Newsle er

Values, company cultures and approach to project excellence. We continue to grow our presence across the United States, providing single-source, integrated construction services and a full range of project delivery methods. Building a Better World with each project.

SUMMER 2022

1820

Ames Crosta Co

Founded & Later Acquired by Biwater Services, LTD.

1866

T&C Hawksley

International engineering partnership established.

1844

Thomas Hawksley

Founder of global environmental firm MWH established practice in England.

1890 Dodd & Dodd Public health engineering firm set up in UK.

1920 Harza Engineering Energy and environmental engineering establlished.

1945

James M. Montgomery Environmental Consulting Engineers specializing in water and wastewater established in California.

1990

Montgomery Watson

JMM merged with Watson Hawksley to become the global firm of Montgomery Watson.

1996

MWH Constructors, Inc.

Began Design-Build Public Utility Work

2003

MWH

Montgomery Watson Harza became known as MWH and later as MWH Global.

2015 Slayden Construction Co.

MWH Constructors acquires Slayden Construcion Company.

2018 MWH Constructors, Inc.

MWH Senior Management lead a Management Buy-Out from Stantec, supported by Oaktree-GFI Energy, MWH Constructors, MWH Treatment (UK) and Slayden. All are now privately held, financially stronger with a bonding capacity in excess of $1B.

MWH has a 200-year legacy in the water and wastewater industry with employees worldwide. We have provided collaborative solutions through successful infrastructure projects for over 30 years. MWH is one of the largest and most successful water/wastewater-specific contractors in the U.S. We are a recognized leader in the delivery of municipal projects as evidenced by our ENR rankings. We have delivered more than $5B in water and wastewater projects in the last 10 years alone, generating a wealth of lessons learned across a wide variety of delivery methods.

1934 JD & DM Watson

Partnership formed for municipal wastewater treatment.

1978

Watson Hawksley, Ltd.

Joined to provide International Environmental Engineering Consultancy.

1993

MWH Constructors, Inc.

Established and increased revenue from $1.5M to over $200M in just 10 years.

2001 Montgomery Watson Harza

Montgomery Watson merged with Harza to create global energy, utility, and environmental engineering company.

2010 Biwater Services, Ltd.

MWH Constructors acquires UK water construction and engineering firm Biwater Services, Ltd.

2016 MWH Constructors, Inc. Stantec acquires MWH Constructors as part of MWH Global.

2021

MWH Constructors, Inc.

Acquires Methuen Construction.

We have expertise in preconstruction, construction, design-build, self-performance, commissioning and startup, digital delivery, and alternate project delivery methods. MWH has acquired iconic brands along the way to extend our family and our ability to provide the highest level of service and commitment to our clients and partners. Our commitment to delivering construction services in a manner prioritizing safety, quality, and value remains firmly in place.

Our employees are our greatest asset. At MWH we believe in our people and investing in them is our priority. Our goals include providing the tools, education, and leadership needed to be successful. We are built on our core values, hard work, and a commitment to safety throughout the or. This approach provides steady growth in work volume, successful career development, and a growing list of satisfied clients.

Welcome to this year's summer newsletter for our employees and special clients. In this edition we will highlight:

• The MWH 200 years legacy focused on water globally

• Many new hires joining the ranks of MWH

• Some great projects throughout the US

• And our continued passion of safety, quality, and technology that is Building a Better World

I hope you enjoy this newsletter and I look forward to seeing you on the jobsite.

A Word From Our President & CEO

BROOMFIELD, CO FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 2 3

MWH Constructors, Inc.

JOINING THE MWH RANKS!

ARIZONA

Autumn Auay-Fuay, Marketing Assistant

Savanna Auay-Fuay, Exec. Asst/Office Mgr.

Tom Auay-Fuay, Director of Preconstruction

Adam Bauer, Precon. Estimating Manager

Shad Bowman, Director of BD and Strategy

Andrew Carreon, Project Manager

Valerie DeLawyer, Mobility & Relocation, Mgr.

Philip Edwards, Chief Estimator

David Fagerstrom, Project Executive

Matthew Holopirek, Project Executive

Jonathan Hunt, Director of Scheduling

Bradley Lunda, Senior Estimator

CALIFORNIA

Michael Dietrick, Construction Manager

Mesadak Ezzat-Agha, Scheduler

Mario Figueroa, Project Engineer II

Cecilia Gamboa, Environmental Compliance

Patrick Hughes, Resident Engineer

Joshua Koelle, Senior Inspector

James Kreizinger, Inspector

James Mitchell, Senior Project Engineer

Vanessa Pierce, Project Scheduler

Grace Prendiville, Contracts Manager I

Zea Ranger, Administrative Assistant

Robert Savell, Engineering Manager

Garth Simkins, Inspector

Elizabeth Trueblood, Project Engineer

COLORADO

Todd Allen, Electrical Estimator

Krista Dawson, Staff Accountant

Rebecca Gloria, Contracts Manager

Janet Jacobson, Office Manager

Manuel Jurado, Carpenter Journeyman

Teel Miller, Estimator

Lorenzo Noris, Carpenter Journeyman

Iris Page, Senior General Ledger

MAINE

Justin Langlois, Project Engineer

NEW HAMPSHIRE

Steven Striffler, General Counsel

OREGON

Khaled Abou-Zeiter, Regional Manager

Ashleigh Beck, Construction Intern

Brandon Burbank, Laborer Group 2

Chad Carlson, Yard Support

Nicholas Cunningham, Laborer Group 1

Curtis Fenner, Asst. Project Manager

Anthony Garner, Construction Intern

Brian Goetz, Truck Driver

Paul Grady, Senior Project Manager

Dmitry Hice, Laborer Journeyman

Adam Horecki, Senior Project Manager

Joel Knight, Operator Group 5

Jason McCarthy, Project Manager

Jacob McIntire, Laborer Group 1

Garrett Miller, Laborer

Daniel Newsome, Health & Safety Mgr.

