MINE WATER MANAGEMENT

The five key lessons learned in implementing a mining water evaporation solution.

FEATURING

SEPTEMBER 2021

WEBINAR

MINE WATER MANAGEMENT 1. WELCOME 2. EDUCATION 3. SELECTION 4. APPLICATION 5. PERFORMANCE 6. OUTCOME 7. SUMMARY 8. Q&A The five key lessons learned in implementing a mining water evaporation solution. AGENDA

SPEAKERS

OUR

OUR SPEAKERS

CHAPADA, BRAZIL

APPLICATIONS

• Process & produced water disposal • Tailings & storage dam overloading increasing risk of catastrophic failure and collapse • Legacy & mine closure site wastewater issues • Landfill water management • Closure of ash basins, dewatering • Leachate water management • Uncontrolled release of contaminated mine water causing environmental harm • Extreme rainfall events and flooding

1

EDUCATION

#

UNDERSTANDING WATER EVAPORATION MANAGEMENT SYSTEMS

1. 2. 3. 4. Appropriate (Air/Water) 2000:1 Ratio Water Droplet Particle Size High-Velocity Air Stream Large 4mm dia. Orifice Water Fracturing Nozzle Design FOUR KEY PRINCIPLES

EVAPORATORS IN ACTION

PANEL DISCUSSION

SELECTION

#2

COMPARING WATER EVAPORATION TO OTHER ALTERNATIVE APPROACHES

COMPARISON

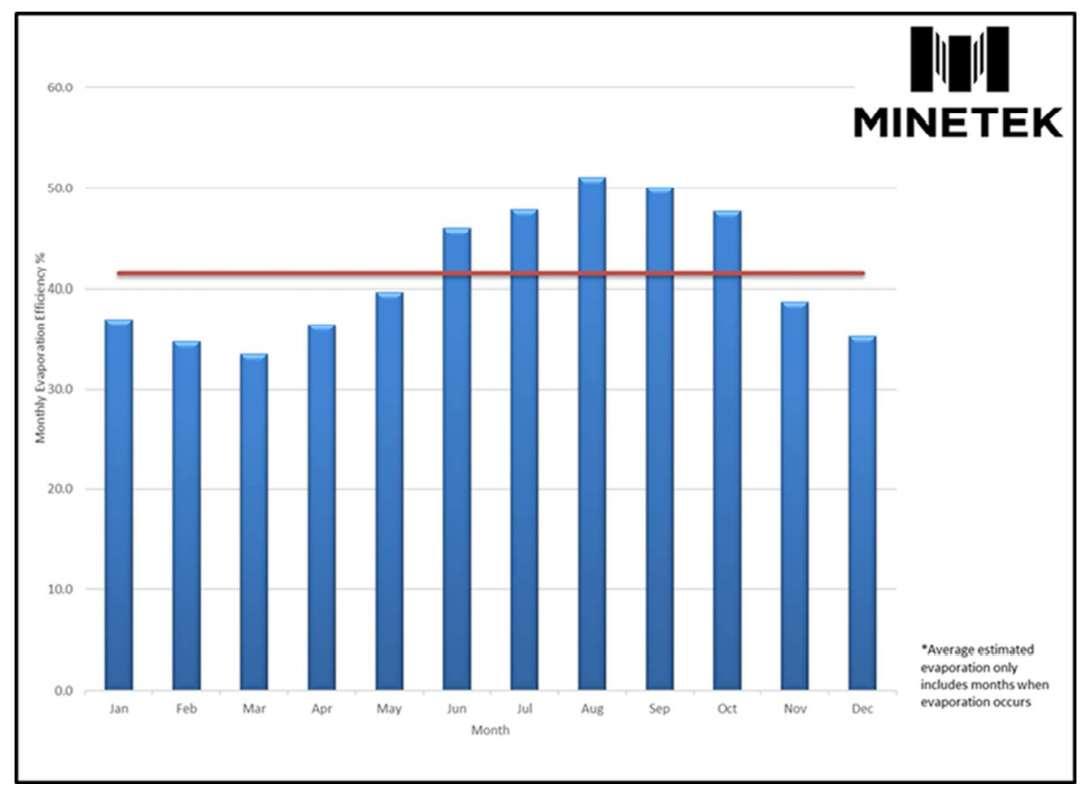

EVAPORATION PERFORMANCE MODELLING

• Site Specific Meteorological Data Modeling • Optimum Site Specific Air to Water and Energy Ratio Selections • Chemical and Physical Characteristics of the Water • Droplet Evaporation Modeling

