COMMERCIAL MARINE BUSINESS

COMMERCIAL MARINE BUSINESS

COMMERCIAL MARINE BUSINESS

COMMERCIAL MARINE BUSINESS

presented at Europort 2025

Hall A1: Stand 1304

• Heatmaster is showcasing its products and services in Rotterdam, their home town.

• The marine industry is undergoing changes due to stricter emission and environmental regulations, leading to the adoption of greener solutions.

• Heatmaster has been enhancing ship efficiencies for over two decades, contributing to the industry's environmental goals.

• Recent vessels equipped by Heatmaster use Methanol fuel for boilers, electric heaters, and convert waste heat to electric power.

• Heatmaster is actively involved in the green transition within shipbuilding and shipping sectors.

After the fantastic growth recorded in both 2023 and 2024, Hs.Marine aims to close 2025 with another record-breaking increase (tripling the turnover of 2023), demonstrating the reliability of its products and the low cost of ownership that continue to be recognized and rewarded by the market.

“These important increases that highlight the value of our work and the efforts of our entire team,” explains Stefano Forni, co-founder and Managing Director of the company. “But we continue to look ahead, driven by the desire to grow and to further expand our market penetration.”

“The result - Forni continues - of a strategic plan launched five years ago and still evolving. Just consider that in recent years we’ve expanded our team—both in the technical office and in production, in

Subsea connection for Shetland Islands

upgrades More revamps to accommodate wind

monopile World's largest offshore wind farm has last foundation installed

concept

on keeping it above board

for the new fuel?

target?

floating wind a feasible option?

the spare parts department, and in the warehouse. And we’re not standing still when it comes to infrastructure either. Even though we built a new facility just last year, we are already working on another expansion. Without careful planning, state-of-the-art facilities, and highly skilled personnel attentive to every detail in both production and processing,” Forni continues, “we would never have been able to achieve and handle successfully the kind of growth we’re experiencing.”

“One of our strongness – underlines Forni -, is to be very flexible and we know that quality always pays back. It is certainly no coincidence that in a context of significant turnover growth, we have managed to improve the company's efficiency and further increase quality by introducing new procedures both for suppliers and for ourselves".

The world’s largest offshore structures will be able to board Allseas’ new vessel when it’s delivered – expanding heavy-lift and towing capacity for offshore industry.

Click here to read article on Maritime Journal online

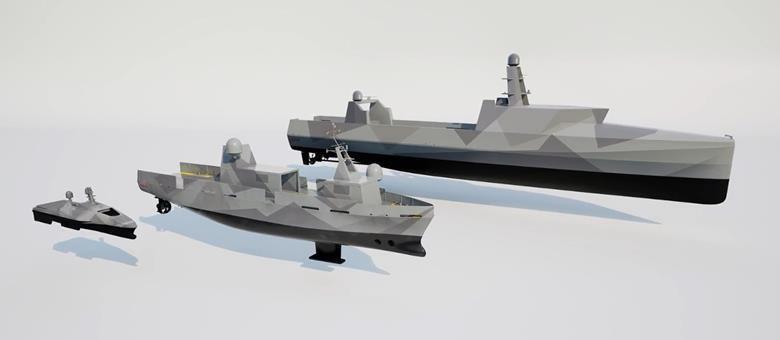

Damen Shipyards has won a contract from vessel operator Serco for 24 new vessels to refresh the UK Royal Navy’s maritime services fleet.

The vessels – a mixture of tugs, barges, crane barges and pilot boats – are part of a £850 million (€980 million) contract over 10 years in which Serco will organise the modernisation of the navy’s in-port fleet and support essential daily operations such as towage, passenger transfers and barge and tank cleaning at the naval ports of Devonport, Portsmouth and the Clyde.

Serco has provided in-port services to the Royal Navy for about 30 years, and all along has worked closely with Damen Shipyards.

“The Defence Maritime Services Next Generation Vessel Replacement Project represents a significant step forward in modernising the Ministry of Defence’s auxiliary fleet,” said Guy Barker, Serco’s Maritime Services director.

USV launch

In August, Serco launched the ‘No Manning Required Ship’ (NOMARS), – an Uncrewed Surface Vessel (USV) – for the US.

The USX-1 Defiant is a prototype vessel for a NOMARS programme, and Serco says it

signalled ‘a pivotal moment in Serco’s future of naval architecture and autonomous operations’.

“The USX-1 Defiant represents a radical departure from traditional ship design, conceived from the keel up with no provision or expectation for human crew,” said Serco.

“This ‘clean-sheet’ approach aims to deliver

unprecedented advantages in size, cost, at-sea reliability, hydrodynamic efficiency and survivability, ultimately enabling a new class of highly capable and cost-effective unmanned surface vessels (USVs).”

Some 80% of Serco’s order intake is now in Defence.

After a grounding last September nearly ended her useful life, a half-century-old vessel has been showcased after setting sail for a new career. Our reporter Peter Barker paid her a visit.

Click here to read article on Maritime Journal online

Bernhard Schulte has christened its newest Commissioning Service Operation Vessel to work in the offshore energy sector.

Windea Clausius was named on September 4 after German physicist Rudolf Clausius, whose work on thermodynamics established fundamental principles for understanding energy transformations, including wind energy.

Norway’s Ulstein Verft built the vessel, which was delivered a few weeks after sister vessel Windea Curie was delivered in June, and completes the company’s modern offshore fleet of five, said managing director Matthias Müller. The other three vessels are Windea La Cour, Windea Leibniz and Windea Jules Verne.

The vessel has hybrid battery propulsion and his been built with ‘methanol fuel readiness’, says the company.

Windea Clausius has two sterns and azimuth propellers fore and aft to ensure ‘optimal’ DPS performance and improving fuel efficiency.