Erik Pederson, Carpenter Journeyman

Emma Pietrok, Laborer Group 1

James Rowland, Project Coordinator

Aaron Schomus, Laborer

Zachary Schultz, Carpenter Group 1

Wyatt Sherwood, Construction Intern

David Sullivan, Operator Group 6

Konrad Twarowski, Carpener-Craft

Wayne Welch, Laborer

RHODE ISLAND

Sammie Jacobs, Inspector

Andrew Latosek, Inspector

TEXAS

Amanda Aldrow, CSU Intern

Alexander Dockwiller, Intern

Roman Gonzalez, Leadman 2

Michael Huffman, Crane Operator

Robert Mitchell, Director of Engineering

Michael Moreno, Pipe Layer

Ramon Rodriguez, Intern

Jim Snowden, Superintendent

William Taylor, Civil Estimator

WASHINGTON

Charles Hosley, Laborer Group 1

Barry Morris, Proposal Manager

Donald Sorensen, Asst. Project Manager

MWH Constructors / CONTENT JOIN #TEAMMWH IN BUILDING A BETTER WORLD MWH welcomes new team members. Building A Better World isn't just our tagline, it's the heart and soul of our work. We are seeking certified professionals to provide leadership and support for projects involving cutting-edge technology and helping us exceed our goals in growth and development coast to coast. Rise of Technology - Digital Delivery Is Here New Portland Water Filtration Online Safety by Design - Zero Incidents Zero Lost Time Saco River Water Treatment Facility - Maine Water Culture & Community - Company Highlights Logan Regioinal Wastewater Treatment Facility 6 10 12 16 18 22 26 CONTENT

Welcome to our Summer Edition! With the extra hour of daylight and warmer temperatures, construction is in full bloom. MWH Constructors provides clients with improved construction technology and assures facilities operate trouble-free and on schedule for decades DIGITAL DELIVERY, TECHNOLOGY Making new and existing operations smarter and construction decisions efficient through preliminary explorations WE'RE HIRING! FOR OPEN POSITIONS COAST TO COAST For latest available positions contact: John Caskey, Recruiting Manager

FOUNDATIONS NEWSLETTER 5

TECHNOLOGY IN CONSTRUCTION Digital Delivery Is Here

Digital tools democratize the construction information and empower team members to innovate. Stakeholders including construction staff, clients, end operators, and trades can review models and share their construction expertise with design teams to improve design changes prior to beginning work on site.

Rise ofTechnology

Digital Delivery Is Here

Specialization of Virtual Design and Construction. Employing programming to aid in the process of analyzing, creating, managing, and optimizing 3D models throughout the construction and design process

From the Stone Age to the current digital age, the construction industry has continually evolved. The industry has regularly faced challenges to deliver sustainable, safe, environmentally friendly, and cost-effective solutions to society and our clients.

MWH is at the forefront of this evolution in the water sector. Maintaining the principles of continuous improvement to Building a Better World, MWH has the vision to deliver construction solutions and exceed expectations. As a part of achieving this vision, MWH embarked on the journey to adopt Building Information Models (BIM) and digital construction tools.

The early project success achieved using digital tools (BIM) led to the creation of a digital delivery team. This team built the Digital Delivery process and implements this process to provide support services to our clients and project teams. The adoption of digital delivery tools transformed and enhanced the construction delivery processes.

MWH continues to invest in and explore various Digital tools (BIM) that can be used effectively on projects to improve collaboration, productivity, safety, and the wellbeing of its staff.

MWH Constructors / DIGITAL DELIVERY

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 6 7

What is Digital Delivery?

Digital Delivery is the application of digital tools and technologies to improve the construction process. This translates to delivering successful projects through increased collaboration, providing safer working practices, improved productivity, and well-being of project personnel.

Benefits to Project Construction

Digital delivery enhances every aspect of the construction process including Design, Estimation, Scheduling, Information/ Document Management, Site Logistics, Construction/Installation, Commissioning, and Startup all the way to Asset Data Management.

Digital delivery utilizes various BIM tools such as 3D models, 4D Schedule, Laser scanning, Drones, Virtual Reality, and Augmented reality tools to harness the intelligence embedded in the design models issued from the Clients and provides certainty.

Visualization and Collaboration

The goal is to encourage exploring the synergies between scientific and information visualization to integrate spatial and nonspatial data. Simplified, introducing BIM in the beginning phase of the project lifecycle greatly assists through design, construction, and operation. The 3D CAD model opens interesting opportunities to correlate between digital and physical worlds. The model acts as the main connector between all relevant data throughout the facility's lifecycle. MWH uses

Estimation & Clarity

See project plans and data development in real-time. Empowering teams to make better business and building decisions and create a deep understanding of the project

this data to develop innovative solutions and gain a competitive advantage throughout each phase of the project.

Virtual and Augmented Reality

Essentially, BIM uses the 3D CAD model as a high-fidelity digital replica of the construction project. The 3D models are overlayed in real-world spaces to create a composite view of what currently exists with what construction is required. It allows engineers, designers, and construction teams to find conflicts and resolve them digitally before being faced in the real-world installation, thereby reducing change order cost and collaboration on improvements. With augmented reality, applications range from tracking construction progress to assisting

in maintenance works of operational facilities.

Digital Delivery provides benefits to all stakeholders on a project. MWH Constructors’ projects involve several construction disciplines: structural, mechanical, electrical, etc. Each stakeholder performs a different analysis using different information but can use the same BIM dataset.

Implementing digital delivery is no additional cost, it is an efficiency center enabling early risk identification, cost accuracy, improved scheduling, safety enhancement, and overall wellbeing of the project and those involved.

EARLY UTILIZATION

LASER SCANNING 3D MODELING MODEL COORDINATION 4D SIMULATION CONSTRUCTABILITY REVIEW DIGITAL REHEARSAL CONSTRUCTION SUPPORT

