Regulars

8 SWITCH ON

Ourlatestround up of model lyingnews.

72 PILOTS’PICTORIAL

Send us apic ture of anew or favourite modeland it couldappearinour reader s’ models galler y

85 COUNTERPOINT

Aselec tion of newkit s, bits andg adgets foryou to buy

92 GOINGPLACES

Ourupd ated list of modelevent sand competitions foryou to visitoverthe next fewmonths

94 MARKETPLACE

Sell o� fyourunwanted airframesand enginesormaybe buya fewnew ones

95 NEXT ISSUE

Take alookatwhat’scominginthe July ‘25issue of RCM&E

98 PARTINGSHOT

24 BASINGSTOKEFLY-IN

Mike Freemanrepor ts from the BasingstokeMAC AllElectricFly-In2024

38 ARFREPAIRS MADE EASY

Dick vanMourikshows howtoput back together acra sh damagedAlmostReady to Flyaeroplane

44 DAFF Y’SREARGUNNER

Harr yCur zon’smodel of theDefiant interceptorhas aneattrick centred around it sreargun turret

59 USINGFOLDING PROPSASPUSHERS

Mike Freemano�fer sadvicefor when usingafolding propellertoprovide thru st on apushermodel

62 BIG UP THEINDOOR

Dave Goodenough report sfroman indoor ly-in especially arranged forthe ‘kid z’ -young andold!

80 FUNDROID

SUBS CRIBE…

andreceive Modern AerobaticTeams &HalfCentury,Baby! bookazines FREE!See page 46 fordetails

ArnaldoCorreia captures afriend’s Eadweard Muybridgemomenta she launches aBirdofTimeglider

Reviews

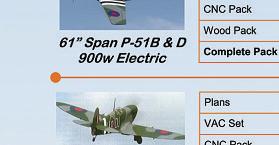

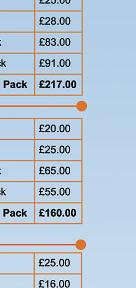

10 SK YHAWK

Alex Ma xfieldbuild saUKdesigned andmanuf ac turedF5L championship winningglider

68 SUPERMARINESPITFIRE

A ter lyingXFly’sprototype desert schemedmodel KevinCrozier finally managestosee sk ybelow theD-Day version’swheels!

Features

18 SPACEWALKERFLIES AGAINPar t2

Martin Hardycontinues hisconversion of aquarter sc aleSIG Spacewalkerto elec tric power

Continuing from thelastissue,Mike Bell finishesand lieshis FunFly model madefromhybridmaterials

86 GOLDEN GLOW

Neil Hall returnswithmoreadvicefor wannabeu sers of glow enginesand to gladdenthe hear ts of thosealready smit tenwithICpower

Columns

32 SCALEGLIDING

ChrisWilliamsshows howtomake reinforced butt joints before introducing hislatestgull-wing Minimoa

74 THEINSIDER

Asmall andsimplemodel givesJohn Stennard asurprisingamountof satisf ac tion

Free Pro-Plan

48 COSMIC CLOUD150

Dave Goodenough ex tr ac ts af avourite smallgliderdesignfromhis memory andenlargesitfor radiocontrol and elec tric power

Please come andjoin us.Full details canbe foundonthe event websites: https://www.interglide.co.uk/online-entr yform/ (Book here.)

https://www.interglide.co.uk/pilots/ (Check registrations andhistorical info.)

Theorganising bodyisthe British AssociationofRadio Control Soarers (a Specialist Body of the BMFA). Please contact Nick Jacksonon+44 (0)7879 654863oremail whitstable.nick@outlook.com

Thecompetitionwill be runaccording to the current F5J rules in the FAISportingCode. ‘Earlybird’ reductions areavailable forthose

booking beforeMay.Entries arelimited to amaximumof60and booking will close before16th June if themaximumisreached earlier.Any further entries will be kept on a reser ve list.

