FOOD & DRINK PROCESSING & PACKAGING

Issue 47 2023

Meeting the surge in demand for grain-based foods

Rotzinger develops innovative adaptive packaging machine enabled by CoreTigo’s IOLink Wireless solution

daysoft® celebrates its 1 billionth 1,000,000,000 daily disposable contact lens made in the UK and sold direct around the world for half the price of competing brands from 20p delivered.

www.daysoft.com

Contents Features B-HIVE INNOVATIONS < 8 ROTZINGER < 16 GOUGH ENGINEERING < 22 AROUND NOON < 26 INNOVATIVE TECHNOLOGY < 30 LEUZE < 38 DELTA < 42 NORD < 46 NSK EUROPE < 48 REDEX GROUP < 50 VERLINDE < 56 RUSSELL FINEX < 58 Editor Amanda Buckingham editor@fdpp.co.uk Digital Sales Manager Jessica Bennett T: 01227 392571 Business Manager Josh Holmes josh@mhmagazine.co.uk Digital Manager Jamie Bullock jamie@fdpp.co.uk Tel: 01227 392571 M H Media Global Ltd. 18/20 Newington Road, Ramsgate Kent, CT12 6EE Tel 01304 806039 www.fdpp.co.uk Every effort is made to ensure the accuracy and reliability of material published in Food & Drink Process & Packaging however, the publishers accept no responsibility for the claims or opinions made by the contributors, manufacturers or advertisers. No part of the publication may be reproduced or transmitted in any form or by any means, mechanical, electronic (including printing), recording or stored in any information retrieval system without the prior written consent of the publisher. All web addresses are interactive, simply click the web address of your choice to view the company website. There is also a useful tool bar where you can search for a specific product. Please mention FDPP when responding to items in this issue. Publishing Director Martin Holmes martin@fdpp.co.uk Studio Designer Richard Bland richard@mhmagazine.co.uk The Team FDPP - www.fdpp.co.uk 3

Smith’s snackfoods installs large-scale Bulk handling system for new chip line

Smith’s Snackfoods began manufacturing potato crisps (chips) in Australia in 1931 and was the first to offer flavoured crisps in Australia. Today, as a unit of US-based PepsiCo, its brands include Twisties®, Burger Rings®, Doritos®, Parker’s® pretzels, as well as reduced-fat products such as Sakata® rice cakes, and Sunbites® Grain Waves® whole grain chips and Sunbites® air popped popcorn.

In January 2019, Smith’s installed a process line to manufacture Smith’s® Oven Baked potato chips, which contain 50 percent less fat and have more crunch and texture than traditional fried crisps.

For the powder handling and blending portion of the new line, Smith’s worked with Flexicon Corporation Australia. Due to the size and scope of the new system, the supplier’s Project Engineering Division

(PED) handled much of the design and specification work.

UPSTREAM BATCH AND DOWNSTREAM CONTINUOUS PROCESSES

The new powder handling and blending system consists of two upstream batch

processes that feed a downstream continuous process.

In one batch process, major ingredients received in bulk bags are dispensed by weight from two Bulk-Out® model BFC bulk bag dischargers supplied by Flexicon. Installed facing one another, the matching dischargers are each equipped with an electric hoist and trolley that travel on an I-beam common to both frames, allowing bulk bags to be loaded from a single floor location.

The dischargers are each equipped with a Spout-Lock™ clamp ring atop a Tele-Tube™ telescoping tube that applies continual downward tension as the bag empties and elongates, directing material through the bag spout. The sealed systems of both dischargers are vented to a dust collection system installed in an

4 FDPP - www.fdpp.co.uk

Twin bag tip stations for adding low volume ingredients flank a bag compacter which compresses empty bags for dust-free disposal. The large buffer hopper (right) receives blended batches that are transferred pneumatically to the downstream process.

adjacent room, preventing contamination of the plant environment.

Flow-Flexer™ bag activator plates raise and lower opposite bottom edges of the bags on timed cycles, ultimately forming a steep “V” shape that promotes total discharge. Both are also equipped with a Power-Cincher™ flow control valve in which contoured stainless steel rods cinch the bag spout concentrically, allowing dustfree retying of partially empty bags.

When a batch is initiated, the rotary airlock of either discharger begins metering material into a common pneumatic conveying line leading to a Flexicon filter receiver suspended on load cells. Weight gain information is transmitted to the system controller that runs the airlock valve at high speed, then at dribble feed rate which, together with programmatic compensation for material in-flight, achieves precise batch weight accuracy.

Once major ingredients are batched in sequence from bulk bags, pre-weighed sacks of low-volume ingredients are positioned using a 25 kg vacuum sack lifter,

and dumped manually through a Flexicon bag tip station with integral dust collector and rotary airlock valve feeding the same pneumatic conveying line. A chute through the sidewall of the bag dump hood leads to a Flexicon bag compactor with pneumatic ram that compresses up to 150 bags into a plastic lined container for dust-free disposal.

The batch accumulated in the filter receiver is then gravity discharged into a paddle mixer. Blended batches are discharged into a Flexicon buffer hopper that is sized to provide a continuous supply of material to the downstream process through a second pneumatic conveying system and filter receiver.

In a separate batch process, a Flexicon bag tip station–also with integral dust collector, compactor chute, and rotary airlock valve–is dedicated to manual additions of preweighed, pre-mixed inclusion ingredients. Positioned adjacent to the first bag tip station, it shares the same bag compactor, but meters material into a third pneumatic conveying system and filter receiver.

The second and third filter receivers are suspended on load cells that signal the system controller when to convey additional blended material from the buffer hopper, and from the second bag dump station respectively. These rotary airlock valves provide material on an as-needed basis to a pair of loss-in-weight (LIW)

gravimetric feeders, which allow rapid changing of screws to suit material flow characteristics, at throughputs from 4 to 400 kg/hr (8.8 to 880 lb/hr). The overall arrangement allows the LIW feeders to provide an uninterrupted supply of material to a new continuous mixer at precise ratios and rates, completing the powder handling and blending portion of the new Oven Baked potato chips line.

MANAGING LOCKDOWNS AND LOGISTICS

Flexicon’s Project Engineering Division recommended equipment specifications, coordinated multiple equipment manufacturers, and developed a controls and automation package for the bulk handling system that integrates with Smith’s overall process control system. For parts to be imported, the supplier obtained special exemptions to COVID-19 restrictions on crossing state borders.

“We had an aggressive schedule to get the new production line installed and commissioned on time and we ran into numerous challenges as a result of the COVID-19 pandemic,” says Nayantha Abeysiri, PepsiCo project manager. “However, Flexicon found solutions to those challenges while staying on budget to get the equipment manufacturing completed on schedule.

“The equipment design is efficient, hygienic, simple, and meets all EHS requirements and food safety standards,” he says, adding that Flexicon is in the design phase for another project.

Flexicon (Europe) Ltd

+44 1227 374710

sales@flexicon.co.uk

www.flexicon.co.uk

FDPP - www.fdpp.co.uk 5

Flexicon found solutions to those challenges while staying on budget to get the equipment manufacturing completed on schedule.

A professional yet flexible approach

Patterson & Rothwell is a wellestablished company based in Oldham, Northwest, specializing in toolmaking and injection moulding. With their state-ofthe-art facilities and extensive experience, they are experts in bringing new products to market and partnering with companies for trade moulding work. Their capabilities include a range of 66 injection moulding machines, 30t -1100t, a dedicated toolroom, component and tooling design and a commitment to automation for sustainability improvement.

Operating from a 130,000 sq ft facility on a 7-acre site, Patterson & Rothwell has a team of 160 employees and processes over 500 tons of polymer monthly. They offer flexible injection moulding solutions to a diverse range of industries, including electrical, healthcare, horticultural, food & beverage, windows, and roofing. Recently, they have expanded their capabilities with a dedicated assembly area to meet customer requirements effectively.

Patterson & Rothwell is a well-invested and profitable company, with a continuous focus on growth and innovation. They regularly invest in new moulding machines, and their owners actively support the development of their own product ranges. The company also partners with entrepreneurs and startups to help bring new products to the market. Additionally, they take pride in providing high-quality trade moulding work in attractive markets.

Their comprehensive services include manufacturing both large and smallscale plastic parts, from design and prototyping to tooling and moulding. They ensure a professional and flexible approach, paying attention to detail at every stage of the process. Patterson & Rothwell holds various certifications, including ISO14001:2015 for environmental management, ISO9001:2015 for quality management, IATF16949:2016 for automotive quality, and BRCGS for food packaging. Environmental responsibility is a priority for Patterson & Rothwell, as they are a zero landfill site. They actively monitor and calculate greenhouse gas emissions, focusing on Scope 1 and

Scope 2 requirements. This allows them to identify areas for reducing their carbon footprint and working towards a net-zero approach.

Customers highly praise Patterson & Rothwell, describing their services as excellent across all aspects, from tooling to production. Their problemsolving abilities and dedication to finding solutions, whether in CAD design or logistics, have earned them a reputation for exceptional service.

