MATERIAL V ISIONARIES

Diving deep into how interiors can make an impact

Diving deep into how interiors can make an impact

Thoughtfully designed and carefully curated, making it easy to create sophisticated spaces that address every need.

8

EDITOR’S LETTER

Making Righteous Choices

10 SUSTAINABILITY LAB

Metropolis and The Mart return to NeoCon with resources to help the interiors industry make a positive impact on people and the planet.

22 METROPOLISLIKES

Review the winners of this year’s MetropolisLikes NeoCon awards and the interior design trends they represent.

40 BEGINNING AT THE END

In Metropolis’s Sustainability Lab, PROWL urges visitors to consider the afterlife of design.

80

WASTING AWAY

Artist Latham Zearfoss transforms exhibitor waste into a thought-provoking installation for Metropolis’s Sustainability Lab at The Mart.

HOT LIST 2023

Meet the designers and manufacturers committed to bringing the industry greater disclosure and verifiable claims for building materials.

42

LONA RERICK

The ZGF principal is leading a seismic industry shift away from harmful materials and drawing a bold line between what is healthy and what is hype.

50

KATIE ACKERLY

The David Baker Architects principal discusses specifying healthy interiors that are also sustainable and affordable.

54

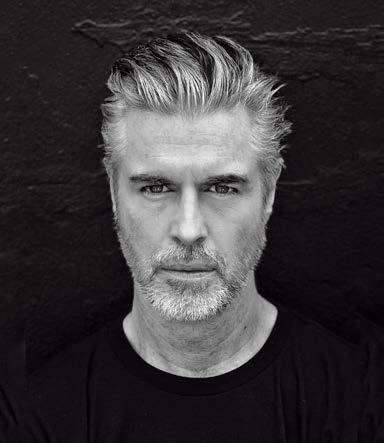

SCOTT STAR

The leader of Gensler’s product development arm explains why a specifier’s viewpoint is gold for manufacturers of the next hot product.

60

LUCAS HAMILTON

The manager of applied building science at CertainTeed is on a mission to have you grasp its sustainability measures as well as he does.

62

CHRISTINA VERNON

One of Steelcase’s directors shares what role the camera plays in their new tech-led approach to office product design.

66

COURTNEY BROOKS

The director of design for Unika Vaev shares his vision for deepening sustainability and engaging young specifiers while growing the company’s textile division.

70 AQUAFIL

The sustainable yarn supplier is leading the charge to reduce the carpet industry’s carbon output.

76

JAROD BRAMES

The director of sustainability for OFS shares the company’s unsung legacy of environmental stewardship.

EDITOR IN CHIEF Avinash Rajagopal

DESIGN DIRECTOR Tr avis M. Ward

DEPUTY EDITOR Kelly Beamon

EDITORIAL PROJECT MANAGER Laur en Volker

DIGITAL EDITOR Ethan Tucker

ASSOCIATE EDITOR J axson Leilah Stone

DESIGNER Rober t Pracek

COPY EDITOR Benjamin Spier

FACT CHECKER Anna Zappia

EDITORS AT LARGE Ver da Alexander, Sam Lubell

VICE PRESIDENT, PUBLISHER Carol Cisco

VICE PRESIDENT, MARKETING & EVENTS Tina Brennan

ADVERTISING DIRECTOR Tamara Stout tstout@sando wdesign.com 917.449 .2845

ACCOUNT MANAGERS

Ellen Cook ecook@sando wdesign.com

Gr egory Kammerer gkammer er@sandowdesign.com

Colin Villone colin.villone@sando wdesign.com 917.216 .3690

Michael Croft 224.931.8710

L aury Kissane 770.791.1976

MARKETING & EVENTS MANAGER Kelly Kriwko kkriwko@sandowdesign.com

EVENTS MANAGER Lorraine Brabant lbrabant@sandowdesign.com

SENIOR DIRECTOR, CONTENT DISTRIBUTION Amanda Kahan

SENIOR MANAGER, DIGITAL CONTENT Ile ana Llorens

SOCIAL MEDIA COORDINATOR Zoya Naqvi

METROPOLISMAG.COM

@metropolismag

CHAIRMAN Adam I. Sandow

CHIEF EXECUTIVE OFFICER Erica Holborn

CHIEF OPERATING OFFICER Michael Shavalier

CHIEF DESIGN OFFICER Cindy Allen

CHIEF SALES OFFICER Kate Kelly Smith

EXECUTIVE VICE PRESIDENT + DESIGN FUTURIST AJ Paron

EXECUTIVE VICE PRESIDENT, STRATEGY Bobby Bonett

SENIOR VICE PRESIDENT, PARTNER + PROGRAM SUCCESS Tanya Suber

VICE PRESIDENT, HUMAN RESOURCES Lisa Silver Faber

VICE PRESIDENT, BUSINESS DEVELOPMENT Laura Steele

SENIOR DIRECTOR, PODCASTS Sam Sager

DIRECTOR, VIDEO Steven Wilsey

SENIOR DIRECTOR, STRATEGIC OPERATIONS Keith Clements

CONTROLLER Emily Kaitz

DIRECTOR, INFORMATION TECHNOLOGY Joshua Grunstra

SPECIFY is a publication of SANDOW

3651 FAU Blvd. Boca Raton, FL 33431

info@metropolismag.com

917.934.2800

FOR SUBSCRIPTIONS OR SERVICE

800.344.3046 customerservice@metropolismagazine.net

EXECUTIVE DIRECTOR, FINANCE & OPERATIONS Lorri D’Amico

DIRECTOR, SPECIAL PROJECTS Jennifer Kimmerling

PARTNER SUCCESS MANAGER Olivia Couture

SANDOW was founded by visionary entrepreneur Adam I. Sandow in 2003, with the goal of reinventing the traditional publishing model. Today, SANDOW powers the design, materials, and luxury industries through innovative content, tools, and integrated solutions. Its diverse portfolio of assets includes SANDOW DESIGN GROUP, a unique ecosystem of design media and services brands, including Luxe Interiors + Design, Interior Design, Metropolis, DesignTV by SANDOW; ThinkLab, a research and strategy firm; and content services brands, including The Agency by SANDOW, a full-scale digital marketing agency, The Studio by SANDOW, a video production studio, and SURROUND, a podcast network and production studio. SANDOW DESIGN GROUP is a key supporter and strategic partner to NYCxDESIGN, a not-for-profit organization committed to empowering and promoting the city’s diverse creative community. In 2019, Adam Sandow launched Material Bank, the world’s largest marketplace for searching, sampling, and specifying architecture, design, and construction materials.

THIS MAGAZINE IS RECYCLABLE. Please recycle when you’re done with it. We’re all in this together.

Taboroid is a personal locker, charging station, and impromptu stool that gives everyone freedom to work anywhere, with everything you need at hand.

you need at hand.

Volta™

Portable Power

Volta is our removable battery pack that goes anywhere and can charge a typical laptop up to four times on a single charge. Truly all-day power needs.

that goes and

Media

With Volta™

can be with batteries,

The customizable tall Gira Walls can be outfitted with batteries, or with line-voltage outlets. With Taboroids, they can all gather together for a quick huddle.

Panel without and come in a

Gira lets you remodel your workspace anytime without hiring contractors. Removable panels snap onto fixtures and come in a variety of sustainable materials.

The way we work has changed. But the way we furnish offices hasnʼt. Until now.

