Advanced Metrology Services

Comprehensive Inspection, Engineering, & Equipment Services

Total Metrology Solutions

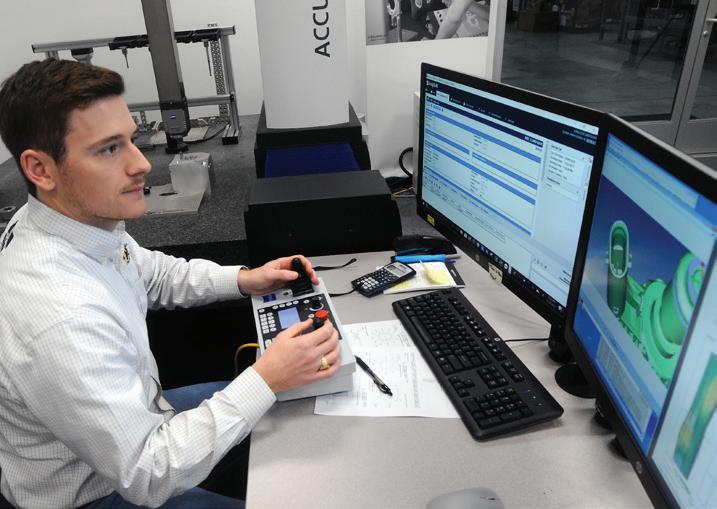

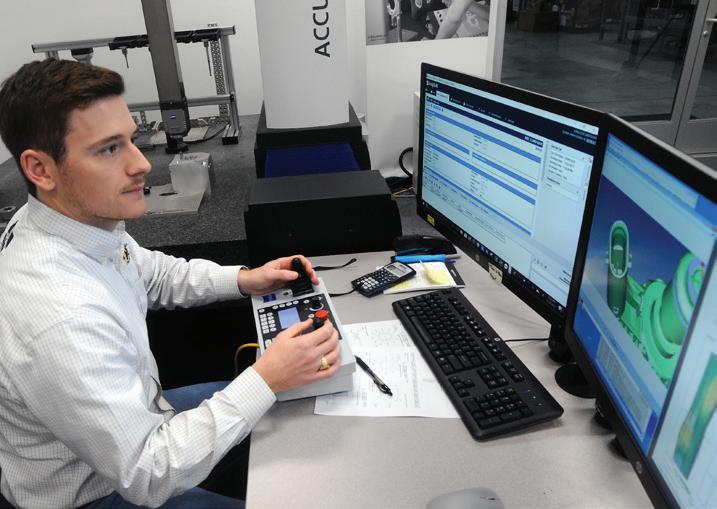

MSI Viking is a leading provider of ISO 17025 Accredited inspection and engineering services. Our team works with you every step of the way to understand your exact challenges and offer solutions that save you time, money, and effort. From first article inspection and reverse engineering to CMM programming and turnkey solutions, you can always count on our service and support.

