FOOD & DRINK PROCESSING & PACKAGING

Issue 48 2023

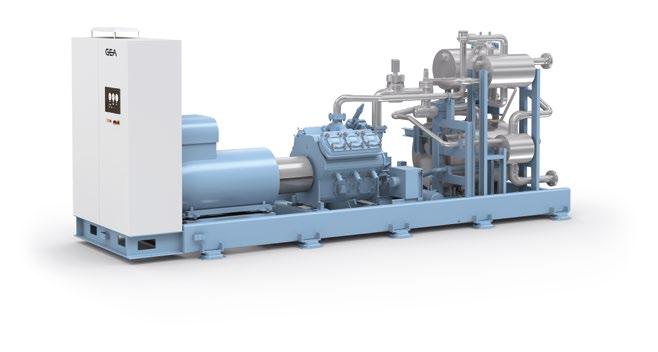

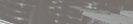

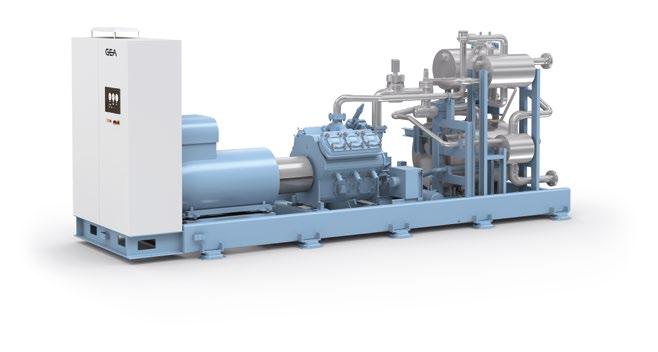

GEA heat recovery system helps Britvic reduce its carbon footprint

PPMA Show set to showcase the latest developments in the UK’s processing and packaging industry

World-leading

Valves for Hydrogen, Carbon Capture, Topside, Subsea, and Pipeline Applications.

Instrument & DBB Valves

• Manifolds, Needle, Check and DBB Valves to 22.5K psi

• Cryogenic

• Severe Service 650ºC, 10K psi

• Forged & Bolted Construction

Hydrogen & Carbon Capture Valves

• Instrumentation, Ball, Needle and DBB Valves for Hydrogen and Carbon Capture Applications

• Pipeline Ball Valves upto 18”

• 10K Ball Valves for Hydrogen Fuelling Stations

Pipeline Valves

• 1” to 20” Bore Size

• High Temperature

• High Pressure

• Cryogenic

• API 10K Design

Subsea Valves

• Diver & ROV Operated Needle Valves

• Ball Valves Upto 15K

• Manual & Hydraulic Parallel Slide Gate Valves 3/8”, 1/2”, 3/4” and 1”

We Manufacture Valves for Global Energy Projects. To Find Your Local Supplier, Contact Us Today.

+44 (0)1565 632 636 | sales@valves.co.uk | www.valves.co.uk Reliability Under Pressure Oliver Valves Ltd Parkgate Industrial Estate, Knutsford, Cheshire, WA16 8DX, United Kingdom

We Innovate Valves. We Build Valves. We Are Valves.

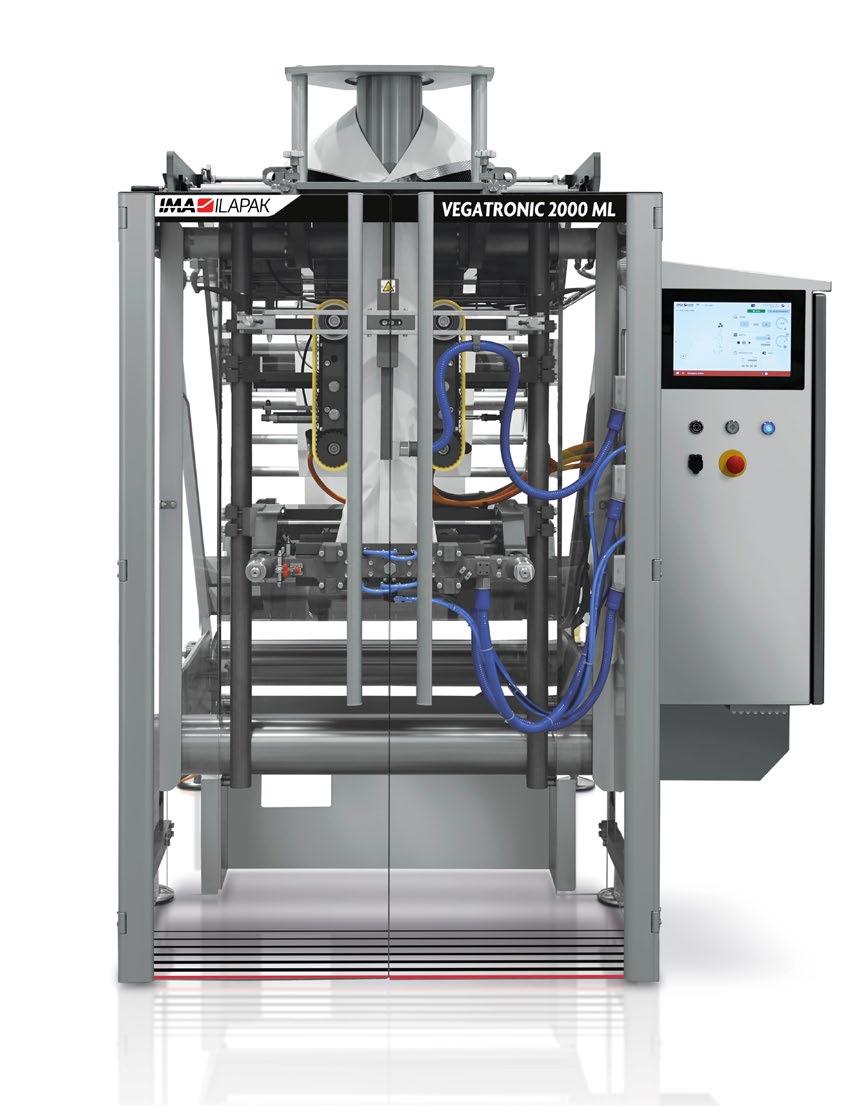

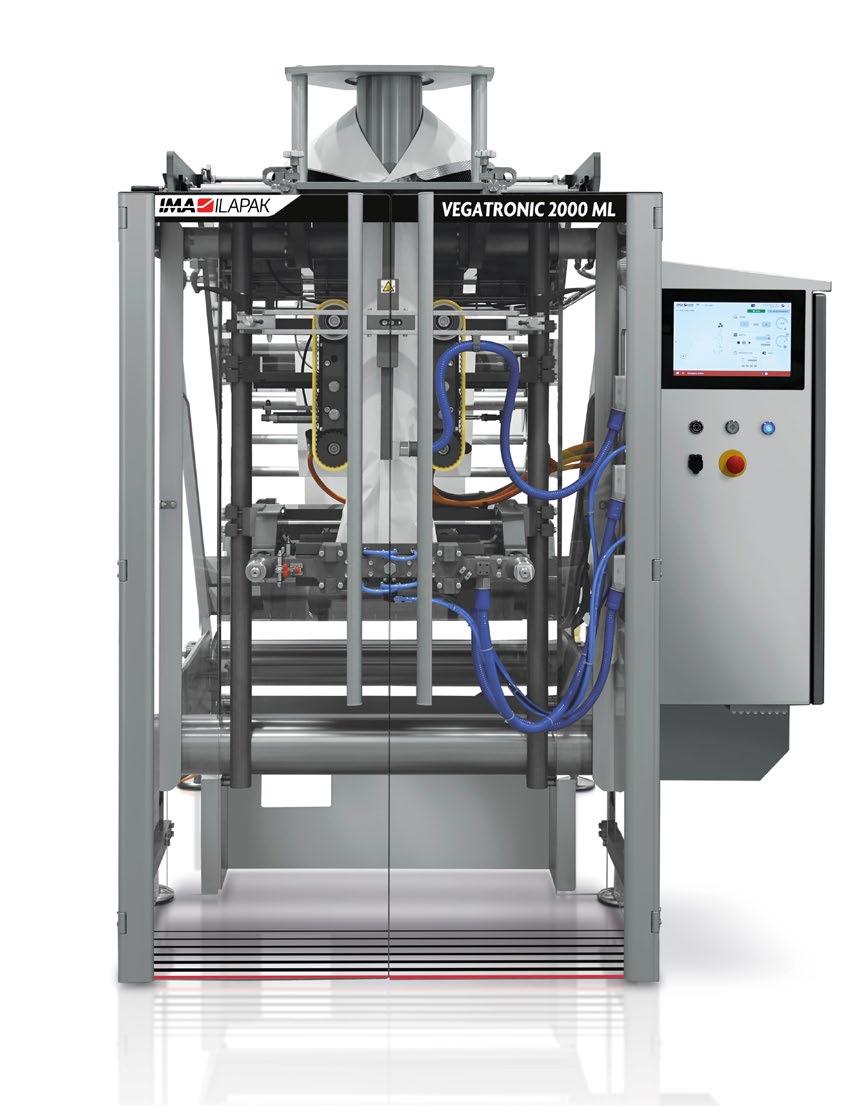

Contents Features PPMA SHOW < 6 ANRITSU < 14 TRANSCEND PACKAGING < 22 BIXOLON < 30 ADVANCED ENGINEERING < 32 DUSTCONTROL UK < 40 IFM < 50 CORETIGO < 72 ILAPACK < 82 B-HIVE INNOVATIONS < 90 GEA < 102 LEUZE < 106 LORYMA < 108 NORD SYSTEMS < 112 Editor Amanda Buckingham editor@fdpp.co.uk Digital Sales Manager Jessica Bennett T: 01227 392571 Business Manager Josh Holmes josh@mhmagazine.co.uk Digital Manager Jamie Bullock jamie@fdpp.co.uk Tel: 01227 392571 M H Media Global Ltd. 18/20 Newington Road, Ramsgate Kent, CT12 6EE Tel 01304 806039 www.fdpp.co.uk Every effort is made to ensure the accuracy and reliability of material published in Food & Drink Process & Packaging however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including printing), recording or stored in any information retrieval system without the prior written consent of the publisher. All web addresses are interactive, simply click the web address of your choice to view the company website. There is also a useful tool bar where you can search for a specific product. Please mention FDPP when responding to items in this issue. Publishing Director Martin Holmes martin@fdpp.co.uk

Designer Richard Bland richard@mhmagazine.co.uk The Team FDPP - www.fdpp.co.uk 3

Studio

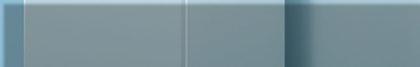

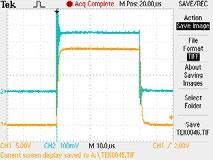

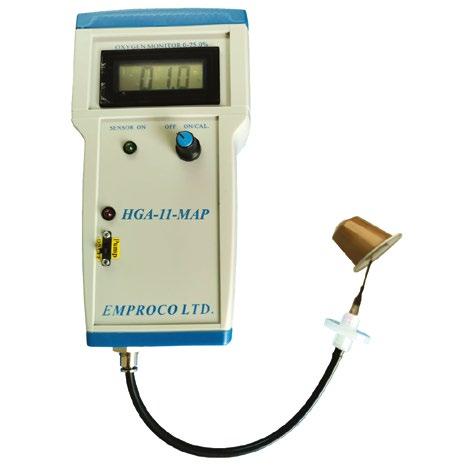

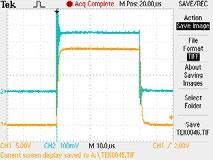

Pulse shapes:

• positive rectangular,

• fronts/tails ~1 µs;

• ~5% flat at 50µs: V(t) & I(t) at 25kV >

up to absolute STERILIZATION

by

Strong Pulsed Electrical Fields

of juices & wines or honey & creams keeping unchanged its properties with our scalable pilot production system, ready for your evaluation:

• for R&D:

1x PEF chamber for solids & creams and 1x coax PEF chamber for liquids;

• for pilot production: two in line coaxial chambers at same or different optimally enhanced pulsing using batch or direct flow through processing.

Broadest changeable SPEF parameters:

• Pulse rates in Hz: 4, 20, 100, 500, 4-125;

• Pulse lengths in μs: 2,5, 5, 10, 50, 2,5-20;

• electrical fields 5-50kV/cm;

• selectable pulsing time 1s-9h;

• 25kV 2kW pulser, up to 10kW options;

• overcurrent protection is build-in with a reset;

• convenient in use, simple to maintain, safe!

PEF sterilizes by stretching bacteria up to its ruptures by electrical fields with 20- 50kV/cm strength delivered by sharp square pulses: more in details.

Inactivation of bacteria in juices with this system can reach 3-6 logs at 250l/h and 2-4 logs at 500 l/h with one or both coax chambers. Plus, its unique set of broad pulsing values with up to 50kV/cm fields allows finding optimal parameters for your future cost-effective production system.

Wek-Tec offers to evaluate or to develop your optimal PEF process which work can be credited to your possible purchase of our system. This work is done at our place with a bio-support from a local certified food lab.

Our Pilots and lab R&D systems have been successfully used past 23 years worldwide and brought valuable scientific results referenced in various academic and in industrial publications.

