Understanding OES Analysis: A Key Tool in Material Testing and Quality Control

In the world of metallurgy and material science, precision and accuracy are everything. Whether it's automotive, aerospace, or construction, knowing the exact composition of metals is essential. One of the most trusted methods used for this purpose is OES Analysis, or Optical Emission Spectroscopy Analysis. This technique helps determine the elemental composition of metallic samples, ensuring high standards of quality and safety.

What is OES Analysis?

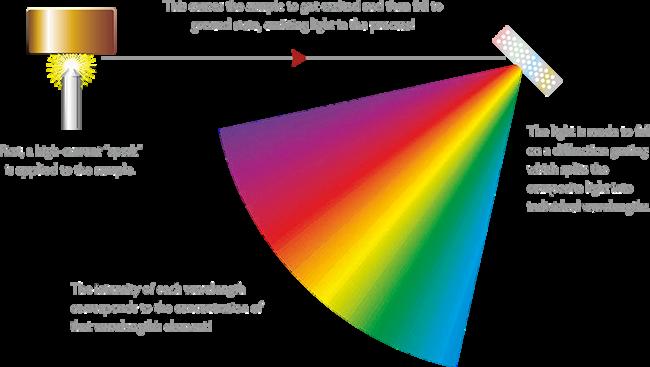

OES Analysis is a rapid and reliable technique used to analyze the chemical makeup of metals and alloys. It works by using an electrical spark to excite atoms in a sample. When these atoms return to their normal state, they emit light at specific wavelengths. A spectrometer detects this light and interprets it to determine the presence and concentration of various elements like carbon, iron, nickel, aluminum, chromium, and more.

Applications of OES Analysis

OES Analysis is widely used across multiple industries due to its precision and speed. Here are a few sectors that heavily rely on it:

Automotive Industry: Ensures the right alloy mix is used for engine blocks, transmission components, and frames

Aerospace Industry: Verifies the composition of critical parts to meet strict safety standards

Construction: Confirms the strength and durability of structural steel.

Metal Recycling: Sorts and grades scrap metal based on composition.

Advantages of OES Analysis

One of the main benefits of OES Analysis is its speed. It can produce highly accurate results within seconds. Additionally, it's non-destructive, meaning the sample remains mostly intact after testing. It's also highly sensitive, capable of detecting even trace levels of elements.

Other benefits include:

High throughput for mass testing

On-site testing capabilities with portable OES devices

Reliable for both ferrous and non-ferrous metals

Limitations to Consider

While OES Analysis is extremely e�ective, it has some limitations. It typically requires a flat surface and may not work well on very small or irregularly shaped samples. Additionally, it may not detect non-metallic inclusions or very low levels of certain gases like oxygen or nitrogen.

Why OES Analysis Matters

In today’s quality-driven market, ensuring that products meet strict compliance and performance standards is critical. OES Analysis provides the confidence manufacturers and engineers need. It not only helps prevent costly errors but also contributes to environmental sustainability by allowing e�ective sorting and recycling of metals.

Conclusion

OES Analysis plays a vital role in modern-day material testing and quality assurance. With its unmatched speed, accuracy, and ease of use, it's no wonder why industries around the world rely on this powerful technique. Whether you're ensuring compliance or striving for the highest quality standards, OES Analysis is a must-have tool in your testing arsenal