Inspection Services Engineering Services Equipment Services

Dimensional Inspection

Mechanical Testing

Metallurgical Testing

Non-Contact Surface Topography

Sample Preparation & Mounting

Turnkey Processes

Reverse Engineering

Process Capability Studies

Gage R&R Studies

Custom Fixtures & Probes

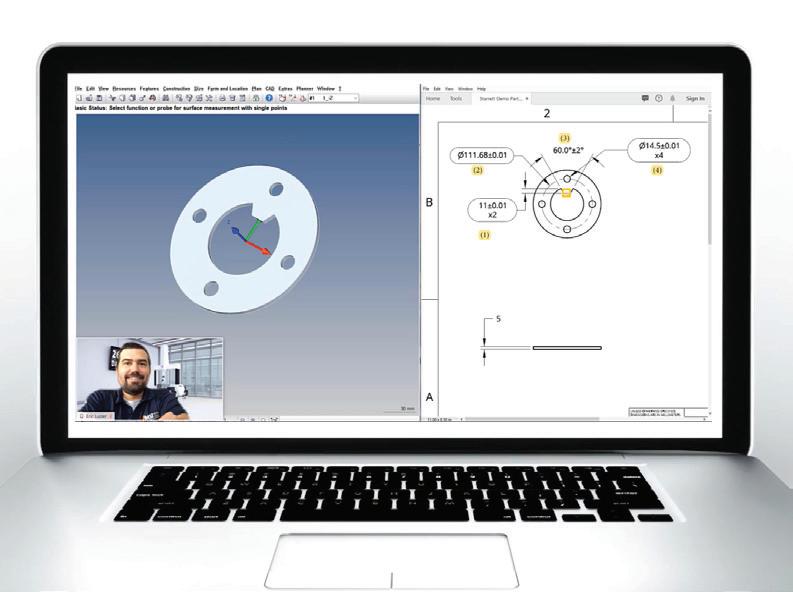

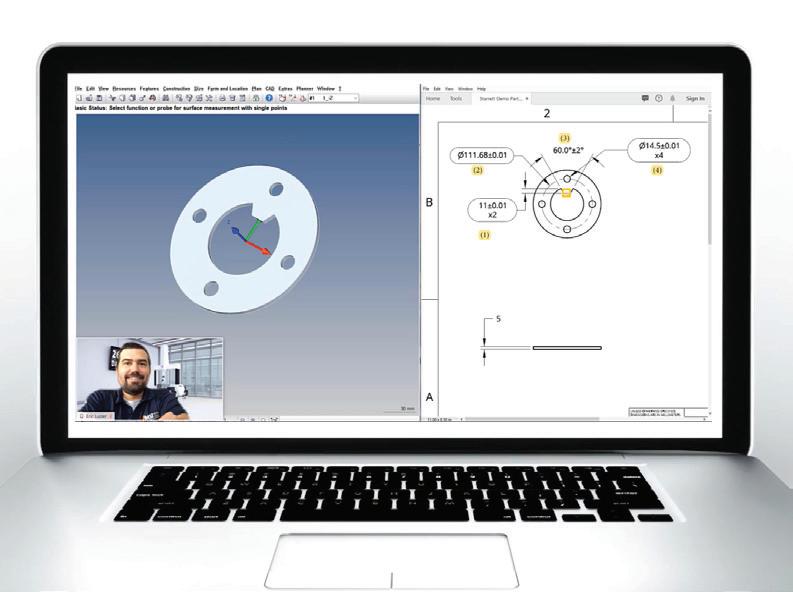

CMM Programming

CMM Calibration, Retrofits, Repair

Metrology Equipment Programming

Application-specific Training

Equipment Set-up & Training

On-Site Support

Customized Reporting

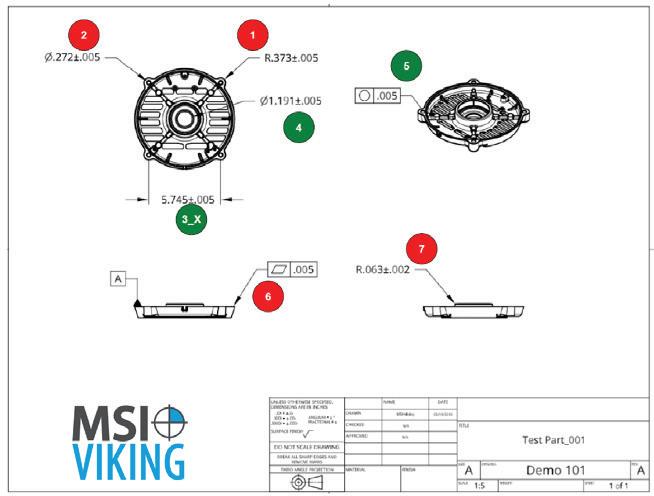

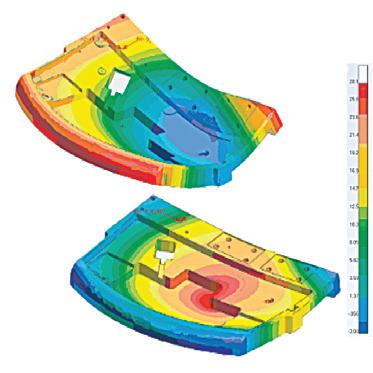

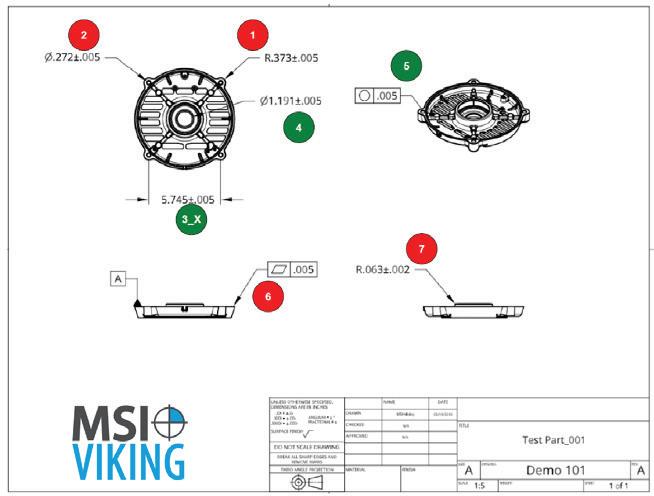

With any of our inspection services, you’ll receive detailed reporting tailored to your needs. Our results are NIST traceable and our knowledgeable staff is always available to discuss the results with you.

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

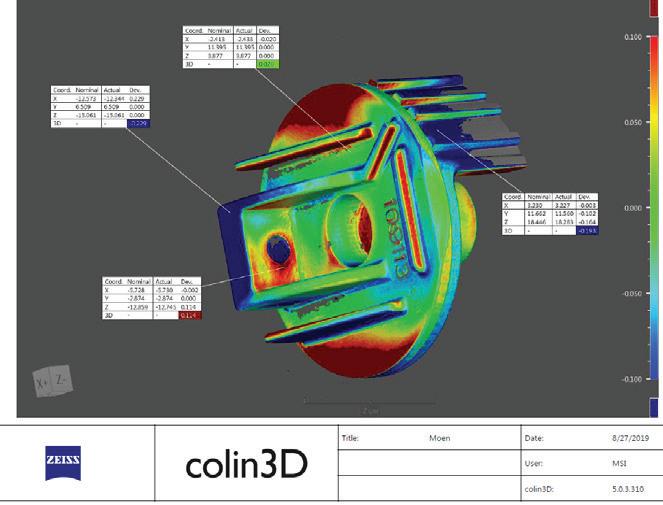

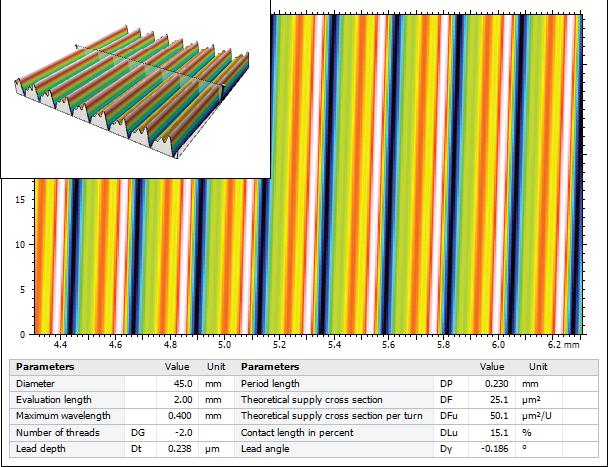

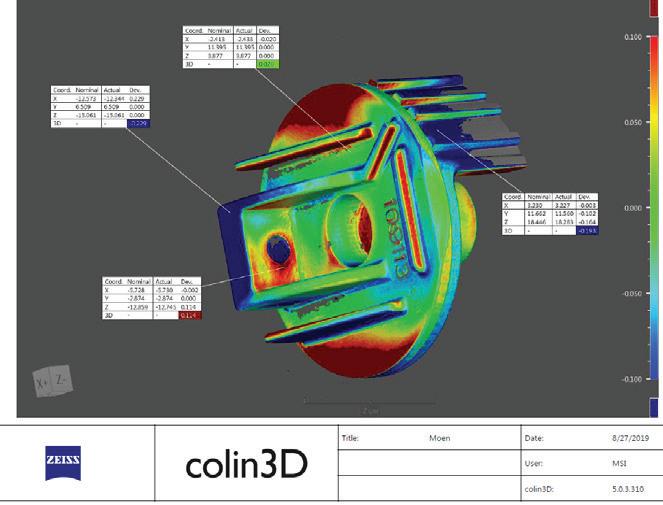

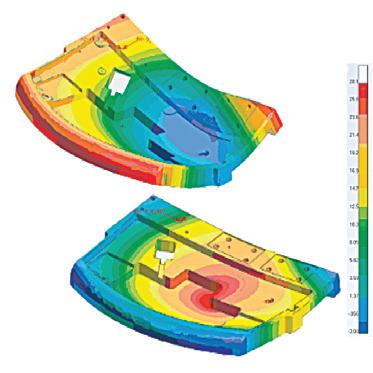

Reporting options include 3D color gradient heat maps, First Article Inspection (FAI), form plots, spreadsheets, custom reports, and more.

