Lifting the Lid

After a Pittsburgh Bridge collapse, should uncoated corten steel be coated anyway?

Up Front

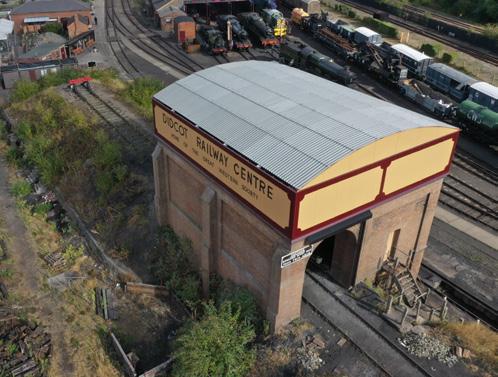

A refurbishment of the steam train refuelling tower water tank at the Didcot Railway Centre

Analysis

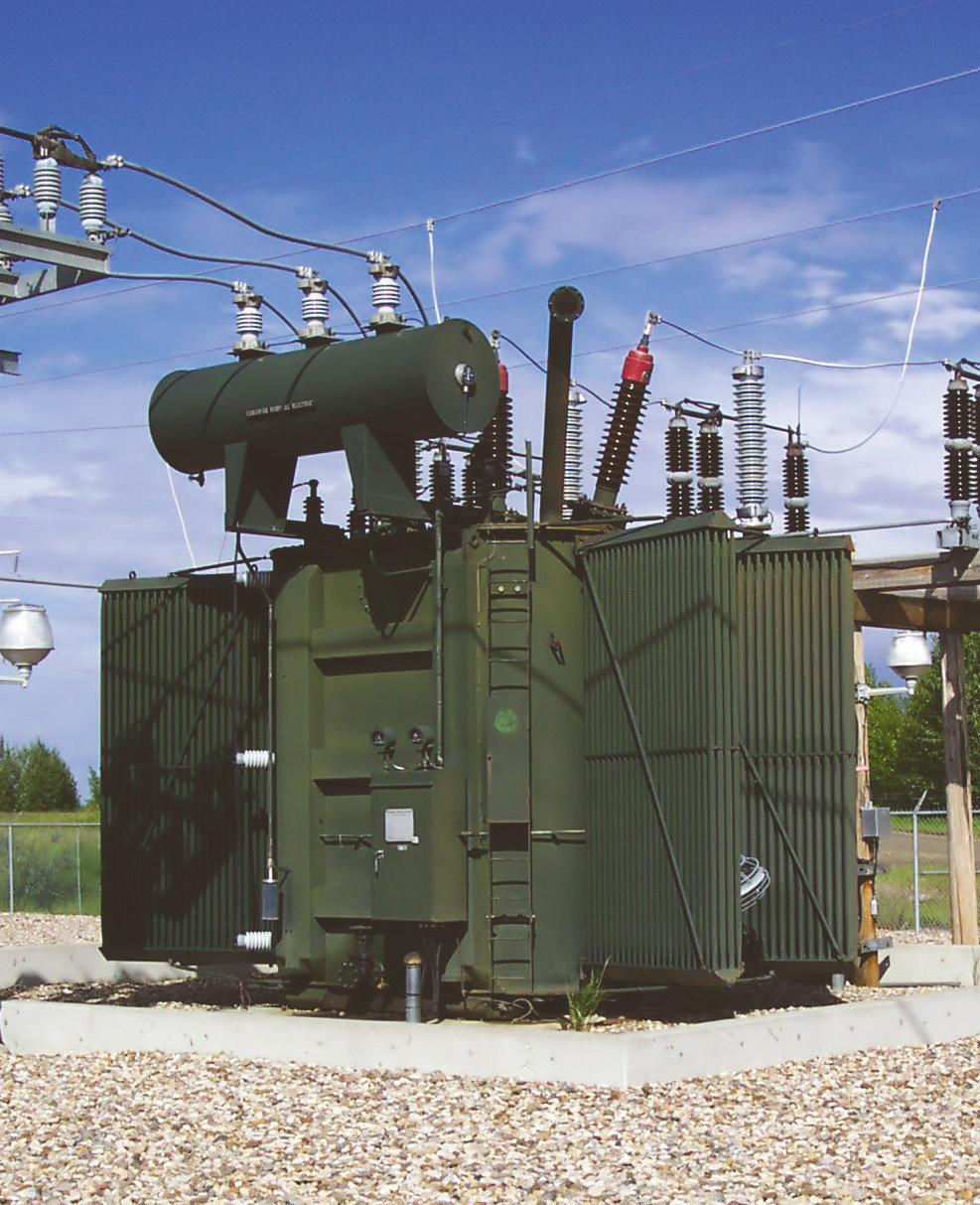

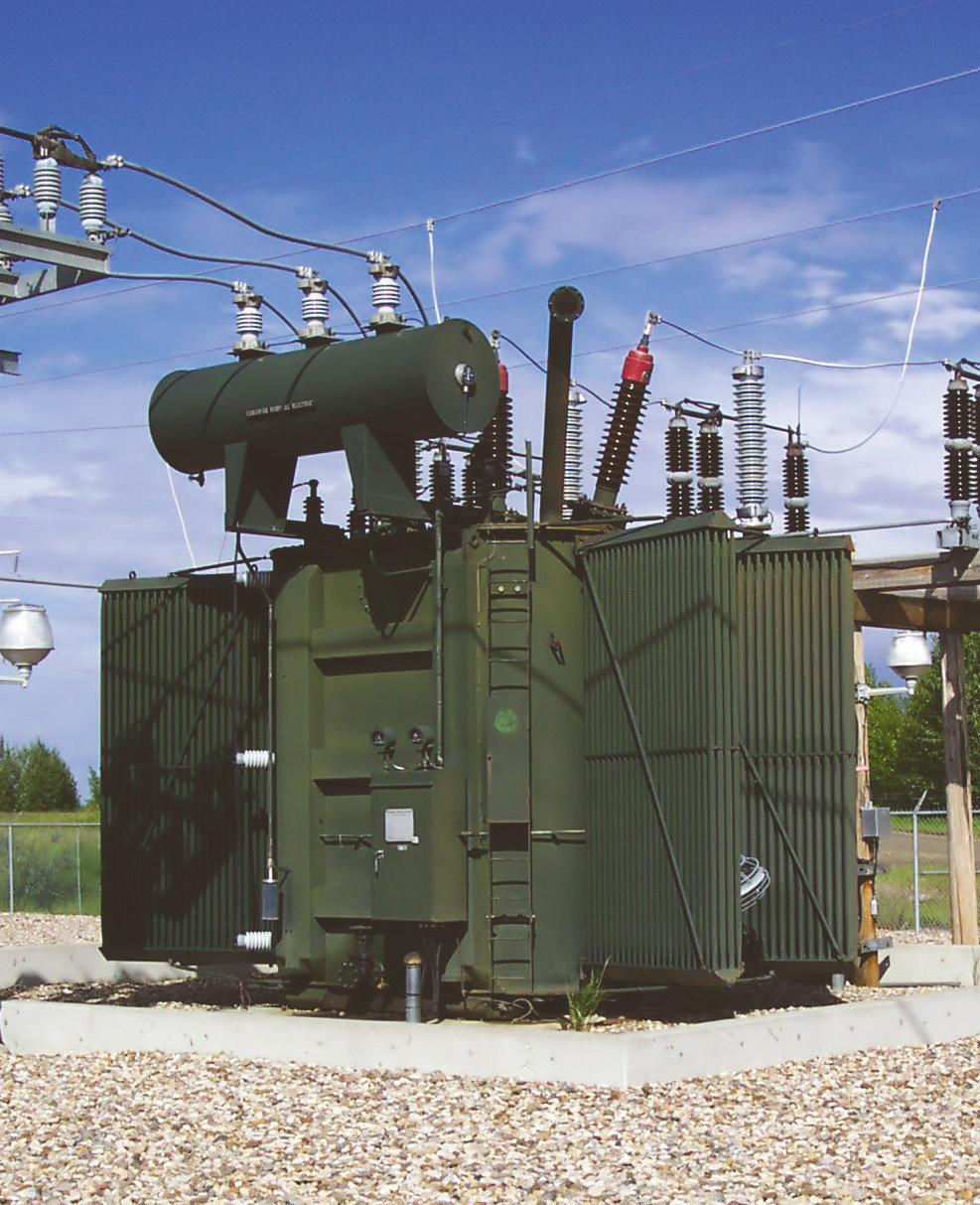

Identifying the paints and coatings that offer nextlevel protection for transformers

July - September 2023

IN THIS ISSUE:

The Leading Protective Coatings Magazine

Scan this QR code to read this and past editions.

Discover high-performance SHIP CLEANING SYSTEMS

ECONOMICAL

ENVIRONMENTALLY FRIENDLY SAFE

HIGH QUALITY

SURFACE PREPARATION WITH AN EDGE SPIDERJET® M Edge

Powerful and versatile with a uniform removal pattern right up to every edge.

This is the newest addition to our unique product line of high-performance ship cleaning systems.

OUR UNIQUE RANGE OF SHIP CLEANING SYSTEMS IS YOUR EDGE ON THE COMPETITION

Working heights: up to 32 m

Working widths: 374 – 1000 mm

Operating pressures: up to 3000 bar

Flow rates: up to 94 l/min

Experience the full range of Hammelmann ship cleaning systems:

GET IN TOUCH FOR A CUSTOMIZED SOLUTION, PERFECT FOR YOUR DEMANDS

www.hammelmann.com

Hammelmann GmbH Carl-Zeiss-Straße

59302

mail@hammelmann.de Tel.: (0) 25 22 / 76 - 0 Fax: (0) 25 22 / 76

140

6–8

Oelde / Germany

-

CONTENTS FEATURES…

Lifting the Lid Uncoated corten steel or weathering steel has a long and generally successful service record for bridges and other infrastructure around the world, but after a Pittsburgh Bridge collapse, should uncoated corten steel be coated anyway, asks Carboline

4

12 Up Front The steam train refuelling tower water tank at the UK’s Didcot Railway Centre was exhibiting heavy corrosion and leaking, requiring significant refurbishment. Corroless Eastern removed all the existing coatings and coated it with Eon Coat – a revolutionary steel protective coating that permanently protects steel and iron assets by alloying the surface of the steel

20

Spotlight There has been considerable growth in the wind power industry over the past few years. However, further exponential growth of the industry is required in order to ensure that the net-zero-by-2050 pathway is met, but what role does polymeric technology have to play, asks Belzona

46

Analysis Transformer manufacturers are facing many challenges: the looming winter storm season, supply chain challenges, labour shortages and more. Whilst many factors are beyond their control, identifying paints and coatings that offer next-level protection for important metal components is within their purview, explains PPG

Volume No.15 ■ Issue No.3 July – September 2023 ■ ISSN No. 2054-1813

For several decades, Steelpaint PUR coating systems have been proving their worth in hydraulic engineering applications. Even after years of exposure to seawater, Steelpaint systems have been shown to stay more elastic, not to embrittle and not to become porous. Regular on-site inspections have demonstrated that PUR coatings provide reliable and long-lasting corrosion protection, so they are designed for extreme environments like coastal zones and tidal areas. Pictures reproduced with the kind permission of Bremenports.

4 Lifting the Lid

After a Pittsburgh Bridge collapse, should uncoated corten steel be coated anyway, asks Carboline.

12 Up Front

The water tank at the UK’s Didcot Railway Centre was exhibiting heavy corrosion and leaking, requiring significant refurbishment.

20 Spotlight

The multipurpose icebreaker MSV Nordica, owned by Arctia, gets a fresh coat of durable paint.

32 In Focus

AkzoNobel says it will help shipowners save $100k a year from the new EU carbon levy and Nexxis looks at the challenges presented in the inspection of a flare knock-out drum on an offshore platform, including the advantages and practicalities of employing robotic inspection.

42 Analysis

Whilst many factors are beyond manufacturers’ control, identifying paints and coatings that offer next-level protection for important transformer metal components is within their purview, explains Maria Lamorey, Commercial Strategy Manager, PPG.

52 Update

What role does polymeric technology play in the burgeoning wind industry, asks Belzona’s Chloe Hirst.

60 Review

Cortec looks at how to choose the right paint for metal in a fast-paced, extraslip, high-temperature environment, and Jotun explains how a major expansion of its fire protection coating R&D facilities will further secure its position within the global structural fire protection industry.

28 Article from Steelpaint

Steelpaint was commissioned to provide long-lasting protection for the new Columbus-quay.

Editor: Mark Langdon mark@pce-international.com

Contributing Editor: Mike Garside mike@pce-international.com

Advertisement Manager: Nick Carugati nick@pce-international.com

Production Manager: Tatum Le Patourel tatum@satzuma-creative.co.uk

Designer: Fiona Andreanelli fiona.andreanelli@mpigroup.co.uk

Accounts: Claire Long claire.long@mpigroup.co.uk

Publisher: Andrew Deere andrew.deere@mpigroup.co.uk

70 News

The latest products, appointments and industry news.

MPI Group

Peel House, Upper South View

Farnham, Surrey GU9 7JN, England

Tel: +44 (0) 1252 732220

Email: info@mpigroup.co.uk www.mpigroup.co.uk

MPI Group, as a body, is not responsible for any opinions expressed in PCE by contributors. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording or otherwise, without prior permission of MPI Group.

© Marine Publications International Ltd 2021

The Leading Protective Coatings Magazine Scan this QR code to read this and past editions.

2 CONTENTS PCE JULY –SEPTEMBER 2023

For highly corrosive environments

SP-PUR Protection

Bremerhaven,

1985

Columbus-Kaje

Foto

A CORROSION PROTECTION DILEMMA

After

the Pittsburgh Bridge collapse, should uncoated corten steel be coated anyway, asks Carboline.

the Pittsburgh Bridge collapse, should uncoated corten steel be coated anyway, asks Carboline.