™

THIS YEAR AT METROPOLIS we returned to Specify’s roots as a tool for sourcing the best materials. We asked ourselves, “What kinds of product information do designers need most right now?”, “Which certifications, ingredients, and omissions actually distinguish a healthy material versus one heavy on hyperbole?”, and “Which manufacturers are excelling not only in making that data transparent, but also easy for specifiers to understand and use?” Naturally, these queries, routinely considered for product coverage in our magazine, deepen the specifier-manufacturer conversation.

As you’ll read in this year’s Hot List (p. 42), professionals involved in various stages of the product development and interior design process came clean: There are leaders at manufacturing companies who are sifting through metrics for meaningful data, and architects who are continuing to apply pressure on the industry to provide greater disclosure and verifiable claims.

Those are also characteristics of the products that received this year’s MetropolisLikes awards (“Object Lessons,” p. 22) and those highlighted in the Metropolis Sustainability Lab (p. 10). Join us in our quest to keep uncovering what is truly responsible, healthy, and climate-friendly.

—Kelly Beamon, deputy editor

—Kelly Beamon, deputy editor

Cheers to 40 years of glass sustainably made in Chicago

JUNE 12-14 2023

The Merchandise Mart, 11th Floor, Suite 1120

Come visit us at Metropolis’s Sustainability Lab at NeoCon, an exhibit and destination to help you take the next step towards making a positive impact on people and planet. At the Lab, you’ll learn about the most innovative products and dive into new initiatives and resources to help advance your work. Plus, we have thought-provoking installations and informative workshops to keep you on the cutting edge of sustainable design.

REGISTER FOR PROGRAMMING

SPONSORED BY:

ON THE 11TH FLOOR OF THE MART, Metropolis’s Sustainability Lab returns to NeoCon this year with activities, programs, and, of course, information on products and initiatives that help the A&D industry make a positive impact on people and the planet.

This year’s Lab includes 17 showcases about design manufacturers’ progress toward a circular, regenerative, and healthy future. Alongside these brand initiatives and product spotlights, the Lab raises questions and provocations for a regenerative future through two special installations, two workshops, and a Leadership Summit.

International art consultancy Farmboy brings artist Latham Zearfoss’s “Stardust” to the Lab, prompting attendees to expand their frame of reference beyond Planet Earth as they think about sustainable choices. Meanwhile, San Francisco–based PROWL Studio’s prototype Peel chair travels from Milan Design Week to the Lab, suggesting a future for the furniture industry based on renewable resources and circular processes.

On June 12, mindful MATERIALS will lead a workshop at the Lab on how to choose materials while navigating the complexity of sustainability certifications. The next day, in partnership with Interface, Metropolis will host a workshop by Rainey Shane, the social sustainability director, Americas, for JLL, about SEAM, the world’s first commercial real estate certification in social equity.

The Lab will open with a Leadership Summit on the future of the interior design profession, and close with a reception cohosted with Material Bank.

With workshops, programs, and a showcase of sustainable manufacturing, this year’s hub shines a spotlight on circularity and regenerative design.

Cube™ is Autex’s lightweight, semi-ridged acoustic panel made from compressed polyester felt. Each inch-thick panel contains the equivalent of 222 recycled 20-ounce water bottles. Autex is the first carbon-neutral acoustics manufacturer in the world, offering carbon-neutral products with emissions offset by certified carbon credits since 2020, and continues to monitor and report the embodied carbon of its products.

autexacoustics.com

A major industry breakthrough, Xorel Biobased is the world’s first commercial-grade plant-based, carbon-positive performance textile. Since 2013, Carnegie has grown this revolutionary product line with a wider selection of patterns and colors while offering broader applications and end uses, including outdoors. For every ton of Biobased Xorel yarn, 2.5 tons of carbon are captured and sequestered, making it a carbon-positive product. carnegiefabrics.com

Clarus’s rolling glass whiteboard go! Mobile is a practical and dust-free alternative to other types of writing surfaces such as chalkboards, making it a perfect product for offices and classrooms. Made with tempered safety glass, it resists stains and is easy to clean. Clarus go! Mobile is the display system used in the Metropolis Sustainability Lab. clarus.com

In August 2022, the entire product line from bent-metal furniture company Division Twelve was officially certified carbon neutral. Based in North America, Division Twelve prides itself on its bold personality, bolder color palette, and solid commitment to conducting Life Cycle Assessments for every product.

division12.com

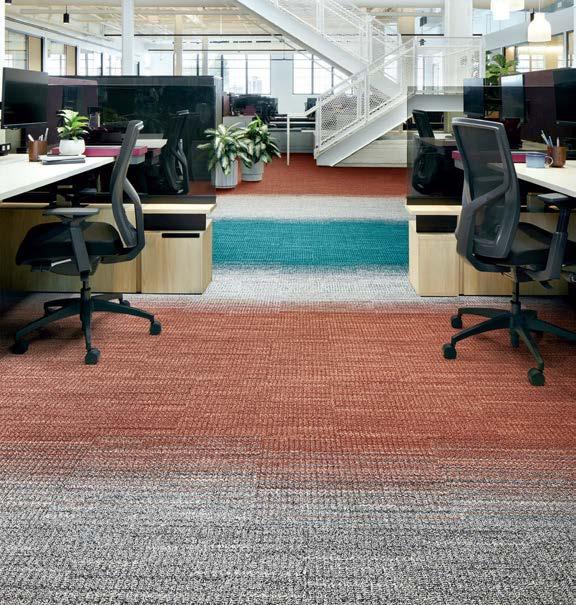

At the foundation of culture is connectivity, the driving factor in returning to a shared workspace. With our newest flooring collection, we celebrate the collaborative process. Visit us at Design Days to explore the art that emerges when we create together. Fulton East, Chicago | June 12–14

The fabrics in Duvaltex’s Clean Impact Textiles® collection are made by repurposing discarded materials, and their production features innovative technologies that minimize their environmental impact at the end of their useful lives. This process is helping clean our oceans and reduce plastic pollution worldwide.

duvaltex.com

Farmboy is a full-service international art advisory with a simple purpose: to change lives with art. With over 20 years of experience collaborating with global interior designers, architects, brands, and Fortune 500 companies, it designs ambitious art programs for environments across hospitality, corporate, health-care, multifamily, senior living, and other settings. At the Sustainability Lab, Farmboy helped commission an installation by artist Latham Zearfoss that utilizes repurposed materials. farmboyfinearts.com

Garden on the Wall® is the world’s only preserved plants-and-moss wall supplier with 16 third-party tests and credentials to ensure the sustainability, transparency, safety, and material health of its installations. Its creations help designers build environmentally and behaviorally healthy environments with biophilia in mind.

gardenonthewall.com

A defining aspect of Interface’s history is its decades-long sustainability journey. Since 1994 it has reduced the environmental impact of its operations and flooring products on a global scale. Making changes to its factories, product design processes, and supply chain helped Interface achieve carbon neutrality in 2019 under its Mission Zero initiative. Today it has the lowest carbon footprint in the industry for carpet tiles. interface.com

Jade is an ergonomic office chair made from sustainable materials, including recycled plastic felt, 100 percent REPREVE® 3D knit, and recyclable steel. It is designed to be harmonious with the earth and your body. The Vale collection transforms recycled plastic bottles into sophisticated chairs for a comfortable, sustainable sitting experience.

kfistudios.com

Tessellate products represent the future of acoustics—solutions that divert plastics from waste streams as well as control sound. Combining style with sustainability, Tessellate baffles and pendants trap rogue sound waves in a triangulation of recycled PET planes.