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1000-2022

Total Metrology Solutions

Advanced Metrology Services

Comprehensive Inspection, Engineering, & Equipment Services

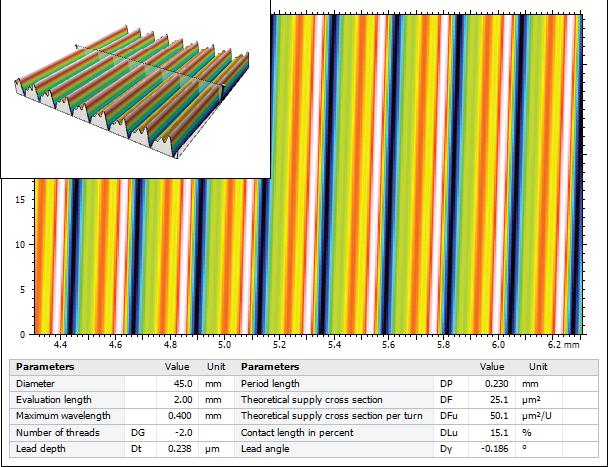

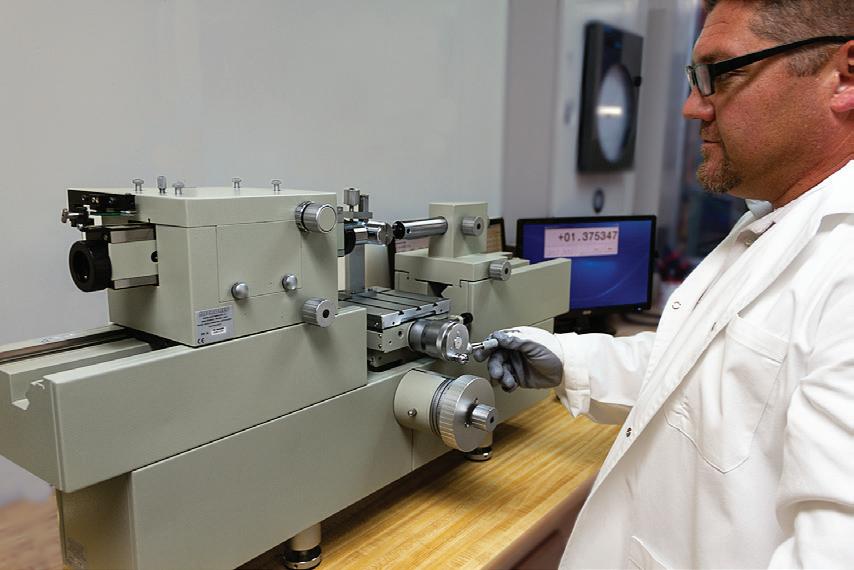

MSI Viking provides accredited inspection services using the same metrology systems we service and sell. Whether in our climate-controlled labs or at your facility, our team makes sure you’re getting fast and accurate results every time. Our engineers work with you to find the most effective way to measure your part. We offer contact and non-contact dimensional measurement, mechanical testing, metallurgical testing, surface topography testing, and sample preparation. With our extensive scopes we’re able to tackle nearly any measurement challenge you bring us.

Dimensional & Mechanical Testing

GD&T Roundness

Form

Fracture Toughness

Tensile Strength

Elongation Testing

Compression Testing

Abrasion & Wear Testing

Bend Testing

Pressure Testing

Metallugical Testing

Impact Testing

Stress Rupture

Fatigue Testing

Shear Testing

Torque Testing

Non-Contact Surface Topography

Sample Preparation Services

MSI Viking Inspection & Testing Labs

Our Accredited inspection labs are fully equipped with the most technologically advanced systems including Multisensor CMMs, 3D Scanning Systems , X-Ray CT Systems , Vision Systems , Video Comparators, SF&G Systems, Laser Displacement Sensors, Industrial Microscopes and much more. Set up a metrology “pre-op” assessment to learn more about what we can do for you.

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

Surface Finish

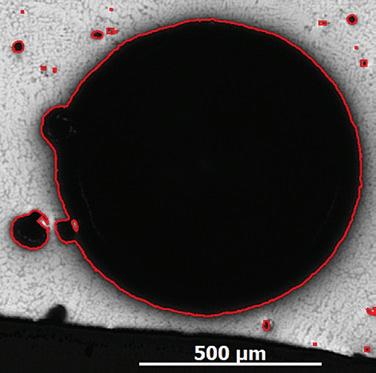

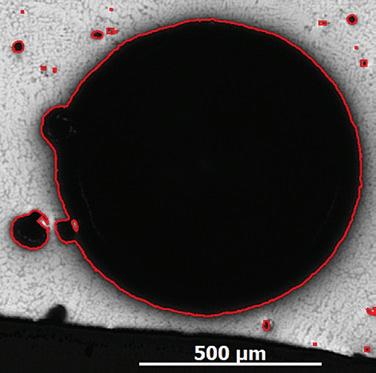

Grain Analysis Particle Analysis Layer Thickness Phase Analysis Non-Metallic Inclusions Graphite in Cast Iron Hardness Testing Porosity Weld Inspection Documentation

Tribology Evaluation BGA Coplanarity Voids & Structures 2D & 3D Surface Fast Fourier Transform Fractal Analysis Grain Analysis Contour Analysis Area Twist/Lead Angle Depth Flatness

Cutting Mounting Grinding Polishing

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771

MSI-LC-1000-2022

Complete Services Equipment Sales Consumables Sales

Precision Metrology Systems

For Industrial Quality Control

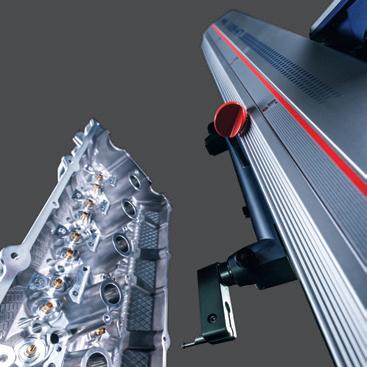

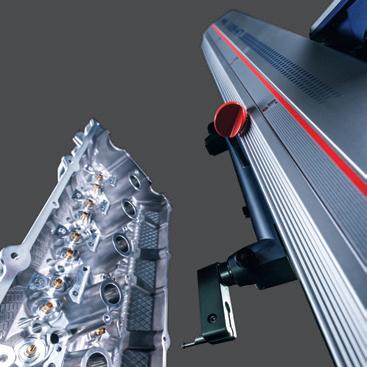

ZEISS Industrial Metrology Systems

ZEISS drives innovation within automotive, aerospace, plastics, mechanical engineering, and medical technology industries. From exploration and processing of raw materials to manufacturing and assembly, ZEISS multidimensional metrology solutions are crucial to the production of high-quality products around the world. Our applications engineering experts navigate ZEISS’s deep and diverse portfolio to pair you with exactly the right solution to produce better, faster, more reliable results.

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

Metrology

Total

Solutions

Coordinate Measuring Machines Vision Measuring Systems Contact & Optical Sensors Surface & Contour Systems Roundness & Form Systems Computed Tomography Systems X-Ray Imaging Systems 3D Scanning Systems Light & Confocal Microscopes Inspection Services ZEISS Software CMM Styli & Fixturing EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1005-2022

Total Metrology Solutions

Precision Metrology Systems

For Industrial Quality Control

Starrett Optical & Vision Systems

When it comes to comparators, there’s only one clear choice – Starrett. Starrett combines advanced optics and imaging technology to ensure bright, sharp images and exceptional accuracy. With a vast selection of styles, sizes, stages, lenses, and other accessories, Starrett has a comparator for most any application.

Starrett video-based measurement systems combine high-resolution imaging, powerful intuitive software, and precision mechanical platforms to deliver high accuracy and repeatable measurement results. .

