FOUNDATIONS

Welcome to our summer newsletter! Things at MWH continue to heat up as this impressive year progresses. We want to thank our fantastic team, clients, and partners who make our journey rewarding. Together, let’s dive into the latest and greatest at MWH!

At MWH, we’re all about finding extraordinary solutions that drive efficiency, sustainability, and quality, all while managing costs. Whether we are building water treatment facilities, making waves in water reclamation projects, or developing pure water solutions for semiconductor fabs, MWH delivers. We’ve continually championed strategies that address diverse needs, ranging from cutting-edge water and wastewater treatment infrastructure for municipalities to efficient water reclamation facilities and pristine water solutions tailored for our industrial clients. No matter the need, MWH delivers results.

In this edition, we’re focusing on our legacy, commitment, and impact on water reuse and reclamation. In addition to our water reuse features, you’ll find insights into our Oregon, San Francisco, and Nevada projects, our community efforts, and our recent awards in Utah. We’re also thrilled to

announce the opening of our new office in Phoenix, which enhances our ability to support our semiconductor clients.

As we move through the second half of the year, let’s leverage this momentum and growth to inspire positivity and drive progress. Construction is a platform for meaningful change, especially in the water industry. Every step forward contributes to building a better world.

Whether we are building water treatment facilities, making waves in water reclamation projects, or developing pure water solutions for semiconductor fabs, MWH delivers.

The STMWRF goes beyond conventional treatment.

Read more on page 06

As a leading U.S. contractor in water, wastewater, and industrial water construction projects, we are committed to delivering maximum value to clients and their communities. MWH history dates to the early 19th century and features some of the world’s most groundbreaking water and wastewater innovations as well as specialization in client-focused collaborative delivery methods.

Copyright 2023 by MWH Constructors. All rights reserved. MWH, the MWH, Slayden and Methuen logos and Foundations are service marks of MWH Constructors. MWH is an equal opportunity employer.

EDITORIAL TEAM : Lana Piskorowski, Alexis Gee

CONTRIBUTORS : Marco Aieta, John Evans, Kelly Jegorow, Kiersten Lee, Jackie Leach, Corey Maxfield, Lance Ota, Andrew Pharis, Tom Paul, Dean Rusciolelli, Jeff Wall, Quentin Williams, Danielle L’Antigua

A significant component of this expansion is water reclamation, a concept gaining significance in today’s environmental landscape.

Nestled in the heart of Washoe County, the South Truckee Meadows Water Reclamation Facility (STMWRF) 2020 Expansion Project is underway. Collaboratively led by joint venture partners MWH Constructors and KG Walters (MWH&KGW, a Joint Venture), this venture seeks to increase plant capacity, ensuring the county’s wastewater and reclamation needs are met well into the future. This article sheds light on the project’s progress, exemplary concrete work, innovative solutions, and the team’s commitment to positively impacting the community.

A significant component of this expansion is water reclamation, a concept gaining significance in today’s environmental landscape. The STMWRF goes beyond conventional treatment through the process of sending treated water into a reservoir, where it receives additional treatment before being distributed to the local community

Author: Lana Piskorowskifor farm and landscape irrigation, making it a prominent water reuse facility.

One of the standout technologies employed in this journey is the Biological Nutrient Removal (BNR) process, which removes nitrogen and phosphorus from wastewater before its discharge into the ecosystem. The facility’s commitment to advanced treatment processes ensures the water supplied is clean and suitable for irrigation.

MWH&KGW began the STMWRF 2020 Expansion Project with a focus on delivering exceptional quality. Taking on the challenge of selfperforming all concrete work at the reclamation facility, the team has poured a remarkable 8500 cubic yards (about twice the volume of an Olympic-size swimming pool) to date for process structures such as bioreactors, wet well, grit structure, blower building, Vactor dump station, and more. Before pouring concrete, the team developed 15 different batch mixes that underwent rigorous testing to ensure they met the highest quality, durability, and longevity standards. The team aims to save time and resources by eliminating the need for rework and contributing to the project’s success. “I’m truly impressed with the strong relationship we have with our joint-venture partner, KG Walters. Our coordinated efforts, seamless teamwork, and capability to self-perform and manage critical path elements has bolstered our efficiency and success. This collaboration has been truly outstanding,” shared Corey Maxfield, MWH Project Executive.

Challenges have arisen during the project, particularly a high groundwater table eight feet below the site’s surface. Drawing upon the experience of our JV partner KG Walters’s decades of experience at this site, MWH&KGW was able to save Washoe County $950,000 through strategic planning and execution of the dewatering system. The goal is to ensure smooth and efficient progress, saving Washoe County valuable funds. Supply chain issues and budget constraints have posed additional challenges. “The project’s parameters have encouraged us to explore innovative, costeffective solutions while enabling the client to achieve their project goals. In addition, we’re addressing supply chain hurdles, particularly in acquiring electrical equipment, to ensure project timelines remain on track,” said Maxfield.

Amidst their dedication to the STMWRF expansion project, MWH&KGW has shown unwavering commitment to the community. In a remarkable gesture, the team contributed 20,000 cubic yards of excavation spoils towards constructing the Nevada Cares Campus in Reno. The Nevada Cares Campus provides counseling for people experiencing drug addiction and shelter for people experiencing homelessness while providing crucial case management support to facilitate their transition into stable and independent housing.

As the project progresses, the team continues to extend its support beyond the boundaries of the STMWRF. Their involvement with the Nevada Cares Campus showcases their dedication to positively impacting the lives of their fellow residents. By addressing societal challenges and supporting those in need, the MWH&KGW team exemplifies the spirit of community engagement and social responsibility.

I’m truly impressed with the strong relationship we have with our joint-venture partner, KG Walters. Our coordinated efforts, seamless teamwork, and capability to self-perform and manage critical path elements has bolstered our efficiency and success. This collaboration has been truly outstanding

The South Truckee Meadows Water Reclamation Facility

2020 Expansion Project remains a beacon of progress, driven by collaboration, innovation, and community care. As construction continues, MWH&KGW’s commitment to delivering high-quality concrete work and strategic planning sets the stage for a successful outcome. This expansion will increase the plant capacity by 48%, with an average daily flow of 6.86 million gallons of wastewater per day - ensuring that Washoe County can meet projected needs well into 2040 and beyond. MWH&KGW paves the way for a brighter and more sustainable future for Washoe County by weaving together their expertise, innovation, and community engagement.

COREY MAXFIELDIn July, MWH stood as a proud sponsor of the AZ Water Association’s Arizona Water Reuse Symposium—an annual gathering that serves as a cornerstone for vital discussions on both present and future water demands. This event plays a pivotal role in fostering the growth of water reuse projects across the southwestern region of the United States.

Our dedication to this cause runs deep - our commitment is to provide communities and industrial clients with a resilient, dependable, and high-quality water source. Our steadfast belief is that these efforts contribute to the well-being and sustainability of the areas and organizations we serve.

In September, we eagerly anticipate our sponsorship of the WateReuse Texas Conference. At this event, the Trinity River Authority (TRA), one of our esteemed clients, is set to be lauded as the Utility of the Future Today for the third consecutive year. This prestigious recognition is a tribute to TRA’s forward-looking approach to water resource recovery facilities. MWH is now building the Phase III-B Solids Management Improvements project for TRA, which features cutting-edge Cambi Thermohydrolysis technology.

Further down the calendar, in November, our involvement extends to the California Water Reuse conference. As we continue to embrace opportunities to sponsor events that drive dialogue and innovation in the realm of water reuse, we reaffirm our dedication to fostering sustainability and addressing the evolving water needs of our communities.

ARIZONA SYMPOSIUM

July 23–25, 2023

TEXAS CONFERENCE

September 20-22, 2023

CALIFORNIA CONFERENCE

November 5-7, 2023

Earlier this year, the City of Saco selected MWH as the Construction Manager At-Risk for the $50M Water Resource Recovery Facility Upgrade project. The project consists of a new treatment building with aerobic granular sludge treatment processes, secondary filtration, and UV disinfection with upgraded grit removal and solids handling, as well as the conversion of existing clarifiers for additional stormwater storage and site grading alterations to mitigate tidal flooding from the adjacent Saco River.

Coming off the heels of the successfully completed Saco River Drinking Water Resource Center (SRDWRC) project, MWH’s Maine-based key team took a proactive approach to pursuing the Water Resource Recovery Facility Upgrade project. To familiarize themselves with the project’s aerobic granular sludge technology during the proposal phase, MWH’s project team visited the Aqua-Aerobic Systems facility in Loves Park, IL, to gain a comprehensive understanding of how the AquaNereda® technology works and learn the best methods for installing and commissioning the complex system firsthand. MWH’s UK-based sister company, MWH Treatment, also provided the team

with hands-on training and best practices derived from installing and operating eight AquaNereda® systems. The knowledge gained from these efforts continues to be tremendously beneficial as the project progresses.

Today, MWH is constructing this project using a phased approach to complete and commission the new treatment processes before modifying the existing infrastructure with minimal downtime to the facility.

MWH is well known as the constructor of similar water and wastewater projects in New England. Early last year, MWH completed the Maine Water Company’s $44M SRDWRC project in Biddeford, ME, while keeping the project on schedule and under budget. The project featured stormwater management and wetland preservation to ensure the conservation of valuable local natural resources, including a red maple swamp and a wild brook trout habitat. These elements along with other project efforts led to the project’s recognition with the Envision Silver Award from the Institute for Sustainable Infrastructure.