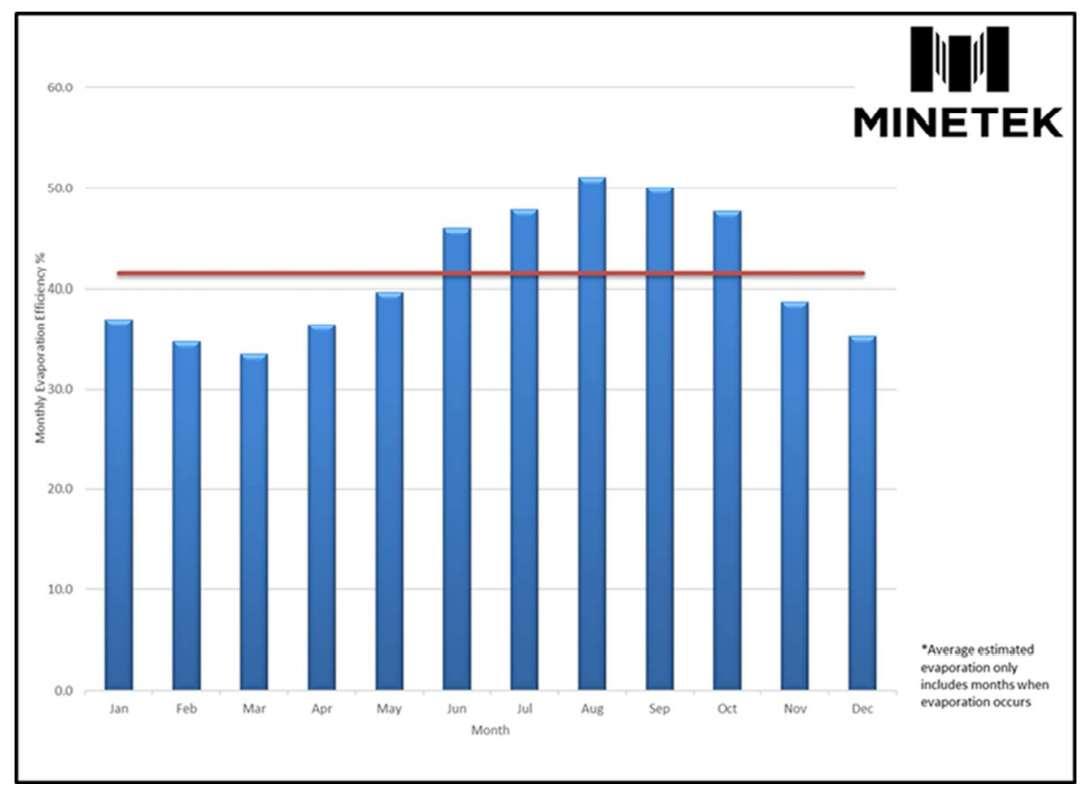

EVAPORATION EFFICIENCY ESTIMATES

EVAPORATION EFFICIENCY ESTIMATES

EVAPORATION EFFICIENCY ESTIMATION Based on 41.5% a single 600/300 evaporator will evaporate… 41.5% > 56m3 / 249 GPM > 896m3 / 358,560 GPD Hour Day Year > 327,040m3 / 130,874,400 GPY BY THE NUMBERS

PERFORMANCE MODELLING

PROBLEM SOLVING

COMMUNICATION

QUALITY

PRODUCT +

+

+

+

PANEL DISCUSSION

3

APPLICATION

#

ENGINEERING & INSTALLING A NEW SYSTEM

SOLUTION

COMPLETE ENGINEERED

• Evaporation efficiency modelling • Water quality analysis and review • Materials of construction selection • Plume modelling and analysis • Designing system requirements to achieve target evaporation rates • Design of automation control & operational parameters • Design & scope of mechanical and electrical requirement • Construction & Operation