Applications

Comparison Measurement

Dimensional Measurement

Multi-Part Measurement

Geometric Tolerancing

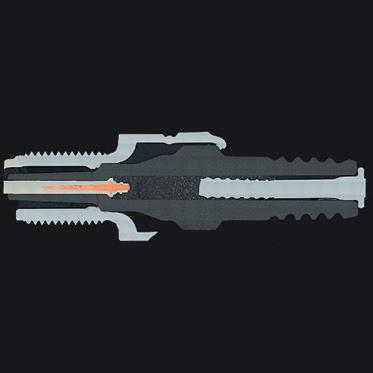

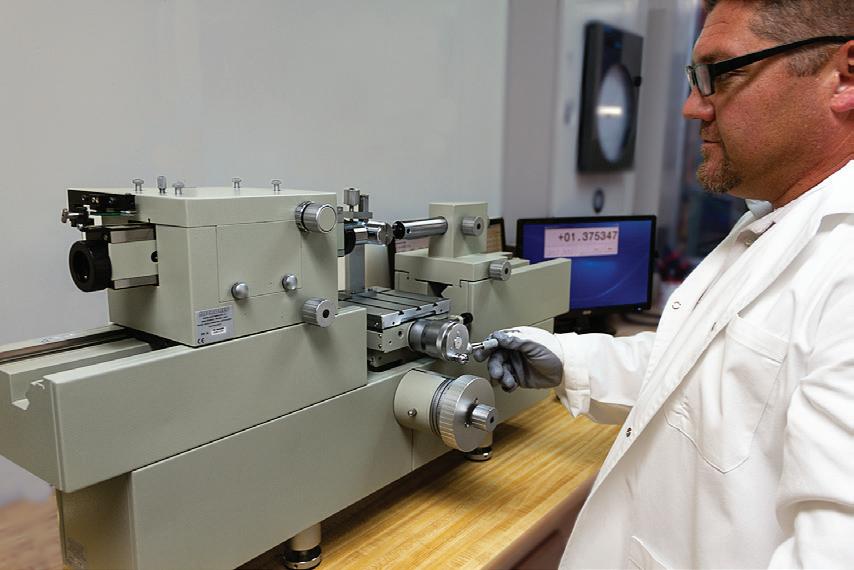

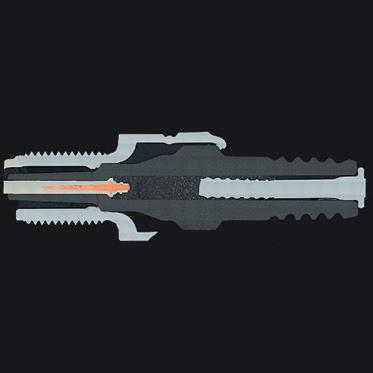

ViciVision Optical Shaft Systems

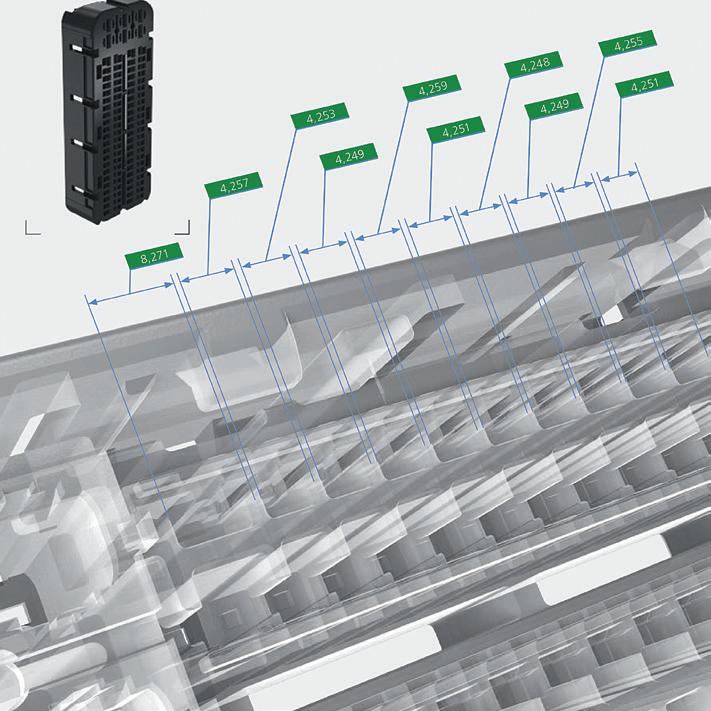

ViciVision high-speed optical measuring systems deliver best in class speed, accuracy, and reliability for shop floor measurement of shafts, cylinders, and other turned, ground, or extruded parts. ViciVision systems can accommodate parts from 8mm to 180mm in diameter and from 100mm to 1250mm in length.

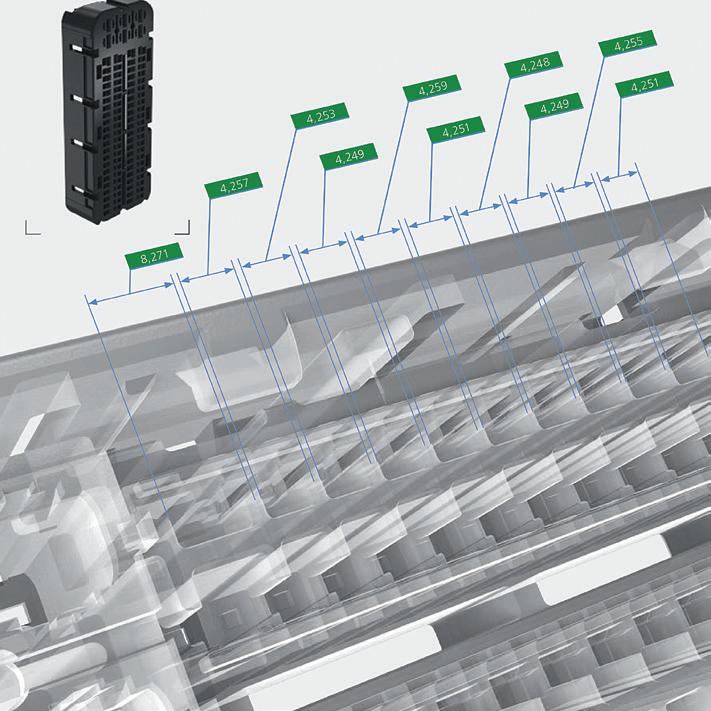

ViciVision advanced software enables measurement of lengths, diameters, distances, angles, radii, form, position, runout, and profile tolerances. Add CAD comparison and other specialized software to measure threads, camshafts, and crankshafts. Optional touch probe system to detect features such as keyways, shafts with splines, gear teeth, and more.

Applications

Crankshafts

Camshafts

Turning Operations

Screw Machine Operations

Turbines Dental Implants Valves & more

optional touch probe self-programming software

Metrios Large FOV Optical Systems

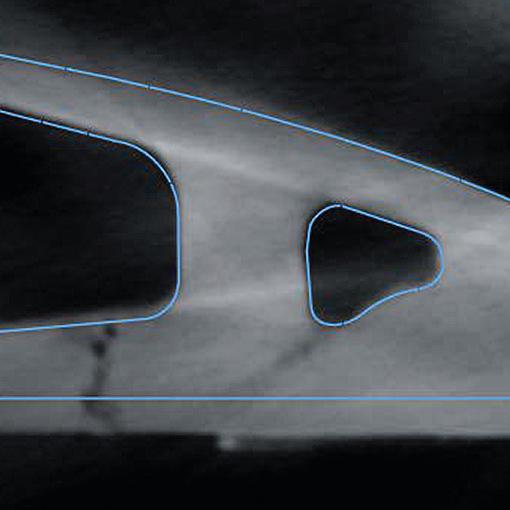

Metrios is an automated optical measuring system with large field of view (FOV) for fast, accurate, and easy to achieve measurement results. Simply “place and press” for instantaneous measurements!

The most complete lighting systems in its category, Metrios performs the measurement through a non-contact system, consisting of a high-resolution camera and three different lighting systems. Through a motorized ring light illuminator, Metrios can change the angle of incidence of the lights on the part and provide different angles of the light source within the same measurement cycle.