Overall, Patterson & Rothwell is a trusted partner in the toolmaking and injection moulding industry, offering a wide range of services and a commitment to customer satisfaction. www.patterson-rothwell.co.uk

6 FDPP - www.fdpp.co.uk

Their comprehensive services include manufacturing both large and small-scale plastic parts, from design and prototyping to tooling and moulding.

INJECTION MOULDING

Attention to detail at every stage

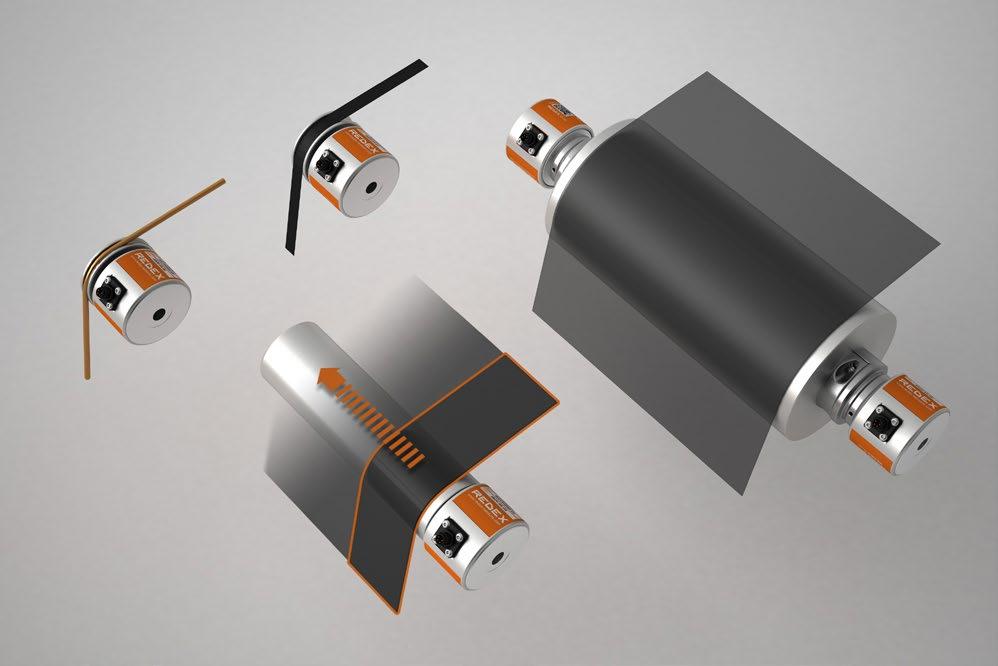

Product Design

Tool Design

Toolmaking

Production

Patterson & Rothwell Ltd

Bee Works, Shaw Road, Royton, Oldham, OL2 6EH

enquiries@patterson-rothwell.co.uk

T 0161 621 5000

patterson-rothwell.co.uk

Supply chain innovation

Agri-tech innovator’s potato disease detection system enters advanced testing phases

Root crop disease and defect monitoring system TuberSense – under development by innovative agri-tech business B-hive Innovations - has entered its next project phase to revolutionise how technology can anticipate issues in tubers before the crop loses its quality and value.

Future Leaders Fellow Dr Barbara Correia secured funding from UK Research and Innovation (UKRI) in Summer 2021, and since then has been conducting the first phase of research, development and testing with the wider project team, including potato producer Branston Ltd and research institutions.

Barbara’s initial research to define the link between potato diseases and volatile compounds released by the tubers

was carried out with UWE Bristol and the James Hutton Institute, while the University of Warwick has partnered on the project to develop gas sensors to measure the gases produced.

Following a series of first-phase trials, the R&D sensing system has now been developed to use volatile biomarkers as means of detecting crop diseases and defects that can cripple potato supply chains, including soft rot, dry rot and black heart in potato tubers.

Barbara said: “The first phase of our research has provided us with tremendous novel insights into the range of diseases and defects that, unless detected early, can enormously compromise the overall quality of the

crop that enters the supply chain.

“Through the first project phase, we have gained a great understanding of which diseases are most distinguishable through the use of gas sensing technologies.

“Conversely, we have also become more aware of which defects may not be detectable through such means, which already gets us thinking of other ways that we might detect those defects at an early stage.”

To ensure optimal testing conditions, Barbara and the team have been conducting experiments using a mix of field testing with growers alongside semi-controlled trials, including the use of industrial shipping containers.

8 FDPP - www.fdpp.co.uk

The Tubersense team, frm left: Prof Darren Reynolds (UWE Bristol), Dr Rob Hancock (James Hutton Institute), Dr Robin Thorn (UWE Bristol), Dr Barbara Correia (B-hive Innovations), Prof James Covington (University of Warwick), Dr Andrew Gill (B-hive Innovations) and Dr David Nelson (Branston)

The team has also shipped a TuberSense system to a sweet potato supplier in North America for further testing, as the project looks to expand the breadth of crop the technology can be compatible with. Sweet potatoes can be even more susceptible to disease and defects, especially considering long shipping times, and therefore there is a higher rate of crop wastage.

To better understand the demand from growers, the research team embarked on a 12-week Scaling the Edge project funded by with UKRI. Three quarters of the growers faced disease and defect

problems with their crop, and the majority of these are keen that a gas sensing system for early detection is made available.

With the first phase of the project now nearly completed, the team is starting to develop the second iteration to feature an improved gas sensor, with aims to commence testing with units by the end of the year.

Barbara added: “Research and development combined with market research has made it clear that growers and packers of root crops require greater insights into disease and defect detection at the earliest point possible.

“While we have made some great breakthroughs during the first phase of the project, we have a lot of confidence from our ongoing analysis to trial a 2.0 iteration - that will extract even more insights into using volatile markers for gas sensing in stored crop.

“By undertaking detailed data analysis, we believe that we can detect some

tuber diseases and defects more accurately through further refinements to the underlying technology, and we are working through making those changes.

“We are also exploring technology from other partners. This includes graphenebased sensors from Altered Carbon, who we have partnered with recently, alongside our own bespoke sensor array to see how much we can push the limits of sensitivity of the system.

“By the end of the project, we want to be in a position where our findings can inform the production of commercial detection systems for the industry.”

If you would like to support the project, the TuberSense team is asking different players of the fresh produce industry to contribute with their views by filling in the following questionnaire below (which should take 5-10 minutes to complete) to help it achieve the highest impact for its R&D efforts: https://survey.sogolytics.com/r/K3Vfy1 www.b-hiveinnovations.co.uk

FDPP - www.fdpp.co.uk 9

Research and development combined with market research has made it clear that growers and packers of root crops require greater insights into disease and defect detection at the earliest point possible.

THE TRUE COST OF A FORKLIFT TRUCK

When considering purchasing a forklift, it’s crucial to assess not only the upfront costs but also the total cost of ownership (TCO). The amount you pay your supplier for a truck is only a fraction of its lifetime cost. TCO includes the purchase price of the truck and all the associated expenses, both direct and indirect, that arise during its entire lifespan. The main costs are summarised below. You can save money by choosing the right supplier and trucks that reduces these ongoing expenses.

LIFECYCLE COSTS

• Purchase price (or monthly lease or rental payments)

• Depreciation (how quickly the truck’s residual value falls, year by year)

• Disposal (recycling of truck at end of life)

DRIVER PROVISION

• Wages

• Training

• Sickness absence (including illnesses due to workrelated stress and strain)

• Extra driver’s wages to cover sickness absence

GENERAL RUNNING EXPENSES

• Insurance

• Fuel or electricity consumed

• New batteries (replaced at end of service life)

• Other new parts (replaced due to wear or end of service life – including tyres, filters, fluids, brake pads etc.)

• Maintenance (labour/time cost plus replacement parts and materials)

DOWNTIME

Loss of productivity when forklift is out of action due to:

• Battery charging and/or changing

• Maintenance

• Accident damage repairs and clear-up

In today’s data-driven world, managing fleet costs has become increasingly reliant on harnessing the power of information. By taking into account the comprehensive range of expenses associated with owning and operating a forklift, fleet managers can optimize their TCO and improve cost e ciency. Remember, understanding the complete picture of TCO is paramount in making sound investment choices and ensuring long-term success in managing your forklift fleet, so why not contact us at Impact Handling and let our experts assist you in assessing your fleet costs.