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 8 9

Digital Delivery Process Flow

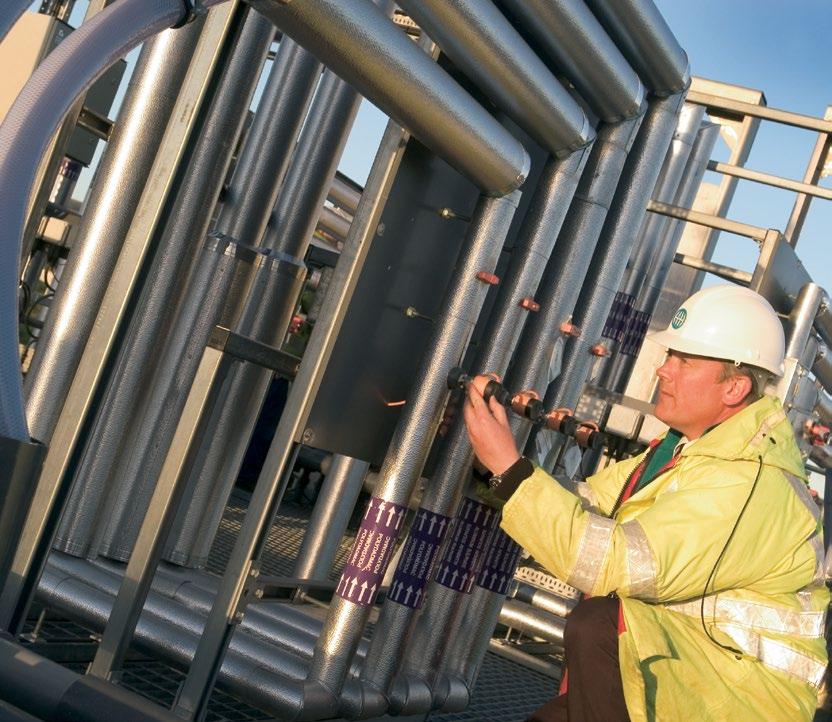

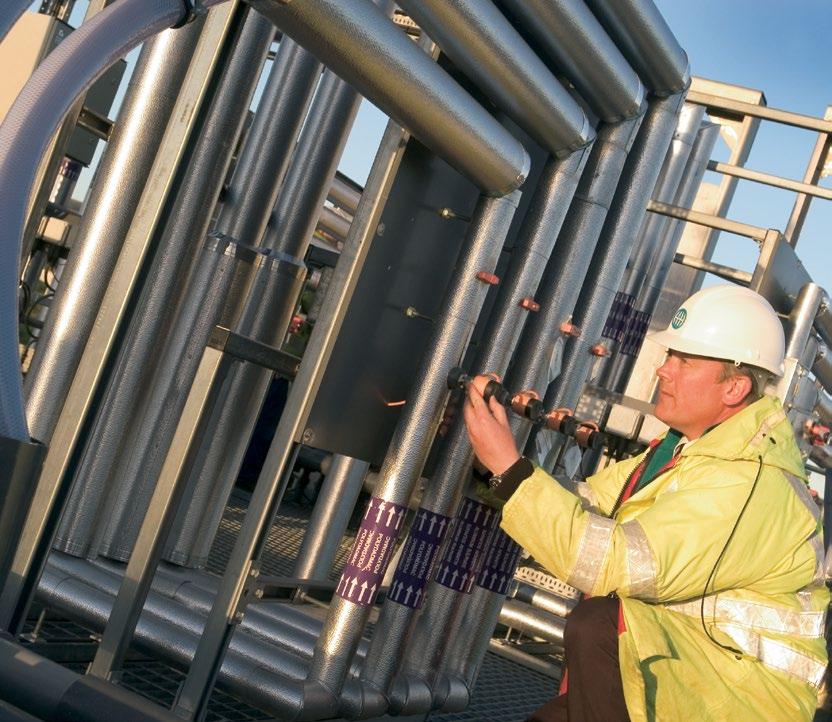

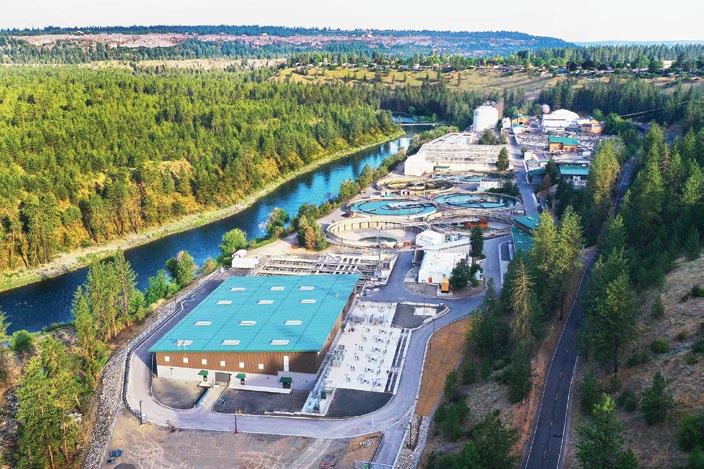

NEW PORTLAND WATER FILTRATION ONLINE

New corrosion control treatment facilities at the Portland Water Bureau's Lusted Hill Treatment Facility comes online.

Filtration Project

The Portland Water Bureau completed upgrades to its Lusted Hill Treatment Facility intended to reduce lead exposure in residential drinking water.

With the improvements, the system now uses sodium carbonate and carbon dioxide to increase the pH and alkalinity of Bull Run water, making it less corrosive to the older plumbing found in some of the homes and businesses throughout the community.

MWH Constructors served as general contractors for the project. The upgraded treatment system came online at the end of April 2022.

The project team exceeded equity contracting goals, according to the Water Bureau. More than $4M, or approximately 55% of the project's hard construction costs, was subcontracted to firms certified by Oregon's Certification Office for Business Inclusion and Diversity (COBID): The city's goal was 22%.

More than 11,000 work hours were performed by minority or women apprentices and journey-level tradespeople; this participation percentage exceeded the city's goal of 31%, stated the Water Bureau.

One percent of the contract dollars were invested in the city's Community Opportunities and Enhancement Program providing grants to increase the diversity of construction industry business owners and tradespeople in Portland.

"The Improved Corrosion Control Treatment Facility is our strongest tool yet to make drinking water safer for everyone, regardless of the plumbing inside their home, school, and building." Water Bureau Director Gabriel Solmer stated in a news release. "I am proud of our dedicated water quality and operations teams who have honored our commitment to the community."

The project was financed in part by a Water Infrastructure Finance and Innovation Act loan from the U.S. Environmental Protection Agency. That money helped maintain affordable water rates, the bureau stated.

The Water Bureau is planning to build a new plant to filter out cryptosporidium from the drinking water, which can be a harmful microorganism. Construction is expected to begin next year. The plant must be online by September 30, 2027, to comply with state and federal rules.

The Portland Water Bureau has improved water treatment to help protect the health of nearly a million people who drink Bull Run water.