THE LID All images © US National Transportation Safety Board LIFTING THE LID PCE JULY –SEPTEMBER 2023 4

LIFTING

LIFTING THE LID PCE JULY –SEPTEMBER 2023 5

In May 2023, the US National Transportation Safety Board (NTSB) did something it almost never does – it published an urgent notice to state and federal agencies with findings from an investigation it had yet to complete.

Citing the January 2022 collapse of the Fern Hollow Bridge in Pittsburgh, Pennsylvania, the notice urged authorities nationwide to “review inspection reports and identify incomplete follow-up actions that need to be resolved for bridges made of uncoated weathering steel.”

“NTSB investigators found corrosion, deterioration, and section loss on all four of the bridge’s legs due to the continual accumulation of water and debris,” the Board wrote.

The bridge legs were made of corten steel, also known as weathering steel, which typically is not coated. The oxide layer that forms on its surface naturally in reaction to atmospheric exposure protects it rather well, very much like the green patina that forms on copper.

Corten steel has a long and generally successful service record for bridges and other infrastructure around the world. Famous buildings include the John Deere World Headquarters in Illinois, the Courtyard Theatre, Stratford-upon-Avon in the UK, the Design Museum in Holon, Israel, the Barclays Center sports arena, New York, Leeds Broadcasting

Tower in the UK and rather more famous, the Angel of the North sculpture in Tyne and Wear in the UK.

So what happened in Pittsburgh, and why was this different?

The collapse and investigation

The Fern Hollow Bridge carried Forbes Road over a ravine at the north end of a local park. A light snow was still falling when it collapsed about an hour before dawn on 28 January, 2022.

Four cars and a city bus were on the bridge when it fell 100 feet (30m) down into the ravine. A fifth car drove off an abutment after the collapse because it couldn’t stop in time. Four people were hurt in the collapse, two of them seriously.

It didn’t take long for investigators to develop a theory of the cause. According to a supplemental report accompanying its urgent notice, the NTSB “found extensive corrosion damage and deterioration” of the bridge legs.

Worse, that damage was not new.

“Starting in 2005, each of these (National Bridge Inspection Standards) inspection reports documented corrosion damage and deterioration of the bridge legs, including the most recent inspection report”, which was filed four months before the collapse.

LIFTING THE LID PCE JULY –SEPTEMBER 2023 6

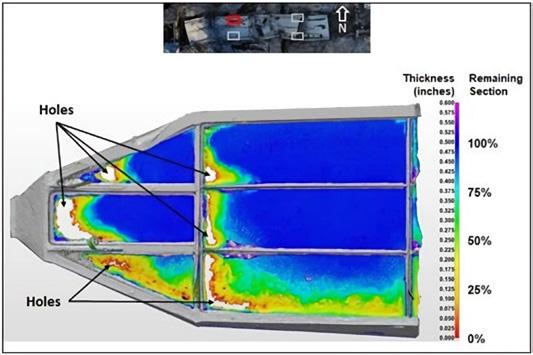

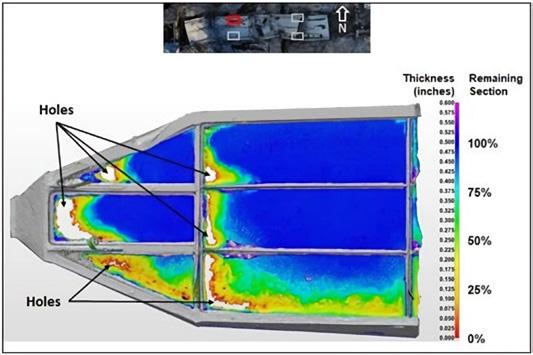

Laser scans of the corroded portions of the bridge legs supported empirically what was plainly visible to anyone who had looked: the bridge legs had suffered an alarming loss of thickness. In some areas, where there had once been a web of steel, only fist-sized holes remained.

Environmental conditions

The NTSB noted that environmental conditions influence corten performance. Most simply stated, the steel must be exposed to moisture but also be allowed to dry for the most complete development of a protective oxide layer. The addition of other airborne contaminants also contributes to speedier patina formation. These reasons are why corten steel can last well over 100 years in more arid climates, and why patina forms more quickly on corten steel erected in cities where pollution is more concentrated.

With all this in mind, investigators have developed a clear explanation of why the collapse happened.

As engineered and built, the bridge legs wouldn’t have been in contact with layers of moist debris. But over time, drains on the road deck became clogged. Instead of being harmlessly channelled away as intended, rainwater, snowmelt, and some debris leaked

over the edge of the bridge where it collected against the bridge legs.

Incidentally, the contaminants not helpful for patina formation on weathering steel include chlorides. Instead of contributing to a corrosion cycle that eventually ends, chlorides accelerate corrosion until there’s nothing left to corrode. We observe that it snows in Pittsburgh and assume that road salt had been applied to the bridge over its lifespan.

And it bears repeating that, time and time again, bridge inspectors reported these conditions and urged action that was not taken for 18 years.

Coat the corten steel?

Maybe – it’s complicated.

And it’s complicated because corten steel features a much more difficult surface to prepare compared to general-purpose carbon steel. The porous rust layer that forms on carbon steel clings to the substrate rather loosely. When a corrosion cycle is completed and the rust sloughs off (or when the steel is

LIFTING THE LID PCE JULY –SEPTEMBER 2023 7

Four cars and a city bus were on the bridge when it fell 100 feet (30m) down into the ravine.

abrasive blasted), a new cycle begins. It’s an endless loop.

But the rust layer that forms over weathering steel is much denser and clings far more tightly to the substrate by design. This can be blasted away, but abrasive blasting a Fern Hollow Bridge’s worth of weathering steel would require a much higher volume of abrasive material than is ordinary and many more labour hours than most contractors are comfortable paying for.

In our view, a partial coat would be effective. Preparing and coating only the sections of an asset at highest risk of corrosive exposure can

defend against section loss, especially if an asset’s recommended maintenance is going to be neglected. We hate saying it that way, but it happens too often not to be said plainly.

Our other view is that while uncoated weathering steel is a proven material for all manner of industrial and infrastructure assets, it is not universally ideal. Pittsburgh’s snowy winters, road salt, rain, and humid weather made corten a risky choice from the start, and the neglected maintenance that led to an unintended but widespread corrosion attack practically sealed the Fern Hollow Bridge’s fate as far back as 2005 – it was only a matter of time.

LIFTING THE LID PCE JULY –SEPTEMBER 2023 8

LIFTING THE LID PCE JULY –SEPTEMBER 2023 9

Coating recommendations

If you’re responsible for the care of weathering steel in conditions you believe are risky, we suggest blocking moisture and corrosionaccelerating chemicals with the following generic coating systems.

Zinc-rich primers are a very sound choice, but these products require comparatively more intensive surface preparation because all rust and mill scale must be removed for best adhesion. It is very difficult to achieve a ‘near white’ surface finish on corten steel. For that reason, applying a barrier epoxy is a viable and common alternative.

Whether a zinc-rich primer or barrier epoxy is specified, we also recommend a low-gloss, UV-stable urethane or polysiloxane topcoat. In addition to enhancing protection, this will help blend in the painted area with what is left unpainted. It probably won’t be perfect, but it is preferable to no attempt at blending at all if aesthetics is a concern.

As for which specific products are best, that will depend on climate and weather-driven atmospheric exposures and service environment characteristics –Carboline’s Technical Service Engineers are your best resource here.

But before you do anything, thoroughly inspect corten steel assets, and if those inspection reports urge action – then act.

Carboline is a St. Louis-based coatings manufacturer with a global reach. The company, founded in 1947, produces highquality performance coatings, linings, and fireproofing products in more than 20 manufacturing facilities around the world. Carboline’s cutting-edge research and development centre reflects its commitment to remaining at the forefront of the protective coatings industry. ■

LIFTING THE LID PCE JULY –SEPTEMBER 2023 10

Laser scans of the corroded portions of the bridge legs supported empirically what was plainly visible to anyone who had looked

LIFTING THE LID PCE JULY –SEPTEMBER 2023 11

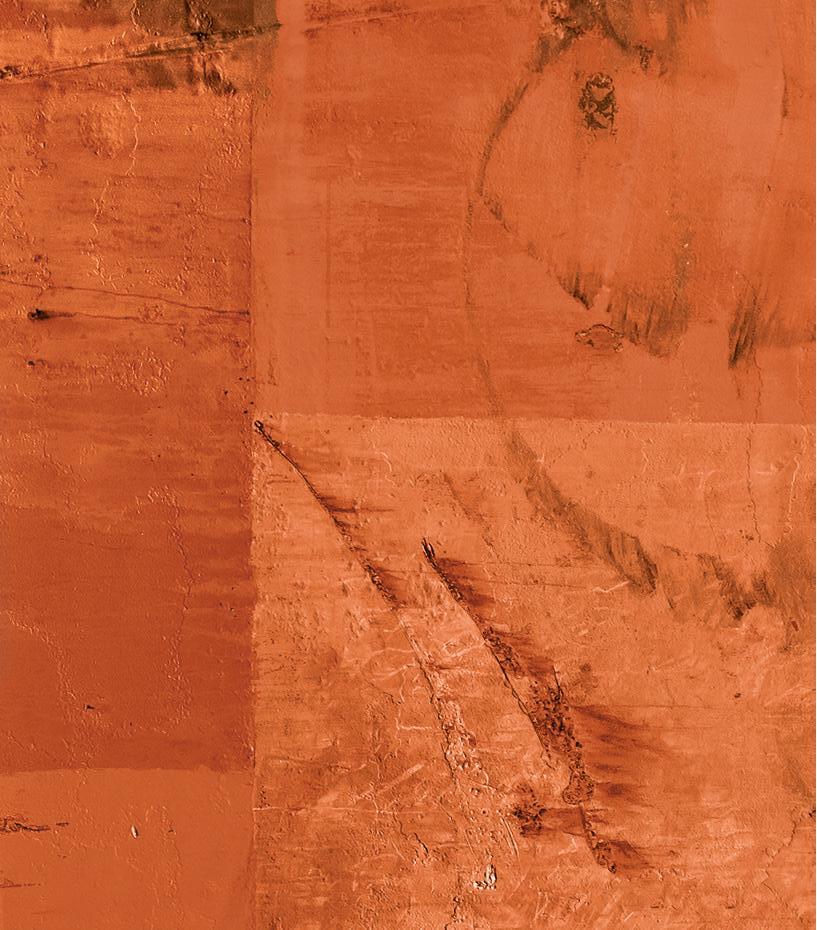

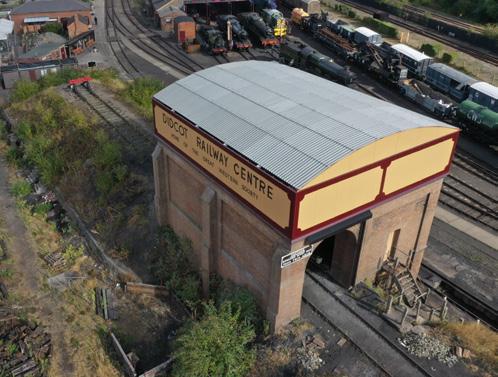

UP FRONT

Steam train refuelling tower restoration

The water tank at the UK’s Didcot Railway Centre was exhibiting heavy corrosion and leaking, requiring significant refurbishment.