ACCIDENT COSTS

• Repairs to building and storage structures

• Repairs to equipment

• Repairs to lift truck

• Damage/loss of goods

• Downtime for repairs and clear-up

• Driver absence due to injury

• Replacement driver’s wages

OTHER PRODUCTIVITY LOSSES

Anything about the truck that makes the driver less productive, including inferior design in relation to:

• Manoeuvrability

• Ergonomics and comfort

• Vision and precision

• Smooth control

• Safety and protection

© 2023 MLE B.V. (registration no. 33274459). All rights reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

0800 169 9789 sales@impact-handling.com www.impact-handling.com

POWER UP TO NEW LEVELS OF EFFICIENCY & PERFORMANCE With their compact design, intelligent control systems and low energy consumption, the latest Cat® 1.4 to 5.5 tonne lithium-ion forklifts are the automatic choice for e cient handling in fast-paced, tough conditions. Additionally, you’ll benefit from a great return on your investment, and low total cost of operation. © 2023 MLE B.V. (registration no. 33274459). All rights reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. 0800 169 9789 sales@impact-handling.com www.impact-handling.com Contact us now, it’s time to power up your fleet and boost your business.

KHS offers beverage industry new tool for calculating the carbon footprint

The impact the packaging has on a bottler’s carbon footprint can now be measured in figures with the help of calculation tools KHS developed together with independent experts. The systems supplier thus provides the beverage industry with a reliable guide when planning machine conversions and switching to a sustainable portfolio.

With this new tool KHS is adding a further component to its holistic packaging services. In cooperation with the Hamburg Institute for Environmental IT (ifu), a leading independent international software developer for material and energy flow analyses, the Dortmund systems provider clearly shows its customers which style of packaging has which impact on the climate and whether a conversion for a stretch blow molder, for instance, has a positive effect on their carbon footprint or not.

In principle, the solution is a simple Excel tool fed with data where in

a first step all parameters that impact the climate are recorded in the entry mask. These include, for instance, the materials used for the conversion, packaging, transportation and the distance engineers have to travel for installation. The tool then computes how much CO2 has been ‘spent’ on the conversion. In a second step the number of kilowatt hours the conversion has saved is then entered in the computer, plus the customer’s location and which type of electricity it uses or itself produces. Once combined, these figures show how long it takes for the CO2 expended during the conversion to be neutralized.In order to be able to express the respective advantages of a particular container in figures

and help beverage bottlers reach a decision as to which kind of packaging will prove to be the most climatefriendly for them, the tool is used to compare various styles of primary packaging with one another, such as PET bottles made of recycled or virgin material, glass bottles, beverage cans, HDPE containers and carton packs, with respect to the impact they have on the environment. The KHS service is rounded off by a program that calculates the carbon footprint of secondary packaging. To facilitate its development the engineering company supplied Hamburg’s ifu institute with the parameters for all of the packaging options in its entire portfolio to enable their global warming potential (GWP) to be calculated according to DIN EN ISO 14067.

www.khs.com

12 FDPP - www.fdpp.co.uk

With this new tool KHS is adding a further component to its holistic packaging services.

AND WE KNOW WHERE.

A SPECIAL SERVICE FROM

Your KHS line optimization service gets more performance out of your existing production lines.

The longer a machine is in operation, the more its level of efficiency drops. There are many reasons for this which are not always immediately recognizable. Our line optimization service thoroughly screens your lines, pinpointing all weak points and optimizing your machine efficiency by up to 30%. Interested? khs.com/line-optimization

Why have food processors in the uk chosen cool lockers?

• 15 Year warranty

• Corrosion resistant

• Doors will not dent

• Outdoor or indoor use

• Maintenance free

• Very secure extremely robust

• Several locking options, inc no key

• Quiet open and close

• 100% Recyclable

• Quiet open and close

• May be washed daily

• 20+ Colours

COOL LOCKERS UK LTD, UNIT 1 FOSSE CROSS INDUSTRIAL ESTATE, CHELTENHAM, GL544NW TEL: 01285238954 MOB: 07521093512 WEB: www.coollockers.co.uk COOL LOCKERS UK LTD CO REG 19269349 VAT 426962275

Heavy duty industrial lockers providing durability and value to food processors all over the world

No matter what industry your business operates in, our industrial lockers here at Cool Lockers offer unrivalled durability. From the storage of work equipment to safety gear, they are easy to clean and require no maintenance. Our industrial lockers come in a wide variety of sizes, meaning that you are guaranteed to find something in our range that will suit your specific needs, no matter what they may be. From MOBILE PHONE LOCKER to FULL HEIGHT OVERALL. You can even customise your storage with our online locker builder! Our hard-wearing industrial lockers are a highly-functional feature across industries and organisations across ,the UK and Europe

At Cool Lockers, we pride ourselves on producing industrial lockers that are second to none. For more than 20 years, we have been making high quality lockers for organisations throughout theUK and Europe, from large corporations to small businesses, schools, sports centres and much more. We are the top choice because of our dedication to offering best quality lockers, so you can rest

assured you will be making the right choice when you choose Cool Lockers

COOL LOCKERS

Long term value with an unrivalled 15 Year Warranty

A leading provider of lockers in the UK and Europe, over the years the Cool Lockers team have refined our manufacturing processes to ensure that we are always delivering the best quality products to our customers. Our lockers can be found in businesses operating in the manufacturing, education and hospitality sectors —to name but a few. No matter what you choose from

our range, Cool Lockers gives you the peace of mind knowing that you will be receiving a premium storage solution which will last for many years to come .

www.coollockers.co.uk

Cool Lockers - saving you money!

Some capex decisions are difficult to justify. This is not one of them , you do the maths for your company

For example:

If you have 150 employees on minimum wage and they spend just 2 minutes in every hour on private mobile phone usage,

It costs your company £410 per day in lost productivity

If their mobiles were locked securely away in a cool lockers phone locker you would

Pay for the lockers in around 2 weeks.

After 2 weeks you would save £2050.00

A week.

Nearly £100,000 pa .

As an added bonus you get reduced health and safety and security issues

CONTACT COOL LOCKERS UK LTD

sales@coollockers.co.uk

m 07521093512

t 01285238954

FDPP - www.fdpp.co.uk 15

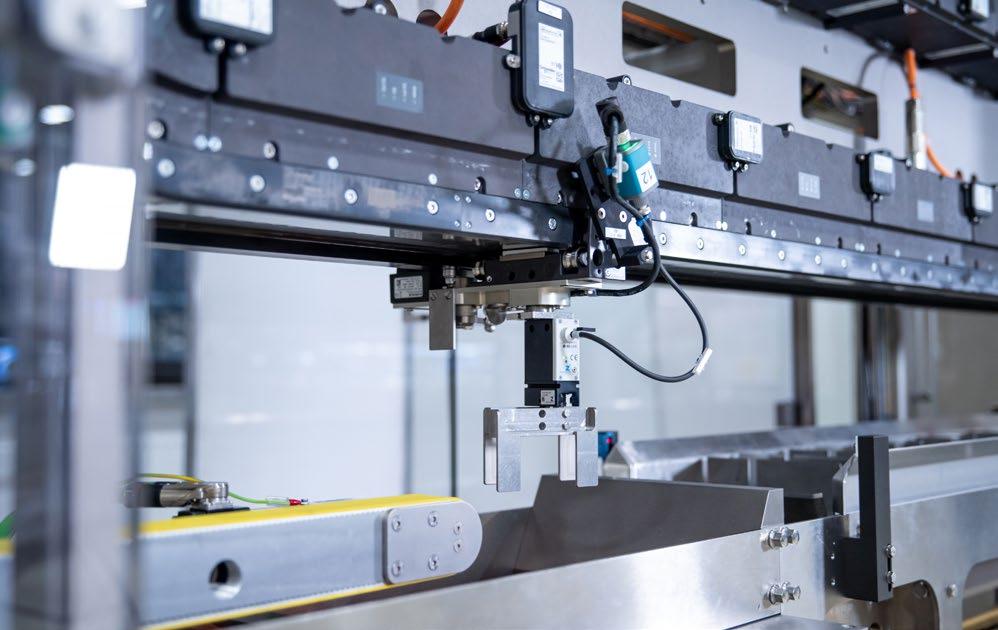

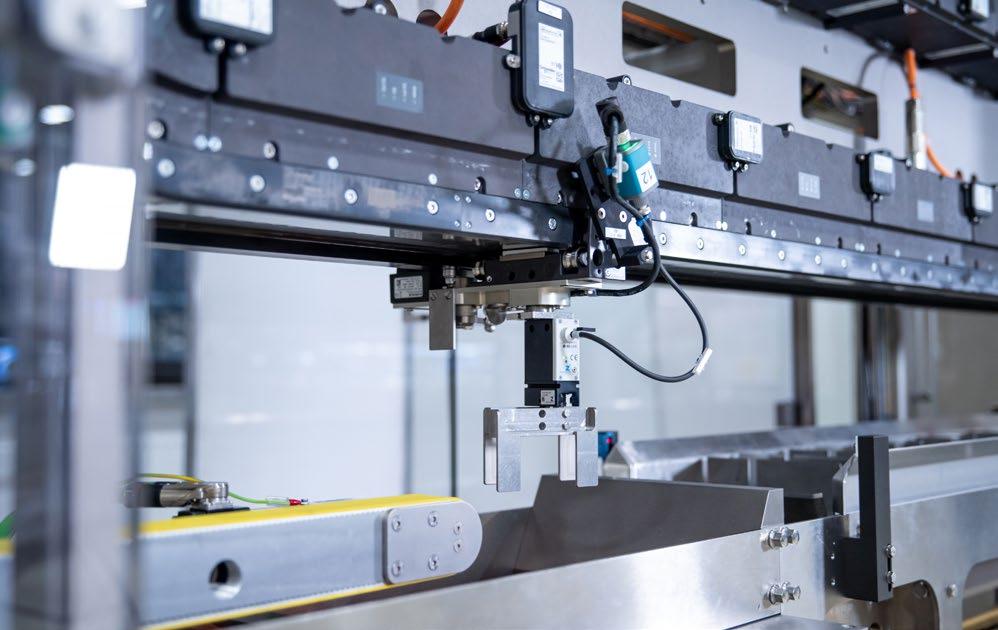

Rotzinger develops innovative adaptive packaging machine enabled by CoreTigo’s IO-Link Wireless solution

Rotzinger, a leading provider of packaging & cosmetics machinery solutions, and CoreTigo, a provider of Industrial Wireless Automation solutions, are excited to announce their partnership and collaboration.