Applications

Punched Parts

Flat Gears

Fasteners

Precision Machined Parts

Molded Plastic Parts

Sealings

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

video edge detection

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771

multi-part measurement

17-inch multi-touch screen ring light illuminator

MSI-LC-1005-2022

Total Metrology Solutions

Defect Control Systems

ZEISS Industrial Metrology Imaging Systems

SRE Max

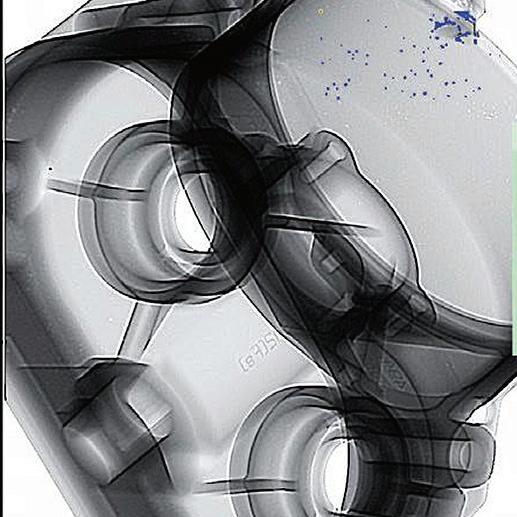

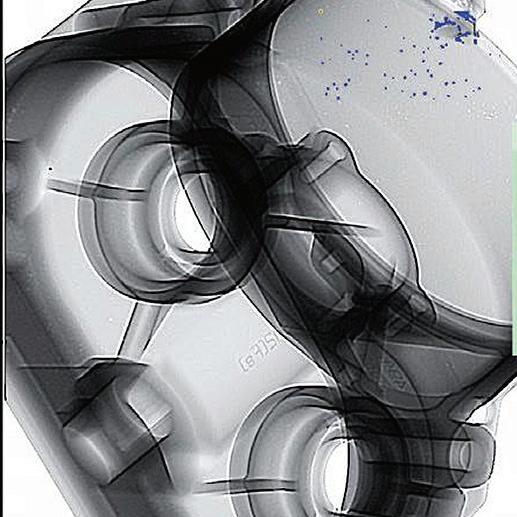

SRE Max 2D & 3D Lab/Shop Floor Radiology

• 2D / 3D Evaluations of Porosity, Inclusions, and Defects

• Computed Tomography option available on some systems

MODELS AVAILABLE

SRE Max (shown)

Broad Range of Use

SRE Hex

Entry Level Radiology

Acre 49

Configured for Batteries

Acre 94

Configured for Pistons

Thunder

Configured for Wheel Evaluations

OMNIA

Configured for Large Parts & Automated Loading (9 axes)

VoluMax

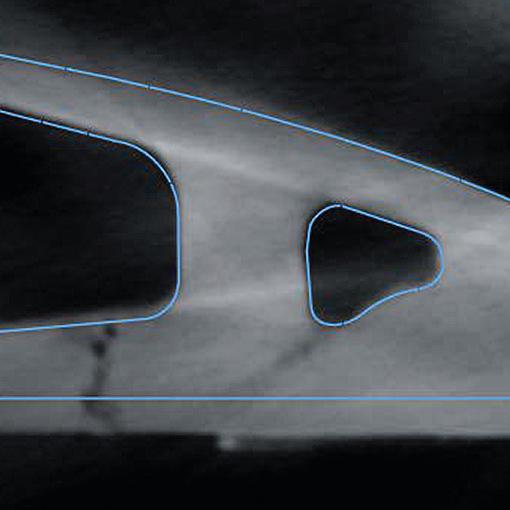

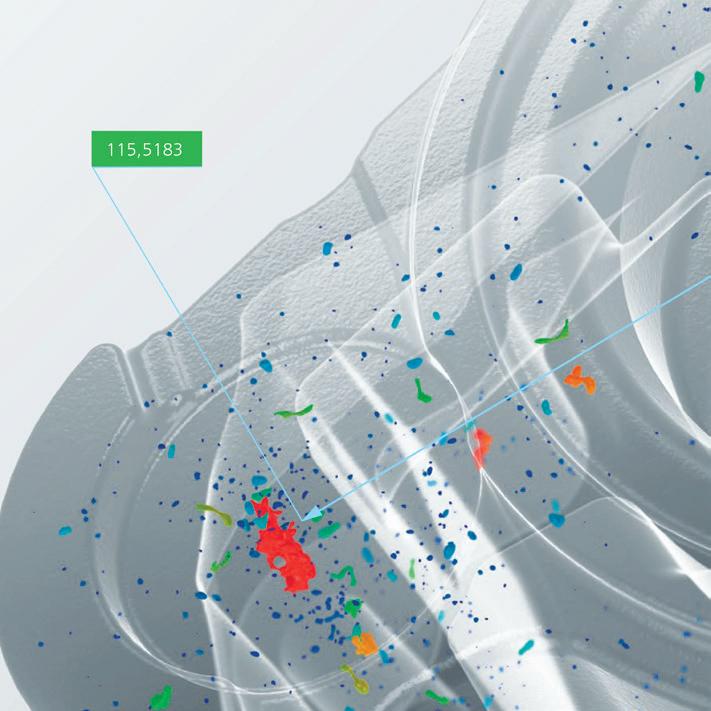

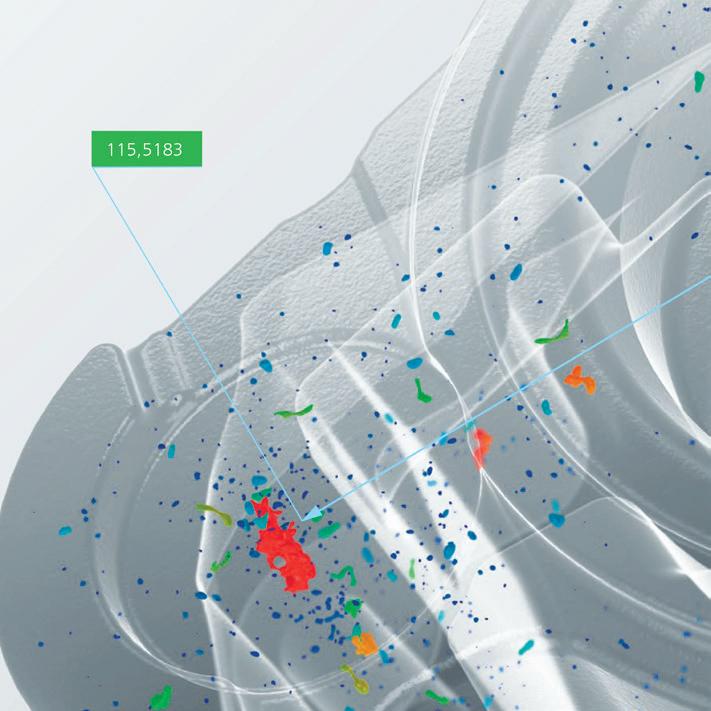

VoluMax In-Process 100% Inspection

• Combine multiple scans into one data set

• Analysis of Porosity, Blisters, Shrinkage, and defects

• High speed evaluations from 5-120 seconds! (dependent on part and measurement objectives)

• Use CAD nominal geometry as accept/reject automatically prior to machining any surfaces