kireiusa.com

Free of PVC, ortho-phthalates, PFAS, halogens, plasticizers, and chlorine, the Proxy collection is uniquely crafted with sustainability in mind and features the outstanding performance of Mannington’s Quantum Guard Elite® technology. The company is making strides toward delivering flooring solutions that have a positive impact.

manningtoncommercial.com

For the benefit of all humankind, the time to take meaningful action is now. That’s why Milliken’s flooring products feature 100 percent transparency when it comes to their chemistry, down to 100 ppm (parts per million). The company is continuing to invest in new technology and flooring products that enable designers to make better choices. All Milliken carpet, resilient, and entryway tiles are fully transparent, recyclable, and reusable.

milliken.com

This multicolor solution-dyed fiber is a breakthrough that delivers the visual texture and dimension of a space-dyed yarn, but with the lower environmental impact of one that’s solution-dyed. Mohawk Group saves 331,000 gallons of water each year by replacing traditional space-dyed yarns with Color Pulse fibers. This advancement is part of the company’s commitment to providing flooring products that are net positive water.

mohawkgroup.com

Wood is inherently ecofriendly, but unless you consider the harvesting, processing, and chemical treatment, there’s no guarantee that it is. That’s why Rulon International’s goal is to ensure that every project it takes on meets the highest standards of transparency. Each Rulon wood product is assessed on environmental footprint, material composition, sustainable sourcing, and indoor air quality.

rulonco.com

BottleFloor, an innovative new hybrid flooring collection made from postconsumer PET bottles, illustrates Shaw Contract’s commitment to the circular economy. Each square yard of BottleFloor contains an average of 62 recycled plastic bottles. This is the first collection to launch on Shaw’s ReWorx™ platform, making it easy to recycle through the company’s re[TURN]® reclamation program.

shawcontract.com

Turf created the award-winning color palette Hues by leaning into the challenges of making new products from postindustrial waste. The collection of 32 nuanced tones—offered exclusively on Turf’s 9-millimeterthick, recycled PET panels—reflects the heathered effect of their reused content. The panels are salvageable in their entirety, and Turf’s reclamation program takes back used acoustic solutions and disposes of excess components responsibly.

turf.design

By 2025 all Ultrafabrics-brand furniture-grade products will have reached the company’s goal of including at least 50 percent rapidly renewable and/or recycled content. This is five years ahead of the company’s original goal. Ultrafabrics is achieving this target through material innovations, including man-made cellulosic fibers, sustainable and recycled yarns, and biobased resources.

ultrafabricsinc.com

REPREVE® is the world’s leading brand of performance fiber made from recycled bottles. Advanced fiber technology delivers a material that enhances comfort and improves performance of other products ranging from clothes to sofas. As REPREVE is the only eco-performance fiber with Unifi Manufacturing’s U TRUST® product verification, its transparency and traceability are ensured.

repreve.com

WE ALL WANT to make a difference in the world, but at a time of overlapping crises it can be hard to know where and how our efforts will be most effective. For example, when you think about climate change, are you moved more by the fate of future generations of humans or the impending extinction of honeybees? Do you believe that long-lasting change comes through

revolutionary thinking or through incremental measures?

The Metropolis Sustainability Lab’s Positive Impact Quiz will help you find your sweet spot in the movement toward enlightened design. Take this quick, lighthearted quiz to find out what you contribute to the greatest design project ever undertaken: saving civilization from civilization’s mistakes.

Lost Palms™ carpet tile collection features nine styles that deliver large-scale pattern in smooth and super-plush profiles. Designs range from stone-inspired visuals to graphic patterns showcasing classic southwestern looks and a modern Palm Springs aesthetic.

interface.com/lostpalms

This year’s winners of the MetropolisLikes

NeoCon awards represent the best furnishings and finishes for creating healthy, sustainable, work-anywhere interiors. Here’s what innovation looks like now.

By Kelly Beamon

By Kelly Beamon

With looser expectations about where work happens, a lighter mood in the design of work furniture has emerged in lively curves and colors.

Simon’s purpose is to Spark listeners to lead countries, companies, and communities differently. His framework is based on his 30 years’ of experience in the hospitality industry, including serving as sales director for Disney Institute, based at Walt Disney World Resort in Orlando, FL.

BY ASID

BY ASID

All members of the design community are invited to gain insight and new perspectives at ASID’s national conference, GATHER. Three energizing keynote sessions will feature outstanding leaders sharing their unique stories to motivate, activate and inspire your design practice!

Genevieve’s soulful style and genuine enthusiasm have made her one of America’s favorite interior designers for years. She is the founder and director of the Genevieve Gorder brand, a television host, designer and producer, a home product designer, contributing author, and global ambassador for home and human rights.

Christian is a graduate (MFA) of Savannah College of Art and Design, as well as NY School of Interior Design. As a member of Waterfront Workshops collective, he is the principal of a custom design/build company. His aesthetic is a contemporary blend of the organic and industrial.

Unprecedented material transparency in their supply chains and deeper knowledge of toxins has led manufacturers to engineer those chemistries out—especially VOCs, PVC, and PFAS.

SUBMISSIONS ARE NOW OPEN

Deadline: July 21

Early Bird Pricing Ends: June 26

METROPOLIS’S PLANET POSITIVE AWARDS

recognize the most creative projects, product, and people from around the world that benefit people and planet. Judged by industry experts, the winners and honorable mentions represent the highest achievements today in design and innovation that address climate action, ecological regeneration, health, and equity.

We will share and celebrate the wonderful work being done around decarbonization and carbon reduction, material and product use, and community engagement, to name a few.

For many manufacturers, reuse of some material is now standard. This year’s updates not only increase the percentage of recycled content, but accelerate efforts to make more items recyclable to close the loop.

Explore the core values and new initiatives of industry innovators across disciplines with METROPOLIS editor in chief Avinash Rajagopal as part of the Leading Edge series. Watch the full series on DESIGNTV by SANDOW to see what sets architecture and design practices apart.

As users are more connected and more mobile, manufacturers are making sure more power follows them, in-hand or integrated directly into furniture.

