“In the Gunnison Valley, a story unfolds, of people and nature and things to behold, biochar, a substance of great worth, made from biomass, it's a soil amendment of the earth.

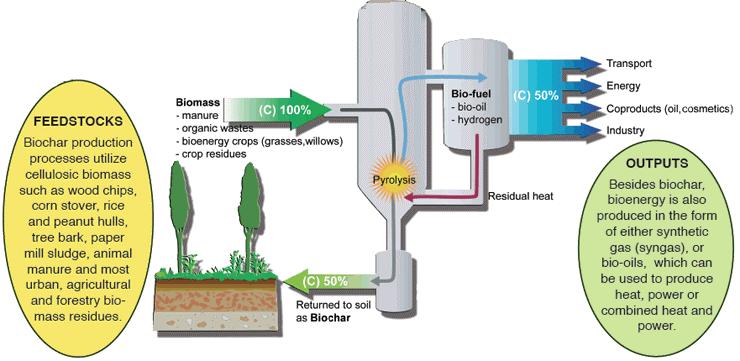

Using pyrolysis to create this substance so rare, oxygen-limited thermal decomposition, with less CO2 to spare.

This is a story of people taking matters into their own hands, creating something beautiful, from waste and despair. Biochar, a substance of great worth, has a story to share.”

- Sandy Loamgrubber

Editor: Matthew C. Eshed

Research Advisor: Professor Ricardo Vazquez-Perales, PhD

Research Fellowship: Coldharbour Institute

Master of Environmental Management Thesis Project 2023

Western Colorado University, Gunnison, CO

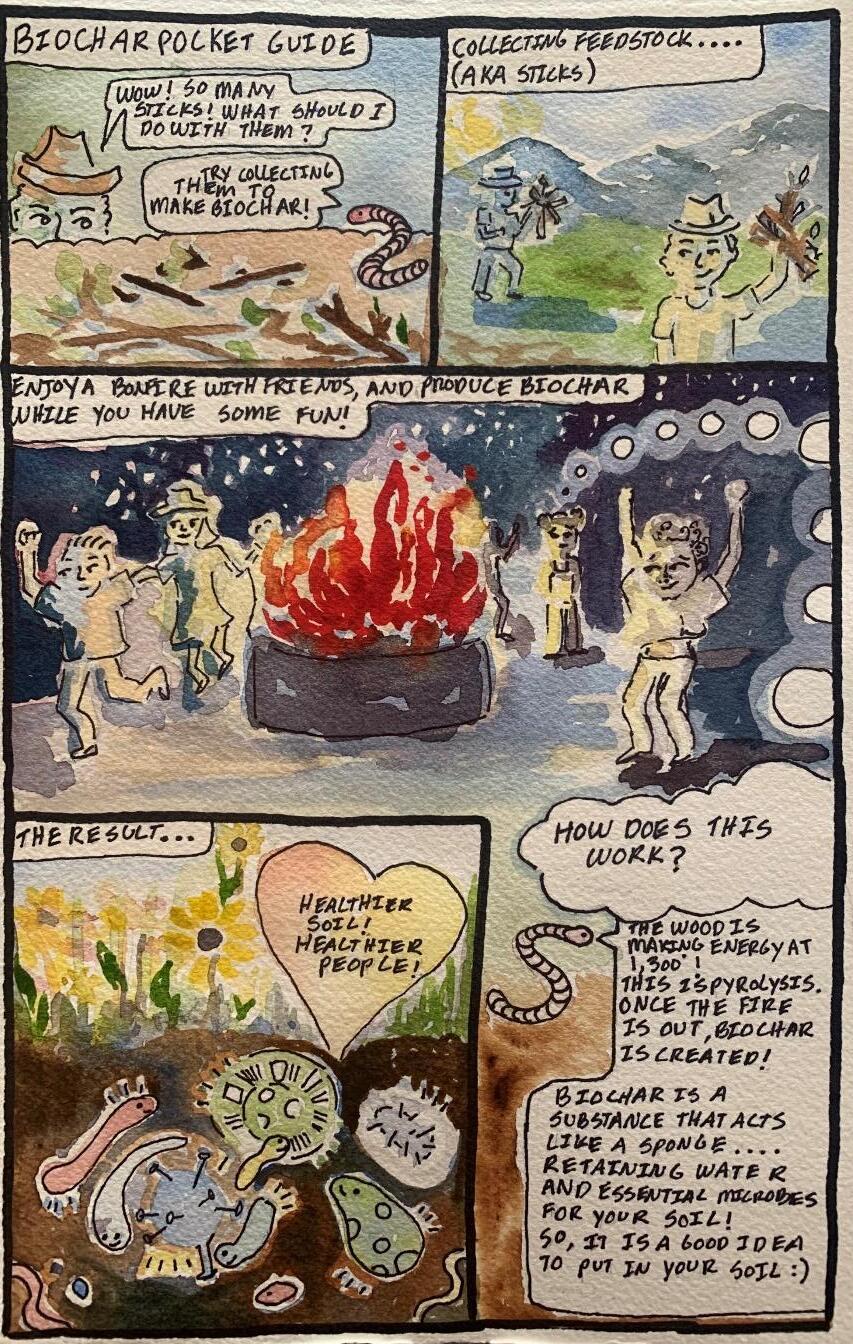

This ‘zine-styled biochar user’s guide is a pilot for communicating regenerative science in the future. The goal is to resonate and transcend boundaries of exclusion to include those with many languages for learning and communicating. It is meant to be pocket-sized, ready for writing on, smudging with dirt, sharing with friends, reprinting, remixing. It is to be experienced off-line, in the sensual world beyond the screen. It is intentionally interpretive and free-flowing, both within the boundaries of science and professionalism and outside, into the realm of aesthetics and visual arts.