CoreTigo’s IO-Link Wireless products and technology have been integrated into Rotzinger’s advanced packaging machinery, resulting in new and advanced capabilities that are driving maximum flexibility, throughput and sustainability.

Rotzinger, a Swiss group of companies, with a mission to continuously optimize product flow for its customers, offers first-class solutions, services and software for a variety of industries such as pharmaceuticals & cosmetics and food & beverage. Rotzinger was asked by a leading food manufacturer to develop an adaptive secondary food packaging machine that meets very high demands of throughput along with the ability to support multiple package and product variations, all on a single machine. The machine is based on a multi-carrier smart conveyer system which requires doing actions on products while in constant high-speed motion. Cables were not a possible option for such a complex and high-speed task, nor were conventional

wireless solutions. By utilizing CoreTigo’s IO-Link Wireless based products which were designed specifically for wireless control and monitoring in factory automation, Rotzinger could now wirelessly control grippers on the movers without needing additional external robots, cables or other types of equipment.

This innovative machine design results in reduced changeover time, machine footprint reduction, maximum capacity, and full flexibility to support multiple product and package types. These ultimately result in greater

sustainability, as less energy, space and parts need to be used within a machine. The number of machines decreases as well, since this allows for one machine to handle various products and package designs. An example of this machine in action and the benefits gained from the collaboration of Rotzinger and CoreTigo can be found in this video: https://youtu. be/HSshEGywV4A

“We are delighted to partner with CoreTigo and to integrate their IO-Link Wireless products and technology into our advanced packaging machinery.” States Andreas Graf, Rotzinger

16 FDPP - www.fdpp.co.uk

PharmaPack CEO, “This partnership has allowed us to provide our customers with even more advanced capabilities and benefits, resulting in

adaptivity, increased productivity, and sustainability.”

“Rotzinger is a leading company in the packaging machinery industry, and we are proud to have our IO-Link Wireless technology be part of their innovative machinery.” Says Eran Zigman, CoreTigo CEO. “The collaboration between CoreTigo and Rotzinger is a perfect example of how technology can be leveraged to meet the evolving needs of the industry.”

Partnerships and developments such as demonstrated by Rotzinger and

CoreTigo are creating a fully connected ecosystem that enables real-time control and monitoring at any stage of the manufacturing process. Machines and production lines are enabled with more flexibility and an optimized design to improve operational efficiency and productivity. Such a packaging machine with IO-Link Wireless is breaking barriers that exist today with machine communication, and enabling solutions and designs that were not possiblebefore.

www.rotzingergroup.com

FDPP - www.fdpp.co.uk 17

The collaboration between CoreTigo and Rotzinger is a perfect example of how technology can be leveraged to meet the evolving needs of the industry.

IBC & Drum Mixing stations

Offer consistent product quality at the point of use for a wide range of applications, guide rails position the IBC and the mixer is raise and lowered into the IBC with a push button operated electrical actuator.

Fixed or mobile mixing stations are supplied complete with a control panel and safety interlocks.

Standard IBC mixing stations can be adapted to integrate with systems on site including pumps, valves, weighing and measuring instrumentation and controls to meet specific site requirements.

18 FDPP - www.fdpp.co.uk

Please call or email our application engineers will be happy to help Email : sales@euromixers.co.uk | Tel : 0161 486 5099 | Web : www.euromixers.co.uk Euromixers Ltd Landmark House Station Road, Cheadle Hulme, Cheshire SK8 7BS

Cleaning up in an explosive atmosphere

Kerstar’s brand new range of KEVA Premium industrial vacuum cleaners include patented filter cleaning technology. They are able to safely and efficiently collect loose debris such as crumbs, powders and other small particles, and are effective in cleaning up spills - preventing them from spreading and potentially contaminating the production area.

Maintaining a clean and sanitary environment is crucial in food production to ensure product safety and prevent the growth and spread of bacteria, allergens, and other contaminants. Substances regularly used in the food industry, including flour, sugar and starches and various other organic ingredients, also have the potential to explode. Regarded as the perfect all-rounder, the modular range is also ATEX certified and classed as Category 3 equipment, making them suitable for applications in Dust Zone 22 – an atmosphere where air and flammable dust can be explosive.

The two new models - the KEVA Premium CBS (continuous bagging system) and the Keva Premium 50L (50 litre drop down collection container) - include patented ‘reverse pulse cleaning’ on the first stage filtration system, preventing undesired wear issues caused by traditional shaking methods found on other vacuum cleaners.

Dust that is produced as a result of food production can have serious effects on the health of employees. Exposure to particles such as flour, can cause serious skin conditions and even occupational asthma. Cleaning the filter in seconds, Kerstar’s patented system eliminates the need for dismantling the vacuum and manually cleaning the filters - saving time and protecting your employees.

Other products in the range are the KEVA Type H and the compact KAV Type H model vacuum cleaners, both suitable for Zones 21 & 22 and tried and trusted in the food industry for nearly 20 years.

The Kerstar range also includes a host of optional extra equipment such as anti-static suction hoses, floor nozzle box and anti-static accessories. It also offers Anti-Static Carbon Fibre Wand Sets which are suitable for high reach cleaning alongside the KEVA 20-45, KAV 15-45 and KEVA Premium models. models.

To find out about the Kerstar range of vacuum cleaners from Filtermist visit www.kerstar.com or email sales@filtermist.com

FDPP - www.fdpp.co.uk 19

+44 (0)1952 290500 To discover how we can improve your production environment visit www.filtermist.co.uk sales@filtermist.com or speak to one of our sales team Let us take air contamination off your plate Cleaner, safer, more productive food processing environments Centralised vacuum & conveying systems Servicing, spares and LEV testing Vegetable oil mist removal Dust extraction systems Release agent removal Industrial ventilation Odour control

7 Considerations for ensuring an Efficient Hygienic Process

Selecting a pump for a process application can be a difficult choice.

Whether you’re looking to avoid clogging, separation, downtime, or another issue – an incorrect solution could prove costly with time wasted troubleshooting and lower production meaning missed production targets and lower profit.

A sanitary pump is the solution but choosing the right one can feel like stepping into a minefield.

You know what you need it to do but with so many options, it’s difficult to know which is best for your process and parameters.

Here are 7 considerations for your process when selecting a pump:

Fixed Pump only or Multipurpose Pump Kit

Fixed pumps assume only one application or process. It can be a great solution if one process or batch is operating repetitively, but what if a process or batch frequently changes? Or what if there are series of infrequent applications across site?

We have found that users are more commonly opting for multipurpose pump kits which can be ported between processes to reduce manual handling, reduce risk of injury or product loss, automate transfer, eliminate spillage and free staff for other processes.

Built to order, units are configured for portability, consistent repeat batching and with controls allowing easy of use with minimal training.

Reversible Two Applications in one – For Decanting & Filling

Reversible designs enable pumps to be used for more than one process. Whether it be the filling or emptying of containers if known at the outset units can be accommodated to handle two process

needs which work at the push of a button.

Cleanability –Manual SIP, CIP, for Reduced downtime during batch changes

Pumps can cleaned in a variety of ways not just for preservation of hygiene, but also to safeguard against cross contamination between food products, and the mixing of colouring’s or flavorings between light and dark prepared mixtures such as creams, or sauces.

Pump designs can vary from having to be cleaned manually which can be ok for small designs used infrequently, but with larger designs this can be laborious and time consuming.

Processes which operate 24/7 or in facilities where frequent downtime is not an option may automate cleaning, using cleaning In Place (CIP) or Sterlisation in Place (SIP) technologies to effectively and efficiently clean pumps in the least amount of time.

Seal Less or Mechanical Seal for Process Security

Seal less and valveless units mean fewer pump issues and ensure your process continues to run smoothly with less pinch points for product to become trapped, clog or hygiene risks to present.

Using seal less designs means the chance of Leakage is vastly reduced, as well as vastly reducing maintenance time.