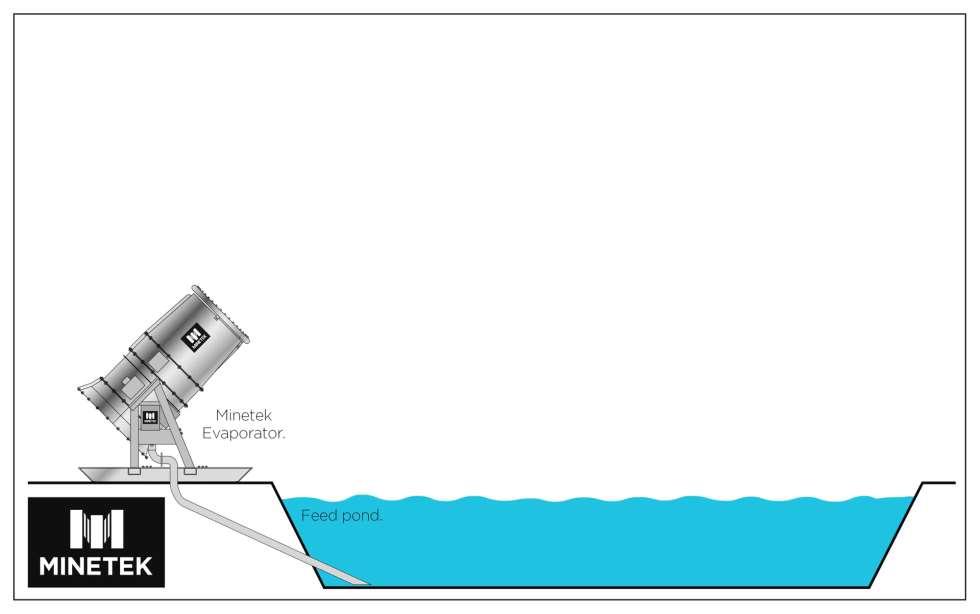

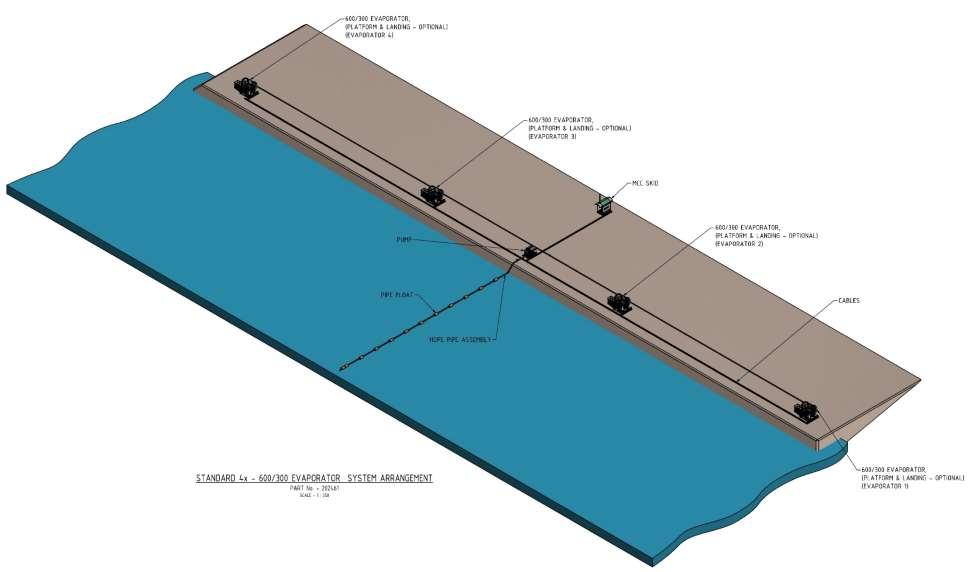

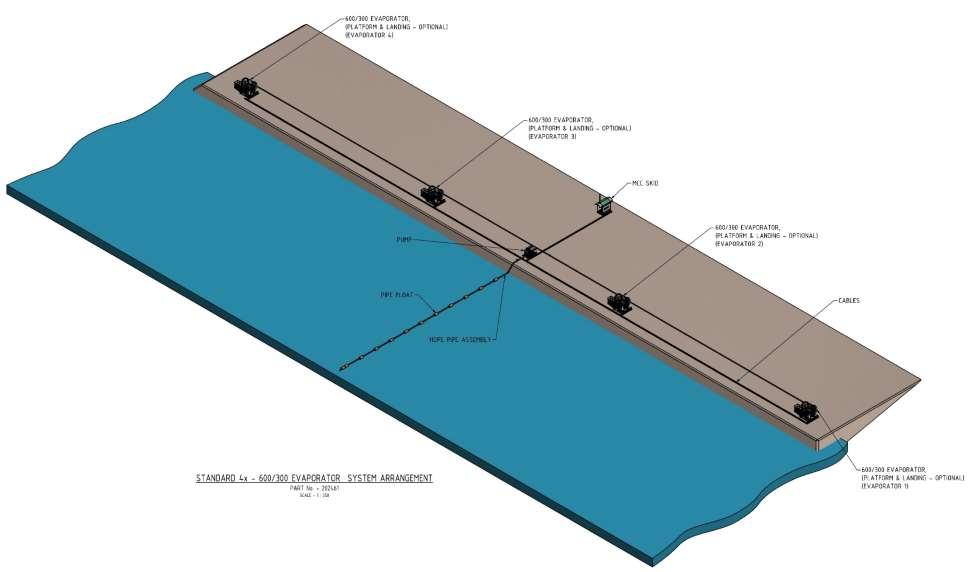

UNIT LAYOUT OPTIONS

UNIT LAYOUT OPTIONS

TURNKEY SOLUTIONS

ELECTRICAL MCC ON SITEBANK OF EVAPORATORS OPERATING

PIPEWORK SET UP WEATHER STATION ELECTRICAL CABLE

PUMP ON SITE

ELECTRICAL MCC ON SITEBANK OF EVAPORATORS OPERATING

PIPEWORK SET UP WEATHER STATION ELECTRICAL CABLE

PUMP ON SITE

MINETEK MODEL 600/300 EVAPORATOR 600/300 UNIT, FITTED WITH OPTIONAL SAFETY PLATFORM AND STAIRWAY 600/300 Water Flow Rate 600 GPM (135m3/hr) Power 120 HP (90kw) Pressure 145 PSI (10 Bar) Mobile skid mounted unit Galvanised steel, EPOXY coated or 316 Stainless steel 316 Stainless steel wetted parts Globally patented technology

MINETEK EVAPORATORS 600/300 400/200 200/100

ENVIRONMENTAL MANAGEMENT SYSTEM (EMS)

To maximise the performance of the MINETEK

Evaporators, a control system is available to autonomously operate the Evaporators under varying environmental conditions.

The automation systems are designed by MINETEK and utilize high quality PLC’s, robust Australian made weather sensors and high quality motor control components to provide the tools necessary for autonomous operation.

shut down due

High humidity

Rain

Automatic

to: •

•

• Excess drift (high wind speed) • Unfavorable wind direction • Set time periods

AUTOMATIC ANGLE ADJUSTER (AAA)

The Automated Hydraulic Angle