MODELS AVAILABLE

VoluMax 400 130kV

VoluMax 800 130kV

VoluMax 1500 225kV

VoluMax 9 Flash 225kV

VoluMax 9 Titan 450kV

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1001-2022

Metrology and Research Systems

Total Metrology Solutions

Metrotom

Metrotom High Accuracy Metrology Systems

• Laboratory Metrology CT Evaluations

• Comparison to Nominal CAD Files

• Reverse Engineering

MODELS AVAILABLE

Metrotom

Metrotom

• In Situ Measurements

• Highest Resolution Available

MODELS AVAILABLE

Versa 520 (shown)

Premium Offering

Versa 510

High Resolution and Contrast

Versa 410

Entry Level

Ultra 810

Low Density Materials

Ultra 800

Higher Density Materials

MSI-LC-1001-2022

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771

1 130kV Metrotom 6 225kV

800 130kV

800 225kV

Versa/Ultra High Resolution, Non-Destructive X-Ray Microscopy 1500 225kV

Metrotom

Metrotom

• Purpose: Micro/Nano CT

Versa/Ultra

ZEISS Industrial Metrology Imaging Systems

Total Metrology Solutions

Advanced Material Testing

Testing Technologies for the Full Spectrum of Material Properties

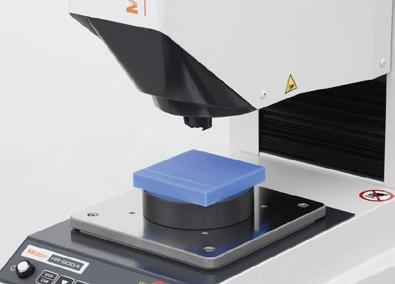

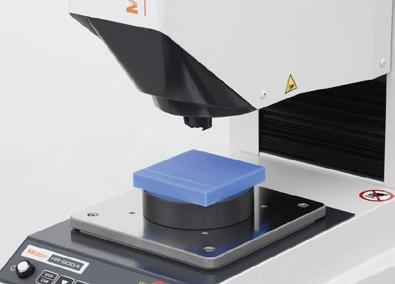

Hardness

MSI Viking offers a full range of high quality Hardness Testing equipment for virtually any application and sample type. The type of material and desired hardness will determine optimal test method and system. We have solutions deliver unmatched accuracy, stability, measurement reproducibility and quality. Our expert engineers can help determine which workbench system, handheld device, or even customized solution will best meet your needs..

Applications

Weld Inspection

Kic Crack Inspection

Decarbonized Screw Thread Testing

Rockwell, Vickers, Knoop, & Brinell Testing

Force

STARRETT and MARK-10 are the leaders of MSI Viking’s wide range of force and material measuring equipment. Offerings include handheld force gages, mechanical stands, motorized stands, and a complete range of software and accessory options customized for any application. Our collection of precision instruments from the world’s leading brands emphasizes ease of setup, operation, and maintenance, so you can count on reliable, repeatable results no matter the environment or operator.

Applications

Tensile Testing

Spring Testing

Weld Force Testing

Bearing Torque Testing

Cable Tension Testing and many more...

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

tailored customized all scale types & systems exceptional accuracy spring

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1002-2022

testing tensile testing bearing torque testing

Total Metrology Solutions

Advanced Material Testing

Testing Technologies for the Full Spectrum of Material Properties

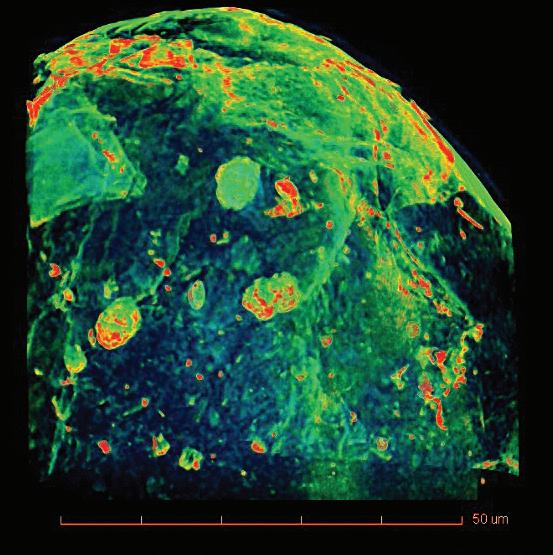

Microscopy

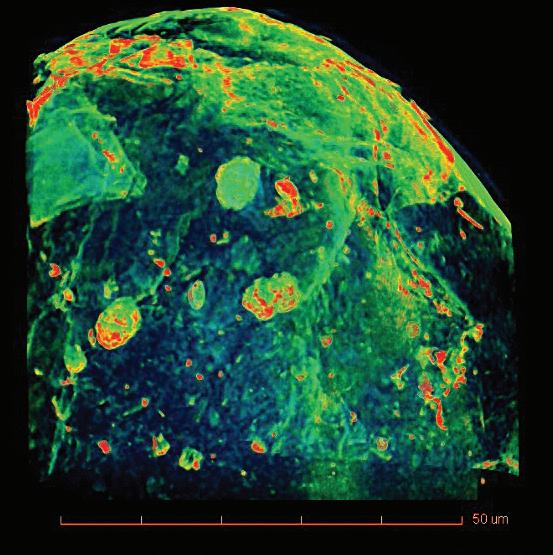

ZEISS delivers innovative solutions and services for materials research, industrial quality control, technical cleanliness, and corelative microscopy. ZEISS systems are used for manufacturing and assembly in high tech industries as well as exploration and processing of raw materials worldwide. Whatever your task or application, our experts will find the perfect light, confocal, electron, or X-ray microscope to get the results you need.

Applications

Layer Thickness Determination

Structure Evaluation

Grain Structure Analysis

Phase Fraction Determination

Structure Development Quantification

Sample Preparation

METKON brings total preparation solutions in metallography. We cover the complete range of instruments and consumables for Metallographic Sample Preparation, from manual machines to sophisticated microprocessor controlled preparation systems. We will work with you to find the best processes to save time and money.

Applications

Cutting

Mounting

Grinding

Polishing

Consumables

Cutting Fluids

Mounting Resins

Grinding Discs

Polishing Cloths

SHOP ONLINE | PRODUCTS | CALIBRATION | REPAIR | INSPECTION | AUTOMATION

milled aluminium (3D view) spot LED illumination

grain structure

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1002-2022

central force application resins for mounting

Materials Research & Metallography

ZEISS Industrial Microscopy

Compound Microscopes: Upright and Inverted

Performance-ready, with all features working in concert to deliver a complete metallography solution for the materials laboratory: cameras as the most important interface for digitizing your sample data, lenses with application-specific properties, and an imaging software specially developed for materials research and metallography.

FEATURES & OPTIONS

• Easy Image Acquisition

• Ergonomic Operating Concept

Perfect Control of All Stage Axes

• A Turnkey Metallography Solution

• Imaging Software with Integrated Materials Modules (Grains, Particle Analysis, Phase, NMI, Layers & more)

Smart Zoom 5: Automated Digital for Routine and Failure Analysis

ZEISS Smartzoom 5 smart digital microscope is ideal for quality control and quality assurance applications in virtually every field of industry. Quick and easy to set up, fully automated and equipped with dedicated quality assurance and quality control components. Even untrained users will produce excellent results. How easy? Smartzoom 5 features a macro recording mode for quickly repeating same-type sample analyses.