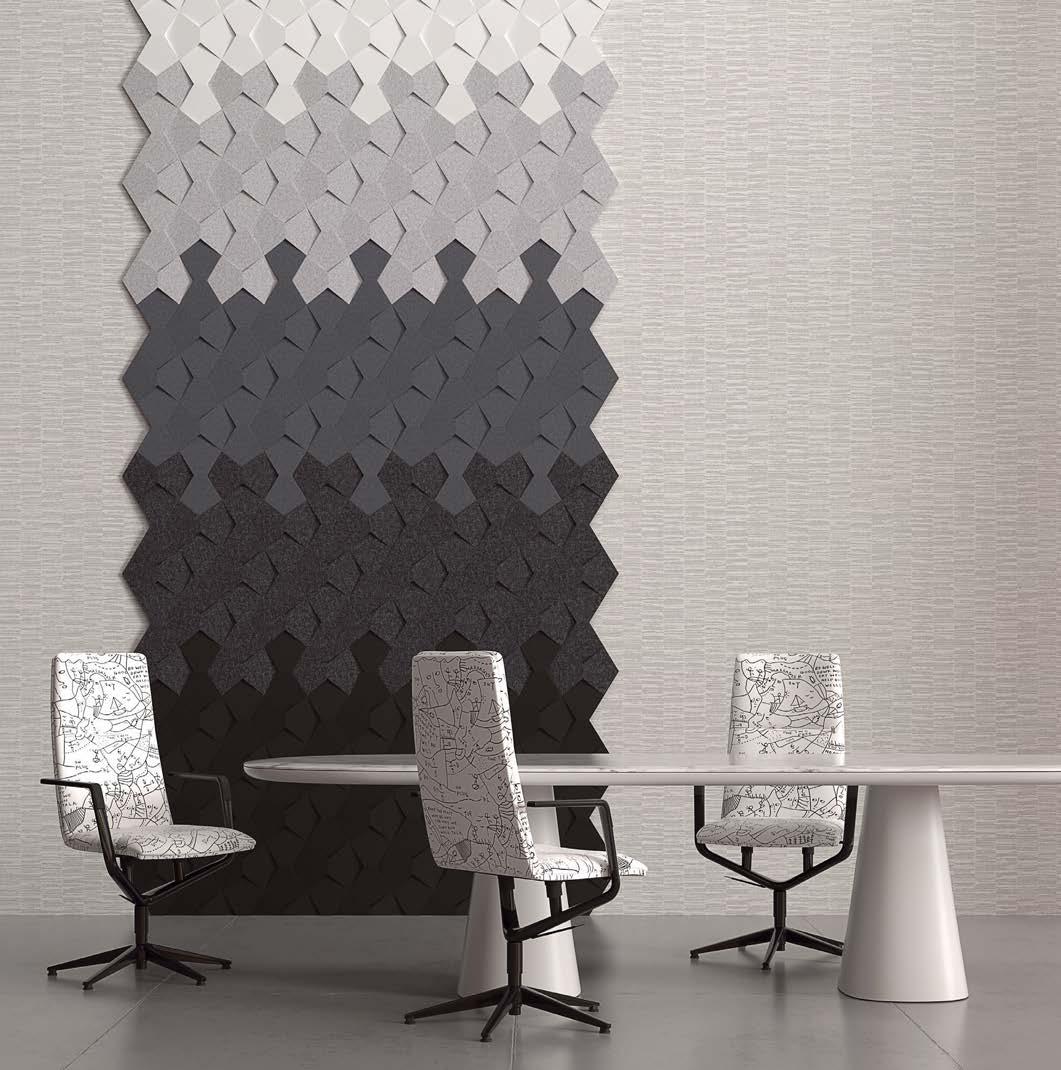

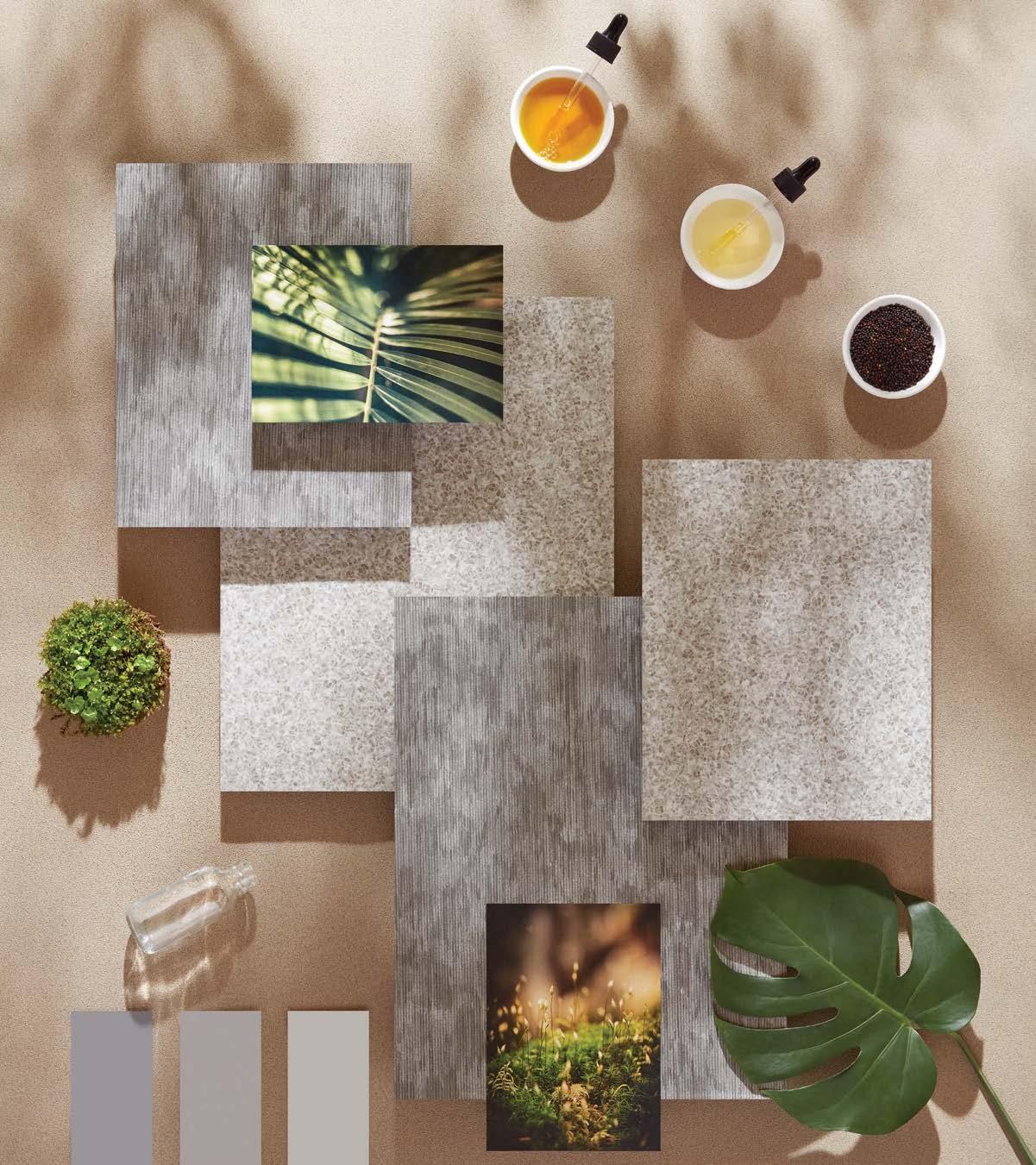

PINDROP: TUXEDO IN CRISP WHITE, HEATHER GREY, SHALE, IRON & BLACK

TEXTILE: SHANTELL MARTIN, WELL WELL WELLWHITE

WALLCOVERING: ONSLOW WS –PEARL QUARTZ

Space-saving and space-making describe a new class of flexible solutions—from foldaway seats to expandable ceiling systems—that enable quick reconfigurations of a place.

Over 50% of our products contain renewable and/ or recycled resources. We build sustainability into our materials so you can make the easy, responsible choice. Experience beauty, performance, sustainability, and comfort without compromise.

Pastel and muted palettes distinguish several items, from wallcoverings to tables, promising an equally soothing workday or hotel stay.

Gazing into the illuminated canopy of the night sky, with its cascade of stardust and moonlit celestial spaces, offered the stellar inspiration for Cosmos and Galaxy Organic silhouettes are reflected with subtle colorations with nuances of warm and cool neutrals that flow across 18” x 36” tiles. Cosmos and Galaxy are the perfect light, airy coordinates to many other products within our portfolio.

The pandemic taught everyone an appreciation for health-care workers, so manufacturers prescribed more items designed specifically for a germ-averse new normal.

LAURYN MENARD AND BAILLIE MISHLER’S PLANS for a practice centered on regenerative design began when they met ten years ago working for the same San Francisco design studio. “We wanted to do more for the planet,” recalls Menard. In 2021 they founded their studio PROWL with a mission to set new standards for the design industry. “Instead of asking how we can do ‘less bad,’ we ask how we can do ‘the most good,’ ” says Mishler. “We begin with the end—to fully understand what the next life of each product, material, or space we design could become.”