NON-INVASIVE

For more info click our logo dr.alex.wekhof@wek-tec.de

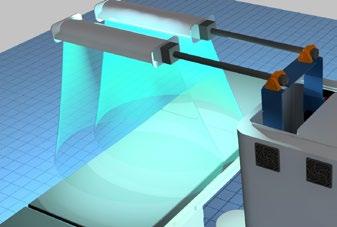

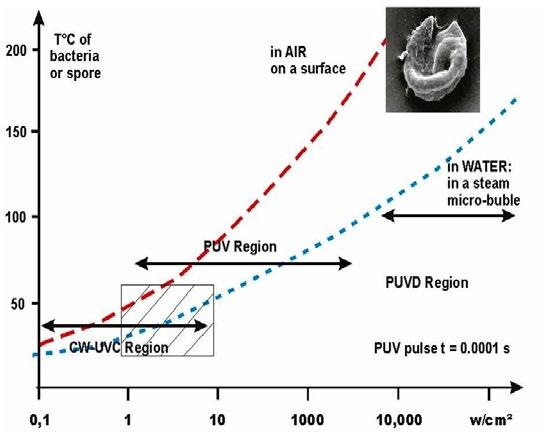

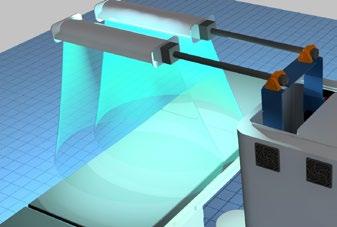

Intense UV pulses fully sterilize clear-packed clear liquids

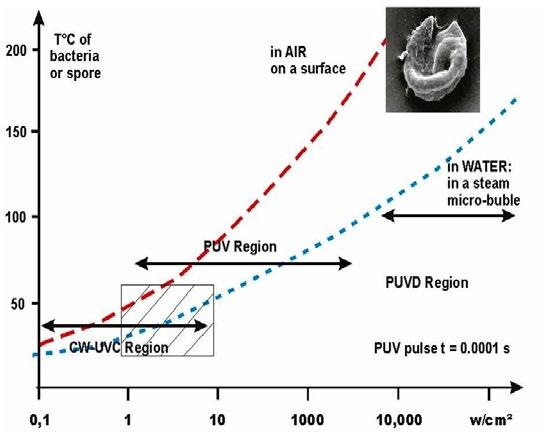

Pulsed UV light becomes very efficient only with substantial increases of pulse power from identical to the continuous UVC light by low pressure Mercury vapor lamps to turning on accelerated DNA damages possible only for more and more intense UV pulses. Further increases of pulse power in w/cm² enters the PUVD region where the joint power of UV and also of the visible light pulses physically disintegrate all bacteria and spores.For this process to happen, these pulses have to be very short, intense and rapid. It makes it possible to sterilize vaccines in vials, clear-packed food items, etc. first identified in peer-reviewed articles by Dr. A. Wekhof in 1990`s., linked here

Our works on PUV are the base for the absolute (=6 logs) sterilization of packages and various food staffs including those inside clear PE packs.

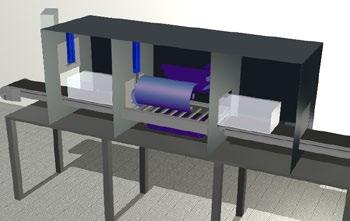

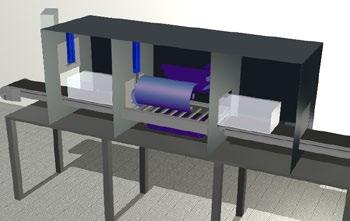

To reach your objectives we offer to select optimal parameters for your application with these two systems. Or to sell you those. The tests results will also to design and to construct full-scale production PL sterilization tunnels or systems also for other usages

R&D UV system for powders in a flow-through sanitation or its photo-chemical modifications (e. g. by UVB enriching the D2 vitamin in mushroom powders) is designed for up to 100kg/h and for further adjustments as per data from your powder evaluation on our Vortex >

We offer evaluation tests at our place or can sell such Vortex. It allows a cost-effectively to reduce micro-organisms at 1-2 logs & more.

< in Vortex powders are moved around a UVC lamp by a forced air flow with the Oxygen being replaced with the Nitrogen gas.

Wek-tec e. K. looks for a capable partner to mutually benefit from our IP and suppliers.

With our systems & services come benefits of German manufacturing.

as proven on our PUV system by Baxter Corp. with UV resistant spores of B. Pumilos.

as proven on our PUV system by Baxter Corp. with UV resistant spores of B. Pumilos.

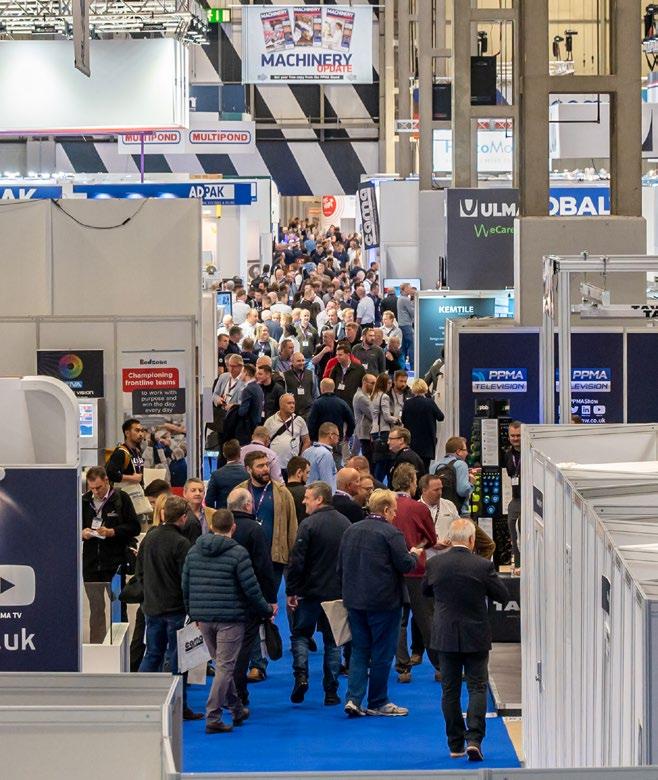

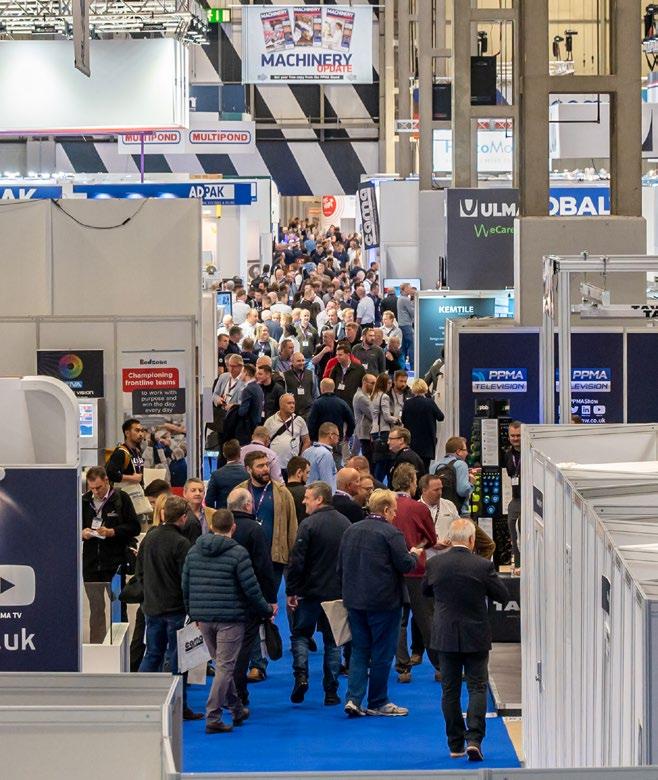

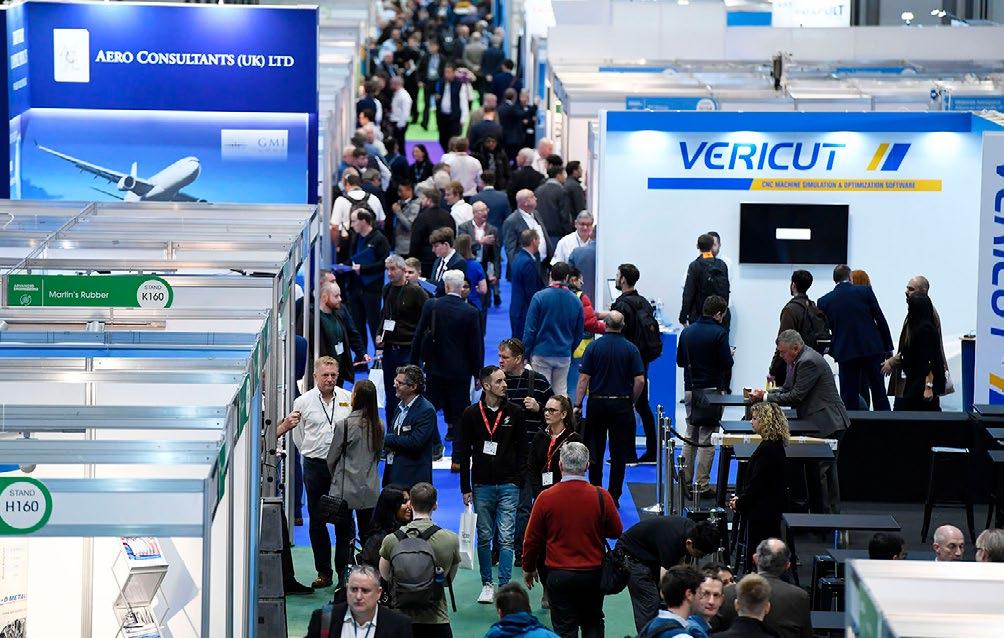

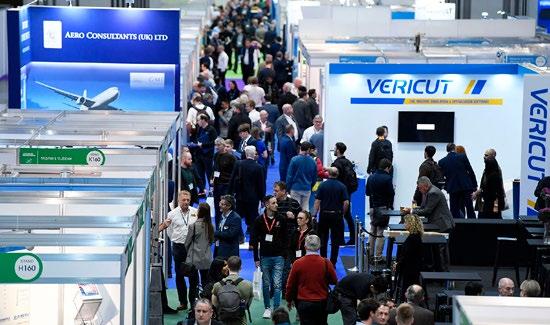

PPMA Show set to showcase the latest developments in the UK’s processing and packaging industry

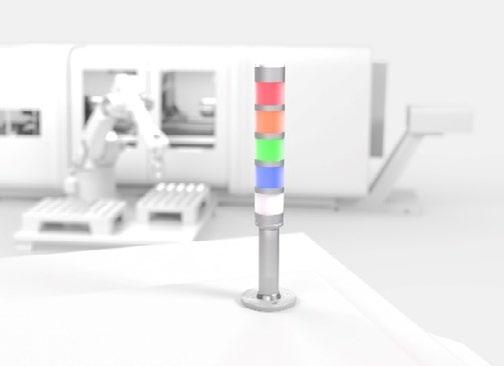

The PPMA Show is the UK’s largest processing and packaging machinery exhibition showcasing the latest in processing and packaging machinery, robotics and industrial vision systems.

The showpiece event on 26-28 September spans the full spectrum of the processing and packaging industry, with exhibitors displaying the latest innovations for sectors including food, beverages, pharmaceuticals, household products and toiletries, building materials and supplies, pet care, micro-brewery and distilleries, FMCG, as well as contract packers and more.

When the show opens its doors at the NEC in Birmingham, visitors will have the opportunity of networking with over 300 exhibitors. There will be a host of new product launches and a content-rich seminar programme that will appraise people of the latest technological innovations and products helping to shape the various markets.

Virtually every aspect of the production line will be represented, from labelling, filling and packaging to processing, robotics, automation and industrial vision systems. Visitors will have the opportunity to source new ideas and solutions for innovating their processing

and packaging solutions, added to the opportunity of meeting with new suppliers and influencers, and tapping into the knowledge of leading experts in their field, all under one roof.

Here is a flavour of what visitors can expect:

• Live demonstrations of new machinery in action

• Video presentations by influential industry experts broadcast on screens across the exhibition and later on PPMA TV

• Networking opportunities

• Benchmark best practice

6 FDPP - www.fdpp.co.uk

• Building new relationships, sharing information, and gaining valuable insights

For those needing to source new solutions, visitors need look no further than the cutting-edge machinery on display. By integrating new machines into their own business, visitors can streamline processes, improve efficiency, and boost productivity. Whether they are looking for ways to reduce costs or improve output, all visitors can learn how new machinery will help them achieve their goals.

Where the PPMA Show really scores is the opportunity it gives visitors to experience the complete production line event in action from start to finish.

This is a rare opportunity to see how everything all connects.

The show’s unique seminar programme will help visitors stay ahead of trend so far as the latest processing and packaging solutions are concerned. Visitors can hear from a range of industry experts about the latest trends and innovations in their sector and how these can be applied to their own business.

Keynote speakers lined up so far include:

• Ross Verrall, Artificial Intelligence specialist, Nvidia. Ross will speaking about the disruptive nature of AI, the Industrial Metaverse, Robotics & the function of Digital Twins.

• Dimitrios Spiliopoulos, Industrial IoT Lead for Manufacturing, Amazon Web Services. Dimitrios will be addressing the importance of smart factories and the innovation offered by Machine Learning and AI.