“Equipped with a large, height-adjustable, centrally located walk-to-work gangway and elevator tower for personnel and cargo transfers, the vessel also includes a 3D motion-compensated crane for offshore lifts of up to five tonnes,” says the Schulte Group. “Onboard logistics are optimised with

spacious storage areas and stepless access to offshore installations. In addition, Windea Clausius features a height-adjustable boat landing system that allows for safe and stepless transfer of personnel and equipment between the CSOV and smaller crew transfer vessels—an important safety aspect

Nordic USV A/S is expanding its fleet with two new REAV-47 hybrid uncrewed surface vessels (USVs) built by HydroSurv

The vessels, named USV Kuling and USV Storm, will join the pioneering USV Bris to scale up autonomous survey operations and marine monitoring along Norway’s coastline.

“USV Bris has proven the value of remote operations, demonstrating long-range autonomous performance with zero field personnel,” said HydroSurv in a statement.

Proven expertise

In a pioneering demonstration of remote autonomy, USV Bris recently completed a 320 km mission in 41 hours for Aqua Kompetanse AS, sailing between Ranfjorden and Velfjorden to map hydrographic conditions with no field personnel on site.

Nordic USV said that its new vessels will strengthen the use of uncrewed surface vessels for sustainable, highendurance marine survey missions in challenging coastal and fjord environments.

USV Bris has proven the value of remote operations, demonstrating long-range autonomous performance with zero field personnel

Once deployed, the expanded fleet will meet increasing demand for autonomous vessels in marine survey, bathymetric mapping and deepwater profiling.

Each REAV-47 platform features 72-hour hybrid-electric endurance and integrated payload systems, enabling scalable, low-emission survey operations.

The collaboration between HydroSurv and Nordic USV highlights a shared commitment to advancing uncrewed surface vessels for next-generation marine monitoring and sustainable ocean science.

HydroSurv has already started on-water trials for USV Kuling, while USV Storm is in its final production stages.

The New Generation Maritime Affairs Patrol Vessel (PAM), featuring windassisted propulsion, has officially entered its construction phase with the first steel cutting on 18 September 2025.

This milestone marks the shift from design to assembly, following the project’s tender award in December 2024 and formal announcement in January 2025.

Developed by France-based naval architect Mauric, the vessel integrates advanced technologies to enhance operational efficiency and reduce environmental impact. Naval architects and marine engineers have completed the vessel’s detailed design, including the placement of wind-assist systems and the integration of stabilisation technologies.

Sea-keeping simulations guided the development of anti-roll tanks and active fin

■

stabilisers, while computational fluid dynamics studies optimised the hydrodynamic shape of the bulbous bow and defined an active trim control system.

The vessel’s hybrid propulsion system combines diesel-electric power with wind assistance, enabling a cruising speed of 10 knots and a top speed exceeding 18 knots.

Construction is structured around eight modular blocks. The first block, located in the forward hull section, is now ready for cutting at Socarenam’s shipyard in Boulogne-sur-Mer. Delivery remains scheduled for the second half of 2027.

The 53.7-metre vessel features a steel hull and aluminium superstructure. It supports a crew of 16 and can accommodate four special forces personnel, with 12 days of autonomy and up to 200 days of operation per year.

Primarily operating in the Bay of Biscay, the PAM will conduct missions including maritime surveillance, fisheries control, environmental monitoring, search and rescue, and regulatory enforcement.

News that Dutch tug owner Seacontractors has sold its smaller vessels to France-based Jifmar marks a strategic change of business direction for the company.

Click here to read article on Maritime Journal online

Sanmar Shipyards has launched what it claims is the world’s first purpose-built dual-fuel methanol escort tug.

The beneficiary is Kotug in Canada, which will use it to service Canada’s Trans Mountain Expansion Project to escort LNG tankers from the harbour limits of the Port of Vancouver to the Pacific Ocean.

It is the first of two methanol escort tugs being built by Sanmar, which says the two vessels will be the most powerful escort tugs in Canada, with 120 tonnes of bollard pull.

“The methanol-fuelled tugs represent another major step forward to a cleaner, greener future,” said Sanmar. “Measuring 44m in length, the escort tugs will operate in some of the harshest environments in the world and have been customised to meet the demanding operational and environmental requirements of this project.”

Based on Robert Allan’s RAsalvor 4400-DFM design, the twin tugs will provide long-range towing, anchor-handling, rescue and salvage and will have the largest spill response capabilities on the British Columbia coast.

“The launch of this radically new tug, the first of twins, is an important day for the whole tug industry,” said Ali Gürün,

Sanmar’s vice chairman & CEO. “It marks a major step forward in the use of alternative fuels to protect our planet. These are

(0)1482 329600

Email: info@proutmarine.co.uk

www.proutmarine.co.uk

among the most powerful tugs ever built, yet have environmental protection at their heart.”

As fears about rising sea levels grow, countries are protecting their coastlines with sand replenishment projects. Here is a taste of some of the ongoing works.

At the heart is obviously the Netherlands, whose very name means ‘Lower lands’, with 26% of its land mass under sea level.

Marine contracting giant Van Oord is often tasked with the work, and at the moment is deploying one of its trailing suction hopper dredgers to deposit 1 million cubic metres of sand onto and in front of Banjaard Beach, in the NoordBeveland of the Netherlands.

The €8.6 million replenishment will be done by a vessel, says Van Oord, that will run on Bio-LNG for the first time in the Netherlands.

This beach is one of three that will be replenished by Van Oord, the others being Goeree Westkop and Heemskerk, as part of the Coastline Care programme, which aims to strengthen the Dutch coastline with regular sand deposits.

“Bio-LNG is produced from sustainable bio-based materials, including organic household waste and agricultural waste. The bunkered fuel is certified under the ISCC EU certification system, which ensures compliance with the European Union’s legal requirements for sustainable fuels,” says Van Oord.

Portuguese projects

Two notable projects are being undertaken in Portugal.

A million cubic metres of sand will be added to 6.6km of the Caparica coastline at a cost of €8.6 million, according to the Portugal News. The project is to begin imminently, lasting around two months.

In January, the paper says, the government said it would spend another €20 million ’in priority coastal protection projects’ to stabilise cliffs, protect coastal infrastructure and reinforce the most vulnerable beaches.

“The measures ‘combine advanced engineering with nature-based solutions, promoting climate adaptation and sustainable coastal management’,” it says.

