation. IAG’s experienced team expertly utilizes the proper equipment for each application and inspection purpose, yielding rapid production rates and extensive quality reporting

Safety is a top priority at GE Vernova. How do you evaluate and align your service partners on safety performance, particularly in high-risk fields like rigging, hydraulic systems, and electrical installations?

Safety is the biggest concern at Vernova. Whether we incur incidents or not, our main goal is to ensure that all employees within the organisation, and those partnering with us, return home healthy and safe at the end of their workday.

To this purpose, our EHS department has developed rigorous procedures for any type of on-site work. For our suppliers performing hazardous on-site activities, we have devised an ad hoc program to certify them before deployment at our (or customers’) facilities. This is a thorough process, after which suppliers must demonstrate an almost perfect knowledge and mastery of our safety procedures, and they are re-evaluated on a recurring basis.

Since my first days at GE, I have always been impressed by the attention, effort, and dedication placed on all aspects of safety. I still vividly remember a fatality involving one of our electrical services contractors in Turkey almost eighteen years ago, and the deep and extensive investigation that followed.

Although the path to total safety is never complete, suppliers such as SG Energy, our key provider of electrical services and turbine status diagnostics, testify that it is possible to work safely and with the highest performance standards.

As GE Vernova continues to evolve, what role do you see partners playing in shaping the future of service sourcing, and how are you preparing to deepen collaboration in areas like digitisation and decarbonisation?

Obviously, Vernova does not operate in a bubble isolated from the rest of the world. As with other enterprises, its evolution is integrated with and heavily affected by what happens around us. The strategic blueprint needs to be constantly recalibrated.

Nonetheless, I am positive and optimistic in seeing that both Vernova and its partners are well equipped and ready to benefit from the upcoming challenges. I foresee an ever more relevant role for our service partners in the years to come. They will be more integrated not only in our planning and execution stages, but also in the commercialisation of our service solutions, providing add ons that Vernova cannot (or does not have the strategic intent to) include in its internal capabilities.

This will require from suppliers a fully open and transparent approach in sharing data and metrics to be further analysed and processed by analytical tools, as well as an expansion of their current capabilities to support a faster, leaner, and more sustainable value chain.

Companies such as K Machine Industrial Services, Applied Technical Services, and all the others I have previously mentioned have clearly demonstrated the potential for the kind of future collaboration envisioned above.

“GE Vernova and its partners are well equipped and ready to benefit from the upcoming challenges”

GE Vernova is a global energy technology company focused on accelerating the transition to a more sustainable future. Bringing together decades of expertise across power generation, renewables, and grid technologies, GE Vernova delivers innovative solutions that help generate reliable, affordable, and lower-carbon electricity. With operations in over 100 countries, the company supports the global shift toward cleaner energy through advanced technology and strategic collaboration.