FDPP - www.fdpp.co.uk 7

Where the PPMA Show really scores is the opportunity it gives visitors to experience the complete production line event in action from start to finish.

Topics covered in other presentations will include food packaging innovation, sustainability, successful selling and how manufacturing is evolving to meet the needs of the processing and packaging sector.

Here are a few exhibitors taking part: Reiser, ULMA, Omori UK, Ishida Europe, PFM, Somic, SMC, and Beckhoff.

Scott McKenna, Group Exhibitions and Membership Manager at the PPMA Group, said: “We know from experience and previous research that the PPMA Show attracts a lot of the upper tier purchasers and senior engineers who will report back with the knowledge they acquired at the PPMA Show. This all translates into potential sales and is what the exhibition is all about, an opportunity for our exhibitors to generate excitement within end users in relation to what they could be achieving for their businesses.”

To register for a free ticket to this year’s show, visit: https://ppma-show2023-visitor.reg.buzz/website

8 FDPP - www.fdpp.co.uk

‘It feels just right’

Cat® platform stackers boost operator confidence and productivity

The new heavy-duty platform stacker range from Cat® Lift Trucks gives operators a reassuring sense of balance, responsive control and power. From their very first ride, it feels just right. And that confident feeling continues consistently through every shift.

Those confidence-inspiring qualities, combined with the trucks’ short, narrow, lightweight structure and strong, fast performance, enable high output. Cat NSV12-16N3 and NSF12-16N3 platform stackers are ideal for high-intensity, multi-role applications in factories and warehouses. They will stack to 5.4 metres and can also be used for transport and order picking.

OPERATOR-CENTRIC DESIGN

At the heart of their operator-centric design is a highly stable and agile chassis. The class-leading, ergonomic emPower tiller head is easily accessible with user-friendly controls allowing rapid but precise and safe manoeuvrability.

Powerful motors with advanced control technology enhance both speed and safety in travelling and load handling. The result is increased work rates with less risk of accidents and associated costs.

Meanwhile, a smooth, comfortable user experience minimises fatigue, strain and the related need for sick leave. Effective platform and mast damping is crucial to this. There is even the option of electrically adjustable damping on fixed platform models.

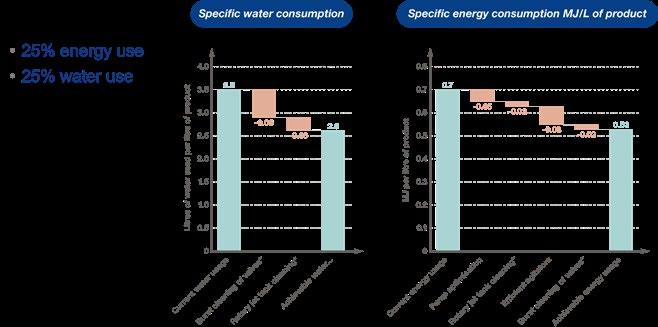

LOWER TCO

As well as increasing productivity, these stackers reduce total cost of operation (TCO). They are highly energy efficient, robustly constructed for heavy duties, and designed to minimise maintenance needs.

Unprecedented levels of component sharing within the Cat stacker and power pallet portfolio bring additional gains. Fixes are faster. Less stock investment is needed. And fewer service van and parts delivery journeys mean a smaller carbon footprint. Everyone wins!

APPLICATION-MATCHED CHOICES

There are 12 models to choose from, with capacities from 1.2 to 1.6 tonnes. The fixed platform (NSF) versions have wraparound protective barriers with a choice of side or rear entry. On the

folding platform (NSV) versions, optional protective side bars can be easily deployed or folded away. An overhead guard is fitted as standard or optionally available, depending on model and configuration.

Initial lift variants give greater ground clearance, which helps when working on steep ramps and loading docks. They can also be used for double pallet handling, to halve the number of transport movements required.

Customers can also select the most suitable steering system for their application from three different designs. Trucks are further configured with a wide range of duplex and triplex masts. Their feature-packed standard specification may then be customised with additional features from a long list of optional extras.

Impact’s expert sales teams will work with you to identify the ideal model and specification for your application, and maintain its productivity levels and TCO savings through their first-class national support network.

10 FDPP - www.fdpp.co.uk

www.impact-handling.com

POWER UP TO NEW LEVELS OF EFFICIENCY & PERFORMANCE With their compact design, intelligent control systems and low energy consumption, the latest Cat® 1.4 to 5.5 tonne lithium-ion forklifts are the automatic choice for e cient handling in fast-paced, tough conditions. Additionally, you’ll benefit from a great return on your investment, and low total cost of operation. © 2023 MLE B.V. (registration no. 33274459). All rights reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. 0800 169 9789 sales@impact-handling.com www.impact-handling.com Contact us now, it’s time to power up your fleet and boost your business.

Game-Changing Recyclable Pump Technology Optimises Manufacturing Efficiency

Quantex, a PSG® brand, offers a unique and patented recyclable pump technology that is revolutionising liquid dispensing across industries. From consumer-facing dispensers in retail environments, hotels, offices, & vending machines, to industrial manufacturing lines in factories, Quantex is saving valuable time spent on cleaning, maintenance, and product replenishment, whilst providing an accurate and hygienic dispensing solution for food and beverage liquids.

These revolutionary, lightweight, plastic pumps form a part of the product’s primary packaging, similar to the way a wine tap is already fitted on a bag in box, except, rather than manually pressing the tap that allows the product to dribble out using gravity, the pump is clipped into a standard, low cost motor drive in the fixed equipment, and the product is dosed with precision, at a wide range of flowrates with high vacuum for effective bag evacuation.

When a product supply is finished you simply replace the bag and pump with a new bag and pump which means that no costly pump maintenance or calibration

is required. No fluid travels through the fixed parts of the machine and therefore, products can be swapped in and out of the same channels in seconds, without cross-contamination, providing valuable uptime for manufacturing lines.

The pumps are primary container agnostic, so can be attached to a rigid cartridge, pouch, vat, bottle, syringe, or jerry can for example. The simple mechanics in this system mean that equipment footprint is more compact and low cost compared to other pump systems like peristaltic or gear pumps. The range of pumps available can accurately dose micro-volumes of highly concentrated flavourings or additives

from as little as 24µL, to faster flow ingredients up to 75mL/s (or 270L/h). The pumps can handle very high viscosity fluids from honey, jams (with seeds and fruit pieces smaller than 4mm in diameter), mayonnaise, ketchup and relish, highly concentrated apple or orange juice, all dairy products up to the viscosity of sour cream, as well as high acid and high alkaline concentrates.

A reverse cycle capability combined with a valve on the outlet means dispensing can be completely drip-free if required, and there is flexibility with the configuration because the pump can sit above as well as below the product it is pumping.

12 FDPP - www.fdpp.co.uk

Quantex offers ‘Dilution’ versions of its pumps where a filtered waterline can be introduced directly into the pump to mix accurately with concentrates. This is particularly exciting for brands who are interested in saving cost and carbon emissions on shipping by taking water out of the distribution channel.

The positive displacement rotary action of the pumps means that fixed volumes are transferred, and by counting the number of revolutions, the motor drive can calculate the amount dispensed in real-time, providing valuable data to IoT platforms monitoring equipment. RFID or NFC chips can tell the machine how fast to run the pumps for each specific product and can transfer information to the cloud about the product’s ingredients and expiry date, for example. This makes product changeover times even faster since there is no need to programme data into systems.

Quantex is already producing its pumps in high volume for several forward-thinking global customers in lights out, white room automated assembly, with air pressure testing, and printed batch numbers for traceability. Quantex was a privately owned company until it was acquired

in the summer of 2021 by PSG, an operating company of Dover Corporation, headquartered in Chicago, US. Having the support of a multi-billion-dollar global business behind it means that Quantex is perfectly positioned for rapid growth. The Quantex team now works collaboratively alongside 13 other PSG pump and flow measurement brands, including Mouvex® and Wilden®.

Quantex strives to help its customers meet their business needs, an example of this led to the development of an aseptic version of its pumps. Phil Medcalf, Quantex’s Product Manager, explains the benefits this brought to the customer: “Due to an aseptic version of the BiB19 pump, one of our customers is now able to ship fresh products at ambient temperatures rather than keeping them frozen in transit. This aseptic version of the pump uses a self-piercing foil seal, and the customer gamma irradiates the

pump and bag. Shipping ambient product has enabled global distribution as well as reducing shipping cost and carbon emissions – it feels very rewarding to have provided such an impactful solution.”

An interesting application area for Quantex is the burgeoning refill market, where the consumer brings a reusable bottle to refill in a supermarket instead of using single-use plastic, pre-packaged bottles. Quantex’ Director – Marketing, Gillian Harding-Moore, recognised that Quantex provides the key to rolling liquid refill out at scale, and is driving this market segment. She explains: “Quantex is exciting many refill equipment manufacturers, global brands, and retailers, who are keen to meet sustainability goals and reduce single-use plastic packaging waste. Up until now, dispensing food & beverages hygienically and accurately has been challenging, and machines are usually too costly and time-consuming to maintain, but Quantex solves these common painpoints, providing a compact and low-cost, scalable platform. We are at the dawn of a historical movement, changing the way we distribute our goods and shop, and Quantex is at its centre, surrounded by innovators with a collaborative mindset. I am thrilled to be contributing to the sustainability of our planet.”

For more information about Quantex, visit www.quantex-arc.com or email quantex-info@psgdover.com.

FDPP - www.fdpp.co.uk 13

When a product supply is finished you simply replace the bag and pump with a new bag and pump which means that no costly pump maintenance or calibration is required.

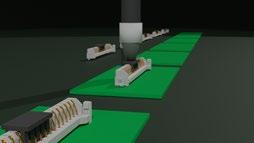

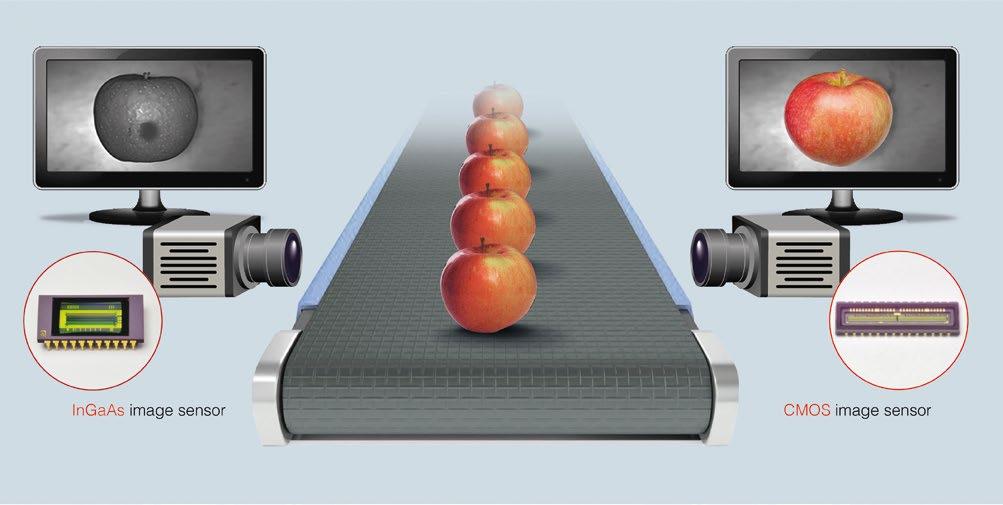

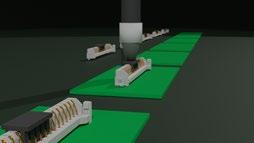

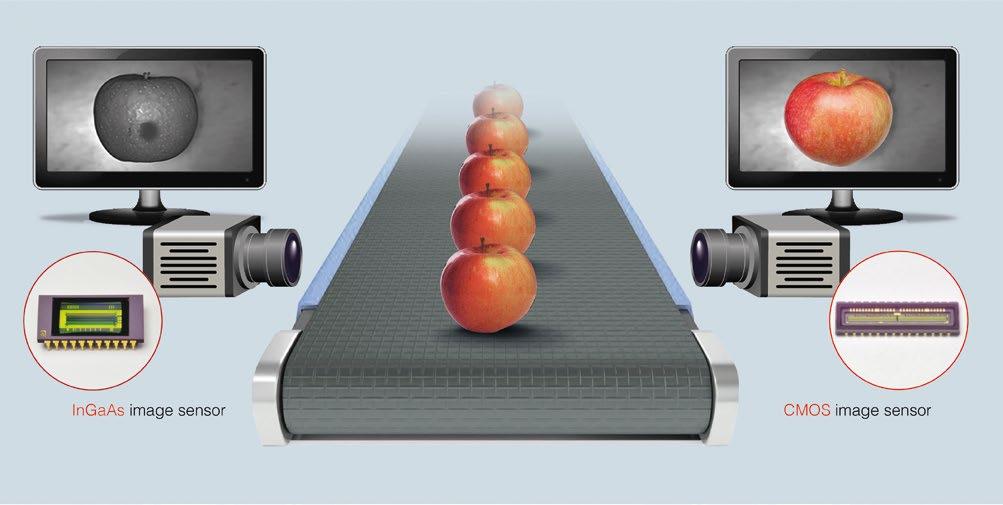

Class leading Anritsu DualX+ to make UK debut on Omori stand at PPMA Show

Anritsu Infivis Ltd, global leader in food inspection technology, is teaming up with UK partner Omori UK Ltd to showcase a brand new best-in-class range of detection equipment - for the first time in the UK - on stand G20 at the PPMA Show (26-28 September, Birmingham NEC).