Over on the holiday spot of the Algarve, at QuarteiraGarrão, €13 million has been made available to protect 6.6 km of coastline from erosion by dredging sand from an offshore borrow site and pumping it onto the beaches. The public tender was opened in late August/early September 2025, and the contract is expected to be awarded and works completed before the end of 2026.

Kingdom

In the UK, £7 million (€8 million) is regularly spent on annual beach replenishment in Lincolnshire, an eastern county which, like the Netherlands, is below sea level.

Experts Van Oord have been called in again this year, and in fact the £7 million is just a fraction of £2.65 billion that has been committed by the government for flood protection works.

“Replenishing the sand means that the beaches, instead of hard defences like sea walls, take the brunt of the waves’ force and energy,” said Deborah Higton, Flood Risk manager at the Environment Agency.

“This reduces the amount of damage and erosion to those hard defences and lessens the risk of water overtopping them.”

Moves are being made towards a network of subsea tunnels to connect four of Scotland’s remote Shetland Islands, which are nearer to Norway than the Scottish capital city of Edinburgh.

The Inter-Island Transport Connectivity Programme is looking at building tunnels, ‘fixed links’, between the four islands of Unst, Yell, Whalsay and Bressay.

A Strategic Business Case has been laid out, and money put aside for a feasibility into the idea, which could transform lives in some of the most remote areas of the UK.

“Tunnels - prevalent in the rural and island communities of neighbouring countries - could supercharge growth in key industries from space to aquaculture, not to mention allowing for a redesign of key public services and more housing,” says one of the documents.

“With an average age of over 32 years, our ferry network lacks the resilience to offer a reliable lifeline, meaning that patients cannot attend hospital appointments when the weather is inclement, those who live alone cannot be reached by visitors.”

The Shetland Islands Council has been looking to the Faroe Islands for ideas on its tunnels, given that life has been transformed

in the Denmark-owned archipelago by the building of more than 20 tunnels – including four subsea tunnels.

Spearheaded by the Unst and Yell Tunnel Action Groups (UTAG & YTAG) funds have been raised to begin investigative work and Norwegian consultancy Norconsult has been engaged to take it on.

“Tunnelling in Shetland is, ultimately, about future-proofing our island population,” said council leader Emma Macdonald. “Transport connectivity is central to creating sustainable islands, which provide good homes and good

jobs for our people, and which can reverse decades of depopulation.

“The experience of our neighbours in the Faroe Islands is clear - tunnelling from mainland Shetland to our outer islands could increase their population, lower their average age, and increase their economic prospects. It’s also critical that we continue to invest in a resilient and reliable ferry service to support all our islands.”

Shetland MP Alistair Carmichael said: “We have seen a few false dawns on tunnels for Shetland – now is the time to deliver on their promise. I am glad that the Council is putting investment into this project to move it to the next stage.

“Tunnels have the potential to be transformative for Shetland’s economy and our communities. It has been a long road just to reach this point and there is still a long way to go but I am glad that progress is being made. I look forward to working with the Council and indeed with the UK and Scottish governments to keep up the momentum.”

A key milestone has been reached in the Dutch Fish Migration River project, marking a step forward for marine construction and innovative nature restoration.

The project involving Van Oord, commissioned by the Province of Friesland, is designed to restore fish migration routes at the Afsluitdijk between the Wadden Sea and Lake IJsselmeer.

Van Oord’s final contribution was the completion of a protective dam, crucial for managing brackish water flows and shielding the Fish Migration River from wind, waves and currents.

“The successful completion of our contribution to this project is an important milestone for Van Oord. In close cooperation with the province of Friesland and many other stakeholders, we have worked for many years to ensure the sustainable implementation of the Fish Migration River,” said Ronald de Geus, Director Dredging & Infra at Van Oord.

”This project shows how innovative marine engineering and ecological recovery can reinforce each other, and really puts the Netherlands on the map. We are proud of the collective effort and of our contribution to this special initiative.”

Habitat restoration

During the project, Van Oord applied its marine civils expertise and sustainable dredging methods to minimise environmental impact.

Using the cutter suction dredger Biesbosch, 400,000 cubic metres of sand were extracted locally from Lake IJsselmeer, avoiding 18,500 truck journeys.

Additionally, 20,000 tonnes of quarry stone from the Afsluitdijk reinforcement project were reused. By working with natural materials from the area, the project improves fish orientation while reducing carbon footprint.

The Netherlands will be the first country in the world to

build a Fish Migration River, with full implementation set to continue in 2026.

Van Oord has been in the news alot for its nature restoration projects recently.

This month, MJ reported that the company is to breathe life into thousands of oysters to mitigate the damage caused to the North Sea bed by the growing scale of wind farms, cables and other infrastructure.

Back in August, we announced that the project to build artificial reefs and tidal pools along the Lauwersmeerdijk is to be expanded following ‘an explosion of marine life’ that has been recorded in the four years since it started.

The German Port of Kiel has completed the installation of one of the biggest shore power supply systems in Europe.

It means the port can now supply up to three cruise ships and four ferries with electricity simultaneously, and the port claims this is one of the most extensive systems in the world.

The new facility at Ostseekai has a capacity of 16MVA, 50/60 Hz, 6.6/11kV.

“In the past and current seasons, there have been several days when two cruise ships wanted to use shore power at the Ostseekai,” said Seehaven Kiel (the port) managing director Dirk Claus. “This sends a strong signal; demand from shipping companies for shore power is extremely high and we are delighted with the excellent

cooperation we have enjoyed here.”

Partners in building the facility included PowerCon, Siemens, Inros Lackner and Stemmann, with funding from the state of Schleswig-Holstein and the European Union.

Many of Europe’s major ports have joined the tide to offer shore power – including the Port of Hamburg, which was the first in

Europe to offer it for container ships and not just ferries and cruise liners.

The Vasco de Gama (IMO 9706889) of the CMA CGM Group became the first container ship to be regularly supplied with shore power at berth, the port announced in May 2024.

“From 2025, all large cruise and container terminals in the Port of Hamburg will have shore power connections,” it pledged.