UP FRONT PCE JULY –SEPTEMBER 2023 12

A clean Tallink Baltic Princess at Turku Repair Yard in March 2023

UP FRONT PCE JULY –SEPTEMBER 2023 13

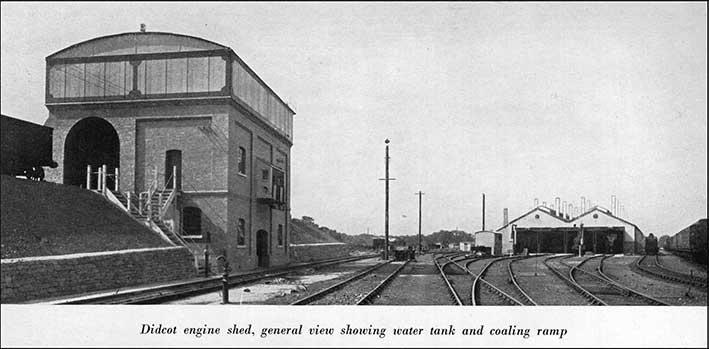

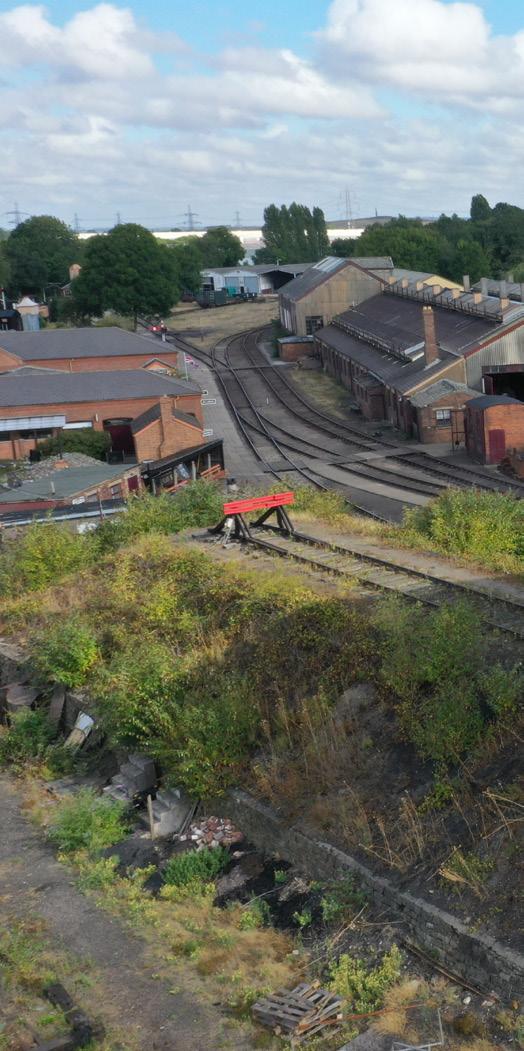

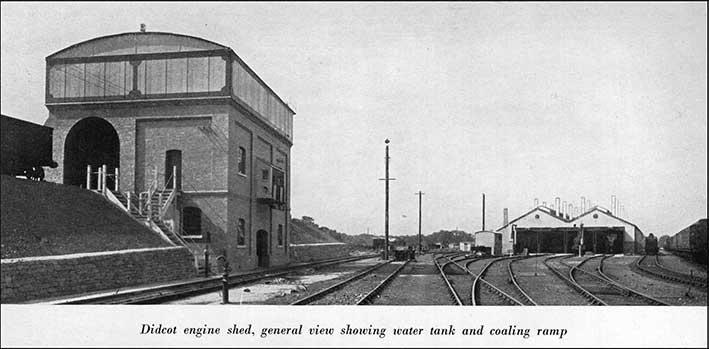

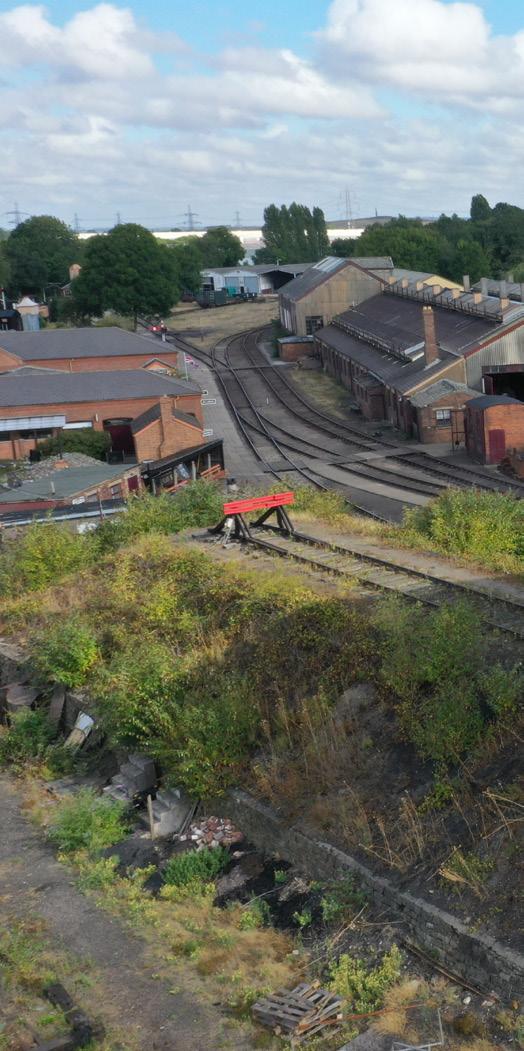

The tower, which was constructed in 1932, also incorporates a coal stage beneath for refuelling steam trains. This Grade II listed water tank and coal stage required significant refurbishment to allow their continued use serving the Great Western Society and its fleet of steam engines.

Internally, the tank was lined with a thin film bitumen coating, and a coating system which had incorporated a red lead primer had been applied externally in the 1980s. This presented a health hazard that needed careful consideration, given the close proximity of the museum and Didcot Parkway train station.

A particular and unique challenge for this tank lining and protective coating contract was that all the plant, equipment and materials had to be brought into the site by train as there is no access by road.

The solution

Corroless Eastern proposed the removal of all existing coatings, followed by the application of Eon Coat – a revolutionary steel protective coating that permanently protects steel and iron assets by alloying the surface of the steel.

Due to the presence of lead-containing coatings and also the inability to fully encapsulate the tower, it was proposed to use ultra-high-pressure water jetting to remove the existing coatings. On aged steel with sufficient surface profile, this is the perfect preparation for Eon Coat, as the material requires some surface corrosion present for optimum bonding to the steel substrate.

Following the removal of the existing tank lining and protective coatings, Corroless Eastern did however uncover something very unusual that it had not experienced before.

UP FRONT PCE JULY –SEPTEMBER 2023 14

The water tank was exhibiting heavy corrosion and leaking, requiring significant refurbishment

UP FRONT PCE JULY –SEPTEMBER 2023 15

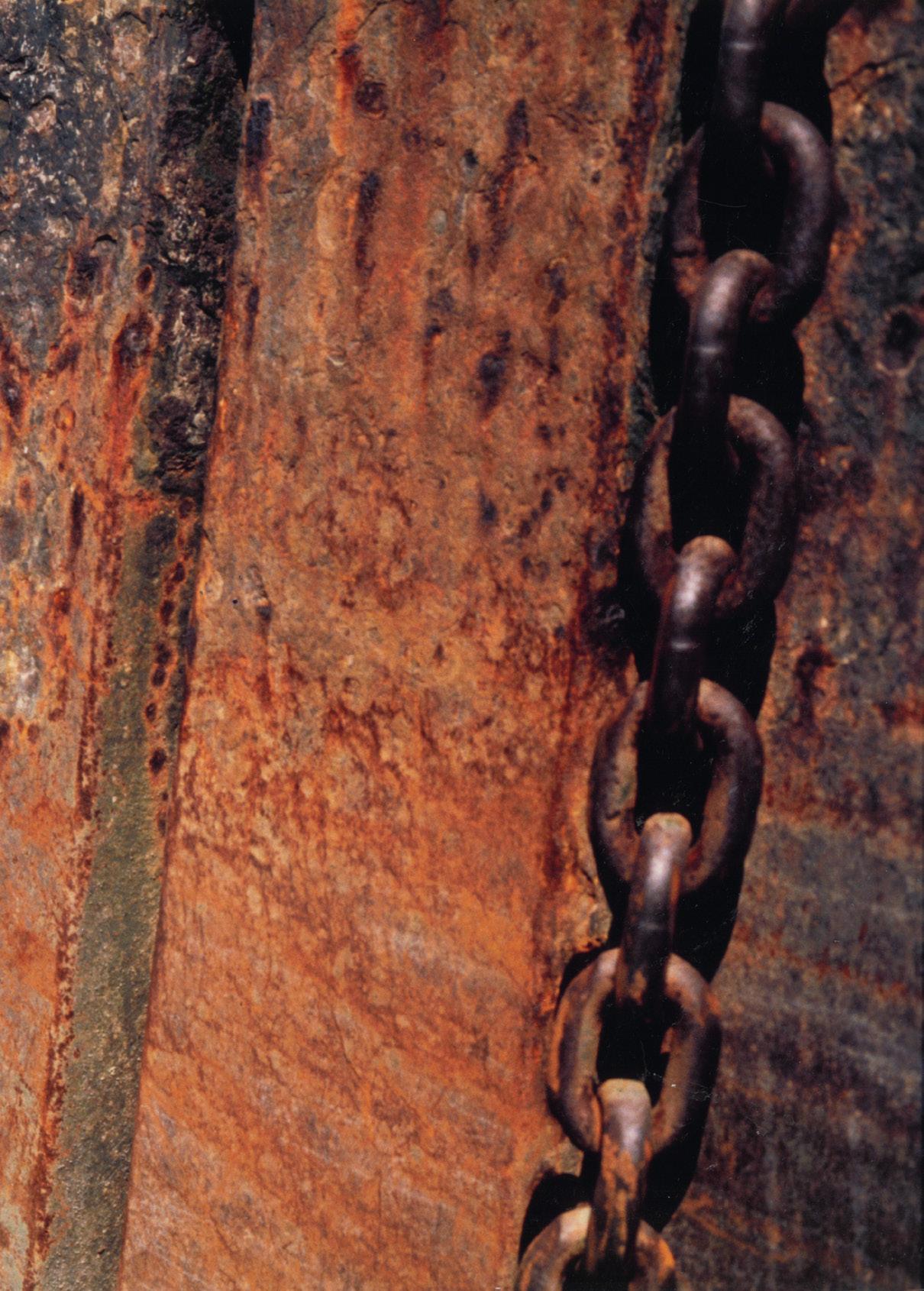

Both the tank internals and externals exhibited corrosion and delamination of the steel layers.

After some investigation and consultation with industry experts and engineers, it appeared that the water tank may have been constructed from recycled armour plate from World War I. This is formed by laminating layers of steel and then forging them together. The layering process prevents the penetration of bullets. To ensure an effective tank lining and protective coating application, these sharp edges needed to be removed to expose the corroded steel beneath and provide a thickness of steel sufficient to protect.

Initially, Corroless Eastern explored removing these areas using an abrasive wheel. However, during the trial it was found that this was too aggressive and the heat energy imparted caused further delamination of the steel layers.

Fortunately, the company already had some new steel plating which had been installed that required abrasive blasting to remove mill scale prior to the tank lining application. With the equipment already transported to the site by train for this application, a trial was undertaken to see if it were possible to feather back these areas of delamination.

By experimenting with abrasive blasting aggregate size, flow and air pressure, Corroless Eastern was able to carefully feather back

UP FRONT PCE JULY –SEPTEMBER 2023 16

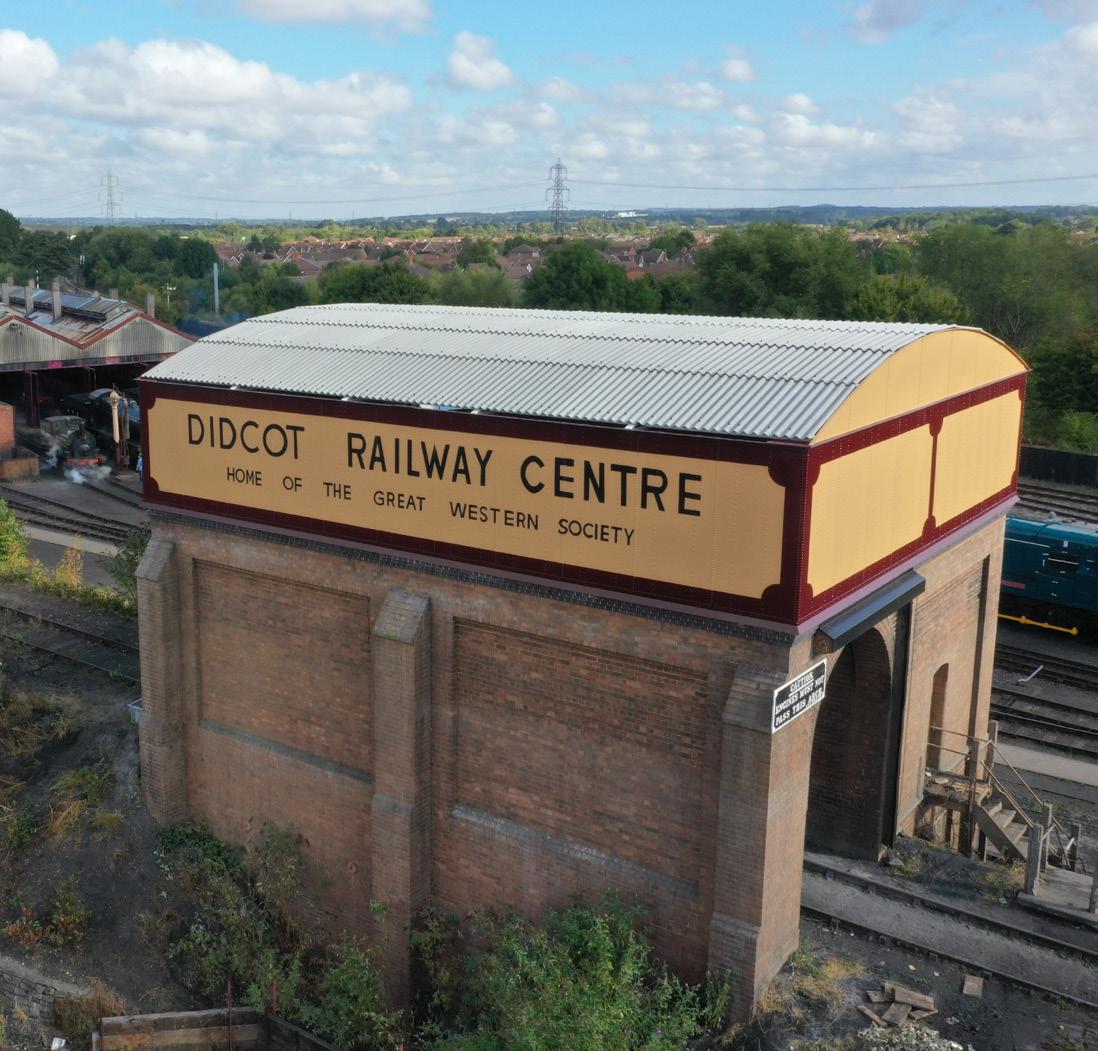

Eon Coat was applied as a tank lining internally and as a primer to the tank externals