Centre stage on the Omori stand will be the XR75 DualX+, the latest innovation in X-ray technology from Anritsu. DualX+ is a next generation Photon Detector technology, with specific algorithms for fish and poultry too. The images are meaningfully sharper, delivering superior detection capabilities and lower false rejection rates. Contaminants on the targets are clearly displayed and

identified by the shadows they cast and foreign bodies are more readily identified - even ones that are smaller and thinner in shape, such as tiny fish and poultry bones and fine metal fragments.

Omori UK has over 70 years’ experience in providing high-end packaging, processing and weighing and inspection technology, with solutions often developed bespoke to meet customers’ requirements. From design and engineering to installation and maintenance, the company is dedicated to innovation and low cost of ownership, as well as the development of environmentally friendly solutions that help customers to reduce their carbon footprint.

Sharing the stand with the DualX+ will be Omori’s own range of eco-friendly packaging, processing and weighing solutions designed for the food, pet food and pharmaceutical sectors. Chris Keenan, Sales Director at Omori UK, explained: “Our comprehensive range of equipment and services helps businesses of all sizes improve their packaging and processing output, and the Anritsu machines that we recommend and specify are the perfect addition to our offering.

“At Omori we’re dedicated to meeting the highest quality standards and delivering exceptional performance and the DualX+ couldn’t be a better match to our own solutions, as well as the other

14 FDPP - www.fdpp.co.uk

Anritsu machines we supply. The costs associated with missing a contaminant in food can be catastrophic in terms of both bottom line and reputation, so this latest X-ray technology from Anritsu plays a vital role in food and pharma industries across the world.”

Anritsu’s highly effective inspection systems - which also include high spec metal detectors - can detect a variety of foreign objects in food, including metal, glass, bone, stone, plastic and cement. Equipment selection and placement depends on inspection objectives. In addition to saving consumers from contaminants, and companies from a potentially disastrous legal recall, the equipment has been designed to reduce power consumption and total cost of ownership.

Michael Stuart, Anritsu’s European Sales Director, added: “PPMA is the UK’s biggest annual packaging event and we’re delighted to be joining Omori at the show to help demonstrate the really significant benefits that UK customers can gain from our latest innovations. Poultry and fish bones in particular can be miniscule, so any inspection equipment needs the highest sensitivity - and that is what we have delivered with the DualX+. Visitors will see how this latest technology has evolved to eliminate contaminants from the food chain, even when products are non-uniform in size and shape. It’s a real game-changer.”

For more information visit Omori and Anritsu on stand G20 at the PPMA Show (26-28 September, Birmingham NEC). Or go to:

www.anritsu.com/en-gb

www.omoriuk.co.uk/

FDPP - www.fdpp.co.uk 15

Visitors will see how this latest technology has evolved to eliminate contaminants from the food chain, even when products are non-uniform in size and shape.

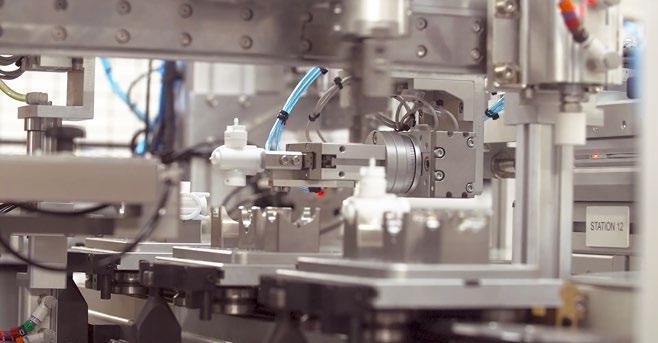

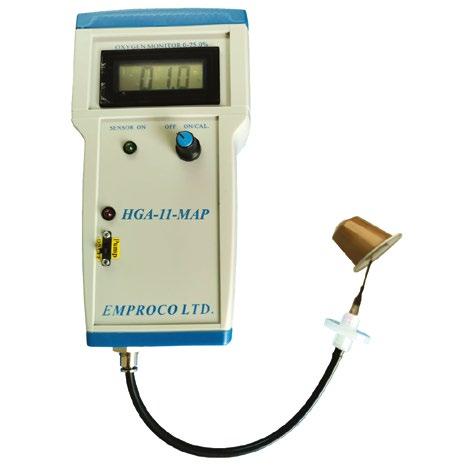

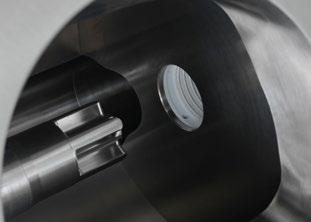

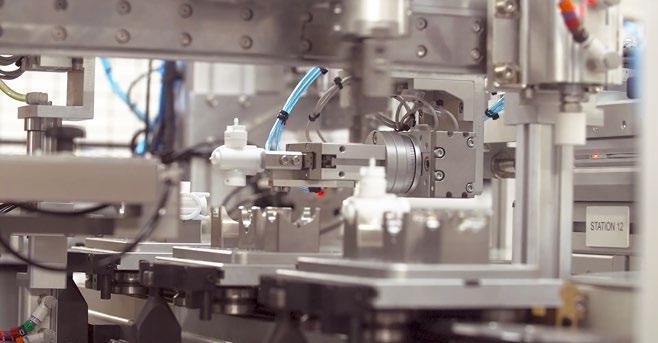

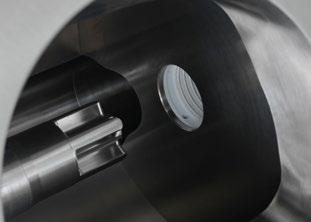

Excellence in machined components for demanding applications

It’s never easy to find a reliable manufacturing company, but if you are dealing with a supplier that is trusted by the likes of Ocado, Ford and BAE Systems you know you are in good hands.

With a 50-year anniversary in its sights, South Wales based DJJ Precision Engineering works closely with all these companies and many more blue-chip manufacturers across industries that demand the highest levels of quality, reliability, and service. These include key sectors such as food & drink processing and packaging, aerospace, automotive, medical, defence, security, and energy.

In more recent years DJJ has experienced considerable growth working with food producers and distributors looking to reduce the financial exposure and risk of shipping delays that come from using overseas suppliers. Projects from fruit picking robotics through to bottling plants and complex grocery picking grid bots have become the norm.

The company offers a complete 24/7 manufacturing service for turned and machined components, producing components in everything from steels, complex metals, and exotics to a wide range of engineering plastics and machined castings. This is complemented by all the added value processes that allow it to offer a truly onestop-shop. These services include finishing, laser marking, grinding, surface treatments, assembly, inspection certification and delivery.

Everything is manufactured in conformance with industry requirements and certified to the highest global standards.

DJJ has embraced the opportunities that have come from advances in robotics and CNC machining and made significant investments in cutting edge manufacturing technology to meet industry’s evolving needs.

During the pandemic DJJ invested in

automating manufacturing processes for customers such as Ocado. It introduced unique robotic machining cells to meet production requirements in both Europe and the USA, alongside full five-axis machining and high-end turning centres from the world’s leading manufacturers.

By utilising state-of-the-art technology, it has been able to enhance its capabilities, optimise production processes and deliver excellent results whilst also offering unprecedented flexibility.

DJJ Precision Engineering Ltd

The investments have allowed DJJ to extend capacity for automated round-the-clock operations, whilst achieving production efficiencies that ensure fast turnarounds, consistent quality, minimised energy consumption, reduced carbon footprint and, more importantly, a genuine competitive advantage on costs for both DJJ and its customers.

The high level of service provided by DJJ is underlined by supplier awards from Ford Motors Global, quality accreditations and the membership of leading industry bodies including Make UK Defence, ADS, the SMMT and the MTA. All manufacturing operations are covered by the highly regarded TUVRheinland ISO 9001:2015 QMS quality assurance accreditation.

In March this year DJJ was supplier certified by the highly prestigious JOSCAR register. This is a list of accredited suppliers to leading industry organisations and is by invitation only. Once invited companies must pass a series of stringent audits before they are

accepted. As a member of JOSCAR, DJJ is now an accredited supplier to organisations such as BAE Systems, the MoD, Rolls-Royce, Boeing and Raytheon. DJJ was also a recent winner of the BAE Systems International Chairman’s Award for providing design support and final production on a project that has been submitted for worldwide patent.

In the automotive sector DJJ is a Ford Motors Global Tier 1 Supplier for deliveries direct to vehicle, and in the food, sector has been successfully supplying Ocado with components for grocery picking grid robots. Other projects include medical diagnostic equipment, widgets for Cola cans, agricultural robotics, airport radar and mining equipment.

Managing Director Dennis Jones said: “There is also an exciting future ahead, with the development of a new energy efficient manufacturing facility, so far 3 years in design. The extension is set to increase production surface areas and provide additional clean room extensions, whilst also providing unique training facilities for engineering skills development.

“With the substantial labour challenges faced by manufacturing businesses every day, DJJ has decided it’s time to grow its own! The expansion will provide real hands-on skills experiences and encourage interest in manufacturing and the inevitable robotisation of CNC machining.”

He concluded: “We can help you with all your machined component requirements and are always looking forward to building new partnerships, helping customers solve their problems and ensuring that they can compete in today’s tough markets. Our investments in high accuracy machinery allows us to remain competitive during constantly evolving industry challenges and make a difference to our customers. Please get in touch to discuss how we can work together.”

Shirley Jones

Email: mail@djjengineering.com

Contact: 01495 760561

16 FDPP - www.fdpp.co.uk

Introducing WineGuard™

WineGuard™ is the new and secure way to send your bottled beverages through the post/courier system. Protect your glass bottles in transit with Wineguard Allpack’s range of bottled beverages transit packaging solutions.

Manufactured using fully recycled materials and being fully recyclable, our pulp fitment ranges fit into specially designed cartons that can securely hold multiple bottled beverages, providing functional, affordable transit packaging protection.

Pulp Fitments and corresponding carton sizes available for the following amounts of bottles -

• x3

• x6

• x12

Scan to visit the full WineGuard™ range

100% recyclable WineGuard™ is manufactured from recycled materials and can be fully recycled or composed.

Designed for maximum safety

Designed for operational effectiveness with interlocking fitments, to save spills in-transit.

Supplied by

Drop Tested for Peace of Mind

WineGuard™ exceeds ISTA drop test protocols and removes in-transit damages/ breakages or spillages.

www.allpack.uk.com sales@allpack.uk.com 01543 396 700

Putting Packaging to the Test

Cerulean’s Laboratory Carton Tester (LCT): providing a measure for the crease quality and frictional forces between carton surfaces.

This instrument measures the torque required to fold the carton crease, as well as the coefficient of friction. Allowing the testing of fold, form, spring back and friction for creased carton board, corrugated board and complete cartons and boxes. Four instruments in one with the newly released V1.71 CT software which enables the user to devise a structured carton performance assessment.

End users gain from an improved running efficiency on form-and-fill lines whilst also offering converters a reduction in rejected cartons leading the less wastage along the production line.

World-wide support; we are your global, local supplier.

info@cerulean.com

www.cerulean.com

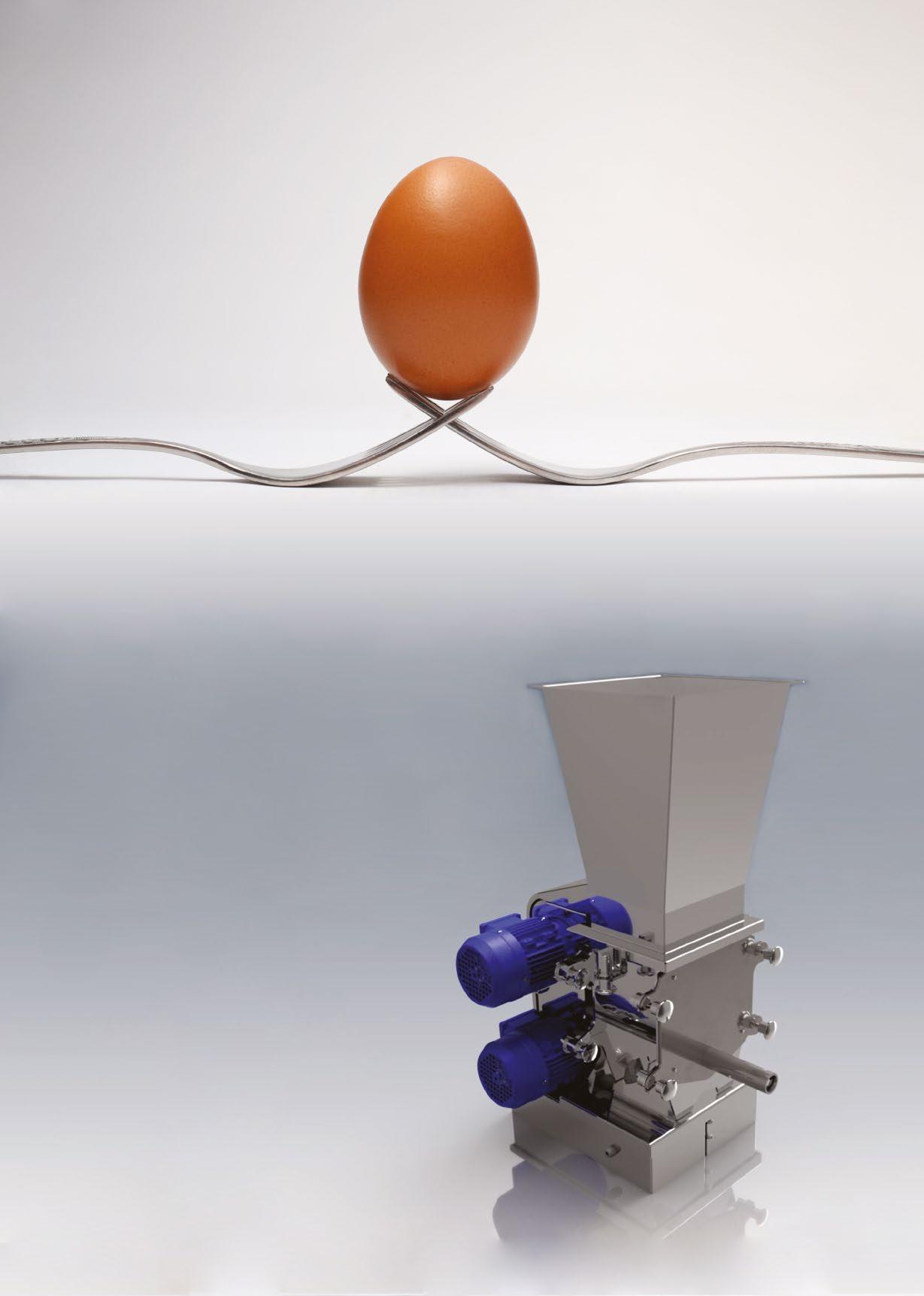

Robust new pump for animal rendering plant cuts downtime

In our latest case study, we’re looking at a recent project where we were asked to supply a high capacity solid transfer pump to a client who operated a facility which rendered animal products. They wanted a rugged, reliable unit which would pump a 50/50 mixture of water and dry solids made up of dry meat, bone and tissue solids at around 350L/min at 2 bar.