Author: Lana Piskorowski

Author: Lana Piskorowski

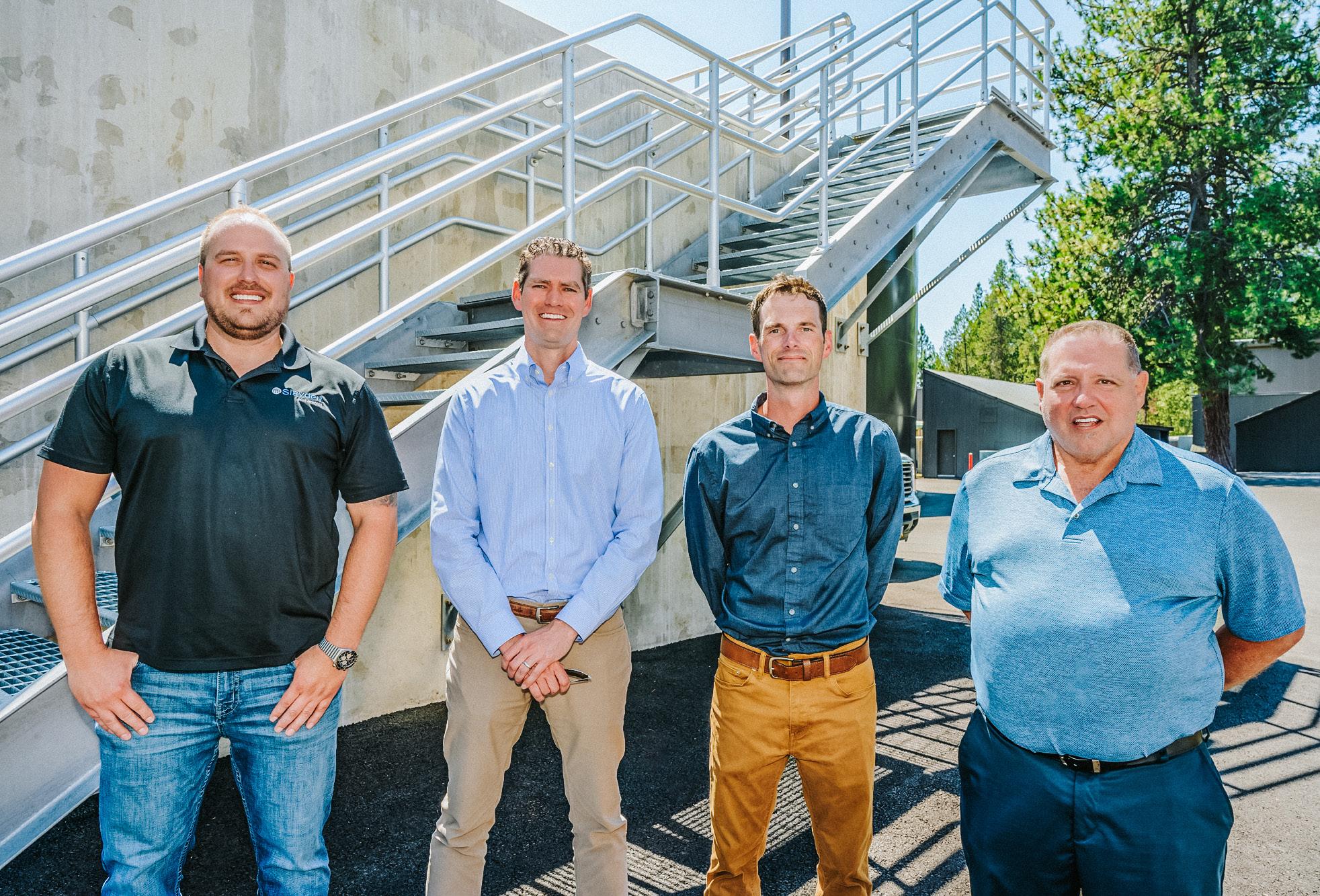

On July 19th, 2023, Slayden Constructors marked the completion of a monumental four-year endeavor – the Sunriver Utilities Wastewater Treatment Plant upgrade in Sunriver, Oregon – with a ribbon-cutting event. With an investment of $18.5 million, this state-of-the-art facility has undergone a significant evolution, now capable of processing 1.5 million gallons of wastewater each day.

Beyond addressing community concerns via noise reduction, odor control, and aesthetic enhancements, the upgrade also brings in a sustainable factor - water recycling. The heart of this achievement lies in the implementation of cutting-edge membrane bioreactors and advanced biological treatment processes. These technologies work in harmony to produce Class A recycled water, which is used for irrigating an 18hole golf course nestled in the northern reaches of Sunriver, elevating the course’s sustainability and preserving precious freshwater resources. Additionally, the plant’s forwardlooking processes yield byproducts that can be used as compost. “Being a part of this transformative project has been a great experience,” said Andrew Pharis, Director of Operations at Slayden. “The project’s emphasis on water recycling by repurposing reclaimed water for irrigation in an arid region perfectly mirrors Slayden’s commitment to sustainable water practices.”

“We extend our heartfelt gratitude to every individual who played a role in bringing this project to fruition,” said Jeff Wall, Vice President and Senior Project Manager at Slayden. “This milestone not only showcases our technical prowess but reinforces our dedication to creating lasting solutions that resonate with the communities we serve.”

The project’s emphasis on water recycling by repurposing reclaimed water for irrigation in an arid region perfectly mirrors Slayden’s commitment to sustainable water practices.

ANDREW PHARIS Director of Operations Slayden Constructors

ANDREW PHARIS Director of Operations Slayden Constructors

After a year of meticulous planning and excited anticipation, MWH’s Phoenix Team moved into their new office on June 1, 2023. Let’s take a look around!

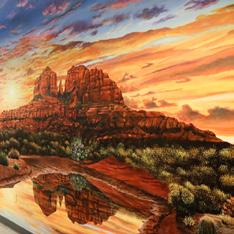

All who walk into the open-concept lobby are welcomed with a stunning view of Scottsdale’s famous Papago Park, the well-stocked Water Bar, and a hand-painted mural of insert location in the spacious kitchen and dining area.

From the color scheme to the Water Bar, this sleek new space’s design builds on the best aspects of MWH’s Broomfield office. The bar is a beloved spot at MWH HQ where coworkers, clients, and trade partners gather. Understanding the benefits of having a unique social hub in the office, the MWH Design Team created a similar gathering place with water and local beer on tap.

Now, the Phoenix Team congregates at the bar to eat lunch, conduct impromptu meetings, and ring the bell after major wins. Team members also invite potential new hires to the Water Bar to discuss their career goals and the many benefits of becoming a part of our growing team.

The new office boasts several unique rooms that were designed to accommodate a variety of uses, such as interdepartmental events, executive meetings, and educational workshops. Cactus is a private meeting space with a beautiful view while neighboring Coyote is a stately conference room

featuring a glass wall frosted with the MWH logo and a breathtaking view of Papago Butte.

The War Rooms are the Phoenix Team’s favorite collaborative area thus far. This adaptable space, which can be divided into two separate rooms, is equipped with large TVs, glass wall-mounted whiteboards, and whiteboard desks that can be configured to meet the needs of any event. Within just the first month of opening, the Phoenix team held Marketing and Estimating Summits in the War Rooms, hosting MWH, Slayden, and Methuen team members from across the US.

The private offices, bullpens, and cubicles are bright and bustling with coworkers hard at work. Each of these fresh workspaces were built with innovation, collaboration, and comfort in mind. The Phoenix office truly has a work area to fit the needs of each team member. All work areas include:

6 Adjustable standing desks

6 Ergonomic chairs

6 Easy-to-use docking stations

6 Mounted dual monitors

6 Ample and secure storage

Opening this new office required countless phone calls, dozens of meetings, and many months of hard work. From developing the design and coordinating with contractors to selecting furniture and adding

finishing touches, the team driving the new office effort gave it their all to make what was once a wish for the future into a stunning reality.

MWH and the Phoenix Team extend their deepest appreciation to:

Shannon Rowley and Mark Crouser (Conceptualization, Design & Planning)

Savanna Auay-Fuay (Logistics & Coordination)

Kevin Hoskins (Project Manager)

Finally, a place to call home away from home. After a year of shuffling around from shared office spaces to the temporary office, then to this beautiful office was a welcoming experience. The Water Bar provides a different experience where we can gather and talk shop without the feeling of being in a meeting room.

TOM AUAY-FUAY Director of Pre-ConstructionI was completely in awe with the desert mural in the break room when I arrived on the first day. The lighting is excellent throughout the office and boosts mood and positivity. I also love the organization in the kitchen and how it’s stocked with so many amenities! Having an extra microwave really helps!

MARIA CONTRADA Contract Manager

MARIA CONTRADA Contract Manager

Our new Phoenix office is multiple levels ahead of any other company that I’ve seen. This is an office we are all proud to invite our owners, JV partners, subcontractors, suppliers, and others to show off the MWH brand. Well done team!

MATT HOLOPIREK Senior VP & Project Executive

MATT HOLOPIREK Senior VP & Project Executive

noted, “We needed to install this collection, treatment, and distribution system of water to bring Cape Coral into the 21st century.”

In the early 2000s, Cape Coral, a rapidly growing city in Florida, faced a pressing need to develop its water and wastewater infrastructure to accommodate its booming population. This challenge prompted city officials to devise a comprehensive master plan that included the Facility and Utilities Expansion Projects. MWH served as the builder, designer, and engineer for this ambitious undertaking.

Developers in Florida spurred growth by purchasing land and establishing limited infrastructure like roads, electrical lines, and drainage. However, they didn’t plan for water and sewer systems, so landowners used wells and septic tanks John Evans, the Florida Regional Manager who worked on the Cape Coral projects, pointed out that as the city expanded, septic tanks ended up very close to neighbors’ wellssometimes just 25 feet apart. Moreover, Cape Coral’s location near the ocean and its swampy ecology meant residents had brackish water in their wells. Due to the poor water quality, residents had to resort to private water treatment methods like reverse osmosis. Evans

