THE JOURNAL FOR THE MOHAIR INDUSTRY VOLUME 60 2018 / 2019

Front Cover

Photographer – Riaan Marais

Model – Nathan Wienand

Location – Dirko Farm, Cookhouse

Special thanks to Mark, Robin and the kids.

The Mohair Journal

127 Fordyce Road, Walmer, Port Elizabeth, 6070

Telephone: 041 581 1681

E-mail: info@mohair.co.za

Website: www.mohair.co.za

Official journal of the SA Mohair Growers Association, Angora Ram Breeders Society and Mohair South Africa.

Editor: Riaan Marais

Contributors:

Marco Coetzee

Linda Cortright

Cobus de Klerk

Mackie Hobson

George Hope

Proofreading: Helen Crooks

Chris Louw

Mariska Spoormaker

Pierre van der Vyver

Sanmarie Vermaak

Design and Layout: WalkerDigital.co.za

Printing: Cadar Printers

The Mohair Journal does not accept responsibility for any claims made in advertisements. The opinions of contributors are also not necessarily those of the Mohair Journal.

Mohair Journal 2018/2019 3

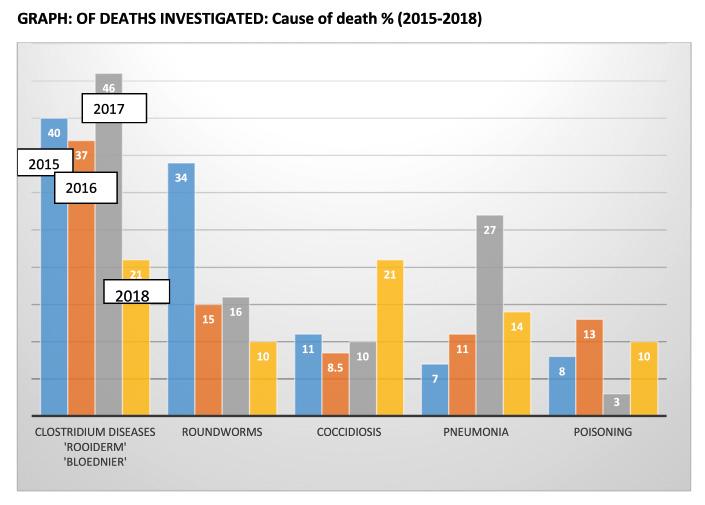

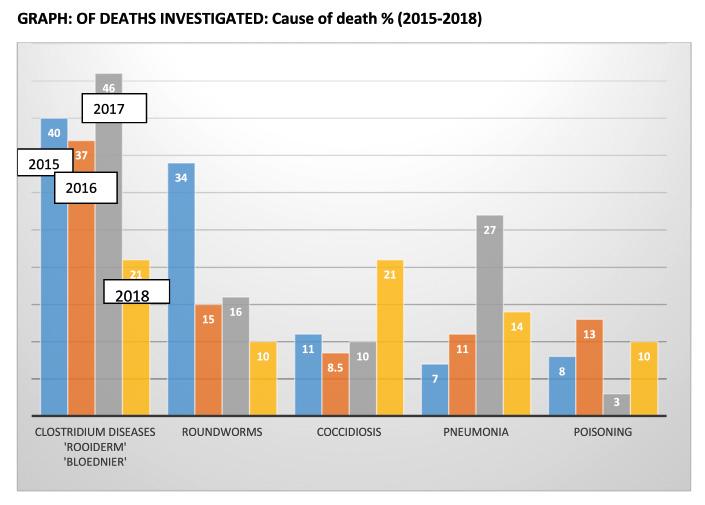

Contents Message from the Chairman of the South African Mohair Growers Asssociation, Cobus De Klerk 4 Message from the Editor, Riaan Marais 5 From the Samga Office 7 2018 Mohair Report, Marco Coetzee 8 Producing Mohair Responsibly 12 Sustainable Management –award winning farming with nature in mind . 14 RFID technology 17 Eye in the sky 20 Miyuki Keori trophy still on the Van Hasselt mantle 24 Fitzhenry brings Daidoh Trophy to Aberdeen 25 Another Zegna title for Lategan 27 Vogue Knitting Live 28 Handarbeit & Hobby 30 Pitti Filati 31 From dirt to director 32 Wild Fibers’ tour of South Africa 36 China Mohair Fashion Design Competition 40 Designing to Break Boundaries 46 Educating the future of Mohair 48 Supplementary Feeding 50 Empowerment vision, a thing of Beauty 52 OVK News 54 Angora Ram Breeders’ Society 56 BKB Mohair Report 2018 59 Veterinary Overview 2018 61 In memory of Ronnie Smith (1960 ~ 2018) 63 Kids and Kids 70 Directory: Mohair Management and Contact Details 64 SA Mohair Growers’ Association 65 Angora Ram Breeders Society 67 Spinners 67 Local Manufacturers 69

The period of 2018/19 will probably go down as one of the most challenging years in the South African Mohair industry’s history, mostly due to the relentless drought which intensified over recent years. Field conditions deteriorated to the point where there was little or no natural grazing left, leaving producers to feed animals out of their own pocket, at a massive cost.

Our industry thanks every individual and institution that made a contribution to help producers with feed and other resources. In particular, we would like to express our gratitude to the Mohair Trust and the South African Wool and Mohair Buyers’ Association (SAWAMBA) for their crucial contributions in this regard. Without everyone’s help we were steering toward an unimaginable catastrophe.

We are grateful for the rain that has brought new life to large parts of our mohair producing regions, and we spare a thought for those critical areas still in dire need of rain. It will take years of good rain before natural grazing recovers in these areas, and our hearts go out to you.

Amid these sombre conditions, our producers still managed to achieve decent prices – keeping in mind that they spent much of their profits to attain these prices.

Our industry also faced an onslaught from animal rights groups, but thanks to quick action by the team at Mohair South Africa (MSA), we were able to defuse the situation. Unfortunately, despite a decade of implementing sustainable production guidelines, it did leave some scars on our industry and highlighted the need for

Message from Cobus de Klerk, Chairman of the

South African Mohair Growers Association

us to intensify our efforts for a totally sustainable and responsible industry. This will keep our product in demand internationally. Over the past year we have said goodbye to a number of people, but also welcomed some new faces into the industry.

» Deon Saayman left to join Cape Wools, and we would like to thank him for many years of loyal service. As Managing Director of MSA, he and the marketing team carried our mohair into the world. Deon, thank you for all you have done for our producers, it will be remembered for many years to come.

» Anle Marais left MSA’s marketing team to pursue other business interests, and we thank her for her efforts over the years.

» Congratulations to Lindsay Humphreys on her appointment as MSA’s General Manager. Her years in the marketing department have shown us what she is capable of and we know she will lead MSA to new heights.

» Lindsay will be assisted by Siobhan Momberg, a welcome new addition to our marketing team.

» The South African Mohair Growers’ Association is also proud to announce the appointment of Sanmarie Vermaak as its new manager, and we wish her all the best.

I want to wholeheartedly thank all the industry roleplayers for their continued support. MSA, the Growers’ Association, the Mohair Trust, Empowerment Trust, SAWAMBA, our Mohair brokers, and every single individual – your ongoing cooperation is greatly appreciated.

We all have the same goal. WORLD LEADERS IN ALL ASPECTS OF MOHAIR PRODUCTION.

Mohair Journal 2018/2019 4

The picture attached to this article was taken on Erekroon – an Angora goat farm in the heart of Mohair country, owned by the Strydom-family and run by the father-and-son team of Marx Sr. and Marx Jr. Special thanks to Linda Cortright, editor of Wild Fibers Magazine, for taking this picture.

I had the privilege of leading her and two American tour groups through the Karoo last year, showing them the mohair value chain – from the Angora goats, right through to the garments that appear on the shelves of luxury stores around the world (see page 36 for her article on the visit). While leading this tour group I realised a number of things:

» One – South African farmers, especially mohair producers, have an unrivalled passion for what they do. Any one of them could have chosen another career path. But farming is not a career, it’s a calling.

» Two – No matter what you throw at farmers in the Karoo, they take it in their stride. Crippling drought, animal rights activists, government pressure, and increasing concerns for their safety. They smile, shrug it off, and keep moving forward.

» Three – The so-called “noble fiber” around which our industry revolves is so special and valuable that we received global support when going through our darkest days. We are humbled and extremely grateful for all the support.

» Four – When swearing at traffic in Afrikaans, make sure there isn’t a person of Dutch descent in the car with you. The two languages are very similar and

Message from the Editor, Riaan Marais

your American tour group’s opinion of you can quickly change once your vocabulary has been identified.

» Five – There are few places in the world as beautiful as the Karoo after it received some much-needed rain. Seeing green grass among the arid planes, and bakkies (pick-up trucks) caked in thick red mud from waterlogged dirt roads, puts music in your heart.

» And finally – You cannot even think about farming without the words “sustainability” and “responsible farming” going through your head. So with that in mind, the thread of good farming practice, and looking toward the future of the mohair industry, is a visible theme throughout this edition of the Mohair Journal. As with last year’s publication – I hope you enjoy it just as much as I enjoyed putting it together.

Mohair Journal 2018/2019 5

Mohair Journal 2018/2019 6 Luxury Sustainable email: yarns@samil.co.za tel: +27 41 486 2430 @samil_natural_fibres | @african_expressions_yarns www.samil.co.za | www.africanexpressions.co.za

From the SAMGA office Text | Sanmarie Vermaak

At the start of 2019, large parts of our production area were still in the grip of the drought that has plagued the country. Recently large parts of our country received much-needed rain, although some of our production areas are still critical. Fortunately, our producers were able to keep their heads above water with good mohair prices and assistance from the Mohair Trust and other outside organisations. SAMGA would like to take this opportunity to thank every organisation, business and individual, for their generosity in helping our farmers in these dire times. Many were on the brink of giving up. We would also like to thank our producers for their loyalty in these tough times and the support they have given SAMGA, who had the difficult task of distributing funds and feeds to those most in need. We would like to thank our branches for their help in these distributions.

In trying to manage the drought, we also had to contend with the attacks from animal rights activists. Our Sustainable Production Guidelines have been in place for the past decade, and by following these guidelines renewed effort, we hope to prevent more unwarranted attacks on our beloved industry. I would like to thank all our producers that gave their full cooperation with

the sustainable assessments. Approximately 95 percent of our producers have been audited. Special thanks to Sarel Hayward, MSA’s sustainability officer, and his team that did the audits under extreme pressure to get as many producers assessed before mohair sales. I believe that we can all work together to make our industry the best industry for local and overseas markets.