That ethos will be on full display during NeoCon in Metropolis’s Sustainability Lab at The Mart, where visitors will get to see PROWL’s newest furniture concept, the Peel chair. The biodegradable, compostable, hemp-based stacking chair will be featured among hemp-based packaging, hemp bio-leather curtains developed by

material research studio Veratate, and a hemp brick “stage.”

“Inspired by hemp stock and how different parts of the plant are removed to be harvested for reuse, Peel marries utility with responsibility,” says Menard. “It serves its purpose, but only for as long as it needs to.” To emphasize the product’s end of life, the installation will display parts of the chair sinking into soil, as if returning to the earth.

With Peel, Menard and Mishler say they hope to counter the fast-furniture trend from within, noting that low-quality, toxic materials and the pressure to keep pace with the latest styles lead to more than 12 million tons of furniture waste in the United States each year. “Like all living things, we must also expect the ‘death’ of our products when they no longer serve us or we no longer value them,” Mishler says. “We don’t have time to design in any other way. This is a moment for critical design.” ■

In Metropolis’s Sustainability Lab, PROWL urges visitors to consider the afterlife of design.

The Dappled Light Collection captures the enchanting play of light in forest settings, tree cover, and the idea of refuge in the built environment. This bio-based, PVC-Free sheet is made with renewable content, including rapeseed, canola, and castor oils. Dappled Light is also optimized for low embodied carbon and is carbon neutral.

The ZGF principal is leading a seismic industry shift away from harmful materials by clarifying what is healthy versus what is hype.

By Anna Zappia Photography by Christine Dong

The ZGF-designed PAE Living Building is the largest commercial urban Living Building in the world. It is designed to use less energy, water, and material than comparable buildings while delivering superior levels of occupant comfort through daylight, operable windows, and other biophilic strategies.

ack when she was a recent college graduate, ZGF Architects principal Lona Rerick attended a lecture given by architect William McDonough, a pioneer of sustainable green design. That was a pivotal moment when she realized that not all ingredients in a product are benign, and that they can actually be harmful: “It was the first time I was introduced to Cradle to Cradle [design], when it was a new concept. I was shocked that there were so many potentially hazardous chemicals in the products that we were putting in our buildings.”

Now, having focused on architectural design for two decades, Rerick notes that materiality always interested her. “I was in the trenches and doing the drawings, but I kept gravitating toward materials,” she says, “because they are central to how designers and architects work. We are using other people’s materials and products, and every single one has an impact.”

She recalls how her concern and her approach to managing that impact grew. When Rerick worked on an early

While Rerick’s career has focused on architectural design, she shapes healthy materials policies and practices as a member of groups within AIA, mindful MATERIALS, and the U.S. Green Building Council. At right, she’s shown with samples in ZGF’s library.

LEED-targeted project in Oregon, she made a list of problematic chemicals, calling and emailing manufacturers to ask if those substances were found in their products. She quickly learned that this critical information was not readily available, and that she’d have to dig deeper to find it. “I realize now how naive I was,” Rerick says, adding, “This isn’t a problem that can be fixed on a project-to-project basis. A marked transformation has to take place.”

She decided to help drive that transformation from outside ZGF as well. In 2018, Rerick led the American Institute of Architects’ Materials Knowledge Working

Group to create the A&D Materials Pledge. She is also on the mindful MATERIALS Steering Group, a member of one of the U.S. Green Building Council’s LEED Technical Advisory Groups (TAG), a founding cochair of the Portland Materials Transparency Collaborative, and on the board of the Health Product Declaration Collaborative.

The work has led to progress but is not immune to problems: With more than 10,000 Health Product Declarations published last year, for example, Rerick has noticed that more labels, product challenges, and checklists can lead to confusion and unattainable goals. “Clients are increasingly

receptive, but there’s a lot of noise,” she says. “There are no Red List–free buildings. My role is to assess if there is enough traction in the marketplace to say, ‘You should be doing this.’ With little or no added cost, they can start on their journey that way.”

Additionally, while there’s increasing awareness of the harm that toxic materials pose to people and the planet, there are also buzzwords that garner attention but ultimately lead to greenwashing. “There are trends in sustainable materials, and we’re seeing hype surrounding embodied carbon, but that’s problematic. A petrochemical product that has fairly low carbon can sort

Rerick believes that progress lies in simplifying processes, making information available and easily digestible, and looking at materials holistically.

of hide behind that. And we can do all the math and modeling that we want, but if we have poisoned our ecosystems and destroyed our communities, we haven’t solved climate change crises.”

Rerick believes that the next evolution will move beyond just generating lists of harmful ingredients to producing integrated, intuitive tools that become a regular part of the workflow.

But the design industry needs to first harness the technology that is crucial for that. “It does feel like the architecture and design industry is woefully behind, especially in data management of materials,” she explains. Making the newest standards and most current figures available to as many people as possible is easier said than done: “It’s hard to look at all of the issues and balance them out. And there are just so many things to consider when choosing a material. I do think we have to simplify the process and make the information more approachable.” She likens the staged progression of transparency in the design field to that of the food industry, describing the proliferation of processed meals, the scrutinizing of labels, the review of every ingredient, and finally consumers choosing locally grown, organic produce.

“I would love to get to a place where we are looking at materials holistically, and I try to play my part in that change and the bigger industry at large, so that we can all make better choices.” ■

The David Baker Architects principal discusses the ins and outs of specifying healthy interiors that are also sustainable and affordable.

Interview by Murrye Bernard

Interview by Murrye Bernard

Specify: Designing sustainable, affordable housing must be quite a challenge in San Francisco, one of the most expensive cities in the U.S. Is there one right way to do it?

Katie Ackerly: You know, it’s really interesting to observe, since we work with nearly every major nonprofit developer in the Bay Area and have the ability to compare how different clients approach doing the same thing.

Specify: What’s the toughest challenge of managing housing developers’ expectations in particular?

KA: You’d be surprised how much some of these things do come down to personal values and decision-making. That’s made me aware that buildings are complex entities in general. There are things that are basically more art

than science when it comes to these perceived trade-offs between sustainability and cost. For example, we have clients who are nonprofits, and it’s really rare to see basic systems commissioning, which is a little bit puzzling given that these are owneroperators and they will see a return.

Specify: Research plays a large role in your practice. What have you been delving into these days?

KA: An interesting part of our business is [that] we are on a couple of research demonstration grants that are funded by the California Energy Commission. They are both centered around zero-carbon affordable housing. One of them is demonstrating industrialized solutions for deep energy retrofits for primarily low-rise affordable housing. And then there’s a more recent grant that is focused around the design for a new-construction mid-rise affordable housing project. And so it’s not just about being zero energy over the course of the year, but actually a lot of it is load shifting out of the peak time and evaluating the resilience and financial benefits of that. It’s funny how California policy moves so fast that you start a project

like this, and by the time it’s done, the policy has already caught up to what you were doing!

Specify: Very true! Tell us about some of your recent projects and their standout features.

KA: Coliseum Place has a really unusual heat-pump hot water system that uses individual water heaters instead of a recirculating loop to dramatically reduce the energy use. Located in an area of East Oakland that is particularly devoid of your everyday encounters with nature, it also has a focus on biophilia and making connections between residents.

Separately, Blue Oak Landing is a modular project providing permanent supportive housing in Vallejo, California, that is poised to be zero energ y if they install the full set of photovoltaic panels. It will be our lowest energy use intensity [EUI] project to date.