Hamilton Farm Airstrip,Bilsington,Ashford Kent,TN25 7JJisa wonderful locationwitha choice of basic or deluxecamping available Formoreinformationvisit:https://www hamiltonfarm-cl.co.uk/

Basic facilities will be available on thefield in the area outside of thefenced offCaravan Club sitebut do not include use of theCaravan Club siteshowers or toilets.Charge forbasic

WO

SK YHAWK

Alex Maxfield builds aUKdesigned andmanufactured F5L championship winning glider

Words: Alex Maxfield

Photos: Alex Maxfield, SteveHaley

Further to my article on the Encanto F5L competitionthermal soarerinthe January issue, Iplanned to review another design forthe same class and then later writeanother articlecomparingthe flight characteristics of the two. AlthoughI writethat the Encantoand theSkyhawk are competitionmodels,they areequallysuitable forsport flying.

TheF5L class allows foramainly wooden construction, twometrewingspanthermal soarerwith an electric motor forlaunching Thecompetitionrules consider the flight durationwithin aset time windowfollowed by aprecisionlanding foradditional points Theclass dictates the models canonlybe controlled with rudder,elevator andspoilers (air brakes forprecisionlanding) andis

Steve’sSkyhawk fleetshowing theX-tailand V-tail (middle) options.

commonly alsoreferred to as RES.Assuch it is probablythe most a�fordable thermal soaring class,with increasing numbers of pilots competing.

In the UK the British Association of Radio Controlled Soarers (BARCS) is the bodythat supports this andother silent lightclasses, under the watchful eyeofthe BMFA.

THEMODEL

TheSkyhawk is the brainchildofmyfriend (and competitionfield nemesis) SteveHaley. Unarguablyone of the very topthermalsoarers in thecountry,Steve is respected by many fellowcompetitorsasa toppilot in multiple FAI classes such as F5L, F5J,F3F and, in the past,F3B Stevealso lew aSkyhawk to win the 2024 UK Nationals forF5L class gliders.

TheSkyhawk has taken many monthsto perfect andisnow availablein kitformfrom SkyHigh RC.Way back in time, Stevewas

atoolmaker and, as I’ll explain later,that experiencereallyshows in thethought behind the design of the Skyhawk.

Many F5L models do look quitesimilar andoffersimilarlevels of performance

Perhaps thereisnothing trulyexotic about the Skyhawk design, with its familiarwing planformand slightlymodified AG wing section, available in cross-tail or V-tail configuration.But the main takeawayis that it ’s designed in the UK, by aUKpilot for UK conditions

Stevealso has available afuselage without amotor to competeinthe similar F3L class for bungee launch.

UNBOXING

Ipicked up the Skyhawk kitfromSteve’s home, howeverthe packaging would be quitesafein the hands of UK mail delivery companies.A nice touchisapersonallysigned label on the boxfromthe designer

Li ting thelid, atissuewrapper keeps everything together -and there’salot of stu�f in the box. Notincluded with thekit were the necessary glue, servos, motor,prop, speed controller andcovering butotherwise the kit wasverycomplete.

Theexcellent quality wood components are laser cut with great accuracy.Carbonelements forthe spars,joiners,leading edge andboom areequallyofveryhigh quality.The build is extremelywell thoughtout anddelivers a model that is robust andeasy to puttogether. It maynot be the lightest airframe, but it will stand the test of time in the handsofmost pilots

Skyhawk’s lying weightisaround550 g, ballast-able to around 1000 g, giving aweight range to match most of the UK’s lying weather. Ihavebuiltown design models significantly lighter andmost times Ihavehad to leave them in the cardue to the wind being toostrong.

POWERTRAIN SELECTION

Istuck with my go to powertrain, aDualsky 2230 motor,9 x5 GM prop andHyper light 40A ESC/BEC.Together with aGNB 3S 550 mAh LiPo these components arelight, reliable andcan deliveraround240 Wofpowertoeasily and safely haul a500 to 1000 gram modeluptothe desired height in the required time.

