Electrical and Safety Testing Service

Full Range of Services

Australia / New Zealand Standards

Full Range of Services

Australia / New Zealand Standards

With over 20 years of experience in the industry, Electrical Testing Services (ETS), specialises in providing top-quality Electrical, Fire, Biomedical, Patient Treatment Area, Auditing and Commissioning Services across Australia and New Zealand. With Triple ISO certification, and soon to receive NATA accreditation, our expert teams ensure your facilities meet the highest standards of compliance, providing peace of mind for healthcare institutions of all sizes.

Our team of certified technicians and engineers are dedicated to ensuring the safety and reliability of all electrical, fire and general safety systems, helping our clients maintain compliance with national regulations and standards.

Personalised Service: We understand the unique needs of each client and tailor our solutions accordingly. We listen to what you want and help you to achieve your targets.

Time Savings: By consolidating all your compliance needs with the one company, we can in most cases reduce contractor visits by two-thirds, (66%) saving you valuable time and administration costs.

Cost Savings: We promise to lower your combined compliance costs by a minimum of 10%, often achieving even greater reductions, particularly in regional and remote areas of Australia. ** (conditions apply)

Join the multitude of healthcare providers who trust ETS to safeguard their operations and reputation by choosing ETS for all your electrical, fire, biomedical and patient treatment area testing and commissioning. Experience peace of mind knowing your compliance obligations are in expert hands. We will provide the guidance and support you need to navigate the complex world of medical compliance with confidence and well-being.

ETS provides a reduced cost service by offering a combination of

Electrical Safety Testing

Appliance Testing and Tagging

Fire Safety (extinguishers, fire blankets, hose reels etc)

Thermal Imaging (switchboards)

RCD Testing (electrical safety switch)

Exit and Emergency Light discharge testing.

Microwave Radiation Testing

Biomedical Testing (body and cardiac RCD protected areas & biomedical equipment safety testing and performance verification) AS3003 and AS3551

On the spot repairs (fire extinguishers, exit and emergency lighting, general lighting, general electrical etc)

With the one team of employed (Multi-skilled) Electricians, Engineers and Technicians

Electrical Testing and Tagging

ETS use the Seaward Elite and PT 300 with full Data Capture.

This tester enables the test records to be stored Internally, which ensures“Proof of test”

Test records stored are date and time stamped, ensuring total accountability.

(RAW test data can be provided)

Our Testers are calibrated annually, and we maintain the calibration certificates.

Test and tagging is a generic name given to the process of visually inspecting and electrically testing in-service electrical equipment for personal safety. Internally, which ensures “proof of test”

It involves three parts:

