877.638.6190

dmillius@MHWmag.com

Handling

877.638.6190

dmillius@MHWmag.com

Handling

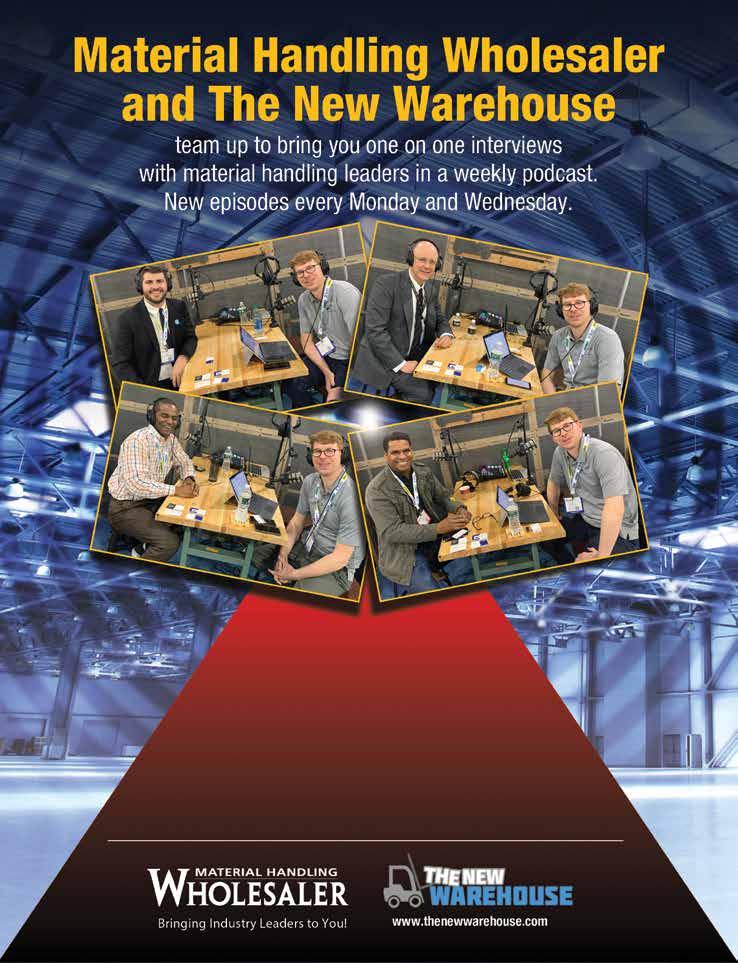

Pandemic conditions have improved, but the new era of labor shortages and increased demand continues for warehouses. In this environment, some say a steady increase of automation within warehouses is occurring. This month, Material Handling Wholesaler talks with industry leaders about how they see automated processes building new opportunities in warehouses across the industry.

At AutoScheduler, CEO Keith Moore said the company aims to be “the brain” inside distribution centers. The company launched two years ago inside Procter & Gamble, where Moore said the business founders “cut our teeth.” AutoScheduler.AI is a warehouse resource planning and optimization platform that “dynamically orchestrates all activities on top of your existing warehouse management system in real-time,” the business website said. The solution is designed to focus on and optimize all of a warehouse’s critical activities, including dock scheduling, loading, unloading, case picking, and creation of transfer orders, the site said.

“With more supply chain challenges than ever, AutoScheduler combines data from numerous systems into a single operational plan for warehouses and distribution centers. It takes disparate data, identifies bottlenecks, and prescriptively creates plans to orchestrate campus operations for optimized efficiency,” the website said. The aim of the company is to help planning to be more effective, according to Moore, who said today AutoScheduler workers with some of the largest consumer goods providers in the industry.

As a solution designed to work on top of a Warehouse Management System to orchestrate plans and processes, AutoScheduler is able to work many moves ahead of what is occurring, according to Moore. He said this is not unlike how technology is now able to orchestrate outcomes in a chess game. In chess, there are 64 squares and 16 pieces under a player’s control, and “since 1997, it has been impossible for a

person to beat a computer,” said Moore, noting how many moves ahead a computer can see.

Similarly, AutoScheduler is designed to incorporate a bigger picture in coordinating items, people, and equipment. The more complexity, the more opportunity, according to Moore.

In the current environment, Moore said he believes inventory concerns for warehouses might “smooth out a bit” but labor will remain in demand. “That’s part of why automation has become so popular over the past few years,” he said, noting there are fewer employees working many years on a job, making it more difficult for companies to build the productivity and consistency desired.

“People are understanding they need to do something to get consistent productivity out of the warehouse, to be able to meet the demand in a consistent way,” Moore said. “The challenge is, people that run operations, they’ve been in supply chain and logistics for a while and they’re not technologists,” he said. This is where AutoScheduler can help, according to Moore.

He said AutoScheduler solutions help to orchestrate planning systems, making sure all of the processes flow and work together. In general, Moore thinks productivity rates are a little lower today versus five years ago due in part to the impacts of labor shortage. “It’s hard to replace a really experienced forklift driver,” Moore said. That said, he also believes warehousing and operation teams are more innovative now.

“Warehouses are probably getting the investment needed,” said Moore, who said there are more technologists and more investment in automation overall. And as focus outside the industry focuses on supply chain and material handling in general, Moore added that it is a “remarkable” industry to work in. “It’s warehousing’s time to shine,” he said. “We can take opportunities and take advantage of what we have to innovate and drive value.”

While most companies look at only the floor space, we look at the whole space. Wildeck offers customized solutions to maximize every part of our customers’ businesses. So, look us up.

Tecsys is also offering solutions for warehouses across the globe. The company’s supply chain solutions software is currently used in over 100 countries across the world, according to Adam Polka, Director of Public Relations. “Our solutions and services create clarity out of operational complexity with end-to-end supply chain visibility. Our customers reduce operating costs, improve customer service, and uncover optimization opportunities,” said the business website.

Bill Denbigh, Vice President of Marketing, described how many of the company’s Nordic partners have incorporated automation in operations of all sizes. “They look at automation as part of being a solution to the future. I think there is a realization that adopting advanced supply chain solutions isn’t anymore just for the big boys,” Denbigh said. As automation solutions are explored in companies of all sizes, tighter circumstances are sometimes a driver, according to Denbigh. “I’ve got to get today’s orders out by 2 p.m. or I’ve got real estate issues I can’t outgrow anymore. Or I want to offer my customers a service that my competitors don’t offer or can’t,” he said.