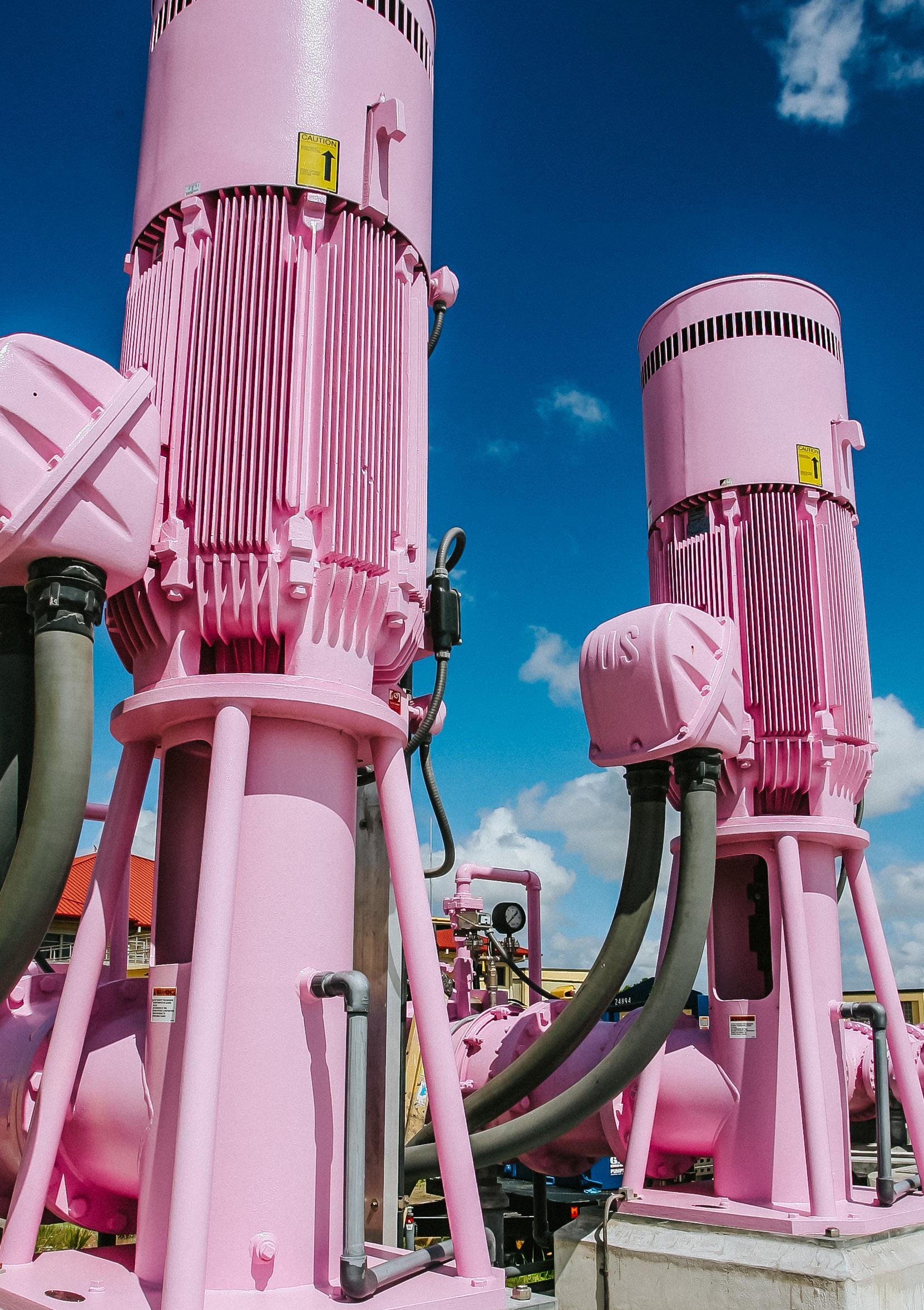

In 2001, the City of Cape Coral began an incredible journey to create a complete water and wastewater infrastructure that would serve the city well into the future. Led by MWH Constructors, the Utilities Expansion Project (UEP) involved the installation of an impressive 720 miles of water, gravity sewer, and irrigation pipelines, along with 240 miles of residential roads and 34 wastewater pump stations. This herculean effort involved meticulous planning and execution. The UEP’s mission was to efficiently moving clean water from existing treatment plants into people’s residences. Additionally, the UEP seamlessly managed the conveyance of wastewater to reclamation facilities for use in non-potable applications such as irrigation. Evans said, “We recognized the city’s urgent need for a comprehensive overhaul of Cape Coral’s water infrastructure. The city’s growth required a forward-thinking approach that could support the rising demands effectively.”

The subsequent phase, known as the Facility Expansion Program (FEP), began in 2004 and expanded Cape Coral’s water and sewage treatment facilities on a massive scale. MWH would go on to double the capacity of Cape Coral’s two water reclamation facilities, the Everest Water Reclamation Facility and the Southwest Water Reclamation Facility, as well as design a new 10mgd North Cape Water Reclamation Facility. MWH also designed and constructed a new North Cape Reverse Osmosis Water Treatment Facility and helped expand the Southwest Water Treatment Plant. The team constructed a total of 27 raw water production wells, three deep injection wells, and several aquifer storage and recovery test wells. Evans noted, “Our team’s dedication to delivering sustainable solutions was evident in every aspect of the project. We aimed not only to meet current needs but also to future-proof Cape Coral’s water infrastructure.”

It is my opinion that a company is only as good as its people, and I believe you and your team are doing an extraordinary jobMIKE FISHER Plant Superintendent Southwest Water Reclamation Facility

A pivotal aspect of Cape Coral’s transformation was its water reclamation efforts. The project collected and transported wastewater to the Southwest Water Reclamation Facility, which featured advanced treatment that included primary and secondary treatment followed by tertiary treatment utilizing deep bed filters, resulting in the production of high-quality reclaimed water. This water was stored in 5-milliongallon tanks and repurposed through a purple pipe system for various uses, including irrigation for residential properties and golf courses. Evans stated, “The UEP was the infrastructure that brought the wastewater to the water reclamation facility and also distributed the reclaimed water.” He added, “Recycling water has long been a priority for cities in Florida due to the state’s proximity to the ocean, necessitating sustainable wastewater practices.”

Purple pipe systems deliver recycled water for industrial use, landscape irrigation, and other non-potable purposes. This distribution occurs through a dedicated network that is entirely isolated from the potable water system.

As the Cape Coral project unfolded over years of dedication and perseverance, it garnered numerous accolades, including the 2011 ENR Southeast Best of 2011 Project Award and the 2011 DBIA National Design-Build Award. Remarkably, the project achieved over 3.3 million work hours with only one lost-time incident, a testament to the meticulous planning and safety measures implemented. Evans concluded, “Cape Coral’s journey was about more than infrastructure; it was about shaping the city’s future. Our success was a collaborative effort that demonstrated what vision and dedication can achieve.”

Water reuse is rapidly emerging as a crucial solution to address water scarcity and promote sustainable water management practices worldwide. While wastewater treatment plants have long been associated with sewage treatment, an underlying role often goes unnoticed; these plants are pivotal water recycling facilities.

MWH has a noble reputation as a leading global construction firm that specializes in water infrastructure and delivers innovative water reuse projects. Our commitment to providing resilient, dependable, and high-quality water sources has earned our firm a distinguished reputation in the industry. To get the complete picture of MWH’s impact on the rise of water reuse, we sat down with two MWH subject matter experts: Dr. Marco Aieta, a seasoned MWH alumni currently serving as Senior Consultant, and Kiersten Lee, PE, Vice President and Director of the Construction Services Group.

MWH’s 200-year-old roots are deeply intertwined with water reuse. At the turn of the 20th century, John D. Watson, the source of the “W” in MWH, was a pioneer in the development of sewage purification. He also constructed the first large percolating filter plant, an innovative departure from age-old methods of land treatment. Then, in the early 1970s, James M. Montgomery, Inc., became part of pioneering research and feasibility studies on some of the first advanced reuse projects in the country, including Orange County Water Factory 21

Thirty years later, MWH developed, designed, and constructed the US’s first semiconductor water reuse facility for a global manufacturing client. The $417M project addressed the client’s need for additional pre-treatment of industrial wastewater before its discharge to the municipal sewer system. Now operational, the facility includes advanced water treatment and reuse systems that enable the reclamation of the treated effluent, reducing the client’s need for potable water and making it

available for use on-site. Recycled water is vital for manufacturing plants like this due to their immense water requirements for cooling towers, chillers, and scrubbers. By recycling and reusing water, semiconductor manufacturers are making significant strides toward becoming more environmentally conscious.

Clean potable water is not usually the first thing to come to mind when thinking of wastewater

treatment plants. In fact, most people shudder at the idea of treated wastewater ending up in their water supply. However, those concerns can be quelled by understanding the treatment process and the importance of reusing or recycling water.

Dr. Aieta illustrated the concept: “Imagine two cities are geographically linked by their connection to a river system. One city’s municipal wastewater treatment plant is upstream and discharges clean, treated water into the river, while the other city’s water treatment plant is downstream, with an intake from the same river, which it then treats and distributes to its customers--that’s reuse.”

Building on Dr. Aieta’s explanation, Kiersten Lee agreed, “In 99 percent of cases, the water

Thirty years later, MWH developed, designed, and constructed THE FIRST SEMICONDUCTOR WATER REUSE FACILITY IN THE US for a global manufacturing client.

discharged into streams by wastewater plants is actually cleaner than the existing watershed due to the stringent environmental regulations they must adhere to. Potable reuse is already happening. People need to understand that the water coming out of the tap is safe and way more regulated than what’s in bottled water.”