UP FRONT PCE JULY –SEPTEMBER 2023 17

A Sherwin Williams Acrolon 7300 Acrylic Polyurethane finish was used externally

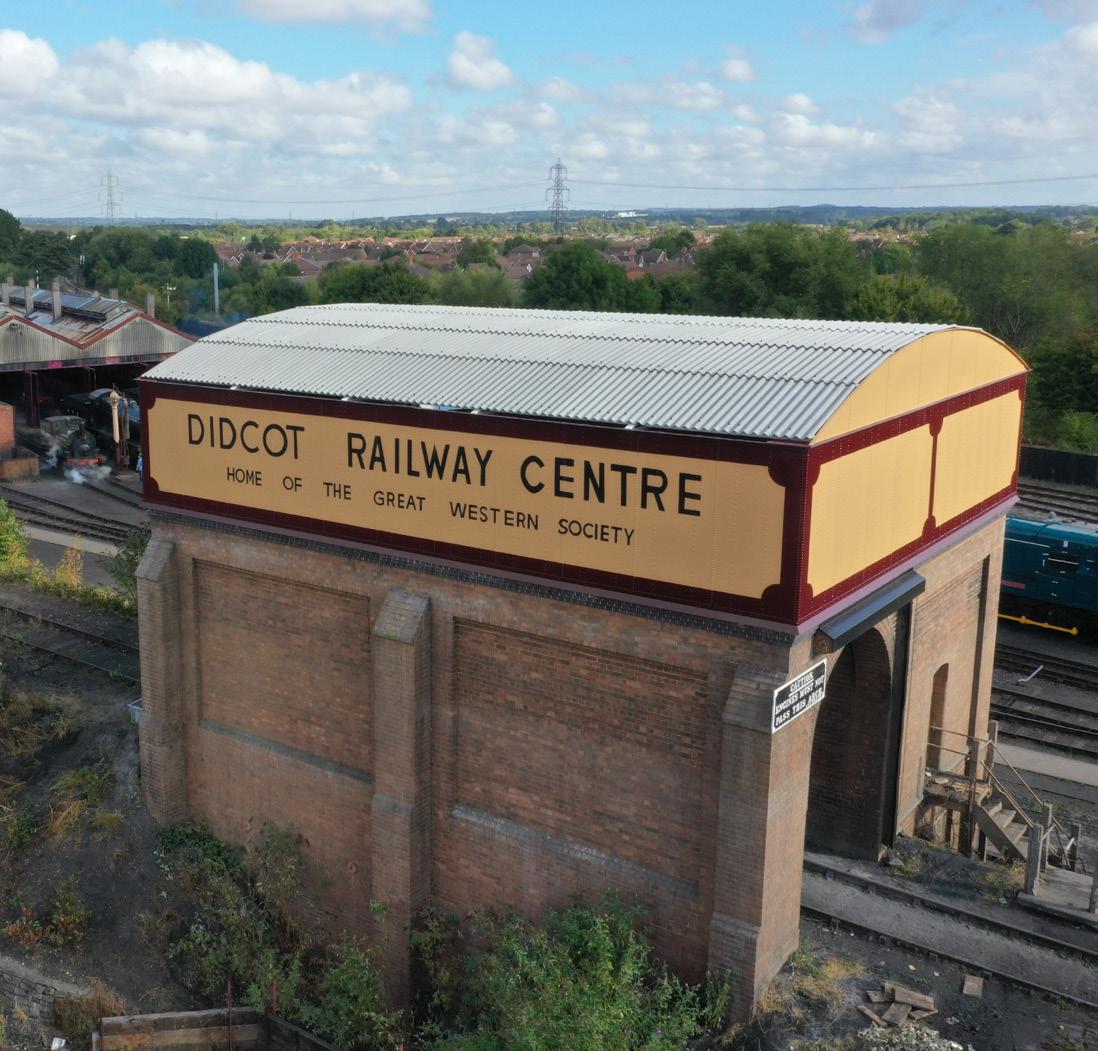

Sherwin Williams Acrolon 7300 Acrylic Polyurethane finish was applied in two coats, with the first coat being diluted to aid adhesion to the Eon Coat to provide the required decorative finish. The decorative border was carefully masked from measurements taken prior to preparation and applied using the same material

these areas to a point where delamination was no longer occurring and the corrosion deposits were removed from the steel surface.

As part of the company’s standard quality assurance procedures, the climatic conditions were tightly monitored to ensure compliance with Eon Coat’s recommendations. Unusually for a tank lining project, the wind speed had to be closely monitored, as specified by Eon Coat, to prevent the material drying out too quickly.

Installing the Eon Coat tank lining

One of the key benefits of Eon Coat for this tank lining and protective coating application was that it likes being applied to corroded steel – it actually needs a degree of surface rusting. This was perfect for a tank lining which was exposed to the elements and could not be controlled with dehumidification equipment.

Eon Coat was applied as a tank lining internally and as a primer to the tank externals. Eon Coat is applied by plural spraying due to the fast gel time of the material. It was perfect for application to the highly pitted internals as the chemical reaction with the steel surface gets to the deepest parts of the surface profile, unlike conventional protective coatings and tank linings.

Eon Coat is applied to a thickness of 500µm, which was checked during application using a wet film thickness gauge. This was then confirmed following cure using a dry film thickness gauge as per best tank lining practice.

Intricate areas were further detailed using the cartridge gun system, particularly around the backs of brackets and stays.

Tank base solution

As part of the refurbishment works a new flashing detail was fitted to the base of the water tank externally. As the bottom of the tank, which is supported by brick walls, could not be accessed, this area was treated using Corroless CCI 400, containing Corroless VCI technology.

Corroless VCI technology works by emitting a vapour which forms a microscopic layer on metal surfaces. This layer has considerable anticorrosive properties and prevents steel and other metals from corroding. Therefore, not only surfaces which are in direct contact with the Corroless product, but also areas in contained void or airspaces above the product, will be protected from corrosion.

The new flashing detail was installed by bolting through the water tank, to avoid damaging the protective coatings and tank lining by welding. As part of the installation Corroless Eastern assisted with the sealing operation by wet-fitting the flashing using a polyurethane sealant. Once cured, each fixing was then further sealed by locally applying two coats of Corroless ACO, a flexible polyurethane tank lining that is ideal for sealing operations.

UP FRONT PCE JULY –SEPTEMBER 2023 18

Decorative finish

Sherwin Williams Acrolon 7300 Acrylic Polyurethane finish was applied in two coats, with the first coat being diluted to aid adhesion to the Eon Coat to provide the required decorative finish. The decorative border was carefully masked from measurements taken prior to preparation and applied using the same material.

The company cannot take credit for the sign writing as this was undertaken by the museum’s own volunteers – using material

provided by Corroless Eastern.

This was one of the most interesting and unusual tank relining and protective coating projects Corroless Eastern has ever been involved in. It was not without its challenges, given the rail access only and the exceptionally hot 2022 summer. However, the company believes that the results speak for themselves and the use of a pioneering technology in the form of Eon Coat will provide corrosion protection for many years to come. ■

UP FRONT PCE JULY –SEPTEMBER 2023 19

Arctia’s multipurpose icebreaker gets a fresh coat of durable paint.

SPOTLIGHT

SPOTLIGHT PCE JULY –SEPTEMBER 2023 20

Nordica comes in from the cold

SPOTLIGHT PCE JULY –SEPTEMBER 2023 21

The icebreaker MSV Nordica, owned by Arctia, is known for its role in securing Finland’s winter maritime transport. Following the icebreaking season, Nordica underwent maintenance at the Turku Repair Yard in May. A ship travelling through ice is exposed to severe mechanical stress, so during drydocking the underwater hull and topside of the icebreaker were treated with a new, durable coat of paint.

Arctia Oy

Arctia Oy is a Finnish state-owned company offering a wide range of maritime services. It is particularly recognised for its fleet of icebreakers, an indispensable part of Finland’s winter maritime infrastructure. In addition to icebreaking, the company holds expertise in fairway maintenance and hydrographic surveying, playing a significant role in maintaining and securing waterway connections.

Arctia’s experience extends long way back into history, to the establishment of the Finnish Pilot and Lighthouse Authority. By combining its extensive experience with modern technology, the company is able to provide its maritime clients with sustainable and suitable solutions.

Arctia’s icebreaking fleet consists of eight

icebreakers: Polaris, Otso, Kontio, Voima, Urho, Sisu, Fennica and Nordica as well as the harbour icebreaker Ahto. The most recent addition to the fleet is Polaris, the world’s first icebreaker to use liquefied natural gas (LNG) as a fuel.

In addition, Arctia’s fleet includes seven hydrographic survey vessels, three fairway vessels suitable for heavy marine operations, one Oili class vessel suitable for medium-heavy tasks and several fairway maintenance vessels as well as a versatile hydraulic engineering fleet. Arctia’s vessels are designed to operate in challenging conditions, equipped with the latest technology to perform their tasks efficiently and safely.

Multipurpose vessel

Arctia’s MSV Nordica is a powerful icebreaker with characteristics ideal for tasks that require manoeuvrability and precision. This multipurpose icebreaker is capable of performing highly demanding tasks in environments such as oil and gas fields anywhere in the world. Like its sister ship, the Fennica, the ship meets the United States Environmental Protection Agency (EPA)’s strict environmental and emission requirements, making it an ideal choice for operations in Arctic areas.

SPOTLIGHT PCE JULY –SEPTEMBER 2023 22

SPOTLIGHT PCE JULY –SEPTEMBER 2023 23

SPOTLIGHT PCE JULY –SEPTEMBER 2023 24

© WindWhisper Racing Team

Drydocking at Turku

MSV Nordica underwent drydocking maintenance at the Turku Repair Yard in May. During the docking, the underwater hull and topside of the icebreaker were repainted. A few tanks also received a new coating. One of the ship’s propeller units was also replaced. Painting, replacement of the propeller unit and other work carried out at the shipyard are related to the re-inspection of the ship, which is done every five years.

The docking took place outdoors, which posed its own challenges to the painting process. Environmental conditions determine the schedule and scope of the repair. In outdoor dockings, it is necessary to react quickly to changes in temperature and humidity.

During the docking of the Nordica, the environmental conditions were surprisingly good. The daytime temperature varied between +12 and +20°C, with nights being slightly cooler, and it only rained on a few days during the docking.

Pre-treatment

Before painting, the areas to be painted were high-pressure washed (approx. 300 bar) in order to remove water-soluble salts and other impurities. In this maintenance, water washing was possible because the air temperature was above 0°C during the docking.

After washing, the damaged areas were blast-cleaned to Sa 2½. In addition, edges of existing paint were feathered in order to have the best possible corrosion protection at the overlap of old and new paint.

Painting process

The ice-going Nordica is exposed to really high mechanical stress, which is why the paint surfaces of the ship’s underwater hull and topside require regular maintenance.

The underwater hull was maintenancepainted with Jotun´s solvent-free Marathon IQ2 epoxy coating. The bottom painting was carried out as touch-up painting, i.e., only the damaged areas were treated. After pre-treatment, the bottom was painted with Marathon IQ2 1×500 µm.

The topside paint reinforcement area (above waterline) was painted with the Baltoflake – Normadur 65 HS painting system. A glassflake-reinforced unsaturated polyester coating, Baltoflake was chosen as the primer because an extremely wear-resistant primer was desired for protection of the bow area. This part of the icebreaker is subjected to the maximum mechanical stress.

The topside was maintenance-painted with Jotacote Universal N10 and Normadur 65 HS. The topside was also painted as touch-up painting in terms of the primer. After pretreatment, two coats of Jotacote Universal N10 epoxy primer were applied. After the repairs

SPOTLIGHT PCE JULY –SEPTEMBER 2023 25

The docking took place outdoors, which posed its own challenges to the painting process. Environmental conditions determine the schedule and scope of the repair.

made with epoxy, the topside was washed to remove impurities and then painted with Normadur 65 HS polyurethane topcoat.

The painting process was carried out within 24-hour overcoating intervals. Most of the maintenance painting was done with Jotacote Universal N10 because it also cures in the cold and the product can be overcoated quickly. This time the docking conditions were pleasant, but the product choice also had to be able to cope with worse conditions.

Products used

Marathon IQ2 is Jotun´s breakthrough solution for ice-going vessels. It combines smoothness and toughness to provide the best hydrodynamic efficiency for icebreakers and ice-going vessels. Marathon IQ2 is an environmentally friendly and user-safe product. It doesn´t contain phenol or solvents. It also has improved application properties and is applicable by single-feed standard airless spray.

Baltoflake is a glassflake-reinforced unsaturated polyester coating. It is an ultrahigh build, extremely abrasion resistant and fast curing barrier coating. The bow area of the icebreaker comes into contact with ice, so a coating that can withstand very severe mechanical stress is needed. Baltoflake is recommended for areas subject to extreme mechanical wear and harsh exposure conditions and where future maintenance is challenging.

Jotacote Universal N10 is a polyamine cured pure epoxy coating. It is a fast drying, high solids and high build, abrasion resistant product. It is specially designed as a universal, all-round, all-year, newbuilding and maintenance coating where fast dry-to-handle times are required. It can also be applied at sub-zero surface temperatures. Typical uses in the marine industry for Jotacote Universal N10 are exterior and interior areas, including outside hulls, superstructures, decks, cargo holds and water ballast tanks.■

SPOTLIGHT PCE JULY –SEPTEMBER 2023 26

The painting process was carried out within 24-hour overcoating intervals. Most of the maintenance painting was done with Jotacote Universal N10 because it also cures in the cold and the product can be overcoated quickly.

SPOTLIGHT PCE JULY –SEPTEMBER 2023 27

Long-lasting Corrosion Protection for new Columbus-quay

Since autumn 2021 the new “Columbuskaje” is being built in Bremerhaven for around €80 mill. The company Steelpaint was commissioned with the corrosion protection of the structure using their one-component, moisture-cure polyurethane-system on the Weser port.

28 ARTICLE FROM STEELPAINT

The public authority Bremenports as principal appointed Arcelor-Mittal from Luxembourg with the delivery of the sheet-piles for the new construction. The working group (ARGE) “Columbuskaje” was nominated as executive general con tractor.

Steelpaint said, the Columbuskaje is a matter of special importance for the company. In the 1980s, professional surveys indicated that the load capacity and further use of the structure could no longer be guaranteed. The corrosion and erosion of the sheet piles was in an advanced stage leading up to pitting in some areas.

On board already for previous quay

The Hansestadt Bremisches Hafenamt, nowadays known as Bremenports, had to make a decision either to preserve the old quay and to save it from further dereliction or to build a new one. Taking into account the financial situation, amongst other factors, led to the consideration of a transitional solution to prolong the servicelife of the old structure for another 10-15 years. Various corrosion protection systems from different manufactures were applied under the extremely harsh application conditions on the actual quay. The test patches had to be applied under real-life conditions in the tidal zone which has a range of 3.6 m. Additionally, an active cathodic protection system was installed which in turn required compatibility of the corrosion protection system.

Steelpaint said, it was the only supplier of a moisture-cure PUR-system in comparison to the conventional Epoxy-systems. After several weeks of seawater exposure, the PUR-system “provided the best pull-off results and the best visual appearance of all test patches,” it was said.

Another decisive aspect was that the PURsystem had been applied using the so called wet-on-wet application method in a single shift. Therefore, the whole system could be applied before the rising tide flooded the fresh coat with seawater.

The old Columbuskaje was treated in this manner. Using a combination of cathodic and corrosion protection, the results exceeded the expected additional corrosion protection life time of 10–15 years by far as the construction of the sheet pile wall only started 35 years after refurbishing the old corroded construction.