This ‘zine / users guide was produced as part of a research fellowship with the Coldharbour Institute, a regenerative agriculture research and ranching 501(c)3 nonprofit in Gunnison, CO. The other deliverables for this project include a literature review, a scientific study into water holding capacity and drought resilience, and capacity building for biochar through hands-on production, aiming to be a multi-modal multimedia science communication experience.

This is especially directed at those in the agricultural sector (including at the backyard scale), in the municipal sector, and in public lands management. Its goal is aligned with the program within which it is born: sustainable and resilient communities.

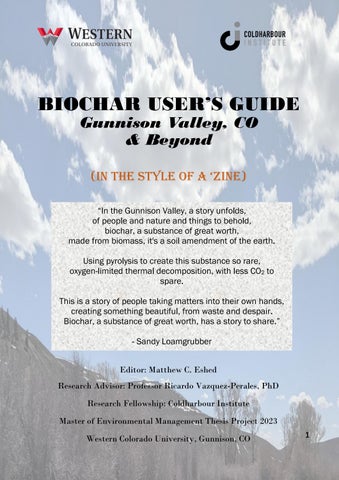

It is important to communicate science, climate, and resilience through art. A call was made for interpretive art pieces, and the three pieces here were contributed, on the cover, opposite page, and back inside cover. Some paragraphs in the gray box on the cover were generated with AI. Otherwise, all images not cited on pages 18-21 are credited to the Editor.

Copyright Ⓒ 2024 by Ricardo Vazquez-Perales and Matthew C. Eshed

Western Colorado University, Gunnison, CO

ISBN: 979–8–218–48776–8

2 Numbered Citations on Page 18-21

Key Characteristics:

➢ pH >8.0

Co-Products:

➢ Gas (CH4, CO2, CO, NOx)

➢ Bio-Oils

➢ Particulate (PM10, PM2.5)

➢ Ash

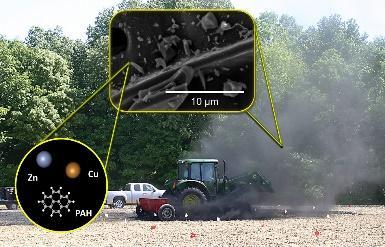

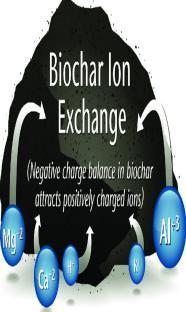

➢ Cation Exchange Capacity (50-200 mmolc/kg (Joseph et al., 2021))1

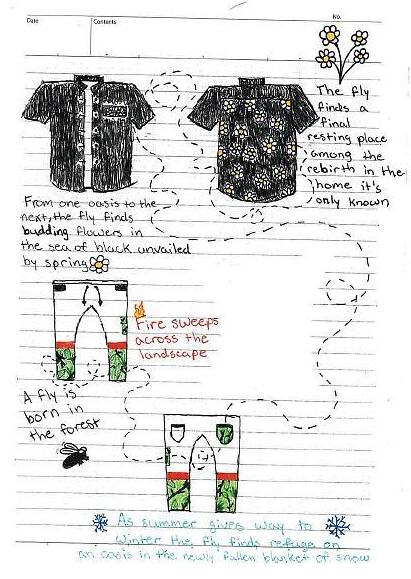

➢ Porosity (8-132+ m2/g (Leng et al 2021))2

➢ Surface Area (1 - 400 m2 / g (Schmidt, H.P., 2014; Kamali et al 2022))3, 4

➢ Carbon >80%

Numbered Citations on Page 18-21

Terra Preta, “Amazonian Dark Earth” soils with high levels of nutrients and organic matter, cultivated by indigenous tribes3 “Engineered” or “Built” soils