This year SAMGA will focus on training local shearers to be completely compliant with our mohair standards. Training will also focus on the general handling of goats. We had a farmworkers’ training day in March 2019 that was a huge success. About 80 farmworkers from the Jansenville region attended the training. The workshop included animal handling and comprehensive education on sustainable and ethical guidelines. Live demo’s and new medical kits for both animals and farm workers were presented. A competition was also held amongst the participants recognising the handler whose goat was in the best condition. More of these training days will be held during the course of the year.

Our Industry is healthy and systems are in place so that we can look forward to exciting times ahead. We would like to wish all our producers a prosperous 2019 with abundant rain, top quality goats and exceptional mohair.

Mohair Journal 2018/2019 7

For more information and news from SAMGA visit our website www.angoras.co.za, or visit our Facebook page: Mohair Growers South Africa.

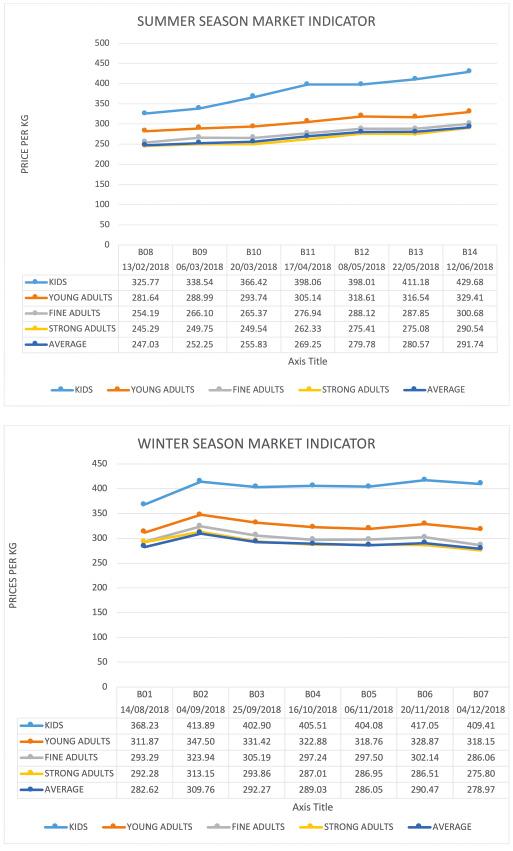

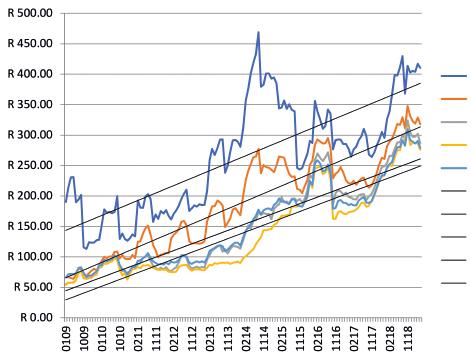

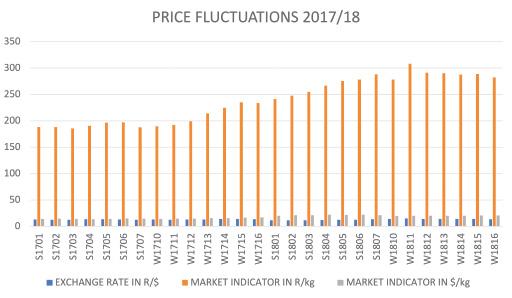

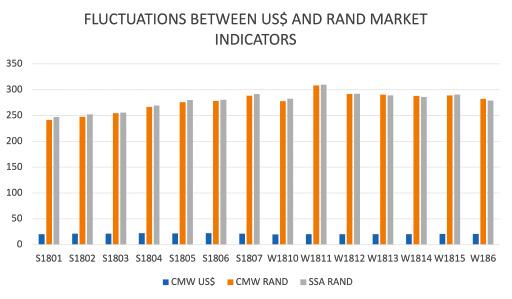

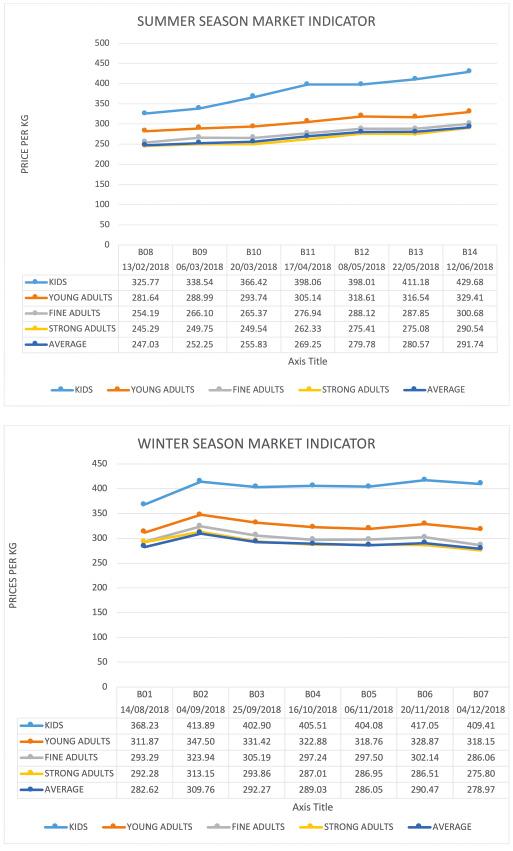

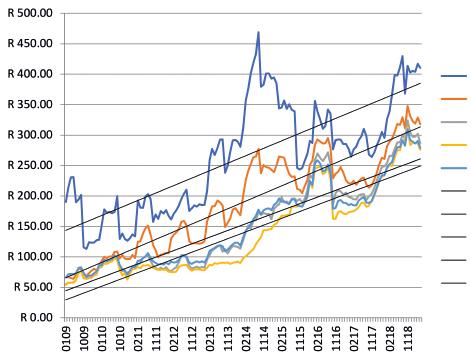

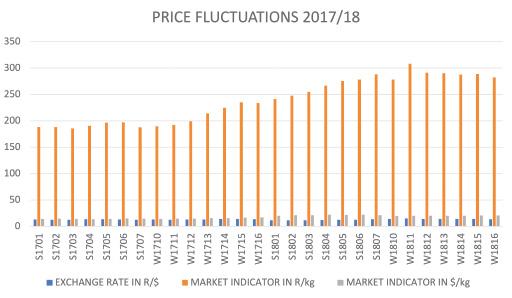

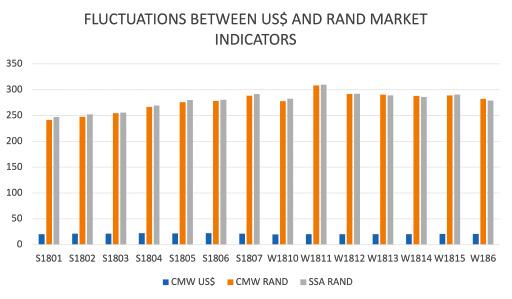

The 2018 Mohair summer season started positively which set the trend for the entire summer season. The average market indicator increased by 5.6% on the first sale compared to the last sale of 2017. This was mainly due to the increase in prices in the adult section of the mohair market. Prices for kids and young goats started to improve from the second sale of the summer season as adult mohair prices continued to rise. By the end of the last sale of the summer season, the average market indicator increased by 18% from the first sale to end at R268.06 p/kg. The winter season kicked of on a stable note with demand and prices steadily increasing throughout the season to close on R289.88, which is 36% higher than 2017 winter season.

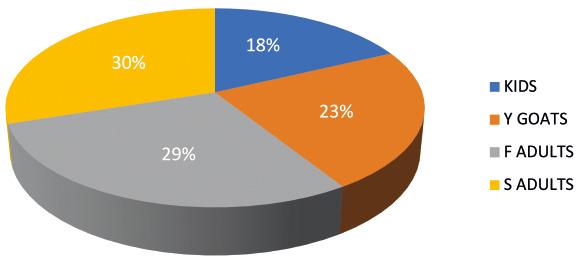

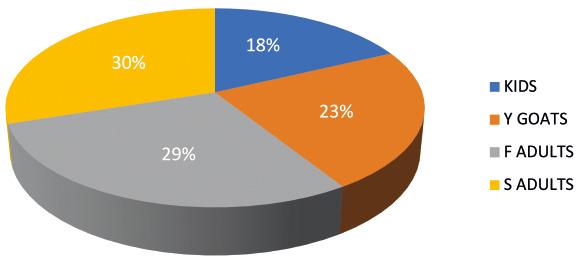

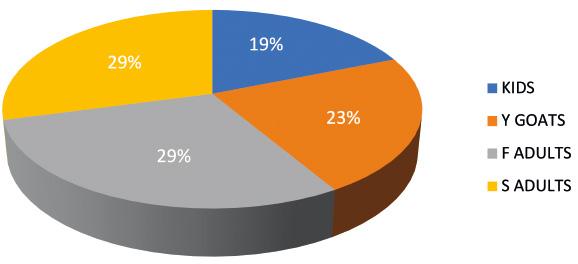

A comparison of the clip composition between 2017 and 2018 can be seen in figure 1 where not much changed as kids increased from 18 to 19% and strong adults decreased from 30% to 29%.

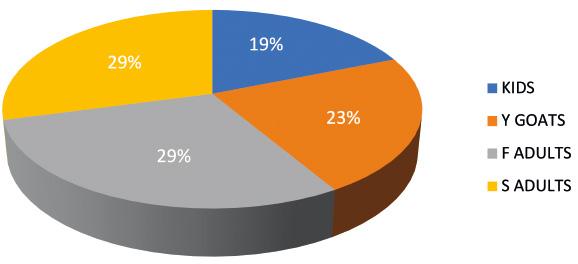

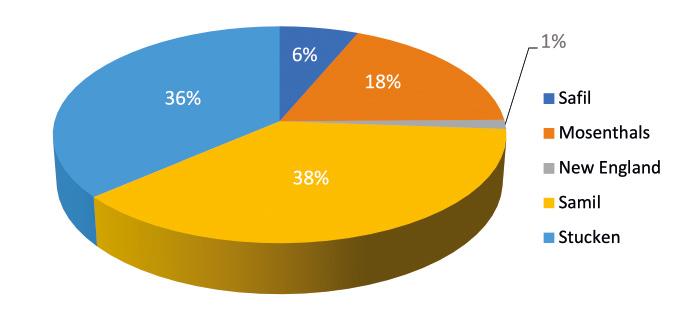

The buyers’ share of the market, indicated in figure 2, remained fairly constant from 2017, with top makers taking up 74% of the market and the greasy buyers 26% of the market share.