Bull Run River

Just 26 miles east of downtown Portland lies a beautiful, temperate rainforest full of centuries-old trees, glistening streams, and rushing rivers that provide most of the city's drinking water. Most have never seen it up close, but in its 102 square miles, the Bull Run Watershed touches the lives of Portlanders every day with its abundance of nature's most important resource.

Although this fresh, natural water source is tapped straight from the river, it takes a lot of human ingenuity and management to turn it into drinking water. The filtration facility is designed to filter 135 million gallons of water per day.

BULL RUN WATERSHED

Located less than thirty miles east of Portland, the Bull Run Watershed's unique geography and rich history make it an iconic part of the story of Portland, Oregon. It serves as the primary drinking water supply for nearly one million people in the Portland metro area.

CMAR PROJECT BY MWH Constructors COURTESY OF Portland Water Bureau SOME WORDS BY Chuck Slothower, DJC Oregon

PORTLAND WATER BUREAU

THE BASICS

CMAR PROJECT BY MWH Constructors COURTESY OF Portland Water Bureau SOME WORDS BY Chuck Slothower, DJC Oregon

PORTLAND WATER BUREAU

THE BASICS

PORTLAND / MWH Constructors FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 10 11

WATER INDUSTRY SAFETY

Modern Practices

Sustainable practices in worker safety and understanding the risks these essential workers face on a daily basis is only the first step. Common risks in the water industry include: High Voltage, Contaminated Water, Poisonous Chemicals, Toxic Gasses, Encounters with Traffic, Working in Confined Spaces, Falls, Drowning, etc.

Safety by Design

At MWH, safety is implemented as part of the design process to minimize hazards and reduce risks to employee and public health throughout the lifecycle of a project. Our goal is zero incidents for every project. To achieve this, one of our core values is: If we see something, we say something.

We have already begun the safety by design process with our SafeStart Program. This program addresses all the hazards we have identified through lessons learned over the past 25 years. Everyone is empowered to stop any unsafe work activity. Each level of management is responsible for demonstrating safety leadership, providing a safe work environment, and promoting safety as a value. We believe mutual support is an essential part of creating a strong safety culture.

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 12 13

ZERO INCIDENTS MWH Constructors / SAFETY

Assessment and mitigation of hazards that can arise during construction, operation and maintenance.

WORKING LIFE

Remain Connected Be Supported, Stay Safe were just a few of the topics reflected on during Construction Safety Week.

SAFESTART

Daily Job Safety Analysis (JSAs) – JSAs detail the potential hazards and mitigation procedures for each task undertaken in a project and are reviewed twice daily or whenever crews switch tasks. A new task cannot be started until everyone on the crew has reviewed and understands the JSA.

Safety Training Programs – MWH has several programs we use to ensure our crews are aware of hazards on the project site and are prepared to deal with any emergencies that might arise. All workers are required to complete an OSHA 10-Hour Construction Industry training within 90 days from the date of hire. Specialtytype training is also required for employees involved in high-risk activities, like confined spaces and trenching/ shoring. Training of workers who have English as a Second Language is also offered in their native language (typically Spanish) to ensure understanding of the Safety Program.

Craft Safety Involvement Program – Our subcontractors are required to establish a safety program to enhance craft involvement in safety, allowing their crews to partner more closely with management in day-to-day safety oversight

Safety Statistical Tracking System – All contractors use the same safety tracking system/software to track injuries, incidents, and deficiency findings from site safety inspections. The use of one system allows for greater efficiency, compiling statistics in one place to create a more comprehensive view of the project. Safety personnel is required to perform and document one inspection for each shift where work is occurring, while supervision is required to complete a minimum of one per week.

Know Your Task

Identify Your Risks

Eliminate the Hazards

PROJECT SAFETY

Our safety culture is essential to our identity as MWH. We have an unwavering commitment to our team members, their families, and the communities we are a part of to prioritize safety in everything we do.

Every day is an opportunity to recognize our hardworking professionals at MWH who work diligently to ensure we have access to clean drinking water and safe wastewater treatment. We are thankful to all of our employees, subcontractors, and vendors who have committed to safety on the job site and as a way of life.

Safety Meetings – An extensive All Hands Safety Meeting is required once per week for all employees. This is in addition to each crew’s daily safety briefing. We host joint safety meetings weekly with our partners and clients to review incidents and deficiency findings from the previous week. Our Safety Managers and representatives for all subcontractors participate.

SMBWA (Safety Management by Walking Around) –MWH leads a weekly SMBWA with subcontractor management to conduct site inspections and audits. The primary objective is to observe workers, reinforce correct behavior, and modify unsafe practices in an effort to achieve an incident and injury-free work environment.

Improve It Program – Improve It is a proactive safety program that empowers workers to identify and immediately correct unsafe conditions, making each individual accountable for the safety of all on-site.

Digital Delivery – Through the use of digital delivery, MWH can review site plans in real-time, pinpointing potential hazards and creating work plans that minimize safety issues.

SAFETY / MWH Constructors

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 14 15

ZERO LOST TIME

At MWH, our priority is for everyone going home safe. Safety is never compromised for expediency or short-term savings. In January 2022 our Phase III-B Solids Management Improvements project team for the Trinity River Authority in Dallas, Texas reached one million man-hours with zero lost time accidents. Trinity River Authority’s Central Regional Wastewater System plant began operations in 1959 as the first regional wastewater facility of its kind. The system is now one of the largest in Texas and has expanded to serve approximately 1.2 million people, providing treatment for 162 million gallons a day (MGD). The treatment process removes 99% of conventional pollutants from raw wastewater and can handle daily maximum flows of 335MGD and two-hour peak flow maximums of 405MGD.

In 2017, MWH was awarded the contract to provide construction and startup, and commissioning support for the Phase III-B Solids Improvements project. This will replace the lime stabilization process with the Cambi® Thermal Hydrolysis Process (THP), an innovative solution to wastewater management producing higher quality biosolids while capturing and treating odors more effectively, and maximizing biogas utilization to produce fuel for steam generation. MWH has significant expertise in the design, construction, commissioning and startup of CambiTHP™ systems. Out of 50 CambiTHP™ systems currently installed worldwide, MWH provided services on more than twenty.

Congratulations

Solids Processing Building Improvements Project finished in 2021 with 350,000 man-hours without a single recordable incident. The project increased treatment plant reliability and the dewatering capacity, giving the Owner and the community peace of mind that their utility services will run smoothly and efficiently well into the future.