Other notable ports that now offer ‘green’ shore power include Aberdeen, in Scotland, which has eight berths delivering it to Service Operation Vessels as well as passenger ferries.

“Longer term, Port of Aberdeen has ambitions to expand its shore power infrastructure to supply green electricity at more berths throughout its 7,600m quayside,” it says.

Belgium has launched its largest unexploded ordnance (UXO) clearance project to support subsea cable installation for offshore renewables.

Boskalis Hirdes EOD Services has deployed the backhoe dredger Manu Pekka and diving pontoon Medusa 1 to begin dredging and UXO clearance off the Belgian coast.

The work is vital for the Modular Offshore Grid 2 (MOG2) project, which will connect to Princess Elisabeth Island – the world’s first artificial energy island designed to support Europe’s offshore renewables expansion.

Milestone project

The Medusa 1 will operate in nearshore zones, where divers will inspect the seabed and identify potential UXOs. In deeper sections, the Manu Pekka will use a multitool to detect and clear hazards.

Later, the offshore vessel Kamara will be mobilised for the deepest parts of the 55-kilometre subsea cable route. Boskalis said this phased approach ensures a safe corridor for the installation of critical offshore energy infrastructure.

Princess Elisabeth Island is already under construction with high-voltage alternating current (HVAC) structure builds underway

following the installation of caissons earlier this year.

When completed, the island will serve as a major offshore hub, channelling at least 2.1 GW of offshore wind energy to Belgium’s mainland.

It is a cornerstone project in Europe’s transition to renewable energy and a key step in Belgium’s electrification strategy.

The marine civils and dredging effort underscores Belgium’s commitment to

■ Boskalis Hirdes EOD Services has deployed the backhoe dredger Manu Pekka and diving pontoon Medusa 1 to begin dredging and UXO clearance off the Belgian coast

developing safe, efficient offshore renewables infrastructure, despite ongoing cost concerns surrounding high-voltage direct current (HVDC) connections.

Boskalis said that this subsea UXO clearance project is a landmark milestone in securing Europe’s future energy supply.

The northern English Port of Tyne is spending £150 million (€173 million) on upgrades to its port to support the offshore wind industry and other manufacturing.

The upgrade will add 400 metres of deep-water quayside and a new heavy-lift quay as part of 1 kilometre of redeveloped quayside.

A 230-acre site will also be set up within an Industrial Strategy Zone for ’advanced manufacturing sectors’, and in total it is expected to create 12,000 jobs, a statement said.

“It’s fantastic that the Port of Tyne is bringing forward a new clean energy terminal with a deep-water dock which will help us in our work to establish the North East as the home of the green energy revolution,” said North East Mayor Kim McGuinness.

“The potential for the site is huge. It could generate thousands of clean energy jobs which will benefit the region in the long-term and further establish a real hub for renewables and offshore sectors on the bank of the Tyne. I look forward to seeing how the project progresses.”

“Accelerating offshore wind, renewable energy and advanced manufacturing is a national priority and requires decisive action,” said Matt Beeton, chief executive officer at the port.

“Boosted by Industrial Strategy Zone status that provides similar benefits to a modern freeport, our expanded Tyne Clean Energy Park is uniquely positioned to support this UK-wide initiative. Located close to emerging North Sea wind arrays, this nationally strategic site offers deep-water access and a major development footprint to enable the creation of world-class infrastructure to support a growing supply chain offering.”

The Port of Tyne is one of the UK’s major deep-sea ports, just 6.5km from the moth of the River Tyne and the North Sea.

the Port

financing

benefit of the North East and all its stakeholders.

Major port infrastructure works are set to begin at the Port of Milford Haven with the next stage of a significant jetty upgrade now confirmed.

Inland and Coastal Marina Systems has been awarded the contract for the latest phase of the port upgrade, which marks a key milestone in the modernisation of the port’s marine construction facilities.

“This investment will create fit-for-purpose facilities that enable us to continue delivering a world-class pilotage service,” said Mike Ryan, Harbourmaster at the Port of Milford Haven.

“It strengthens our resilience and enhances operations across the Haven.”

Future-proofing

Work will begin in November, with the installation of a new 70-metre pontoon and a 33-metre gangway designed to improve efficiency, safety and long-term operational capacity.

The new pontoon, four metres wide, will provide a more resilient and functional asset, capable of meeting current and future

pilotage needs. The upgraded gangway will enhance accessibility and safety, ensuring the jetty is fully prepared to support the port’s new pilot vessel, the NGS42, due to arrive early next year.

Bryan Stewart, sales manager at Inland and Coastal Marina Systems, added: “This flagship marine construction project will ensure safe, all-tide access for crews and provide robust facilities for the world-leading fleet of vessels currently in delivery.”

The jetty upgrade is part of a wider programme of port infrastructure improvements aimed at future-proofing marine operations. Previous work included the replacement of external wave screens, now fully operational.

It will also deliver improved staff facilities and upgrades to mechanical, electrical, fuelling and security systems.

Seaway7 says it has installed all 277 monopile foundations at the world’s biggest offshore wind farm – Doggerbank in the UK.

The 183m-long vessel has a patented monohull shape which, with its fuel-efficient engines, enables a transit speed of 12 knots, Seaway7 says. It has lift heights of 100130 metres and weights of 5,000 tonnes.

Powering the enormous vessel are six 4,500kW main engines, two 5,500kW main thrusters, two 3,500kW DP thrusters, two 1,150kW bow thrusters, giving it a transit speed of 12 knots. It can accommodate 220 people.

Having completed the monopile installations with crane vessel Seaway Strashnov, Seaway7 will then go on to install the transition pieces with Seaway Alfa Lift.

This vessel is even larger, with a length of 244.6 metres and 11 engines in total, including four 6,875kW main engines, three 3,200kW tunnel thrusters, three 5,500kW stern thrusters, and one 3,200kW bow azimuth thruster. The vessel has a 3,000-tonne crane and an 8,000m2 main deck space.

Dogger Bank details

Dogger Bank, which comprises A, B, C and D, is jointly owned by SSE and Equinor across all four except for A and B, which are also owned by Vårgrønn.

