MASTERS OF BRITISH CLOTH

With over 185 years of proudly British manufacturing and design heritage to our name - we are experts in producing woollen cloth of unrivalled character and quality.

Today, we are one of a select few mills within the UK that manufacture and sell our cloth directly to our customers from a single site - allowing us to control every single stage within the production process to the highest standard.

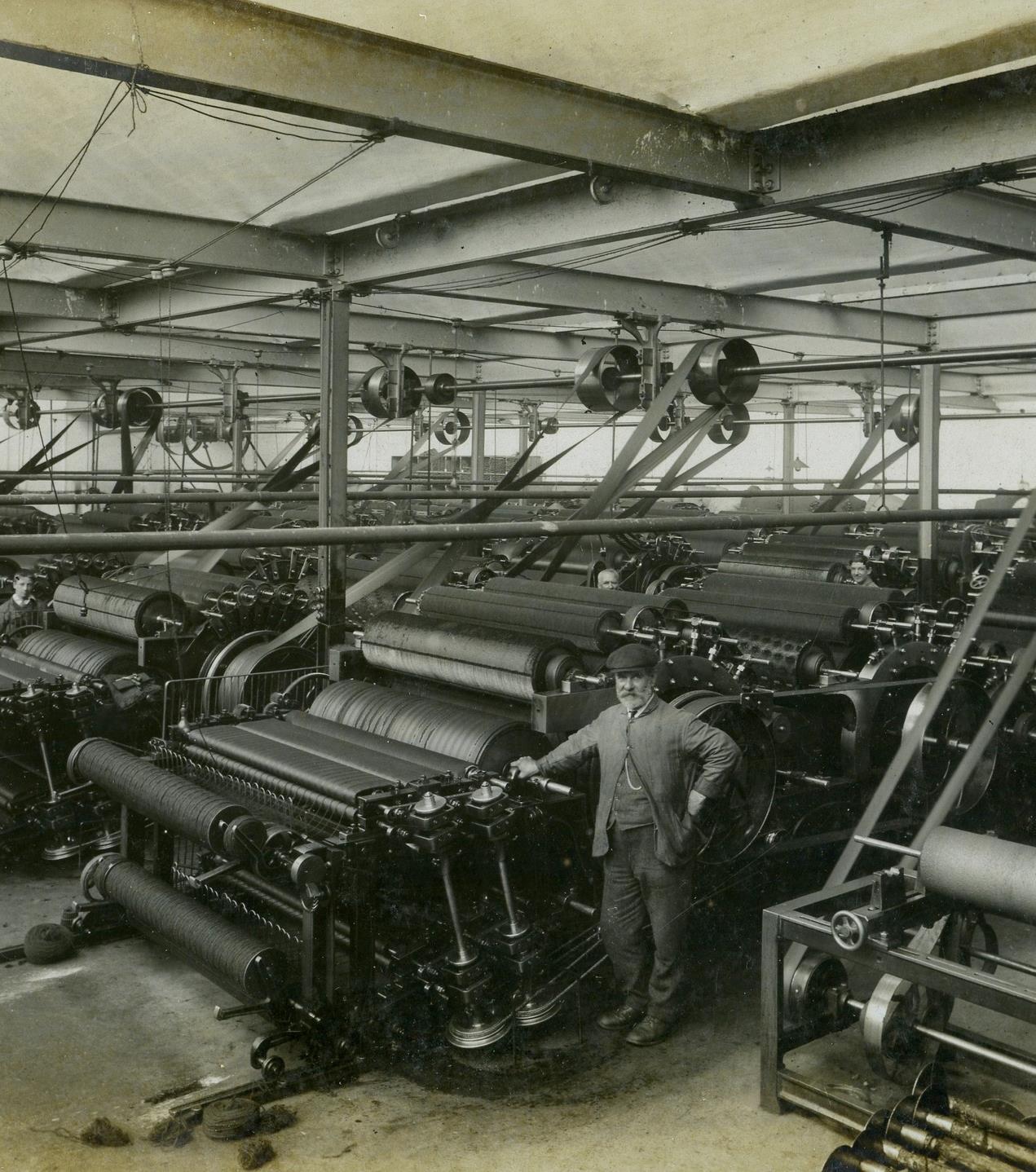

The Moon Mill is a vertical mill - a term referring to mills built in the Victorian era, which would rise several stories, with each floor containing part of the manufacturing process.

Today it remains a unique confirmation of our authenticity - offering unchallenged control over every production stage, from raw wool entering our mill to applying the final finish to the product.

The Moon business was born out of ingenuity and innovation. Our story is a celebration of the British textile industry.

The Moon Mill is well-established within the apparel trade. To this day, it remains the cornerstone of our business.

For many years, our apparel ranges have continued to offer a unique understanding of the ever-changing needs of the apparel industry.

Our combination of traditional methodologies and innovative, modern use of colour and design has helped us to serve leading fashion labels, designers and retail customers across the world.

Our unique collections are found internationally in both domestic furnishings and contract projects, from established British retailers to 5star hotels and even 10 Downing Street.

The name Moon is synonymous with designlead interiors fabrics. No other brand specialises in wool and brings out its luxury and benefits in quite the same way.

Timeless British designs created within our rare vertical woollen mill.

Our extensive range fuses contemporary and classic design while incorporating beautiful colourations, often inspired by the beauty of the British landscape.

We create each of our throws to the highest quality from natural fibres across collections of Merino, Shetland-type and Mohair Wool.

By producing every process under a single roof, from raw wool to the final finish, we can create cloth for our customers to their exacting standards.

Raw wool of the highest quality is delivered to our site from all over the world.

Using precise combinations of dye, pressure, temperature and time, our dyehouse can produce over 500 different shades.

Combining a potential of up to 7 different shades into in single blend, our blending process adds unique character and rich texture to our yarn.

The distinguishing elements that make us unique.

The distinguishing elements that make us unique.

Essential to producing soft, smooth fabrics - the carding process combs and teases fibres into a uniform colourway.

Spinning applies a precise number of twists per inch to the wool, resulting in a fine but strong thread ideal for a wide range of uses.

Yarn is stored, ready to be woven into our beautiful fabrics.

Cones of yarn are wound over a drum in a precise order of colour depending on the pattern required - all accurately checked and maintained by hand.

Capable of weaving up to 30,000m of cloth per week - our weaving process is where our many different yarns are intricately woven together.

Using a combination of wet and dry methods - finishing is used to impart the wonderful 'handle' to the fabric that moon cloth is world-renowned for.

The distinguishing elements that make us unique.

Up to seven different coloured wools are combined to create yarns rich in colour, unrivalled in quality and unique in character.

Within our mill in the heart of Yorkshire, we make extra efforts to be a more sustainable business every day.

• Zero waste through initiatives within our production process, including plastic-free packaging.

• Investment in improvements to our machinery and building for greater energy efficiency.

Wool is, of course, a 100% natural, renewable and biodegradable fibre, which, combined with our commitment to zero waste, recycling and solar energy, creates a product of the highest ethical standard.

• An exclusive source of natural water used within our fabric production.

• Over 300 solar panels were installed to power our warehouse and finishing department.

We are rare in our ability to fashion our premium fabrics in such an ethically considerate manner.