All industries create by-products that need to be reused, reprocessed or disposed of. Animal production and slaughter is no different, and this kind of by-product presents particular challenges.

High capacity solid transfer pumps help convert animal by-products from the meat and livestock industry into usable materials. Rendering is a cooking or drying process that simultaneously destroys pathogens, dries the waste animal tissue and converts it into stable, usable materials.

The process separates the fat from the bone and protein, and produces three main products: water, protein and fat. The water is treated and returned to the environment. The protein and fat are used in a range of products including animal and fish feed, biodiesel, biogas fuel and fertilisers.

WHAT WAS THE PROJECT BRIEF?

Our client was looking to pump a 50/50 mixture of water and dry solids consisting of dry meat, bone and tissue solids at around 350L/min at 2 bar.

The mixture had a viscosity of around 50,000cPs which is similar to ketchup or mustard. In addition, the formulation of the liquid and its consistency meant

that it flows slowly so a pump with a built-in hopper was required.

Having a hopper built into the high capacity solid transfer pump ensures that the mixture doesn’t clog and the hopper pump is not damaged through either dry running, or having oversized solids clogging the inlet.

Rendering pump hoppers can be customised for a variety of liquids and applications. They act as a first stage in the process, feeding the pump with more manageable pieces and making

sure that mixtures which don’t flow are fed into the pumping mechanism evenly.

Hoppers are available in a variety of designs:

BRIDGE BREAKER

These are used to slice large solids found into more manageable pieces which can be accommodated by the pump without processing. Fluids which rat hole, prevent free flow or obstruct pipework often need breaking up and kept moving via the use of paddles.

20 FDPP - www.fdpp.co.uk

Auger Feed Hopper

Rat holing is a common flow problem where material becomes stuck in the rendering pump hopper. Rat-holing causes a funnel flow effect, where the material flows freely above the outlet, but the material that isn’t directly above it doesn’t move and sticks to the hopper sides. If this material can’t be shifted it leads to product being wasted and more downtime as the hopper pump has to be cleaned more often.

AUGER FEED

An auger is a flat spiral-shaped screw that runs from one end of the hopper to the other, controlling the flow and mechanically forcing the material into the pump inlet. It’s specifically designed

for dry solids and sludge which don’t flow freely and need feeding into the pump. It’s an essential part for this particular rendering plant application.

MOTORISED WHEEL

When materials such as liquid mortar, resins, mud, blocks of fat or butter are pumped they can plasticise meaning they change shape rather than break up. This means that clogs form and block the rendering pump inlet. These need to be removed manually, again, resulting in more downtime. Manufactured from metal, a motorised wheel rotates 360°within the hopper to stop solids building up and clumping together.

FITTED WITH A SEAL QUENCH

We fitted the high capacity solid transfer pump with a seal quench which is a device that applies unpressurised oil to a mechanical seal’s outboard faces to keep them clean and free from

contamination. This helps to maintain seal integrity. This was important as the hopper pump would be handling large solids up to 41mm wide at high concentrations.

Rendering pump speed is another vitally important factor during the pumping of solids. So we designed the pump to have a reduced pumping speed of 130rpm using the gearbox. This meant that the unit would suffer less wear and tear, and give many years of problemfree pumping to the client.

If you’re looking to pump a liquid which doesn’t flow, contains large amounts of solids and easily solidifies, a hopper-fed progressing cavity pump could be the best solution for you. To find out more, speak to North Ridge Pumps to see how we can help.

www.northridgepumps.com

FDPP - www.fdpp.co.uk 21

Rendering pump speed is another vitally important factor during the pumping of solids.

Progressing Cavity pumps with Auger Feed

Transcend partners with Klüber Lubrication to deliver paper straws manufactured using vegetable-origin food grade lubricant to market

Transcend Packaging, an award-winning UK-based sustainable packaging leader, has partnered with one the world’s leading manufacturers of speciality lubricants, Klüber. Using Klüberfood 4DC (direct contact) vegetable-based technical processing aid in the manufacturing process of its award-winning paper straws, Transcend will be able to remove all traces of mineral oil aromatic hydrocarbons (MOAH) and mineral oil saturated hydrocarbons (MOSH) from the production process, delivering an enhanced straw product to the market.

Currently, while across the UK&I and Europe there is no homogenous standard

method for MOSH or MOAH analysis, there is legislation around the migration of MOAH components from packaging to food and drink products. However, there are calls from industry organisations to tighten standards regarding these substances in both the manufacturing process of the end food and drink products and its packaging. In some EU countries, such as France, the wheels are already in motion to prohibit packaging from containing MOSH and MOAH (where the mass concentration in the ink or the designated product of these substances is greater than 0.1%), with regulation coming into place on 1stJanuary 2025.

The partnership with Klüber allows Transcend to continue to go the extra mile and evolve the production process, creating an enhanced experience for both customers and end users, by applying an even safer, higher quality lubricant to machinery. By switching to Klüberfood 4DC, Transcend is not only answering demands from some of the world’s largest food and drink brands to completely eliminate traces of mineral oil residue now, but making its products compliant for future legislation which will likely come into effect across Europe, the UK and Ireland.

22 FDPP - www.fdpp.co.uk

The strategic partnership will enhance Transcend’s sustainability credentials - Klüberfood 4DC facilitates lower lubricant consumption by optimising performance and application to reduce waste generation. What’s more, Klüber manufactures the Klüberfood 4DC product with 100% food grade ingredients from sustainable sources and of vegetable origin, free of genetically modified organisms (GMOs) and allergens, this also ensures they are Halal and Kosher. This is in contrast to wax-based lubricants which often consist of high-molecular synthetic polymeric chains, additives and oil (mineral oil, synthetic hydrocarbon).

Lorenzo Angelucci, CEO of Transcend

Packaging, said: “Each manufacturer has a responsibility to find the best available solution and maintain the safest possible manufacturing process – especially when it comes to products which are used with food and beverages. At Transcend, we’re never happy with standing still and are always on the lookout for new ways to develop our existing product portfolio for an even more sustainable future and to stay ahead of shifting regulation and policies.

“We know there is going to be tighter legislation focusing on consumer safety coming into force which will impact products used in the food service and FMCG industry. We can already see that happening with France’s ban on the use of mineral oils in packaging materials. We want to be proactive and give our customers the opportunity to commit to the highest possible level of safety. This partnership with Klüber allows us to do that by strengthening our paper straw proposition. For FMCG and hospitality / QSR businesses who are coming under

increasing pressure from shareholders, customers and staff, this gives a solution so they can continue to demonstrate implementation of enhanced food safety and sustainability practices.”

Estelle Robinson, UK market sector manager for UK Food and Beverage at Klüber Lubrication GB Ltd, explains how specialty lubricants help the food, beverage and packaging industries increase productivity, reduce maintenance tasks, and achieve higher safety standards:

“Food safety is a serious topic, in terms of consumer products being manufactured and the production processes involved, which is why we put compliance and safety at the forefront of all we do and were the first lubricants manufacturer to raise awareness of the MOSH/MOAH topic.

As the market leaders we have developed our innovative 4DC range of processing aids, which can be used in the manufacture of food packaging

FDPP - www.fdpp.co.uk 23

At Transcend, we’re never happy with standing still and are always on the lookout for new ways to develop our existing product portfolio.

such as beverage cans or paper straws, protecting everything that comes into direct contact.

Food and beverages packaged for consumption out-of-home, on-thego, or for delivery directly to consumers continues to play an integral part in the active lifestyles of many. Our innovative product developments meet both regulatory standards and commercial objectives to be more sustainable and ensure consumer safety”.

Transcend launched their first paper straw in 2019 ahead of the EU SingleUse-Plastic (SUP) ban, becoming the first major producer of paper straws in Europe. Today they are the European leaders in paper straw production, providing these and other items, such as cups, moulded fibre lids and cartons to global brands including McDonald’s, KFC and Starbucks.

www.transcendpackaging.com

24 FDPP - www.fdpp.co.uk

Klüberfood 4DC is produced in state-ofthe art ISO21469-certified production facility.

Delivering a tailored solution on time and on budget

Handling complex (axial, radial, & moment) loads

Bearings using cylindrical rolling elements, such as IKO’s range of standard needle roller bearings, ensure smooth rotation around the load axis when loaded properly. These bearings are widely used in the rotating parts of production machinery where compactness, high rigidity, and high rotational accuracy are all key requirements.

Alinear rail and carriage system is many a design engineers first choice for transporting a load, and for good reason. It provides a rugged and precise solution that is inherently self-aligning, offers high load handling capabilities, and can operate in some of the most challenging environments. But the temptation to over-engineer a system can add significant cost to a project, while asking a vendor to supply a non-standard arrangement can dramatically lengthen the lead time.

This is where IKO Nippon Thompson’s in-house design and adjustments service becomes invaluable, with the UK team of applications engineers able to suggest design amendments that can reduce lead times from months to days, and/or remove significant cost from a project. Mark Ross, technical sales engineer at the company’s Milton Keynes UK headquarters, says: “There are a wide range of things we can do at local level, from the everyday to the more unusual, to deliver an application-specific solution, providing a key service that can save UK customers time and money.”

our various global locations, and we can tap into that free stock and have it delivered within a couple of days,” says

stroke length, but then bumped up the rail and carriage dimensions to accommodate the required load? Perhaps they’ve even ended up with a design that uses non-standard length carriages.

“By adjusting the rail and carriage dimensions, we can often find a much more cost-effective approach, selecting more appropriate and standard products or better cost products,” he continues. “We can play

Mark.

“From there we have the in-house capabilities to modify standard products to meet specific customer requirements.”

Examples include cutting rail to specific length at the simplest level, or changing the e-dimension –the measure from the end of the rail to the first mounting hole. “As standard, this e-dimension would be half the normal hole pitch, but that might not suit the application,” Mark explains.

A prime example is the company’s ability to assess the key parameters in a project, and look at what can be easily amended without compromising the performance criteria, so that the project can be serviced from the company’s free stock. “For any supplier, manufacturing a system to order is going to take time, but IKO Nippon Thompson will always have standard products available as free stock at

Applications with complex loads can lead to rapid wear and damage of a standard bearing. In this case, IKO’s crossed roller bearing range (CRB) might be a wise choice. This specialised design consists of V-shaped raceway rings holding cylindrical rolling elements with crossed orientations at right angles to each other. Due to the crossed arrangement of the cylindrical rollers, these bearings can support both axial forces and radial forces as well as tilting moment loads and any complex loads by means of a single bearing. As a result, designs involving two ball bearing positions can be reduced to one single bearing.

A number of types are offered, such as slim, super-slim, high rigidity models to be pressed on to a shaft or into a housing, as well as a model with mounting bolts (pictured below), which facilitates easier mounting.

Cylindrical rolling elements, combined with the design of the bearing structure, improve rigidity compared to using ball bearings. According to IKO, its CRB is three to four times more rigid than a double-row angular-contact ball bearing, as well as offering a more compact cross-sectional dimension.

And these bearings are available in many

Such adjustments and amendments can be important time savers for customers, particularly when they are building a prototype as proof of concept. But IKO Nippon Thompson’s design services can also save customers significant amounts of money, for example when it is clear that the design engineer has over-specified the project, perhaps as a belt and braces approach to meeting particular lifespan requirements.

“We can quickly drill down to the customer’s most important considerations and then look at how that impacts on the rail and carriage dimensions,” says Mark. “By talking through load and stroke requirements, that might lead us to propose alternative carriage lengths. For example, has the designer opted for a shorter carriage to increase

sizes. The highest load rating in the catalogue is 2,640kN. IKO has helped with larger applications, such as radar towers on ships, which use the bearings in setting azimuth accuracy.