THEWINGS

One thing that hits youearly on is the lack of full-sizeplan. Do not let this putyou o�f; the build instructions aresuperband there are several jigs to helpyou get thebuild right.I’d go as farassaying that theinstructions andjigs

No plan required.The wing slotstogether, with the ribs spaced evenly usinga plyjig.Spanwiseweights hold it flat whilethe glue sets.

F5Lclass allows fora mainly wooden 2M thermalsoarerusing an electric motorfor launching.

TAIL GROUP

Tail components arefromhigh quality balsa, giving the right blend of strength andweight It wasa bit fiddlytoattach andthen later shape the cross grain ends to both elevator andrudder, but theydolooknice.The elevator sits on anicely formed mount that is attached to the boom. Ajig is provided fordrilling the back of the boomtoaccept the elevator andfin. This canbeadaunting task, but the jigmakes it very straightforward andguarantees goodalignment

FUSELAGE

Thefuselage is aply pod andcarbonboom assembly.The plyislight andaccurately cut, the sides andformers slotting nicelyintoplace Thewing bolts areheld by plyplatesand these arealso easy to fit in the right place.Again,a plyjig is provided to ensure the fuselage sides andformers areassembled straightand true. At themotor end Iglued in balsa fillets in all four corners in anticipationofrounding the nosetomatch thespinner radius

Ileft the boomunglued in the fuselage formers until Ihad the elevator mountglued to the boom. With the elevator bolted on and the wing inner panel bolted to the fuselage I aligned the elevator andwing andthen glued the boominplace.Later Ijiggedthe fin at 90 degrees to the elevator

Servofitment in the fuselage isquite tight

Iused the first hole on the servo armfor both elevator andrudder,but even with the relatively small throws the control movements

Carefulshaping of thenoseisneededtoblend theply andbalsa parts, allowing thecorners to be roundedso that thefolding propellerfts snugly alongthe fuselage to reduce drag.

were enough using thesupplied rudder and elevator horns. Thepushrods andtubes were feddownthe boomand exited through slots on either side of the boomatthe rear.Icarefully dripped thin CA down theinside of the boomto hold the tubes in place

Theply sides were cladinbalsa topand bottom, then theprocess of

fuselage could begin. Carefulsanding is needed to blendthe harder plytothe softer balsa but with some attentionthe corners can be rounded anda nicecross sectionachieved. This is necessary to allowthe folding propeller to fit snuglyalong thefuselage to reduce drag.

Thecanopyisretained by magnets at the rear,but Iswitched to using atape band

shaping the

Horizontal stabiliser is screwedtoa plymount

Finished cross-tail (aka X-tail)ready forcovering.

Rear of fuselage podshowing tail servoplacementsand rear wing bolt attachment point.

Anotherviewofthe back of thepod,thistimeshowing thelaminated boom support.

or sheath that slides along the fuselage from the nose andsecurely locates andretains the canopy.

BALLAST

Thereisroominthe fuselage,underthe wing, to hold around 200 goflead. Additionalweight canbeslidinside the inner panel spar. Forwing ballast, Iused steel rods weighingaround300 gintotal but cut intoshorter lengths so weight canbeincreased in stages

Whyballast at all? Whynot use some down trim to helpthe modelmoveforward in wind? It’s acommondebate. Thegenerallyaccepted rule is that ballast increases lyingspeed, so youvarythe ballast to match the lyingweight with the wind to maintainnormal lying speed withnoelevator compensation. Down elevator trim alone will adverselya�fectperformance so the model will come down quicker. When it’s windyabit of extraweight also makeslandings easier as the model is less likelytobeblown o�fcourse

I’msurethatballast andwindspeed do not have alinearrelationship but we can approximatealittle.At15mph (awindyday forF5L models) a lying weight of around 1kg is about right forthe Skyhawk (model plus full ballast. At 10 mph (usualUKweather?) around 700 gfeels about right.700 gcan be achieved with just fuselage ballast but sometimes abit of weight outboard in the winghelps to stabilise the model, especiallyifthe air is turbulent