FEATURES & OPTIONS

• Macro recording mode repeats steps

• Fast, reproducible QA/QC measurements for routine as well as failure analyses

• Integrated components: the optical engine combines zoom, overview camera, and coaxial illumination

Smart Proof 5: Confocal Microscope for Surface Analysis

Integrated system for surface analysis: fast, precise and repeatable. Put it to work on a wide range common industrial applications - such as roughness and topographical characterization in QA/QC departments, production environments and R&D labs. This high-quality system is driven by powerful ZEISS Efficient Navigation (ZEN) software.

FEATURES & OPTIONS

• Well suited to production and process monitoring Teachable inspection jobs and the workflow oriented graphical user interface (GUI) guide you through recurring tasks

• Easily analyze data according to international standards and create respective reports in ZEISS ConfoMap

Screw Head Topography Corrosion 3D Topography

Metallography Analysis Phase Analysis Laser Structured Surface Milled Aluminum Profile

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1003-2022

Total Metrology Solutions

Materials Research & Metallography

ZEISS Industrial Microscopy

Stemi 305/508: Compact Greenough Stereo Microscope

Easy-to-use microscope with long-living LED illumination for reflected and transmitted light, plus integrated documentation. Choose between the conventional phototube to have access to all ZEISS microscope cameras or the integrated 1.2 Megapixel WIFI camera to connect several microscopes and share your images via WLAN.

FEATURES & OPTIONS

• Integrated Illumination

• 5:1 zoom or 8:1 zoom models

• All-in-One Device, plug in and start Integrated WIFI and Documentation

• Reflected Light, Transmitted Light & Ring Light illumination available

SteREO Discovery V20 & V12: Modular Stereo Motorized Zoom

SteREO Discovery motorized components are fully integrated into your microscope software ZEN and AxioVision: measure and document your samples reproducibly. Observe parts with enhanced 3D impression over the whole zoom range Capture crisp and rich images with excellent contrast and color fidelity. SteREO Discovery enhances resolution and contrast in quality assurance.

FEATURES & OPTIONS

• Motorized zoom

• Excellent depth perception

• Motorized components for reliable results

• Ergonomic and easy operation and control with the optional touch panel SYCOP

• Illumination and contrast methods based on cold light or LED

Axio ZoomV16 for Materials: Stereo Zoom for Large Fields

The on-axis zoom microscope Axio Zoom V16 delivers both high resolution and a zoom range of 16x. Zoom seamlessly from overview to the smallest details - with a large free working distance and a single objective. Quickly and easily stitch large tile-images at low to medium magnification with impressive double resolution.

FEATURES & OPTIONS

• High Resolution at all magnifications

• Select Brightness, Eyepiece or Camera modes

• EpiRel produces a relief-like image contrast

• Combines 16x zoom with a high numerical aperture and large working distance

The eZoom works with a motorized iris diaphragm coupled to the zoom.

