6 minute read

Clearance Lamps & Reflex Reflectors

By Terry Jones, NATM Technical Director

Compliance with trailer lamp and reflector requirements continuously advances trailer safety and helps NATM Members pass their Compliance Verification Program consultation, making them eligible for NATM decal purchase and use. With this in mind, it is important to periodically review the Federal Motor Vehicle Safety Standards (FMVSS) for trailer lamp and reflex reflector requirements.

Two commonly missed items during compliance consultations are clearance lamps and conspicuity tape on trailers that require them. Trailers 80 inches wide or wider, no matter the gross vehicle weight rating (GVWR), must have front clearance lamps, rear clearance lamps, and three rear identification (ID) lamps. The three ID lamps in the middle of the rear of these trailers are meant to indicate the presence of a wide trailer. The front and rear clearance lamps’ purpose is to show the trailer’s width. The three ID lamps must be red, have a lens coding of P2 or P3, and must be mounted on the rear of the trailer – centered horizontally spaced 6 inches to 12 inches apart facing rearward. The ID lamps must be mounted at the top of the trailer, but can be mounted lower if the door header is narrower than 25 mm.

The rear clearance lamps must be red and have a lens coding of P2, P3, PC, or PC2. One must be installed on each side of the trailer that indicate the trailer’s width and may NOT be combined with tail lamps (clearance lamps may be housed within the same unit but with proper separation). They must be mounted at the widest point–symmetrical on the rear or near the rear of the trailer facing rearward. The rear clearance lamps must be mounted as high as practicable, but they may be mounted lower if ID lamps are at the top.

The front clearance lamps must be amber and have a lens coding of P2, P3, PC, or PC2. One must be installed on each side of the trailer that show the trailer’s width. They must be mounted at the widest point–symmetrical on the front or near the front facing forward, and mounted as high as practicable.

Front clearance lamps and front side marker lamps in amber, as well as rear clearance lamps and rear side marker lamps in red, can be combined into one individual lamp if the lamp is mounted on a 45-degree angle. Additionally, in this case, the lamp must have a lens coding PC or PC2, if it is to serve as both a side marker and clearance lamp. P2 or P3 lens codings in this application will not serve as meeting both requirements for a side marker lamp and a clearance lamp, even if mounted at a 45-degree angle. The lens coding are most easily verified by obtaining the product description for the lamps the trailer manufacturer ordered, which can usually be accessed from the lamp supplier’s website. If the trailer manufacturer’s intent is to mount the lamps at a 45-degree angle, regardless of the intent of combining lamps or not, they should double check to make sure they are utilizing PC or PC2 lamps in that application.

Clearance lamps are to be mounted “at the widest point” of the trailer. Due to the vague language in regulations, NATM adopted the industry standard that the widest point of the trailer is within six inches of the extreme width of the trailer. For example, if a

trailer has 10-inch fenders on each side of the trailer, and the front and rear clearance lamps are mounted on the body of the trailer rather than the fenders, the clearance lamps will not be compliant because they are not mounted within six inches of the extreme width of the trailer.

Trailers with a design where the fenders stick out from the sides in this manner can correct this issue with lamp options that are specifically designed to be mounted on fenders. One popular style is a dual front and rear clearance lamp option that mounts to the top of the fender or the side of the fender. The front half is amber and the rear half is red. Another popular way trailer manufacturers meet front and rear clearance lamps requirements is by utilizing small, individually mounted, ¾ inch bullet style lamps. In the same fashion as the dual front and rear clearance lamps, the bullet lamps must be installed so the amber lamp faces forward, and the red lamp faces rearward. Side marker lamp and clearance lamp photometry requirements can be accessed in the Guidelines in Section B-6 “Lighting/Reflectors/Conspicuity.” Lens codings on lighting are intended to indicate the light is capable of meeting prescribed photometric requirements. NATM recommends trailer manufacturers obtain testing data from their lighting supplier to ensure the lense codings are accurate.

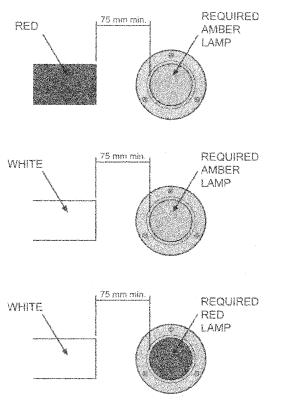

Another commonly missed item during NATM Compliance Consultations is known as the conspicuity tape three-inch rule. Trailers 80 inches wide or wider and with a GVWR of 10,000 lbs. or more must have red and white conspicuity tape marking the sides of the trailers, the rear lower body, the bumper bar or underride if applicable, and the rear upper body of the trailer. The tape must be rated DOT-C, DOT-C2, DOT-C3, or DOT-C4. Further, the edge of red conspicuity tape shall not be closer than 75 mm to the edge of any amber lamp and the edge of white conspicuity tape shall not be closer than 75 mm to the edge of any lamp. For the sake of simplicity, 75 mm is just shy of three inches (2.95276 inches), coined the “three-inch rule”.

In other words, the red and white conspicuity tape running across the rear lower body marking of a trailer cannot have the white portion of the tape closer than three inches to the edge of any lamp. This means the employee applying the tape can either cut the tape back at least three inches from the lamp or plan out the tape application so the appropriate color (red) will sit flush next to a red lamp. The same rule also applies to conspicuity tape on the sides of the trailer.

During consultations, NATM Compliance Consultants often find that production managers and employees working in the final

stages of the trailer manufacturing process are simply unaware of the three-inch rule. For any trailer manufacturer building trailers 80 inches wide or wider and 10,000 lbs. GVWR or more, this topic is worth covering in production meetings. The three-inch rule is best illustrated by Figure 12-2, Trailer Conspicuity Detail II, which can be viewed below as well as on the electronic code of federal regulations website, gov.ecfr.io.

For trailer manufacturers that have questions about other lamp and reflector requirements, the NHTSA trailer lamp, reflector, and conspicuity tape chart is beneficial in understanding and visualizing these requirements: www.One.NHTSA.gov/cars/ rules/standards/conspicuity/Trlrpstr.html. The electronic code of federal regulations website, gov.ecfr.io has additional information on Title 49 CFR 571.108 that is beneficial in understanding lamp and reflector requirements.

Table I-b, required lamps and reflective devices for all trailers is available at the eCFR website gov.ecfr.io. For additional assistance with lamp and reflector requirements, contact NATM Technical Director Terry Jones at (785) 272-4433 or Terry.Jones@natm.com.

Attention Members: ARE YOU GETTING NATM EMAIL COMMUNICATIONS?

WHITE-LIST THE FOLLOWING EMAILS TO RECEIVE FUTURE COMMUNICATIONS: @NATM.COM SAVANA@NATM.CCSEND.COM

It’s not easy to build and run a successful business. It takes hard work, persistence, and determination. We understand and work hard to be the partner you need. With a professional staff, quality products, and streamline services, Novae makes doing business easier.

By Novae®

TM

By Novae®