Automation offers ways to personalize, create unique packaging options, and more, according to Denbigh. He is seeing more engineering work in warehousing, describing one of Tecsys’ customers, a third-party logistics provider, that has many engineers on site. “They take an organization in and say, ‘We’re going to design a system for you. Specific racking, processes, we’re going to allow you to do these things,” Denbigh said.

He also described how one of Tecsys’ customers designed systems to create the special sustainable packaging their own customers wanted. “It’s not going to slow down. It’s going to be a force,” he said, of automated advances, describing how his wife’s shampoo company sends her the product she wants when she needs it and with her name on the label.

All of this requires a sophisticated process. “Think of the technologies that are required to supply that,” said Denbigh, noting how well this tailored approach works. “It’s locked in my wife as a consumer,” he said. A grocery retailer,

however, would not require this type of system, according to Denbigh. So, he envisions a future of specialization within warehouses.

Tecsys offers diverse solutions, from a simple warehouse management system that is implemented from the first touch to life in 28 days to an enterprise-grade system in which a project can be six to eight months, according to Polka. “Automation is not one thing,” he said, advising businesses to consider what a company needs and to make plans and adjustments from there.

“It’s a journey. You don’t take your first steps along a journey unless you know where you are going,” Polka said. “It’s all about understanding what you’re trying to solve, the specifics of where your business is going, and where you want it to be in a few years. The items you’re handling, the volume of orders, and the time frame. And then deciding what kind of automation is needed.”

Denbigh agreed. “Automation’ is such a multi-faced thing. Just because you’ve got cobots running around doesn’t mean you’ve solved your problem,” he said. Denbigh noted some of the low-impact, easy-to-implement automated systems available today didn’t exist five to ten years ago. Mid-to-small size warehouses can adopt them with a level of skill and technology,” he said.

In general, automation is becoming more accessible for warehouse operations, according to Denbigh. “It’s exciting times. There is a lot going on, there are a lot of people trying lots of things,” he said. While supply chain and labor issues continue, there is plenty of progress, too, according to Denbigh. “There’s a lot of success going on. Lots of projects happening,” he said.

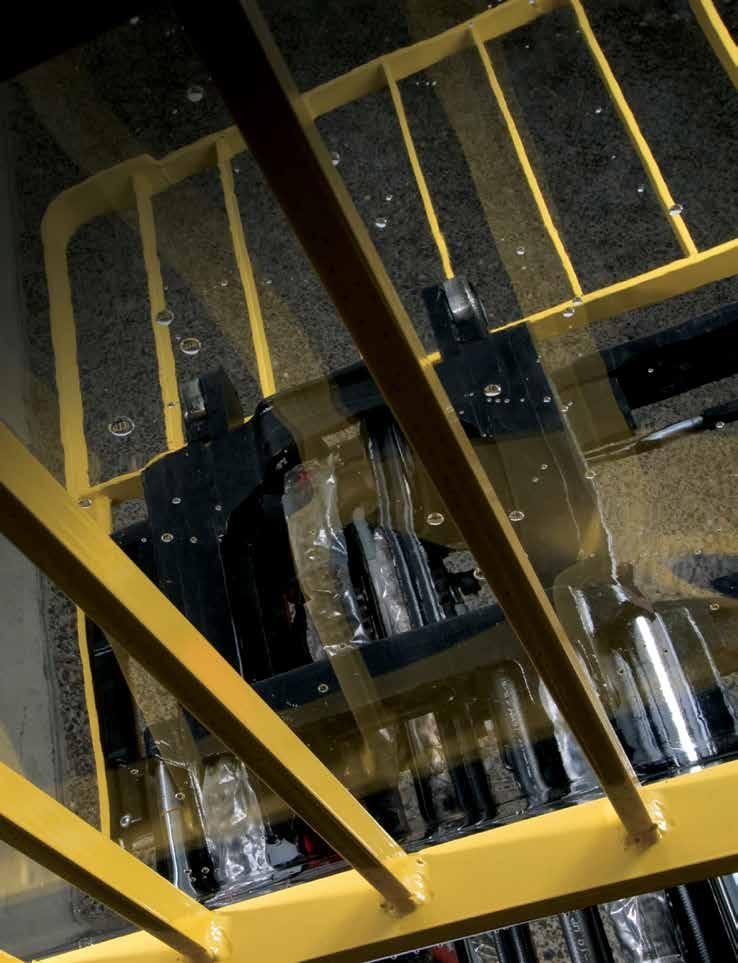

While automation used to be reserved for only large pallets or case warehouses, times have changed thanks to e-commerce, growing SKU catalogs, lean inventory policies, and increasing customer expectations, according to Jon Schechter, Business Development Manager at AutoStore. “In the past decade, new solutions, while important, have also contributed to the pile of brown cardboard boxes that accumulate outside our homes,” he said.

Modern solutions tend to be modular, allowing warehouses to scale down to small and medium-sized facilities, according to Schechter. “What’s exciting is that this collaboration can increase the overall productivity of a workforce by 2 to 4 times,” he said, noting that modular solutions also allow for inventory to be condensed and therefore be located in distribution centers closer to consumers.

Automation is “an enticing draw” for employers in a tight labor market, allowing brands to restructure staff or to get more done with less workforce, said Schechter. In most cases, automation is a goods-to-person solution, which Schechter said can help increase order fulfillment ties exponentially and allow warehouses to better utilize existing resources. The time it takes to deploy automation in a warehouse hinges on several factors, according to Schecther.

“At AutoStore, we’ve been able to deliver working systems in three months, but our standard lead time is 12 weeks from purchase order to delivery from our factory,” he said,

noting that one of the most important things to keep in mind when moving to automation is the amount of time needed to implement the system in the distribution center. “So plan for six to 12 months for most automation projects. In this time period, detailed design, site readiness, software integration, and project planning need to be considered as well,” he said.

Companies should also take into account business growth. “The storage capacity you have at the moment may not be best later down the road. Phasing can allow a seamless transition within a live operation, and more than half of the systems we deliver at AutoStore are expanded at some point to meet growing storage and/or throughput needs,” Schecther said.

To help work around delays that sometimes occur, Schecther advised planning ahead. “The material handling industry has not been immune to the component and transportation delays of the past two years. Shortages put a major strain on distribution centers because e-commerce orders do not cease just because inventory is low,” he said. “At AutoStore, we’ve been able to predict and communicate lead times regularly to ensure we meet customer’s desired dates,” Schecther said.