Because of the continuous improvement in prices throughout the 2018 season, the annual average market indicator for the year increased by 38% from 2017 and came in at R278.97 p/ kg. The longer-term price trends are indicated in figure 3, where the constant growth throughout the year is evident.

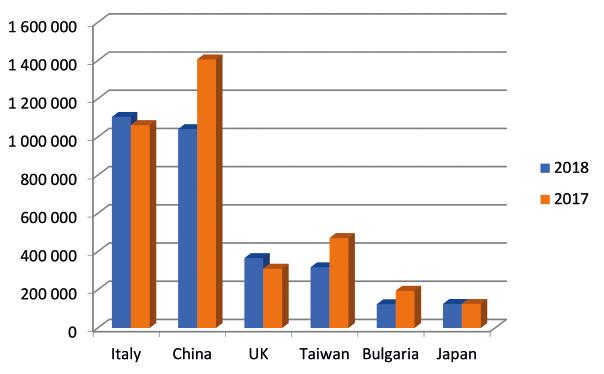

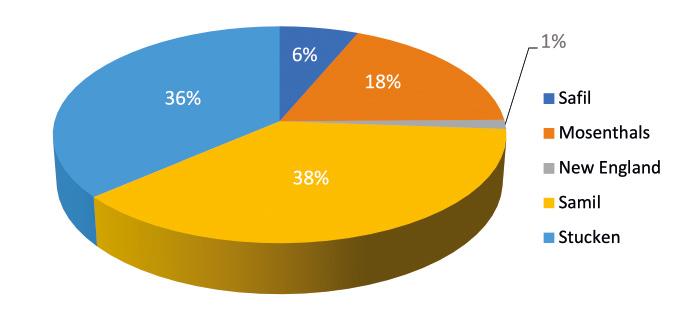

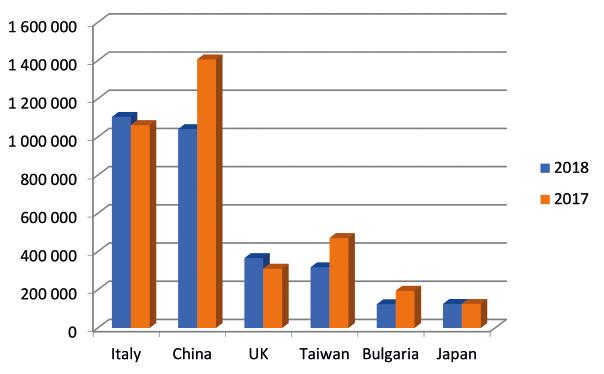

Italy became the new leader in mohair imports from South Africa as they purchased 4% more than in 2017. China and Taiwan figures reduced due to limited orders coming in the last couple of months of 2018 due to their economic conditions at the

2018 Mohair Report

by Marco Coetzee MSA Financial Manager

time. The United Kingdom showed positive intentions and moved into 3rd place in mohair imports from South Africa (figure 4)

The South African mohair is estimated at around 2.2-million kilograms for the 2018 year which is 8% down from 2017. This is mainly due to the extreme drought conditions experienced over most of the production area. Although some regions received some much-needed rain, large parts are still feeling the drought’s grip tightening as 2019 progresses.

A strong emphasis has been placed on sustainability and producing fibres within an ethical environment and the mohair industry in South Africa has all the structures in place to deliver sustainable mohair to the market.

Mohair South Africa will continue to market mohair nationally and internationally as effectively and efficiently as possible.

Mohair Journal 2018/2019 8

Mohair Imports from South Africa

Mohair Journal 2018/2019 9 Clip Composition 2018 Clip Composition 2017

Figure

1

Figure

3

Figure

2

Figure 4

2018

Long Term Price Trends Buyers by weight

KIDS Y GOATS F ADULTS S ADULTS AVERAGE Linear (KIDS) Linear (Y GOATS) Linear (S ADULTS) Linear (AVERAGE) Linear (AVERAGE)

Mohair Journal 2018/2019 10

natural | sustainable | versatile | luxury 127 Fordyce Road . Port Elizabeth . South Africa | Telephone : +2741 581 1681 | E-mail : info@mohair.co.za For natural, sustainable mohair products contact natural | sustainable | versatile | luxury 127 Fordyce Road . Port Elizabeth . South Africa | Telephone : +2741 581 1681 | E-mail : info@mohair.co.za

The road to International Responsible Mohair Standards

Producing Mohair Responsibly

Since 2009 the South African mohair industry has been placing major emphasis on promoting a sustainable luxury fibre, and that focus intensified from 2018 when the industry gained some international backing.

Mohair South Africa (MSA) is working closely with Textile Exchange, a global non-profit organisation that drives industry transformation in preferred fibres, integrity and standards, and responsible supply networks. Textile Exchange identifies and shares best practices regarding farming, materials, processing, traceability and product endof-life in order to reduce the textile industry’s impact on the world’s water, soil and air, and the human population.

The goal of this collaboration is the development of the Responsible Mohair Standard – a working document that will incorporate the South African mohair industry’s existing Sustainable Production Guidelines into the internationallyrecognised Responsible Wool Standard protocol.

MSA General Manager Lindsay Humphreys says the aim is to provide the global market with the promise of responsible farming and production.

“Mohair South Africa is committed to continuously improve the mohair industry throughout the entire value chain, working alongside all sector stakeholders to provide clear and transparent evidence of an ethical and responsible industry,” Humphreys added.

The goal of the Responsible Mohair Standard is to provide the industry with a tool to recognise mohair farmers using

best practices, ensuring that mohair is produced at farms with a progressive approach to managing their land and a commitment to treating their goats ethically and responsibly.

Textile Exchange follows the ISEAL Codes of Good Practice for standard-setting bodies to ensure that they have a robust and transparent process for our standards.

Their highest priorities are to include all parties that may be affected by the standard and to create a tool that balances strict requirements with realistic and auditable criteria. The development of the standard will be done through an International Working Group, representing the full spectrum of interested parties, including animal welfare groups, farmers, supply chain members and industry associations, as well as brands and retailers.

As part of the process of developing a standard, MSA invited Textile Exchange and brand representatives from leading brand Filippa K and member brands Acne and John Lewis on a field trip to learn more about the mohair supply chain.

Their visit explored each stage of the mohair value chain, with particular focus on visiting farms and meeting farmers to better understand how animal welfare and land health is managed and how the draft Responsible Mohair Standard could be applied.

Doreen Chiang, head production manager for Filippa K, said invaluable steps are being taken to ensure the mohair industry’s sustainability.

“It was very encouraging to see that Mohair South Africa and the farms are working hard towards a responsible mohair

Mohair Journal 2018/2019 12

standard. Knowing that all the farms have been audited and that the next step is a third party accreditation, will bring us closer to a sustainable supply chain,” said Chiang.

Karen Perry, partner and sustainability manager for raw materials at John Lewis and Partners (one of the UK’s largest department store chains) said conversations with farmers and their families, as well as employees at mohair brokers and processors, proved to her the passion and commitment of everyone along the mohair value chain.

“Meeting the vet (Dr Mackie Hobson) who supports farmers in adopting best practices in animal welfare was very impressive. It was invaluable to get his views and input into the Responsible Mohair Standard.

“John Lewis and Partners works to ensure that the highest standards of animal welfare are achieved and that is why we are proud to be involved with Mohair South Africa and Textile Exchange in the development of the new Responsible Mohair Standard,” said Perry.

The initial draft of the Responsible Mohair Standard has been published by Textile Exchange for comment and input, and a full discussion around the new standards will take place at their annual conference in Vancouver, Canada in October.

On the home front, the South African Mohair Growers’ Association (SAMGA) has also increased its ongoing educational and training programmes, focusing more on farmworkers and shearing teams working on Angora goat farms.

Besides the physical handling of goats during shearing or medical procedures, these programmes include guidelines on animal treatment in the veld, how to look after them during inclement weather conditions and the use of supplied medical kits for both people and animals.

“Besides training at pre-arranged events and farmworkers’ days, we will look to implement shearer training on the farm before shearing takes place. Farmers will supply our office with the dates when they plan on shearing, and we will arrange officials to give on-site training before the bulk of shearing commences,” said SAMGA manager Sanmarie Vermaak.

The goal is to develop a database of shearing teams that have completed the training and received accreditation and to encourage more shearing teams to complete the process.

“This is just another step we are taking towards further developing a sustainable, responsible mohair value chain,” Vermaak added.

Mohair Journal 2018/2019 13

Sustainable Management

Award winning farming with nature in mind.

Over the past few years, drought has had a stranglehold on the Karoo – the worst in memory.

Diversification and organic farming practices have helped Sarel du Plessis, thirdgeneration farmer on Vergelegen Farm near Oudtshoorn, to not only keep trudging along but to thrive under harsh conditions.

Dedication and determination, coupled with a keen sense of his surroundings, has helped Du Plessis secure the coveted Miyuki Keori prize for Sustainable Farming for a third consecutive year.

Miyuki Keori, a Japanese textile manufacturer, prides itself on the quality of its fibres and ensuring that their products are sustainable from origin to completion. That is why rewarding sustainable farming practices, and crowing the most sustainable and responsible mohair producing farm, is a top priority.

For this, prize mohair producers are judged on principles of animal welfare, environmental impact, economic sustainability, as well as staff management and social responsibility.

From a young age Du Plessis’s father, Johan, engraved a simple notion into him. If you look after nature, nature

will look after you. A methodology he also applies to his staff.

He keeps the ground healthy by ploughing back organic fertilizer, made on the farm, from animal waste from his own livestock – Angora goats, ostriches, Merinos and Bronsmaras. Organic vegetables, vegetable seed and lucerne also thrive in the healthy soil.

He reduced his unproductive livestock but was sure to keep his core animals. Luckily, rain and snow during the months of August and September revived the trickling river that runs through his farm.

But what was the most important thing he consistently did during this time of great need?

“Stay on your knees and keep your eyes on God. Only He can make rain, and His generosity is boundless,” said Du Plessis.

Besides his ostrich flock, Angora goats have formed a major part of his business since his father started farming with them in the 1980s.

“Mohair, just like ostrich leather and feathers, is a luxury item for the fashion industry – an industry that not only judges the quality of a product, but also its origin. In this case, the quality of the farm.”

He believes taking care of his goats is

an ongoing process, and always ensures he is present when they are being shorn.

According to Du Plessis recent spotlight on the South African mohair industry, due to an animal rights activist, was an unfortunate incident that could have jeopardised the mohair industry, but he sees it as a wake-up call for all farmers.

“Consumers have in increasing interest in production methods. People who buy mohair items have enough money to seek out the best products from the best processors and manufacturers.

“That is why the Miyuki Keori prize is so valuable. When our mohair clip appears on the auction catalogue it comes with the Miyuki trademark, so buyers know the quality of the product they are buying,” said Du Plessis.