Working with the correct process partner not tied to a single process technology, can help you understand the advantages and disadvantages of differing designs, helping you to make the right choice for your application.

Shear and Solid Conveyance for ensuring consistency

Transferring solids and viscous liquids

requires careful selection. Some solids need to be transferred gently, such as cooked apple slices without breakage.

Other applications may benefit from the damage pumps can perform to solids assisting their processing such as in fruit and berry transfer in juice processing. Milk, sauces, chocolate and eggs require gentle handling to ensure their consistency does not change.

Level of Hygienic Design & Accreditation for Reduced Risk & Insurance Premiums

Pumps are completely configurable from the material of internal components, level of polishing or third party accreditation of components such as FDA or 3A Approval.

If the unit is located within a hazardous environment or handling a flammable ingredient an ATEX and food grade unit may be required.

Knowing which certification is required at the outset, can ensure the most appropriate design of pump is selected reducing risk and also reduce insurance premiums.

Connection Type to Match Your Process

A range of hygienic connections are available to suit your process, from Ticlamp which is most commonly used to RJT, SMS and others.

Selecting this correctly will ensure pumps integrate seamlessly with your pipework and can be cleaned effectively during CIP or SIP for maximum process efficiency.

If you are looking to reduce wastage, maintenance time, risk, and improve output, process effectiveness and ensure consistency speak to us on 01773 302 660, on livechat at www.northridgepumps.com or email at sales@northridgepumps.com

20 FDPP - www.fdpp.co.uk

Meeting the surge in demand for grain-based foods

More efficient production lines crucial to satisfying rising demand for cereals and other products

There has been a surge in demand for grain-based foods in the United Kingdom. According to the Department for Environment, Food and Rural Affairs, it witnessed a remarkable 9.4 per cent increase in cereal production in 2022, reaching just under 21 million tonnes. How can food manufacturers keep up with this demand? One way is by implementing more efficient production lines. Here, Stephen Harding, managing director at the material handling expert Gough Engineering, proposes a unique solution to help maintain quality and efficiency throughout production lines.

Precision and efficiency are priorities in the production of grain-based food, and essential for manufacturers to meet food safety regulations and maintain consumer trust. To this end, it’s vital that food manufacturers maintain a seamless flow of product throughout their production lines, but issues like bottlenecks can be problematic and costly.

Bottlenecks in food manufacturing can occur when demand for a food product exceeds the capacity of the production equipment. Production bottlenecks lead to delays in subsequent processes and restrict the overall capability – e.g., in time and flexibility of operations, both factors that impede manufacturers’ profits.

As bottlenecks occur on the factory floor, they also occur in global supply chains — especially since the COVID-19 pandemic. Again, these bottlenecks can be attributed to growth versus demand. In 2021, UK factories experienced the fastest order growth since December 2017, driven by a strong domestic and gradual recovery in

global markets, as reported in a survey by the Confederation of British Industry (CBI), according to Reuters.

The report also highlights the need for businesses to manage supply chain constraints. Understanding the relationship between growth and demand is crucial for maintaining production efficiency and preventing bottlenecks. Consequently, manufacturers must address issues as

shortages of raw materials and rising costs to maintain throughput.

SUPPLY CHAIN OPTIMISATION

So, how can food manufacturers modify their production lines to avoid bottlenecks, both on the factory floor and on the global supply chain level? The answer lies in bespoke material handling solutions that are designed to streamline the flow of goods throughout the supply chain.

22 FDPP - www.fdpp.co.uk

One example is batch sieves, which are used to separate particles of varied sizes in food production processes. Batch sieves are vital for ensuring consistent product quality and maximising production throughput, by removing impurities. To ensure food producers benefit fully from the advantages of sieves, the equipment should be bespoke designed to the unique needs of the processing application integrated within existing or new equipment.

For instance, rather than a food production line, let’s use the example of chemical processing. It may be necessary to remove ferrous material from the chemical produced during production. In this case, the batch sieve can be equipped with magnets to remove any potential ferrous material quickly and effectively. Similarly, fine material detection systems are frequently used within bulk material transfer – such as sugar.

Further contamination can be prevented by adding panels with extraction points to the sieve system, and complete hood systems can also be considered. This design feature can effectively contain airborne particles. This safeguards the produce itself, ensuring only quality and clean, uncontaminated product passes

through, minimising and protecting the surrounding environment from contamination and dust or surface residue on personnel.

However, the sieve must be designed appropriately for the application and to suit manufacturer’s unique production requirements. This is where the support of a trusted material handling expert proves essential. Their partnership and design engineering expertise and experience can help the manufacturer consider factors such as mesh size, material composition and sieve capacity affecting machinery specification.

Furthermore, these bespoke design modifications to the sieve system can be applied specifically to maximise throughput and minimise clogging in the production line — thus tackling bottlenecks before they become an issue and preserving desired quality.

ENHANCED EFFICIENCY

A cereal manufacturer based in Yorkshire, UK, turned to Gough Engineering to help design and implement a brand-new conveying, elevating, and feeding system. The new system was required to seamlessly connect the production and packaging sections within the factory.

Gough Engineering’s solution included commissioning four Gough Swinglink® Bucket elevators (GBE), capable of moving a range of cereal products at a rate of 1,000 kilograms (kgs) per hour. The elevator systems would employ a continuous line of swinging pendulum buckets, ensuring the efficient transfer of large volumes of product.

Moreover, these elevators can be arranged in various layouts to accommodate specific production requirements, offering versatility and adaptability. Another essential component of this solution was the integration of a Gough Linear Feeder (GLVF), which can deposit cereals at a rate of 500 kilograms (kgs) per hour.

With the new system, the cereal manufacturer was able to greatly improve its production throughput. The feeders also function as screens for chocolatecoated cereals, sifting out any abnormally sized pieces and redirecting them to a separate system. With these technologies, manufacturers are better equipped to meet surging demands, while ensuring that quality and productivity remain priorities.

To find out more about Gough Engineering’s bespoke material handling solutions, visit its website.

FDPP - www.fdpp.co.uk 23

Delivering a tailored solution on time and on budget

When smooth linear motion is of paramount importance

For applications where reductions in weight are paramount, IKO offers the cost-effective precision linear slide range. Made from stainless steel, and available in recirculating (BSR) and nonrecirculating (BSP) options, this range is highly flexible. It features a simple tworow, four-point contact structure, high motion accuracy and stable load carrying capacity.

Alinear rail and carriage system is many a design engineers first choice for transporting a load, and for good reason. It provides a rugged and precise solution that is inherently self-aligning, offers high load handling capabilities, and can operate in some of the most challenging environments. But the temptation to over-engineer a system can add significant cost to a project, while asking a vendor to supply a non-standard arrangement can dramatically lengthen the lead time.

This is where IKO Nippon Thompson’s in-house design and adjustments service becomes invaluable, with the UK team of applications engineers able to suggest design amendments that can reduce lead times from months to days, and/or remove significant cost from a project. Mark Ross, technical sales engineer at the company’s Milton Keynes UK headquarters, says: “There are a wide range of things we can do at local level, from the everyday to the more unusual, to deliver an application-specific solution, providing a key service that can save UK customers time and money.”

This can be further enhanced using a built-in rack and pinion system in the BSP variant (BSPG) for applications where there is potential for cage creep. This phenomenon is generally seen in many vertically orientated, high-speed applications, and IKO’s design reduces the chance of this occurring.

our various global locations, and we can tap into that free stock and have it delivered within a couple of days,” says

stroke length, but then bumped up the rail and carriage dimensions to accommodate the required load? Perhaps they’ve even ended up with a design that uses non-standard length carriages.

For applications that may receive fluctuating and complex loads, but still need to see consistent repeatable results, the BWU range may be more appropriate. The high rigidity, precision linear slide units offer design engineers the possibility of adding a secure mounting position that can handle loads of up to 12,100N. They are also exclusively made of stainless steel, making them suitable for potentially corrosive environments or cleanrooms. In addition, they are suitable for applications where rust prevention oil is not preferred.

A prime example is the company’s ability to assess the key parameters in a project, and look at what can be easily amended without compromising the performance criteria, so that the project can be serviced from the company’s free stock. “For any supplier, manufacturing a system to order is going to take time, but IKO Nippon Thompson will always have standard products available as free stock at

Mark.

“From there we have the in-house capabilities to modify standard products to meet specific customer requirements.”

Examples include cutting rail to specific length at the simplest level, or changing the e-dimension –the measure from the end of the rail to the first mounting hole. “As standard, this e-dimension would be half the normal hole pitch, but that might not suit the application,” Mark explains.

For designers and machine builders looking to increase load ratings further, while keeping the overall machine size to a minimum, IKO can then offer its crossed roller ways (CRW). This range is available in three different variants, including a rack and pinion option (CRWG) and a heavierduty variant that increases the strength of the internal components (CRWH). These products all utilise cylindrical rolling elements instead of ball bearings, and provide increased load rating capacity and improved rigidity. This, in turn, increases the stability of the overall product.