“For other brands, supply chain shortages have increased the need to expand storage depth onshore to meet demand. This is where automation can play a major role. When the automation solution reduces storage footprint but increases the storage density, there is the potential to increase the SKU volume and breadth,” he said.

Over the last six years, I have spoken with many people in our industry about their company’s digital strategy, more specifically e-commerce and selling their products online. With November being the start of the holiday shopping season, especially online shopping, I thought it would be fitting to write about this topic as e-commerce and digital strategies continue to gain momentum in our industry.

There are many elements you must consider when developing a digital strategy for your business. These elements include digital marketing and advertising, customer communication channels, search engine optimization (SEO), and e-commerce. As I noted in last month’s article, the material handling industry is primarily B2B and these customers increasingly expect B2C convenience and customer experience. Therefore, creating such an experience should be the foundation of your digital strategy. Also, be sure to take note of what your competitors are doing. In addition, be mindful of what your suppliers and manufacturers are doing.

As you consider these elements of your strategy, you need to determine what the goals of your strategy are. Are you looking to increase sales? Are you looking to target new audiences? Are you looking to improve how you appear on search engines? Determine what is most important and tailor your strategy accordingly.

For example, if one of the goals of your digital strategy includes growing the sales of your product portfolio, then your focus and efforts would need to be on the development of an e-commerce site or platform for your customers to purchase your products from you online. If one of the goals of your digital strategy is to increase your brand awareness and customer engagement,

then your focus would be on digital marketing through various channels such as social media and email. If you are looking to target new audiences and increase customer leads, your focus should then be on search engine optimization and targeted content marketing. These various elements of your company’s digital strategy need to be considered during the analysis stage of your digital strategy plan.

Ecommerce was on an accelerated growth pace, even before the COVID-19 pandemic.

As you know, store closures and fear of getting COVID-19 during the pandemic created a major shift in consumer buying behavior, which further accelerated this growth pace. This growth was not just exclusive to things we became accustomed to ordering online like shoes, apparel, and electronics; things like groceries and fast food were now being purchased online by consumers that may not otherwise have purchased online prior to the pandemic. As with everything else, that B2C customer experience and shift of buying behavior to the ease of online transactions is now an expectation of your customers and prospective customers in the B2B world.

It is important, now more than ever, to provide customers with the option to purchase your products online. However, you need to be strategic about what you are setting out to accomplish with your e-commerce site. Let us say, for example, that the goal of your e-commerce site is to increase the sales of your products through your parts department. Awesome! Turn on the e-commerce switch and watch the parts department sales grow, sounds simple, right? Not so fast, there are a few things to consider and missteps to avoid as you look to deploy an e-commerce site as part of your digital strategy.

One misstep I see that dealerships make when developing their e-commerce site is the lack of automation. Your site should not only be an intuitive and seamless experience for your customers but should also be a seamless

transaction for your business. What I mean is that you do not want the transaction to be ‘clunky’ for your staff which creates additional manual steps to process an e-commerce order. Talk with your suppliers, many offer web services integration that allows for real-time pricing, availability, and order submission.

Another misstep along those lines is the service level that accompanies the e-commerce experience. Make sure your e-commerce site allows for easy contact with your customer service staff as needed. Therefore, be sure to implement features like chat, a dedicated phone line, and a dedicated email address or online contact submission form. You still need to keep in mind that your service level will set you apart from the competition. Furthermore, a great user experience in this regard may lead to other opportunities for your other products and services such as new equipment, rentals, or service work.

Another consideration, which I feel is one of the most important, will your e-commerce site interface with your ERP business system? If you are operating on an older business system, this could potentially create limitations for those looking to interface their site with their system. Talk with your ERP provider; see what resources they have available to assist with integrating your business system and your e-commerce platform.

Additionally, consider how you will price your products online. I would recommend exploring a ‘Login’ model. This allows your current and loyal customers to have another avenue to purchase your products but also allows for special, discounted, and volume-based pricing for those customers with a unique login as needed. In addition, will your pricing model be static or dynamic? This is a topic we can explore in future articles.

Finally, seek feedback from your existing customers. Identify any potential "pain points" that exist for customers that purchase your products today. You want your e-commerce site to provide them with the ability to self-service and the ability to order your products at their convenience.

Having a good e-commerce site will not only help you retain and grow existing loyal customers, but it will also attract new customers and help build your brand.

Simply stated, search engine optimization, or SEO, is the battle for the top listing on a given search engine page. More importantly, since Google is the market share leader in the search engine space, let us call it the battle on Google search. You can develop the most intuitive, user-friendly website and e-commerce platform, however, if you cannot be found at the top of a Google search page then obviously you are missing potential customers and business.

There is plenty of information out there on SEO, so not my intention here to define SEO or the differences between B2C SEO and B2B SEO. The point is to ensure your marketing team or whomever you enlist to oversee your e-commerce site, understands who your target customer is. They should consider the buying journey of the audience you are targeting and want to attract to your e-commerce site. So be sure to make SEO a part of your digital strategy and focus on implementing the best practices.

If you do not already have a digital strategy in place, now is the time to develop one for 2023. Dealers that have a good digital strategy in place will prove to be successful as the expectations of customers continue to evolve in this industry. Dealers who have shifted to rely more on digital technologies will continue to improve the customer experience and will enhance the interactions between their customers and their sales teams.

Chris Aiello is the Business Development Manager at TVH Parts Co. He has been in the equipment business for 15-plus years as a service manager, quality assurance manager, and business development manager. Chris now manages a national outside sales team selling replacement parts and accessories in various equipment markets such as material handling, equipment rental, and construction/earthmoving dealerships.

If you have been keeping up with our wonderful economic news you came across comments about Boomers leaving the workforce in droves because they feel they have enough of a nest egg to live on. Hope they are right.

As a result of these retirements, however, there are thousands of businesses for sale, with sellers not really aware of what they have to sell. Some do not even know that what they have is sellable. They will just unload any equipment they own and call it quits.

This scenario is especially prevalent in the construction business because if you are a contractor to whom can you sell? Not many people are not your direct competitors. And if you do that, you can guess what the pricing will be.

Many of these business owners came to that fork in the road. Either to stay the course and do what they must do to grow the business with existing as well as new customers. Or covert assets to cash and move south to warmer climates because as an owner they were not prepared nor interested in doing what you had to be done, nor able to spend the money to upgrade their operation to remain competitive.

In other words, upgrading your business is no longer an option. The digital world is taking over, your customers today grew up in the digital world and they expect to do business via the digital world. Is it any wonder why there are so many family businesses for sale?