And ensuring a good product goes all the way back to the source. Good genetics.

“My flock consists of exceptional quality rams and ewes, and I buy in new rams, very selectively, from time to time to keep my gene pool healthy.”

Good record keeping and selective breeding are essential, especially in determining the quality of mohair where animals are selected in the basis of fineness, length, style and character, as well as

Mohair Journal 2018/2019 14

–

clean yield. And Du Plessis does not shy away from seeking advice from experts.

“In the mohair industry, there are many experts who are willing to assists farmers. CMW (Cape Mohair and Wool), especially Pierre van der Vyver and Matthew Fox, go to a lot of trouble to prepare our clips before they go on sale, which adds value and fetches higher prices.”

He believes Mohair South Africa also does good work behind the scenes to build and market the mohair brand.

Du Plessis also attributes a lot of his success to the people he employs and believes personnel is a key factor in the progress of his business. He employs 32 permanent staff members, with about 50 seasonal workers staying on the farm when they are harvesting crops.

“I have an outstanding staff that are exceptionally loyal and have years knowledge and experience in the products we produce. The Miyuki award shows that our dedication and sacrifice does not go unnoticed.”

He believes staff should be well trained and their living conditions need to be of a high standard. “A happy employee is a good employee,” he said.

Simple steps to farm ing sustainably

» Invest in your staff – Look after them and they will look after you.

» Invest in infrastructure Without the proper tools, the work cannot be done.

» Leave pieces of veld untouched for the sake of biodiversity.

» Farm with animals suited for your environment – Then you are farming with nature.

» Rotate grazing and crops to keep the harmony between animal, veld and soil.

» Only work with the best breeding material, and ensure the fertility of your flock.

» Reduce flock numbers during drought, but keep your core animals.

» Diligent record keeping of flocks, selections and breeding.

» Don’t be scared to call on experts for advice, and always be willing to learn.

Mohair Journal 2018/2019 15

Sarel du Plessis walks handin-hand with God, nature, and the people who work with him to ensure the success of his thriving business.

Text by Mariska Spoormaker First

published in Landbouweekblad

Mohair Journal

RFID technology

…and how it can add value to your production

Radio Frequency Identification (RFID) has been around for many years and has developed to include applications for various industries the world over.

When RFID tags were still a new technology for animal use and reserved only for wealthy people trying to keep track of expensive pets or rare breeds of game, it excluded many potential users. Luckily, as the technology developed and the mass use thereof became more prevalent, the market expanded to include a multitude of customers, including farmers of livestock on a commercial scale.

Fast forward a few years and many farmers, including cattle, sheep and goat farmers (to name but a few) struggle to remember a time before implementing RFID tags for accurate and efficient record keeping.

RFID Experts Africa, South Africa’s leading suppliers of RFID tags and related services to livestock farmers, provide a range of products to suit the needs of farmers looking to add RFID technology to their daily operations.

While farmers are under no obligation to use RFID tags, Schalk de Villiers, business development manager at RFID Experts Africa, believes the time will come when farmers will view this technology as a necessity.

“RFID technology goes hand in hand with precision farming. It makes farming more profitable and simplifies responsible mohair production as it forms the basis of traceability from animal to end product,” De Villiers said.

RFID chips come in many forms. Subdermal implants can be used to store information and even act as a tracking device, but are very expensive and only used in very specific cases. For large scale livestock farming, ear tags are more

common and can store a range of useful information.

“No information is stored on the tag itself. Each tag comes with a unique 15-digit code, and once you scan the code with your RFID reader you have access to any information stored on it. This could include breeding records, pregnancy and kidding records, dosing and vaccine schedules, matching kids with their mothers, as well as an animals’ history of diseases or abnormalities,” De Villiers said.

RFID readers come two forms – a handheld reader that needs to be held close to the ear tag to scan it and retrieve information, or a reader that is built into a larger, stationary scale and automatically scans the tag when the animal steps onto the scale. When scanned the information attached to the tag’s unique code is displayed on a computer, and changes can be made to the information as necessary. For small stock, like Angora goats, De Villiers recommends the use of 25mm FDX ear tags. These tags can be removed from one goat, cleared, and new information can be stored for the new carrier.

The scanner to use would depend on the facilities available on each individual farm. The handheld scanners are obviously portable and can be used almost anywhere. The larger units come with a bigger price tag but have certain capabilities that the handheld unit does not, for example, a built-in scale.

“We have developed a small scale that measures fleece weight during shearing and automatically uploads the information to the specific animal’s RFID tag. This can be compared to information like micron count and add immediate value to your clip,” De Villiers said.

Chris Louw, a mohair producer between Bedford and Adelaide, started implementing RFID tags on his farm in 2018

Mohair Journal 2018/2019 17

and believes the information he has gathered over the past few months will prove to be very valuable moving forward.

“We as farmers have to be more accurate with our selection and record keeping. Computers enable us to store and analyse vast amounts of data, and RFID technology facilitates the collection of the required data.

“Add to that the rapid shift toward traceability and responsible production, and accurate record keeping will become an absolute necessity. RFID tags make that so much easier,” Louw said.

Out of his entire herd of 4600 goats, Louw has equipped 1500 breeding ewes with RFID tags and uses a handheld scanner to gather and store information on breeding records, birth dates and even the weights at which his kids were weaned.

“In the long run, this will make a massive impact on how I manage my stock. I will be able to make better and more reliable breeding selections for my rams

and ewes. And traceability will be a major advantage in the future.” Louw admits that there is some additional admin when scanning tags and storing information, but continuously updating software simplifies the process.

De Villiers added that only the surface of the potential implementations of RFID technology has been scratched, and they are constantly researching new ways of adding value to their products.

“We are currently building devices that will be able to accurately measure an animal’s conversion of feed to product, meaning we can more accurately determine which feeds are better and which animals are more efficient.

“Coupled with a more accurate pairing of ewes and kids, farmers will be able to identify their best ewes based on their performance and make better breeding selections.

“The possibilities are truly endless, and it all works to add value to your clip, animals and overall business,” De Villiers said. For the latest information on RFID products and pricing visit www.rfid-experts.co.za.

Mohair Journal 2018/2019 18

Mohair Journal 2018/2019 19

Potential of stock farming with drones in the Karoo

Eye in the sky

Lfarming operation might sound like the premise for another Terminator sequel.

operations through the use of drones or UAVs (unmanned aerial vehicles as they are also called) is becoming more and more prevalent across various spheres of agriculture.

refers to the effective use of technology, like UAVs, in large scale crop farming. precision livestock farming is also attainable when the right tools are applied properly.

– founder of Agribotix, an American based leader in agricultural UAV development and technology – obtaining real-time, actionable data from your farm is essential for the effective management of your operations, and drones are the most effective way of obtaining the relevant information.

pressures on farmers abating, it makes sense to seriously consider any tool that can boost productivity, mitigate

Mohair Journal 2018/2019 20

Little machines flying overhead, gathering real-time information and checking the daily activities of your farming operation might sound like the premise for another Terminator sequel.

However, monitoring agricultural operations through the use of drones or UAVs (unmanned aerial vehicles as they are also called) is becoming more and more prevalent across various spheres of agriculture.

In most cases the term “precision farming” refers to the effective use of technology, like UAVs, in large scale crop farming. But precision livestock farming is also attainable when the right tools are applied properly.

According to Doctor Tom McKinnon – founder of Agribotix, an American based leader in agricultural UAV development and technology – obtaining real-time, actionable data from your farm is essential for the effective management of your operations, and

drones are the most effective way of obtaining the relevant information.

“With no sign of the current pressures on farmers abating, it makes sense to seriously consider any tool that can boost productivity, mitigate input costs and, ultimately, improve the bottom line,” McKinnon said.

“Drones are still considered a new tool for agriculture, but their demonstrated utility and their compelling return on investment make them an attractive addition to the precision toolkit.”

Here’s a simple example.

Kidding season on a Karoo farm can be a stressful time for any farmer. If your practice is to let your ewes give birth in the veld (natural grazing pastures) it can happen far from where you can keep an eye on them. Cold weather can suddenly set in, natural predators could be roaming around or stock thieves could be aware of your practices – lying in wait for the opportune moment to snatch up some young goats.

A drone could allow you to keep an eye on things from the comfort of your own lounge. You could be sipping your morning coffee, watching the screen on your drone’s remote controller, seeing a live video feed from the drone’s onboard camera, and spot a kid that had become separated from its mother. You might see that jackal that killed a kid the previous night, or spot goats tied to a fence post waiting to be collected by passing poachers.

Being aware helps you to act swiftly.

“Whether farmers purchase and fly their own drone or hire a drone service to fly for them, drones cost-effectively capture aerial imagery with accuracy and unrivalled immediacy. When the window of opportunity for intervention is small, as it is in farming, ease of use and fast turnaround of data is key,” McKinnon added.

Less drastically, a drone with enough range could fly a pre-set route, via GPScoordinates, around your farm, capturing footage of holes in your perimeter fence, or fly by your water troughs to make sure animals out in the veld don’t die of thirst. Locating missing goats across vast expanses is also made easier and a skilled drone pilot could even herd goats when flying low and close enough.

On Claremont farm, near Jansenville in the Karoo, Chris Lee has explored the uses of his drone on his 6 800 hectare Angora goat farm, and found it to be a useful tool for day-to-day tasks.

While the specifications on his DJI Mavic Pro pale in comparison to some more advanced, and much more expensive, models on the market, Lee said his drone repaid its price tag easily.

“The simple question you need to ask yourself is. What is my time worth to me?” Lee said.

“You could spend hours out in the veld, driving or walking around looking for lost stock. I have seen people walk within a few feet of an Angora goat that was hiding in some bush or Spekboom without spotting it. But now I can sit in my vehicle, fly my drone 50 metres into the air, and have a clear view of where the little white goats are scattered along the arid Karoo landscape.”

He said checking water and food troughs while out in the veld is simplified with the drone, and he has even been honing his skills to herd goats when they

Mohair Journal 2018/2019 21

Mohair Journal 2018/2019 22

need to directed in smaller camps.

“Over time the goats will probably become used to the drone, but for now they are still skittish when it comes too close.”

With some costly additions, like extended batteries and thermal cameras, Lee believes his drone could become a crucial tool for predation prevention and personal security. However, having already spent R23 000 on his, he feels the additional expenses are not necessary at the moment.

“Thermal images of predators in the veld, or even unwanted visitors would go a long way towards preventing stock loses,

or even possibly even saving lives. But for now, I am happy with what I can do.”

However, entry level models like Lee’s come with certain limitations.