METRO DENVER PAR 1244 PROJECT

PROJECTS / MWH Constructors

TRA Phase III-B Solids Improvements Projects Dallas, TX

Metro Denver Par 1244 Denver, CO

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 16 17

Metro Denver Par 1244 Denver, CO

Constructors

Resiliency & Sustainability

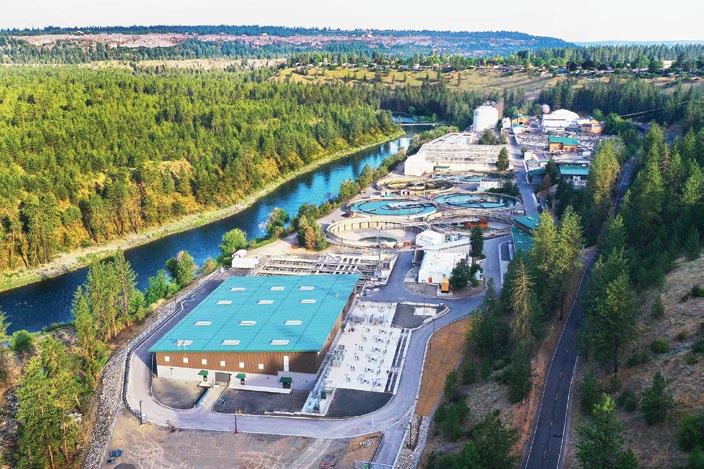

SACO RIVER DRINKING WATER RESOURCE CENTER

Privately held Maine Water Company constructed a new 12 MGD drinking water resource center to replace the existing facility built in 1884.

After a year of working with another CMAR to value engineer their new drinking water resource center, Maine Water was still unable to find a design to fit within their budget.

Maine Water revised the team and after some high-level value engineering was performed, they sent the project out to bid again. MWH was selected as the new CMAR firm based on our 30% estimate of the revised plans.

To keep the revised design within Maine Water's $50M budget, MWH conducted a series of value engineering workshops.

BIDDEFORD, ME CAMP ELLIS HARBOR

The new drinking water resource center is located on South Street in Biddeford, across the street from Maine Water's existing facility. As part of the project, more than 250 acres of forest land will be preserved to provide the community with access to open space, protect the Saco River source, and preserve valuable wetland habitat. The new location also allowed Maine Water to move this important drinking water facility out of the Saco River flood plain, which eliminates the risk of disruptions from flooding.

MWH Value Engineering Resulted in Savings

"Engineering studies have confirmed that building a new treatment facility is a costeffective alternative to renovating the existing facility over a 50-year planning horizon.

Maine Water is committed to investing in our communities and providing the infrastructure necessary for sustainable, reliable, highquality water service," said Maine Water President Richard Knowlton.

Maine Water's drinking water resource center originally had a $50M budget. Through value engineering efforts, we saved $4.5M without sacrificing quality or value. VE items included saving $1.3M by using insulated metal panels instead of pre-cast panels for the building envelope, $1M by installing the HDPE intake pipe for the raw water pump station via directional drilling, eliminating the need for extensive sheet piling, and additional savings in HVAC value engineering, procurement costs, a dual cell cast-in-place concrete tank replaced with a larger pre-stressed tank, eliminating unnecessary interior masonry to reduce schedules, and roofs over clearwell and backwash tanks were revised to precast planks.

SACO

MWH

RIVER /

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 18 19

SUSTAINABILITY Drinking Water Resource Center

"The new Saco River Drinking Water Resource Center is a key infrastructure asset for the Biddefored-Saco community." "Maine Water and its project partners deserve to be commended for their conscious design efforts to respond to near-and-long-term community needs, while rehabilitating environmental functions and the reliance of the facility as the primary drinking water facility for teh Biddeford-Saco region. This Envision Silver Award is testament to Maine Water's leadership and commitment to sustainability."

-Melissa Peneycad, ISI Managing Director

MAINE WATER

Throughout the process the MWH team remained focused on best value solutions rather than simple scope or quality reduction, resulting in a Value Engineering savings of over $4.5M.

The project received an Envision Silver award for sustainable infrastructure. This the first project of its kind in New England to achieve that level of certification.

The 12MGD drinking water facility replaced an aging plant across the street that was originally constructed in 1884 with the most recent significant upgrades to the facility in 1936. The new facility is expandable up to 18MGD and includes a raw water intake from the Saco River, raw water transmission and pumping equipment, chemical feed and storage facilities, prefiltration solids removal, filtration and disinfection processes, residuals handling and disposal, finished water storage and pumping, and a connection to the existing distribution system.

40K Residents Served

Maine Water takes pride in providing customers with clean, high-quality water that is locally sourced, locally treated, and managed sustainably.

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 20 21

Culture & Community

OUR COMPANY HIGHLIGHTS

As mentioned in our July All Hands Meeting, Words Matter. Sometimes we need a reminder to slow down and pay attention to the details. Life can be fast-moving at times, but we should not sacrifice the little things. As the old idiom goes, "The devil is in the details." Expressing the idea that whatever one does should be done thoroughly; that is, details are important.

Agreements & General Communication

Be precise in your words, a lack of clarity comes from unclear thinking or poor planning; this, unfortunately, can lead to negative results. The Project Delivery System is a library of Standard Operating Procedures along with attachments, templates, forms & examples. This is provided to assist you in the delivery of your project and ensure you are following MWH policies.

MWH provides numerous resources on our H20 site not only to support our team members’ skills and purposes, but we believe in arming you with the knowledge to assist in a positive and productive work environment. Our HR department is available to support not only new MWH team members but seasoned staff as well. The HR team can answer questions or direct you to who can answer questions. Feel free to reach out anytime.

WE'RE HIRING!

FOR OPEN POSITIONS

COAST TO COAST

For latest available positions contact: John Caskey, Recruiting Manager

JOINING THE RANKS OF MWH

Proactively seeking qualified candidates to support and lead efforts in critical water, wastewater, and advanced water treatment plant projects across the nation. Check out our career opportunities on our website mwh constructors. ourcareerpages.com

JOIN #TEAMMWH

MWH NEW WINS!