Look how some young entrepreneurs are taking advantage of this situation can be found on YouTube. Look up a young lady named Codie Sanchez and see what she is doing to make herself rich. Right now, she owns 26 companies that she converted from their historical business practices into modern money makers. It is quite an interesting story, and every one of you could duplicate it if you wanted to. It is about an hour presentation but worth your time and your son’s or daughter's time if they are having a tough time figuring out how to make a living so they can move out of your basement.

Why am I discussing this topic with material handling OEMs, part distributors, and dealers? Because I believe dealer networks in the good old USA will find themselves at that fork in the road sooner rather than later.

If you recall, I recently mentioned Ford and its move to sell online direct to customers. They were doing this to stop the gouging taking place concerning their new line of EV Ford 150s. And I said “here we go” with OEMs moving to sell direct.

Guess what. AED, working with McKinsey & Company prepared a paper titled THE FUTURE OF SALES AND SERVICE FOR EQUIPMENT DEALERS. McKinsey sent out surveys to dealers regarding this topic and those responding are most concerned about the interest in OEMs in direct-to-consumer sales models. They were also concerned about NEW COMPETITIVE THREATS and THE INVESTMENTS REQUIRED TO ENABLE NEW SALES MODELS.

The survey also asked what customers were currently doing and what was expected five years from now. Participants answered that currently 14-25% of new, used, and rental transactions originated online, with an expectation five years from now to be between 36- 48%. A meaningful uptick I would say. In terms of completing the purchase, online the current % is 7-15% with an expectation of 29-36 % five years from now.

Back to the fork in the road, because it seems that 57% of the survey participants responded said they made no or minimal progress on building a sales and service model for the future. Which fork will these dealers take? My guess is they will not have a choice.

Digitalization is where this is going and you will either have a program to modernize your operation to use the value of data and analytics to build a digitalized, customer-centric business. Or you will find yourself behind the eight-ball with only the option of selling your dealership to your OEM or another dealer selling similar lines.

You would think OEMs would be pushing this process, and even funding such a program since having their dealers highly digitalized would be to their own benefit.

As you can imagine this will be both a timeconsuming and expensive program to develop and initiate. Only certain dealers will have the

power to create a working sales and service model. The only way I see this working is for OEMs to lead the charge as is happening in the auto and truck industry where OEMs integrate digital sales programs into existing dealer management software. The other option is for a group of dealers to produce the sales and service platforms for their group.

And I have to bring up those Codie Sanchez dealers who will buy today’s dealer and transform it into a dealer of the future, and in the process become a giant in the industry.

OEMs…..wake up.

Garry Bartecki is a CPA MBA with GB Financial Services LLC and a Wholesaler columnist since August 1993. E-mail editorial@ MHWmag.com to contact Garry.

“Hi. How are you today?”

I hate that line. When salespeople call up and say, How are you today? it’s a warning sign line. They’re saying, “I don’t really care what or how you’re doing today, I need to start my sales pitch. And this is the way I’m going to start it.”

I’ve had a revelation that has been 20 years in the making. I used to have all my leads on a database, like an Excel spreadsheet, and I had different color-coded pins to strike out the ones that were Hot or Not Hot. And then there were the yellow highlighted ones when I made the sale.

Then CRM came along. I could never get into it because it was just too cumbersome. For me, it was always a bunch of things that I had to do, that I didn’t really want to do. And the spreadsheet worked just fine. We did use a CRM here at one time for our sales leads, but we needed a consultant to turn it on, literally.

NOTE WELL: We have (finally) found a CRM software that actually works, but I’ll get to that in a minute. What I want to talk about is “why I chose not to use it for those 20 years, and how wrong I was.” By blaming the software for not helping me make a sale, it kept me from tracking important details that I felt were important during the sales cycle.

I had my notes written on my spreadsheet. No Bueno. But what I found to be true is that a CRM, while it may not teach you to make a sale, it keeps all of the facts and all the details online so that you can make a sale easier. I had everything about their kids’ names and their wife’s name, where they grew up, and other “sales forward” information. NOTE: It’s so much more powerful when you discover things in common- like a college or favorite sports team or a kid’s T-ball league. Relationship information that leads to sales.

BACK STORY: People have called our office for years and asked, “Hey, I want to know what CRM you recommend?” And for years, our answer was…none. NONE! None until today, which is kind of crazy. We’re gonna

give you the CRM that we’re now using that is rocking our world. But first, let’s talk about, what made this happen.

For years, I’ve been teaching using creativity and discovering shared values. My philosophy has always been, “find something personal, do something memorable.” So, when you find something personal, and you DON’T document it, you forget about it. That’s the sales-threatening challenge that you have. The personalized element of selling cannot be denied – or omitted.

CRM actually started BEFORE computers with Harvey Mackay – The Mackay 66. In Harvey’s timeless classic “Swim with the Sharks,” he wrote about how important it was to collect 66 important things about every customer. He claimed that when you have these 66 facts, you can’t lose because you know enough to build a relationship, not just make a sale.

He combined that with his Rolodex to save the names and numbers of his customers and prospects. Both of those data collection strategies are passe now, but the information is still strategic to making sales. You still have to collect and store that information in order to be perceived as the best sales option.

When the customer likes you, believes you and has confidence in you, and trusts you – it’s a fit, and you win. And the right CRM can create that for you.

I write down some of the most regular things that people say in passing like, “Tomorrow is my uncle’s birthday.” And then the next time I talk to them, I ask, “Hey, how was your uncle’s birthday?” They don’t even remember the birthday or that they even told me. “Oh, you mentioned you were going to your uncle’s birthday last time we talked.” Then they realize you’re really listening and paying attention because you’re telling them what they told you.

And keep in mind that the CRM combines listening with the most powerful form of listening: taking notes.

We have now invested in a game-changer CRM, and not just any CRM. Before sharing this information with you and my entire audience, I needed to make sure that this was THE BEST CRM. A sales-making CRM that would put time back on your calendar, make relationship building easier, and money in your bank account.

We looked at every CRM that’s out there before deciding on which one would be the best fit.

The only one that I recommend is the one we’re using at Buy Gitomer. And that’s Pipedrive. Once we started using it and realized how critical it’s become to our sales, we connected with Pipedrive and asked them to give you a special offer. And they obliged!

You can go to the Pipedrive URL but you won’t get what they’re gonna give you at our special link. Go to gitomer.com/crm. That will take you to our special link for Pipedrive. You’ll get an extended free trial, a bigger discount, and you’re gonna be treated like gold.