According to the DJI Mavic Pro’s specifications it can fly for 13 kilometres, or 27 minutes, before the battery runs out. Its transmitters allow the pilot to be seven kilometres away from the device, but that range could be drastically shortened as the drone will automatically return to the controller when the battery is low enough.

“Flying in strong winds is a very effective way of losing your new toy, especially in open spaces where there is little shelter

from the elements,” Lee warned.

Lee believes drone technology has endless potential as technology is constantly evolving, and while it has certainly added value to his farm, he does not consider drones to be crucial tools for all farmers at this stage, taking the costs and limitations into consideration.

In contrast McKinnon believes drones are well worth the investment.

“Agricultural drones are here to stay. Farmers that embrace the technology and integrate it into their precision programmes will wonder how they ever got along without it.”

Mohair Journal 2018/2019 23

Price From R20 000 From R25 000 From R45 000 From R70 000 Range from controller 3 km 2 km 3 km 5 km Flying time 27 minutes 25 minutes 31 minutes 35 minutes Top Speed 65 km/h 57 km/h 72km /h 65 km/h Camera specs Built in camera, great video quality Good video quality, specialised thermal imaging Built in camera, great video quality, Thermal imaging capabilities Camera sold seperately Pros Compact, light weight Ideal for fire monitoring, animal tracking Good built in features, can add spotlight and speaker Very versatile. Weather resistant. Can carry up to 6 kg load Cons Limited capabilities, struggles in strong wind Shorter range Avoid moisture/rain, Expensive, bulky and heavy

MODEL DJI Mavic Pro Parrot Bebop Pro Thermal DJI Mavic 2 Enterprise DJI Matrice 600

One of the South African mohair industry’s most coveted titles returned to Prince Albert for the third consecutive year when Van Hasselt Farming were awarded the Miyuki Trophy for their exceptionally high quality fibre.

Mother and son pair Gay and Jordi van Hasselt has won the title of Grand Champion 6 times since 2012, and took second place in 2014.

The awards ceremony, which took place at the Little Walmer Golf Estate on Thursday, rewards farmers for consistently producing high quality mohair throughout 2017. Japanese fashion brand Miyuki Keori, which uses top quality mohair for manufacturing men’s suits, established the annual competition 38 years ago.

Upon receiving the award Jordi van Hasselt dedicated the award to his mother, praising Gay for her hands-on approach to farming.

“She cares for our animals and for the mohair we produce.

“When it’s shearing time she never lets the shearers and the goats out of her sight. She makes sure every is done

Miyuki Keori trophy still on the Van Hasselt mantle

perfectly. She is an inspiration to our whole industry,” he said.

Gert Jordaan, from Aberdeen, was named the Reserve Grand Champion.

Oudtshoorn farmer Sarel du Plessis and Koos le Roux, from De Hooggelegen farm near De Rust, received a special prize for their great achievements in sustainable farming.

A letter from Miyuki Keori president Naoto Yoshida, which was read at the event, praised these farmers for the care they take during the production of their mohair. He said in light of recent reports of animal abuse on mohair farms sustainable practices have become just as important as producing high quality fibre.

In support of the South African mohair industry Yoshida also donated R15 000 to the newly established drought relief fund for mohair farmers. Other companies, including mohair processors Stucken and Co, quickly matched the Japanese company’s donation, and by the end of the night a total of R90 000 had been donated to the fund.

Mohair Journal 2018/2019 24

Front: – Gay and Jordi van Hasselt crowned Grand Champion.

Back: Gert Jordaan, Reserve Grant Champion; Jan Lategan, Champion Summer Clip; Koos le Roux, Reserve Sustainability Champion; Sarel du Plessis, Sustainability Champion.

Fitzhenry brings Daidoh Trophy to Aberdeen

The Aberdeen Club played host to one of the most prestigious events on South African Mohair Industry’s calendar when it welcomed the finalists of the Daidoh Mohair Trophy. And one of the region’s own walked away with top honours after Charles Fitzhenry, from AC Fitzhenry & Sons, was crowned the 2018 champion.

Fitzhenry said he was honoured to have received the award amid continuously tough farming conditions, and thanked the Daidoh Company for its continued support of the South African mohair producers.

The Daidoh Trophy Competition was first launched in 1992, in collaboration with Mohair South Africa, to reward mohair producers for their exceptional summer kid clips. The winner is determined based on the highest average price of their summer kid clip.

In letter from Daidoh Company president Shin Okawa,

read out during the event, he praised the hardiness of mohair producers and encouraged them to keep up their efforts for outstanding quality fibre.

“It is with great pleasure that we return to present the Daidoh Trophy prize again. We are very proud to be associated with an industry that is filled with such dedicated producers.

“This trophy is not only an award, but an effort to inspire each producer to keep up their exceptional work, and to keep producing a product of the highest standard.”

Okawa said they hope to play a ongoing role in the development and prosperity of the South African mohair industry.

Daidoh Company Ltd was founded in 1879 and is a leading Japanese manufacturer high-end fabrics and top quality clothing. The aim of this competition, launched in 1992, is to encourage farmers to improve the overall quality of the South African Mohair clip.

Mohair Journal 2018/2019 25

From left. MSA director Rothner Bekker, Daidoh Trophy winner Charles Fitzhenry, and Stucken Group director Anthony Kirsten

Mohair Journal 2018/2019 26

Another Zegna title for Lategan

Jan Lategan smiled from ear to ear as he stood on stage during the 2018 Ermenegildo Zegna Awards Ceremony, lifting the trophy for a second consecutive year.

South African mohair producers only submit their finest summer kid mohair for a chance at the coveted Ermenegildo Zegna Trophy, and out of the 18 entrants Lategan’s clip ticked all the right boxes for a second time.

“I can proudly say that it is always an honour to recognize the incredible achievements of South African mohair growers,” said Paolo Zegna, Chairman of the Ermenegildo Zegna Group, at the awards ceremony.

“We’ve been celebrating the best quality mohair since 1970 as a testament to the importance of the mohair industry and the on-going commitment of our Group to maintain the exceptionally high qualitative standards of the raw materials we use.

“In extending my congratulations to the finalists, who did an exceptional job to grow such fine mohair despite of the very difficult climate condition of the past seasons, I would also like to recognize the fine work of all the participants, who I encourage to continue targeting the level of excellence we have seen this year. Thank you for your efforts and ongoing commitment.”

The competition winners are selected after their clips are sent for independent testing of the fibre, scoring them on the fineness,

evenness, handle of the fibre and the general appearance.

Besides awards ceremony, all participants also took part in the annual Zegna Special Auction which always provides a lot of excitement.

Records toppled as four lots of summer kid mohair sold for more than R1 000 per kilogram, smashing last year’s record setting R896. The top price went to Van Hasselt Farming that fetched R1246,10 per kilogram.

Mohair Journal 2018/2019 27

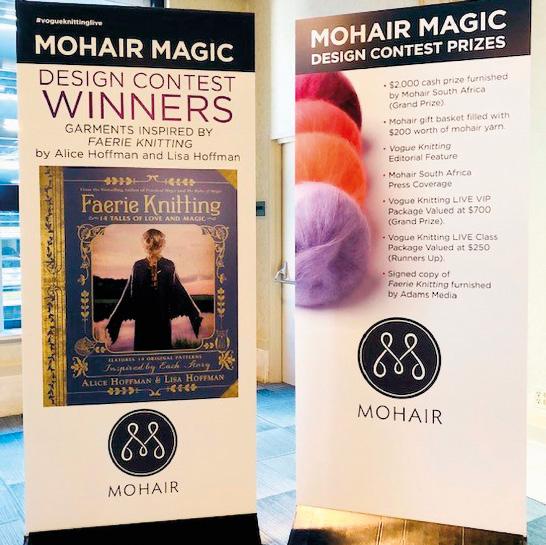

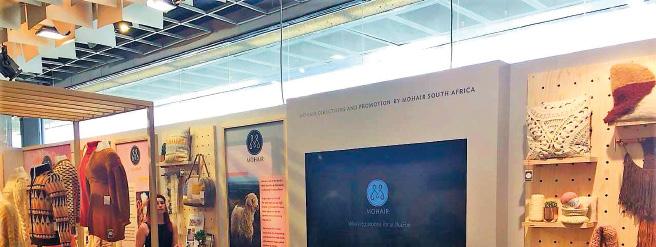

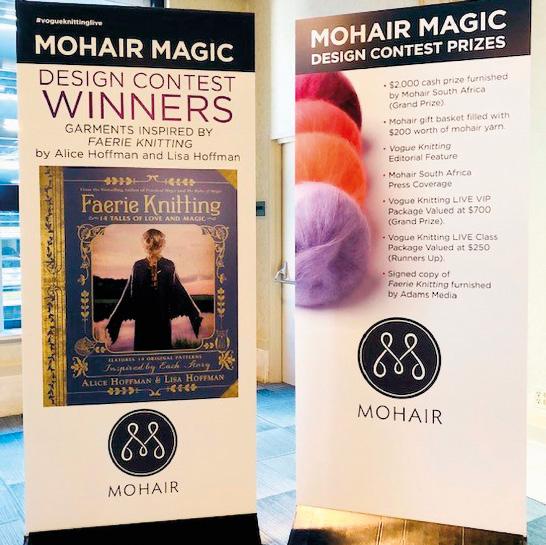

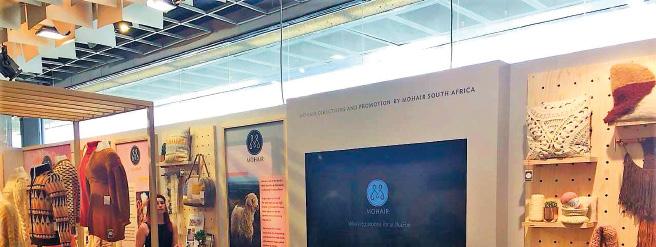

VOGUE KNITTING LIVE

Mohair South Africa has collaborated with Vogue Knitting for 6 consecutive years and has become known for our annual mohair knit contest, which has ranged from full garments, sweaters, beanies, gloves, blankets and shawls. Vogue Knitting Live is an extension of the magazine and offers master-level hand-knitting workshops, a marketplace for knitters to shop and daily fashion shows. The show moves around the US and has 3-4 events annually. Mohair SA offered South African mohair yarns for sale, showcased products previously shown at H&H in Germany, and the very popular mohair handmade goats.

In 2018 Mohair Magic Design Contest proved to be very popular. Inspired by renowned American author Alice Hoffman’s book Faerie Knitting, in collaboration with her cousin Lisa Hoffman, the competition encouraged entrants to bring faerie inspired designs to life for a chance to win the US$2,000 grand prize.