FINISHING

My coveredand finished Skyhawk weighs around 550 grams. IknowSteve is workingon alighter versionfor those days when windand li tisreallylight,but Iwouldn’tget toohungup on the searchfor ultra-light models.Thermal soaring competitions arerarelywon by sitting intowind in ‘minimumsinkmode’. Thereis usuallysomekind of li t somewhereand the abilitytomove,find andworkli tisa much better strategy forsuccess

Alight coveringisrecommended.

IusedOralightfor the wings andtailplanes, andJap tissue anddope forthe fuselage pod.

FLYING

Steveprovidesa guide forsurface throws.He also provides arange forthe CentreofGravity, butthe final positionisusuallyarrivedatby trial anderror.Further forwardgives amore stable model, so is easier to lyand more predictable.Further back provides atwitchier model, better able to sense li tand to turn tightlywhenneeded. Istarted at apositionat the forwardend of the recommended range

Spoiler detail showingthe servoholding it fully extended.Notealsothe smallrubberbandthat ensuresthatitsnaps fullyclosedduringclimb and glide.

Single screws,front andrear, hold thewingtothe fuselage

Bare bonesofthe Skyhawkready forcovering.

Alex used Oralight forthe wings andtail, anddoped tissue forthe fuselage pod.

andthen slowlyadjusted it rearwardsuntil the model behavedhow Ilikeit.

Thepowertrain provides plenty of thrust, easilyachieving the 90-metrelaunchheight in 30 seconds,allowing forsometraversingof the sky looking forlift or shooting out left or right or downwind to something indicatinglift, suchasagliding bird. When fullyballasted the powertrain also delivers the requiredheightin the required time

Forthe maiden flight it wasacold, calm winterday.I launched intowind andSkyhawk climbed steadilyonhalfpower. Ihad disconnectedthe heightlimiter to gain more height andhavemoretime to trim the model. Asmall amount of elevator trim wasrequired. One the second flight Itried to get afeel for the effect of the spoilers on model pitch. Some elevator mix to spoiler wasneeded to maintain aslight nose down pitch whatever amount

DATAFILE

Model: Skyhawk X-tail (V-tail also available)

Modeltype: F5L/RES electric glider (F3L glider also available)

Manufacturer: SkyHigh RC https:// skyhighrc.co.uk

RRP: £275

Wingspan: 2m (78”)

WingArea: 36 sq.dm.

Weight: From 540 g

Functions: Rudder,Elevator,Spoilers, Throttle

Power: 28 mm brushless outrunner (Dualsky 2826EA)

ESC: 30 A

LiPo: 3S 500 mAh

CG: 78 -80mm

of spoiler deployment wasused, so that the spoilers canbeopened or closed with very little effect on the model, except, of course, losing height more rapidlywhen the spoilers were out

On the thirdflight,during the launch, the model picked up height with little power, suggesting liftwas present.I cut themotor at about 70 metres,circled looselyuntilI wasclose to the centreofthe thermal, then I tightened the turn andthe Skyhawk climbed slowlytoabout 150 metres.Anyonewho has experienced the same will probablyagree that thermal soaring is addictive -itstill givesmea buzz everytime!

Overall, flight characteristics were very predictable.This is an easy to flyglidersuitable forawide range of pilot skill levels.The Skyhawk turns well, senses lift well, climbs well andwhen the spoilers areout it descends well.

I’llsoonstart work on the next article, comparing the Encantoand Skyhawk. Ineed to think carefullyaboutthe metrics foruse in the comparisonand trytobeasobjective as I can. If youhaveany ideas,pleaseconnect with me through the BARCS portal andsend me a message. ■

Anyone whohas experiencedexploitingli tatlow levelwillagree that thermalsoaring is addictive.