SLAYDEN

OR - Medford Duff Filters WTP - $50M CMAR

EAST

MA - Somerville Poplar St. Pump Station - $100M CMAR

INDUSTRIAL

OR - ADI Tool Install Program - $80M CMAR

OR - ADI 24k Cleanroom Project - $70M CMAR

OR - ADI UPW/AWN Building Upgrade - $40M CMS

CA - Palm Springs WWTP Digester 2 Improvements$1.27M CMS

GREAT OPPORTUNITIES FOR 2022!

YOU

SLAYDEN - Over $200M in CMAR

METHUEN/EAST - Over $200M in CMAR

INDUSTRIAL - $50M in CMAR

ADVANCED TECH - Over $1B in CMAR/PDB

TEXAS - Over $700M in CMAR/PDB

CALIFORNIA - Over $700 in DB/PDB

CMS - Over $50M in CMS

MWH CONSTRUCTORS NEW WINS & OPPORTUNITIES!

Proactively seeking the support of others does not make you appear weak or vulnerable. A great leader could not be a leader without a team to lead. Never fear letting go of the reins and allow others to support you in meeting goals. Define what you need and what roles others could play. Ask yourself what the critical needs for each of your goals and objectives for success are. Set yourself and your team up to win!

MATTER Support. MWH. Team.

CULTURE & COMMUNITY /MWH Constructors

NEW TEAM MEMBERS

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 22 23

MWH HAS A COMPANY STORE!

This program is for individuals who want to purchase MWH Gear This program is not meant for bulk jobsite orders, we have alternate resources for those. For any questions, please contact Customer Service at +1 800 486 8677

TO ORDER, PLEASE VISIT:

https://www.spor texsafety.com/shop/mwhconstructors

THE OFFICIAL GEAR STORE OF

SUMMER TEMPS

HYDRATION AND HEALTH

Proper hydration is essential to prevent heat-related illness. For those working two hours or more, access to additional fluids containing electrolytes is important. Water, Rest, and Shade. Before you begin construction work, drink two cups of hydrating fluid, then a cup every 20 minutes on average during your day. Carry a portable water bottle when possible. Take breaks as needed in the shade to rehydrate.

When we lose too much fluid, the body protects itself to maintain the most important bodily functions. Kidneys start retaining water, the blood thickens, and the body slows or stops the process of sweating, which makes it hard to regulate internal temperature and can cause heat stress. Common signs of dehydration include thirst, dry mouth, fatigue, headache, yellow or orange urine, and dizziness, but it can be felt and seen in many other ways too. Muscle cramps, dry skin, confusion, sunken eyes, lack of energy, and irritability are all symptoms of dehydration. Stay hydrated.

MWH METHOD PROGRAM

Mentee Experience Through Hands-On Development

MWH is committed to supporting, fostering, and investing in individual and company success through a culture of opportunity, mentorship, and innovation. To achieve this, we have created the MWH METHOD Program. Designed for rising stars in our organization with less than 5 years of experience with MWH and is targeted to employees who primarily work on projects. The MWH METHOD Program will identify, engage, develop, and retain our top talent for future leadership sustainability

https://mwhconstructors.sharepoint.com/sites/HumanResources/SitePages/MWH-Method.aspx

TIMECARDS & DIRECT TIME CODING

Step-by-step guides on H2O for Timesheet Training. Every employee must complete a timecard weekly. Timecards (Completed & Approved) are due Mondays at 9 am MST. Payroll cannot process until all timecards are submitted and approved.

Also, on H20 is a detailed guide to Understanding Your Paystub. Paystubs are sent via email from Gail Newburger. Check benefit deductions, 401(k) contributions, state withholding, and address.

MENTAL HEALTH AWARENESS

Did you know? The suicide rate in construction occupations is 5 times greater than that of all other construction fatalities combined. The construction industry has the second highest rate of depression and suicide in the United States. Don't ignore it - Speak up if you're worried about yourself or another. MWH wants to provide all employees with resources and tips to recognize the signs and symptoms of an employee who may be experiencing mental health challenges or any issues. MWH offers a great Employee Assistance Program (EAP) free and 100% confidential. Contact HR

HYDRATE ALL YEAR

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 24 25

Logan Regional WWTF

"MWH was instrumental to our project as initial project costs greatly exceeded our peliminary budget. Through collaboration between us all, the value engineering efforts that MWH completed yielded more than $34M in savings! A true Success."

-Mark Nielsen, Project Manager City of Logan

Value Engineering = Savings

LOGAN REGIONAL WASTEWATER TREATMENT FACILITY

When someone is asked about the most memorable aspect of a project, it is often the people.

The Logan Regional Wastewater Treatment Facility was successfully completed this summer. In reflection, the team wanted to share why the project was successful and encourage everyone to repeat and expand on positive wins

The People

When someone is asked about the most memorable aspect of a project, it is often the people. We are ultimately a business-driven and directed by people. There were significant participants in the Logan project. The City of Logan’s Representatives, Carollo Engineers, the subcontractors, vendors, and MWH staff were all contributors to ensuring the success of the project.

Within MWH, the team was deliberate about focusing on the success of the project. Members understood that everyone brought strengths and weaknesses to the unit. Strengths were optimized and weaknesses were supported. For example, one of our most senior Project Managers leads the administration of preconstruction and contract execution. The Construction

MWH Constructors / LOGAN

LOGAN, UT

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 26 27

Manager unified the internal team as well as all the subcontractors to a common cadence. Neither individual would excel in opposing positions but would collaborate daily to ensure the project goals were always met.

Success at this level requires knowing one another. We built our team by deliberately getting to know one another as individuals. The team has often referenced ourselves as a family. We each knew the personal wins and losses of one another and supported each other well outside of working hours.

The entire project team, including the owner, engineer, contractors, and vendors were inundated with a constant reminders about communication. Good news and

bad could be managed if it was fresh. We all knew that old news usually meant something unpleasant that had escalated. Transparency was key. Trusting one another to focus on the issue and not the messenger was critical to keeping issues small.

Carollo was led by a senior member in the Salt Lake area. His willingness to actively engage with MWH and the City of Logan was representative of the style of professionalism we all enjoy. He crafted the Carollo team to ensure effective and responsive engineering was dedicated to the project. Construction administration of submittals and RFIs were often expeditious for the success of the project. These items would be discussed weekly to ensure the team’s priorities were met. When questions

LOGAN, UT Team

Colaboration

The communication and project management approach emphasizes teamwork, innovative thinking, and equal participation to achieve objectives.

were raised, he allowed MWH to contact his staff directly. Again, he could trust that construction issues were worthy of the engagement and were ultimately focused on our common goal of a successful project.

