W H IT E P A P E R Introduc tion to IoT in Manufac turing CONNEC TED INDUS TRY G ROW TH PARTNER S A d v i s o r y | Tal e n t | Ve n t u r e s “ We cannot become what we want to be by remaining who we are . ” Max DePree

I oT A N D M A NU F A C T U R I N G T O D AY

F U N D A M E N TA L I oT C O M P O N E N T S F O R MA N U F A C T U R I N G

I oT U S E C A S E S I N M A NU F A C T U R I N G

W HY I NV ES T I N I oT F O R M A NU F A C T U R I N G

H O W C AN M O M E N TA P A R T N E R S C A N H E L P Y O U S U C C EE D

R

E F E R E N C E S

3 4 6 7 7 8 W H I T E P A P E R Introduction to IoT in Manufac turing © 2 019 | momenta.one TABLE OF CONTENTS

The industrial revolution and the Internet of Things (IoT ) is re shaping what ’s p ossible for the world of manufac turing today According to industr y exp er t s, the IoT in Manufac turing mar ket is expec ted to grow to 45. 3 Billion by 2022 , at a Comp ound Annual Grow th Rate (C AGR) of 29 0 % from 2017 20211 The key fac tors driving IoT in the manufac turing space is the growing need for predic tive maintenance, and centralized monitoring of the manufac turing infrastruc ture

Verizon says that since 2017 the manufac turing industr y saw an 8 4% boost in IoT net work connec tions, which was more than any other industr y they sur veyed from Transit to Healthcare

IoT Network Connections 2016 vs 2017 Growth2

E xecutives expec t human to-machine centric environment s to be a common norm by 2020. This trans formation could p oten tially see $50 0 B in savings for manufac turers, and equipment makers from vir tualization , co bot technolog y and real time communication . 6

To push the envelop e of the industr y 4 0, the “Future Smar t Manufac turer ” means to trans form the entire con nec ted eco system beyond the walls of produc tion across R&D, the plant , supply chain , produc t deliver y, and cus tomer ser vice. To better understand the immense opp or tu-nities that IoT brings to the manufac turing industr y we will explore the following fundamen tal comp onent s:

• Connec tivit y

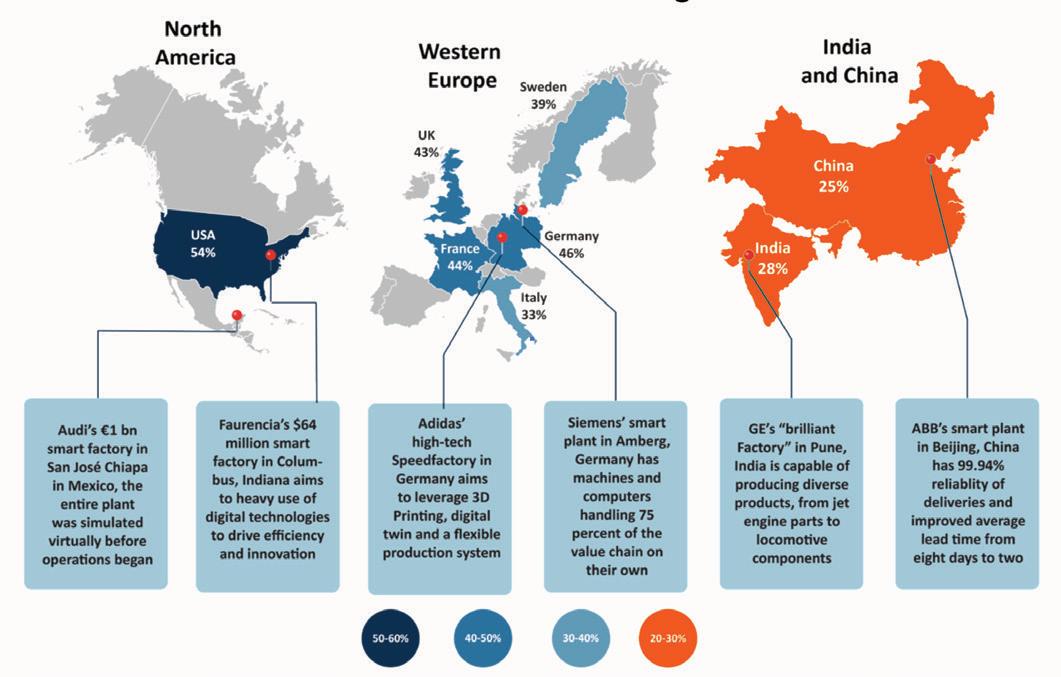

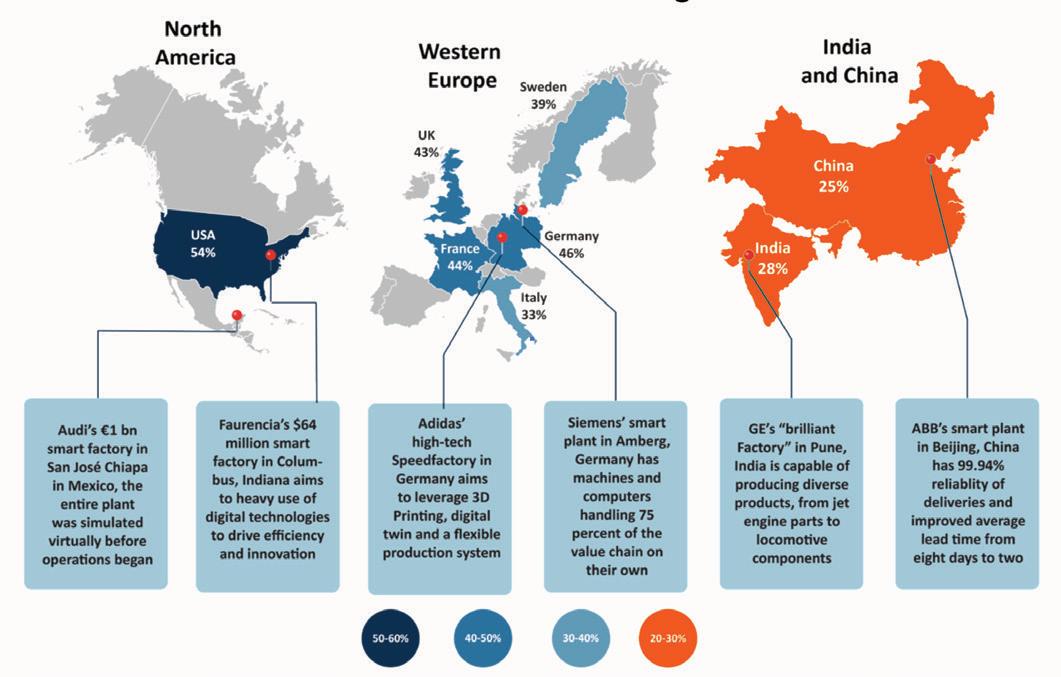

Projec tions from Market by Market s also show that Nor th America is exp ec ted to have the largest market share in the IoT in manufac turing market from 2017 to 2023 3 This dominance cant investment in R&D resources, there fore contributing to the development of new technologies such as IoT

Manufac tures are keen to integrate IoT and Big Data technolo gies into their processes in order to automate the manufac turing

ing digitization in manufac turing by larger enterprises drives the Nor th American IoT in manu fac turing market

According to Capgemini Smar t Fac tories rep or t the US and Western Europe in par ticular have made an early head star t in adopting a smar t fac tor y business model. Nearly half of the man ufac turers in the US , France, G ermany, and UK have an ongoing smar t fac tor y initiative These early adopters have collectively invested over a $100M in these initiatives.4

Hardware

• Platforms

I oT A N D M A N U F A C TU R I N G T O D AY

•

& People • Industries Across Countries Embracing Smart Factories 5 WANT TO LEARN MORE ABOUT IoT CONNECTIVITY ? Visit our Insights page www.momenta.one Healthcare/Pharmacy11% 41% 19% Manufacturing84% 40% W H I T E P A P E R Introduction to IoT in Manufac turing © 2 019 | momenta.one

MANUFACTURING

CONNEC TIVIT Y OP TIONS

When it comes to connec tivit y for Industrial IoT (IIoT ) it can be separated into t wo categories: massive and critical. Massive refers to the t ype of communication needed for connec ted tools, simple automatic machines and Automated Guided Vehicles (AGVs) All these examples are fundamental for a smar t manu fac turer

Critical, on the other hand, requires ver y high , real time connec tivit y in order to work For example, intelligence being moved from the machines and up to the cloud. This is when mobile robot s collaborate with each other, and humans, in real time