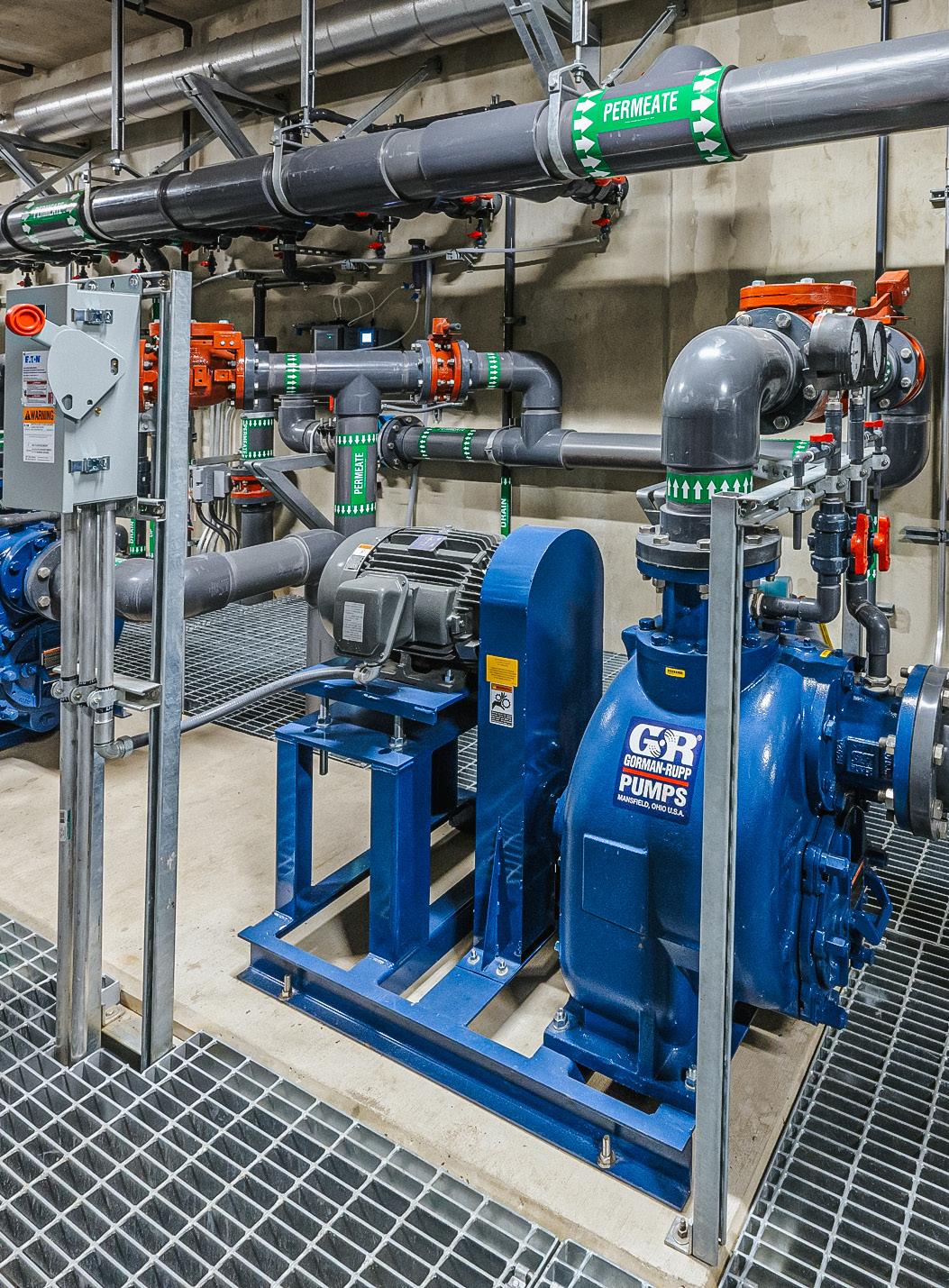

The Riverside Park Water Reclamation Facility in Spokane, WA, is an excellent example of this concept. MWH and Slayden completed significant upgrades to this facility in 2021, adding a new membrane filtration system that significantly reduces phosphorus and other pollutants, commonly referred to as the Next Level of Treatment. This greatly improved the quality of effluent released to the Spokane River.

These facilities play a vital role in the future of humanity, especially as water scarcity and fossil fuel depletion become more and more prevalent. Knowing this, municipalities across the US have been rebranding their wastewater treatment plants as “resource recovery” or “water reuse” facilities for over a decade. The public perception of reusing treated water for potable and non-potable uses is one of the top reasons for this major rebranding, but the valuable resources that these facilities generate

are just as important. Lee explained that “water is just one resource that you can recover. For example, the intent of one of our major Solids Management projects in Texas is to capture and create energy from methane gas…essentially, waste is getting reduced to a point where energy can actually be created from it. To me, that’s very cool!”

The San Francisco Public Utilities Commission’s Southeast Treatment Plant Biosolids Digester Facilities project also focuses on resource recovery. As the Construction Manager/General Contractor for this $1.78B project, MWH is installing an innovative process that turns wastewater sludge into Class A Biosolids, which can be used as fertilizer. This transformation of waste into something with utility bridges the gap between traditional treatment and innovative reuse.

Water reuse, or water recycling, is the process of intentionally capturing wastewater, stormwater, saltwater, or gray water and appropriately cleaning it for designated beneficial purposes, including drinking, watershed restoration, industrial processes, and surface or groundwater replenishment. MWH has been a champion for the responsible

Wastewater Treatment Plantmanagement and reuse of water for over 200 years. With an ethos of environmental sustainability and community stewardship, MWH has been instrumental in furthering the progress and adoption of water reuse for both public municipal and private semiconductor fab projects. Semiconductor clients utilize fresh and reclaimed water, drawing from utilities, on-site wells, and even desalination processes in coastal regions. These clients reduce freshwater consumption and enhance overall sustainability by maximizing water reuse and conservation efforts.

Speaking about the semiconductor industry’s focus on water reuse and building zero liquid discharge facilities, Lee stated, “Water reuse is important for global manufacturers as well as the communities where their factories are based due to the tremendous impact on local water sources. These large companies are taking a more environmentally sustainable approach because they know how much water they need and care about the water they discharge.”

Lee continued, “People usually think that industrial water reuse plants are so chemical-heavy, and they’re just all advanced treatment processes. The cool thing is that’s just not the case.” Each treatment facility is unique, but for many of MWH’s semiconductor fab projects, a combination of traditional and advanced treatment processes is utilized. “The MWH team actually proposed the idea to utilize a biological process called a BNR, or biological nutrient removal, at the first semiconductor reuse facility in the US. There are nuances to it, but to put it simply, there’s a basin with organisms that actively remove critical constituents, like nitrogen and phosphorous, but for that project, it was ammonia.”

“The real story is: it’s all water. It begins as rain, ends up as seawater, and eventually cycles back to rain. In between that timeframe, humans use and contaminate it and subsequently make efforts to purify it before it reintegrates into the natural cycle,” Dr. Aieta noted. “If we do a good job of that, we don’t damage the natural system. We can recycle the water and live in harmony with nature. But, if we don’t do a good job of that, it leads to detrimental outcomes. All of these systems are tied together if you think about it.”

MWH’s long-standing dedication to water reuse demonstrates our commitment to promoting sustainable water management practices, and our innovative projects and collaborations with industry leaders signify a promising future for water reuse initiatives. As water scarcity continues to be a pressing global issue, MWH’s expertise will be pivotal in securing a reliable and sustainable water supply for communities and industries worldwide.

No discussion on water reclamation would be complete without acknowledging the remarkable accomplishments of the Spokane Riverside Park Water Reclamation Facility. The facility secured the Award of Merit in the water and environment category during last year’s Engineering News-Record Northwest Best Projects competition.

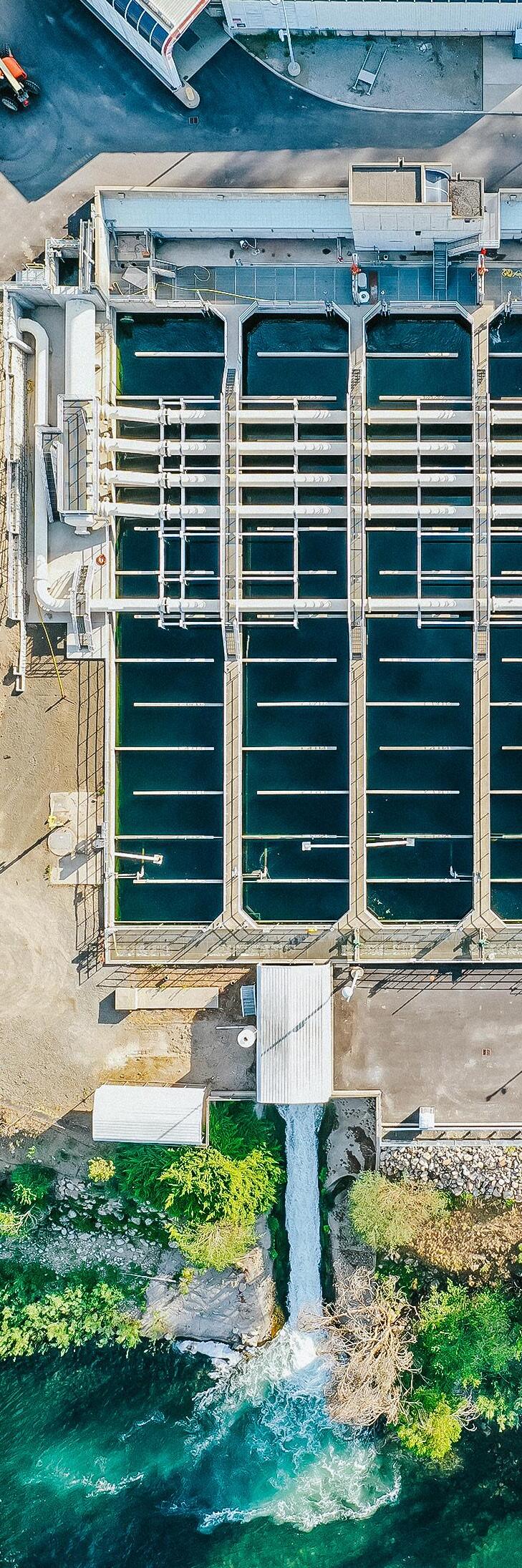

As Spokane’s oldest and most extensive water recycling center, the Riverside Park Reclamation Facility caters to a community of 210,000 residents, providing a combined storm and sanitary sewer system. It processes about 34 million gallons a day (mgd) of wastewater, with peak flows over 150 mgd. The treated water is then released into the Spokane River, underscoring the facility’s crucial impact on the local waterway.

The project utilized an advanced membrane filtration system, the Next Level of Treatment, featuring at the time the largest membrane system of its kind. Opting for the Pall Aria™ FLEX system was motivated by its noteworthy cost efficiencies, superior water recovery, simplified integrity testing, reduced maintenance needs, and streamlined construction process. This customized system successfully met the objective of curbing phosphorus levels, enhancing phosphorus removal from the Spokane River discharge to an impressive 99%.

“It’s incredibly rewarding to be part of a company dedicated to environmental betterment,” noted Andrew Pharis, Director of Operations at Slayden, “In this project, we lowered phosphorus levels and enhanced effluent quality. The restoration of the Spokane River holds the promise of healthier aquatic life and revitalized fish habitats.”

The new system improved the vitality of the river and increased the removal of heavy metals, PCBs, and hazardous pollutants. Future UV disinfection will advance treated water to Class A standards, paving the way for its reuse in irrigation, wetland augmentation, and groundwater recharge. Jeff Wall, Vice President and Senior Project Manager at Slayden recalled, “Being involved in the Spokane project was truly exciting. Our installation of a membrane tertiary treatment system marks a pivotal stride towards facilitating water reuse in the region.”