Entries were received from the US and 14 different countries, as far as the Ukraine. The entries were of an exceptional standard, with many types of techniques used, and the ten finalist products were displayed at the show.

Mohair SA hosted its own ‘yarn tasting’ with South African manufacturers supplying mini giveaway skeins that proved to be very popular. There were also two exclusive mohair fashion shows with garments from the last six months Vogue Knitting magazines. The beautifully styled fashion show was very well received and there were numerous requests for the patterns and yarns afterwards.

Mohair workshops on the latest trends and colours provided an opportunity to engage with consumers and share information about the newest, as well as upcoming, products on the market.

Mohair Journal 2018/2019 28

San Francisco, USA

Mohair Journal 2018/2019 29

Cologne, Germany

H&H, as the trade fair is known, is the world’s largest fair for creative handicraft and hobby supplies. In total around 16 000 visitors from 73 countries attended, placing orders with the 423 exhibitors for the vast range of supplies on offer.

This was the second year Mohair South Africa exhibited at this event and after meeting with the show director in 2017, Mohair SA was awarded sponsored space on condition that South African companies would be promoted. The showed handicraft, crochet, weaving, knitting, embellishing and embroidering in one space, featuring brands like Samil’s African Expressions, Cowgirlblues, Adele’s Mohair, Hinterveld, BabyMo, GTI and Frances van Hasselt mohair carpets. Four of the above-mentioned brands had stands of their own and we worked very closely with them.

Handicrafting is still one of the favourite leisure-time hobbies. The thing that especially counts in the handicraft sector is that the project is fun and allows people the opportunity to take a brief time-out from everyday life and reduce stress. According to research by the event’s organisers, the overall market for handicraft supplies in Germany for 2017 is estimated to be €1.22-billion (R19.5billion or US$1.37-billion), measured in end consumer prices. The handicraft market has become younger, more fashionable and more diversified. Living creatively and developing one’s own style has become part of modern life.

H+H dedicate a special area focusing entirely on sustainability in a very prominent position in one of the halls, highlighting the growing trend movement toward sustainably sourced materials.

The collections on display included soft yarns made of highquality materials, including alpaca, merino and cotton blends. Being lightweight as well as voluminous gave mohair a competitive edge.

Statistics from the organisers:

The trade fair hosted 423 exhibiting companies from 45 countries, of which 73 percent were from outside Germany. About 16 000 visitors attended the event, and 38 percent of them were international visitors, representing 73 different countries.

The exhibitors included manufacturers of knitting, crocheting, machine and sewing yarns, as well as haberdashery, home textiles and tapestry suppliers. Visitors ranged from retailers, wholesalers and department stores, to schools and the general public interested in crafting supplies.

Handarbeit & Hobby

Mohair Journal 2018/2019 30

Pitti Filati

Pitti Filati is the ‘not-to-be-missed’ calendar event of the year. It has proven to be an invaluable platform for Mohair South Africa, where we engage with designers and buyers from international brands and key industry media. In Italy, where business is largely built on relationships, this event also serves as the perfect opportunity to engage with all the mohair spinners under one roof.

The event presents world-scale excellence in yarns to its audience of international buyers and designers from the biggest names in fashion that come to Florence looking for creative inspiration. The shop reached more than 5000 buyers, and an encouraging sign was increased interest from Italian buyers, whose numbers had dwindled over the past two years. Brands form dozens of countries attended, and countries with the biggest presence at the event were the United Kingdom, Germany, the United States and France.

This was the third consecutive year that Mohair South Africa showed at Pitti Filati, but the spotlight cast on the mohair industry by animal rights activists led the majority of conversations revolving around animal treatment. Dozens of Q&A sessions showed that the majority of visitors were open to understanding and educating themselves to ensure they were using an ethical product going forward.

Confindustria Toscana Nord partnered with Mohair South Africa, Textile Exchange and ICEA to host the Sustainable Textile Workshop. The workshop provided an opportunity for brands, suppliers, media and other industry players interested in sustainability to understand the process and build long-term strategies for success.

Mohair Journal 2018/2019 31

Florence, Italy

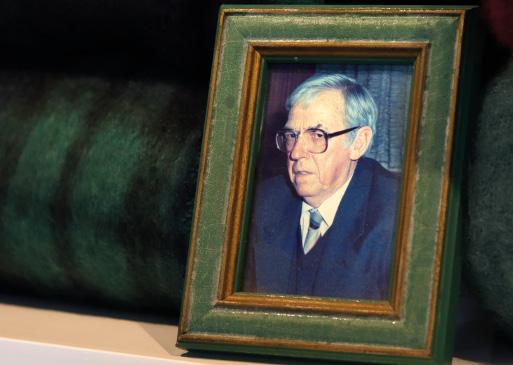

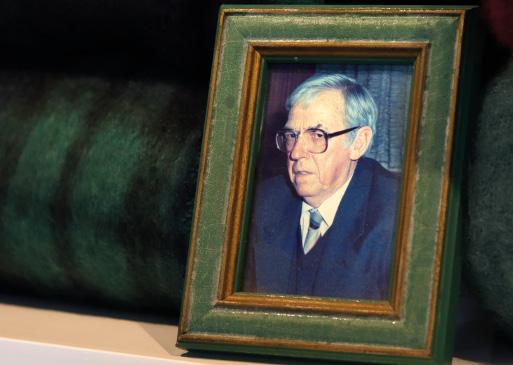

From dirt to director

Bruce Paterson’s journey through the old days of Mohair

The men in suits.

Looking back over more than 40 years in the fibre industry, Bruce Paterson conjures up images of men in full suit and tie – whether they were standing in the dusty fields of Karoo farms, or classing mohair in the balmy stores where the bales were kept.

“It was an industry of gentleman representatives. They drove big cars - there were no bakkies back then - and never took their suits off. Even when visiting remote farms, the suits did not come off,” Paterson said, the faintest smile crossing his face.

Sitting in his Mill Park home at the age of 85, only a few streets away from the house where he was born, Paterson remembers his father Alec working as a manager at Dunell Ebden wool and mohair brokers (years later it would be amalgamated into BKB). After completing matric at the nearby Grey High School, Paterson took up a position with the same firm as a clerk.

He married his wife Merle in 1959 and together they had three sons and a daughter. He later furthered his education and completed a National Diploma in Business Management at the Port Elizabeth Technikon (now the Nelson Mandela University), while juggling family and work.

He laughs as he recalls his first days at Dunell Ebden.

“There was no position low enough for me. My job consisted of making up stock sheets in the wool and mohair stores. I was 19 at the time and the lowest form of dirt at the company.”

However, Paterson worked his way up the ranks, and early in his 30’s was appointed as director of the company, in no small part due to his passion for the fibres he worked with.

“We used to handle big quantities of Cape and Lesotho mohair, and I liked to attend the auctions. You can always get a sense of the market from sitting at the auctions,” Paterson said.

One of his favourite parts of the industry was doing farm visits across the Karoo and Lesotho, to see where the fibre came from and learn more about the people producing it.

“Back then we only had about eight field officers across the country, so I saw this as an opportunity to visit our farmers often. We drove on bad roads in big cars that weren’t built for it. But that is one of the things I miss the most.”

Robert Scott, a former colleague, fondly remembers sitting in his Cape Town office and having phone conversations –sometimes very brief ones – with “Boss Bruce”, after mohair and wool sales, held exclusively in Port Elizabeth.

“My phone would ring around midday on sale days. Sometimes the entire conversation would be. ‘Hello Robert, the market is in buyers favour. Goodbye’. And that was the end of the market report.”

He fondly remembers Paterson as a gentleman “in all his ways and manners”, always wearing a white shirt and tie.

“I will never forget his words to me one day. ‘There is always work in a wool store, even if you wash the windows’. And one day when he bought himself a BMW I told him I also wanted one. His reply was simple. ‘One day when you are a big boss’.”

Paterson became an internationally recognised name when he started writing reports on the wool and mohair markets for publications across the world. According to him, writing

Mohair Journal 2018/2019 32

came purely by accident after his monthly reports for the Wool Record started circulating to other publications.

His old colleague and fellow director at Dunell Ebden, Danie Cronjé, recalls Paterson’s witty articles and his ability to accurately predict the fibre markets for the coming season.

“He predicted the markets six months in advance, advised buyers on those predictions, and was never too far out. It was uncanny.

“And even after his retirement at 63 he still maintained his connections with the farmers in Lesotho. I think he really missed visiting them,” Cronjé said.

He attributed the current display system for wool and mohair samples before sales to Paterson, saying it was a simple solution to an old problem.

“Before using cardboard boxes with samples of lots, brokers had to have the entire lot, sometimes more than one bale, strewn out on the floor. But we were running out of space, and Bruce suggested samples.

“Remember, this was before coring was done on bales, so buyers had to take the broker’s word on the content of the bales based on the sample. But we made it work,” Cronjé said.

Paterson’s daughter, Elizabeth, said many people have echoed Cronjé’s point of her father’s ability to predict the markets accurately, and attributes that to his passion for the industry he worked in.

“His other passion was his family. He rated education very highly and encouraged all of us to be all we could be. My parents made big sacrifices for us. My younger brother and I were able to further our education without student loans, and I know that must have been tough for my parents.”

Editor’s Note: I was heartbroken to hear that Bruce passed away a few weeks after I had visited him at his home in Port Elizabeth. I had only met him once, but through that brief conversation and information I gathered through my research I could tell he had left a mark on every person he came into contact with, including me. His knowledge of the industry, his perseverance through more than four decades of “mohair stores and men in suits” and his ability to predict market trend well in advance (according to multiple sources) made him a true legend and gentleman of the industry. I want to thank his old colleagues and daughter Elizabeth for filling in the blanks after my interview with him, and I hope this article pays even a fraction of the tribute he is worthy of. Rest in peace Bruce.

Mohair Journal 2018/2019 33

Wild Fibers’ tour of South Africa

Editor and publisher of wellknown US natural fiber based magazine, Linda Cortright, brought an American tour group to experience the mohair, the Karoo, and a good old-fashioned braai.

Mohair Journal 2018/2019 36

Marx Strydom, of Erekroon farm, Jansenville answering questions about his farming operations.

Icame to Port Elizabeth in 2007, attended my first ram auction in Graaff-Reinet, and visited several mohair producing farms. I was so taken by my experience, I made an impromptu trip to Lesotho for the sole purpose of interviewing even more angora farmers. And so began a long distance love affair with one of the most versatile and lustrous fibers on the planet.

A decade later I found myself returning to South Africa. Initially, I had come to do a story about the mohair industry for my US based magazine, Wild Fibers, which has the luxury of focusing not only on every type of natural fiber imaginable (from the tiny silkworm to the prehistoric musk ox), but also on those who have lovingly tended these animals for generations.