Such adjustments and amendments can be important time savers for customers, particularly when they are building a prototype as proof of concept. But IKO Nippon Thompson’s design services can also save customers significant amounts of money, for example when it is clear that the design engineer has over-specified the project, perhaps as a belt and braces approach to meeting particular lifespan requirements.

“We can quickly drill down to the customer’s most important considerations and then look at how that impacts on the rail and carriage dimensions,” says Mark. “By talking through load and stroke requirements, that might lead us to propose alternative carriage lengths. For example, has the designer opted for a shorter carriage to increase

Despite the variation in materials and structure, all of the models share a similar design. With single linear caged bearings consisting of ball or roller elements running along inner and outer tracks. These bearings are arranged in parallel, one on each side of the slide, to support the weight of the table (or carriage) and its mounted load as it moves.

The various designs all provide precise accurate motion, normally over short stroke lengths. In the BSP, BWU and CRW ranges, this motion is further enhanced by their non-recirculating design. Due to the compression and release of the rolling elements as they pass in and out of contact with the raceways seen in recirculating designs,

“By adjusting the rail and carriage dimensions, we can often find a much more cost-effective approach, selecting more appropriate and standard products or better cost products,” he continues. “We can play

there is no chance of the balls causing any background distortions in the data gathered. For the same reason, the bearings run very quietly. In addition, maximum speeds of 50m/min can be achieved.

with parameters such as preload to see if this provides a better way to meet specific application criteria. Or we can butt together standard rails to deliver longer, non-standard lengths at given profile dimensions without impacting precision.

“In addition, we can add seals and scrapers to protect the rolling elements on some product types, as well as offering different coating options to protect against rust or to alter the products’ aesthetic appearance if that’s a requirement too. The addition of rail caps can also be a further simple (yet cost-effective) way to increase the longevity of the system, and is something which, whilst basic, is often overlooked.”

All of this comes hand in hand with the capability to provide CAD drawings and models, and to port those designs straight into customers’ models.

IKO Nippon Thompson is conscious, too, of the cost of logistics for its customers, and so can supply pre-packaged sets to reduce packaging, handling and stock management. And then there is the company’s on-site training in addition to its telephone and web video support.

“It’s all part of a service that means we are much more hands-on with our customers than perhaps other suppliers are willing or able to be,” concludes Mark. “We want to be more involved because it benefits all of us – we get to deliver the most appropriate solution and customers get time- and cost-saving benefits.”

While IKO prizes quality over pricing, one thing for customers to keep in mind when buying precision linear ways is how many parts are included. This is particularly important when specifying the CRW range. While, for historical reasons, many competitors sell these parts in what is essentially only half of a full set required for any motion profile – two ways with one cage and rolling elements – IKO always sells CRWs as a complete kit: four ways with two cages and rolling elements. For that reason, a price that is perhaps 75% higher for an IKO full set (for example) when compared to a competitor’s set might prove to be a more cost-effective option, as two sets of the competitor’s product would be needed to make up the same quantity as IKO’s offering.

By offering the right bearings in an installation-friendly manner, IKO aims to meet its customers’ needs – and often exceeds them.

Contact IKO UK today at 01908 566144, or email enquiries@iko.co.uk to discuss your motion control needs. Alternatively, visit the IKO website.

24 FDPP - www.fdpp.co.uk

27 INDUSTRIAL TECHNOLOGY • WWW INDUSTRIALTECHNOLOGY CO UK

www.ikont.eu • Email: enquiries@iko.co.uk Tel” 01908 566144

We talk to the experts at IKO Nippon Thompson about how linear rail and carriages can be easily adjusted and modified, and how projects can be redesigned around standard products, to save customers time and money

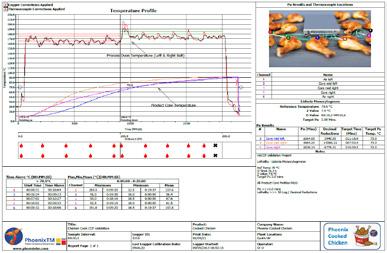

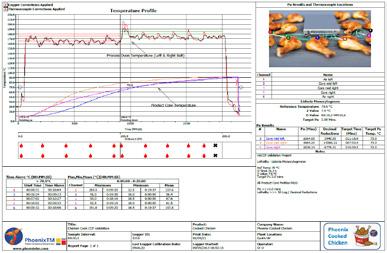

Phoenix Temperature Measurement Efficient HACCP Cook & Chill CCP Validation Thru-process temperature monitoring solutions for all your cook applications 25 Earith Business Park, Meadow Drove, Earith, Cambridgeshire PE28 3QF, UK T: 01353 223100 E: sales@phoenixtm.com www.phoenixtm.com

HACCP

ü

Where experience counts ! PhoenixTM Technology • Accurate IP67 data logger (Type K or T) • 10 Measurement Points for full oven mapping • Thermal barrier options to suit cook regime • Comprehensive thermocouple range • Standard miniature thermocouple plugs • Calibrated thermocouple options • Food trays and thermocouple jig options • Full lethality (Fo/Pu) and reporting • Real Time RF Telemetry options • Local efficient calibration and service support

Product Safety Process Efficiency Improved Product Yields Rapid Fault Finding Full

Certification

Around Noon secures M&S own label supplier approval

on island of Ireland

Around Noon, the award-winning foodto-go manufacturer, has secured muchcoveted M&S own label supplier status in a major endorsement of the company’s commitment to quality from one of the most trusted brands on the high street.

It comes as the Newry firm announces significant new investments in readiness to grow its business, including the purchase of new equipment, upgrades to its facilities and the creation of new management positions, including a new quality manager and an NPD manager.

The rigorous approval process benchmarks companies across the food supply chain and evaluates their food safety, quality and culture against the retailer’s high own label manufacturing standards.

The accreditation sees Around Noon supply a range of own label products to M&S stores on the island of Ireland, increasing the range of the supermarket retailer’s sandwich offering.

It’s the continuation of an existing partnership that b¬egan last year when Around Noon secured a contract to supply sandwiches from its TWELVE Handmade in County Down range into stores as part of a deal worth £3.5m in retail sales.

Around Noon Sales Director, Philip Morgan, said: “We are driven to produce quality food from the finest ingredients and always with local provenance in mind. The initial response to our TWELVE range of sandwiches across the M&S store network in Ireland was one of resounding success, which we’re pleased to build upon further now as an own label supplier.

“The retailer has one of the finest reputations for quality with stringent qualification criteria for its suppliers. As such, we’re proud that M&S recognises our shared emphasis on quality and is trusting our expertise and market knowledge to inform and shape the future of its food-togo offering on the island of Ireland.”

Eddie Murphy, M&S Trading Director for Ireland & Northern Ireland, said: “Quality is at the heart of everything we do. We are committed to maintaining the high standards our customers expect and this represents another step in the transformation of our food business in Ireland. In order to deliver on this promise we look to build new partnerships with

trusted suppliers that share our values.

“We have been hugely impressed by the high standards that underscore Around Noon’s dedication to ingredient sourcing, product development and manufacturing, and we’re very pleased to welcome them into the M&S family.”

At present, Around Noon supplies 19 M&S own label sandwich lines to stores across Ireland with plans for a further 13 products to be launched throughout 2023.

Around Noon has been in business for over 30 years. In recent weeks, it acquired The Soho Sandwich Company, based in London, bringing its headcount to over 800. Around Noon supplies a broad range of high-quality chilled, hot, frozen and bakery products to customers including forecourt, convenience and multiple retailers and cafes throughout the UK and Ireland.

26 FDPP - www.fdpp.co.uk

www.aroundnoon.com

We are driven to produce quality food from the finest ingredients and always with local provenance in mind.

Newry firm now supplying an increased range of M&S foodto-go sandwich offering

Donghua chain on the menu

The Food Processing industry demands chain that offers maximum working life with reduced maintenance downtime – and with chain that is compatible with the leading food equipment manufacturers, Donghua has quickly become the chain of choice.

Donghua Limited, the UK arm of one of the world’s largest chain manufacturers, has an enviable 25,000 sq ft warehouse in the West Midlands packed with high quality chain used throughout the food processing industry.

H1 FOOD GRADE LUBRICATION

Our chain is supplied in a range of materials and finishes including H1 lubrication which is commonly used in food processing environments where there is the possibility of food contact. Our chain is hot-dipped in a metal vat so it penetrates into bearing areas which standard lubrication would not reach. As the chain cools, surplus lube drains away leaving an oil deposit inside the chain. The initial lubrication of chain is the most important a chain receives and helps to significantly extend wear-life.

Our special alloy coating also protects against corrosion caused by wash down procedures.