“Water has always been vital to civilization, and water scarcity is becoming even more prevalent. I’m enthusiastic about being in an industry that centers on enhancing our environment through water-focused initiatives,” said Wall, “We have a responsibility to enhance our water conservation methods.”

Water has always been vital to civilization, and water scarcity is becoming even more prevalent. I’m enthusiastic about being in an industry that centers on enhancing our environment through water-focused initiatives

JEFF WALL VP and Senior PM Slayden Constructors

In light of skyrocketing freshwater demands and ever-intensifying weather shifts, the imperative for establishing sustainable water infrastructure becomes even more pronounced. As a firm with a 200-year history steeped in water and wastewater treatment innovation, MWH partners with municipalities, public utility providers, and private industrial clients to effectively tackle water quality and scarcity challenges.

Advancing water reuse is an increasingly attractive solution that will address a diverse array of intricate water management issues, from bolstering the resilience of water supplies in the face of mounting pressures to accommodate growing populations to mitigating saltwater encroachment. Water reuse is important because it aids in mitigating the impacts of severe weather events and sewer overflows, providing a comprehensive approach to adapting our water systems to the changing environment.

Non-potable water reuse involves treating wastewater to a quality suitable for specific non-drinking purposes. This method is used for irrigation, industrial processes, and more. Technologies include:

6 Secondary Treatment: Basic treatment methods like sedimentation, biological processes, and disinfection can be employed to remove solids and pathogens.

6 Tertiary Treatment: Advanced filtration, microfiltration, UV disinfection, and chlorine treatment enhance water quality.

6 Decentralized Systems: Modular treatment units installed at the point of use can provide efficient non-potable water sources for individual buildings or communities.

When discussing non-potable reuse, MWH’s Vice President and Director of Construction Services, Kiersten Lee, PE, explained, “Our team is always focused on reusing water during construction. We seize as many opportunities as possible to use nonpotable water for dust control, hydrostatic testing, concrete, and commissioning.”

Non-potable reuse is not new, but MWH consistently tries to find better ways to drive sustainability. “One of the innovative things that we constantly focus on is how to be good stewards of water when there’s no water around,” remarked Lee. “On the Southern Delivery System project, we built 15 miles of pipeline, three pump stations, and a 50 MGD plant in the middle of nowhere. There was a lot of effort to successfully move and store water so we didn’t have to discharge and bring new water out there. Now, we use the lessons learned from that Colorado Springs project to benefit water-scarce project sites, such as the Portland Water Bureau’s Bull Run Filtration and Pipeline projects.”

We constantly focus on is how to be good stewards of water when there’s no water around.

KIERSTEN LEE Vice President and Director of Construction Services

Water reuse for non-potable applications has long been accepted and is a successful means of maintaining freshwater supplies. Though it may not be common knowledge, revitalizing aquifers and augmenting water supplies with reused water has been happening for years and continues to escalate today as the world experiences greater water scarcity.

“Depending on where you live, you’re already consuming reused water, whether you know it or not,” Lee advised. “Municipal wastewater and drinking water are more regulated and more closely monitored than bottled water, which is regulated by the Food and Drug Administration.”

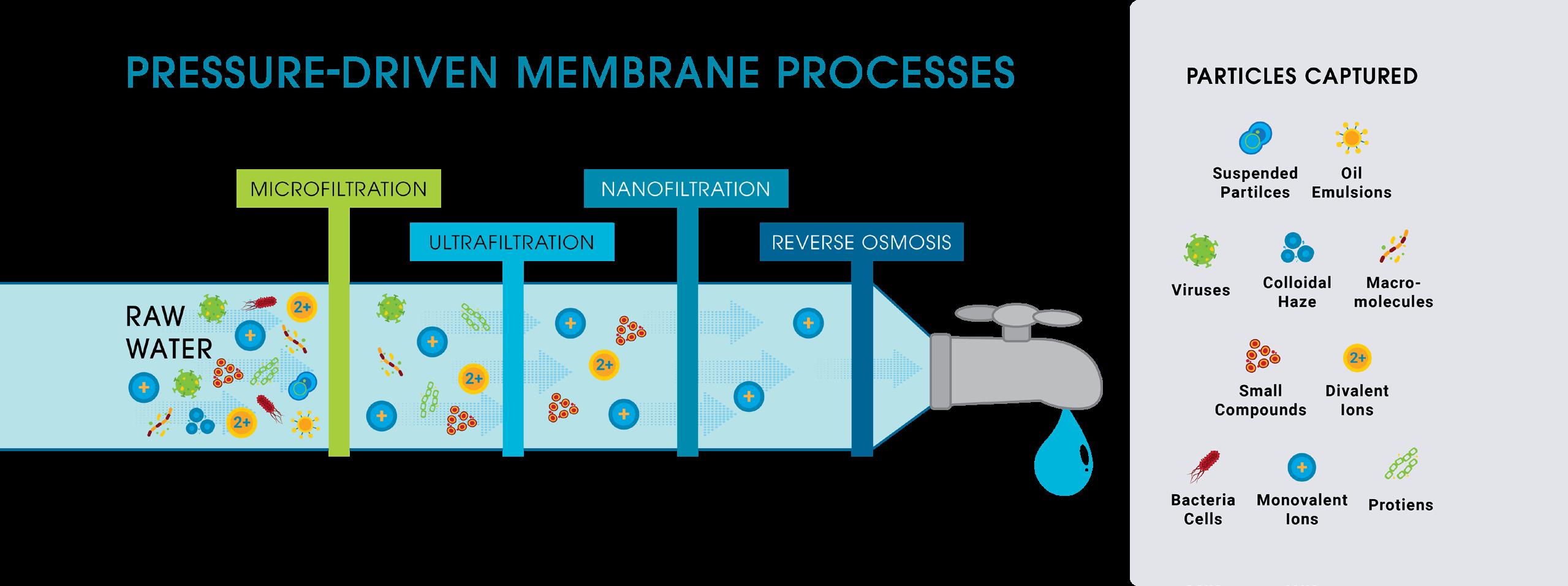

DPR involves treating wastewater to a level that meets or exceeds drinking water quality standards. This treated water is then introduced directly into the potable water supply. Advanced treatment processes are utilized, including:

6 Microfiltration and Ultrafiltration: These processes use fine membranes to remove particles, bacteria, and some viruses from the water.

6 Reverse Osmosis: This high-pressure process forces water through a semipermeable membrane to remove salts, dissolved solids, and contaminants.

6 Advanced Oxidation Processes: Techniques like UV (ultraviolet) and ozone treatment break down organic and chemical contaminants.

IPR involves injecting treated wastewater into nonpotable water sources, allowing natural processes to purify the water further before it’s used for potable purposes. Key steps include:

6 Advanced Treatment: Similar to DPR, advanced treatment technologies are employed to ensure high-quality reclaimed water.

6 Aquifer Recharge: Injecting treated water into underground aquifers provides natural filtration, with the soil and rock acting as a barrier against contaminants.

6 Groundwater Recharge and Recovery: After a period of underground storage, the water is pumped out and treated further before entering the drinking water system.

“Just because water comes from an aquifer doesn’t mean it hasn’t been blended with treated water from a municipal source,” Lee commented. “If one community is doing deep well injection to recharge its aquifer, wells downstream pull water out of the same aquifer to serve the surrounding community.”

Other cutting-edge water reuse technologies include:

6 Membrane Bioreactors (MBR): Combining biological treatment with membrane filtration, MBR systems efficiently remove organic matter and pathogens, producing high-quality reclaimed water.

6 Forward Osmosis (FO): FO utilizes osmotic pressure to draw water through a semipermeable membrane. It’s being explored for desalination and concentrating wastewater, thus reducing disposal volumes.

6 Electrochemical Processes: Technologies like electrocoagulation and electrooxidation use electrical currents to treat wastewater, removing contaminants and producing reusable water.

6 Nanotechnology: Nanomaterials can be employed in water treatment processes, such as nanofiltration and adsorption, to enhance contaminant removal and increase efficiency.

6 Smart Water Management: Integration of sensors, realtime data monitoring, and predictive analytics enable optimized water reuse operations, minimizing energy and resource consumption.

6 Biofiltration and Natural Systems: Constructed wetlands, natural filtration basins, and living machine systems mimic biological processes to treat wastewater in a sustainable and ecologically friendly manner.

“We are determined to build systems that make people feel confident that reclaimed water is to drink,” Lee explained. “As an industry, we have to succeed in building confidence in water reuse to ensure water security for the future.”

KIERSTEN LEE Vice President and Director of Construction ServicesWhile water reuse technologies offer promising solutions, challenges remain, including public acceptance, regulatory frameworks, and upfront investments. With increasing awareness of water scarcity and sustainability, innovative water reuse technologies have the potential to revolutionize how we manage and conserve water resources for generations to come.

We are determined to build systems that make people feel confident that reclaimed water is to drink. As an industry, we have to succeed in building confidence in water reuse to ensure water security for the future.

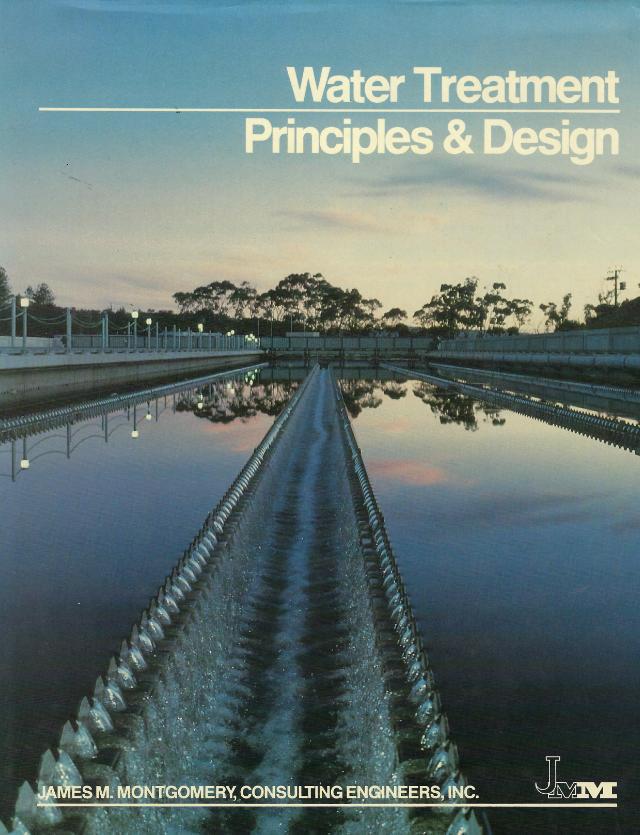

In 1945, James McKee Montgomery laid the foundation for an environmental engineering consultancy firm named James M. Montgomery Consulting Engineers, Inc. (JMM) in Pasadena, CA, focusing on water and wastewater solutions. You

out of college at the time. It was intimidating being around all the senior professionals and the high expectations. It gave me the motivation to excel and learn in order to keep up to speed,” recalled Rusciolelli.