Alex startedata CG position at theforward endofthe recommendedrange and then slowly moveditrearwards untilthe modelbehaved howhelikes it

Alex’s next articlewillcompare theEncanto previously reviewed (Jan ’25issue), in hisle thand, andthe Skyhawk.

tube bonded to the spar.The secondtube has a2 mm hole boredabout acentimetre from its outer end. Abrass M2 nut is aligned with the hole andso tsoldered to the outer surfaceofthe tube.When the tailplaneisfully assembled an M2 screwisinsertedthrough the soldered captive nut andthe hole in the tube to acorresponding hole through the carbon rod. This single screwprovides the lock to secure the tailplaneouter sections to the centresection andhence to the fuselage

An assortment of K&S square andround brass tube were usedtomakeupthe elevator drive.The system relies on the ability of atube to slide accurately intoacorrespondingstyle tube of the next larger size. Each elevator half has theinner portionofits sparreinforced to support asquare brass tube.Thistube extends about onecentimetrebeyondthe inboard end of the elevator andisepoxied andscrewed to the reinforced portionofthe elevator. Alignment of these tubes,both with the

elevator hinges andwith each other,isrequired forcorrect operationwithout binding. Both tubes areadditionallystrengthened against twistingbythe insertionofa length of ‘next size down’square tube,securedinplace with cyano.

Some so t soldering is required to make the centrefitting which transfers theelevator pushrodmovement to the square tubes on the elevator halves. In thephotonearbythe elevator pushrodconnector andthe operating lever areshownfolded lat forclarity

Theoperating lever is brass square tube.The lowerend is lattened anddrilled to takethe pin of the pushrodend fitting. Theother end of the tube is cut back andshaped to fit over the sides of another short square brass tube, one sizelarger thanthose fitted to the elevators. This jointissoldered to secure the tubes at right angles to each other

Next,two roundbrass tubes were produced These have an inside diameter su�ficient to allowthe larger square tube (just soldered) to

rotateeasilyinside it without binding. These twotubes arethen soldered to apiece of brass sheet in the positions shown. Once soldered the brass sheet holds thetubesinalignment andisepoxied to the rear face of thetailplane centresection. As each tailplane half is being fitted to the centresectionall that is required is to adjust its elevator positiontoallowits brass tube to slide intothe central square tube. This aligns both elevator halvesand connectsthem to the drive from the elevator servo.

Finally, theinboard triangularareaofeach elevator wasskinned topand bottom with 0.4 mm birchply to furtherstrengthen the vital joint between the elevator driveand the elevator itself With the tailplane/elevator assemblies completed they were assembled and checked forfull andfreemovement without lubricantapplied to showupany areas of binding. Lubricantwas applied later,once covering wascompleted, andpriortotesting of the controls

Tailplanewas builtinthree pieces.Outer sections aresupported by carbon rods fedintobrass tubesbuilt into thefuselagemounted centre section.

Tailplanelocking screwinposition.

Elevator connectionstothe centraloperating lever. Tailplanefully assembled.

Thetailplane centresectionwas placed in positiononthe fuselage,the outer sections fitted andwhole assemblychecked several times using aspirit level andtape measure to ensure correct alignment.The centrepartof the tailplane wasthen glued to the fuselage frame. Acarbonfibretube,supported mid-way down the fuselage,connectedthe elevator control armtoits associated servo

Next the fin andrudder were fitted, with the rudder post extending the full height of the fuselage frame.

TAILWHEEL

Thehuntwas then on through the ‘spares’ drawer forasuitable tailwheel anda closed loop control armfor the rudder.The result was atailwheel controlled via springs from the rudder control arm.

Tail ballast,ifrequired, canbefitted inthe bottomright-hand corner of the fuselage.The twoscrews holding the tailwheel brackettothe fuselage would be replaced with longeronesto secure the ballast

AILERONSERVOS

Attentionthen turned to the wing. Thewing needed aileron servosfitting, the wiringbeing routed to the fuselage viathe paper tubes fittedthrough the wingribs.Screw-onservo covers hadyet to be made andfitted.