Adjuster automatically adjusts the angle of the Evaporator based on different wind speeds.

This mechanism works in conjunction with the EMS and provides flexibility for the evaporator to operate in a broad range of weather conditions.

PANEL DISCUSSION

PERFORMANCE

#4

ASSESSING THE CAPABILITIES OF WATER EVAPORATION MANAGEMENT

CHAPADA, BRAZIL

CASE STUDY: GOLD MINE IN NUNAVUT

Client: Gold mine in Nunavut System Configuration: 5 x Model 400/200 evaporators, stainless steel Automation: Fully automated design System Capacity: 2000 GPM (450m3/hour) pumped (5 units) Task: Gold mine tailings dam effluent management solution to reduce volume or TSF. Water Quality: Extreme saline water Seasonal northern climate

CASE STUDY: GOLD MINE IN BRAZIL

Client: Gold mine in Brazil System Configuration: 2 x Model 400/200 & x 600/300 evaporators, stainless steel System Capacity: 2000 GPM (450m3/hour) Task: Gold mine tailings dam effluent management solution to reduce volume of TSF. Features: EPOXY coated evaporators for low pH water, sound attenuation package. Urgent delivery

CASE STUDY: POWERPLANT IN MONTANA

Client: Powerplant in Montana System Configuration: 10 x Model 400/200 evaporators, stainless steel Automation: Fully Automated design System Capacity: 4000 GPM pumped (900m3/hour) pumped (10 units) Water Quality: Coal ash pond water, high TDS

PANEL DISCUSSION

OUTCOME

#5

EVALUATING THE RESULTS

DID WE OFFER THE BEST SOLUTION?