Smar t manufac turers will require a thoroughly connec ted, inte grated infrastruc ture across the entire manufac turing ecosystem from engineering /R&D through to the supply chain and cus tomer ser vice Depending up on the manufac turing process and desired output different t yp es of connec tivit y can be required from hard wiring , Wi Fi, Bluetooth , RFID, LTE M and Low Power, Wide Area Net works including LoRa Below we have explored the c apabilities of the different options:

CELLUL AR

For manufac turing is a smar t , stable and secure connec tivit y op tion A s net works evolve from LTE to 5G , cellular becomes even more p ower ful, as does the value that it enables

5G - Mobile Net work Operators (MNO’s) are looking at releas ing 5G connec tivit y at the latter end of 2018 and nationwide by 2020 in the US . 7 It is said to provide connec tivit y sp eeds up to 20 times faster than 4 G LTE with a download peak of 20 Gb/s 8 This would give manufac turers the opp or tunit y to utilize technolo realit y

4 G LTE technolog y offers high bandwidth of up to 10 0 mega by tes p er second and has a range of more than ten kilometers Reliabilit y and availabilit y are also good. Wireless carrier have

NB IoT provides ex treme optimization for low cost , low p ower, low throughput , delay tolerant stationar y IoT use cases Down load peak of 250 Kbps

CAT 1 delivers scalable per formance and seamless mobilit y for high p er formance IoT use cases D ownload peak of 10 Mbp/s

CAT-M1 optimizes for the broadest range of IoT applications with high reliabilit y and low latencies Download peak of 1 Mbp/s.

LPWAN - LoR a , SIG FOX

Low Power, Wide Area Net works primar y use case is for station ar y asset s with low data requirement s Each LPWAN technolog y

Sig fox manages it s own net work, while LoRa has over 50 0 par tners Sig fox has a download peak of 10 0 Bp/s and LoRa has a download peak of 29 0 Bp/s - 50 Kbp/s.

SATELLITE

Orbit (MEO), and G eostationar y orbit IoT stakeholders tend

since it has the highest cost s S o generally, you see it used in High and tracking. Manufac tures can track their cargo containers all over the globe using GPS and Satellites The global nature of satellite systems and their abilit y to broadcast to multiple p oint s

ear th Satellite transmissions can work seamlessly with terrestri al net works to attain global coverage

UNLICENSED CONNEC TIVIT Y

Unlicensed connec tivit y solutions Wi Fi, Bluetooth and Zigbee are relatively inexpensive compared to the other connec tivit y options we have explored and allow manufac turers to manage their own net works, rather than relying on MNO’s to do so. On the downside, unlicensed technologies can be vulnerable to inter ference and only func tion well in shor t-range

Bluetooth communication is a global shor t-range wireless communication protocol t ypically used for device to-device. BLE is a version of Bluetooth designed for lower p owered devices that use less data To conser ve p ower, BLE remains in sleep mode except when a connec tion is initiated. This makes it ideal for manufac turers wanting to use it for RFID readers to track inven tor y and asset s ensuring distributors and manufac tures

Wi Fi and Wired Ethernet have a well develop ed set of deploy ment capabilities and are the most well known /utilized unli censed connec tivit y option with a bandwidth of up to 1 Gbp/s Wi Fi with a wireless mesh top olog y allows for ex tended range and is great for monitoring large physical objec t s and tracking pallet s with a highly reliable wireless connec tivit y net work Mesh net works can allow manufac turers to easily track key data

issues before they happen

IoT COMPONENTS FOR

W H I T E P A P E R Introduction to IoT in Manufac turing © 2 019 | momenta.one

Momenta is the leading Digital Industry venture capital + growth firm accelerating deep-tech innovators across energy, manufacturing, smart spaces, and supply chain. For over a decade, our team of deep industry operators have helped scale industry leaders and innovators via our award-winning executive search and strategic advisory teams. 3 Practices Hyper Focused on the Enterprise IoT. Executive Director: ken@momenta.one Email: info@momenta.one EU: +41 41 562 00 07 US: +1 917 765 3600 To read the full report DOWNLOAD HERE I

oT A N D M A NU F A C T U R I N G T O D AY

F

U N D A M E N TA L I oT C O M P O N E N T S F O R MA N U F A C T U R I N G

I oT

U S E C A S E S I N M A NU F A C T U R I N G

W

HY I NV ES T I N I oT F O R M A NU F A C T U R I N G

H

O W C AN M O M E N TA P A R T N E R S C A N H E L P Y O U S U C C EE D

R

E F E R E N C E

S 3 4 6 7 7 8 TABLE OF CONTENTS