California’s abundant population and susceptibility to arid conditions in the western region positioned it as a focal point for water reuse advancement. Based in Pasadena, JMM played an active role in this landscape. As the late 1960s ushered in the era of advanced water reuse systems, JMM became deeply involved in numerous projects and feasibility studies. In the next twenty years, they experienced significant growth. JMM designed treatment facilities for the Metropolitan Water District of Southern California (MWD) and San Diego Water in Southern California, expanding with new offices in Northern California and acquiring various

may recognize “Montgomery” as the “M” in MWH. The company was officially incorporated in 1954 and offered a range of engineering and construction management services.

MWH’s Construction Management Services (CMS) West Department proudly carries JMM’s construction management legacy into today. Dean Rusciolelli, now Senior Construction Manager for CMS West, shares his connection to JMM. “My time with JMM was interesting. My dad was an electrical engineer for Cutler-Hammer, who worked with JMM guys way back in the 60s, 70s, and 80s. He always bragged about JMM, emphasizing how they were the elite engineers of the day and how he enjoyed working with them. So, when I joined the company, I was really thrilled and proud. I was right

clients in the water and wastewater sectors. In a significant milestone, JMM published “Water Treatment: Principles and Design” in 1985—a comprehensive work addressing fundamental aspects of water quality crucial for water reuse and still cited in reclamation studies. This pivotal text was originally intended to be a textbook, but it evolved into something even more impactful. The book became the go-to reference in the industry for water treatment facility design, from basic science and design principles to operational considerations.

Dr. Marco Aieta, an MWH veteran currently serving as Senior Consultant, was recruited by Rhodes Trussell of JMM in 1986 to lead their Applied Research Department. “Back then, the EPA introduced a wave of new regulations, and we would do pilot studies for our clients to determine the best way to meet those regulations. We had over 100 publications,” notes Aieta. “The work we did formed the foundation for the technology that is used today for direct and indirect potable reuse. It also formed the foundation for current technologies used for groundwater cleanup.” Interestingly, Dr. Aieta’s wife, Jennifer Aieta, wrote all the sample problems and was the technical editor for the third and final edition of Water Treatment: Principles and Design. After working at MWH for a decade, Jennifer went on to start her own firm in the 2000s. “She’s the really smart one in our family,” Dr. Aieta remarked.

Dr. Aieta’s work with JMM began years earlier, in 1975, when Orange County introduced Water Factory 21, a substantial reclaimed water facility utilizing reverse osmosis to treat wastewater. The treated water was injected into the ground, creating a hydraulic saltwater barrier to counterbalance the overdrawn groundwater aquifers in the area. JMM conducted viral assays and provided technical direction for the virus phase of the project, contributing to wastewater contaminant removal at Orange County Water Factory 21. Over three years, the James M. Montgomery Environmental Research Laboratory was used to conduct virus monitoring. Eventually, Water Factory 21 moved a step further into direct potable reuse, being one of the first facilities in

Historical Image of Orange County Water Factory 21, courtesy of OCWD

Historical Image of Orange County Water Factory 21, courtesy of OCWD

Historical Image of Orange County Water Factory 21, courtesy of OCWD

Historical Image of Orange County Water Factory 21, courtesy of OCWD

California to do so. “My history with Water Factory 21 goes way back to my Stanford days. I worked alongside Perry McCarthy, a celebrated professor at Stanford, analyzing data for the facility. It was the early 1980s when computers took up an entire room,” recalled Aieta.

JMM’s Applied Research Department, under Aieta’s leadership, tackled a project for the city of Pasadena to address significant groundwater contamination from the Jet Propulsion Laboratory (JPL) in the Devil’s Gate region of the Arroyo Basin. Aieta’s team studied a then-emerging technology called advanced oxidation, focusing on methods such as UV/O3, UV/ H2O2, O3/H2O2, and more to neutralize the toxic compounds. “Advanced oxidation is all based on the fundamental scientific concept of free radicals. When you generate free radicals, they don’t exist very long, but in the presence of the contaminant, they will oxidize and break apart those target compounds,” explained Aieta.

The focus of JMM’s research efforts shifted to San Fernando Valley, where the Los Angeles Department of Water and Power (LADWP) heavily relied on well water. Collaborative efforts led by Bill Glaze of UCLA and Aieta introduced advanced oxidation processes, seeking to address historical contamination from Lockheed Martin’s World War II activities. Aieta notes the project’s success, “We worked together with LADWP to do a long study for them where we looked at implementing ozone peroxide advanced oxidation. Our research results showed we were able

to remove most of the compounds down to nondetectable levels without detrimental byproducts.” The team decided to elevate the scale of the pilot study to that of a demonstration project, running at roughly 1000 gallons a minute. “We designed the facility and built it in the North Hollywood wellfield. It was a turnkey job and may have been the first construction job MWH ever did,” Aieta noted.

Such studies have significantly influenced the development and implementation of modern water reuse technologies and systems. They stand as a testament to JMM’s enduring impact on advancing sustainable water practices. Aieta aptly encapsulates their legacy: “In the very beginning, we developed the science for water reclamation and reuse, then we took the science to the industry and helped them develop the technology that is now being used in the field.”

The work we did formed the foundation for the technology that is used today for direct and indirect potable reuse.

MARCO AIETA

MWH Senior Consultant

Former Applied Research Department Director for JMM Consulting Engineers

Safety is the foundation of every MWH project. Recognizing the importance of ensuring the wellbeing of every individual on the job site, MWH proudly sponsored Construction Safety Week 2023 in May. The core ethos of this annual week-long event is understanding that safety is not just a series of procedures and protocols but a culture that empowers every person on-site to be safe and aware of their surroundings. By joining forces and setting aside competition, MWH and over 70 other construction firms demonstrated their commitment to celebrating the hard work and dedication of those prioritizing safety as the foundation of their work.

This year’s Safety Week focused on strengthening the construction industry’s safety culture and performance. Craft professionals, project leaders, and business executives were empowered to speak up and act on any potential risks, emphasizing the importance of collective responsibility. Safety Week also advocates for improved safety processes, mental health resources, and equipment standards

to reduce the risk of injuries and create safer work environments. Building a holistic safety culture encompasses physical well-being, mental health, and a focused mindset.

MWH’s commitment to safety extends far beyond Safety Week, emphasizing the need for continuous improvement and a steadfast dedication to safety on every job site, every day. Senior managers were encouraged to lead from the front by attending and engaging in weekly safety meetings, pre-shift meetings, Improve It walks, and Stretch and Flex sessions. By evaluating the effectiveness of safety culture at each job site, senior managers can provide valuable feedback to improve safety practices companywide. This hands-on involvement of senior managers underscores MWH’s commitment to fostering a safer industry and reinforces the importance of safety at all levels of our organization.

To understand the importance and impact of this critical week, we spoke with MWH Regional Health & Safety Manager Luke Tallant, CHST, and Slayden Regional Health & Safety Manager Lendel Del Cid, GSP.

“Safety Week is a good platform for spreading knowledge and cultivating a strong culture of safety that lasts. Each year for Safety Week, we always try to bring in vendors or outside resources to spend 20 to 30 minutes with the crews,” Luke Tallant explained. “We shut the jobs down and do nothing but talk about safety and the daily topics.” Safety Week 2023 covered various topics to promote safety awareness. MWH, Slayden, and Methuen crews across dozens of job sites took part in daily activities and toolbox talks, which provided valuable insights and practical guidance to empower all those on-site to make safe choices.

The efforts that we put into safety week are for our people. In construction, success is not just measured by the finished project but by the stories of lives protected.

LENDEL DEL CID

Regional Health & Safety Manager Slayden Constructors

1

The week began with reflective sessions on the mission of Safety Week and discussions of how to maintain a personal commitment to safety. “You can really tell that it brings safety to the forefront of everyone’s mind,” Tallant remarked while reflecting on how crew members act during and after Safety Week. “The efforts that we put into safety week are for our people,” stated Lendel Del Cid. Building strong teams who work safely is the most important job for everyone on every construction site, and those who are empowered to step in, speak up, and work together to stop anything that risks safety.

2

Day two’s toolbox talk delved into the concept of risk identification. Participants were encouraged to acknowledge error-prone situations and utilize evaluation processes to identify hazards and critical task steps to ensure safety. “People have to be hyper-aware of their surroundings, because so much changes during construction, not just on a daily basis but even minute by minute,” mentioned Tallant. Not all hazards are apparent or easy to recognize, even to those who see and face them every day-some hide in plain sight.

MWH takes great strides to provide environments where employees are empowered to sharpen their safety skills, help their fellow team members, and maintain a safety-first mindset. Our Improve-Its Program implores field personnel to identify ways to complete tasks related to construction equipment and processes safely and efficiently. “If someone sees something in the field, they can honestly whip out their phone, take a picture, put it in the system, and in real-time, it goes to the people associated with that risk so they can get right back out there

and fix or correct the issue,” Tallant remarked. These weekly safety submissions must be corrective or serve as a teaching moment and be high quality, meaning they must include a photo, a description, and a due date based on the severity or risk associated with the safety item.

“Improve-Its allow us to rapidly address safety concerns,” Tallant explained, “They give us insight into what topics we should go over with each crew to increase safety awareness and preparedness.” Logging and categorizing Improve-Its are vital in identifying leading indicators needed to take a proactive approach to safety management and training. In 2022, MWH exceeded the goal of generating 10,000 Improve-Its. This year, MWH updated the Safety Improve-It and Safety Observation quota for project teams, requiring one Improve-It/Observation per person per week.