Pipedrive works. It’s mind-blowingly awesome, and did I mention it’s simple? Just move your prospect through the buying stages. You just drag and drop anything. You can have your forms go directly into it. You can set activities and reminders. And they’ve made it so user-friendly, that even I can use it.

This is the challenge. You’re only going to know if you try it yourself.

Let me know how it works for you – send your notes and thoughts to helpme@gitomer. com.

Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com. For information about training and seminars visit www.Gitomer.com or email Jeffrey at salesman@gitomer.com or call him at 704 333-1112.

Felling Trailers, Inc. conducted its tenth annual online auction of an FT-3 drop deck utility trailer to benefit a non-profit organization: Eagle’s Healing Nest. A winning bid of $7,752.00 won the auction that ended at noon on the 27th of August. The bid winner was Joe Welch of Caledonia, MN. Joe, an equipment dealer, has followed Felling Trailers’ Trailer for a Cause auctions for a few years. “This was the first auction I was able to catch before it closed. When I saw the cause, I really wanted to help support the Eagle's Nest’s ‘Promises Made Promises Kept’ mantra. This is an exceptionally important mission they are undertaking that not only affects the people getting assistance by the entire community and the community of volunteers that assist in their cause,” said Joe. With just six minutes left in the auction, Joe placed his bid of $7,752.00, winning the bid at the close of the auction.

www.felling.com

H&E Equipment Services, Inc. has announced the signing of a definitive agreement to acquire One Source Equipment Rentals, Inc. (“One Source”), a provider of non-residential construction and industrial equipment with operations in the Midwest and Southern U.S. One Source, which is employee-owned, operates 10 branches, including three locations in each of Illinois and Indiana, two locations in Tennessee and

one in each of Kentucky and Alabama. Under the terms of the definitive agreement, H&E is expected to pay $130 million in cash for One Source, before customary adjustments. The transaction is expected to close during the fourth quarter of 2022, following regulatory clearance and the completion of other customary closing conditions.

The Caldwell Group Inc. will lead a series of initiatives this fall to raise money for breast cancer charities, including offering its most popular beam in pink. The manufacturer of material handling and rigging equipment has made its Model 20 low headroom lifting beam available in pink when ordered in lengths up to 10 ft. The adjustable beam is available in various capacities (0.5 tons to 40 tons) and spreads (3 ft. to 18 ft.) with an additional option to add pink paint for a donation of $100. The concept was developed by Doug Stitt, the company’s president and CEO—and his connection to the cause is a personal one.

The WERC Advisory Council has selected Orlando, Florida as the destination for WERC’s 46th Annual Conference. Mark June 4-7, 2023, on your calendar now to share and hear others’ best practices for “Growth Through Disruption” — the theme for this event. WERC members will gather in person at the Hilton Orlando.

Equipment Services Inc. (H&E) announces the opening of its New Castle branch, the first in the state of Delaware.The branch is located at 9 Bellecor Drive, New Castle, DE 19720-1763, phone 302991-1700. It includes a fully fenced yard area, offices, and a separate repair shop and is capable of handling a variety of construction and general industrial equipment for customers working throughout Delaware, eastern Maryland, and southern New Jersey.

MODEX 2024 will be held March 11-14 at Atlanta’s Georgia World Congress Center. MODEX is the largest international supply chain expo, bringing together solution providers who demonstrate the full spectrum of equipment, technology, systems, and services for manufacturing, supply chain, and transportation operations. Over 900 exhibitors will showcase their solutions on the MODEX show floor totaling over 405,000 square feet of manufacturing and supply chain solutions.

LiuGong North America has added North Carolina-based Tri-Lift Industries to its dealer lineup. Founded in 1968, the third-generation family business covers a three-state area across North Carolina, South Carolina, and Virginia

Seegrid Corporation, a provider of autonomous mobile robots (AMRs) for material handling, has announced that Joe Pajer has joined the Company as President and Chief Executive Officer (CEO). Mr. Pajer succeeds Jim Rock, who will continue as a Seegrid shareholder and advisor. Mr. Pajer will also serve on the Board of Directors.

Supreme Systems, a courier and trucking solutions provider in North America, marked its 35th anniversary on September 14th. Supreme Systems was founded by Eric Bennett in 1987 and has since grown into a premier on-demand courier and trucking provider with more than five million deliveries made to date, reaching an estimated 30 million customers coast to coast.

Tubelite Inc.'s Steve Green will retire as Vice President of Sales in March 2023 at the end of the company's fiscal year. A search is underway and a successor will be announced in the coming months.Green has been a key part of Tubelite's leadership team for more than 32 years, and his colleagues attribute much of the company's success to his contributions. In his current role, Green oversees the sales and client service teams for Tubelite, as well as for two additional Apogee Enterprises businesses, Alumicor and Linetec.

The Marine Travelift/ Shuttlelift/ExacTech, Inc. family of companies has announced the promotion of Kurt Minten to Executive Vice President of Marine Travelift. As the longesttenured employee in Marine Travelift history, Kurt has many years of experience in all aspects of the business and has held positions in both engineering and sales leading up to this promotion.

Kurt’s experience with Marine Travelift began even before he was an employee of the company. Early in the company’s history, engineering services were outsourced to a local company called RA Stearns, which is now known as Bay Engineering. Kurt worked as a drafter at Stearns and was assigned to the Marine Travelift product line in 1981.

PLA has announced the opening of its newest pallet

facility in Houston, Texas. The addition of this facility brings PLA's total number of facilities to 76. The new location is centrally located to bring new and recycled pallet supply, transportation, and other supply chain services to customers throughout the greater Houston metro area. The nearly 23,000 square foot facility on over eight acres will feature 10 dock doors and process over 3 million pallets annually. The Houston facility will bring at least 35 new jobs to the area and is located at 112221 N. Houston Rosslyn Road, Houston, TX, 77086.

UgoWork™ just announced that industry veteran, Tim Ballard, is now the company’s Director of Sales. This is yet another initiative UgoWork has taken as it continues to make inroads across the US and Canada. Tim has over

two decades of proven experience in material handling. He worked in several management positions at ProLift Industrial Equipment, an official full-service and material handling dealership for Toyota. Apart from an in-depth and pragmatic understanding of industry needs and trends, Tim’s strengths reside in his track record of working in all aspects of material handling, including operations, sales, training, and support.