Logan City utilized its Public Works Director as the project representative. Mark Nielsen stepped out of his director position to be the on-site project manager. This move was instrumental in decisionmaking. As a singular point of contact, Mr. Nielsen was able to call upon the different parts of the City’s team to assist in the largest single project the community had ever contracted. He would maintain communication with the State’s financial oversight, work with Carollo on design

issues, maintain a field presence, and generally receive the respect of every individual associated with the project.

Finally, the subcontractors and vendors of the project were highly engaged and dedicated to its success. Many of the subcontractors were local to the Logan area, many more were from within the region, and all of them were from Utah. Soliciting local contractors was very important to the City. The contractors that were selected knew this importance and took pride in their contribution to the greater picture. Everyone understood the importance of this facility to the local community and wanted to ensure their part would become a reason for the project’s success.

"May the roof above us never fall in. And may the friends fathered below it never fall out."

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 28 29

— LUKE SKYWALKER

The Process

The City of Logan previously utilized 490 acres of ponds as the primary treatment of wastewater. A twoman operation, the ponds would simply allow water to migrate through a series of lagoons. Although the water appeared clean, testing demonstrated levels of nitrogen and phosphorous that exceeded EPA limits. This was common throughout Utah plants. Due to the nature of the lagoon system, Logan elected to pursue the design and construction of a new facility.

The new Logan WWFT utilizes an industrial technology that has never been used on a wastewater system this large. BioMag is a product by Evoqua. The premise of the BioMag system is to create a ballasted sludge. By creating an environment where sludge is heavier than a standard process, sludge can be separated from the stream faster, requiring smaller clarifiers and ultimately reducing the plant’s overall footprint.

The plant itself consists of a headworks with fine band screens, grit removal, and influent pumps. From the headworks, influent is pumped approximately one mile to the three bioreactors. The bioreactors aerate and zone the water for nitrification. From the bioreactors, water flows to the clarifiers. The clarifiers allow clear water to flow out to the UV disinfection and out of the plant. The remaining heavier sludge is pumped to either the beginning of the bioreactors or is redirected to the BioMag equipment.

BioMag is introduced to the sludge (RAS) that is returned to the bioreactors. BioMag is a black powder, like iron, that allows sludge to create microscopic floc. To recover the powder, Evoqua utilizes a system that breaks the floc apart and extracts the magnetite with magnets. The recycled material is supplemented with new magnetite and is fed back into the sludge stream going to the Bioreactors. The broken floc is pumped to a solids holding tank.

Finally, the wasted sludge is pumped from the solids holding tank into the thickening building where polymer is added and the sludge is squeezed to create a waste cake. The solids are then hauled offsite.

BioMag is a black poweder, like iron, that allows sludge to create microscopic floc

Safety and Quality

Construction is a dangerous business. The industry has a depleting workforce of skilled tradesmen. It is important to actively engage with the people doing the work to ensure they understand the nature of the risks involved. After understanding the risks, planning and executing the work safely must be a vigilant pursuit.

At the Logan WWTF, MWH worked with our subcontractors to educate and monitor the work for safety and quality. Planning work ahead of the crews allowed efficiencies for the teams. When the workforce habitually is successful, the pride in the work increases and key performance indicators improve. Here are some notable items:

• ZERO lost time accidents

• Daily Job Hazard Analysis for each crew

• 3 recordable injuries in 43 months

• 19,552 Improve its

• ZERO failed third-party inspection

• Nearly 1000 independent inspections of concrete strength, pipe, and concrete structure water leakage

• Finally, a minimal punch list. The team made every effort to monitor the quality of the project at each step of construction. By ensuring that each phase of work was completed and accepted by the next trade, any potential issues could be addressed immediately with the most knowledgeable team. This minimized the time to make corrections and kept crews moving forward. By taking care of items immediately, the crews kept moving forward – perpetuating a winning spirit.

Accidents

It is important to actively engage with the people doing the work to ensure they understand the nature of the risks involved.

LOGAN / MWH Constructors

CITY OF LOGAN BioMag

LOGAN TEAM Zero

Lost Time

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 30 31

LOGAN, UT

Innovative Thinking

"If everyone is moving forward together, then success takes care of itself." ~ Henry Ford

Innovation

The best builders are problem solvers. The premium builders have the foresight and prevent problems. Anticipating issues and presenting them to the team allowed collaborative environments of engagement.

There were some notable innovations executed in Logan.

Driving the schedule required the Construction Manager to review the Master Schedule and disseminate the sub-steps. The CM would work with the subcontractor superintendents to forecast anticipated activities and crew commitments. This information was verified with the crews in a daily morning meeting. The environment allowed the crews from different subcontractors to voice their work plans and cooperate with one another. All parties knew their supervisors had already worked out the general direction and priority. The MWH superintendents could then assist with plan execution, building momentum of success upon success.

Long-term material storage has the potential to be forgotten or minimized when the exciting action is at the workface. MWH worked diligently to time deliveries to be within a month of planned installation. Inevitably, schedules change, and equipment may be on site for a length of time. The MWH project engineers created meetings with reminders to notify the responsible teams to do maintenance on the equipment. The maintenance was based on the long-term storage requirements provided by the manufacturer. Logs were created that were signed off with autographs ensuring the vendor and MWH that proper maintenance was completed in a timely manner.

During construction, a concrete structure needed to be constructed around the existing influent pipes. Flow from the two 48” Reinforced Concrete Pipes needed to be bypassed with pumps. The entire wastewater stream of the community was pumped for one month. This work was performed in the middle of winter in northern Utah. Temperatures were always below freezing. The plan was collaborative with the City, Carollo, and the subcontractors to minimize the risk of failure. From the plan, the crews met daily goals ensuring exposure was mitigated. Upon completion of the work, MWH had large concrete slabs precast on-site to plug flow from entering the new Headworks. Wastewater resumed its flow, through the new structure, for over a year. When the new plant was ready to accept wastewater, the precast concrete slabs were lifted out and the influent was able to enter the new construction exactly per plan.