Steelpaint offers a 10 year warranty against corrosion on the new quay – as well as on all new structures in hydraulic engineering. These warranties are protected by the producer’s liability insurance provided by Gothaer Insurance AG. This insurance was signed in 1985 with a maximum coverage of €5 mill per project. Until today the insurance never had to be claimed nationally or internationally, Steelpaint says.

The old Columbuskaje was one of the very first hydraulic engineering structures that had been coated with the special material from the company Steelpaint. In the first years, the coating

The Columbuskaje before service works in 1985 – extremely corroded.

The Columbuskaje before service works in 1985 – extremely corroded.

29

Some old sheet piles had to be replaced After corrosion protection works 1987

experiences showed that the moisture-cure PUR-systems were offering superior performance, especially in cases where a long-life warranty was required on hydraulic engineering structures.

Epoxy material stopped

Therefore the delivery of Epoxy material was terminated which had still been offered as an alternative in the Eighties. For the management, “it was the right decision.”

Since 1986 Steelpaint is only offering its PUR-systems for the hydraulic engineering, marine and offshore segments in case an extreme corrosion protection was required for steel structures in or near the sea. Since the early Eighties millions of square meters have been coated with moisture-cure PUR material “offering long-lasting protection from corrosion in Germany and abroad to the full satisfaction of the respective principals,” it is added.

Among the successfully executed projects on the coastline of Germany in the last decades are those in Bremerhaven, Cuxhaven, Wismar, Kiel, Emden, Hamburg, Luebeck and Brake and other facilities under control of different regional maritime authorities (WSAs) throughout the country.

Protection for Jade-Weser-Port

The sheet pile wall at the young deep sea port Jade-Weser-Port was coated with moisture cure PUR-Systems double-sided as both sides are constantly exposed to seawater. Construction period was from 2008–2012.

The total area of the ports’ sheet pile wall that had to be protected is 400.000m2. Also, the sheet pile wall of the naval port was coated with the same system.

Over 10 years have passed since the first paint material deliveries. The condition of the corrosion protection is still good which was the minimal expectation after this time of exposure given the higher initial costs for the superior corrosion protection in comparison to conventional coating systems.

The applied coating system is expected to still perform after another 10 or even 20 years from now in the most highly stressed tidal zone. The coated sheet piles at depths from 2m below low water provide a reliable corrosion protection of several decades, as they almost do not corrode with decreasing oxygen content. Extended life cycles like that should be the minimal requirement for all costintensive large constructions..

After more than 10 years of operation, the corrosion protection at Jade-Weser Port is intact

Pitting has formed

After more than 10 years of operation, the corrosion protection at Jade-Weser Port is intact

Pitting has formed

30

Old and embrittled expoxy coating Intact PUR corrosion protection after 22 years

Steelpaint is a subsidiary of the coatings company Emil Harrasser GmbH, established in 1890 in Kitzingen, Germany, who produce a wide range of coating substances based polyurethane, epoxide, acrylic, vinyl, alkyd and other raw materials.

Steelpaint produces only high-performance singlecomponent coatings based on polyurethane and silicon. These products are marketed worldwide under the Stelpant brand, a registered trademark, for use in hydraulic and civil structural engineering and the shipping industry.

Steelpaint GmbH P.O. Box 231 D-97305 Kitzingen Tel: + 49 (0) 9321 3704-0 Fax: + 49 (0) 9321 3704-40 E-mail: mail@steelpaint.com www.steelpaint.com 31 ARTICLE FROM STEELPAINT

NAVIGATING CHANGE

AkzoNobel says it will help shipowners save $100k a year from the new EU carbon levy, says Chris Birkert, AkzoNobel Marine’s Coatings Segment Manager.

IN FOCUS IN FOCUS PCE JULY –SEPTEMBER 2023 32

IN FOCUS PCE JULY –SEPTEMBER 2023 33

AkzoNobel is supporting the marine industry to mitigate emissions and help shipowners navigate upcoming additional costs, or risk facing an additional six-figure levy annually once new EU Emissions Trading Scheme (ETS) legislation comes into force from 2024.

The EU ETS carbon levy will affect all CO2 emissions on shipping journeys to and from an EU port, including when the vessel is docked. Emissions on voyages in and out of the EU will be ‘taxed’ at 50%, unless the journey is less than 300 nautical miles, when a 100% tariff applies. Methane and nitrous oxide will also come under the scheme from 2026.

The carbon tax is about $85 per tonne of CO2 emitted, and under the plan, fines will increase over time, with an initial allowance of 45% of emissions paid from next year increasing to 75% in 2025, and moving up to 100% from 2026.

AkzoNobel’s marine coatings business has been working with its customers to navigate these latest changes to both law and emission charges, as part of an ambition to lead the way in decarbonising the marine industry.

Right coatings choice

While the industry is aware of the scheme, many could be unaware of the sheer impact that the right coatings choice could have on this levy and their vessels’ performance.

“The goal of the new legislation is to compel shipowners to actively reduce their CO2 emissions,” explains Chris Birkert, AkzoNobel Marine’s Coatings Segment Manager.

“Shipowners are facing a wide range of legislative changes already, and there is more on the horizon, with the IMO indicating that they will bring their own additional measures in to drive essential reductions in CO2 emissions.

“In response, there is an almost neverending line of new technological advancements that promise to help in cutting emissions.

“However, through our advanced data scientist capabilities, we’ve been looking to model these changes alongside our coatings schemes to calculate the real financial impact that specifying the right coatings scheme can make. We already know, from years of in-service track record, that Intercept 8500LPP, for example, can deliver a high level of fuel savings. This, combined with the work our data scientists have delivered, puts this into real terms and is aligned with the guidance of changing legislation.

Hull performance

“Our International HullCare package helps shipowners to accurately track, maintain and report on hull performance, and when matched with our most technologically advanced coatings, Intercept 8500 and Intersleek 1100SR, we are able to demonstrate beyond doubt both the reduction in CO2 and the fuel saving, which outweighs the initial cost of investment over a five-year period,” explains Birkert.

“We’re actively working with shipowners who are already hitting the CO2 targets and are reaping the benefits commercially – including making a saving of more than $550,000 in fuel

IN FOCUS PCE JULY –SEPTEMBER 2023 34

across the five-year period. We’re inviting other owners and operators within the industry to work with us on how best to hit their own emissions targets via the use of the right coatings schemes and hull performance package.”

The EU is on a mission to decarbonise the marine industry as part of its ‘Fit for 55’ plan, which aims to reduce greenhouse gas emissions by at least 55% by 2030 compared to 1990 levels.

It comes after the Energy Efficiency Index and Carbon Intensity Indicator, which measures CO2 efficiency on vessels, were brought in as part of the decarbonisation agenda. ■