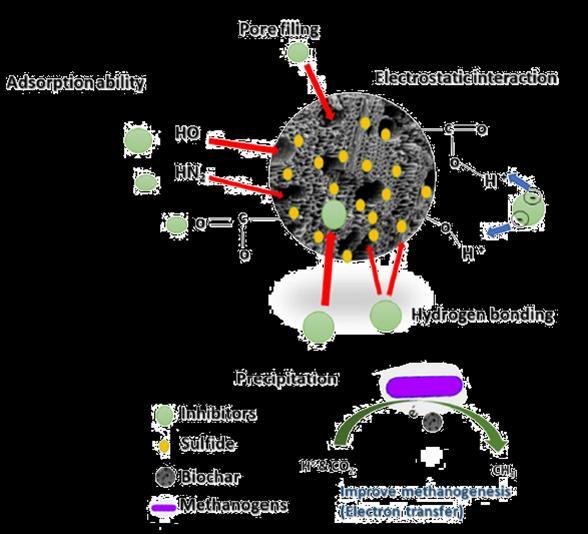

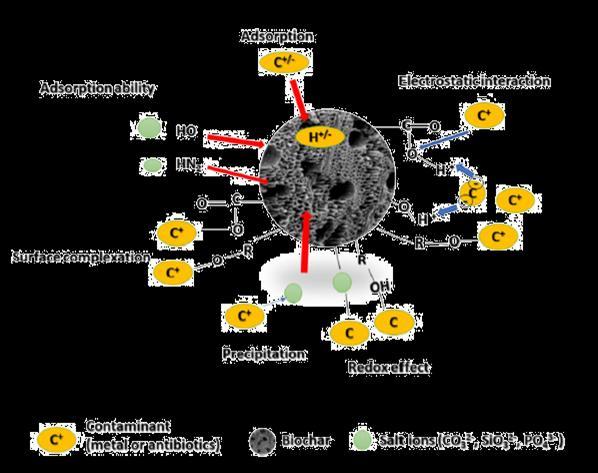

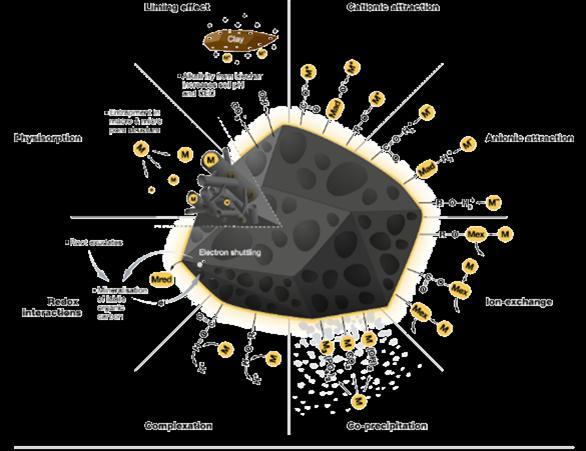

Biochar’s unique properties, including adsorption, precipitation, bonding, electrostatic interaction, and pore filling, enable biochar to remove digestion inhibitors such as ammonia and sulphide1

Biochar is cooked in a flame-cap kiln, under oxygen-limited conditions, burning

> 600°C for 1-3 hours

Measured with infrared & thermocouple probe

Numbered Citations on Page 18-21

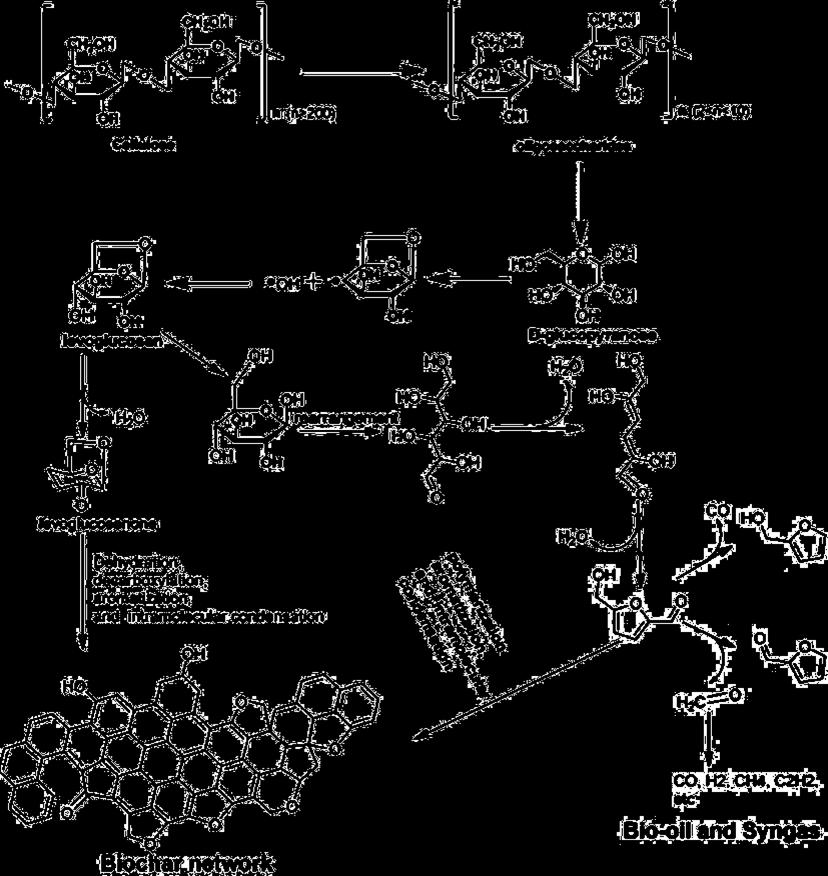

How amazing is the chemical network of biochar – upon closer inspection its properties can be explained!

Even if you don’t know organic chemistry, the transformation of cellulose into biochar, bio-oil and syngas is a kind of dance…!

Flame-cap kilns: woody biomass and agricultural residue, contained by smokeless fire.

Retort kiln: woody biomass and agricultural residue in vessel engulfed in flame

Contaminants Handling: Flame Cap & Retort

Proper temperature necessary, contaminants can volatilize into atmosphere (best case) or be contained in char (worst case). Preferred to avoid contaminants.

8 Numbered Citations on Page 18-21

Custom reactors enable temperature and gas control

Enclosed reactors can take sewage sludge, have temperature and gas handling and gas/oil collection