Edwina Benner Plaza, which has been completed for a few years, is another one of these pilot demonstrations and it was one of the first CO2 central heat pump water heater projects, and I believe the first affordable housing project that used that technology. That was great because with Energy Commission funds we were able to make sure that the system was monitored and commissioned for a full year. The operating costs have borne out and everything, so we were able to use those lessons learned on subsequent projects.

Specify: Much of the work you’ve mentioned is located in the Bay Area. Around five years ago, David Baker Architects also opened an office in Birmingham, Alabama. How did that come to be?

KA: The firm has a number of people that come from the Rural Studio program at Auburn University. Principal Amanda Loper is one of them: Her family grew out of their rent-controlled one-bedroom in San Francisco, and she made the tough decision to move back home to Birmingham. So she opened the office there and it’s been really successful. ■

Part of the International Living Future Institute’s Living Building Challenge Affordable Housing Pilot, Coliseum Place (opposite) achieved a high level of sustainability in its systems.

The global leader of Gensler’s product development practice explains why a specifier’s viewpoint is gold for manufacturers of the next hot product.

By Ethan Tucker

By Ethan Tucker

lobal architecture and planning firm Gensler has been a formidable player in the product design space for more than 15 years, collaborating with companies that have let it steer new products to market ranging from desks and seating to lighting and flooring. Scott Star, a veteran of industrial design who joined Gensler in 2015, is a big part of the reason for that unique success story.

With his background at brand-name manufacturers such as MillerKnoll, General Electric, and Mohawk Industries, Star

estimates he has commissioned product designs approximately 2,000 times over the course of his career. And as global leader of Gensler’s product development, he has helped fine-tune a special tool of successful product design: the specifiers’ point of view.

Gensler-led designs include tables and case goods for Halcon, sustainable flooring for Mohawk, glass systems for Muraflex, desking for Fantoni, seating for Stylex and Humanscale, and lighting for Artemide. And most begin as project-specific solutions. An in-house product design division comes in handy when any of Gensler’s 7,000 employees from 53 offices covering 29 practice areas can’t find the exact right item for their projects. What’s remarkable is how those in-house solutions are changing the marketplace for everyone.

Gensler’s research and sheer size give it the ability to forecast trends and identify gaps in the market. One of the latest gaps in the design furnishings marketplace that

Star’s team has begun to address is in ADA-compliant millwork edge pulls, bathroom accessibility hardware, door handles, and signs that also look stylish.

Edge-mounted millwork pulls designed for hardware manufacturer pba, for example, met an unaddressed need for fittings that won’t detract from millwork facing and can be opened with one hand without the need for grasping, pinching, or wrist twisting. “We really love rolling up our sleeves to solve problems that a lot of people think are unglamorous, but for us, we see them as an opportunity to improve the built environment,” Star says. “A lot of people just consider those [hardware items] to be utilitarian. We consider them a canvas for not only improving functionality and inclusivity but also [an element] that can look better and integrate better into spaces.”

Though such projects began as ways to help Gensler’s interior designers, Star rejects the notion that the product development practice is one of the firm’s appendages. “My elevator pitch is always that ours is the only industrial design resource associated with the world’s leading A&D firm,” he says. “We’re able to put all the knowledge and insight gained via our A&D work into our product design work. It’s all on tap.”

That expertise and firsthand experience as specifiers yields surprising insights. For example, Star recalls a commission to design a demountable wall system for Maars Living Walls. “We knew that interior designers weren’t looking for more products like this—there are plenty already,” he admits. “What they were really after was a partition system that could bring structure to the open areas of the workspace. One that would be hackable and user-controlled.” The resulting product, called M923., is all about extreme versatility, responding to space needs that change throughout the day.

Indeed, flexibility is a common thread linking most of Gensler’s product commissions, which have applications across a range of typologies. It’s a priority Gensler’s product division can amplify in a way manufacturer-based designers aren’t always able to do, because it is rooted in the firm’s internal research. Star points to Gensler’s annual workplace survey, which in December of 2022 confirmed that workers

From top to bottom: Frame Out, a minimalist exit sign designed by Gensler for Picasso Lighting; RIVIO, an ergonomic door handle designed for Formani; Ascari, a conference table designed for Nucraft; and Brera25, a workstation designed for IOC Project Partners.

are interested in coming into the office more, if they can get the right mix of experiences, spaces, and furniture that supports the many different modes of work. Collections like Resonate, the modular lounge seating that Gensler designed for Haworth in 2020, address these needs. Unlike most lounge seating, it is extremely compact, an important product feature that can help make employees feel welcome as team rooms get smaller.

“The one common denominator is flexibility,” Star opines. “Whether [it’s] expressed through adjustability, reconfigurability, hackability, or other devices of user control, it is the key way that product design can assist interior designers in creating the best spaces for the evolving workplace,” he says. ■

The Gensler-designed patterns of 3form’s Global Expressions were inspired by textiles.

The manager of applied building science for CertainTeed is on a mission to have you grasp its sustainability measures as well as he does.

Interview by Murrye Bernard

AMID MAJOR PLANT UPATES (including at a gypsum plant set to be the first zerocarbon drywall factory in North America), CertainTeed is also weaving sustainability into its specifier relations. The company’s manager of applied building science, Lucas Hamilton, shares how.

Specify: Given today’s global supply chains, learning every ingredient that’s in a building material is challenging. How do you turn all that data into something meaningful?

Lucas Hamilton: You have to do a great deal of homework. Some of that homework can include life cycle assessments (LCA) for products. LCAs are similar to creating a personal inventory as you might do when facing a life event. You come up with a large amount of information that needs to be evaluated and acted upon. LCAs capture the holistic impact of a product, from the energy involved in the extraction of the raw materials to the manufacturing, to the transportation, to the installation, to the impact it will have on the building and the disposal or recycling after its useful life. As we go forward, all building professionals will need to be conversant in LCA language and understand how to evaluate an LCA.

Specify: How is CertainTeed changing the way specifiers engage with its products?

LH: CertainTeed is making the process for specifiers more efficient through transparency and accessibility. Builders, designers, and architects can work together to help recommend sustainable building materials to their clients. That’s why we offer an extensive collection of continuing education units (CEUs) through the CertainTeed Building Knowledge Academy of Continuing Education (ACE).

In addition, CertainTeed is both a sponsor and a member of the Construction Specifications Institute (CSI). Groups like CSI help the company learn more about what specifiers need, are looking for, and answer any questions along the way. In return, this allows us to adopt new practices when sharing information with specifiers.

Specify: In what specific ways do you provide transparency?

LH: Most CertainTeed products come with a Health Product Declaration (HPD), a list of contents and associated health information for products used in the built environment, and third-party-verified Environmental Product Declarations (EPD), which disclose the life-cycle environmental performance of products. Also, our Ecomedes-powered site, which we share with fellow brands under parent company Saint-Gobain North America, is a tool that specifiers can use to find the information they need in one place. Ecomedes provides buyers with a comprehensive place to obtain product, and performance and sustainability features for nearly all of CertainTeed’s products. Information provided includes all eco-label certifications, rating system contributions, product identifiers, recycled content and reusability, product images, manufacturing locations, links to easily facilitate purchasing, and more.

Specify: How do you support sustainable design through your product development?