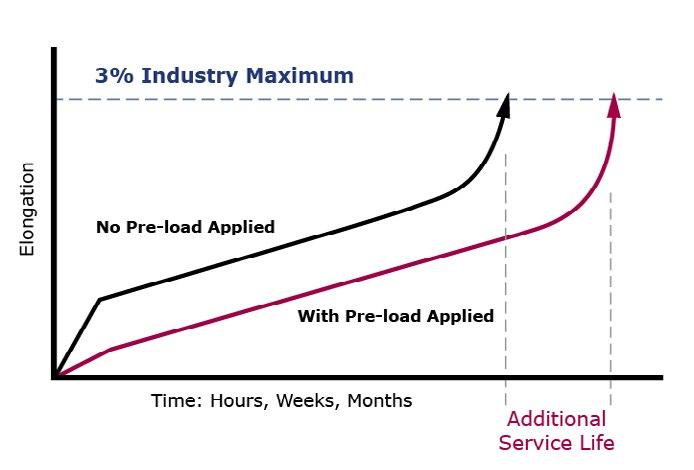

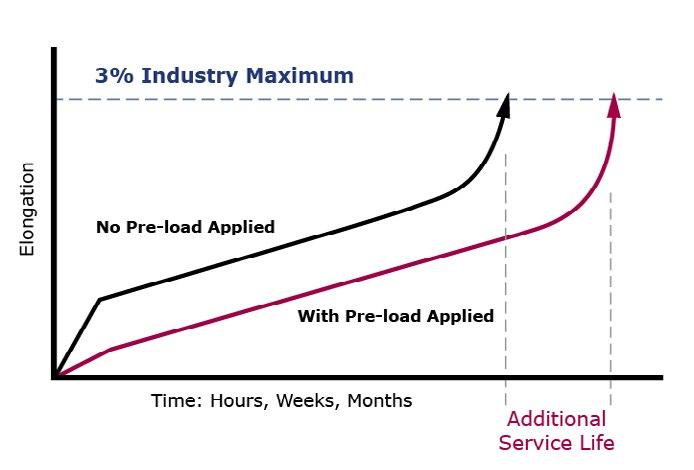

PRE-LOADING AND MATCHING OF CHAIN

Our food chain is also pre-loaded and matched which helps to reduce fatigue and extend the wear-life of chain. Chain that has little or no pre-load applied will suffer significant elongation during initial use and will need to be changed sooner.

Matching of chain to within a close tolerance maintains high length accuracy along the entire length which is particularly important when two chains are used in parallel. Donghua chain is produced to very narrow tolerances and chain from the same production batches are on average within 1/3rd DIN standards. Using our in-house chain length

measuring machine means production tolerances can be even further improved.

Key chain supplied to the food processing industry include:

Polymer Chain – plastic conveyor chain designed specifically to prevent the ingress of foreign matter and reduce maintenance costs and downtime. With less moving parts and with no roller to wear down, this chain reduces the need for additional maintenance.

Stainless Steel Chain including Drytec chain which is designed with plastic sleeves – provides maximum wear life due to its corrosion resistance. Suitable for use in high and low temperature conditions.

Bespoke Chain – specially designed attachment chain, built to client requirements.

Universal Attachment Chain – our ‘one chain fits all’ attachment chain which replaces 99% of other manufacturer’s chain. Available in standard, nickel plated, zinc coated, self-lubricating and stainless steel finishes.

Our food processing chain is supplied through our growing network of Product Partners, Stockists and Distributors.

To find out more about our Food Chain, visit our website:

www.donghua.co.uk/food-industry/

28 FDPP - www.fdpp.co.uk

Supplied in a variety of materials and finishes, with H1 food grade lubrication, Donghua Chain is the chain of choice for maximum working life and reduced maintenance downtime. Donghua supplies the food production industry with a range of high quality chain compatible with leading food equipment manufacturers including: donghua.co.uk/food-industry Tel: 01902 866200 Donghua Limited Sidings Close Wednesfield Way Wolverhampton West Midlands WV11 3DR Food Industry Chain Tube Baker Perkins, Bradman Lake, Ishida, Johnson, Krones, Meurer, Panamat, Rademaker, Raque and more...

Innovative technology that is revolutionising the food and beverage industry

Advancements in technology and the development of AI have enabled the food and beverage industry to make changes to the way it operates. In doing so, businesses can innovate and improve efficiencies within the sector and improve safety for workers and quality in produce.

With 81% of businesses reporting increased production costs in 2022, and demand increasing too, there is opportunity for the further development and implementation of technology to have industry-wide benefits.

INCREASED FOOD SAFETY

Food safety and regulations are critical in all steps of the industry, and

advancements in technologies have allowed companies to have even more control over their food safety and hygiene.

Meeting regulations in relation to food and beverage safety is crucial; insight shared by Paul Taylor, Product

Manager FPE Seals, Industry experts in sealing solutions for food and beverage processing, who says:

“The ideal seals used in food and beverage machinery can be tricky to find, and they must show compatibility and durability against a range of different food types and ingredients, such as sugar, fats, acids and oils.

Across the food and beverage industry machinery is widely used, and whatever the machine, ensuring smooth running and compliance with FDA regulations is imperative. A specialist can help you look after machinery, including providing components such as seals and gaskets.”

30 FDPP - www.fdpp.co.uk

Across the food and beverage industry machinery is widely used, and whatever the machine, ensuring smooth running and compliance with FDA regulations is imperative.

Regulations in food manufacturing are essential in order for the business to operate. The consequences of not meeting standards can be dire for an organisation, and the digital aspect can certainly assist with compliance to this. The term digital transformation can be attributed to businesses within the industry, as they look to introduce a top-down strategy of digitising their procedures.

AUTOMATION AND ARTIFICIAL INTELLIGENCE (AI)

There is a multitude of reasons that the development of AI can aid the food industry and streamline a number of processes to enable greater efficiencies. One key role technology and automation has to play is that of administrative tasks.

Outdated technologies are something that many manufacturers have been addressing and replacing in order to deal with disruptions and supply chain problems, including the implementation of automated systems to look after many admin tasks that are vital to the business but time-consuming for employees.

In addition, responding to customer demand is very important; too much produce can spoil and go unsold, but too little produce will not enable you to keep up with demand and miss out on all-important sales. AI can allow brands and manufacturers to predict the

buying habits of existing and potential customers, to make a more efficient supply and demand process.

By using elements of technology, companies can streamline processes and allow for a more stringent food hygiene protocol. There are smart apps, that enable checklists and documentation to be stored digitally. These processes can allow a company to offer greater transparency of their supply chain, something which 94% of people deem as something that will make them more loyal to a brand.

By utilising technology, brands can create and share checklists, digitally time stamp, and store everything in one place. This cuts down on admin procedures and

manual processes, and reduces risks of documents being lost along the way.

ROBOTICS

The implementation of robotics allows for the efficient production of food, something which is a very important requirement for increasing food production. In 2021, food and beverage production increased largely due to the pandemic, but 67% of manufacturers reported that an increase in 2022 was largely down to new customers and business performance.

To keep up with demand and customer expectations, technology is an option that many businesses are considering. Robotics can be utilised to enhance, rather than replace, the human input of a production line while increasing production levels.

Crucially, the real benefit will come from integrating robotic technology into the overall production, though they can provide benefit as a standalone machine. The benefit, aside from increased efficiency as the robots can perform the tasks faster, comes from increased safety to human workers. These workers can then be utilised in other, less risky areas of the production cycle. This element of technology is also used in customer facing areas of the industry, in kitchens to assist with butchery and even food preparation.

FDPP - www.fdpp.co.uk 31

Science Based Solutions - For Food & Beverages

Gem Scientific has been supplying and providing services to the Food & Beverage sector for over 25yrs. With a strong focus on scientific advancements and cutting-edge technologies, Gem Scientific plays a crucial role in helping businesses in the industry enhance their operations, ensure food safety, and improve product quality.

A Legacy of Excellence

One area where Gem Scientific excels is in providing advanced laboratory equipment and analytical solutions. These tools enable food and beverage companies to perform accurate and efficient testing, monitoring, and analysis of their products. Gem Scientific offers a wide range of instruments, including spectrophotometers, pH meters, microbial testing systems, and more, which assist in assessing the composition, purity, and safety of food and beverage samples.

Gem Scientific also specialises in delivering innovative solutions for food safety and quality management. They provide access to rapid detection methods for contaminants, such as pathogens, allergens, and toxins, which is crucial for ensuring consumer safety. By implementing these solutions, businesses can detect and mitigate potential risks more effectively, preventing recalls and safeguarding their reputation.

Commitment to Innovation

In addition, Gem Scientific actively collaborates with research institutions and industry experts to stay at the forefront of emerging trends and technologies in the Food & Beverage sector. They participate in scientific conferences and trade shows, sharing knowledge and insights that can help businesses stay ahead of the competition.

Customer-Centric Approach

Furthermore, Gem Scientific offers comprehensive training and support services to help companies effectively utilise their products and technologies. Their team of experts provides guidance on equipment operation, data interpretation, and compliance with regulatory standards. By empowering their customers with the necessary knowledge and skills, Gem Scientific ensures that businesses can maximize the benefits of their innovative solutions.