IN FOCUS PCE JULY –SEPTEMBER 2023 35

All images © Nexxis IN FOCUS PCE JULY –SEPTEMBER 2023 36

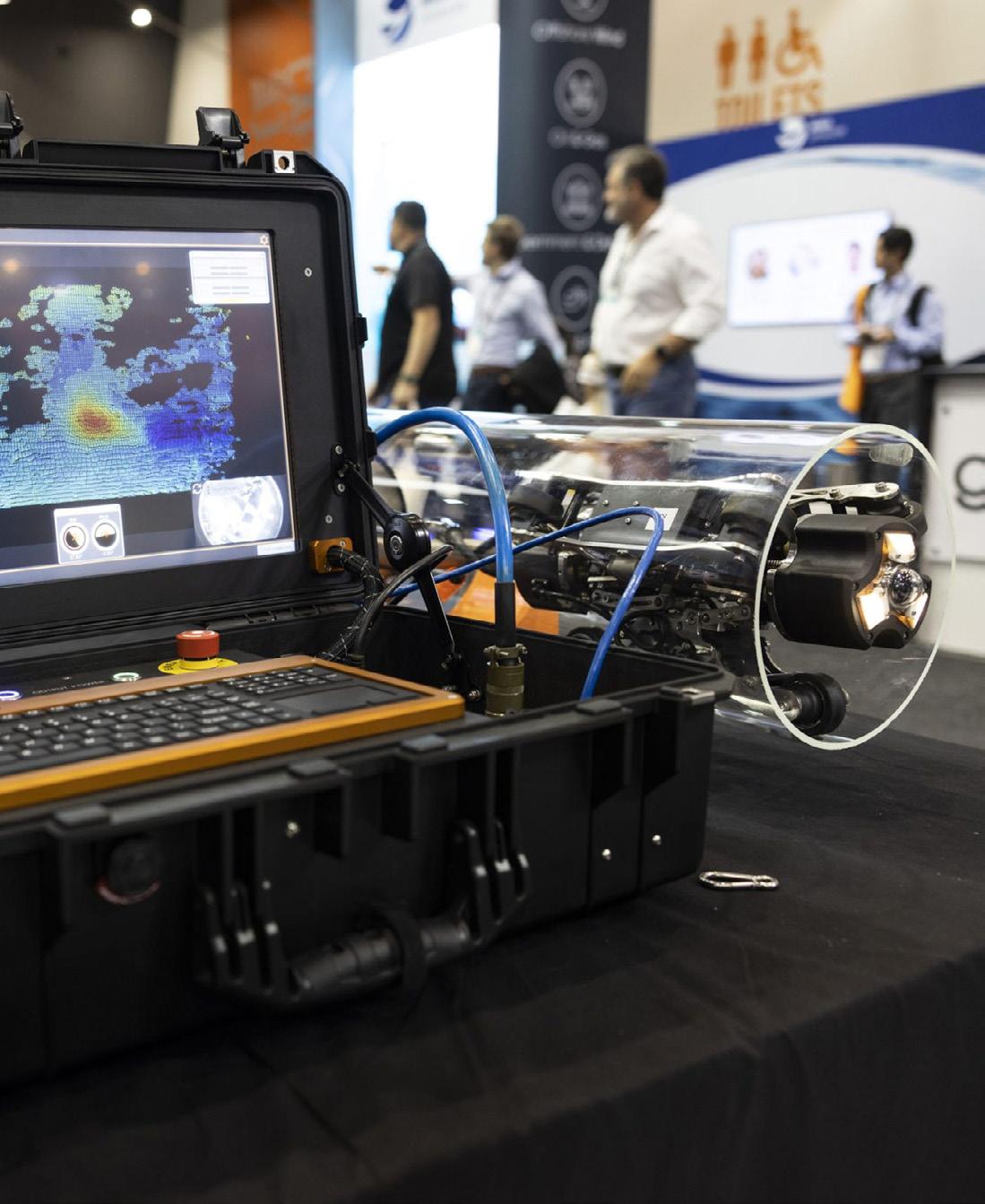

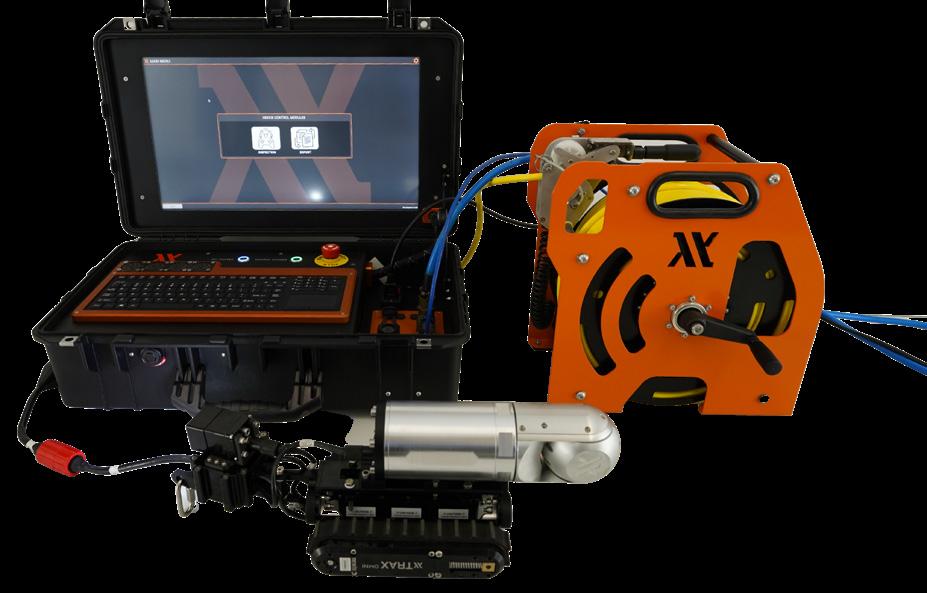

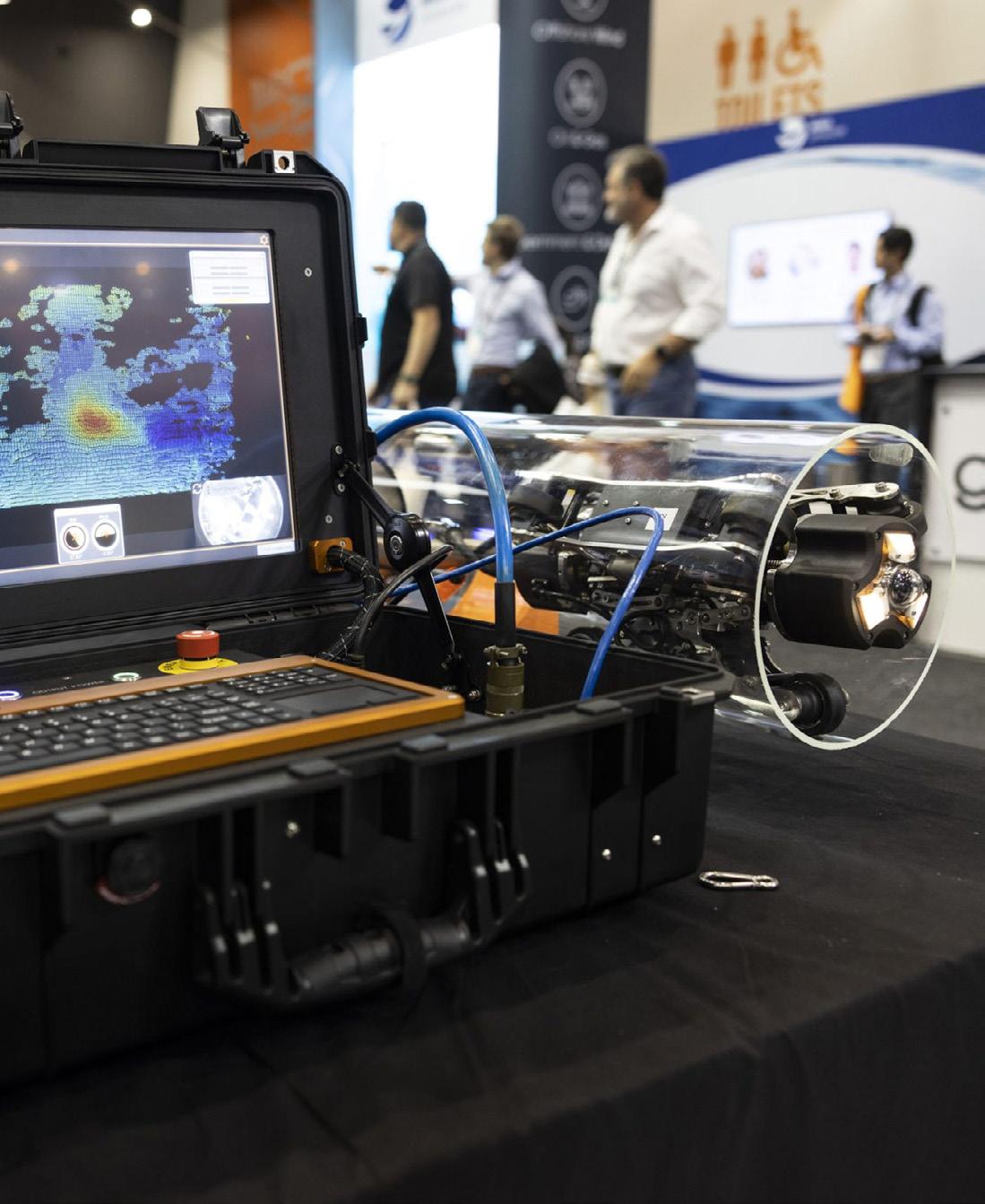

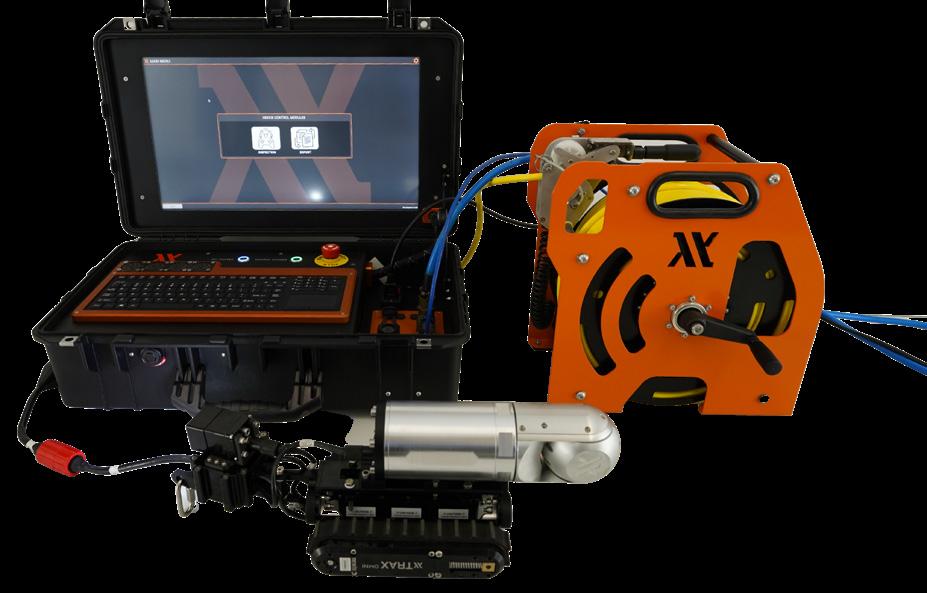

Robotic offshore inspection

The challenges presented in the inspection of a flare knockout drum on an offshore platform, including the advantages and practicalities of employing robotic inspection in the role.

IN FOCUS PCE JULY –SEPTEMBER 2023 37

The inspection of flare knock-out drums (flare/vent scrubbers or relief drums) is typically carried out every five years. Currently, the industry norm is that of primary visual testing (VT) followed by further nondestructive-testing (NDT) should it be deemed appropriate.

Flare knock-out drums on an oil rig are the final asset in the production chain, removing the liquid droplets that carry over with the gas relief sent to the flare. The purpose of testing is to determine the integrity of all internal components, such as the welds, separators, nozzles and heating lines.

The key elements and challenges of current VT practice are as follows:

. The need for human entrance into the confined space of the knock-out drum.

. More than 80% of assets are found to be in good condition, and don’t require any further testing or intervention.

. VT leads to extended downtime and presents significant hazards to those carrying out the inspection.

In 2016 an oil platform operator in the North Sea commissioned the use of a remote visual inspection (RVI) crawler to carry out the inspection of a knock-out drum on the platform. This was the first time this had been carried out on the Norwegian shelf, with the aim of discovering what advantages robotic inspection offered over that of VT.

The study

The knock-out drum had previously been inspected using VT in 2011. The company instructed its inspector to carry out the robotic inspection to compare it against more traditional methods.

The first factor was to determine the type of remote vehicle to be utilised. After considering various technologies, such as an inspection

IN FOCUS PCE JULY –SEPTEMBER 2023 38

The Panther Crawler is able to climb steel walls and inspect pipework

IN FOCUS PCE JULY –SEPTEMBER 2023 39

arm, a magnetic crawler was selected as the most appropriate for the task. A non-intrusive inspection was then carried out to establish that the flare knock-out drum was suitable for robotic inspection. Two inspectors were to be trained in the use of their chosen robotic platform – such as those manufactured by Nexxis – and carry out the task.

The inspection involved determining the condition of the inside of the drum, that the inlet arrangement was intact, that the bolts and plates weren’t loose and that the coating on the bottom wasn’t compromised.

The findings

The inspection resolution provided by the camera was good, detecting light surface corrosion that was verified and checked using phased array from the outside. The inspection data was reviewed by the inspection and operation group, and the results showed that the tank was in adequate condition and therefore didn’t need to be opened for further VT during the turnaround this year.

Practical considerations

The results of this test study were extremely positive, and were determined as the following:

. The use of a robotic crawler removed the requirement for human entry and negated the need for blinding, cleaning and scaffolding the tank for inspection.

. This saved around 1,500 man hours.

. HSE was improved by not exposing inspection personnel to a hazardous environment.

. The data returned by the RVI was of high quality and the results were verified with phased array during the turnaround.

. Monetary savings amounted to one million NOK (€100,000).

Based on the successful results of the study, a change was made to the company’s standard inspection procedure for flare knockout drums, utilising remote robotics as the preferred choice for all future inspections.

Implications and way forward

This case study is a classic example of how crucial it is for companies to be aware of and embrace such advances. In a constantly changing market, equipment provider Nexxis is at the forefront of such global robotic technology, and partners with its customers to determine the solutions necessary to have the much-needed competitive edge. ■

IN FOCUS PCE JULY –SEPTEMBER 2023 40

The Snowcat Crawler offers a 360 degree tilt camera

ANALYSIS PCE JULY –SEPTEMBER 2023 42

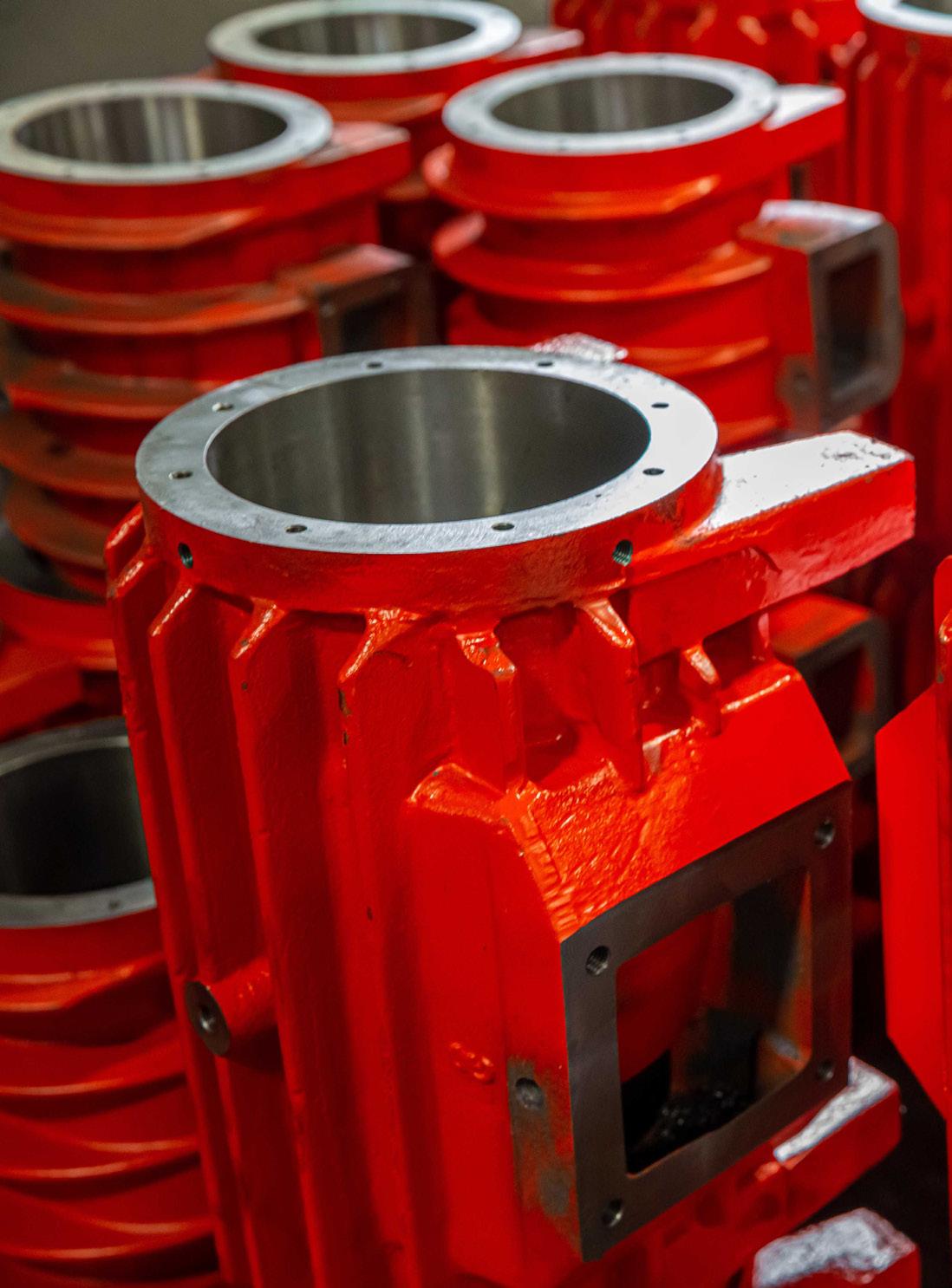

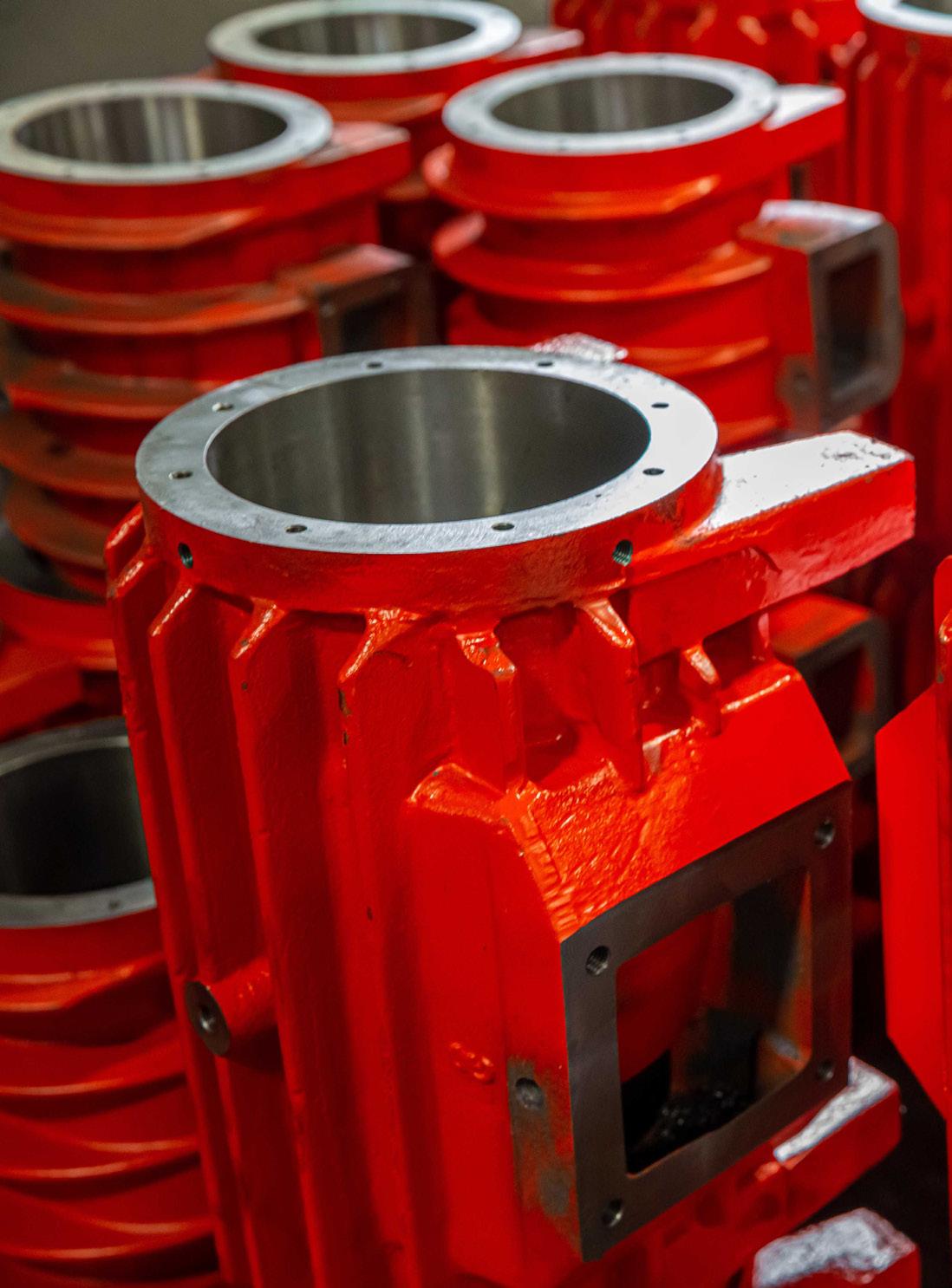

TRANSFORMER PROTECTION UPGRADE

Transformer manufacturers are facing many challenges: the looming winter storm season, supply chain challenges, labour shortages and more. Whilst many factors are beyond their control, identifying paints and coatings that offer next-level protection for important metal components is within their purview, explains Maria Lamorey, Commercial Strategy Manager, PPG.