10 hr.

standard

featured

much

pallet jacks, consider the fully automatic STC taper charger. Plugs into any 120V outlet for convenience and portability.

the ultimate in efficiency and flexibility, consider the Access high frequency charger. Models are available for both conventional and opportunity charging.

IMI SalesLeads announced today the September 2022 results for the newly planned capital project spending report for the Industrial Manufacturing industry. The 154 new projects increased from August 2022 140 manufacturing projects, however, down from 162 in September 2021.

The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 154 new projects in the Industrial Manufacturing sector.

facility in LOUISVILLE, KY. They have recently received approval for the project.

INDIANA: Automotive mfr. is expanding and planning to invest $491 million for a 6,000 sf expansion, renovation, and equipment upgrades on their manufacturing facility in MARION, IN. They are currently seeking approval for the project. Construction is expected to start in early 2023.

The following are selected highlights on new Industrial Manufacturing industry construction news.

Industrial Manufacturing - By Project Type

• Manufacturing/Production Facilities - 133 New Projects

• Distribution and Industrial Warehouse - 61 New Projects

Industrial Manufacturing - By Project Scope/Activity

• New Construction - 59 New Projects

• Expansion - 43 New Projects

• Renovations/Equipment Upgrades - 44 New Projects

• Plant Closings - 16 New Projects

Industrial Manufacturing - By Project Location (Top 10 States)

• North Carolina - 10 • Ohio - 10

• Indiana - 9 • Texas - 9

• California - 8 • Pennsylvania - 7

• Wisconsin - 7 • Michigan - 6

• Alabama - 5 • Georgia - 5

During the month of September, our research team identified 19 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more.

The largest project is owned by Micron Technology, Inc., which is planning to invest $15 billion in the construction of a manufacturing facility in BOISE, ID. They are currently seeking approval for the project.

MICHIGAN: Battery component mfr. is planning to invest $3.6 billion for the construction of a manufacturing facility on 18 Mile Rd. in BIG RAPIDS, MI. They are currently seeking approval for the project.

KENTUCKY: Automotive mfr. is planning to invest $700 million for the renovation and equipment upgrades at their manufacturing

TEXAS: EV mfr. is planning to invest $365 million for the construction of a lithium-hydroxide refining plant in ROBSTOWN, TX. They are currently seeking approval for the project. Construction is expected to start in late 2022, with completion slated for 2024.

ARIZONA: Plant-based packaging product mfr. is planning to invest $280 million for the renovation and equipment upgrades on their manufacturing facility in GILBERT, AZ. Completion is slated for late 2023.

SOUTH CAROLINA: Automotive component mfr. is planning to invest $200 million for the renovation and equipment upgrades on their manufacturing facility in ANDERSON, SC. Completion is slated for 2026.

MISSOURI: Consumer products mfr. is planning to invest $180 million for the expansion, renovations, and equipment upgrades on their processing facility in ST. LOUIS, MO. They are currently seeking approval for the project.

OHIO: Truck mfr. is planning to invest $150 million for the expansion of their manufacturing facility in NEW PHILADELPHIA, OH. They are currently seeking approval for the project.

TEXAS: Steel tube mfr. is planning to invest $75 million for the construction of a 125,000 sf manufacturing facility in SEGUIN, TX. They have recently received approval for the project.

ALABAMA: Laminated timber products mfr. is planning to invest $62 million for the construction of a 140,000 sf manufacturing facility in DOTHAN, AL. Completion is slated for 2024. The project also includes equipment upgrades on their existing manufacturing facility in DOTHAN, AL.

Since 1959, SalesLeads, based in Jacksonville, FL is a leader in delivering industrial capital project intelligence and prospecting services.

•Exclusive Leads vetted by CIP Solution

Specialists. Our dealers close 50% of CIP leads.

•CIP Lifts are manufactured in-house and adhere to all government and industry specs.

•Fast, Responsive Support.

•Hands-On Training.

•Marketing Incentives.

Elevate your bottom line by being a CIP Dealer now!

TomTom (TOM2), the mapmaker and geolocation specialist, has introduced GO Navigation’s truck plan – an offer designed to meet the needs of professional truck drivers. In addition to GO Navigation’s premium navigation capabilities, enables drivers to plan routes that account for their vehicle’s dimensions, fuel requirements, desired maximum speeds, and cargo (such as dangerous goods). Drivers will also be able to plan multiple drop-offs and gain access to an overview of upcoming points of interest (POIs) – such as fuel stations suitable for their vehicle and truck stops.

Good things come in threes: This beast of a triple caster Hamilton designed for an engineering design firm. Each 21-inch wheel is impressive in its own right. But when banded thrice together to support four corners of an 80,000-pound movable assembly, it’s a threesome worthy of Godzilla, Rodan and Mothra combined. This customer needed to make it mobile at speeds up to 3 mph to travel through various docks and concrete roadways around an outdoor shipyard. So, they added the three-wheel concept to provide maximum footprint and load distribution. Hamilton chose solid pneumatic tires for extra cushion and shock absorption.

Mitsubishi Logisnext Americas group has announced the launch of its Cat DP60HPDP100CP forklift series. The 13,00022,000 lb. capacity internal combustion (IC) pneumatic tire lift trucks are built for some of the most challenging environments and can lift and haul heavy loads with amazing speed and productivity. These forklifts excel in a number of industries, such as the metal industry, lumber yards, industrial machinery, and distribution centers.

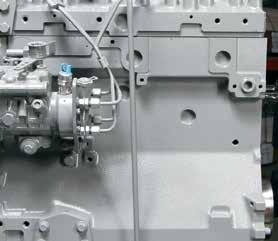

Handling launches its newest edition to the industrial truck family with the Linde Series 1204 IC enginepowered truck, available in diesel and LPG and capable of moving heavier loads from 3.5 to 5 tons. The Series 1204 combines exquisite performance, rugged construction, and intuitive handling, creating a versatile and ergonomic truck. The Linde Series 1204 is the product of extensive research and discussions with different industries in creating a truck that meets and exceeds any industry's expectations and material flow challenges.

www.kion-na.com

Sealed AGM, Gel, TPPL, and Lithium Ion batteries are often selected for use in pallet jacks, forklifts, and emerging industrial applications such as solar arrays and UPS backups. With the new Advanced Battery Steward for Sealed Batteries system from Flow-Rite, it's easy to wirelessly monitor the health of one or more batteries in the field with a mobile device to make informed maintenance decisions. Leveraging IoT technology, the Advanced Battery Steward Sealed Battery Tracker monitors critical data like voltage and half-voltage, current in and out, temperature, and battery impact and angle. Each event and measurement is time and date stamped for Machine Learning (ML) processing to create high-value metrics and realistic gauges of battery performance.