Dogger Bank D is in the proposal phase, and SSE and Equinor have just finalised the seabed lease to progress the project.

It will maximise the capacity of Dogger Bank C, ‘unlocking up to 1.5GW of additional renewable electricity capacity from the 3.6GW Dogger Bank Wind Farm’, the developers say.

Dogger Bank D has plans for up to 113 installed offshore wind turbines on fixed-bottom foundations as well as up to two offshore substation platforms on what will be a 262km2 seabed site.

“Reaching this milestone for the Dogger Bank D development provides future opportunity to unlock more value and volume from the world’s largest offshore wind farm whilst building on our expertise and presence in the North East of England, said Melissa Read, head of Regional Development - UK Renewables - with Equinor.

Dogger Bank D has plans for up to 113 installed offshore wind turbines on fixed-bottom foundations as well as up to two offshore substation platforms on what will be a 262km2 seabed site

“The UK is a core strategic market for Equinor and Dogger Bank D demonstrates how there is the potential to further develop our future UK portfolio by having the opportunity to increase future value from quality existing assets. We look forward to maturing the project further with SSE and continue to support the UK’s offshore wind and net zero ambitions.”

Dogger Bank D is one of seven UK offshore wind farm projects with existing seabed leasing agreements that have been identified for potential development as part of The Crown Estate’s ‘Capacity Increase Programme’, which intends to unlock up to 4.7GW of potential electricity.

You can’t calm the ocean, but you can control its impact. And that’s the difference between getting the job done, or not. Because downtime isn’t an option. Choose Sleipner.

* Patent pending. Contact Sleipner for more details

Sleipner develops thrusters and stabilizers that set the industry standard for precision, reliability, and control. Our systems are trusted by commercial operators and shipyards worldwide for their proven performance in demanding conditions.

Visit sleipnergroup.com/commercial to learn more.

The Dutch government has announced nearly €1 billion in subsidies for offshore wind projects just four months after shelving two major projects.

Announcing the subsidies, to be issued in 2026, and unveiling an ‘Offshore Wind Energy Action Plan’ this week, the government has changed course quickly since abandoning the IJmuiden Ver Gamma-A and Gamma-B wind farms in May because of ‘deteriorating market conditions for offshore wind energy projects, partly due to lack of large-scale demand for electricity’.

The Action Plan, which has been published after a report said the Netherlands was unlikely to hit climate goals, includes legislation to enable the Contracts for Difference (CfD) method, used in the UK, which guarantees wind farm operators are subsidised during low-price periods but repay them when prices rise.

The Netherlands has about 4.7GW of installed offshore wind, way short of the government’s target of 21GW by 2032. The deadline has actually been extended by two years and the report, the Klimaat- en Energieverkenning (KEV) 2025 (Climate & Energy Outlook Netherlands 2025), said climate targets were very likely going to be missed.

”The chance that the Netherlands will achieve the climate target is less than 5%,” it says. “The Netherlands is also not on track to achieve binding European targets for renewable energy and energy consumption.”

On the demand side, the government will extend its “Indirect Cost Compensation” scheme for energy-intensive industries until 2028, with about €150 million earmarked to keep power affordable for businesses as renewable output grows.

The chance that the Netherlands will achieve the climate target is less than 5%. The Netherlands is also not on track to achieve binding European targets for renewable energy and energy consumption ‘‘

Other steps include adjusting site planning, such as potentially merging offshore zones to optimise shared infrastructure, and easing certain permitting requirements to reduce upfront risks for developers. Long-term policy changes will be needed rather than piecemeal measures, says the report, partly blaming rising demand combined with slower-thanexpected efficiency gains.

Dutch offshore wind vessel operator Cadeler has secured a contract with Ocean Winds to install 26 offshore wind turbines at the BC-Wind project in the Polish Baltic Sea.

The agreement, first inked back in February, covers the transportation and installation of Siemens Gamesa 14MW offshore wind turbines, located 23 km off the Pomeranian coast, in support of Poland’s ambitious offshore renewables strategy.

“With this firm contract now signed, we are ready to bring our best-in-class fleet and experienced crews to support Ocean Winds on this important project,” said Mikkel Gleerup, CEO of Cadeler.

“Poland is establishing itself as a key offshore wind market in Europe, and this project will be a significant step in strengthening the country’s renewable energy ambitions.”

Construction project

BC-Wind marks Ocean Winds’ first offshore wind venture in Poland. Construction is expected to begin in 2028 and last around four months.

Once complete, the 390MW windfarm will supply clean electricity to nearly 500,000 homes.

During the project, Cadeler will deploy one of its O-class wind turbine installation vessels, operating from the Port of Gdańsk.

The contract follows a Vessel Reservation Agreement signed earlier this year and represents the first direct partnership between Cadeler and Ocean Winds, though both have collaborated on previous windfarm construction projects in Europe.

It’s a deal which further strengthens Cadeler’s presence in Poland’s offshore renewables market. The company is already active on major projects including Baltic Power, Baltica 2 and the Bałtyk 2 and 3 offshore windfarms.

Collectively, these projects highlight Poland’s growing role in European offshore wind development.

Business is booming for Cadeler. It recently reported better than expected results in the sector, despite all the turmoil being created for European renewables operators across the Atlantic.

Back in May, it bought a new Wind Turbine Installation Vessel (WTIV) to meet growing demand for operations and maintenance.

The new vessel, already on the water at the Shanghai Boqiang Heavy Industry Group in China, will need to be upgraded to be capable of installing 15MW turbines.

Charge Offshore has completed installation of the charging system for the ‘world’s first’ diesel-to-electric retrofit crew transfer vessel (CTV).

The e-Ginny project, funded by the UK Government’s Zero Emissions Vessel and Infrastructure (ZEVI) competition, marks a major step forward in vessel electrification for offshore wind operations.

“Robust offshore charging infrastructure is critical to support the industry as it ramps up the transition to electrification,” said Paul Cairns, CEO of Charge Offshore.