I have travelled with nomads in the Gobi Desert, hung out with camel herders in Oman, and I have interviewed opium farmers in Afghanistan now raising silkworms instead of the naughty stuff. I have interviewed fiber artisans of every description, forever reminding them that without the unsung sheep, or goat, or yak, they would be drowning in a sea of synthetics.

It’s worth noting that I began leading fiber-based tours in 2012. My first tour was to India’s High Himalayas, watching thousands of cashmere goats descend into the valley at sunset. I have also led fiber tours to The Falkland Islands, and “chased” after musk ox in Alaska. Surely a trip to South Africa would be tame by comparison.

A tour started to take shape, and with the help of Deon Saayman (then Managing Director of Mohair South Africa) we ironed out the details. The tour would include the processing plant at Gubb & Inggs, a tour of the manufacturers of mohair products Hinterveld, and a farm stay at the opulent Wheatlands guesthouse, to name but a few stops.

There was only one problem – through word of mouth the tour sold out before everyone had received their copy of Wild Fibers in the mail where the tour advert was listed.

“Sold out?” Came more than one disgruntled reader over the phone. “But my magazine just arrived – less than an hour ago!”

The solution – two tours, back-to-back.

Many of my readers are either fiber farmers or indulge in some type of fiber-ly craft, like hand spinning, weaving, or knitting. Two of my guests were angora farmers, but not farmers with a capital “F.”

Excluding Texas, modest-sized herds of fifty or less are typically the norm in the US, and some of my guests had seen Mini-Mills in action. But no one was prepared for the scale of operation at Gubb & Inggs. Even the receiving warehouse, which wasn’t particularly crowded at the time, created a cacophony of jaws banging on the floor over the sheer volume.

I knew the weaving at Hinterveld would capture their attention, and the showroom their wallets. But they clearly had no idea as to mohair’s standing in the world of high fashion. A few swatches of Chanel suiting left a lasting impression, no doubt

Mohair Journal 2018/2019 37

Texas may be big - really bigbut it’s not the Karoo.

The Wild Fibers tour group visited Wheatlands farm, between Jansenville and Graaff-Reinet.

causing some to return home and report, “Did you know Chanel uses mohair from South Africa!” (I say this because that’s exactly what I said after my first visit.)

Our tour into the Karoo was led by Riaan Marais (Mohair South Africa’s media and communications officer) and Marco Coetzee (Mohair South Africa’s financial manager) where the tour group visited, Wheatlands, stopping at Erekroon in Jansenville along the way.

Whether you have goats, sheep, dogs or even a bowl of goldfish, nothing catches an animal’s attention like the arrival of food. At Erekroon, farmer Marx Strydom filled the grain bins, knocked on the metal side a few times, signalling the proverbial dinner bell, and soon word spread throughout the flock faster than another irreverent Tweet from Trump.

Mohair Journal 2018/2019 38

In the end, the vote was unanimous. There wasn’t anything they would have done differently.

Editor of Wild Fibers, Linda Cortright

Trigger keeping a close eye on Wheatlands’ rams

Still in full fleece and with a generous complement of kids in tow, the arrival of hundreds…and hundreds…of angora goats delighted all. Not surprisingly, none of the goats were keen on being touched, but back at the barn, Strydom had a small paddock of bum kids where a serious round of touching, fondling, squeezing, and threats of kidnapping, yes KID-napping, ensued.

We arrived at Wheatlands by mid-afternoon. The collonaded entrance flanked by a surprisingly green lawn was in stark contrast to the miles of nearly desiccated landscape that is just now coming back after the prolonged drought. When Americans typically think of drought, they picture thousands of Californians forgoing hot showers and washing their Tesla’s with a rag and a bucket. They often don’t realize the enormous ramifications drought has not only for livestock but wildlife as well.

Arthur Short and his son David hosted the group for the farm tour, including a visit to the kidding pen adjacent to the main house, and walkabout the shearing shed. Once again, the scale of operation seemed unfathomable, a point that was further underscored as we took off in the “bakkie” that evening to see Wheatland’s breeding rams. I overheard one of my guests remark (incorrectly) that they don’t have ranches this big in Texas!

We still had one more stop on our mohair journey in South Africa, a trip to see the “Amazing Adele” in Port Alfred.

Adele Cutten is South Africa’s “Mohair Maven.” A title she has rightly earned in her thirty-plus years of hard work and dedication to the industry, and the ladies she employs.

Unlike Gubb & Inggs, and Hinterveld, with big machines gnashing and crashing about, Adele’s ladies eschew modern machinery, preferring to spin, knit, and dye the “old-fashioned way”. Sitting outside on a sublime spring afternoon, the ladies

smiled at my group of “fiber foreigners”, allowing them to inspect the various items they were working on, and some, in turn, reached into their bags to produce the knitting they had brought with them. Once you know “fiber-speak,” you don’t need anything else.

With four days of all things mohair in our wake, we were finally on our way to see the much-anticipated elephants at Addo. Not five minutes into our first game drive a solo black rhino was standing fifty yards from the vehicle. Every member of the group was frozen in their seats because they have never been that close to a rhino without some type of barrier protecting them.

After fifteen days, including a visit to Coral Stephens Handweaving in Swaziland, for even more lessons in mohair, I asked the group if there was any moment during the trip that stood out more than the rest. They fell uncharacteristically silent. Eventually, they began reciting every stop along the way. Who they saw. What they did. Where they ate. In the end, the vote was unanimous. There wasn’t anything they would have done differently. Not only do they now have a much clearer understanding of the importance of South African Mohair, but they also understand that seeing the elusive black rhino at close range is almost as precious as a mohair suit from Chanel.

One of the rewards of being a tour leader is providing people with an opportunity to experience another land, another people, and another way of life. No matter how many Animal Planet reruns you watch, no matter how many times you see Jacques Cousteau plunge into the dark sea, nothing will ever replace the value of boots on the ground, wind in the hair, and the taste of a delicious “braai” cooked-up for a Saturday night special.

Mohair Journal 2018/2019 39

Marx Strydom, of Erekroon farm, Jansenville answering questions about his farming operations.

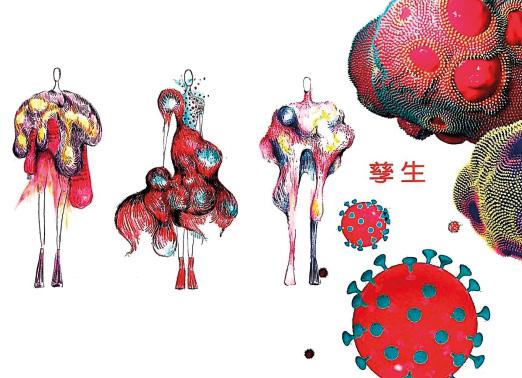

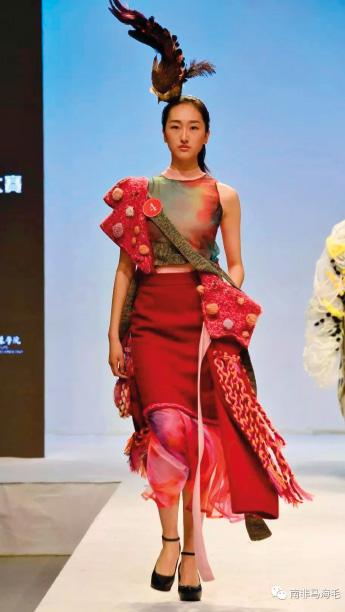

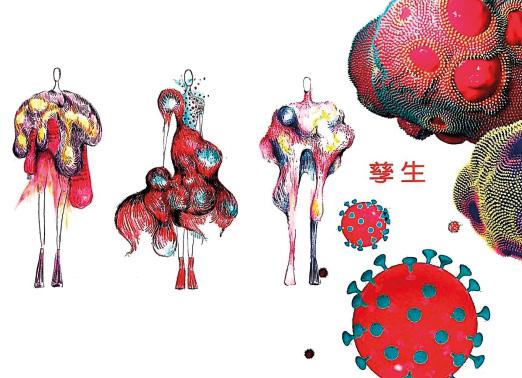

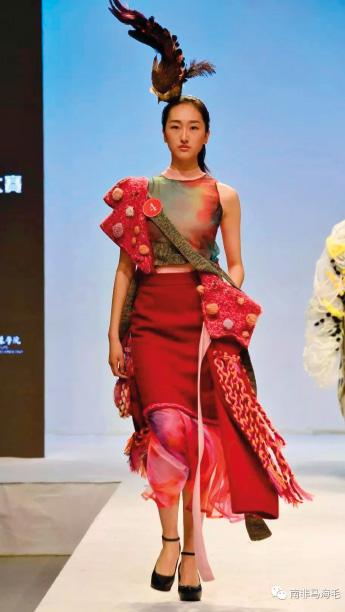

China Mohair Fashion Design Competition

students would walk away with the title of Champion or one of the six special category prizes awarded each year.

Mohair South Africa marketing executive Anle Marais believes the design skill and technique displayed by the students is world class. “The participants flexibly used mohair yarns and fabrics and used excellent knitting techniques to incorporate different forms of mohair in their designs. The integrity of their work, and their expression of design concepts show their understanding of broader market prospects for mohair clothing,” said Marais.

Shanghai, China

For the past four years, young designers from some of China’s most prestigious fashion schools have come together to turn mohair into wonderful garments that stretch the limits of their creative imagination.

The 2018 edition of the China Mohair Fashion Design Competition, in collaboration with Mohair South Africa, did not disappoint. About 40 students from four of China’s most prestigious fashion schools were selected to showcase their designs at a special fashion show in April at Donghua University.

The theme “Awakening Feeling” paved the way for some outlandish yet brilliant designs that brought colours, textures, technique and creativity together seamlessly.

The participating schools – Donghua University, Beijing Institute of Fashion Technology, Xian Polytechnic University and Hubei Institute of Fine Arts – each hoped one of their

Li Lei, general manager of Shanghai Hanzhe Industrial Co. Ltd., one of the event’s main sponsors, said over the last four years this fashion show has established itself as the unofficial authority for mohair trends and designs.

“The number of participating universities continues to increase, and the quality of work showed here has also steadily improved over the last four years. The event calls on society and industry to pay attention to mohair, as it serves as a platform for discovery, training and design talent.

“Here everyone can exchange ideas through competition, and the technical support for yarn manufacturer UPW takes these designs from impossible to possible. This competition truly is the authority and popular source of mohair design,” said Lei.

Top honours at the 2018 competition went to Yuan Renjie, from the Xian Polytechnic University, for his range titled “No Colour”. Ironically his range also won first place in the Best Colour Use category.

