WASTEWATER | SPONSORED EDITORIAL

The key to efficient wastewater remediation? Modular and flexible Bulk Liquid Storage Tanks

The environmental remediation of contaminated sites is a complex operation that requires multiple technological solutions. The solutions deployed for the removal and treatment of contaminants vary from site to site, with strict environmental regulations necessitating the need for flexibility in equipment. With over a decade of experience designing and engineering tanks for on-site wastewater and liquid treatment, SCF’s tanks and bunded containers have been utilised in multiple wastewater and remediation projects across the country. SCF recently collaborated with contamination environmental remediation specialists, Sarjaro, to supply a range of Bulk Liquid Storage Tanks, ISO Tanks and Dangerous Goods Containers, as part of a major wastewater remediation project north of Brisbane.

F

ollowing the acquisition of the 200-hectare Petrie Paper Mill Site in 2015 by the Moreton Bay Regional Council, Sarjaro was engaged by Orora to design, manufacture, install, commission, operate and maintain a bespoke multi-barrier water treatment plant (WTP) to remediate soil, groundwater, surface water and other sediments. The safe removal of 60 pollutants including multiple Per and Polyfluoroalkyl Substances (PFAS), metals and hydrocarbons, whilst adhering to strict regulatory limits, will allow discharge into the North Pine River and adjacent Moreton Bay Marine Park. Building on a strong existing relationship with SCF, Sarjaro approached the company to supply

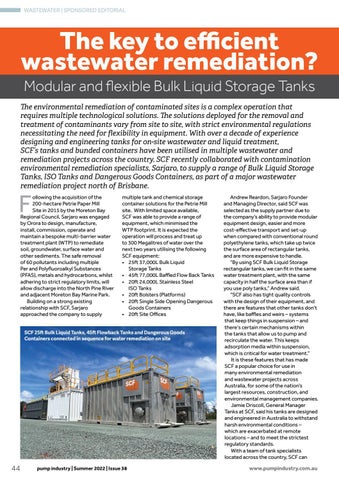

multiple tank and chemical storage container solutions for the Petrie Mill site. With limited space available, SCF was able to provide a range of equipment, which minimised the WTP footprint. It is expected the operation will process and treat up to 300 Megalitres of water over the next two years utilising the following SCF equipment: • 25ft 37,000L Bulk Liquid Storage Tanks • 45ft 77,000L Baffled Flow Back Tanks • 20ft 24,000L Stainless Steel ISO Tanks • 20ft Bolsters (Platforms) • 20ft Single Side Opening Dangerous Goods Containers • 20ft Site Offices

SCF 25ft Bulk Liquid Tanks, 45ft Flowback Tanks and Dangerous Goods Containers connected in sequence for water remediation on site

44

pump industry | Summer 2022 | Issue 38

Andrew Reardon, Sarjaro Founder and Managing Director, said SCF was selected as the supply partner due to the company’s ability to provide modular equipment design, easier and more cost-effective transport and set-up when compared with conventional round polyethylene tanks, which take up twice the surface area of rectangular tanks, and are more expensive to handle. “By using SCF Bulk Liquid Storage rectangular tanks, we can fit in the same water treatment plant, with the same capacity in half the surface area than if you use poly tanks,” Andrew said. “SCF also has tight quality controls with the design of their equipment, and there are features that other tanks don't have, like baffles and weirs – systems that keep things in suspension – and there's certain mechanisms within the tanks that allow us to pump and recirculate the water. This keeps adsorption media within suspension, which is critical for water treatment.” It is these features that has made SCF a popular choice for use in many environmental remediation and wastewater projects across Australia, for some of the nation’s largest resources, construction, and environmental management companies. Jamie Driscoll, General Manager Tanks at SCF, said his tanks are designed and engineered in Australia to withstand harsh environmental conditions – which are exacerbated at remote locations – and to meet the strictest regulatory standards. With a team of tank specialists located across the country, SCF can

www.pumpindustry.com.au