“This landmark e-Ginny project demonstrates that, with the right systems in place, we can finally eliminate reliance on fossil fuels and unlock a new sustainable future for offshore wind operations.”

■ The e-Ginny project marks a major step forward in vessel electrification for offshore wind operations

During the project, the project’s CTV, named e-Ginny, will demonstrate how engine retrofit technology can deliver zero-emission propulsion while providing essential support

to offshore windfarms.

Charge Offshore, a spinout of MJR Power & Automation, has developed the Aquarius Eco charging system to deliver emissions-free power from offshore wind generation.

Its connector deployment system will soon be installed on a fixed offshore structure in the North Sea, enabling fast, safe and reliable charging for e-Ginny.

Charge Offshore has successfully delivered and installed the connector ‘catcher’ for its Aquarius Eco charging system, designed to deliver power from offshore wind generation. The connector deployment system will then be installed on a selected fixed offshore structure in the North Sea, providing safe, fast and reliable charging for e-Ginny during her charter.

Powering progress at sea

Pioneers AYK Energy and Leclanché drive the electric wave with safe, scalable batteries

Innovation meets reliability

EST-Floattech and Wärtsilä show how advanced engineering is making battery power viable for vessels of any size

Charging ahead off and onshore

From buoy and wind farm options to containerised solutions, charging must be more available

Navigating uncertainties

The feasibility of electric tugs – some in favour, some against

1,500 battery vessels signal a positive electric future

report

The maritime industry is in the midst of a profound transformation when it comes to the future of propulsion.

While there is a vast range of opinions on what the ultimate solution will look like, few would disagree that it will be a mixed picture: no fuel has yet turned up or been developed that has everything diesel has – the price, the abundance and the performance, all wrapped up in one – and different fuels are suitable or attractive to different vessel types.

As regulators tighten emissions targets and operators seek cleaner, more efficient technologies, the spotlight has turned to electrification – and with it, batteries.

Long seen as the cornerstone of the transition to low- and zero-emission shipping, batteries are now being deployed at scale across a growing range of vessel types, from ferries and tugs to offshore support ships and even coastal cargo carriers.

Innovators are noticing the potential, and in this Special Report we talk to some of the battery makers who are flagging their products in the charge towards full-scale adoption in the commercial marine sector.

This report, which is sponsored by one of the pioneers in this field, AYK Energy, looks at the situation to date from the perspective of the marine battery maker. In each of our interviews with battery makers, similar themes emerged: cost; the safety element; charging challenges and how sustainable batteries actually are. There is no significant recycling being done in the world at the moment, for example: marine batteries are at such an early stage they have not reached end of life yet, so this is a looming issue. Heralded as a clean alternative to fossil fuels, they are nonetheless linked to difficult questions around mining practices, supply chains, recyclability and lack of charging infrastructure.

The companies we spoke to who make marine batteries – our sponsor, AYK Energy; EST-Floattech; Leclanché and Wärtsilä – are obviously confident in this space or they wouldn’t be in it; however a senior employee at one of the world’s largest tug operators, who asked to remain anonymous, expresses huge doubts over battery feasibility in tug operations.

Safety is paramount, and with a number of car carriers experiencing fires that could have emerged from their cargoes of electric vehicles, it’s something that has to be resolved – we speak to one consultant who has stark warnings about the safety of lithium batteries and how ‘green’ they are – but others make the case that there are solutions out there.

When it comes to charging, a plethora of ideas is emerging: read our interview with Stillstrom, which has come up with offshore charging buoys that could keep the big boats out of our ports to limit emissions there; or AYK Energy, which believes one answer may lie in containerising batteries to swap in and out, rather like coach drivers switched tired horses for fresh ones long before the car was invented.

What is clear is that the pace of change is accelerating. With more than a thousand battery-powered vessels already in operation worldwide and many more on order, electrification is becoming mainstream – it’s just how it will happen that is the question.

It’s an uncertain world – and how best we are going to fuel it remains one of the greatest uncertainties.

Debbie Mason Editor, Maritime Journal

From 12MWh ferry systems to a future with containerised power, AYK Energy says it’s leading the world with its fast, safe, cost-effective marine batteries. Maritime Journal spoke to founder Chris Kruger about the company’s meteoric rise and its plans for an electric future.

As a company formed less than 10 years ago (2018), AYK Energy is a relative newcomer marine battery field – but it has already made huge strides that must be the envy of much older players.

In July 2023, the company opened its first automated manufacturing facility with a 300MWh annual output, expandable to more than 1GWh. Its solutions now power some of the largest vessels in Europe, including Brittany Ferries’ hybrid electric ships Guillaume de Normandie and Saint-Malo.

It’s also struck a deal to supply a 6MWh battery for the world’s first battery-methanol tug, for Svitzer.

Former director of Engineering with battery specialist Corvus Energy, Chris Kruger certainly knows his science –and with a clear vision to deliver cost-effective, safe marine batteries, he has steered AYK Energy into a position where they have now achieved positive EBITDA (Earnings Before Interest, Taxes, Depreciation and Amortization).

Siting its factory in China, AYK has stayed close to the supply chain, although Kruger says he intends to open another one in Europe in the non-too-distant future.

Keys to success

“When I started this company I looked at everything I’d learned – what’s worked in the past and what hasn’t worked,” he says. “I started with a clean sheet of paper. What are the key points I need to hit to make this battery work? It took a bit of time and luck to get the money, and the partners I had in

China had a value proposition and came on board. A good partnership and mutual respect are the key ingredients.”

Kruger emphasises that AYK is not a Chinese company –the marketing and engineering is all done outside – but by manufacturing in China, the company has achieved cost effectiveness and with his engineering knowhow, safety. It’s also about trust, he says.

“In my opinion, success really has to do with the fact that somebody like me knows the industry and the technology side, can speak to the customer and has their trust. That’s at the heart of the company – to be accepted and make a change. I’ve always been hands on, at the frontline.”

The batteries

AYK Energy’s batteries, Kruger admits, are not the cheapest on the market, but they are the safest and most cost effective.

The company uses lithium iron phosphate, which is less likely to produce thermal runaway, a chain reaction that can heat the cells, risking fire.