3

Safety Week’s Fall Prevention Day aligned with OSHA’s National Safety Stand-Down to Prevent Falls in Construction. Falls are preventable, but in 2021 alone, 38% of construction industry deaths were due to falls from elevation (OSHA, 2023). “We brought in third-party trainers to do fall protection presentations where they bring a special truck and drop a dummy outfitted with an old harness that was known in the industry years and years ago,” Tallant commented. “This allows us to compare the old to the new technology that we have for fall protection

with retractable and other critical features like that, which really opens everyone’s eyes to see the difference and the true impact of a fall.”

On Fall Prevention Day, Slayden Regional Health & Safety Manager Lendel Del Cid was on-site at the Geren Island Water Treatment Plant Ozone Upgrades project in Salem, OR—a project that requires working in confined spaces. “We had Ritz Safety do a confined space training, and while the trainer was explaining the importance of the air monitors and sufficient oxygen, one of our Superintendents spoke up to share a story.” Del Cid recounted how Kenny Pollard, a Superintendent who’s been with Slayden for over 30 years, shared a harrowing experience with 45 to 50 crew members listening, “he described how a former coworker went down in a confined space and how it could have been a life-threatening situation if all of the proper safety protections had not been in place. When stories come from someone other than the safety guy, it really hits home.”

Although Pollard’s story would be a stark reminder for almost any worker, the crew listening that day was particularly impacted because they had just celebrated one of their team members receiving a spot bonus for vigilantly monitoring air in a confined space. “Had the employee become complacent with the air monitoring procedure…it could have been very, very serious,” Pollard noted.

4 5

Interactive demonstrations led by experienced crew members empowered attendees to share their knowledge while promoting safer and more efficient work practices. “That day gave us the opportunity for seasoned veterans to speak up on some of their own experiences throughout their careers and be able to pass that knowledge along to the newer employees,” Tallant explained.

“Listening to seasoned workers like Kenny tell stories about unforgettable safety situations not only relates to the training but also drives home the idea that no matter how safe we think we’re being, we’re not going to do anything until we have every safety measure in place,” noted Del Cid. “We have to be prepared for the worst, even if we’re doing everything right.”

On the final day of Safety Week, our toolbox talks shed light on silica exposure’s hazards and health effects. “Silica is always a big one for us because it’s still relatively new, even though it’s been about six years since the whole standard changed,” explained Tallant. Participants learned about preventive measures to minimize overexposure and protect their health.

Crystalline silica is a common mineral found in construction materials such as sand, stone, concrete, brick, and mortar. When materials containing crystalline silica are cut, ground, drilled, or crushed, a fine dust known as respirable silica dust is created. Because it’s 100 times smaller than a grain of sand, people can unknowingly inhale silica dust, potentially leading to the development

The most rewarding part of my job is seeing that even when I’m not on site, people still call when they have questions or concerns. They’re not afraid to reach out to the safety department, and that just goes a long way in showing that we have built that culture where everybody wants to be their brother’s keeper.

LUKE TALLANT Regional Health & Safety Manager MWH

of lung cancer, silicosis (an irreversible scarring and stiffening of the lungs), kidney disease, and chronic obstructive pulmonary disease.

To limit exposure to silica dust, MWH requires all employees and subcontracted personnel to be trained in silica awareness and how to utilize the “Specified Exposure Control Methods When Working with Materials Containing Crystalline Silica” Table issued by OSHA. MWH also established and implemented a Written Exposure Control Plan, which guides field personnel in limiting operational silica exposure and documenting cases of worker exposure.

“The end of the week is an opportunity to show our appreciation to the crews, not only for following our safety policies and programs but for all their efforts throughout the project,” Tallant remarked. “The most rewarding part of my job is seeing that even when I’m not on site, people still call when they have questions or concerns. They’re not afraid to reach out to the safety department, and that just goes a long way in showing that we have built that culture

where everybody wants to be their brother’s keeper. They work together on a daily basis and use all the resources they have to make sure that they don’t put themselves or anyone else at risk.”

Agreeing with Tallant, Del Cid commented, “We celebrate our safety and our people. These kinds of milestone celebrations go a long way. They show our people how much we appreciate their dedication and hard work. In construction, success is not just measured by the finished project but by the stories of lives protected.”

Safety Week 2023 served as a rallying point for the construction industry, uniting companies, workers, and leaders under a common goal: building a stronger, safer industry. The collective efforts of MWH and over 70 other top construction firms exemplify the commitment to making safety a fundamental aspect of every construction project.

Safety Week empowers individuals at all levels to be strong voices and make safe choices through engaging toolbox talks, interactive demonstrations, and hands-on involvement. By continuously improving safety practices and fostering a culture of shared responsibility, the construction industry can create safer work environments, protect workers’ well-being, and positively impact the communities they serve. Together, we build a safer industry for the present as well as the future.

Occupational Safety and Health Administration (2023)

6 National Safety Stand-Down to Prevent Falls in Construction. www.osha.gov/stop-falls-stand-down

6 OSHA’s Fall Prevention Campaign. www.osha.gov/stop-falls

Slayden Crews at Geren Island posing with a signed Safety Week PosterMWH is thrilled to announce the achievement of a significant milestone as the Portland City Council recently authorized the first phase of construction for two vital water infrastructure improvement projects. This authorization comes on the heels of completing the preconstruction phase, where MWH closely collaborated with the project design teams and the Portland Water Bureau (PWB), starting at the 30% design milestone. Led by MWH in separate joint ventures, the Bull Run Filtration Facility and Bull Run Filtration Pipelines projects are crucial to enhancing water quality and reliability for Portland and wholesalers throughout the region. The $1.473 billion investment in these critical water initiatives marks a significant step forward for the City and demonstrates MWH’s commitment to sustainable water solutions.

MWH has worked with the PWB over several years to improve water treatment and help protect the health of nearly a million people who drink Bull Run water. In Portland, the primary source of lead in water is the corrosion of plumbing in homes and buildings. To significantly reduce exposure to lead at the tap, MWH

completed the Improved Corrosion Control Treatment project in April 2022 on time and under the PWB’s $24.4 million budget. The final project cost of $20.2 million included a construction guaranteed maximum price of $17.9 million from MWH, with more than $4 million of hard construction costs contracted with minority and women-owned firms. Committed to supporting the local community and achieving PWB’s vision, MWH ensured that 55% of the project’s hard construction costs were subcontracted with firms certified by the state’s Certification Office for Business Inclusion and Diversity, exceeding the City’s 22% goal

The Bull Run Filtration Facility project aims to establish a new water filtration facility to improve water quality in the Bull Run water supply. Set on a vast 95-acre parcel in rural Multnomah County, this cutting-edge facility will employ granular media filtration technology, enabling it to process an impressive 135 million gallons daily (MGD).

MWH, in a joint venture with Kiewit, will oversee site preparation and earthwork during the first phase of this two-phase project. The strong project team comprises industry leaders, including the Brown and Caldwell program management team and the multi-firm design team of Stantec, Carollo Engineers, and MWA Architects. Construction is set to commence in fall 2023, with a September 2027 projected substantial completion.

Photo from the Improved Corrosion Control Treatment Project.

Photo from the Improved Corrosion Control Treatment Project.

The Bull Run Filtration Pipelines project focuses on installing pipelines to convey water to and from the filtration facility and existing water infrastructure to ensure efficient water delivery throughout the region. Bull Run Conveyance Partners, a joint venture between MWH and J.W. Fowler, serves as the project’s construction manager/general contractor, while Jacobs spearheads the design effort. Construction is scheduled to commence in spring 2024 and reach substantial completion in 2027.

Over three years, MWH and PWB have focused on cost management for these vital projects. Through value engineering efforts, MWH has played an integral role in successfully reducing construction costs for PWB by $200 million. To help maintain water rate affordability while these long-term improvements are made, MWH is helping the Water Bureau ensure compliance with the Water Infrastructure Finance and Innovation Act (WIFIA) federal financing assistance program. This loan will significantly lower the cost of investment for affected ratepayers and provide at least $247 million of debt-service savings over the loan term. These cost management strategies are part of our commitment to responsible and efficient allocation of resources as we work towards delivering the highest quality infrastructure.

At MWH, we are excited to begin these vital projects that will further strengthen PWB’s infrastructure. We are dedicated to delivering exceptional results for our community through sustainable design, cuttingedge technology, and collaborative partnerships. As we move forward with construction, we remain committed to managing costs effectively while upholding the highest quality and environmental stewardship standards.

Stay tuned for more updates as we progress on these significant water infrastructure ventures that will shape the future of Portland’s water systems and ensure a sustainable and resilient water supply for generations to come.

Led by MWH in separate joint ventures, the Bull Run Filtration Facility and Bull Run Filtration Pipelines projects are crucial to enhancing water quality and reliability for Portland and wholesalers throughout the region.

We are thrilled to share that Methuen Construction has been awarded a $51M contract to upgrade and retrofit the Water Purification Control Facility (WPCF) in Vernon, CT. Working in collaboration with Tighe & Bond, this crucial project will involve retrofitting the powdered activated carbon activated sludge system into a new

Integrated Fixed-film Activated Sludge (IFAS) treatment system – which combines the advantages of conventional activated sludge with those of biofilm systems by combining the two technologies in a single reactor.

The project will also convert the effluent sand filters into a new cloth media filtration system, chlorine contact tanks into a new ultraviolet disinfection system, abandoned digesters into new sludge storage tanks, and retrofit an abandoned vacuum filter room for use with new Rotating Drum Thickeners. Spaces will be modified to fit new chemical storage and metering systems. The upgrades aim to bolster the facility’s water treatment capabilities and ensure a more efficient and sustainable water purification process for the Town of Vernon.

On June 16, Under Secretary of the Navy Erik Raven and US Senator Angus King paid a visit to the Portsmouth Naval Shipyard to tour the highly anticipated Paint, Blast, and Rubber Facility in Kittery, Maine, currently under construction by Methuen Construction.

With a budget of $95M, this cutting-edge project is nearing completion and is set to consolidate shipyard operations, streamlining them into one state-of-the-art facility. This optimization aims to enhance efficiency and support the Navy’s crucial submarine maintenance and overhaul operations.