Contaminants Handling: Enclosed Reactors

Precise temperature is easier to achieve than simpler options. Exhaust

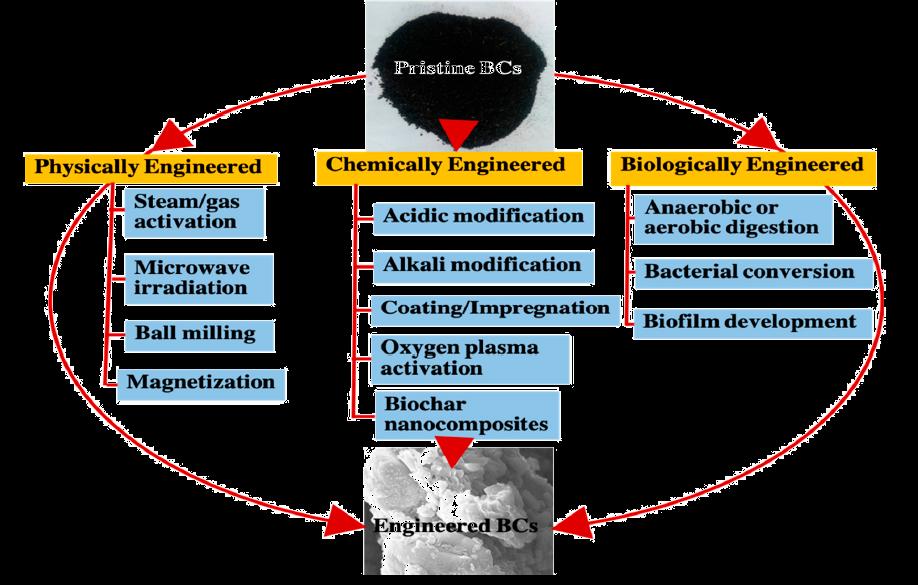

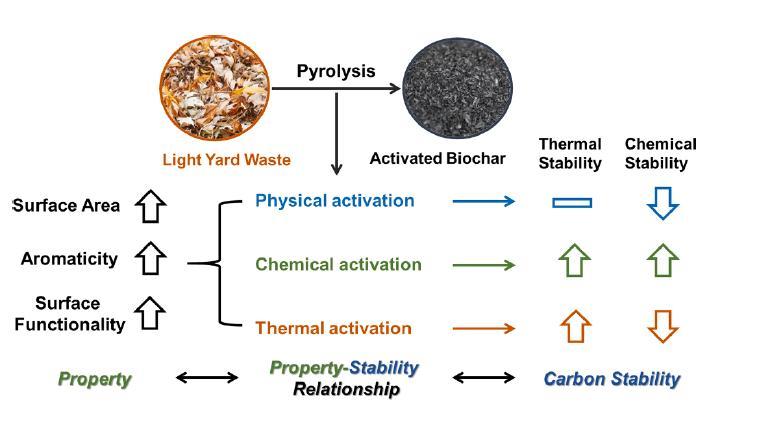

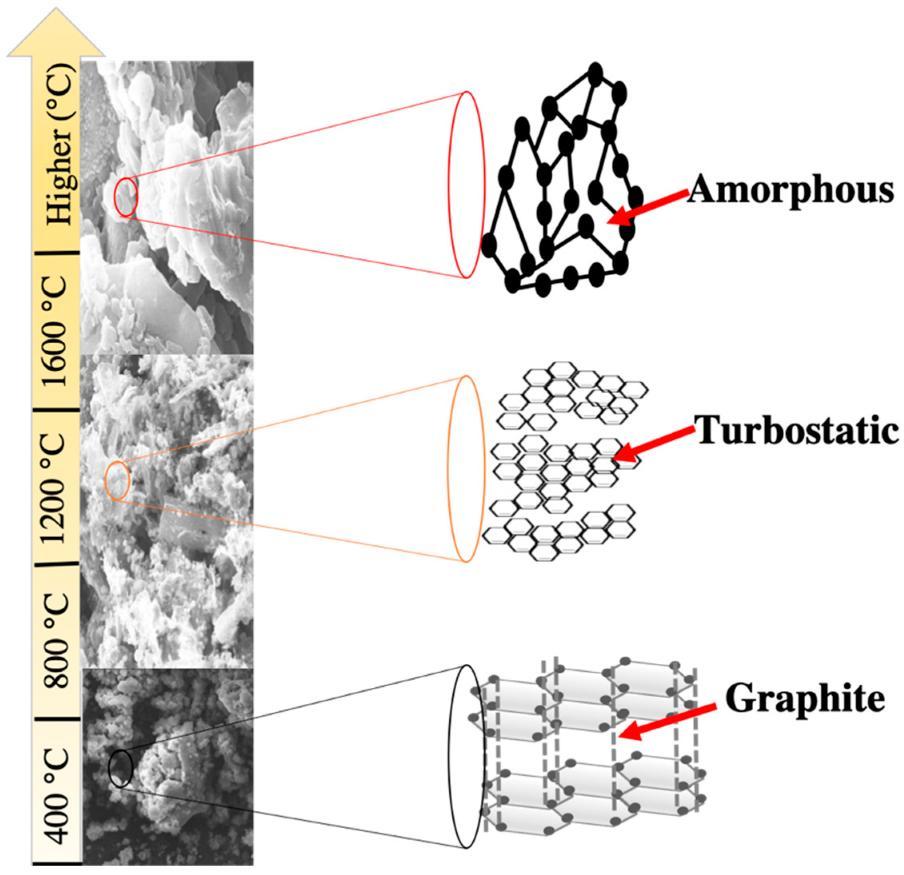

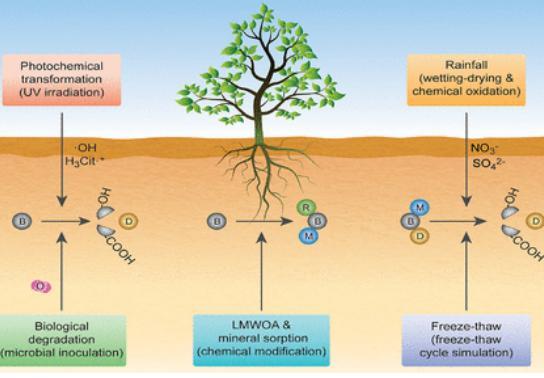

Engineered biochars (BCs) represent a promising area of development, where charcoal material is activated for specific material properties to satisfy specific uses.