FLEXIBLE STOCK HOLDING

More than £3.5m of product stock is kept centrally in Milton Keynes, a significant portion of which is freely available for general sale.

“We’re flexible; we get product in and monitor that so it’s always here, or at worst on its way from the factory, so customers can maintain their manufacturing requirements,” says Technical Sales Engineer Mark Ross. All the company asks for is regular communication, so that variations in

with parameters such as preload to see if this provides a better way to meet specific application criteria. Or we can butt together standard rails to deliver longer, non-standard lengths at given profile dimensions without impacting precision.

supply, for example, can be adjusted for.

“In addition, we can add seals and scrapers to protect the rolling elements on some product types, as well as offering different coating options to protect against rust or to alter the products’ aesthetic appearance if that’s a requirement too. The addition of rail caps can also be a further simple (yet cost-effective) way to increase the longevity of the system, and is something which, whilst basic, is often overlooked.”

All of this comes hand in hand with the capability to provide CAD drawings and models, and to port those designs straight into customers’ models.

IKO Nippon Thompson is conscious, too, of the cost of logistics for its customers, and so can supply pre-packaged sets to reduce packaging, handling and stock management. And then there is the company’s on-site training in addition to its telephone and web video support.

And if an urgent stocking need arises unexpectedly, IKO can draw on global stocks. That is just another way in which IKO is helping customers satisfy their production commitments, even for specialised items such as crossed roller bearings.

“It’s all part of a service that means we are much more hands-on with our customers than perhaps other suppliers are willing or able to be,” concludes Mark. “We want to be more involved because it benefits all of us – we get to deliver the most appropriate solution and customers get time- and cost-saving benefits.”

In addition to these crossed roller bearings, IKO manufacture a wide range of other radial, linear, & mechatronic products including cam followers, rail & carriage combinations, crossed roller ways, precision slide units, linear bushings, & ball splines ….. to name but a few

Contact IKO UK today to discuss your motion control needs.

Email: enquiries@iko.co.uk

Tel: 01908 566144

Website: www.ikont.eu/en

We’re flexible; we get product in and monitor that so it’s always here, or at worst on its way from the factory, so customers can maintain their manufacturing requirements.

27 INDUSTRIAL TECHNOLOGY • WWW INDUSTRIALTECHNOLOGY CO UK

www.ikont.eu • Email: enquiries@iko.co.uk Tel” 01908 566144

We talk to the experts at IKO Nippon Thompson about how linear rail and carriages can be easily adjusted and modified, and how projects can be redesigned around standard products, to save customers time and money

• 1000’s of Castors and Wheels for Next Day UK Delivery

• Diameters from 50mm to 455mm. Loads from 50kg to 1500kg

• Friendly Expert Advice, over 45 years experience

• Free UK Mainland Delivery over £90 order value

• Discounts for Quantity Orders

• Easy Online Ordering or Telephone & email orders welcome

• Download Product and Price Datasheets

• CAD Drawings available

• Castor & Wheel Selection Guides

Tel: 01243 607029 | Email: info@basicscastors.co.uk www.basicscastors.co.uk

Torus Manufacturing

Our experienced and dedicated team provide design and precision machining services to a variety of industries throughout the UK and internationally. Our in-house design engineers have a background in practical mechanical design across an array of engineering sectors and industries, as well as our toolmaking team providing both CNC and conventional machining services. A comprehensive fabrication service is also available, no matter the size or quantity required. From precision machined components to general machining requirements: we can supply to your specification.

Our state-of-the-art Toolroom provides a range of engineering solutions. With more than 25 years’ experience in toolmaking, whether you require a turnkey, 1-off or high-volume manufacturing solution, you can be assured that Torus Manufacturing has the answer. Additional services we offer include quality and inspection carried out in our UKAS accredited laboratory, tooling care services for jigs, fixtures and gauges through our regular maintenance programs and shipping and freight. We understand the demands of fast paced engineering and manufacturing environments. Focused on delivering highquality, cost-effective manufacturing products and services, we strive to work with our customers to meet their production needs.

Tel: +44 (0) 1952 210 020 | Email: tml.sales@torus-group.com Web: www.torus-group.com

Torus Modular Frameworks

Torus Modular Frameworks offer a range of flexible, high quality, robust aluminium profile solutions for commercial and industrial environments including office, production, manufacturing, and factory facilities.

Our range includes (but is not limited to) workstations, enclosures, controlled environments, partitioning, and bespoke solutions. Each product has several options and configurations that customers can choose from to meet their own unique requirements, including colour, panel material and amenities such as air conditioning and electrical fit outs. This ensures that your requirements are met and are within budget. Our team will support you with your product from enquiry to installation. We will firstly discuss your requirements in detail along with all the available options. Our inhouse design team will then produce CAD drawings and with your approval, your product will be built/installed on site.

All our solutions are designed, machined, managed, and built in-house at our factory in Telford, Shropshire, UK, from the highest quality aluminium extruded profile and sheet materials, making for a hardwearing and robust solution.

Tel: +44 (0) 1952 210 020 Email: tal.sales@torus-group.com Web: www.torus-group.com

26 FDPP - www.fdpp.co.uk

Titan Enterprises’ NSFApproved Flow Meter Best Value for Beverage Industry

Titan Enterprises maintains certification for their Beverage flow meters and 800 Series turbine flowmeters under NSF/ANSI 169 as equipment for food products. This accreditation is especially important for food and drink manufacturers, food production and handling machinery, and processing and dispensing, as these flow meters can be installed securely in the knowledge that they meet NSF standards. These NSFApproved flowmeters, constructed from food-safe PVDF, are also used in the pharmaceutical and medical industries where end products are consumed.

Titan’s Beverage flowmeters are widely used to monitor the accurate delivery of beer, cider and spirits in distilleries, to automated batching and dispense systems, bar taps in mobile bars and your local pub.

Collaborating with OEMs in today’s modern food and beverage industry, Titan is enhancing production processes such as fast batching, and developing technology capable of differentiating between liquids in the production line, e.g. beer and cleaning solutions.

Having been in production for 26 years, Titan’s liquid flow Beverage meter is a low-cost measurement sensor used for multiple applications in the food and drink sector. It is an exceptionally effective, low cost and reliable method for direct beverage dispensing – beer, coffee, spirits – and dosing additives and colourants, transferring and dispensing accurate and repeatable liquids such as syrups or flavourings into beverages, cider and beer for example.

Neil Hannay, Senior R&D Engineer with Titan Enterprises, says: “Our expertise

in beverage applications translate robust and compact design into longterm performance. We offer liquid flow measurement solutions to ensure beverage dispense systems operate consistently every time a glass or bottle is filled!”

The alcoholic drinks market is expected to see continuous growth between 2023 and 2027, and the demand for soft drinks, including fruit juices, is at an all-time high. To meet this rising demand, major beverage producers face challenges related to waste reduction, increased throughput, inventory minimization, and improved quality. Accurate measurement of ingredients is crucial, especially for high-value

constituents used in small quantities. The accuracy and reliability of Titan’s NSF-Approved Beverage flowmeters contribute to efficient and consistent beverage production and dispensing processes, and with over 41,000 sold each year, are industry proven worldwide.

For full technical information on Titan’s NSF-Approved turbine flowmeters please visit https://flowmeters.co.uk/ product/nsf-approved-beverage-flowmeters/

Contact Titan Enterprises: Tel: +44 (0)1935 812790

Email: sales@flowmeters.co.uk

Website: www.flowmeters.co.uk

FDPP - www.fdpp.co.uk 27

Accurate measurement of ingredients is crucial, especially for high-value constituents used in small quantities.

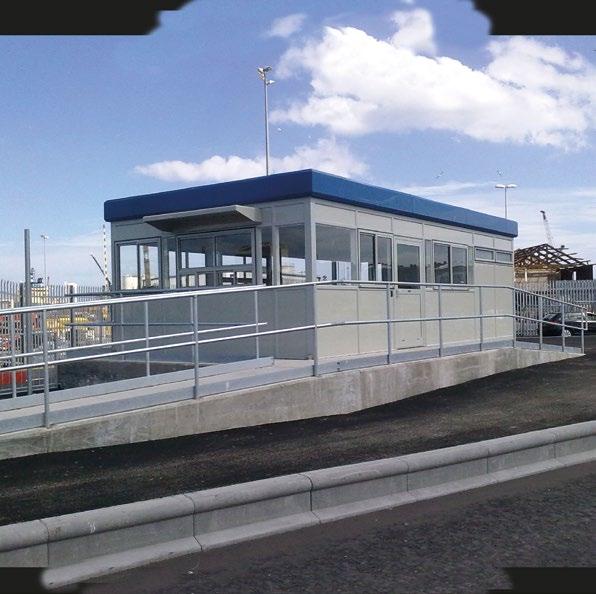

Installing an instant building – doing it your way

By Jason Lynock, Smart-Space Sales Director

One of the things that always strikes us are the different levels of supply that our customers prefer. On one hand we have those who are simply looking for us to supply and install a temporary building. And then we work with organisations of all sizes who ask us to take care of everything, from design and planning right through to maintenance.

How it all starts… Smart-Space has the kind of infrastructure that can manage exactly what the customer needs. It almost always begins with a site visit from one of the sales team - a conversation to establish what the building will be used for, a site survey and a quotation.

Shaun Stephens, our UK Sales Manager, has been with the business for several years and his time-served understanding is incredibly valuable when it comes to advising our customers. “Sometimes I can see exactly what the customer is asking for but know it won’t work for any number of reasons. It’s my job to find a solution that’s as close as possible to their vision

but that will also tick all the boxes in terms of planning, application and health and safety” said Shaun.

Going to site… Then our site survey team looks at the logistics in a little more depth, factoring in use, utilities, boundaries and any unique information that relates to the site. Planning permission is something we undertake regularly but equally can be managed by the customer if preferred.

Picture this… If the project needs drawings we have skilled CAD designers who can show the building elevations from every angle – it’s very useful for the planning permission process and also the customer’s own general project planning.

LOOKING

Bringing it all together… There’s a lot to do in terms of project co-ordination: from making sure we have the correct materials and installation supplies, installation teams scheduled (with accommodation if necessary), health and safety assessments and other paperwork, any plant or equipment needed and the appropriate vehicles. And, of course, all of that has to co-ordinate with the customer’s plans as well.

For aftercare… our maintenance team, headed by Sam Stokes, responds quickly to any customer requests and they also work with customers who have a maintenance contract with us, making sure the buildings continue to be fit for purpose. It’s a well-oiled machine!

Ultimately, this is a system that works seamlessly and serves the business and its customers very well. Because of the way it’s set up it means customers are perfectly able to pick and choose which elements they want to include in the service. And that works well for everyone.

www.smart-space.co.uk

WAREHOUSING I STORAGE I FACTORY SPACE

Talk to our friendly, professional, experienced team - we can advise on the best options from a range of solutions. Our British supply chain and directly employed teams means we are quick and reliable. We are also completely flexible: you can hire or purchase (or switch whenever you like) and you can off-hire at any time. We do everything - from building only to turnkey solutions (and everything in between).

28 FDPP - www.fdpp.co.uk

SPACE? FLEXIBLE I RENT OR BUY I FAST SOLUTIONS smart-space.co.uk Talk to the team Jason Lynock: 07971 542357 Shaun Stephens: 07535 117181

FOR INSTANT, FLEXIBLE, ADDITIONAL

26-28 SEPT 2023 NEC, BIRMINGHAM, UK STAND H30

BIXOLON Showcases Its Dedicated range of labelling printing solutions at LabelExpo 2023

BIXOLON Europe GmbH, a subsidiary of BIXOLON, the global manufacturer of advanced Receipt, Label and Mobile printers, announces its presence at LabelExpo 2023, where it will showcase on stand 9A63 its dedicated range of labelling printing solutions on the stage of the world’s largest label and package printing event.

Key exhibition product highlights will include:

• Linerless vs Liner Labelling Printing Zone – BIXOLON will put the spotlight on comparing linerless and liner label printing by showcasing its extremely reliable, environmentally friendly and cost-efficient XL5-40 4-inch (114mm) desktop direct thermal linerless label printer side by side with the XD3-40 4-inch (118 mm) direct thermal traditional label printer, giving visitors the opportunity to understand the many different advantages of traditional liner and linerless labelling technologies.

• RFID Labelling – BIXOLON will present a comprehensive selection of RFID print and encode printers, including mobile, desktop and industrial models. Among them, the XM7-40R 4-inch (112mm), the premium mobile RFID label printer with advanced features, and the XD5-40tR

4-inch (118mm) RFID enabled thermal transfer desktop label printer. In addition, the XT5-40NR 4-inch (114mm) thermal transfer RFID label printer, which provides outstanding power and performance for industrial use.

• Best Seller Highlights – Offering high performance variable width printing solutions, BIXOLON will present its bestselling range of labelling printers, including the popular XM7 series featuring the premium XM7-20 2-inch (58mm), XM730 3-inch (80mm) and XM7-40 4-inch (112mm) auto-ID mobile liner and linerless label printers, along with a wide range of accessories. Alongside, the budget-friendly XT3-404-inch (114mm) industrial labelling line, the unique XQ-840 4-inch (118mm) two-in-one, stand-alone label printing solution with integrated tablet, and the compact SLP-DX220 2-inch (60mm) barcode label printer, together with the

highly reliable XD5-40 4-inch (118mm) desktop direct thermal printer suitable for small to mid-range businesses.