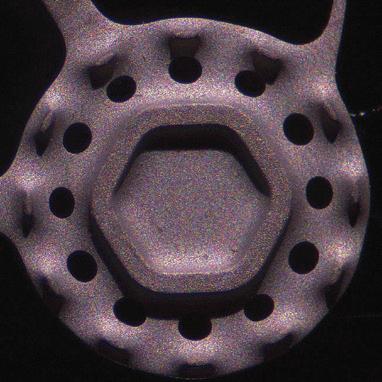

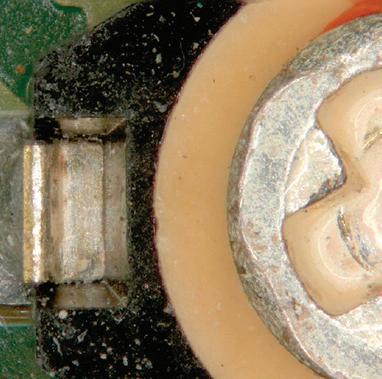

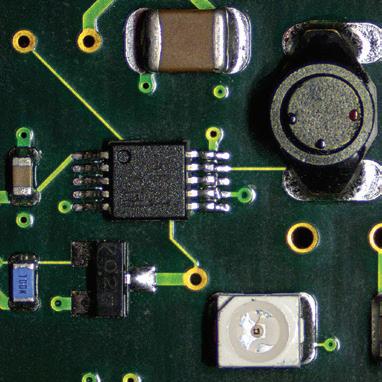

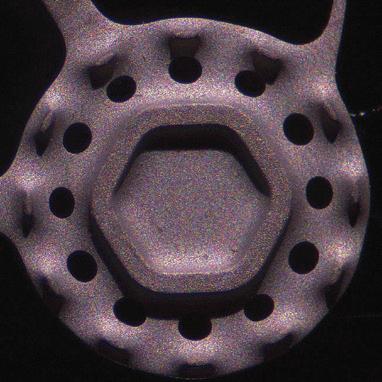

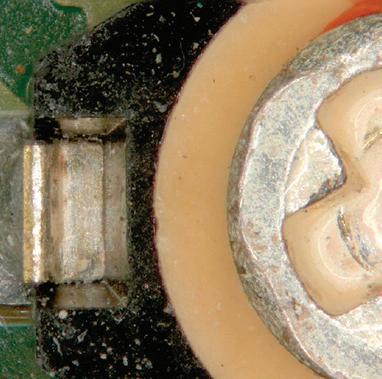

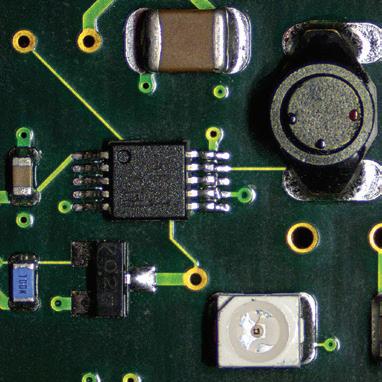

Automotive Component Circuit Board Electronic Component

FEM

Base

Cast Iron Porosity MosaX Spark Plug

Deformation

Plate

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1003-2022

Total Metrology Solutions

Total Metrology Solutions

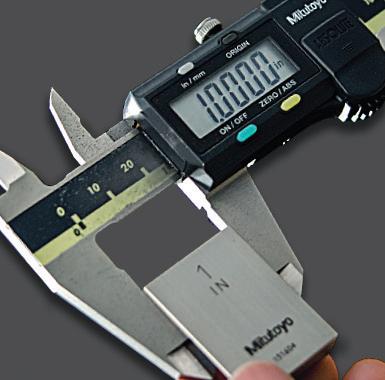

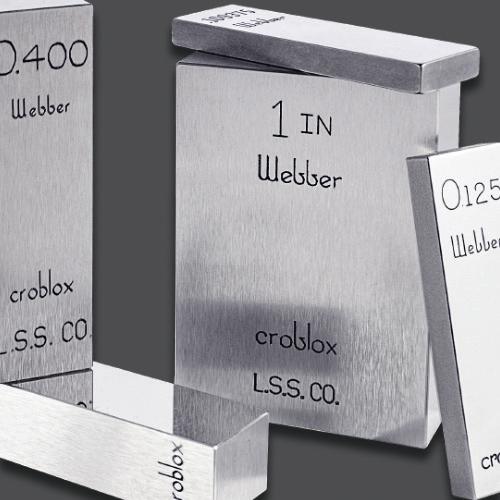

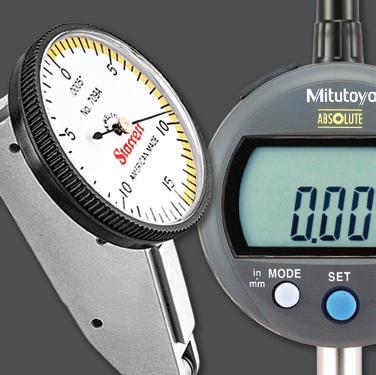

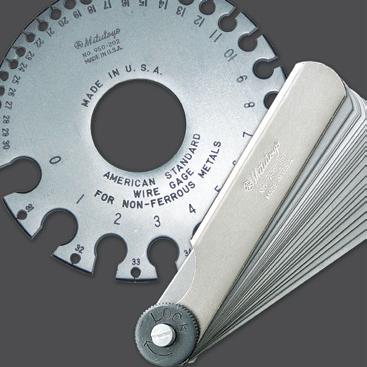

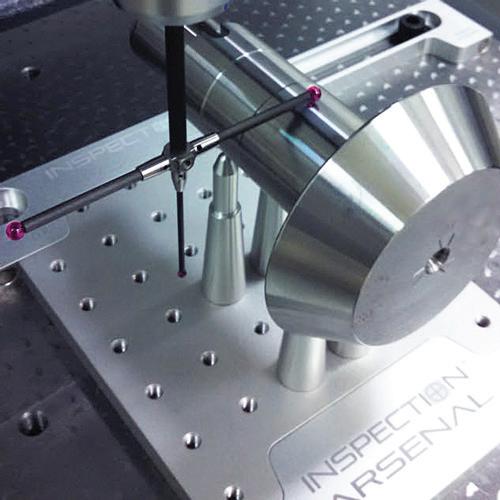

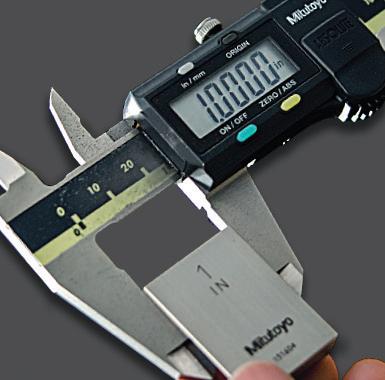

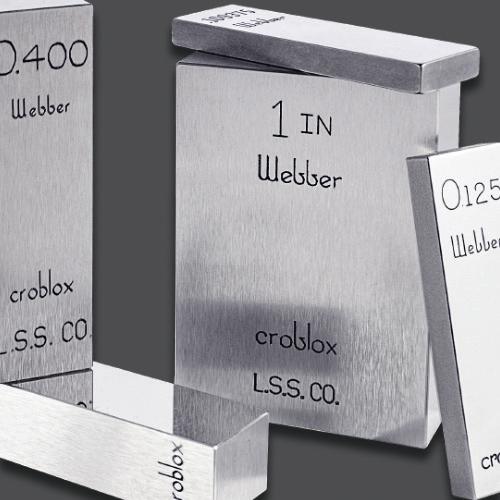

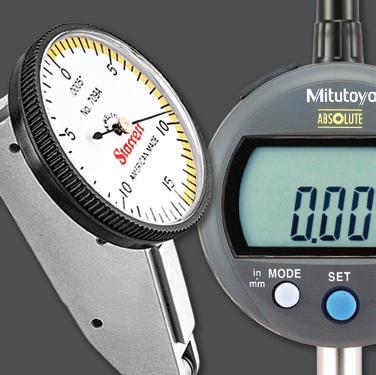

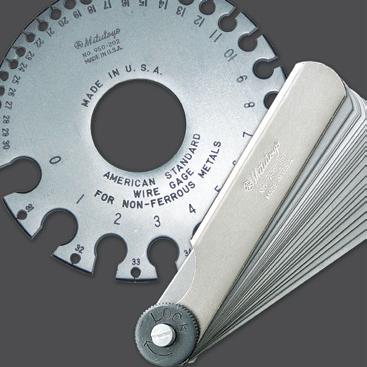

Precision Gaging Solutions

Master Distributor of the World’s Leading Brands

Air Gages

Bore Gages

Calipers

CMM Fixtures

Data Collection

Depth Gages

Force & Torque

Gage Blocks

Granite Surface Plates

Hardness Testing

Height Gages

Indicators & Probes

Length Measuring ULMs

Linear Scales & DROs

LVDTs & Linear Probes

Micrometers

Optical Comparators

Reference & Feeler Gages

Scales & Balances

Snap Gages

Surface Profillmeters

Temperature & Moisture

Thickness Gages

Torque Tools

Vision Systems

Air Gaging: Metro/Stotz

Beta LaserMike

Brown and Sharpe

Carl Zeiss

Dorsey

Dyer Gage

Flexbar

Gedore

Heidenhain

Insize

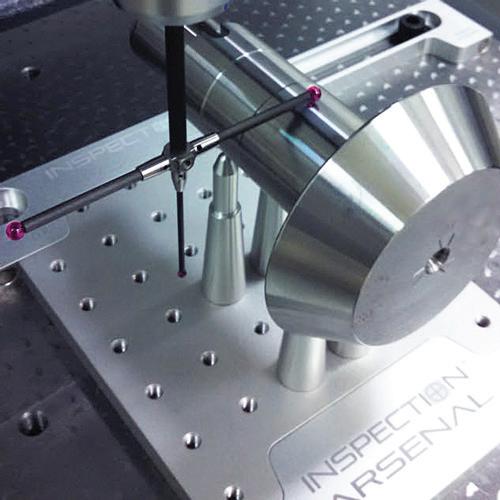

Inspection Arsenal

Johnson Gage

Microrep

MicroRidge

Mountz

NDC Technologies

OASIS

Ohaus

Phase II+

PrymeFix

Renishaw Fixturing

Snap-on Industrial Solartron

Swiss Precision – SPI

Tohnichi

Western Gage

Williams

Witte-Alufix and dozens more!

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1004-2022

Cylindrical & Thread Gaging Products

Total Metrology Solutions

Sometimes your application is so unique that existing instruments don’t measure up. If we can’t find the right equipment within our vast catalog of hard gaging products from the world’s leading brands, we’ll create one to fit your needs. Our team of engineers is standing by to build the perfect solution for you.

Hard Gaging Brands

Vermont

Mid-Tech

Meyer Gage

Hemco

Deltronic

Glastonbury Southern Gage

PMC/Lone Star - Van Keuren

Gage Assembly

Johnson Gage & dozens more

Calibration & Repair Services

A2LA Accredited ISO 17025 Calibration Service

At MSI Viking, we’re committed to delivering top quality products and service without sacrificing convenience. Ordering a new gage with ISO 17025 Calibration is fast and easy: just add calibration to your order and your gage will arrive ready to go. Thanks to our extensive Accreditation Scope (available online), we provide comprehensive service for everything we sell — even if you didn’t buy it from us!

Factory Authorized & Trained Repair of all major brands:

Heidenhain

Tohnichi

• Hexagon/TESA • Fowler • Mitutoyo • Mahr • LS Starrett • Solartron

•

• Snap-On/Williams • INNOVATEST • Microrep and

Mountz

more!

EQUIPMENT | CALIBRATION | REPAIR | INSPECTION | CUSTOM SOLUTIONS MSI-VIKING.COM 864.433.9771 MSI-LC-1004-2022