Overall, Gem Scientific plays a vital role in driving innovation in the Food & Beverage sector through their advanced laboratory equipment, analytical solutions, food safety expertise, and collaborative efforts with industry stakeholders. By leveraging their offerings, businesses can enhance their processes, meet regulatory requirements, and deliver high-quality products to consumers.

Science Based Solutions for the Food & Beverage Sector

Hygiene Monitoring

We stock a range of Hygiene monitoring products including:

z ATP Luminometers

z ATP swabs

z Water ATP swabs

z Surface Protein swabs

z ALP Testing

Microorganism Testing

For all your microbiological testing needs:

z Rapid Test swabs - Indicator Organisms

z Incubators

z Transport swabs

z Environmental swabs

z Agar plates & Petrifilm

z Dipslides

Allergen Management

We stock a full range of allergen tests:

z Rapid Allergen Tests

z General Allergen Protein Tests

z Allergen Specific

z ELISA Allergen Tests

At Gem Scientific, we don’t just provide products; we offer complete solutions. Our team of highly knowledgeable specialists are dedicated to delivering personalised support and guidance at every step of your scientific journey. From initial consultation and product selection to installation, training, and ongoing technical assistance, we are committed to helping you achieve optimal performance and productivity.

We pride ourselves on building long-term partnerships with our clients, and our commitment to customer satisfaction is unwavering. We understand that every project is unique, and we go the extra mile to tailor our solutions to your specific requirements. With Gem Scientific by your side, you can trust that you have a reliable and knowledgeable partner to navigate the complexities of the scientific product landscape.

Brochure

Request

Robots get sacked!

Rediscover the synergy between AI and humans in manufacturing

With the development of AI, the manufacturing industry is considered one of the most impacted industries across different sectors.

While AI improves efficiency and production, it also raises worries about job displacement and ethical ramifications. As a result, seeking a balance between exploiting AI’s benefits and addressing humanitarian concerns is critical for a responsible and sustainable manufacturing future. In this article, we discuss some good practices of AI in the manufacturing industry and rediscover the synergy between AI and humans.

THE RISE OF AI IN THE MANUFACTURING INDUSTRY

There have already been some innovative practices within the manufacturing industry. McKinsey predicts that by 2030, fully autonomous cars will be able to operate “anywhere, anytime” with Level 5 technology, without the need for drivers. Imagine a world where vehicles operate autonomously, offering the potential to reduce accidents caused by fatigue or impaired driving, for a future where safety and convenience go hand in hand.

There are other notable innovations taking place in the manufacturing industry. The University of Lincoln, in collaboration with industrial partners, has revolutionised fruit picking through the development of innovative robots that aid growers in vital tasks. The robots pick the strawberries accurately and at a decent pace, greatly enhancing the efficiency and productivity of fruit harvesting processes.

Embarking on the exciting journey of AI development, Harford continuously improve our solutions to support manufacturers on their journey to operational excellence. To that end, we’ve strengthened our partnership with Visicon Vision Inspection Solutions.

Using sophisticated cameras with ‘Deep Learning’ software, we have already helped manufacturers detect and quantify the ingredients in ready meals even when the ingredients have similar colours to the background.

With the rapid development and increasing impact of AI in factories, more and more people are concerned about technology. Will autonomous vehicles displace drivers? Will robots replace workers? Will machines take over human operators?

ROBOTS GET SACKED: HUMANS RECLAIM THE SPOTLIGHT

Despite the widespread adoption of AI and robots in the manufacturing industry, Toyota has taken a unique approach by reintroducing human workers to assembly lines and workstations that were previously automated using robots, due to their lack of quality consistency.

Beyond addressing the underperformance of robots, factories that only implement robots can become stagnant in their development stage. While robots excel at executing repetitive tasks, they lack the creative thinking and discernment needed to identify opportunities for continuous improvement. Human’s invaluable contribution and creativity go beyond the capabilities of robots alone.

THE SYNERGY OF HUMAN-CENTRICITY AND AI

It’s the spirit of a human-centric, smart technology approach to automation that can drive manufacturing performance to a new level. AI has great potential to transform the manufacturing industry, but it should not replace human workers. Through combining the creativity and capabilities of human workers with cutting-edge AI technologies, factories can continuously improve their efficiency and reduce wastage.

At Harford, we not only offer cuttingedge MIS/MES systems to help factories eliminate risk, reduce wastage and improve performance, but also provide a consultative approach for manufacturers to give them practical advice on how to further reduce wastage and improve their efficiency.

The journey toward a tech-centric and human-centric manufacturing industry requires responsible MIS/MES technology and worker empowerment. By embracing collaboration between AI and humans, we can create a harmonious ecosystem where technology and humanity thrive together.

To find out more, call our team on 01225 764461 or contact us at www.harfordcontrol.com/contact/ See us at PPMA23 on Stand B46.

34 FDPP - www.fdpp.co.uk

Ensure product quality and compliance with advanced machine vision solutions and deep learning software Learn more +44 (0)1225 764461 www.harfordcontrol.com Harford vision inspection solutions go far beyond accurate label verification, accurate recognition of printed text, and 2D code assessment. With automatic rejection systems, pattern matching and 100% inspection capabilities, our solutions ensure exceptional product quality through the additional use of SPC to prevent rejects. *See us on Stand B46 at PPMA 2023

UK Manufacturer Extends its Protection of Stored Bulk Crops Across the Globe

Liquid flowmeter specialist Titan Enterprises and agrochemical specialist Stored Crop Conservation Limited have been collaborating for over 20 years. Incorporating Titan’s 900 series turbine flowmeters, Stored Crop use a modified application system to extend the life of crops before and after harvest and maintain healthy storage environments.

Having established themselves in a niche market, designing fogging systems to treat customer environments, Stored Crop has seen demand for their crop ‘fogging’ machines installed around the world. Nick Green, Stored Crop’s CEO, enthuses: “Where we are primarily servicing the food packaging industry and major food processing companies in the UK, our fogging machines are being requested by an international market. This has significantly increased our manufacturing demand, and Titan’s excellent service and response to demand has been a great support.”

Stored Crop’s fogging machines utilise Titan’s 900 series turbine flow meters to record and monitor the volume of dispensed chemical used to treat and protect crops, grain stores, poultry units and glasshouses. Hygiene and the elimination of pests and fungus is a major problem in the storage of bulk crops in modern agriculture. From the preparation of buildings used for food production through to mass food stores, cleanliness is essential to ensure the quality of the raw materials. For example, when potatoes are put into storage, the efficient application of a sprout-suppressing agrochemical extends the life of the product.

Titan Enterprises and Stored Crop have much in common, both being UK-based manufacturers, family-run companies and specialists in their field, so it’s not

surprising that the relationship is still going strong.

Nick Green reflects: “Early on in our operation, we found a sprayer that utilised Titan’s flowmeters. We trialled one of Titan’s measuring devices, working with them to adjust the flow meters to meet our exact requirements. We use both the PVDF and stainlesssteel cased mini turbines as they are able to function accurately and reliably with aggressive chemicals where careful control of application volume is absolutely critical.”

Stored Crop’s system for fogging agricultural food stores and crops with a very fine mist of appropriate agrochemical, ensures the whole volume is treated evenly. The flow and volume of dispensed chemical is measured by Titan’s 900 series mini turbine flowmeters to ensure consistent and safe dispersal of these controlled chemicals. The durability and chemical resistance of Titan’s flow meters means that the different ‘fogging’ chemicals dispensed through Stored Crop’s machines, can be used in Europe, Argentina, Russia, China and Pakistan, for example, where each country has its own regulations regarding chemicals used for this process.

Neil Hannay, Senior R&D Engineer with Titan Enterprises said: “These turbine flow measuring devices are an ideal lowcost component for OEM applications. The combination of chemically resistant flow meter design and low flow rates to ensure precision measurement is well suited for chemical dispensing or batchfilling systems.”

Titan’s 900 series offers 6 flow ranges from 0.05 to 15 L/min. The sapphire bearings give long life and reliability, and the choice of body materials makes this the ideal choice for metering aggressive chemicals, including ultrapure water.

For further information on Titan’s 900 series turbine flowmeters please visit https://flowmeters.co.uk/product/900series-turbine-flow-meters/

Tel: +44 (0)1935 812790

Email: sales@flowmeters.co.uk

Website: www.flowmeters.co.uk

36 FDPP - www.fdpp.co.uk

Secure Sustainable Solutions

Looking for a sustainable way to securely seal your container or bottle? Look no further, Viscose Closures has a range of ecofriendly seals for all your tamper evidence needs.

We provide environmentally conscious producers & brands with our unique plastic free, biodegradable, home compostable, selfshrinking bands. Made from plant-based materials derived from wood pulp, our self-shrinking bands are heat and machinery free making them the perfect choice for heat sensitive products such as food, perfume, and flammable liquids.