BIXOLON will also be joined on the stand-by Iconex™, the iconic inventor and continued leader in receipts and leading provider of unrivaled, best-in-class labelling and tracking technology, who will showcase its MAXStick® Linerless paper and Iconex Sticky Media™ liner-free label identification solutions in conjunction with BIXOLON printers.

“LabelExpo provides an immersive trade fair experience, offering a comprehensive overview of cutting-edge advancements in the label and package printing industry. With a focus on the latest labelling trends, BIXOLON’s participation at LabelExpo reaffirms the company commitment to continuous innovation in this everevolving market” explains Jay Kim, Managing Director, BIXOLON Europe GmbH. “Exhibiting alongside Iconex™ at LabelExpo is the perfect opportunity for both companies to expand our networks within this significant industry.”

To find out more, visit BIXOLON at www.BixolonEU.com or contact sales@bixolon.de to make an appointment to meet the team.

30 FDPP - www.fdpp.co.uk

Exhibiting alongside Iconex™ at LabelExpo is the perfect opportunity for both companies to expand our networks within this significant industry.

Precise adjustment of Focus & Iris USB connector standard Inspection while moving focus

• Easy Installation

• High Resolution at any position

Connection

MORE THAN 70,000 STANDARD COMPONENTS

• Outstanding repeatability • Low voltage and current • Superior and versatile interface

of optics

THE BIG BOOK GREEN

THE BIG GREEN BOOK EDITION 2022

n Get your copy of THE BIG GREEN BOOK easily online.

info@norelem.co.uk www.norelem.co.uk GREEN MEANS GO. Find it. Get it. Go. Norelem 8521 Food Drink Processing & Packaging Half Page V2 AS.indd 1 15/02/2023 15:33

FDPP - www.fdpp.co.uk 31

• Superb stopping accuracy computar-global.com info@cbcuk.com 020 8457 2618 catalyst

Diagram

LensConnect … Zoom, Focus & Iris remote-controllable from PC Introducing the award-winning computar LensConnect Series

n More than 70,000 standard and operating parts from one place: simply ordered - delivered immediately. n Design even faster without configuration thanks to free CAD data

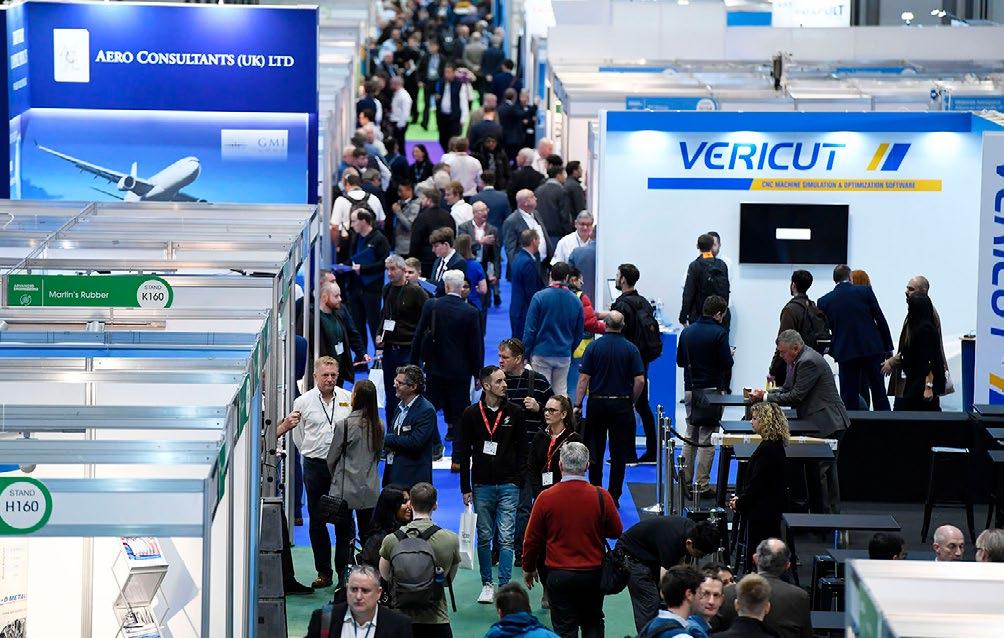

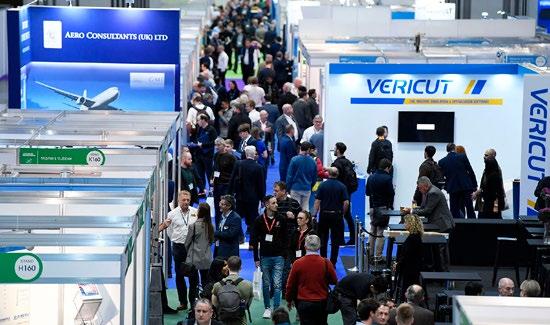

What’s going on at Advanced Engineering in 2023?

Advanced Engineering, the UK’s largest annual gathering of engineering and manufacturing professionals, is set to open its doors in a few weeks. Now in its 14th year, this year’s show comes with a fresh rebrand, removing the previous show zones and introducing a main stage for the event’s well-attended forums.

Advanced Engineering, taking place on November 1 and 2 at the NEC, Birmingham, was previously divided into several zones. However, in order to meet the future demands of the engineering and manufacturing sectors, the show has been re-engineered to encourage even more cross-industry collaboration.

This year, the long-established composite zone will remain, but the automotive, aerospace and connected manufacturing zones will be removed. However, these sectors will still have a strong presence

at the event, with the industry-specific forums remaining. There will also be a central stage on this year’s floor plan where discussions about key challenges in the industry will be discussed.

“Making these changes wasn’t an easy or a quick decision,” explained Alison Willis, director of Easyfairs, the organiser of Advanced Engineering. “We spoke to over 200 exhibitors, visitors and speakers to make sure that any changes made were future-proof and reflective of all stakeholders. We realised that many of the issues that our exhibitors and visitors are facing align. Take sustainability for example — we wanted to make sure that our floor plan allows attendees to share ideas and solutions to challenges like this,”

“Advanced Engineering has expanded greatly over the years, starting as a specific aerospace event 14 years ago.

2023 felt like the right time to fully encourage collaboration across industries and to prepare the show for a new era of manufacturing and engineering.”

With the rebrand, Advanced Engineering returns with a speaker programme made up of some of the leading figures in UK engineering and manufacturing. This year’s day one keynote is Richard Noble, OBE, former holder of the world land speed record and serial innovator at ThrustWSH. Also on the main stage, Eman Martin-Vignerte, Director of External Affairs and Government Relations at Bosch, will share her thoughts on digitalisation and automation. In the afternoon, there will be a women in manufacturing panel, followed by a discussion from a Make UK representative on how new industrial technologies are affecting the skilled workforce.

32 FDPP - www.fdpp.co.uk

On day two, the opening keynote will be given by Make UK, and will be followed by talks from Made in Britain on innovation in British engineering and design, and a second panel on women in composites. Two exciting competitions will also be held on the main stage, with the Enabling Innovation competition in the morning and the SAMPE Design and Make competition in the afternoon.

At the aerospace forum, visitors can meet experts from H2FLY, Rolls-Royce, YEET Aerospace, MGI Engineering, ADS, Midlands Aerospace Alliance, Satellite Applications Catapult and more, who will cover topics ranging from digitally enabled supply chains to propulsion technologies.

Meanwhile, exhibitors can learn about composites circularity, the future of

composites and digitalisation being the key to productivity at the composites forum. Attendees can also see Pim van Baarsen, CEO at Silverstone Technology Cluster, and Lucy Parsons, Sales Account Manager at Nikon Metrology UK, who will be discussing and showcasing innovative products at the automotive forum.

Advanced Engineering will also showcase groundbreaking innovations throughout its exhibition area. One of these is the prototype of the ThrustWSH boat. In what is a collaborative effort with PRF Composites, ThrustWSH has achieved the world land speed record and will allow visitors to see whether the boat can conquer the water speed record at the show.

In addition, MGI Engineering is speeding ahead in their journey to net zero and will demonstrate never seen before technologies to the sector, including an F1 car and eVTOL drones. Meanwhile, SCU Motorsport has also booked up an exclusive exhibitor spot, pioneering its 3D learning environment for students that will involve augmented reality, virtual reality and mixed reality technologies.

It’s clear to see why this year’s expanded

floor plan is quickly filling up. One of last year’s exhibitors, George Chetwood, Business Development Manager at Cognitiv Spark, said, “The show has been great — we’ve met so many new people and had great conversations. We’ve met clients that we’ve already been in talks with and have advanced those conversations. Our director has secured a spot next year, so we’ll be back then.”

Lee Brent, Sales Manager for Southwest Fabrications, commented, “This is our first year exhibiting at Advanced Engineering but it will not be our last. After a friendly and helpful team helped us decide on our stand in the most appropriate location, we have seen a tremendous amount of visitors flow through our stand, with over 100 individual companies interested in the products and services we offer. We have been so pleased with our experience and look forward to exhibiting for many years to come.”

To secure your visitor pass, see a current exhibitor list and check out the growing list of confirmed speakers, visit the Advanced Engineering website.

For further information, please visit www.advancedengineeringuk.com

FDPP - www.fdpp.co.uk 33

2023 felt like the right time to fully encourage collaboration across industries and to prepare the show for a new era of manufacturing and engineering.