The company makes a wide range of battery sizes, weights and density according to the vessel they are destined for, whether RoPax ferries, inland cargo ships or tugs.

In July, it won DNV type approval for its Pisces, Pisces+, OrionAN and OrionAN+ series, which will immediately allow the company to install a 10.4MWh system on the biggest retrofit ever done – the hybrid-electric RoPax ferry Aurora Botnia, owned by Wasaline, which operates a daily service between Finland and Sweden.

I started with a clean sheet of paper. What are the key points I need to hit to make this battery work? A good partnership and mutual respect are the key ingredients ‘‘

“We have listened to industry and developed this range to deliver higher energy density, which is ideal for ferries, workboats and tugs,” says Kruger. “And at the same time we’re innovating systems that strike a balance between power and energy density, which works better for hybrid applications.”

In response to scepticism over how sustainable batteries actually are, he says the company has done carbon studies – “and overall, we come out on the positive side, especially when you operate the battery for a long time.

“Most of the carbon generation comes from the making of the cells, so if you can use green energy to do that, it becomes a lot cleaner.”

When it comes to recycling, Kruger accepts it isn’t yet being done on a meaningful scale, but because batteries in marine are relatively new, most have not yet reached end of life, and there are big ideas in stationary storage for batteries that are no longer fit for marine use.

Containerised future

Chris Kruger is also eyeing up the opportunities for batteries that could be used much in the same way that tired horses were swapped for fresh ones by coach drivers before the automotive was invented.

“We are planning to put batteries in containers – fill half a TEU with 2.8MWh of batteries, or 5.6MWh in a full container,” he says. “A port crane could easily handle half a container of batteries, which would weigh about 21 tonnes. They could be charged out at a wind farm, brought back and swapped out with another container – like horse swapping.

“We’ve talked to people about using containers on tugs, and I think this is going to enhance the use of batteries. Today you can’t charge a battery in a harbour unless you have a power plant nearby for cold ironing, and it’s expensive.

The first battery I ever designed was for a Svitzer tug in Australia. Years later, we’re supplying Svitzer again. It shows how far the industry has come ‘‘

“This is one of those cogs that isn’t in place today. It’s going to take a huge amount of money to get it to scale, but we already have guys who want to do the cold ironing and bring the battery to the shore.

“We need high-volume manufacturing: if we get the volume, we will be able to bring the cost right down and it will be way more cost effective.”

Kruger is looking for other financing options to set up a factory and move out of China, he says, somewhere in Europe, where his market is.

In some ways Kruger’s career has come full circle.

“The first battery I ever designed was for a Svitzer tug in Australia, the Gorgon project,” he says. “Years later, we’re supplying Svitzer again. It shows how far the industry has come.”

In a maritime sector increasingly pressured to cut emissions and embrace clean technologies, EST-Floattech is making waves with its advanced battery systems.

Founded more than 15 years ago as a system integrator for electric components on luxury yachts, Amsterdambased EST-Floattech is now a specialist in maritime battery solutions, boasting hundreds of successful deployments and a growing international presence.

At the heart of the company’s offering are its two flagship battery systems: the Green Orca and the Octopus. Indeed, it has just expanded its Octopus range with LFP (Lithium Iron Phosphate) batteries.

“We have for 12½ years had the Green Orca product, which was delivered to more than 200 projects – 16MWh in total,” says Joep Gorgels, CFO and co-director of EST-Floattech. “And since the last 2½ years we have the Octopus product and that has also been a success, with more than 110 projects and 70MWh.”

The company partners with Singapore-based DuraPower, sourcing NMC (Nickel Manganese Cobalt) cells manufactured in China. These cells are designed into complete, typeapproved maritime battery systems by EST-Floattech’s inhouse engineering team.

“We design battery systems for maritime purposes and we have them certified by the major class certificates,” says Gorgels.

Tailored technology and safety

EST-Floattech’s batteries are being installed in a broad array of vessels, from ferries and tugs to inland barges and 10,000ton coastal ships.

“More and more [coastal ships] are enjoying large batteries to make zero-emission port calls,” says Gorgels, highlighting the dual purpose of their products: environmental compliance and operational efficiency.

Beyond propulsion, its battery systems provide energy for hybrid configurations, blackout prevention, peak shaving and hotel loads.

“You can have batteries for full electric propulsion, but also for hybrids, to have ships become zero emissions ultimately,” he says.

You don’t want a big fire on board a ship with 200 people in the middle of the lake or the sea ‘‘

Joep

Gorgels, CFO and co-director of EST-Floattech

Safety and reliability are core to EST-Floattech’s design philosophy. “You don’t want a big fire on board a ship with 200 people in the middle of the lake or the sea,” says Gorgels. “In a car, you can let the car burn and step out and you’re safe.”

To prevent such disasters, EST-Floattech has developed what Gorgels describes as ‘one of the most reliable and redundant battery management systems’ on the market. The system monitors everything ‘from cell level, to module level, to string levels’ and includes cell-to-cell propagation prevention and a safe exhaust system outside the battery room and the ship.

Balancing energy density and use case

Gorgels acknowledges that battery chemistry still limits how far electrification can go, particularly with larger vessels like container ships.

“Batteries are becoming more energy dense… but I think there will ultimately be limits because it’s chemistry for the

recently

moment,” he says. While solid-state batteries and supercapacitors are on the horizon, they are not yet ready for maritime deployment. “Not yet. Indeed, they are not commercialised enough for larger applications like shipping, but that might come in the next decade or so.”

Currently, EST-Floattech supports both NMC and LFP battery chemistries, each with its own strengths.

“You don’t have cobalt and nickel in the LFP solutions –that’s not there. So you could argue LFP in that respect is a bit better,” Gorgels says, referring to growing concerns around the ethical and environmental impact of cobalt and lithium mining.

But while LFP may be preferable for sustainability, it doesn’t suit all applications.

“We’re not going away from the NMC because NMC batteries can have a much higher number of cycles and short cycles in a day and can have much higher C rates,” he says.