Winter construction in Logan Utah adds an element of difficulty due to a typical inversion that traps colder than normal temperatures in Cache Valley. The construction team reviewed the work and determined a change in sequence would be beneficial. During the summer and fall,

MWH Constructors / LOGAN

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 32 33

LOGAN, UT Planning the Scope

By engaging the selfperform superintendent months in advance, material and equipment were procured and on-site before the crew arrived.

concrete slabs were prioritized over walls. Heating and conditioning concrete walls in the winter were much more manageable than large slabs. By recognizing this constraint early, the overall schedule was maintained and improved.

A brand-new facility requires a lot of construction material handling. Cranes are the most effective way of transporting material and equipment from a staging area to the work. MWH coordinated with RL Wadsworth to utilize their cranes. Wadsworth was able to provide traditional lattice boom crawler cranes as well as a new mini tower crane. Changing cranes out maintained efficiencies for all the subcontractor crews.

Some of the structures were evaluated for constructability. In some cases, different construction joints in the concrete would improve how safely the sequences could be built. Carollo worked with MWH and the subcontractors to evaluate and verify changes to the design. This work allowed the work to be installed in a manner that protected people and the new structure.

Lastly, MWH self-performed a scope of mechanical installation. The scope was completed in four months. Innovation took place in the planning of the scope. By engaging the self-perform superintendent months in advance, material and equipment were procured and on-site before the crew arrived from Denver. The crew was able to finish their work well in advance of their plan due to the careful analysis and collaboration with the team on site.

SELF-PERFORMING

Saving time. Saving money. Controlling quality. Ensuring safety.

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 34 35

Collaboration

Collaboration is an indicator of a wellperforming team. Individuals present their best ideas and the group uses a combination of those ideas to reach a solution.

Communication is the core to the success of the team’s collaborative nature. Maintaining regularly scheduled meetings, having point-to-point conversations, respectfully challenging each other, and being prepared to yield to a better idea all allowed the Logan team to collaborate in successful actions.

The definition allows structure. The MWH team spent time and effort establishing the roles and responsibilities of everyone as well as the flow of administrative tasks. By having these important items defined, the team could adjust appropriately when disruptions attempted to impede the flow of the work.

To ensure the schedule was maintained, MWH and the subcontractors met weekly to forecast activities and look at possible overlaps of crews in workspaces. By discussing activities with the different contractors and different priorities, the leadership of the parties could agree to the sequence ahead of the group. Once the information was collected by the MWH CM, a Gantt schedule was produced for the week and the crews would review the schedule daily. This sequence ensured buy-in at all levels of the work.

MWH had the ability to self-perform a small mechanical equipment scope of work. The onsite team determined the scope of work was too small to hire a local crew and too large to subcontract. The best option was to bring a crew to

Logan from Denver. A traveling crew has added costs in per diems and can lose money even if the work is done on time. Knowing this, the on-site MWH team worked with the traveling superintendent to break down the scopes of work and make work plans. Materials were procured in advance and equipment was reserved for their arrival. When the crew traveled in, they were greeted with areas of construction ready for them to perform. Eliminating wait times and changing directions due to missing components ensured the outstanding performance of the self-perform crew.

Understanding what is required to startup and commissioning a new facility improves the success of the commissioning team. MWH’s commissioning team was in constant communication with the on-site team months prior to their arrival. Outlining systems and sequences of systems allowed the construction team to prioritize resources. Ironically, a building that was nearly complete first was commissioned last. Focusing the resources available on the areas of work that would be commissioned first ensured that the commissioning agent would be working in areas that were construction complete.

A collaborative team is like a well-oiled machine. Everyone wants to be part of that group. To get there requires trust. Trust in each other. Integrity. Knowing that the team member will do what they say because they said it. Honesty. No BS. Respect. Be empathetic and realize each person will only excel when they feel supported first.

MWH Constructors / LOGAN

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 36 37

Partnering

Partnering is intended to assist project teams with setting goals, resolving disputes, and improving project outcomes. The construction partnering team is made up of the project’s owner (client), the consulting engineers and/or architects, the contractor(s), and other key project stakeholders. Construction partnering has been used both in the United States and elsewhere since the early 1980s as a methodology to reduce litigation and improve productivity.”

Wikipedia

At the beginning of the project, Logan City specified a formal Partnering process. Through a series of sessions led by an independent facilitator, the project team refined goals and lines of communication. These decisions were agreed upon and were a catalyst for several successful issue resolutions.

In an effort to ensure the greatest influence of these partnering sessions, subcontractors were invited to participate and be recognized as stakeholders. They joined the owner, engineer, and general contractor in creating and achieving the Project Goals:

1. Safety

a. Zero Accidents.

2. Schedule

a. Substantial Completion by June 30, 2022.

3. Quality

a. Deliver a user-friendly, showcase project

b. Complete an award-winning project

c. Demonstrate pride in work

4. Budget

a. Stay on budget

b. Make profit

5. Fun

6. Award-Winning Team

a. Build a strong team where every entity wins

7. Strong relationships at end of project

8. Proactive Planning

a. Minimize changes

b. Minimize impact to the public

9. Have fun!

PARTNERING

Officially engaged in partnering to ensure common goals were aligned. Excellent relationships with all of the subcontractors’ representatives. Mutual respect. Mutual respect in relationships built between individuals and subcontractors. Members recall events of the project over personal events. The project could have been the perfect job. If there is a perfect job, this one.

NEW ERA Ribbon Cutting

Cache Valley marks a ribbon-cutting new era in wastewater treatment. June 27th, 2022

LOGAN / MWH

Constructors

FOUNDATIONS NEWSLETTER FOUNDATIONS NEWSLETTER 38 39

BUILDING A BETTER WORLD mwhconstructors.ourcareerpages.com slayden.ourcareerpages.com mwh constructors.com 8001 Arista Place Suite 500 Broomfield, CO 80021 Join us in... FOLLOW US:

CMAR PROJECT BY MWH Constructors COURTESY OF Portland Water Bureau SOME WORDS BY Chuck Slothower, DJC Oregon

PORTLAND WATER BUREAU

THE BASICS

CMAR PROJECT BY MWH Constructors COURTESY OF Portland Water Bureau SOME WORDS BY Chuck Slothower, DJC Oregon

PORTLAND WATER BUREAU

THE BASICS