10 Numbered Citations on Page 18-21

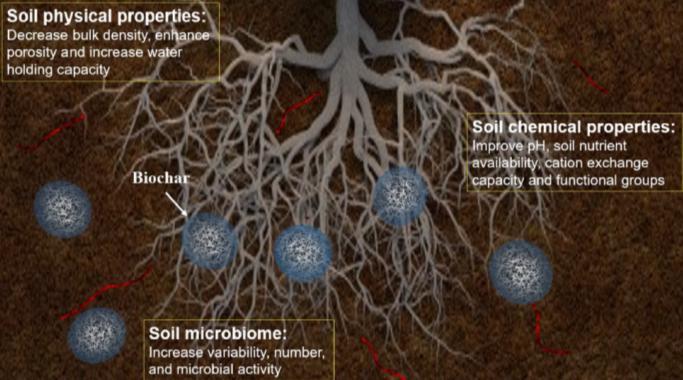

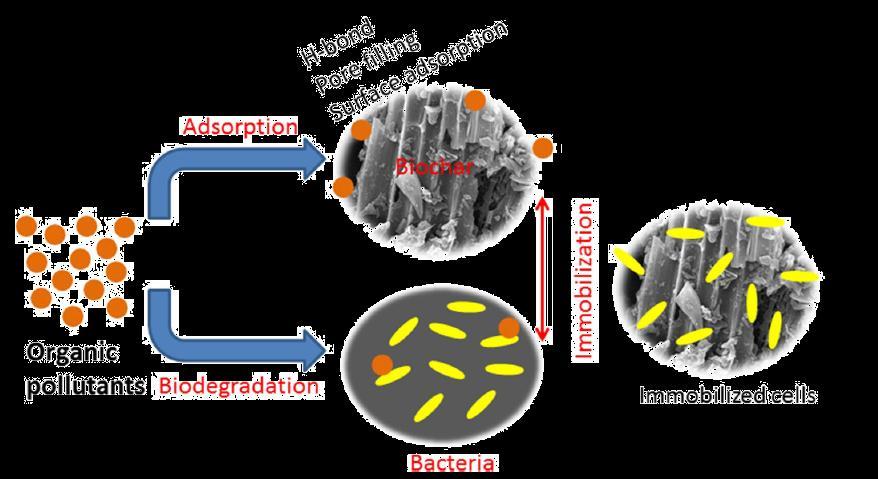

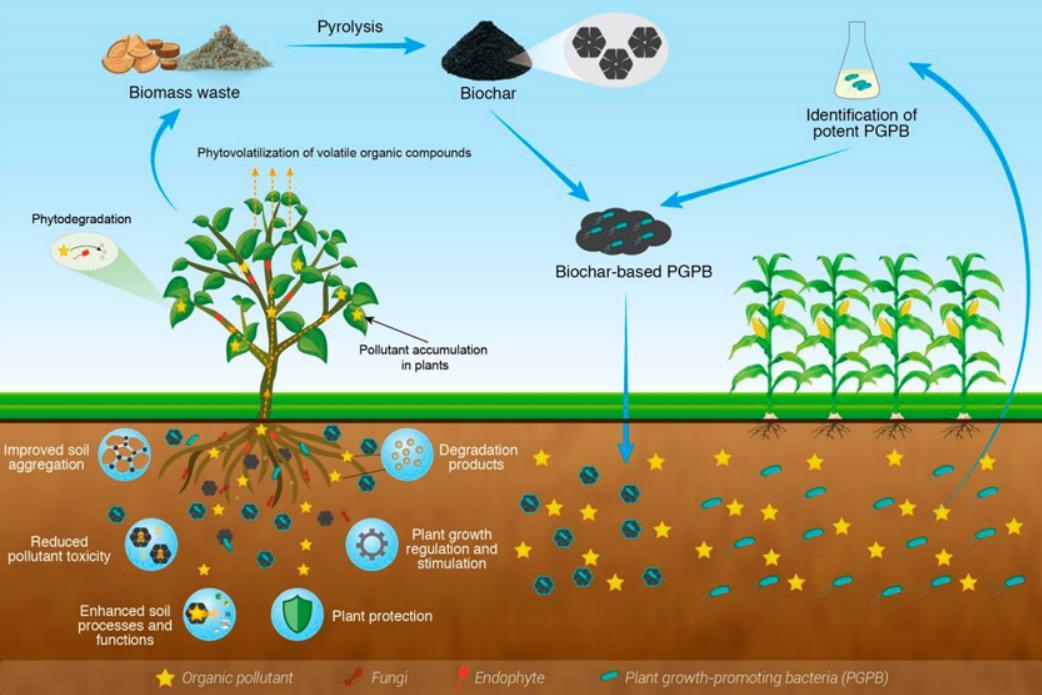

Biochar’s porosity provides a substrate for bacteria which can degrade organic pollutants trapped by the cationic characteristics of biochar.

12 Numbered Citations on Page 18-21

“…loving the soil… is loving your past, your present, and your future…”

1. Top dress (erosion risk)

2. Root zone

3. Mixing deeper: follow revegetation best practices

Many features of biochar allow to remove pollutants such as heavy metals and antibiotics. Contaminants can be passivated via adsorption, surface complexation, redox effect, ion exchange, precipitation, electrostatic attraction, and pi-pi interactions during anaerobic digestion. The heavy metal pollutants affecting the anaerobic digestion process could reduce either mesophilic or thermophilic operation system, which verifies the wide aspect of biochar efficiency on heavy metal removal at various digestion conditions2 .

Durable and transportable biochar kilns can be used to convert “slash piles” into biochar, potentially reducing emissions compared to pile burning, and generating a soil amendment that may play a role in ecosystem regeneration. Knowledge centers are in Oregon, the Forest Service Rocky Mountain Research Station, and Utah State University Forestry Extension

16 Numbered Citations on Page 18-21

Biochar is used in revegetation blends to enhance the durability of compost and other amendments. Its adsorptive qualities can also be used to immobilize and bio-uptake (or phytoremediate) heavy metals and organic pollutants through plants and fungi.

Slash piles may have a use, after all: reclaiming mines and degraded lands!