*Special thanks to Textile Apparel Weekly

Mohair Journal 2018/2019 40

Champion and Best Colour Application.

Yuan Renjie –Xian Polytechnic University Range; “No Colour”

Mohair Journal 2018/2019 41

Mohair Journal 2018/2019 42

Mohair Journal 2018/2019 43

Winners of the 2018 China Mohair Fashion Design Competition

Top Left: Best Creative Design. Yang Mengtong –Donghua University • Range. “Under the Microscope”

Top Right: Best Craft Skill. Sun Ruijia –Hubei Academy of Fine Arts Range. “GMO. OMG!”

Centre Left: Best Market Potential. Zhang Yong –Hubei Academy of Fine Arts • Range. “Twining Power”

Centre Right: Best Online Popularity. Lyu Dian –Hubei Academy of Fine Arts • Range. “Extravagant”

Bottom Left: Best Yarn Application. Sun Wei –Donghua University • Range. “Over the Top”

Mohair Journal 2018/2019 44

Mohair Journal 2018/2019 45

Ageneration that is trying to break away from labels and live without restrictions has found a voice in a young designer from Port Elizabeth.

It has been a busy year for Gugu Peteni, 24, and if all goes according to plan the hardest work is yet to come, as she aims to take her fashion from the biggest stages in the country, to the epitome of fashion on the African continent – Lagos Fashion Week in Nigeria.

“My ranges symbolise freedom. Freedom from labels, freedom of the imagination, freedom to be whomever you want to be. I want to show our generation that anything goes, and I want to do that within an African context.

“That is why Lagos is the dream – to show my work at the peak of African fashion,” said Peteni.

Growing up as one half of a twin-sister pair, Peteni found a way to express her individuality through creativity – more specifically, creativity in designing and making clothing. She remembers getting into trouble at a young age for cutting pieces from her mother’s curtains to make clothing. Her passion just grew from there.

Her studies at the Nelson Mandela University’s Fashion Design School marked the point when she fell in love with mohair and all the qualities hidden within the “diamond fibre.” To this day all her designs have some element of mohair incorporated into the wider theme of her ranges.

Her breakthrough range “Golden State of Mind” set a series of events in motion that had Peteni featuring at one of Africa’s premier visual arts events, Design Indaba in Cape Town. Her follow-up range “Rise” added to her growing success, securing her a spot

Designing to Break Boundaries

on the popular fashion television programme Project Runway.

“I was completely stunned when my application for Design Indaba was accepted. I think I was still reeling from that experience when I got the call about Project Runway. In fact, it’s still a little surreal to think that I was on the show,” said Peteni.

Project Runway takes 12 fashion designers from across the country and issues them with weekly challenges that are presented to a panel of judges and, through weekly eliminations, one designer is chosen to be crowned the winner.

“I made it halfway into the season before I was voted off, but I am not disappointed at all. I was the youngest designer on the show, went in with an unlimited mindset and knew I was willing to challenge myself. I really learned a lot and made some amazing friends and connections.

“Looking at the pool of talent that was competing for first place, it really was anyone’s game. Any one of the designers could have won it because everyone brought something else to the table. When I left I was happy. It was my time and I think I achieved what I needed to.”

Peteni believes her appearance on television was recognition for the hard work she has put into her career, and has made her much more recognisable among her peers.

Since returning to reality Peteni has not taken a single day off. She immediately immersed herself into her new range “Utopia” and has lined up a string of fashion shows to showcase her work, in preparation for her end goal of Lagos.

“With my previous ranges, I focused a lot on African women and their identity. Golden State of Mind was about getting black women to fall in love with themselves and to affirm their beauty.

Mohair Journal 2018/2019 46

“Rise was the follow-up knitted range, building on the previous theme. It was inspired by the #MeToo movement that saw women speak out against abuse and oppression.”

Her latest range “Utopia” transcends her previous themes and seeks to break away from genders and labels. Peteni refers to the definition of the word utopia - the perfect imagining of the perfect world – and believes this was the next step in the development of her collections.

“Utopia focuses on freedom across genders and labels. The range is not exclusively female and seeks to break away from all restrictions. It is for everyone, yet still keeps its African identity and context.

“The use of mohair elements, no matter how big or small, adds an even more special and unique touch to the range,” she said.

Peteni has lined up a series of fashion shows around Port Elizabeth and further afield. This will help her grow and develop her range, helping her to gauge which items are more popular and what elements she should add before heading to Lagos in October.

“For now that is the goal and, once I achieve that, I will focus on the next step. I am not sure what that is right now, but I am very excited to find out,” said Peteni.

Mohair Journal 2018/2019 47

The rise of a young Port Elizabeth designer

Educating the future of Mohair

The sustainability of any industry relies heavily on having responsible practices and green innovations in place.

Equally important is having programmes in place to ensure the continued growth of an industry, and making sure there are future generations to maintain the existing structures, as well as building on the efforts of previous generations.

Luckily the South African mohair industry has to look no further than the Grootfontein College of Agriculture, the only tertiary educational institute in the country to offer a programme specifically aimed at Angora goat farming and mohair production.

Situated in the heart of the Karoo region, where the majority of the world’s mohair is produced, Grootfontein has been the alma mater of generations of young Angora goat farmers and played an instrumental role in ensuring the longevity of the mohair industry.

“Furthering your studies in the field of agriculture is always a good idea. Many young people believe they can learn what they need from their parents on the farm and, while their experience is invaluable, the knowledge gained through further studies about newer technology and scientific research is very important,” said Hans Greeff, senior agricultural scientists with the Angora goat programme at Grootfontein.

Greeff joined Grootfontein 25 years ago as an agricultural development technician. He grew up in Willowmore, one of South Africa’s top mohair producing regions, and as a child spent most of his free time on family farms, learning about Angora goat farming. After school he studied at the University of Stellenbosch, basing much of his final thesis on Angora goat farming.

Upon completing his studies he joined Grootfontein, and 20 years ago assisted in developing the college’s Angora Mini Farm programme – a practical farming programme that puts third-year students in charge of their own goats and veld.

“In their first year of studies students are taught mostly theory and history, about the various structures in charge of managing the mohair industry. In their second year they do a little more practical farming, learning about goats and the actual fibre, but still spend most of their time learning about sustainable farming practices – breeding, feeding, veld management, agricultural economy and the classing of mohair,” Greeff said.

“In the third year, they get to put everything they have learnt to practical use. They are given a piece of land, a herd of goats and put in charge of ‘their own farm’ so to speak.”

The Angora Mini Farm allows for 11 third-year students to specialise in Angora goat farming and mohair production. Greeff believes the Mini Farm is crucial for cultivating a deep love and passion for the animals that these young students want to make a career of.

Third-year student Phillip Schutte plans to put his Grootfontein education to work when he takes over the family farm, Middelkraal, near Willowmore in the future. But for now, his goal is to become his region’s top field officer.

“The farmers in our region should look at me and say. Now that field agent knows his stuff,” Schutte said, laughing.

Mohair Journal 2018/2019 48

Grootfontein’s Mini Farms, innovations and passion leading the way for mohair.

“Working as a field agent is another important step for me to learn as much as possible about these animals and our industry. All that experience will come in handy when I take over the family farm from my father one day.”

Schutte believes the future of the mohair industry lies in top genetics and feels all farmers should be more hands-on with their goats.

“I am a firm believer that if you look after your animals, they will look after you,” Schutte said.

His classmate Sibahle Ngqondala grew up in a farming community near Cradock, with pigs and vegetables being the main source of income. She was not even aware of Angora goats until she came to Grootfontein.

“As I studied here I learnt more about Angora goats and became increasingly fascinated with their hardy nature and the economics of how efficiently they convert feed to fibre. Every time I go home I tell my family about these goats and they have fallen in love with Angoras just as I did.

“I already have an agreement with my uncle to bring goats to our family farm. We want to get the whole community involved in our future Angora goat farm,” Ngqondala said.

A fascinating development in recent years has been the interest in Angora goats by female students, and how they have reaped top positions both academically and practically.

Last year the South African Mohair Growers’ Association awarded the two top Angora Mini Farm students, Nienke Scholtz and Tanya Hechter, with 10 ewes and a breeding ram for their achievements.

“I think the cute factor of the Angora goat kids plays a role. Few girls can resist the pretty little goats,” Greeff laughed.

“Joking aside, I think the girls pay careful attention to detail. Pair that with hard work and dedication and it’s easy to see why they walk away with top honours.”

Greeff said the development of young woman farmers plays a large part in ensuring the sustainability of the mohair industry. In addition, Grootfontein is constantly researching new science and technology to set Angora goat farming apart from other livestock industries.

“We are always open to new ideas that could possibly advance our industry. Among some of the innovations we have been involved I think our research into the freezing of Angora goat semen was very important,” Greeff said.

Mohair Journal 2018/2019 49

Phillip and Sibahle Phillip Schutte and Sibahle Ngqonodala working on the Angora Mini Farm.

Hans Greeff and his students

For more than 20 years Hans Greeff has been working closely with prospective Angora farmers.

Phillip Schutte Phillip Schutte hopes to take over his family’s Angora goat farm one day.

Grootfontein

The Grootfontein College of Agriculture has the only Angora goat specific programme in the world.

Supplementary Feeding When should we feed Angora Ewes Text |

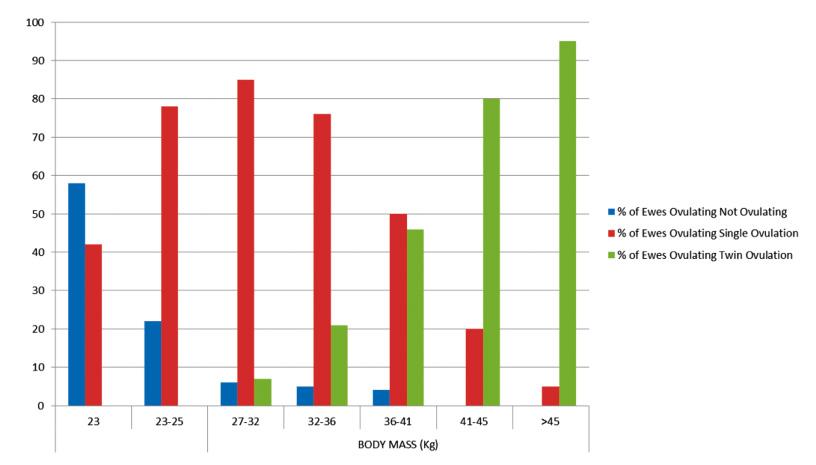

The seemingly endless drought has led farmers to review what the effect of supplementary feeding has had on their ewe and kid production.