ANALYSIS ANALYSIS PCE JULY –SEPTEMBER 2023 43

Considering a transformer’s exposure to extreme weather conditions, outdated and substandard coatings systems can – and do – lead to impairments and disruptions in power services. The right coating system that offers durability and resilience at every layer of protection can extend the service life of transformers and reduce the risk of coatings-related failures – a move that helps to protect manufacturers’ business and their brand. It all starts with a detailed and up-todate paint specification.

Strong defence against corrosion

When it comes to the metal components of a transformer, corrosion is Public Enemy Number One and prevention is the top line of defence.

Metal electrical equipment parts corrode for any number of reasons. Some factors include the intersection of two metals with different corrosion thresholds; continuous or repeated exposure to high temperatures and humidity from decades in the field, and damaging acidic pH levels, electrolytes, chemicals and ultraviolet rays from sunlight.

Coatings specification: the building block of better protection

If the goal of an electrical equipment manufacturer is to build next-generation components that exceed performance mandates while protecting its brand reputation, paint specifications should be reviewed and updated regularly.

Selecting the right coating system and a supplier that utilises advanced formulations will help transformer, switchgear and other electrical equipment manufacturers outperform competitors, extend the lifecycles of their products and reduce warranty claims.

On average, finished electrical components are composed of about 70% metal and 30% non-metal substrates. Yet despite the importance of high-quality protective coatings in terms of durability and performance of their goods, most electrical equipment manufacturers view painting metal as beyond their core competency.

Whilst most electrical equipment holds a minimum life expectancy of 20 years, many components are expected to survive 50 years or more. Harsh elements can accelerate corrosion and leave sensitive instrumentation vulnerable during storms and compromise its reliability.

ANALYSIS PCE JULY –SEPTEMBER 2023 44

ANALYSIS PCE JULY –SEPTEMBER 2023 45

Establishing and maintaining a standard colour can be challenging

Unfortunately, many manufacturers still combine old “cutand-paste” specifications that date back 20-30 years with current industry-standard regulatory requirements written by IEEE, UL, CSA and ASTM when painting and protecting new equipment.

Coatings manufacturers can contribute to the problem by relying on standards dictated by their customers, or by taking the path of least resistance and continuing with existing solutions instead of exploring more advanced technologies that are proven to perform better in the field.

The foundation of any great coatings system starts with the right specifications. Here are some important factors to consider when specifying products:

Coating type: Coating manufacturers offer a variety of resin chemistries to improve resistance to corrosion and UV exposure, including epoxies, polyesters, urethanes and acrylics, as well as hybrid coatings, which incorporate a combination of resin chemistries. Each has its strengths and weaknesses.

For example, epoxies are ideal for chemical resistance and mechanical properties, but are lacking in UV resistance and weatherability. Polyesters, urethanes and acrylics all offer exceptional weathering characteristics, but each offers a different benefit, such as great

physical properties for polyesters; chip, scuff and mar resistance for urethanes and exceptional surface appearance for acrylics.

Product codes: Electrical equipment producers should avoid using a specific paint manufacturer’s product code. Codes can be ambiguous or difficult to find, as they often change or may be unique to a specific customer. Instead, detail the specific coatings technology the equipment demands (pre-treatment, liquid, powder or electrocoat), and then detail the resin chemistry of the desired coating.

Colour: Establishing and maintaining a standard colour can be challenging. It is important to detail an acceptable range of colour variation and use a proven and consistent method for determining that the colour of painted parts falls within specification. The Pantone, RAL, Munsell and ANSI colour-cataloguing systems are commonly

ANALYSIS PCE JULY –SEPTEMBER 2023 46

ANALYSIS PCE JULY –SEPTEMBER 2023 47

used for these purposes, although some equipment manufacturers choose to create their own in-house standards. Maintaining colour standards is an entirely separate topic, so it is best to work with a reputable paint manufacturer to understand the intricacies of creating a colour standard and how to detail its parameters in the specification.

Gloss: Like colour specification, gloss range specification can have a big impact on a product’s finished appearance. It is important to provide a specific gloss range in a paint specification, as variations in gloss can cause the same colour on a piece of equipment to appear in different shades.

Texture: In the electrical industry, some ‘orange peel’ (minor paint dimpling) in the finish is considered preferable, as it tends to hide flaws and wear well over time. Regardless, standards for texture types and variation should be written into the paint specification.

Product handling and storage: Manufacturers suggest specific rules for handling and storage in their product data sheets, including an acceptable range of temperature exposures and fixed expiry dates to ensure inventory is properly rotated.

Performance: Regulatory standards such as UL or IEEE should be detailed in the paint specification. These standards are written to include a range of acceptable results for products undergoing laboratory-based performance tests, which have been agreed upon by the industry for their ability to mimic real-world performance environments.

The role of performance testing

While many coating systems are robust enough to pass industry-accepted performance tests, they can fail in the field because the real-world conditions can be much more demanding.

It is strongly recommended that manufacturers include the tests that most accurately reflect a product’s ability to fulfil a warranty or expected service life into the paint specification. For example, does a specific impact test predict the likelihood of paint chipping once installed in the field? Or does it depict real-world colour fade or coating breakdown with an accelerated weathering test?

Performance testing must also correspond to field troubleshooting. If a coating fails in the field, correlating the failure to a specific testing method will enable the equipment and paint manufacturers to identify the reason for the failure more quickly, which can lead to quicker corrective action.

Some of the most common performance tests written into electrical equipment paint specifications include:

Salt spray: This is the most commonly specified test in the electrical industry. UL1332 requires 600 hours of salt-spray exposure for electrical enclosures and switchgear. Many transformers require between 1,000 and 2,000 hours of exposure.

QUV ultraviolet accelerated weather: In this test, coated panels are exposed to ultraviolet (UV) light of varying types, resulting in “maintain X% specific gloss level after X number of hours” rules as detailed in a specification. These tests are designed to predict how a coating will fade outdoors over time.

Simulated Corrosive Atmospheric Breakdown (SCAB): In this test protocol, painted panels are scribed and then cycled through exposure conditions produced in the following environments: an oven, a freezer, immersion in a sodium chloride solution, room temperature and high humidity. The IEEE test for SCAB requires 15 total cycles with prescribed times in each area. This testing is designed to predict how well a coating will maintain its integrity when subjected to a succession of regular and extreme performance environments.

Humidity: During this test, painted panels are typically placed in a humidity chamber for 1,000 hours and then examined for evidence of blistering or softening. This testing is designed to predict how well a coating resists water.

Impact resistance: For this test, panels are exposed to an array of impact hazards, measured according to pounds. Transformers are typically tested at 80lbs (36kg) of impact. This test is designed to predict how well a coating will resist force from an object, such as a tool or machine. It also may predict a coating’s resistance to chipping when a bolt or other fastener is tightened onto its surface

ANALYSIS PCE JULY –SEPTEMBER 2023 48

Cross-hatch adhesion: In this test, a tool is used to cut a lattice pattern into a metal substrate. A quick pass/fail rating is assessed to the full coating system to gauge its ability to adhere to a substrate.

Gravelometer: Road gravel is air-blasted onto coated panels, which are then placed into a salt-spray chamber to assess the corrosion resistance of the exposed parts. This test is designed to predict a coating’s ability to withstand road gravel and chip resistance.

Other tests that are occasionally used and built into specifications for electrical equipment include:

Pencil hardness: During this test, a pencil is pressed through the surface of a coating to measure its adhesive strength.

Adhesion: This test method involves applying tape across a painted surface in a cross-cut method, then removing it to determine how effectively the paint sticks to the surface. There are also many types of chemical tests, including an insulating fluid test to determine a coating system’s ability to resist exposure to certain types of chemicals.

Consider the optimal coating technology: liquid, powder, electrocoat or a combination

Selecting the right protective coating helps products look better and last longer, improves application efficiencies and can reduce operating costs. But manufacturers need to consider important factors to determine the best-fit solution for the application.

A complete review of mechanical and chemical pre-treatment options is the foundation of every coating system, followed by the pros and cons of electrocoat, powder and liquid solutions. By working closely

with the paint supplier, manufacturers can get a clearer understanding of which coating is best, based on performance needs, application ease, sustainability considerations and cost.

Liquid coatings use solvents or water and are applied to pre-treated metal with electrostatic spray, dipping and other conventional methods before being air-dried or force-cured. When used as part of an

Coating Thickness Gages

NEW

and

NEW Weatherproof, dustproof, and

IP65-rated enclosure n NEW Updated user interface retains the same layout and menus n NEW Up to 30% longer batter y life

NEW On-gage help explains menu items at the touch of a button

NEW Ergonomic design with durable rubberized grip

n

Larger 2 8” impact resistant color touchscreen

redesigned keypad for quick menu navigation n

water-resistant

n

n

NEW

DeFelsko Corporation l Ogdensburg, New York USA Tel: +1-315-393-4450 l Email: techsale@defelsko com Backwards Compatibility! Accepts ALL coating thickness, surface profile, environmental, soluble salt, hardness, and ultrasonic wall thickness probes manufactured since 2012 1-800-448-3835 www.defelsko.com

Design and Features

ANALYSIS PCE JULY –SEPTEMBER 2023 49

Manufacturers are increasingly turning to powder coatings for their performance, aesthetic and sustainability advantages

integrated primer, pre-treatment and topcoat system, liquid coatings offer exceptional resistance to corrosion and chemicals, excellent sag resistance and strong adhesion. Newer product offerings in waterborne liquid technologies offer a more sustainable option as part of an integrated coating layer.

Manufacturers are also increasingly turning to powder coatings for their performance, aesthetic and sustainability advantages. In fact, powder coating is the fastest-growing technology due to these advantages.

Powder coatings are formulated for applications that require the ultimate combination of corrosion resistance, weathering performance and operational attributes. These coatings are typically formulated with specific resins combined to provide excellent corrosion and chemical resistance and all-around application versatility.

Since powder coatings are made without solvents, they generate virtually no volatile organic compound (VOC) emissions. This can help manufacturers achieve environmental compliance and reduce material usage, energy consumption and maintenance costs thanks to a first-pass transfer rate of up to 85%.

Coatings suppliers make valuable partners

Equipment manufacturers should involve paint and pre-treatment suppliers in the design process as early as possible, preferably with a proven coatings company that can offer both pre-treatment and paint capabilities as an integrated package.

Integrated, full-service coatings suppliers typically have a deep understanding of the entire coatings process, along with a wide range of products and resin chemistries that have been tested according to standard industry criteria.

Coatings suppliers can be valuable partners by helping to identify potential vulnerabilities to corrosion and recommending protective solutions to prevent it.

Most integrated coatings suppliers have a global presence and partnerships that span a wide range of industries. This broad expertise, along with dedicated lab resources, can be invaluable to manufacturers in helping them to identify the best test methodologies to measure a product’s potential service life, quickly correct coatings failures and troubleshoot general coatings-related production problems. ■

ANALYSIS PCE JULY –SEPTEMBER 2023 50

ANALYSIS PCE JULY –SEPTEMBER 2023 51

UPDATE PCE JULY –SEPTEMBER 2023 52

SUPPORTING A NET ZERO FUTURE

What role does polymeric technology play in the burgeoning wind industry, asks Belzona’s Chloe Hirst.

UPDATE UPDATE PCE JULY –SEPTEMBER 2023 53

There has been considerable growth in the wind power industry over the past few years. However, further exponential growth of the industry is required in order to ensure that the net-zero-by-2050 pathway (outlined in the Paris Agreement) is successfully reached.

In order to support this seismic growth, polymeric repair and protection technology has an important part to play. Designed to safeguard the integrity of wind turbine blade leading edges for the long term, this technology plays a critical role in supporting this burgeoning industry.

Wind electricity generation needs to grow fourfold by 2030

According to the International Energy Association (IEA)’s Wind Electricity Tracking Report (September 2022): “In 2021 wind electricity generation increased by a record 273TWh (up 17%). This was 55% higher growth than that achieved in 2020 and was the highest among all renewable power technologies.”

While the industry has undoubtedly experienced impressive levels of growth in these years, according to the IEA, wind electricity generation needs to reach four times the record

Wind electricity generation needs to grow fourfold by 2030 (IEA. License: CC BY 4.0)

UPDATE PCE JULY –SEPTEMBER 2023 54

Leading edges can be damaged by erosion

UPDATE PCE JULY –SEPTEMBER 2023 55

Surface preparation using an orbital sander

levels set in 2020 by 2030. The Report said: “Our pathway calls for scaling up solar and wind rapidly this decade, reaching annual additions of […] 390GW of wind by 2030”.

