Lundin Mining Case Study

Water evaporation solution at Chapada Mine.

Water evaporation solution at Chapada Mine.

Lundin Mining’s Chapada operation in Brazil is an open-pit copper and gold mine. It has been in production since 2007 and by the end of 2021 it is scheduled to have produced 50,000 tonnes of copper and 76,000 tonnes of gold.

Lundin Mining had already explored many mine water management solutions, including using water cannons and sprinklers. The low success rate of these past solutions led Lundin Mining to initially question Minetek’s water evaporation proposal.

Proven results were paramount to the Lundin Mining team, so Minetek presented Lundin Mining with evaporation efficiency and performance modelling, comparisons to other solutions, cost analysis and more.

Localised climactic conditions such as temperature, humidity, rainfall, wind speed and direction, and elevation are all factored into the analysis. This environmental analysis is part of Minetek’s standard service and demonstrates the estimated evaporation rates throughout the year.

Lundin Mining contacted three previous customers before agreeing to the partnership with Minetek.

All three customers, from different climactic conditions in Canada, Australia and America endorsed Minetek’s water evaporation solution. Their positive testimonials and varying environmental conditions were vital to the decision-making process.

Ed Kelleher - Director of Environment Lundin Mining CorporationWhat we got from Minetek: Enhanced ability and capabilities for mine water management

After the initial proposal sign-off with Lundin Mining Management, Minetek finalised the engineering and design process with the team on-site at Chapada. Working closely with the operations team, the Minetek project team were agile with final changes to specifications.

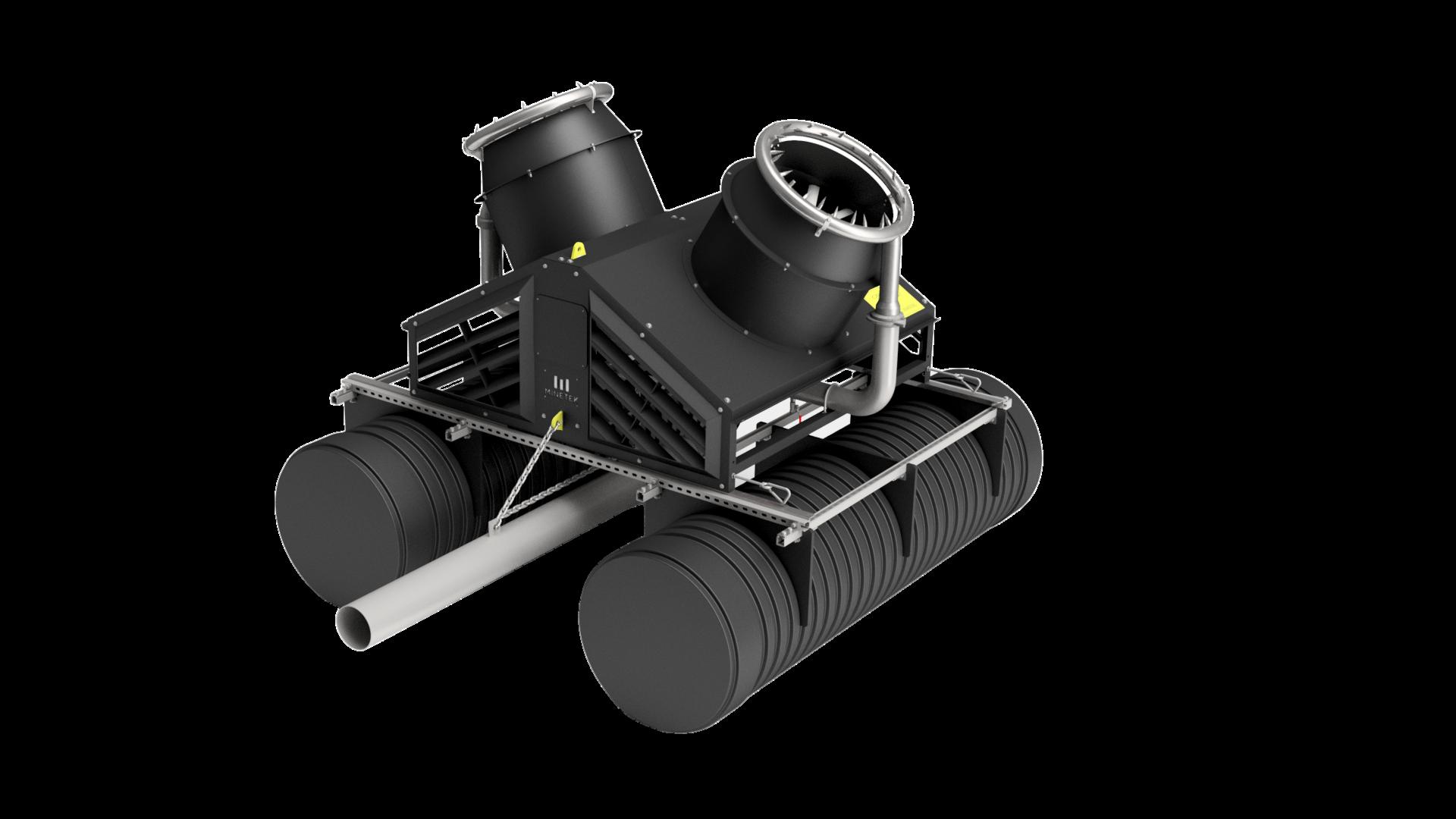

The 600/300 water evaporator model was selected as the best fit for Lundin Mining’s requirements at the Chapada site.

The water evaporator model selected was epoxy coated for additional longevity. Once completed the water evaporators were shipped from Australia to the site in Brazil, where the on-site team installed them with the support of Minetek’s project management team.

Water flow rate

Power Pressure Features

Imperial 600 GPM (gallons per minute)

120 HP (horsepower)

145 PSI (pounds per square inch)

Mobile skid mounted unit

Metric 135m3/hr (cubic meters per hours 90 KW (kilowatt) 10 Bar (unit)

Galvanised steel / epoxy coated / 316 stainless steel

316 stainless steel welded parts Globally patented technology

To maximise the performance of the Minetek Evaporators, a control system is available to autonomously operate the evaporators under varying environmental conditions.

The automation systems are designed by Minetek and utilise high-quality PLCs, robust Australian-made weather sensors and high-quality motor control components to provide the tools necessary for autonomous operation.

Automatic shutdown due to:

High humidity

Rain

Excess drift (high wind speed)

Unfavourable wind direction

Set time periods

Based on a single 600/300 evaporator. Operating in the humid climate of Brazil.

After the successful installation of water evaporators at Chapada, Lundin Mining has continued to work with Minetek to install water evaporators at additional sites, including their Neves-Corvo site in Portugal.

While Lundin Mining is still collecting long-term data on the results of the new evaporation system, they have been positive about the initial results. Due to this initial success, additional evaporation solutions are being implemented across other Lundin Mining sites.

Minetek will continue to work with the individual locations to customize the solution, based on their unique climactic conditions.

Each project is treated like a new customer, which means that each site will receive site assessments, evaporation modelling, and ongoing support.

Water flow rate - 135m3 per hour or 600 gallons per minute

Water

Water