www.flow-rite.com

The Noblelift

FE4P50Q (5,000lb capacity), FE4P60Q (6,000lb capacity), and FE4P70Q (7,000lb capacity) Four Wheel Lithium-Iron Phosphate (LiFe4OP) Forklifts are highly efficient, durable Lithium-iron forklifts. They are designed for indoor and outdoor applications. The mast system, front/rear axles and chassis are engineered to be tough like an Internal Combustion Engine (ICE) forklift, but with all the advantages of Lithium-iron. AC drive technology is used to achieve high performance with low operating and maintenance costs.

www.nobleliftna.com

Bally Ribbon Mills (BRM), has announced the availability of a wide range of lightweight two-and threedimensional woven materials that serve as the structure or substrate for critical rigging and tie down applications that require strength, interlaminar shear, enduring resistance, or conductivity. BRM custom designs specialty applications with high strength-toweight ratios, flame/heat resistance, flexibility, low elongation, and abrasion resistance.

For applications that require frequent cycling (lifting and lowering) of lift tables, Southworth offers high-duty cycle packages that increase recommended maintenance intervals from 50,000 cycles to 200,000 cycles. The dramatic increase in cycles is attributed to upgraded components including more rugged and durable wear parts. In addition to better accommodating higher cycles, these components also deliver longer life and better performance in applications that involve oversized or non-uniform loads which can cause uneven wear in standard lifts.

M3000 demonstrating its capabilities in booth N-5546 at PACK EXPO 2022, Oct. 23-26 at McCormick Place in Chicago. The M3000 Case Packer is designed to fill a need for mid-range

Smart Vision Lights (SVL) announces the release of its JWL150, the first in the new Camera-to-Light (CTL) series. Unlike other external illumination products designed for machine vision cameras and smart cameras with built-in illumination that falls short, the JWL150 delivers an intense, compact light source with an integrated camera mount. Compatible with most major machine vision cameras, the JWL150 can be directly connected and controlled through a camera’s trigger output.

LEDtronics® Inc. has announced its newest series of UL-listed LED Post Top Lamps that put out an impressive amount of uniform, omnidirectional and brighter light for their compact size, with much more energy efficiency and longer life compared to the old technology and larger post-top bulbs. Because they are thermally managed, these LED bulbs are UL approved for enclosed applications (-40°F to 113°F) and are perfect for easy, direct drop-in installation into existing E26 Edison medium and E39 mogul screw-based lighting fixtures.

CLARK Material Handling Company announced the launch of new products that help its customers manage large fleets: CLARK SMART, and CLARK SMART Fleet.

Reach speeds up to 50 cases per minute Brenton is launching a new continuous motion side-load case packer aimed at CPQ customers looking to pack between 30 and 50 cases per minute. Plan to see the

CLARK SMART simplifies fleet data and empowers customers to improve operational safety, efficiency and decrease costly accidents. CLARK SMART Fleet, available to CLARK National Accounts, is the next evolution of intelligent fleet management. This powerful new tool from CLARK simplifies the customer’s complex forklift fleet by collecting and reporting on unit utilization, service history, invoice consolidation, and much more.

Portable Storage Racks

All-Steel Stack

Pallet

Posts

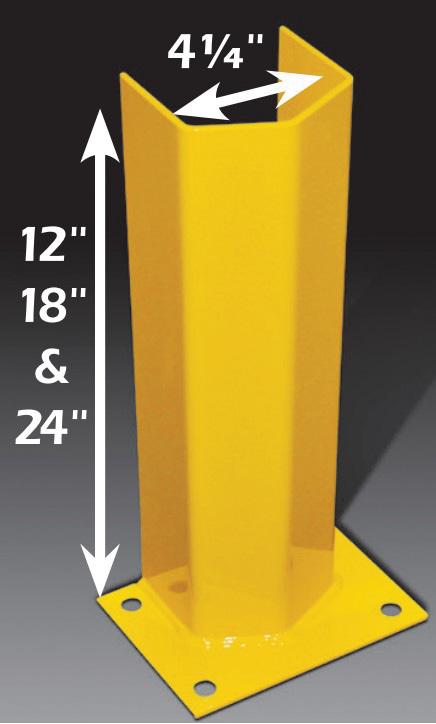

Rails

Durable steel protection.

for

and easy

Stronger than typical handrail.

Top Rail

FALL

and

Modular hand rail protects employees from entering unsafe areas.

Easy installation, simply assemble and anchor down.

Stocked in 4’, 6’, and 8’ sections.

42” tall standard.

MEETS OSHA

from

mostly

damage to your controls.

any control box mounted to a building column – fan switches, thermostats, and light switches.

in minutes with 8 pre-drilled mounting holes. Simply Tek screw to your column and you’re done!

to fit 10” or 12” columns.

and Standard.

tall,

for 6”, 8”,

Yellow is standard, but red, lime green, and orange are available.

and

reflective band standard on lime green and orange.

Serving the needs of our customers is our top priority.

From offering the right part at the right price to delivering the parts when needed, TVH is dedicated to providing a customer experience that is second to none.

Seventeen years ago, Terry Sroka and Reva Bily “decided to leave the large corporate world of decisions by committee, meeting after meeting and burdensome policies,” they said. The two founded West Point Rack, a Nebraska company that sells exclusively to material handling dealers. “West Point Rack is a smaller company with a highly dedicated staff. This allows us to ‘turn on a dime,’ respond quickly and to innovate whenever the opportunity presents itself,” said Sroka, chief executive officer. “I don’t want to be one of the biggest rack companies out there, just one of the better ones. Our primary goal is to support our dealers, satisfy their customers, earn trust and be the ‘Vendor of Choice’ for rack products and racking systems.” Company president Bily said if an end-user calls, they refer them to a dealer. “There is nothing wrong with selling direct to the end user, but you don’t do both,” Sroka said. “Draw the ‘line’ and stay on one side or the other. In order to build a good relationship with a dealer and to have him trust you, it is necessary that he really believes that you will not go around him and make the sale direct. Dealers are independent businesses that spend time and money to build up a customer base and the last thing they want to see is a manufacturer go around them and sell to one of their prospects who is shopping price.”