P. 4

1. Joseph, S., Cowie, A. L., Van Zwieten, L., Bolan, N., Budai, A., Buss, W., Cayuela, M. L., Graber, E. R., Ippolito, J. A., Kuzyakov, Y., Luo, Y., Ok, Y. S., Palansooriya, K. N., Shepherd, J., Stephens, S., Weng, Z. (Han), & Lehmann, J. (2021). How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenergy, 13(11), 1731–1764. https://doi.org/10.1111/gcbb.12885

2. Leng, L., Xiong, Q., Yang, L., Li, H., Zhou, Y., Zhang, W., Jiang, S., Li, H., & Huang, H. (2021). An overview on engineering the surface area and porosity of biochar. Science of The Total Environment, 763, 144204. https://doi.org/10.1016/j.scitotenv.2020.144204

3. Schmidt, H.-P., & Taylor, P. (2014). Kon-Tiki flame curtain pyrolysis for the democratization of biochar production. The Biochar-Journal, 11.

4. Kamali, M., Sweygers, N., Al-Salem, S., Appels, L., Aminabhavi, T. M., & Dewil, R. (2022). Biochar for soil applications-sustainability aspects, challenges and future prospects. Chemical Engineering Journal, 428, 131189. https://doi.org/10.1016/j.cej.2021.131189

5. Rasmussen, E. (2012, December 9). Hope Mine Biochar Project | BioEnergy Lists: Biochar Mailing Lists. http://biochar.bioenergylists.org/node/1821

6. US Forest Service. (2011). Hope Mine Project. https://www.fs.usda.gov/soils/hopemine.shtml

P. 5

1. Osman, A. I., Fawzy, S., Farghali, M., El-Azazy, M., Elgarahy, A. M., Fahim, R. A., Maksoud, M. I. A. A., Ajlan, A. A., Yousry, M., Saleem, Y., & Rooney, D. W. (2022). Biochar for agronomy, animal farming, anaerobic digestion, composting, water treatment, soil remediation, construction, energy storage, and carbon sequestration: A review. Environmental Chemistry Letters. https://doi.org/10.1007/s10311-022-01424-x

2. McKey, D., & Rostain, S. (2015). Farming Technology in Amazonia. In Encyclopaedia of the History of Science, Technology, and Medicine in NonWestern Cultures. https://doi.org/10.1007/978-94-007-3934-5_9893-2

3. Lehmann, J., Kern, D. C., Glaser, B., & Wodos, W. I. (2004). Amazonian Dark Earths: Origin Properties Management. Kluwer Academic Publishers; https://doi.org/10.1007/1-4020-2597-1.

https://link.springer.com/book/10.1007/1-4020-2597-1

18 Numbered Citations on Page 18-21

PP. 6-7

1. Zhu, X., Li, Y., & Wang, X. (2019). Machine learning prediction of biochar yield and carbon contents in biochar based on biomass characteristics and pyrolysis conditions. Bioresource Technology, 288, 121527. https://doi.org/10.1016/j.biortech.2019.121527

2. Wilson, K. (2016, September 30). Flame Carbonizers For Biochar: In Practice and Theory. https://wilsonbiochar.com/resources

3. Seow, Y. X., Tan, Y. H., Mubarak, N. M., Kansedo, J., Khalid, M., Ibrahim, M. L., & Ghasemi, M. (2022). A review on biochar production from different biomass wastes by recent carbonization technologies and its sustainable applications. Journal of Environmental Chemical Engineering, 10(1), 107017. https://doi.org/10.1016/j.jece.2021.107017

PP. 8-9

1. Source: Jais, N. (2022, July 1). From plans to build A Kontiki kiln for charcoal making | Beyond Buckthorns https://www.beyondbuckthorns.com/content/kiln/plans-build-kontiki-kilncharcoal-making

2. High Plains Biochar. (n.d.). Rocketchar | High Plains Biochar | Furnaces. High Plains Biochar. Retrieved April 11, 2023, from https://www.hpbiochar.com/boulder-biochar-barrel

3. Anderson, PhD, P. S. (2020). Rotatable Covered Cavity Kilns for Pyrolitic Production of Biochar and Energy (BC&E). https://woodgas.com/wpcontent/uploads/2020/12/RoCC-Kiln-Manual-2020-04-13.pdf

4. Smith, A. (2019, September 9). Small Scale Biochar | Nebraska Forest Service. https://nfs.unl.edu/publications/small-scale-biochar

5. Booth, M. (2023, April 7). Will a Colorado biochar company lock up enough carbon to help the planet? The Colorado Sun. http://coloradosun.com/2023/04/07/biochar-carbon-capture-climate-change/

6. PYREG GmbH. (n.d.). Our Technology. PYREG GmbH. Retrieved April 3, 2023, from https://pyreg.com/our-technology/ PP. 10-11

1. Islam, T., Li, Y., & Cheng, H. (2021). Biochars and Engineered Biochars for Water and Soil Remediation: A Review. Sustainability, 13(17), Article 17. https://doi.org/10.3390/su13179932

2. Wu, P., Wang, Z., Bolan, N. S., Wang, H., Wang, Y., & Chen, W. (2021). Visualizing the development trend and research frontiers of biochar in 2020: A scientometric perspective. Biochar, 3(4), 419–436. https://doi.org/10.1007/s42773-021-00120-3

PP. 10-11 Continued

3. Xu, Z., He, M., Xu, X., Cao, X., & Tsang, D. C. W. (2021). Impacts of different activation processes on the carbon stability of biochar for oxidation resistance. Bioresource Technology, 338, 125555. https://doi.org/10.1016/j.biortech.2021.125555