LH: CertainTeed shares the same mission of its parent company Saint-Gobain to be a leader in light and sustainable building materials. Our building materials are created with the future in mind, rather than focusing on popular trends, to ensure that the products maintain their durability,

Most CertainTeed products, including its Decoustics Architectural Forms ceiling system (left), come with third-party verified Environmental Product Declarations (EPD), which disclose the life-cycle environmental performance of products.

appearance, and performance for years to come.

Specify: In addition to material transparency, it seems that factories are being tweaked to reduce embodied carbon.

LH: From a corporate perspective, CertainTeed has been investing in renewable energy for many years. Recently, the company invested $91 million to upgrade its Montreal gypsum plant to become the first zero-carbon drywall plant in North America. We have also invested in other renewable energy sources such as solar farms and wind fields.

Internally, CertainTeed has an internal cost associated with carbon. This cost is incorporated into business decisions as part of the continuous improvement of its products to determine how they can decrease their environmental impact. Additionally, CertainTeed and SaintGobain North America have launched a circular-economy business to accelerate how to reuse and repurpose end-of-life materials.

Specify: What are the company’s long-term sustainability goals?

LH: We hope that these investments encourage others in the industry to access and adopt more sustainable business practices. Looking ahead to 2050, Saint-Gobain aims to become carbon neutral, driven by the purpose of “making the world a better home.” ■

One of Steelcase’s directors shares what role the camera plays in their new tech-led approach to product development and design.

By Nigel F. Maynard

By Nigel F. Maynard

Steelcase wants you to forget everything you think you know about office interiors. Long rectangular tables facing a short wall are out. Seating arranged toward the monitor is also gone. As the notion of workspace evolves, Steelcase is evolving its very process for developing office products along with it.

The Grand Rapids, Michigan–based furniture and case goods manufacturer is spearheading a practice of designing for

deep technology integration in its effort to keep pace with change. That, the company says, means rethinking traditional paradigms such as conference rooms so that they work for everyone who is in-person and remote—designing for the camera as much as for people in the room.

“Just over a year ago, we created this category to think about hybrid collaboration, distributed collaboration, and different ways of creating collaboration opportunities in our spaces,” says Christina Vernon, the manufacturer’s director of distributed collaboration solutions and technology partners.

Consequently, many of Steelcase’s latest design solutions seem to have begun to grow out of new non–design industry alliances: “We have a great partner ecosystem with Microsoft, Zoom, Logitech,

Crestron, even VergeSense. We work with these tech partners early to understand some of their customers’ pain points and where they’re seeing their technology going in terms of road maps, and how we could be innovative and integrate tech into the spaces.”

That approach, Vernon says, underscores the importance of grasping the capabilities of specific technology for everyone creating holistic interiors. “We’re now focusing on routing housing and mounting technology in the spaces because they require a lot more than previous years,” she explains. “You need a lot more technology to manage in the space, so we’re really trying to think of room sight lines, traffic flow around tables, and how to create those collaboration moments.”

In fa ct, considering the orientation and shape of the room while integrating technology can solve two significant problems: One is increasing equity between remote and in-person workers by elevating the remote workers’ experience so they enjoy as much access as room occupants to real-time events; the second is supporting collaboration—the number one reason people want to come into the office, Steelcase says. So far, people are dissatisfied with spaces for hybrid work.

“As people think about how they’re going to work in the office or at home, we think about ease, equity, and engagement,” says Vernon, adding that there are questions that need to be asked such as, “How do you keep people engaged in the actual meeting? If they’re joining remotely, how do

you make sure that they’re staying engaged, that they can see content, that they can collaborate thoughtfully? Those are the types of issues we are trying to solve.”

Steelcase is already thinking about the next iteration of tech-led interiors. Earlier this year, the furniture manufacturer partnered with Logitech on a new videoconferencing device called Project Ghost, which seeks to allow for more personal conversations and connections than traditional video meeting services.

“It’s designed to help us understand how we could create better one-to-one conversations between groups that maybe have direct reports that are not in their same spaces,” Vernon explains. “We are in the feedback collection [phase] right now with clients.” ■

The Ocular collection (opposite) includes unique table shapes designed for hybrid collaboration, improving sightlines and creating a more equitable experience for in-person and remote meeting participants. Technology integration is key in Steelcase’s reimagining of products for individual workstations (above) and conference rooms (left) that are designed for the camera as much as for the people in the room.

The director of design for Unika Vaev shares his vision for deepening sustainability and engaging young specifiers while growing the company’s textile division.

Interview by Murrye Bernard

Specify: You’ve been the design director at Unika Vaev since early 2019. Did you come into the role with any particular goals?

Courtney Brooks: The motivation primarily was to grow the textile division and to develop textiles that we like to call “signature.” Unika Vaev has been known for beautiful high-end woolen and sustainable products, but there was a void in the collection vertically from a standpoint of pattern and design.

My mission and focus since becoming design director have been aligning with mills in the United States that are mindful of the environment and follow a philosophy of sustainability, but [are] also ones that I can work with to produce beautiful patterns at medium and larger scales.

Specify: When you design a new collection, where do you usually look for inspiration?

CB: I draw inspiration from everywhere. I’m originally from Chapel Hill, North Carolina, and back in the late 1970s my parents would send me to New York City—I have an aunt and uncle who lived in Soho. They enrolled me in pottery, painting, and sculpture classes, so I was exposed to the arts and museums in New York City at a very early age. I draw a lot of inspiration from fashion, food, and my travels around the country and the world. Our new Pattern Mix collection was inspired by my love of color, Bauhaus design, and architecture.

Specify: How does Unika Vaev’s legacy come into play?

CB: The company was founded in 1975 when we purchased the rights to a small textile mill in Denmark. The name Unika Vaev means “unique weave” in Danish. One of the things that kind of makes Unika Vaev unique is that (and I know this can sometimes be overused) we epitomize the

mindset of a small, boutique provider of high-end textiles and beautiful acoustics and decorative products.

Specify: How has the pandemic changed the way designers are specifying textiles?

CB: There’s been a big push for highperformance products—products that can be easily cleaned and are bleach cleanable—but also for products that embrace sustainability and are free of Red List chemicals and treatments. Designers still want beautiful products and fabrics, but they also want to be mindful of the environment and know that the products are high-performing. So I’ve been focusing on bringing on new products that meet all of these criteria.

Specify: Have you noticed changes in the way the company engages specifiers?

CB: I’ve been in this industry for more than 40 years, in roles from sales to interior design, and there’s been a paradigm shift with millennials and Gen Zers. Gen Zers are very important to us, and we’ve been using social media to reach that audience. Obviously we want to get in front of specifiers, and we know that they are the bulk of the folks who are specifying. ■

The Pattern Mix Collection offers three new signature upholstery fabrics: Block Party, Grid Play, and Rafter. The interplay of color, geometry, and texture creates a vibrant, cheerful palette, and the highperformance characteristics make the line suitable for all market segments.

It may come as a surprise that Americans discard roughly 5 billion pounds of carpet every year. It is even more shocking that the country currently recycles only about 2 to 3 percent of that total. But who could’ve guessed that the company set to reverse those numbers is not a carpet manufacturer but a supplier of the yarn that carpet makers source?

In fact, Aquafil, an Italian textile company already widely known for Econyl, a recycled nylon made from waste, opened its first U.S.-based carpet recycling plant in Phoenix in 2019. The plant receives postconsumer carpets from Aquafil Carpet Collection facilities and disassembles them into three main components: a fiber called Nylon 6, polypropylene, and calcium carbonate.