Scale up financing

According to the IEA’s Report: “Policy support remains the principal driver of wind deployment in the majority of the world.” Indeed, over the past few years, several policies have been launched that are designed to drive forward the roll-out of renewables.

For example, in August 2022, the US brought in the Inflation Reduction Act (IRA) which includes $369bn of investment; in the European Commission’s Green Deal Industrial Plan, $270bn was pledged, and since the UK government’s Ten Point Plan was launched in November 2020, over £26bn of government capital investment has been mobilised.

Polymeric technology

Given the critical role wind power plays in the transition to a net zero future, as well as the significant amount of capital being invested into the renewables industry, the wind power sector is poised to experience considerable exponential growth in the upcoming decades. In order to support this growth, polymeric technology plays a significant role when it comes to maintaining the operational efficiency of the rapidly expanding fleets of wind turbines.

Polymeric systems such as the rebuild blade filler material Belzona 5711 and the cartridgeapplied leading edge protection coating Belzona 5721 are specially designed to repair damaged leading edges and protect them against rain erosion and impact damage for the long term.

In addition to the performance capabilities of these systems, maintenance engineers are investing in this technology due to the simple, in-situ application method and fast cure times the cold-curing systems facilitate. In turn, this helps to keep downtime to a minimum, and allows the turbine to be returned to service in the same day. Belzona 5711 can be directly overcoated with Belzona 5721 in as little as 30 minutes at 20°C/68°F without the need for any additional surface preparation. At the same temperature, Belzona 5721 will be fully cured within five hours.

Wind turbine blade repair and protection

Belzona successfully addressed the wind turbine blade damage issue at Electricity Generating Authority of Thailand (EGAT)’s Khao Yai Thiang Windfarm in Thailand with Belzona 5711 and Belzona 5721.

In 2021 wind electricity generation increased by a record 273TWh (up 17%). This was 55% higher growth than that achieved in 2020 and was the highest among all renewable power technologies.

Using a selfmixing Belzona 5711 cartridge

UPDATE PCE JULY –SEPTEMBER 2023 56

Bottom Caption: Application of the Belzona 5711 repair paste

The completed edge repair

UPDATE PCE JULY –SEPTEMBER 2023 57

Application of Belzona 5721 high-performance coating

UPDATE PCE JULY –SEPTEMBER 2023 58

Successful application of the Belzona polymeric system

The windfarm features wind turbines with 40m-long (131.2 ft) blades. During routine inspections, evidence of damage measuring 300cm x 14cm x 2mm (118in x 5in x 0.08in) was discovered on the leading edge of one of the blades.

System selection

Representatives from the 35-year-old Belzona

Authorised Distributorship

Pan Mechanic Engineering recommended the solvent-free, two-part repair paste Belzona 5711 to reconstruct the damaged area on the blade, followed by the highperformance coating Belzona 5721 to overcoat the area.

Application procedure

The application procedure involved surface preparation using an orbital sander, followed by the direct application of approximately 1.4kg (3.1lbs) of Belzona 5711 from a selfmixing cartridge onto the blade. The repair area was contoured using a piece of Belzona mixing board.

After a two-hour curing period, a visual inspection was conducted to ensure the application’s readiness for overcoating with approximately 3.5kg (7.7lbs) of Belzona 5721. Using a short-bristled brush, this system was then applied to the leading edge and left to cure. The blade was back in service 24 hours later.

EGAT’s technicians were trained at the Belzona Asia Pacific facility to perform the application, with two representatives from Belzona’s Technical Service Department present on site to observe and provide guidance.

Commenting on the application, an EGAT representative said: “We are extremely satisfied with the results achieved by Belzona’s leading edge repair and protection system. The application procedure was very simple, and could be carried out quickly, which ensured that downtime was kept to a minimum. We plan to place an order for more Belzona 5711 and Belzona 5721.”

Supporting a net zero future

In order to support the seismic growth of the wind power sector, polymeric technologies such as Belzona 5711 and Belzona 5721 play a critical role. By safeguarding the integrity of wind turbine blades, this helps to keep windfarms functioning at their optimum efficiency, which in turn supports a net-zero-by-2050 pathway for the planet. ■

Surface Profile

Surface Profile Gauge

Digital depth micrometer measures and records peak-to-valley surface profile height

n Alumina wear face and tungsten carbide tip for long life and continuous accuracy

n Fast measurement rate of over 50 readings per minute ideal for quickly and accurately measuring large surfaces

n Cabled probes available for blasted steel, textured coatings, and concrete profile

Replica Tape Reader

Digital spring micrometer measures and records peak to valley height using Testex Press-O-Film™ replica tape

n NEW Larger opening for easy tape placement

n Linearization feature increases measurement accuracy and reduces tape consumption

3D

Replica Tape Reader

n Capture 3D surface imager y, peak density, and other surface parameters using replica tape

Backwards Compatibility!

PosiTector gauge body accepts ALL surface profile, coating thickness, environmental, soluble salt, hardness, and ultrasonic wall thickness probes manufactured since 2012

techsale@defelsko com

H

+1-315-393-4450 n 1-800-448-3835

n www defelsko com

N E W D e s i g n a n d F e a t u r e s

UPDATE PCE JULY –SEPTEMBER 2023 59

MAKING THE SOLUTION FIT THE NEED

paint for metal in a fast-paced, extra slip, high temperature environment.

Choosing

REVIEW REVIEW PCE JULY –SEPTEMBER 2023 60

REVIEW PCE JULY –SEPTEMBER 2023 61

REVIEW PCE JULY –SEPTEMBER 2023 62

© Leipziger Messe GmbH / Tom Schulze

Finding the best paint for metal involves much more than picking a favourite colour. In addition to good adhesion and rust prevention, a metal coating must be equipped to meet force-dry, high slip, or high temp requirements in certain applications. To address these needs, Cortec offers two specialty versions of EcoShield VpCI-386, a high-performing water-based anticorrosion coating for industrial applications.

Two anticorrosion paints –three special features

EcoShield 386 FD is a water-based acrylic one-coat system that can be applied directto-metal (DTM) for protection in harsh, outdoor, unsheltered applications. It was specifically designed for fast-paced, force-dry applications, common in manufacturing environments. In addition to outstanding corrosion protection at 1.5-3.0 mils (37.5-75 µm) DFT (dry film thickness), EcoShield 386 FD force-dries in just 5-10 minutes at 150°F (65°C) and has good hot hardness. EcoShield VpCI-386 HT Slip Coating is another DTM water-based topcoat that offers excellent corrosion protection at 1.5-2.0 mils (37.5-50.0µm) DFT. It is heat resistant up to 500°F (260°C) or more (depending on colour) and improves surface slip. The coating is thixotropic and resists sagging and running during application. Both EcoShield 386 FD and EcoShield VpCI-386 HT Slip Coating are UV resistant and low VOC.

Where are force-dry, extra slip, high temp coatings needed?

Whilst it would be difficult to list all the industrial applications where force-dry, extra slip, or high temp coatings could be used, the following examples are excellent springboards for exploring options.

. Force-dry applications

Fast-paced manufacturing applications are the number one candidate for EcoShield 386 FD. Many spray or dip lines move so quickly that the parts pile up at the end of the line. This is bad news if parts are hot and sticky – they could easily adhere to each other and potentially damage the coating when components are pulled apart. EcoShield 386 FD, which is designed for force-dry applications and has good hot hardness, will reduce the risk of parts sticking together. This feature is a potentially huge advantage in countless

Fast-paced manufacturing applications are the number one candidate for EcoShield 386 FD

REVIEW PCE JULY –SEPTEMBER 2023 63

manufacturing applications where pipes, hooks, castings and a variety of other equipment components are made.

. Extra slip applications

Electrical conduits are a prime example of where EcoShield VpCI-386 HT Slip Coating is beneficial. A protective inner diameter coating can be critical for new piping stored outdoors or shipped through harsh, corrosive conditions. However, when it comes time to install the conduits, electrical wires must be able to slide easily through the tubing. EcoShield VpCI-386 HT

Slip Coating makes this possible whilst also inhibiting corrosion. The same benefits would apply to other metal surfaces, parts or equipment in need of a protective coating that is slippery.

. High temp applications

In addition to needing extra slip, electrical conduits are a great illustration (although by no means the only example) of a high temp application. These pipes start out as flat pieces of metal that are rolled into tubes, welded, and internally painted before the welding heat can cool down. EcoShield VpCI-386 HT Slip Coating was designed to withstand this extra heat during coating application and similar high heat curing processes. It can also be used on equipment that may reach temperatures up to 500°F (260°C) during operation.

The main purpose of Cortec Coatings is to protect metals from corrosion. However, when special requirements such as force-drying, extra slip or high temps enter the equation, Cortec is ready to make the solution fit the need. ■

The main purpose of Cortec Coatings is to protect metals from corrosion. However, when special requirements such as force-drying, extra slip or high temps enter the equation, Cortec is ready to make the solution fit the need.

REVIEW PCE JULY –SEPTEMBER 2023 64

Electrical conduits are a prime example of where EcoShield VpCI-386 HT Slip Coating is beneficial

FIRE PROTECTION EXPANSION

A major expansion of Jotun’s fire protection coating R&D facilities will further secure Jotun’s innovative position and trusted partner status within the global structural fire protection industry.

REVIEW PCE JULY –SEPTEMBER 2023 66

REVIEW PCE JULY –SEPTEMBER 2023 67

Global paints and coatings manufacturer Jotun, one of the major providers of intumescent fire protection coatings for the infrastructure and energy industries, has announced the completion of major expansion of its global intumescent R&D laboratory to advance new product innovation and technologies.

This ambitious expansion more than doubles the size of the Flixborough, UK global intumescent R&D facility, aiming to increase Jotun’s product development and fire testing capacity and capabilities. The new facilities will accelerate the development of new innovations and more advanced products, whilst providing additional certification support to the company’s existing product range.

Jotun is determined to gain market share in this industry by accelerating development of new and advanced technologies. Its aim is to enter new markets through wider certification and regional product customisation in line with rapidly changing market requirements. This ensures its customers’ assets are fireprotected to latest regulatory requirements, and materials deliver high performance for their specific location.

New furnaces installed

Originally constructed in 2016 and now expanded to 2,900m2, the enhanced facility increases capacity and capability for Jotun’s ongoing development of intumescent fire protection coatings – SteelMaster for steel structures within the infrastructure market and Jotachar for vital assets in the energy industries. The one-year expansion programme included the installation of new furnaces, with associated application and conditioning facilities, combined with new analytical, environment simulation and mechanical testing facilities.

Supported by Jotun’s R&D headquarters in Sandefjord, Norway, the enhanced global hub in Flixborough will continue to focus on leading edge R&D projects, driving breakthrough intumescent coatings technology.

Localised innovation

In addition to the global intumescent laboratory in Flixborough, Jotun has cemented its commitment to localised innovation, ensuring differing certification and environmental requirements are met within each market. Strategic investment in regional intumescent

REVIEW PCE JULY –SEPTEMBER 2023 68

research, development and testing facilities span Norway, the United Arab Emirates, China, Korea, the US and Malaysia.

Jotun’s enhanced capabilities across its network of intumescent R&D facilities represents a significant milestone in its drive to advancing fire safety through research and development. Its growing team of dedicated scientists and industry specialists is capable of engaging with fire protection authorities, global regulators and certification bodies providing guidance on testing, certification and material performance.

A testament to this commitment was illustrated earlier this year when Jotun unveiled its latest advance in intumescent coatings, Jotachar JF570 XT –a patent-pending all-climatecapable intumescent coating, designed to protect oil, gas and energy installations from fire and cryogenic spills, in even the most extreme environments.

R&D vision

“When we opened the Global Intumescent R&D Centre in 2016, our vision was for a facility that could evolve to support our customers across the globe as their structural fire protection requirements become more complex and regionalised,” explains James Irving, R&D Manager Intumescent Coatings. “We are delighted with this major extension, more than doubling the size of our facility, we are now ready to further enable the development of fire protection coatings and technologies to meet these requirements.”

He went on to say: “Our Intumescent R&D team is expanding rapidly. These new facilities will allow our scientists, technicians, and industry specialists to reinforce our position as a global innovator in this safety-critical area of the coatings industry.

“This expansion is a key part of Jotun’s ambitious strategy

to increase market share and grow sales of intumescent coatings by developing a global network of intumescent R&D facilities with Flixborough as the hub.” ■

Coating

N E W D e s i g n a n d F e a t u r e s

N o n - d e s t r u c t i v e l y m e a s u r e s

p r o t e c t i v e c o a t i n g s o v e r

c o n c r e t e f l o o r i n g , p i p e s ,

c o n t a i n m e n t s t r u c t u r e s , a n d m o r e .

n Ready to measure no adjustment required for most applications

n Extended range measures up to 7,600 µm ( 300 mils) ideal for measuring polyurea and other thick protective coatings

n Proven non-destructive technique conforms to ASTM D6132 and ISO 2808

Backwards Compatibility!

PosiTector gauge body accepts ALL coating thickness, surface profile, environmental, soluble salt, hardness, and ultrasonic wall thickness probes manufactured since 2012

+1-315-393-4450 n 1-800-448-3835 techsale@defelsko.com n www.defelsko.com

Thickness Gauges for Non-Metal Substrates

REVIEW PCE JULY –SEPTEMBER 2023 69

Jotun is determined to gain market share in this industry by accelerating development of new and advanced technologies.

NEWS PCE JULY –SEPTEMBER 2023 70

NEW PRODUCT TESTING PROGRAMME

HMG Paints has announced the launch of an exciting opportunity for all professional painters and decorators. The Product Testing Programme is a new initiative where trade professionals can get exclusive access to products and assist in development of new ranges.

The company is reaching out to professionals in the coatings or decorating industries who would like to join the scheme and get early access to HMG Paints products. “Working closely with customers is something HMG has done throughout its history, and as we continue our growth into the trade professional market, we want to ensure we’re engaged directly with users,” explains James Burton of HMG. “We’re keen to listen and learn from the professionals and ensure the products we bring to the market create added value for users. The products will be varied and include products such as Ferrozinc and emulsions to new developments for the light industrial market the R&D team have developed.”