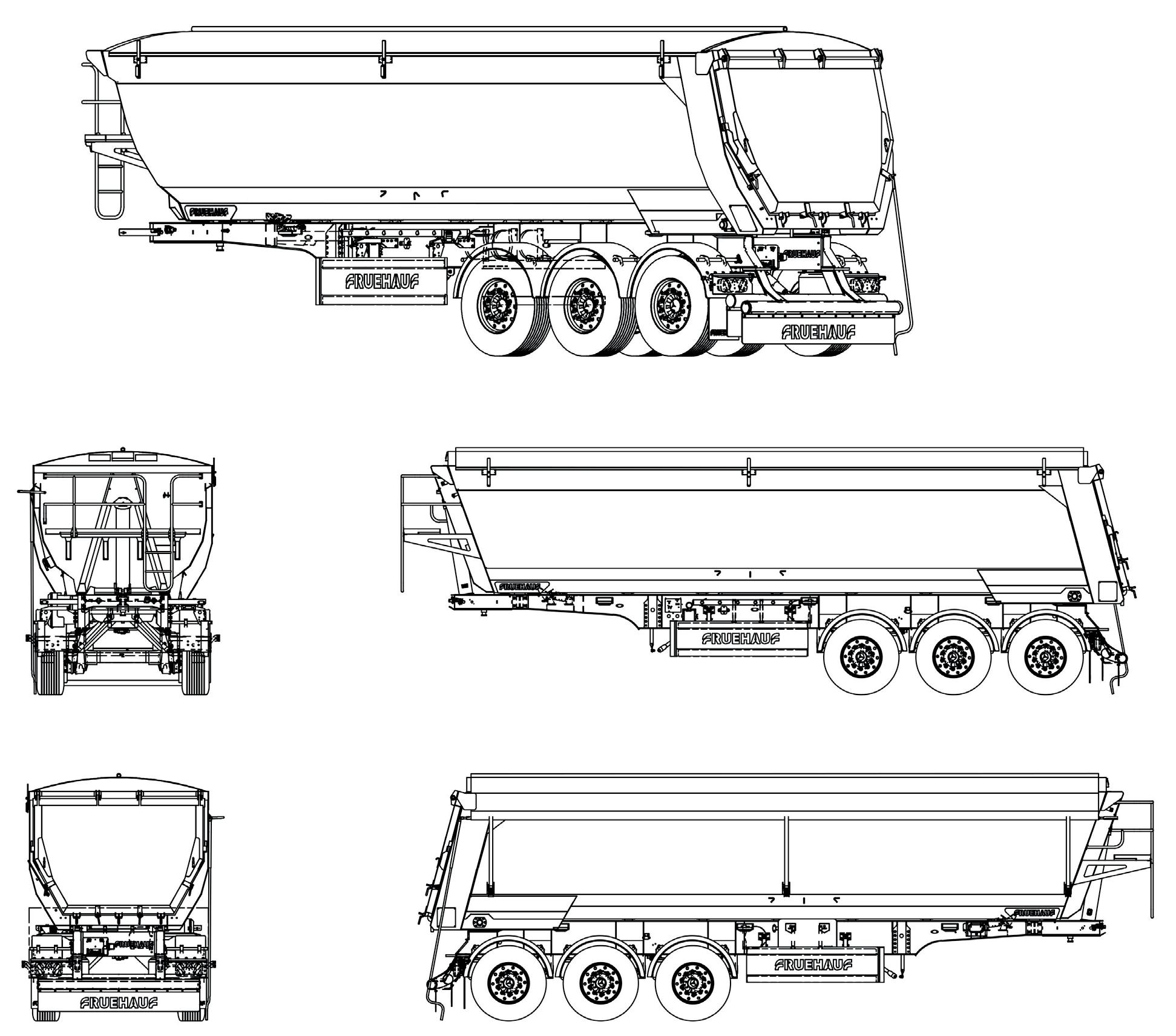

HALFPIPE

Chassis : Fruehauf Performance Straight Frame

Body : Fruehauf full length pressed from 6mm aluminium

Capacity : Various capacities available 40–45 yd3

Paint : Primer, two pack top coat followed by clear coat lacquer

Paint schemes : Full, single or multi coloured available

Tailgate : Air locking tailgate with option of in-cab operation

Sheet : Dawbarn Hydroclear

Floor : One piece 8mm high-strength, wear-resistant aluminium grade 5083-H34 and 5083-H343

Onboard weigher : Chassis mounted, in-cab, and handheld options

Stability : Surpasses IRTE class ‘A’ (7 degree) stability test

Type approval : European whole vehicle type approval

Fruehauf manage all manufacturing process from beginning to end at our Grantham plant. Each aggregate tipping trailer is built to exacting measurements, precise customer speci cations and delivered on time.

As 80% of our production methods are automated, work ow can be increased at any time without diminishing accuracy, consistency or reducing lead time.

The weight saving on a Fruehauf tipping trailer can be as much as 250kg, all structural extrusions are unique to Fruehauf and trailers carry European type approval (TUV). Uniquely, Fruehauf precision engineer both the chassis and body components, starting from raw materials and completing the trailer manufacturing process within two weeks.