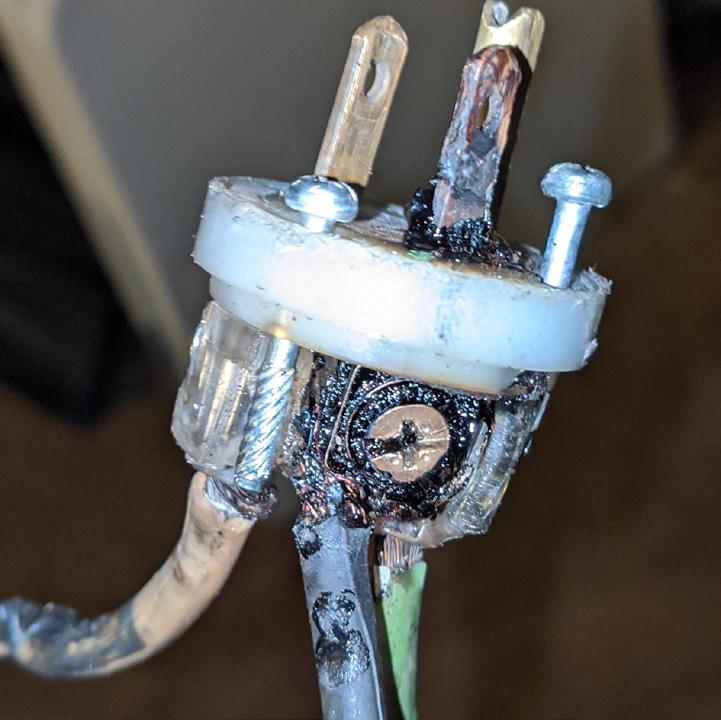

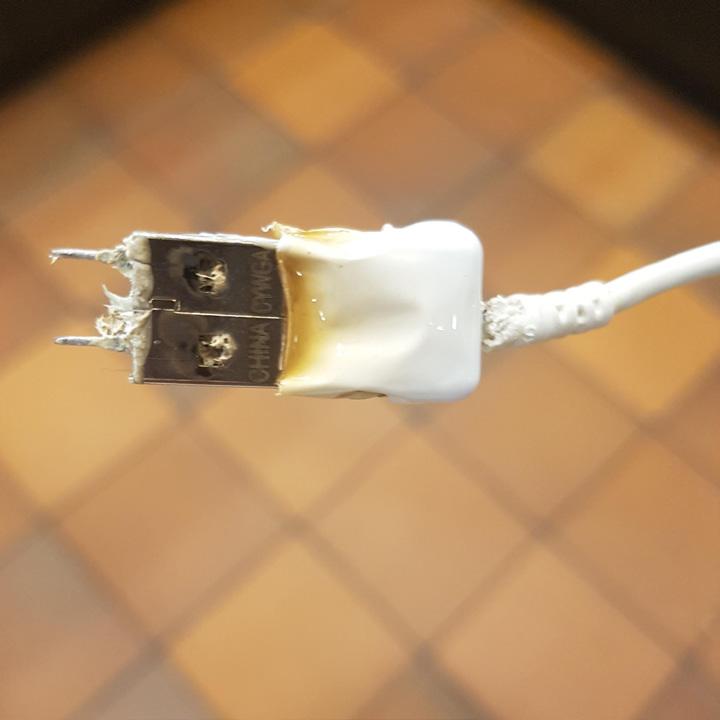

1. Firstly, we unplugged the item and perform a visual inspect of the appliance, looking for any damage to either the body or casing of the item. We also perform a visual inspection of the cable and plug.

2. This process is then followed by an electronic test with a Portable Appliance Tester (PAT) to ensure its electrical integrity and safety.

3. The item is then tagged with a heavy-duty vinyl Test Tag

The Test Tag information consists of:

The persons initials showing who tested it, the date of test and when the next test is due.

A barcode is also applied to the item: The barcode holds all the actual test data and allows the creation of a detailed asset register.

RCD’s (residual current device) are the safety switches fitted in your Electrical Distribution Boards and Patient Treatment Areas (Body Protected Areas).

ETS, again use the PT 300 to test general area RCDs.

However, for Patient Treatment Area’s (Body and Cardiac Protected Areas) we need to use a specific RCD tester for this purpose.

Please note: A standard RCD tester CANNOT test Body Protected Area RCDs

Australian Standard AS3760 – General Area RCDs

Australian Standard AS3003 – Patient Area / Body Protected RCDs

ETS, when performing the RCD testing will need to shut down the power per circuit in order to test the integrity of the RCD. (trip time) Again, I would like to reiterate, we do not shut all the power down at once. This process involves careful planning with the site manager when conducted during business hours. Large Medical Centres, Labs and Radiology will be tested out of hours (night works) and will be planned in advance.

ETS, in those instances will pick up the keys for late night or early morning site access the afternoon before the testing commences. A quick site inspection and briefing with the site manager will also be conducted.