COVERING THEMODEL

Thebuild proper wasnow completed,allowing covering to begin.

Thefull-sizeaircra thaveasteel tube fuselage framewith afabric covering.Inmost areasthe fabric appears to be unsupported, apartfrom whereitcontacts the steel tubes.Toemulate this balsa strips arefitted along the fuselage sides andunderside.This hadabearing on the type of covering selected forthe model aswhen the model is handled the unsupportedareas of covering could be pressed inwardsand the covering stretched. Thewing,finand tailplane likewise have areas of unsupported covering. Atextile-basedcovering wasconsidered to be the best option, preferablyalready coloured

to avoid theneed fora spray-painted finish. The ‘covering materials’ drawer of my plans’ chest produced aselectionofSolartex in various colours andsizes,enough forsmaller items but not forthe twometrespanwings or the fuselage.These required thepurchase of two rolls of Oratex. As the Spacewalker is intended foryear-rounduse colours were selected for good visibility in poorlightconditions

Thetailplane andfin/rudder assemblies were coveredfirst,using some of the longstored Solartex stock. This wasfirst checked foradhesion andshrinkage on atest piece and foundtostill be perfectlyusable.The fuselage sides andunderside were coverednext, followedbythe turtle deck behind the rear cockpit.The cockpit andtop forwardfuselage areas were le tuntil the cockpit fit outs were completeand the windscreens readyfor fixing.

Theailerons, thoughtfullycompleted by the previous owner andalready fitted with hinges, were coverednext.These were followedbythe wing underside,beforethe aileronswerefitted priortothe wing receiving its topsurface covering.

UNDERCARRIAGEFIT TING

Theundercarriage assemblywas metal primed, then painted using rattle cans.The underside of the wing wasalready fitted with groovedwooden supports as part of thewing build. These were joined at thecentreline of thefuselage butdid not takeintoaccount thewing dihedral angle.The grooveshad to be deepened towardsthe centre line forthe undercarriage to fit snugly.

Saddle clamps,mentioned in theSIG manual, hadnot materialised with the model from the lo t.These were replaced with homemade aluminiumplates andservo screws to secure theundercarriage to the wing.

ENGINE COWLING

Theplastic moulding forthe engine cowling wassupplied in twohalvesand required trimming to fit in frontofthe new battery hatch. This wasneeded to allowfor fixing screws to be positioned around therearofthe cowlingintothe firewall.

Youonlyget onechanceona job likethis! With the uncut cowling slipped into position it obscured the frontofthe fuselage,even with astronglight sourceplaced inside the cowl. Thesolutionprovedtobesticking a length of masking tape behindthe cowling, removing the cowling andmeasuring from the frontedge of the tape to thefront edge of the firewall. Measurements were taken every twocentimetres andwritten onto themasking tape.The cowl wasthen tapedinposition, aligned with the spinner and lush with the fuselage topsurface.The measurementswere then transferred to the cowl using afine point marker pen. Another length of masking tape wasused, this time with its rear edge ‘joining the dots’ from the measurements.Slight adjustments were made to keep theedge as straight as possible.Thiswas thenused as the cutting line fortrimming the plastic moulding. ADremel, fitted with acutting diskused at lowspeed, made easy work of thecuts.Further adjustments were made to enlarge theair vents on the underside of the moulding. On the IC versionthe exposed cylinder headwould have contributed to the overall cooling e�fect As this wastobeanelectric model considerationwas given to making dummy turbopropexhaust outlets,rather thanusing the supplied engine cylinder headmouldings This would have been more in keeping with the sound produced by the motor.However,as the Continental O-200 engine is such afeature of the aircra t, the supplied cylinder head mouldings were used. These were o�fset by the

Rudder andsteerable tailwheelftted.Aileron servoftted,withwiringpassing throughthe tube to thefuselage.

Shaped cowl showingmeasurementsand cutline.