The “Smith Shop,” reconstructed and upgraded by Methuen as part of the $42M Structural Shops Consolidation project, can be seen in the background of the photo.

OWNER: Town of Vernon, CT

TECHNOLOGIES/MATERIALS: Major Pump Replacements for Various Systems, Rotary Drum Thickeners, UV Disinfection System, Primary and Secondary Clarifier Upgrades, IFAS Treatment System, Cloth Media Filtration System, and various other mechanical upgrades.

ENGINEER: Tighe & Bond

PROJECT VALUE: $51 Million

OVERVIEW: This project involves retrofitting and upgrading the WPCF as well as replacing significant mechanical and electrical equipment.

Author: Lana Piskorowski

Author: Lana Piskorowski

The Logan Regional Wastewater Treatment Facility in Logan, UT, received the esteemed 2023 Excellence in Concrete Award from the American Concrete Institute’s Intermountain Chapter. MWH constructed this cutting-edge 18 MGD (million gallons daily) treatment plant using an impressive 27,000 cubic yards of concrete.

The project was a triumph of collaboration and innovation, as MWH worked tirelessly with the City of Logan and project partners to construct the stateof-the-art facility from scratch. Engineering expertise was provided by MWH’s long-standing design partner Carollo Engineers, and the concrete effort was supported by trusted subcontractors Ralph L. Wadsworth Construction, Champion Fabricating & Supply Inc., KGS Steel Inc, and concrete supplier Legrand Johnson Construction. MWH recognizes all our project partners for their invaluable contributions to the project’s success.

The facility was designed to address the growing demands of the community and to meet stringent environmental regulations. It encompassed a comprehensive range of complex components, including the largest magnetite dosing (BioMag ™) treatment plant in the western US. The scope comprised solids holding and processing, secondary clarifiers, influent pump station, fine

screen headworks, grit removal structure, biological reactors, UV disinfection, and chemical feed and storage, among other vital elements. The project also required intricate earthwork, auger cast pile foundations, shoring, and complex yard piping.

Our multidisciplinary team’s unwavering commitment to technical excellence and delivering substantial value engineering cost savings was evident throughout the project. Multiple workshops were conducted to identify innovative solutions, resulting in a remarkable cost reduction of $32M from the initial estimate of $171M – reflecting our dedication to providing the best outcome for the city. Moreover, construction took place in harsh winter conditions. The inversion trapping frigid temperatures in the Cache Valley presented unique challenges. Yet, MWH’s experienced construction team skillfully navigated these obstacles, adapting their approach to ensure the project progressed as scheduled.

The Logan Regional Wastewater Treatment Facility is a shining example of what can be achieved when collaboration and expertise unite. MWH takes immense pride in its contribution to this groundbreaking project, which has redefined wastewater treatment capabilities in the area and paved the way for a cleaner, more sustainable future.

2023 EXCELLENCE IN CONCRETE AWARD

Slayden, a prominent name in the Pacific Northwest’s heavy civil water industry, has appointed Tom Paul as its new President. With an impressive track record of 40 years in water-wastewater infrastructure project management and organizational leadership, Tom’s appointment is poised to enhance Slayden’s competitive position and reinforce its position as a regional leader.

The announcement of Tom Paul as the new President brings excitement and optimism to Slayden and its teams. Tom’s extensive experience in the water industry makes him an ideal fit to lead the organization toward bigger and better opportunities.

Beyond his project management prowess, Tom’s contributions extend to broader industry leadership. Notably, he served as the Chairman of the DesignBuild Institute of America (DBIA) Water/Wastewater Annual Conference in 2018. This role demonstrated his commitment to promoting best practices and innovation within the water industry.

With his leadership at the helm, Slayden is poised to navigate the ever-evolving landscape of the water industry with confidence and foresight. Tom’s strategic vision is expected to drive the company’s growth, fostering innovation, and strengthening client relationships.

“Slayden has always been at the forefront of delivering exceptional solutions for our clients, and I am excited to build upon this legacy,” Tom expressed his eagerness to make a positive impact.

Tom Paul’s appointment as President marks an important milestone in Slayden’s journey. As the organization continues to forge ahead in the Pacific Northwest’s water industry, his leadership promises a bright and promising future.

“I am thrilled to be part of such a fantastic organization and look forward to leading our teams to bigger and better opportunities,” remarked Tom upon his appointment.

Tom Paul’s journey in civil engineering began with a Bachelor of Science degree in the field, laying a solid foundation for his career. Over the years, he has gained invaluable expertise in managing waterwastewater infrastructure projects, earning him admiration and respect in the industry.

In conclusion, Slayden’s decision to welcome Tom Paul as their new President is a testament to their commitment to excellence and innovation. With his wealth of experience and visionary approach, Tom is poised to further elevate Slayden’s position as a leader in the region’s heavy civil water industry. As the company embarks on this new chapter under Tom’s leadership, the prospects for growth and success appear exceptionally promising.

Slayden has always been at the forefront of delivering exceptional solutions for our clients, and I am excited to build upon this legacy

TOM PAUL President of Slayden Constructors

Begins his career with an apprenticeship. He was largely self-taught

age 15

age 23

Most engineers at the time had given up on the idea of a pressurized water supply due to heavy leaks

Appointed Chief Engineer to Trent Waterworks Company

age 25

age 59

When cholera struck 16 years later, the town was virtually unscathed, thanks to his concept

age 41

Starts a partnership with his son, Charles, T&C Hawksley, which later merges with JD & DM Watson to become Watson Hawksley, the “W” in MWH

age 64

age 69

Determined, Hawksley collaborated with an ironworks company and local plumbers to design robust, easily repairable pipe fittings His persistence triumphed with the construction of Trent Bridge Pumping Station, the country’s first pressurized system, which served Nottingham

Hawksley lead the design and construction of

OVER 150 waterworks systems in the UK and abroad

He was knighted by Austria, Denmark, Brazil and Sweden for his contributions to water infrastructure

In the annals of engineering history, few names shine as brightly as Thomas Hawksley. Born on July 12, 1807, Hawksley’s legacy as the preeminent water engineer of the 19th century remains an indelible mark on the world of infrastructure and innovation.

Hawksley’s journey into the realm of water had humble beginnings. He cut his teeth as an apprentice under the guidance of architect and surveyor Mr. Edward Staveley at the tender age of 15 with limited formal education. Hawksley’s innate curiosity and determination propelled him forward, leading to a path of self-guided learning that would ultimately define his exceptional career.

Just eight years later, at age 23, Hawksley was appointed Chief Engineer of the Trent Waterworks Company. It was a role that would prove pivotal in shaping the trajectory of his contributions to the world of water infrastructure.

During his lifetime, many engineers resigned themselves to the belief that pressurized water supply systems were an untenable dream due to the seemingly unavoidable occurrence of heavy leaks. However, Hawksley’s unyielding determination and innovative spirit led him to collaborate with an ironworks company and local plumbers. Together, they devised a series of robust and easily repairable pipe fittings, effectively tackling potential leakage.

At age 25, Hawksley’s celebrated his first major achievement with the realization of the Trent Bridge Pumping Station—a groundbreaking project that birthed the country’s inaugural pressurized water system. This system, serving the City of Nottingham, stood as a triumph of Hawksley’s persistence and forward-thinking approach. Little did he know, this achievement would be a saving grace for the city in the coming years.

Sixteen years later, when the specter of cholera reared its deadly head in Nottingham, the city remained remarkably untouched. Thanks to Hawksley’s visionary pressurized water system, Nottingham’s residents were spared from the

devastating effects of the disease.

Hawksley’s impact spread far beyond his homeland as he led the design and construction of over 150 waterworks systems in the United Kingdom and abroad. His influence earned a knighthood from Austria, Denmark, Brazil, and Sweden—a testament to his global contributions to water infrastructure.

At 59, Hawksley joined forces with his son Charles to establish T&C Hawksley, a partnership that would later merge with JD & DM Watson, ultimately giving rise to Watson Hawksley—the namesake of the “W” that now graces MWH. Hawksley also became the president of both the Institution of Civil Engineers and the Institution of Mechanical Engineers—a testament to his stature within the engineering community.

As we reflect on Thomas Hawksley’s life, we honor a man whose indomitable spirit and visionary contributions have left an enduring legacy that we continue to uphold today at MWH. His innovations continue to ripple through time, a source of inspiration for our work, reminding us that the boundless horizons of human achievement are limited only by our imagination and determination.

In July, we celebrated the birthday of the earliest founding name of MWH: Thomas Hawksley. But who was this innovator from 216 years ago?

With a career spanning over a decade, Kiersten Lee, PE, PMP, has established herself as a prominent figure in the field of commissioning and start-up management. Kiersten started her construction journey as an intern at MWH, and she has overseen and participated in the successful launch of numerous high-profile projects, earning her a stellar reputation as a water reuse and resource recovery expert across the industry.

Of her countless achievements, one of the most significant was Kiersten’s instrumental role in operating the first semiconductor water reuse facility in the US. This was a landmark project for the progress of water reuse adoption nationwide.

“Although MWH built the nation’s first semiconductor water reuse plant, this type of facility is not new. We had a smaller version in Israel, and manufacturers across the Pacific Rim have already been doing this. The US is a bit behind the curve, but if we want to bring manufacturing back, we need to be thinking about how to manage the waste streams associated with this kind of manufacturing.”

over 100 million gallons of water, and recently they achieved the billion-gallon milestone—a win for the manufacturer, the local community, and the environment.

Lee emphasizes that major industries have a significant role to play in water consumption and discharge, making them central to the conversation about sustainability. “Getting to a point where we can comfortably and confidently use reuse processes for our wastewater in a potable sense—that’s a critical hurdle,” Lee remarked.

Anyone who works with Kiersten knows that conserving the environment is one of her passions. “I’m Captain Planet at heart, and I’m a huge proponent of eliminating the use of bottled water,” Lee remarked, “Treatment plant discharges are regulated by the EPA, while bottled water is regulated by the FDA. The FDA tries to keep up with the EPA’s drinking water regulations, but sometimes, the FDA’s quality and safety regulations diverge. So bottled water is not as regulated as tap water, and it produces tons of plastic waste.”