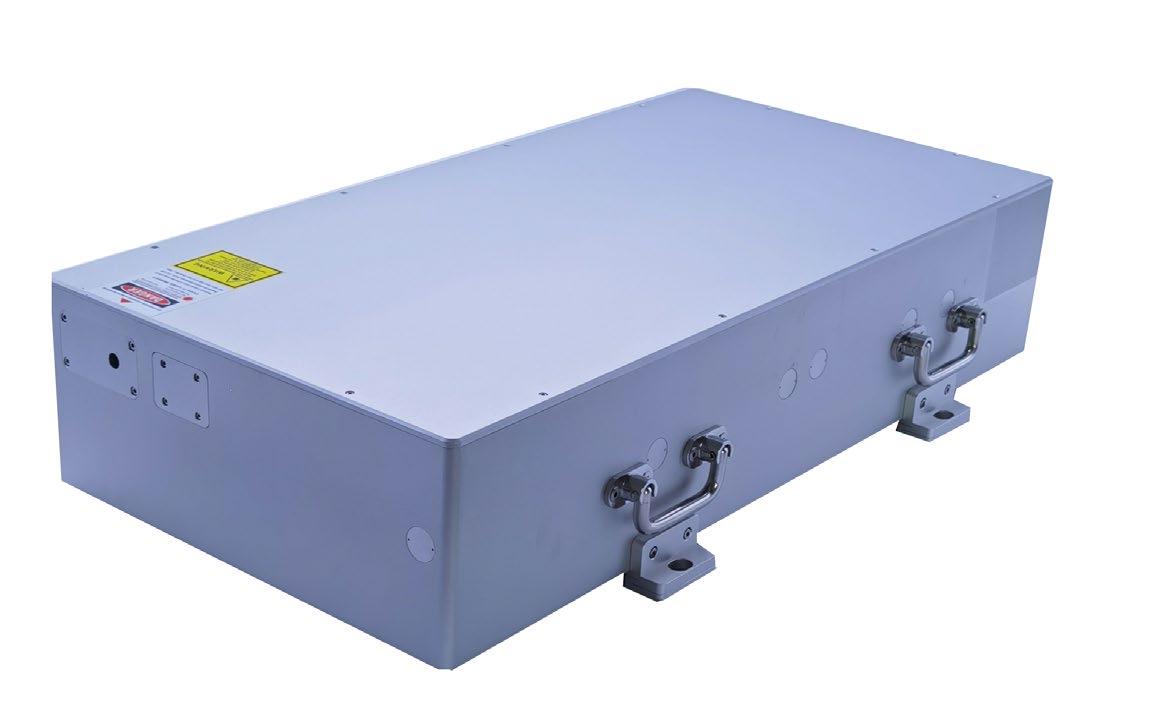

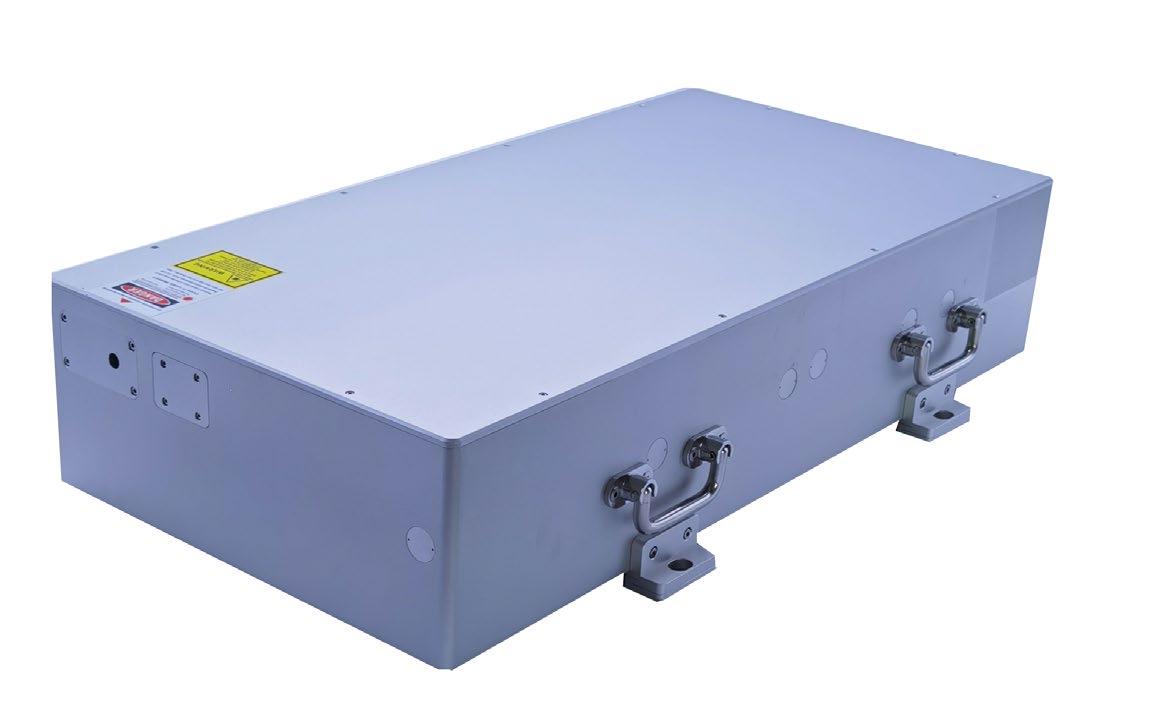

Peak power

High Power Picosecond Pulse Laser

The picosecond pulse laser series FPYL-Q-PS is offered with peak power up to 100W at a repetition rate of 1MHz and a pulse width of <10ps. Available wavelengths are 266nm (1-8W), 355nm (1-50W), 532nm (1-80W) and 1064nm (1100W). The repetition frequency range is between 400kHz and 2MHz. The power stability is <3% (<1% optional). The pulse-to-pulse stability is <2%. Both are measured in rms and over 4 hours. The output beam is transverse mode TEM00 and has high beam quality of M2<1,2. With a beam diameter of ~3mm and a divergence <1mrad the output beam is very well collimated.

The laser is delivered with an appropriate power supply for the

voltage range 100-240V as well as a water chiller.

Due to the high power with pulse widths <10ps these lasers are excellent suited formicro material processing. Typical applications are:

Applications:

♦ Flexible Materials Processing

♦ Brittle Materials Processing

♦ OLEDs Processing

♦ Glass & Ceramic Cutting and Drilling

♦ Semiconductor Industry

www.frlaserco.com

sales@frlaserco.com

The laser is delivered with an appropriate power supply for the voltage range 100240V as well as a water chiller.

34 FDPP - www.fdpp.co.uk

For over 30 years Industrial laser systems have been commonplace in manufacturing and R&D facilities all over the world, providing clean and efficient ways of improving manufacturing processes. Such applications include replacing labelling by direct marking onto components or replacing cutting systems with state-of-the-art laser converting processes, a digital technology that enables manufacturers to produce features that otherwise would be problematic or impossible to cut without the need of tooling.

Lasers for the Digital Era

A NEED FOR CHANGE

Dynamic market conditions and fluctuating demands necessitate the need for changes to traditional processing methods. Market conditions and demands require shorter production runs, faster times to market and environmentally friendly alternatives, thereby requiring the need for fast, efficient, and cost-effective set-up and change overs, cost-effective programme changes, and the ability to process a wide range of materials.

For packaging and converting equipment OEMs, finding a repeatable baseline process to manage dynamic production

needs and incorporate enough processing flexibility to accommodate new materials is challenging. A digitally controlled laser processing systems is the solution; let’s explore some questions on this technology that we are often asked.

WHY USE A LASER SYSTEM?

Quite simply, traditional mechanical processes cannot match digitally controlled laser systems which are very adaptable, and capable of performing multiple processes often in a single pass. Unlike most mechanical methods, laser systems can be combined with other equipment to provide customized latestage alterations, even to finished goods.

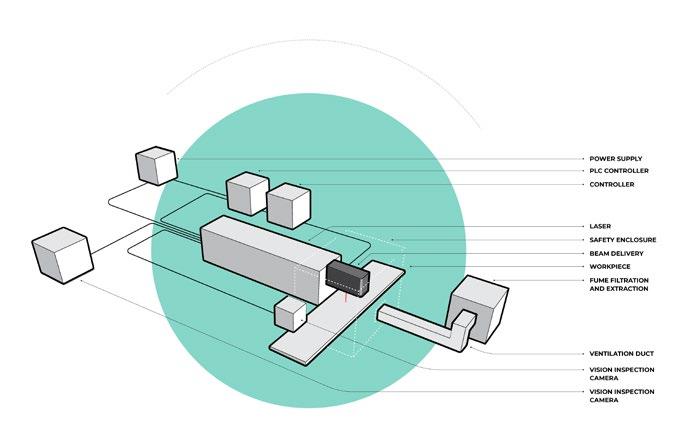

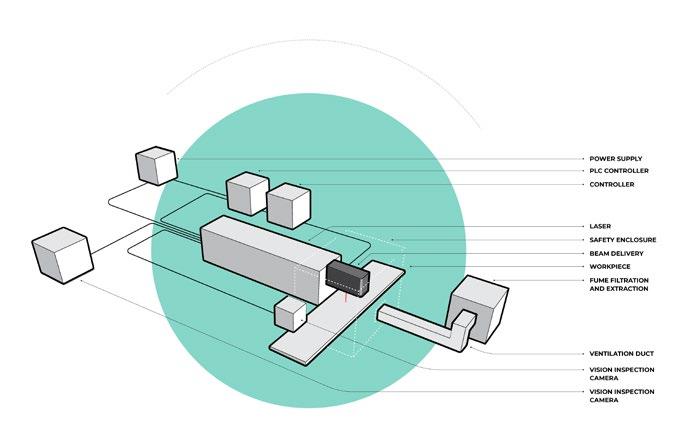

WHAT IS A LASER SYSTEM?

Laser systems are adaptable, digitally controlled, non-contact processing systems, and typically include selfcontained machines, in-line, and robotic systems. A laser system generates a very narrow beam of radiation (light) which is directed to the target material to perform a wide range of interactions (application processes). At the heart of each system is the laser processing sub-system that

Carboard die-cutting.

Cardboard perforating

includes a laser source, beam delivery, controller (software or hardware) and a power supply.

Depending on the type of laser, the application, and the target material, other components may be needed, including chillers, work piece delivery system, fume filtration/extraction, and vision inspection cameras.

WHAT CAN A LASER SYSTEM DO?

Laser processing systems are highly versatile, adaptable to both stationary and in-motion processing. An excellent selection for OEMs and system architects looking to build flexibility and adaptability into their machines or processing systems for applications such as perforation, scoring, scribing, kiss-cutting as well as through-cutting, marking and coding.

WHAT MAKES LASER PROCESSING DIFFERENT?

While there are many hardware and systematic differences between laser processing systems and traditional mechanical systems, for converting and packaging there are several standout

benefits. Zero-touch processing for instance for sensitive materials and sterile processing, and the elimination of mechanical wear resulting in a reduced inventory costs and consumables. The greatest reduction comes from the lack of production down time, with on-thefly changes controlled through software command and control, reducing setup and changeover costs.

THE VALUE OF A LASER SYSTEM?

Integrating Advanced Manufacturing Technologies (AMT), such as laser processing systems can be a significant investment with an extended payback period. However, investing in new technologies is a requirement to stay competitive and brings many benefits, including quick response to dynamic customer demands, greater productivity levels, increased processing, reduced downtime, higher quality products, lower operating costs, and improved operating efficiencies.

BETTER FOR THE ENVIRONMENT

Businesses are becoming more aware of how their systems and processes impact the environment. No one solution is perfect, however laser processing systems offer users ways to reduce their impact on the environment. Implementing steps to reduce your organization’s ecological impacts show your customers, and their customers, you are committed to making a difference. Laser processing systems offer ecological

benefits over traditional processing methods by decreasing waste.

Traditional methods of marking and coding utilize inks and/or additional printed labels. Laser systems, however, can apply permanent marks and codes directly on materials and products, eliminating the need for secondary label printing or consumable marking inks. Manufacturing cartons and boxes typically involves production runs in the thousands of units to be cost effective due to the high cost of changeovers and dies. Laser systems can change die patterns on the fly, significantly reducing changeover downtimes and die costs associated with size and pattern changes. Further, the ability to use a wider range of carton sizes reduces wasted materials, packaging space, and shipping costs.

HOW TO CHOOSE THE RIGHT LASER SYSTEM

Laser Lines Ltd has been supplying lasers to the UK market for nearly 50 years. During this time the company has gained considerable experience when it comes to recommending the right laser system for the application. Not only able to supply the laser system, but we can also carry out application trials at our demonstration laboratories to ensure the customer is fully confident they are buying the right solution. In addition, the company supplies many of the accessories associated with running a laser system, and on the rare occasion there is a problem, we have manufacturer-trained technical support staff to resolve any issues.

FDPP - www.fdpp.co.uk 37

www.laserlines.co.uk

Unlike most mechanical methods, laser systems can be combined with other equipment to provide customized late-stage alterations, even to finished goods.

Basic laser system

Cardstock cuttinng/ stencil –application example.

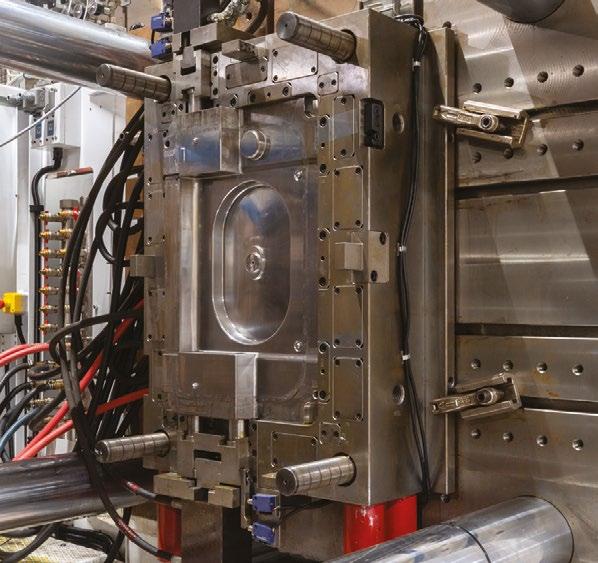

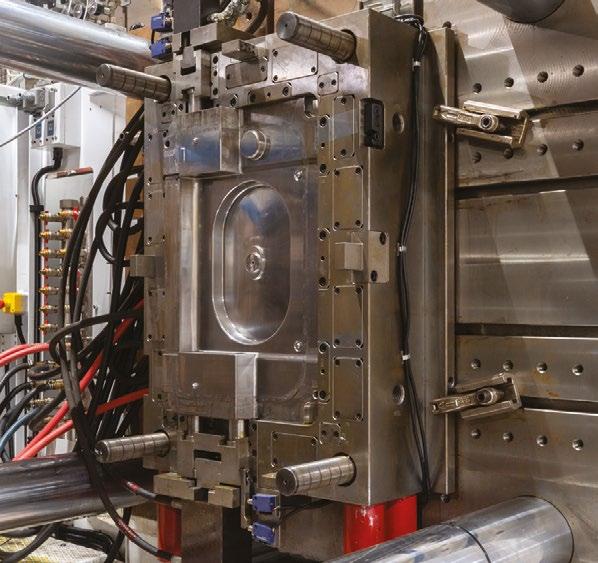

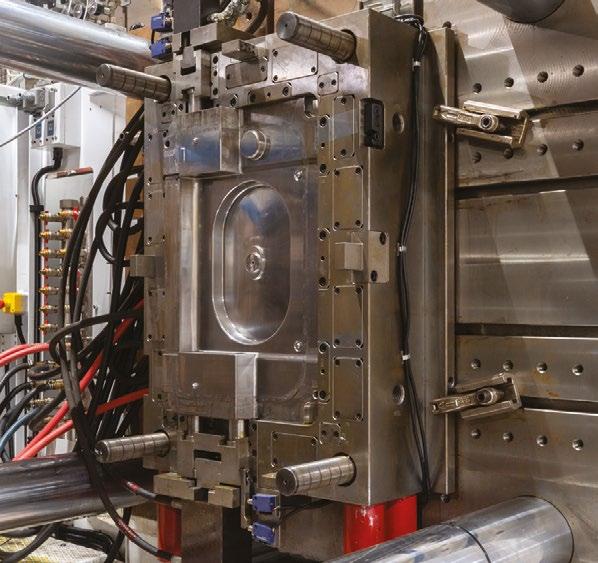

A professional yet flexible approach

Patterson & Rothwell is a wellestablished company based in Oldham, Northwest, specializing in toolmaking and injection moulding. With their state-ofthe-art facilities and extensive experience, they are experts in bringing new products to market and partnering with companies for trade moulding work. Their capabilities include a range of 66 injection moulding machines, 30t -1100t, a dedicated toolroom, component and tooling design and a commitment to automation for sustainability improvement.

Operating from a 130,000 sq ft facility on a 7-acre site, Patterson & Rothwell has a team of 160 employees and processes over 500 tons of polymer monthly. They offer flexible injection moulding solutions to a diverse range of industries, including electrical, healthcare, horticultural, food & beverage, windows, and roofing. Recently, they have expanded their capabilities with a dedicated assembly area to meet customer requirements effectively.