PP. 12-13

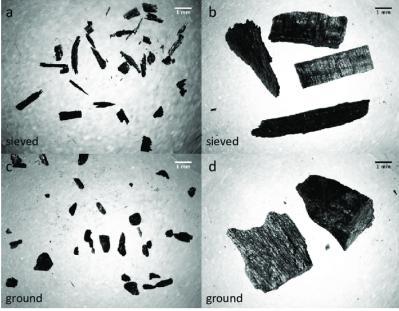

1. Gelardi, D. L., Li, C., & Parikh, S. J. (2019). An emerging environmental concern: Biochar-induced dust emissions and their potentially toxic properties. Science of The Total Environment, 678, 813–820. https://doi.org/10.1016/j.scitotenv.2019.05.007

2. Liao, W., & Thomas, S. (2019). Biochar Particle Size and Post-Pyrolysis

Mechanical Processing Affect Soil pH, Water Retention Capacity, and Plant Performance. Soil Systems, 3, 14. https://doi.org/10.3390/soilsystems3010014

3. Chalker-Scott, L. (2014). Biochar: A gardener’s primer. WSU Extension Fact Sheet FS147E. Washington State University Extension Publications.

4. Wang, L., O’Connor, D., Rinklebe, J., Ok, Y. S., Tsang, D. C. W., Shen, Z., & Hou, D. (2020). Biochar Aging: Mechanisms, Physicochemical Changes, Assessment, And Implications for Field Applications. Environmental Science & Technology, 54(23), 14797–14814. https://doi.org/10.1021/acs.est.0c04033

5.https://www.reddit.com/r/BackYardChickens/comments/fduox6/biochar_app lied_to_mini_run_now_that_higher/#lightbox

6. Thierley, O. (2020, August 14). How to charge Biochar by Co-Composting in 3 Steps. Bottom Up Biochar. https://bottom-up-biochar.com/charging-byco-composting/

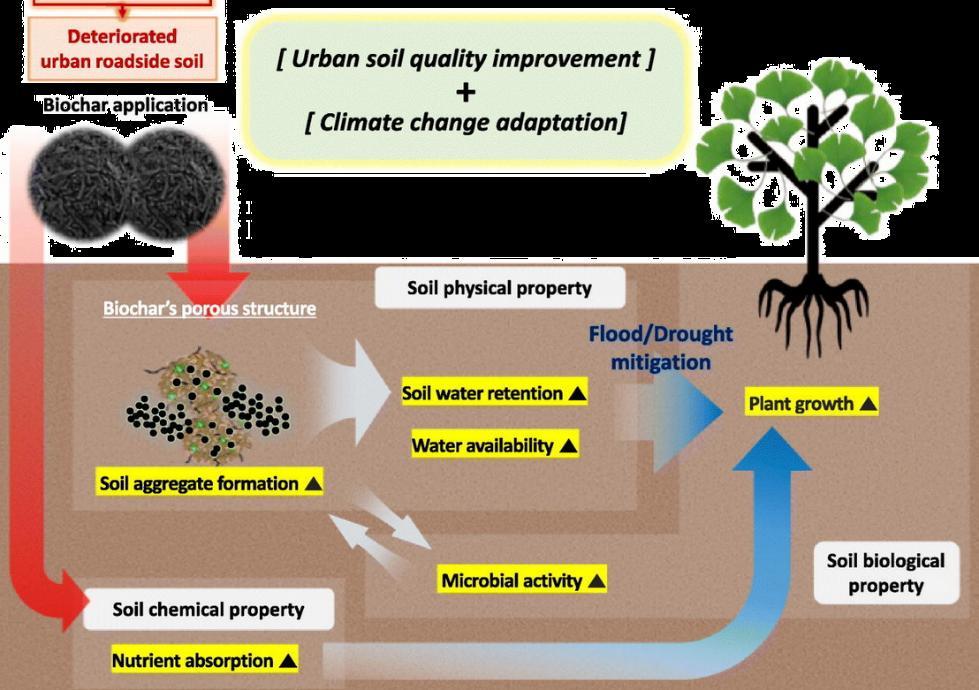

7. Yoo, S. Y., Kim, Y. J., & Yoo, G. (2020). Understanding the role of biochar in mitigating soil water stress in simulated urban roadside soil. Science of The Total Environment, 738, 139798. https://doi.org/10.1016/j.scitotenv.2020.139798

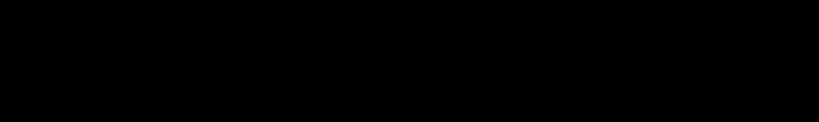

8. Romero, C. M., Redman, A.-A. P. H., Terry, S. A., Hazendonk, P., Hao, X., McAllister, T. A., & Okine, E. (2021). Molecular speciation and aromaticity of biochar-manure: Insights from elemental, stable isotope and solid-state DPMAS 13C NMR analyses. Journal of Environmental Management, 280, 111705. https://doi.org/10.1016/j.jenvman.2020.111705