Bily grew up on a farm and worked in a packing house and electrical sales before she joined the material handling industry. Customer service is the core of what she does, and the key to growth, she said. Customers want prices and delivery quickly. She tries to get back to a customer with a standard quote in 15 minutes, she said.

The relationship with dealers is built on competitive prices, service and standing behind the product, Sroka said. “If product issues do arise, we address those issues immediately with the goal of creating satisfaction for both our dealer and their customer,” he said.

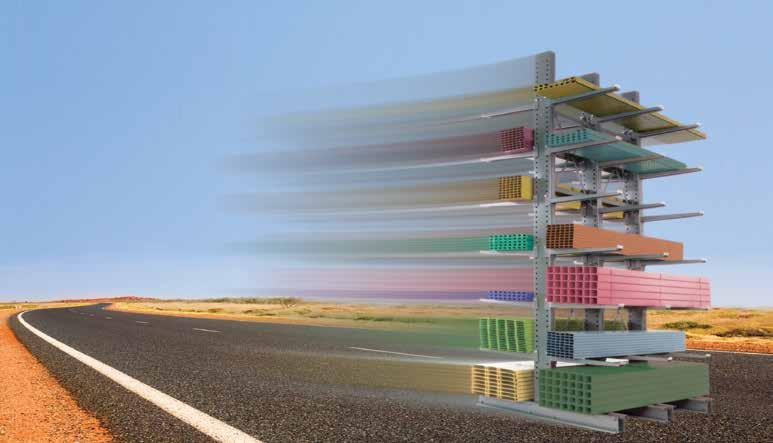

The company sells cantilever racks in light, intermediate, heavy and extra heavy duty configurations, structural pallet racks in galvanized or painted steel and portable stacking racks made to order.

“I always look for things when we do specials,” Sroka said. “Does it have any potential of becoming a standard product? That is how we developed a lot of our standard products.” Specialty products made by West Point Rack include bar cradle trucks, drum racks and handcarts.

West Point Rack has recently added new products to its line of racks. Included is a new line of reel racks, ranging in height from eight to 12 feet.

Vertical racks, which will hold material from 21 inches to 12 feet, feature six-inch deep arms with three shelves made of 14-guage steel. U-Racks, which come with an orange paint finish, can be stacked up to four units high to save space.

“The future looks very positive for West Point Rack,” Sroka said. “Our product base is expanding as is our market penetration. We will continue with the business model and plan that has taken us to this point and will continue to move us forward.”

West Point Rack is one of the fastest growing companies in the industry. Our customers recognize quality products, de pendability of service and competitive pricing.

Our Primary Goal is to support our dealers, satisfy their customers, earn trust and be the “Vendor of Choice” for rack products and racking systems.

We offer a full line of light duty, intermediate duty, heavy and extra heavy duty cantilever racks. We provide multiple configu rations of a wide variety of stacking racks. Our structural pal let racks can be configured for a wide range of applications. West Point Rack has the products that generates solutions for your storage needs.

We also offer specialty products such as bar cradle trucks, drum racks, hand carts and other specialty transport and storage products. Give us a call at 866.245.3630. We may have what you need. Look forward to hearing from you.

Superior Tire & Rubber Corporation has successfully launched the Next Generation line of polyurethane load wheels branded Velocity™. This patent-pending product, redesigned and reengineered, promises to deliver a longer work-life by keeping the bearings and polyurethane cooler through its new innovative hub design.

After a year of trials and almost another year of sales, the Velocity™ has proven to be a game changer. Major warehouses & distribution centers across the US have reported significant longevity and productivity improvements, switching their entire fleets over to reap the benefits. “Heat is the enemy for tires and wheels, shortening work-life of bearings, tire compounds, and the bonding systems of solid tires,” says Joe Peterson, Ph.D.,VP of Engineering & Quality at Superior Tire. “Traditional solid steel wheels don’t effectively dissipate the heat generated during use and they cool slowly even after the vehicle stops. The new hubs help manage the thermal energy generated by the tire, creating a better performing wheel.” Superior Tire’s team of engineers took a common technology found in radiators and computer components and applied it to load wheels, allowing the Velocity™ to limit and maintain a reduced maximum operating temperature thereby prolonging work-life by up to 100% against traditional wheels. They are calling it HeatSink™ technology.

In addition to extending work-life,Velocity™ wheels are approximately 70% lighter than traditional load wheels, not only providing an ergonomic advantage for techs and field staff but also saving in shipping. “The lightweight has no effect on carrying capacity – in the case of traditional solid steel wheels, that excess material is just wasted mass”, states Dr. Peterson. Superior Tire ran dozens of durability tests and found the Velocity™ wheel can easily support more weight than the bearings can hold. A video of one of these tests can be found here:Velocity™ Compression Test

As with any industry-changing technology, there is one caveat – Velocity™ wheels are currently only available for the most popular 5-inch market sizes for Crown, Raymond, and Hyster-Yale Class-2 equipment. Superior Tire is currently in development & testing of 4-inch and 6-inch load wheel variants, with expectations of bringing these to the market in 2023. “This is truly an exciting time on our industry with the overall growth of the market and fleets/operators demanding longer lasting equipment. It’s the perfect time to bring a Next Generation solution to our dealers and OEM partners.”, says Jared Steier – VP of Material Handling Sales and Marketing. “The Velocity™ wheel is a perfect tangible example of our slogan – Engineering Revolution.”

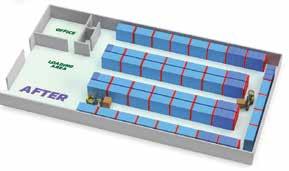

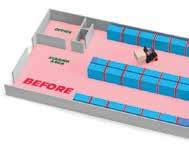

B e f o r e y o u i n v e s t i n u p g r a d i n g t h e i n f r a s t r u c t u r e o f y o u r w a r e h o u s e , f i n d o u t h o w C o m b i l i f t c a n i n c r e a s e y o u r s t o r a g e b y u p t o 5 0 % . W i t h o v e r 2 1 y e a r s ’ ’ e x p e r i e n c e i n v o l u m e o p t i m i z a t i o n , o u r t e a m o f w a r e h o u s e p l a n n i n g e x p e r t s k n o w h o w t o m a k e y o u r s p a c e w o r k h a r d e r f o r y o u C o n t a c t u s t o d a y t o a r r a n g e a s i t e s u r v e y ! O u r w a r e h o u s e d e s i g n c o n s u l t a n c y s e r v i c e i s F R E E a n d w i t h o u t o b l i g a t i o n .

Pallet stacking

warehouse