As Aquafil USA president Franco Rossi explains, the polypropylene is reused to make carpet backing and goes into injection-molding production, calcium carbonate is diverted into road construction and concrete, and Nylon 6 is sent to the Econyl Regeneration System in Slovenia. The company claims that it is the only supplier in the world producing 100 percent recycled nylon from such waste.

“When you make nylon from recycled materials, from old nylon, like we do, instead of making nylon from petroleum, the global warming potential and embodied carbon emissions are reduced by 90 percent,” says Eric R. Nelson, executive vice president of Aquafil Carpet Recycling. “So there’s a massive benefit to our environment when you are able to recirculate that production process. That’s really what it’s all about—decoupling petroleum from the production process.”

To support this circular process, Aquafil operates five carpet collection facilities: the one in Phoenix, which recovers 36 million pounds of old carpets annually, and four additional facilities in Southern California and Arizona that help divert 12,500 tons of both carpeting and carpet pads.

While today’s operations run smoothly, the company’s first effort to recycle carpet did not go so well. “Aquafil launched Econyl at the end of 2010, and from that time on, it has been on a constant search for new secondary material that could be transformed back into nylon without using any fossil fuels,” Rossi explains. “The carpet recycling project is a consequence of that larger project, which is making nylon out of waste.”

Rossi says the company started with a carpet shearing operation in Cartersville, Georgia, where it shaved the face fiber from used carpet and recovered the nylon portion. But after a couple of years, it ran into the issue of disposing of the carcasses. “We had somebody for a period of time who

could take it, but when that possibility went away, the operation did not make sense because we were only recovering 20 percent of the total weight of the carpet.”

But the company did not give up its hope of a carpet recycling program. After leaving Georgia, Aquafil set its sights on the West Coast, specifically California and Arizona. “We looked at California because of its legislation, and we looked at a very different technology,” Rossi says.

The legislation he’s referring to, AB 2398, is a California law enacted to increase the diversion and recycling of carpet in the state. It generates funding through an assessment on each square yard of carpet sold in California.

As for the technology, Aquafil sought a different process from the one used in Georgia. Instead of simply removing the old fibers, the company set about separating the three main ingredients of carpet. The process seems simple enough, but it’s actually quite difficult, and required that Aquafil build custom equipment. “We have our own

Opposite: Depending on its structure and composition, carpet is broken down into three main components at Aquafil’s facilities: polypropylene, calcium carbonate, and Nylon 6. Left: Because carpet isn’t designed to be recycled, Aquafil had to develop custom machinery to take the products apart.

technology, which is mostly a combination of different machinery that was adapted to the scope of work,” Rossi explains.

“I think it’s important to note that carpet is not really made to be recycled,” Nelson says, adding that “it’s not like an aluminum can or a plastic water bottle. It’s very complicated and capital intensive. These machines are ripping apart and trying to separate a mishmash of different materials, so as Franco said, it’s not really a matter of just buying machines off the shelf for this application.”

Aquafil closed its Woodland, California, recycling facility in 2022. It now sends carpet material to its Phoenix plant for recycling. The company says the decision to close the California site was due to insufficient carpet supply to feed two recycling facilities (Woodland and Phoenix). But Rossi still believes the industry must eventually step up its recycling. “It is critical,” he says. “I believe our California story should be used as a marketing tool to promote carpet as an actual recyclable flooring system.” ■

SUSTAINABILITY AT OFS began in the 1960s with the environmentalist views of the current CEO’s father. Director of sustainability Jarod Brames explains how Bob Menke’s philosophy continues to inform the company’s products.

Specify: How has the company’s specific vision for sustainability evolved?

Jarod Brames: The foundation of sustainability at OFS was created back in the 1960s with Bob Menke [father of current president and CEO Hank Menke]. Bob was advocating for proper forest management, pollution prevention, and the reduction of potentially harmful chemicals.

OFS was a much smaller company then and was mainly focused on the wood products industry. The efficiencymindedness of a woodworker coupled with this environmental awareness led to the philosophy around sustainability that has been persistent through our years of operation.

The vision we have for sustainability moving forward is to build upon that foundation and put into action initiatives that address modern concerns, of which there are many! So we have to be strategic in what we would like to accomplish and what our customers, colleagues, and communities would like us to accomplish, and what our approaches should be in trying to tackle these challenges. Recently we put together a low-carbon transition plan that lays out a framework for reducing our carbon footprint.

Specify: And how is that going so far?

JB: We have a good grasp on our Scope 1 and Scope 2 emissions and actions that can be taken to lower these impacts. We recognize, though, that we have a lot of work in front of us gathering Scope 3 emissions and the embodied carbon within our products—both of which are imperative to understanding our organization-wide footprint.

We are also continuing our work regarding the chemicals within our

products and any potential impacts on the environment or human health they could present. When it comes to products, transparency is our first goal. Reductions of both carbon emissions and potentially harmful chemicals come next. Creating products and processes that are conducive to healthy environments both inside and out is the overall goal.

Specify: What’s the company’s design process, and how does it intersect with craftsmanship, sustainability, and innovation?

JB: Part of the vision for sustainability that I mentioned above is to be sure our initiatives align with the OFS values. Two of OFS’s company values are stewardship and simplicity. During any product design brief these two values are addressed either directly or indirectly: directly through clearly communicated goals for material use or a desire for specific sustainable attributes, and indirectly by working with specific designers and product developers that have a natural tendency to simplify the design process.

The Zero guest seating collection is a good example of a simplified, or minimalistic, design. It can be quickly assembled and disassembled to easily

replace, restore, and reuse components. This increases its longevity and allows for easy separation of materials for recycling at the end of its life. The small number of components also makes it easier to document embodied carbon as well as a chemical inventory for the chair, adding to its marketability and our goals for material transparency.

Specify: How are your and OFS’s design priorities changing the way you engage specifiers?

JB: Specifiers can have a wide range of goals for any given project. If we can design products that inherently meet a large number of these priorities, then we are simplifying the process for them. Sustainability is undoubtedly a frequent priority. If we can ensure that the materials and processes used to create our furniture meet specific sustainability standards and demands for transparency, then we’re adding value to that relationship.

Functionality and aesthetics are also high priorities. If we can design a product that can be easily reconfigured to meet changing needs, then again, we are increasing that product’s longevity. A product’s staying power increases even further if it happens to look fantastic! ■

The seat, back, and frame of Zero, a guest seating option from OFS (opposite), are connected by a single fastener. Components are recyclable and can be mixed and matched to create unique combinations.

AMID THE CROWDS AND BUSTLE OF NEOCON, visitors can retreat to the Metropolis Sustainability Lab and contemplate a provocative installation by local artist Latham Zearfoss. Developed in collaboration with international art advisory Farmboy Fine Arts, Zearfoss’s installation will feature large spherical structures resembling planets in our solar system, each emitting vocal interpretations of NASA sound recordings, created with Matt Joynt. Like his other work (“Ships in the Night,” from 2019, is shown), “Stardust”

is composed partly of discarded packing materials. The orbs (a combination of repurposed T-shirts, bedsheets, and towels, hand-dyed with natural pigments) will be stuffed with soft plastics from NeoCon exhibitors’ packaging waste. “As each planet sings out, it will lend an emotive, ambiguous humanism amidst the busy comings and goings of conference attendees,” Zearfoss says. “This work proposes that entire worlds are possible with what we already have, including the ubiquity of low-grade plastics.” ■

In workplaces outfitted with Turf acoustic solutions, the values we want to inspire are quite literally in the air. Learn more about Plaid at turf.design

Plaid Ceiling Scapes, image by Imperfct*

Plaid Ceiling Scapes, image by Imperfct*