20 Numbered Citations on Page 18-21

PP. 14-15

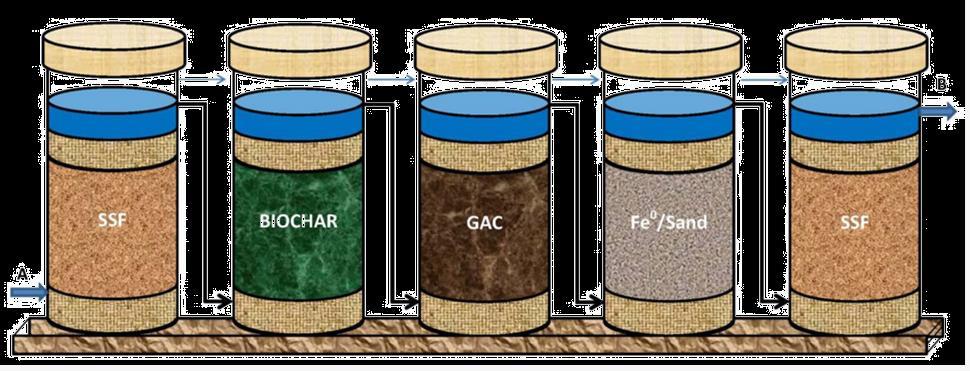

1. Huang, Z., Nya, E. L., Cao, V., Gwenzi, W., Rahman, M. A., & Noubactep, C. (2021). Universal Access to Safe Drinking Water: Escaping the Traps of Non-Frugal Technologies. Sustainability, 13(17). https://doi.org/10.3390/su13179645

2. Osman, A. I., Fawzy, S., Farghali, M., El-Azazy, M., Elgarahy, A. M., Fahim, R. A., Maksoud, M. I. A. A., Ajlan, A. A., Yousry, M., Saleem, Y., & Rooney, D. W. (2022). Biochar for agronomy, animal farming, anaerobic digestion, composting, water treatment, soil remediation, construction, energy storage, and carbon sequestration: A review. Environmental Chemistry Letters. https://doi.org/10.1007/s10311-022-01424-x

3. Joseph, S., Cowie, A. L., Van Zwieten, L., Bolan, N., Budai, A., Buss, W., Cayuela, M. L., Graber, E. R., Ippolito, J. A., Kuzyakov, Y., Luo, Y., Ok, Y. S., Palansooriya, K. N., Shepherd, J., Stephens, S., Weng, Z. (Han), & Lehmann, J. (2021). How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. GCB Bioenergy, 13(11), 1731–1764. https://doi.org/10.1111/gcbb.12885

4. Lehmann, PhD, J. (2022). BIOCHAR TECHNOLOGY. International Biochar Initiative. https://biocharinternational.org/about-biochar/how-to-makebiochar/biochar-technology/ PP. 16-17

1. Carey, H., & Blevins, J. (2021, October 6). Monarch Pass could serve as a new model for wildfire mitigation in treacherous areas. The Colorado Sun. http://coloradosun.com/2021/10/06/monarch-pass-wildfire-mitigation/

2. Stevens, B. W. (2023). Los Pinos Pile Burn. Sent in personal correspondence. 3. McAvoy, D. (2023). Big Box Biochar Production with North West Band of Shoshone Nation, BLM, Wildlife Conservation Society

4. Xiang, L., Harindintwali, J. D., Wang, F., Redmile-Gordon, M., Chang, S. X., Fu, Y., He, C., Muhoza, B., Brahushi, F., Bolan, N., Jiang, X., Ok, Y. S., Rinklebe, J., Schaeffer, A., Zhu, Y., Tiedje, J. M., & Xing, B. (2022). Integrating Biochar, Bacteria, and Plants for Sustainable Remediation of Soils Contaminated with Organic Pollutants. Environmental Science & Technology, 56(23), 16546–16566. https://doi.org/10.1021/acs.est.2c02976

Source: Schmidt, H.-P. (2011, March). Ways of Making Terra Preta: Biochar Activation. Journal for Ecology, Winegrowing and Climate Farming. https://www.ithakajournal.net/wege-zu-terra-preta-aktivierung-von-biokohle?lang=en

As we’ve learned, biochar is POROUS with a super high SURFACE AREA and activated CARBON RINGS, it can play a strong role in your soils. Therefore, it is advised that you CHARGE IT UP before using it. You’re gonna fill those pores with microorganisms, preparing reaction sites and maturing the char.

BIOCHAR WITH COMPOST

Ratio 1:1. Keep it moist. Turn several times. Prepare at least 2 weeks prior to application.

You can also co-compost, where the biochar is in the pile as it is composting!

BIOCHAR WITH MANURE FROM LIVESTOCK

Make strips of moistened biochar on the ground

Spread 3cm thick layer of manure

Put rock dust in it (if you have/need it)

Spread another layer of biochar

Moisten it with water or Effective Microorganisms (EM-A)

Add soil if you need it – also, why not?

Keep it moist for 2 weeks, mix with a rotovator every 3 days, cover w/ fleece

BIOCHAR WITH LIQUID FERTILIZERS

Mix your liquid fertilizer, with high mineral diversity, with biochar, for 2 days to allow complete adsorption of the fertilizer.

Liquid animal manure is better than NPK fertilizer

BIOCHAR + BOKASHI

Bokashi is “lactic acid fermentation of biomass”

Mix straw-rich manure with 10% grass clippings, 10% biochar, 1% rock flour

Spray with 3% EM-A and 3% cane molasses

Compress the pile with a tractor

Cover with airtight fabric, turn as possible

Remove the fabric after 2-3 weeks. Should smell like lactic acid. Water and mix, aerate for several days. Add soil.

22 Numbered Citations on Page 18-21

This is a project of the Coldharbour Institute and the Western Colorado University Master of Environmental Management, Sustainable and Resilient Communities Track, with Advisor and Track Director Dr. Ricardo Vazquez-Perales.

It is to be shared freely, to educate the people of the Gunnison Valley and in similar industrial ecologies. It was produced by Matthew Eshed in 2023, with financial support by the Community Foundation of the Gunnison Valley, the Haley Family, and the Coldharbour Institute, and community support by the Gunnison Valley Producer’s Guild.

“… now I see, there is a place for biochar … “

24 Numbered Citations on Page 18-21