PANEL DISCUSSION

Q&A OPEN QUESTION & ANSWERS SESSION

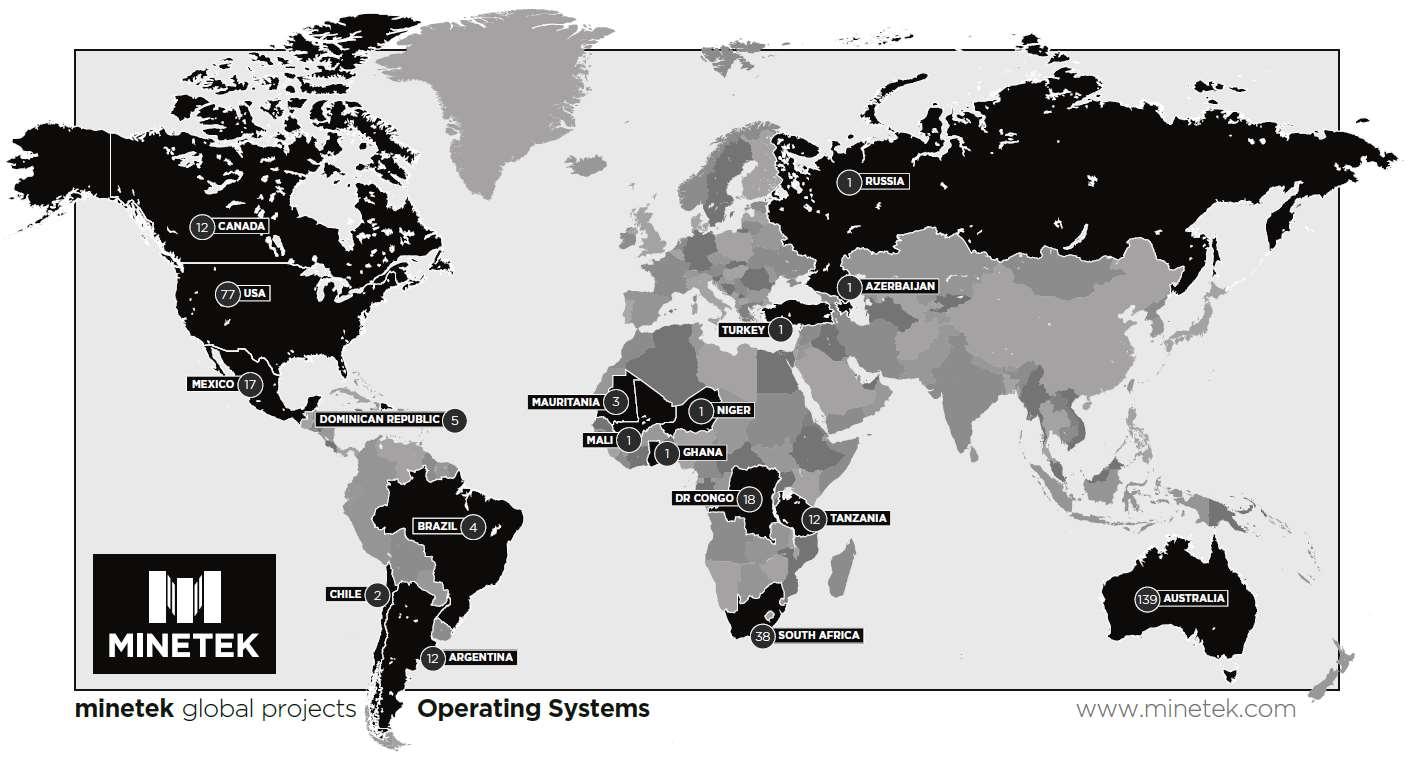

ON THE HORIZON

MINEXPO 2021 SEPTEMBER 13TH – 15TH 2021 LAS VEGAS – NEVADA, USA BOOTH: 3165 NORTH HALL B.C MINE SYMPOSIUM SEPTEMBER 22ND – 23RD 2021 VIRTUAL EVENT SEE MORE OF MINETEK

THANK YOU • ON DEMAND ACCESS • SESSION LINK PROVIDED VIA EMAIL • OUR TEAM WILL BE IN TOUCH