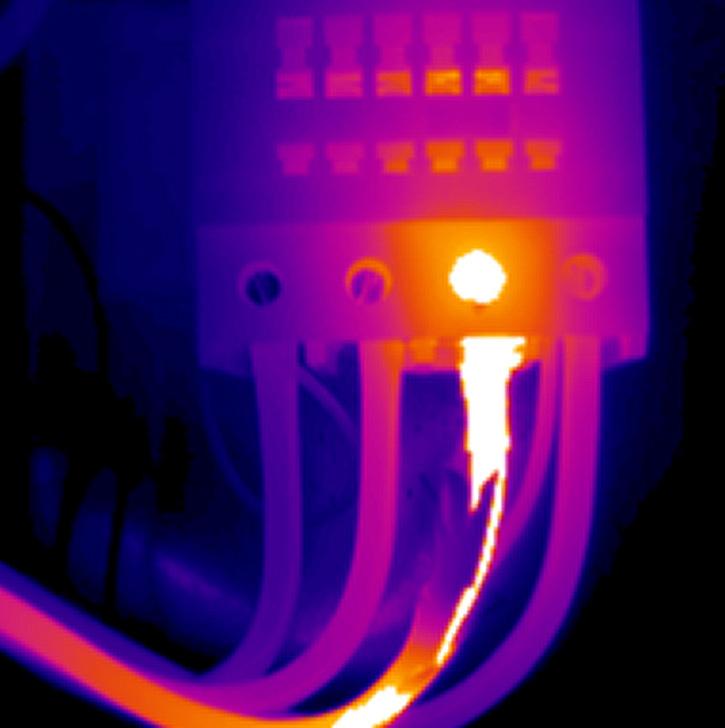

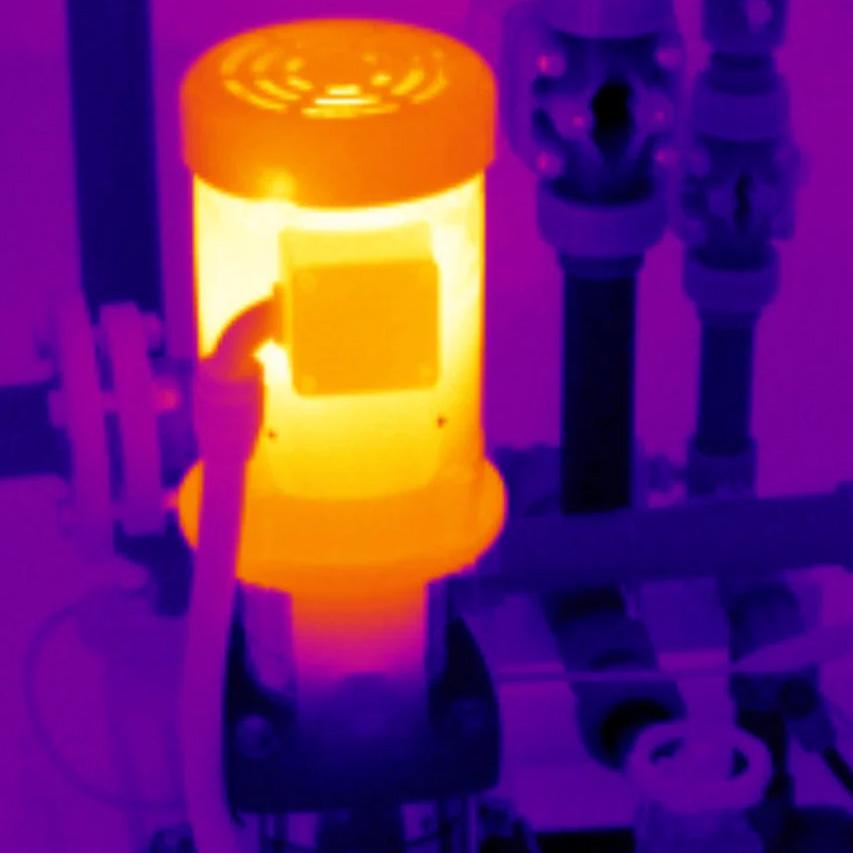

Thermal Imaging detects electrical faults not visible to the naked eye, in most cases before they become dangerous and costly.

Think of thermography as a forensic tool that protects your building and equipment.

ETS look for issues such as hotspots and excessive circuit temperatures.

There are generally caused by:

Excessive loading and phase imbalance.

Loose cables / connectors

If not rectified a failure in the switchboard will occur, generally resulting in a fire.

ETS use the Lindergren Microwave Meter. These meters are one of two professional Microwave Meters that can correctly perform Microwave leakage tests.

ETS do not use cheap inferior meters that seem to be quite common place these days. Our test apparatus are also calibrated annually.

ETS will ensure all testing and maintenance is carried out in accordance with Australian Standards. Any out-of-date Fire Extinguishers will be swapped over on the spot to maintain compliance and save a return to site fee.

ETS, as part of our fire safety compliance service provide Exit and Emergency Light periodic inspection and testing. ETS will conduct a 6 monthly and annual discharge test as required by the Australian Standard. One major benefit of using ETS is that we employ electricians that can perform repairs on the spot keeping your site complaint, as well as saving on costly return to site call outs.

ETS can perform Electrical Safety Testing and Performance Verification on your Biomedical equipment to AS3551 helping ensure that the risks arising from electrical hazards are maintained at acceptable levels during the useful life of the equipment.

As part of this service, we also perform a “Performance Verification”.

Throughout the lifetime of medical equipment in clinical use, there is a need for regular assessment and testing of the medical equipment to ensure it is safe and continues to be safe, whilst providing accurate readings.

Performance verification generally involves both physical inspection and functional testing in accordance with manufacturer guidelines (including device inputs, outputs, alarms and safety or protective functions)

Detailed reports are provided for each piece of Biomedical equipment.

ETS has M-Class license inspectors and a specialist team to provide the following services.

Consulting service on the design of patient areas

Facility audit to ensure patient area requirements are met

Commissioning of new and upgraded body-protected or cardiac-protected areas

ETS will provide detailed service reports identifying all aspects of the service undertaken.

Failed items will be identified and photographed, with a reason for failure noted.

A detailed summary report of all assets tested, including the asset type and the quantity of each item will also be provided as part of our service.

Reporting, including BPARCD Test results for Patient.

Treatment area’s will be provided, meeting all the requirement as per AS3003:2018

Reporting on Biomedical equipment, including Autoclaves and Vaccine fridges will be provided as per AS3551, (Per asset tested).

At ETS we use QR codes for the biomed equipment. This will enable all detailed reporting to be stored against each device for prompt on the spot access.

All switchboards will be barcoded and labelled with a “date of test” tracking system for quick identification of compliance.

QR Codes are provided by ETS in addition to our service, facilitating quick and easy access to:

Completion date

Job Description

Download Compliance Report

Service Report

System Count Summary

Location QR Codes are available - supports quick and easy access to:

Job Site Details

Job Service History

Asset Type Summary

Pass – Fail Summary

Asset Report

Wall mounted or simply place in your Admin Folder.