“With LFP solutions, you can have low C-rate applications, slow charging, slow discharging. But if your ferry has very short crossings and needs to be charged 10–20 times a day with a lot of power, you can’t do that with an LFP solution. You have to have the NMC or LTO battery types.”

A study from the Institute for Energy Research in Australia, Environmental Impacts of Lithium-Ion Batteries, found that more than 98% of lithium-ion batteries end up in landfills, which increases the likelihood of landfill fires that can burn for years.

One landfill in the Pacific Northwest was reported to have had 124 fires between June 2017 and December 2020 due to lithium-ion batteries. Fires are becoming increasingly common, with 21 fires reported on the site in 2018, increasing to 47 by 2020.

At the moment we are not seeing piles of lithium batteries in landfill from the maritime industry because quite simply, they haven’t reached their end of life yet.

“Certainly not with vessels,” says Gorgels. “We are only now getting a couple of batteries back from our first ship, which have had 13 years of service.”

But with a project life span of around 10 years, even if the batteries exceed that, there is inevitably going to come a time when suddenly a lot of them start giving up.

Gorgels thinks there may be an answer, although it was suggested for automotive batteries and hasn’t really happened.

“What I think will happen now and in future is the second life of batteries,” he says.

“Once they have been used in a car or in a vessel, they will have a second life in a containerised solution for a festival, or charging a football stadium, or an office, something like that.

He believes the industry is catching up to the recycling challenge.

"I know of reports that talk about 90 to 95% recycling of batteries, making it already possible to bring the batteries back to the original materials,” he says.

A bespoke approach

Unlike some competitors, EST-Floattech prides itself on codesigning systems with shipbuilders.

“Every project, every ship… is different,” said Gorgels. “We co-design and help them with the choice of which battery to use, how large the system should be. We help them designing the battery room… designing the racking, firefighting systems… and how to mount the system safely.

“The ship is often, of course, in heavy storms or it can tilt or it bangs on the quay. So it has to be robust.”

As maritime electrification expands, Gorgels sees the

battery revolution growing from small-scale vessels to larger operations.

“Everything that you can electrify will or should be electrified,” he says. “It creeps up from small to larger. Easy.”

And with a strong presence in the Netherlands, where ‘electric cars are taking off massively’ and ‘the whole North Sea will be fully covered with windmills soon’, EST-Floattech is positioned at the centre of Europe’s energy transition.

“We’re growing with our clients,” Gorgels says. “More and more ships. Larger packs. And we work with them to make it happen.”

Everything that you can electrify will or should be ‘‘

Swiss battery maker Leclanché says its marine batteries are difficult to compete with, whether in performance, sourcing or recycling. As part of our series of interviews with battery makers, we talk to Guillaume Clément, vice president for Marine Mobility.

As batteries move from the engine room to centre stage in today’s developing electric marine sector, Switzerlandbased battery manufacturer Leclanché claims to be one of the pioneers powering this transformation.

Guillaume Clément, vice president for Marine Mobility at Leclanché, says the company’s offering is special in many ways: not least because every gram of material used within its products have a traceable origin. In a world where cobalt, a critical element in NMC batteries, is mined by children in the Congo and vast swathes of South America have been destroyed by lithium mining, this is an important claim to make.

Leclanché’s journey into the marine world began nearly a decade ago, catalysed by EU funding for the fully electric ferry Ellen

“That project gave us legitimacy,” says Clément. “We weren’t just a battery supplier – we were one of the first in the world with a working marine-certified battery system.”

Today, Leclanché is involved in battery integration across a wide range of vessel types, from ferries to offshore wind installation ships.

Built for the sea

Marine batteries must withstand extreme and unique challenges. Ships require long-life batteries capable of withstanding constant deep cycling and harsh vibrations, and they need strict safety certifications.

“In industrial applications like ships, batteries are used intensively – charged and discharged daily,” Clément says. “They need to have a long life cycle.”

They also have to withstand endure marine-specific conditions like continuous vibration and extreme thermal stress. One of the most feared risks in marine energy systems is thermal runaway, when batteries overheat, potentially leading to fire.

Leclanché has engineered its battery modules to mitigate such events, Clément says. Their proprietary safety design includes an IP-rated protective box for each module, equipped with sprinklers that automatically inject water when high temperatures are detected. A carefully sequenced water-cooling protocol then continues for nearly an hour to suppress the risk of re-ignition.

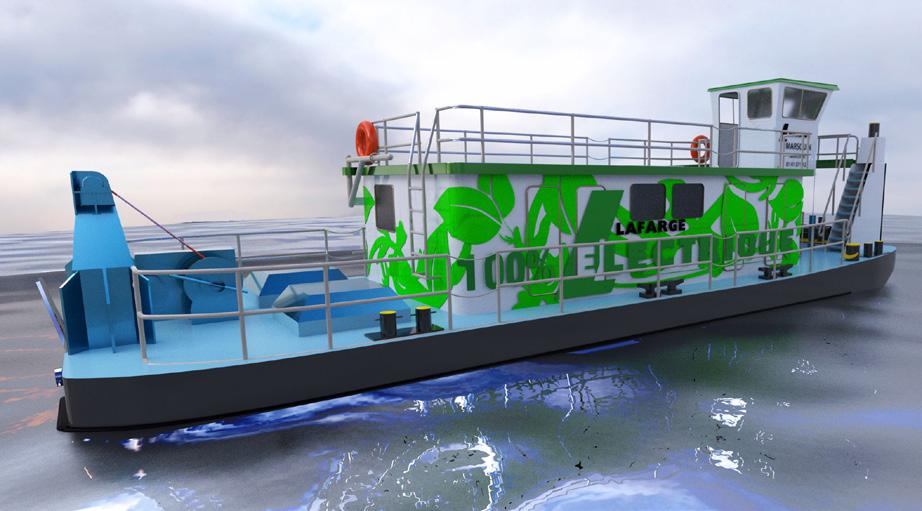

■ Leclanché retrofitted the Marsouin, a 1965-built diesel pusher tug, into a hybrid vessel to operate on the River Seine and surrounding French inland waterways

“We don’t just prevent thermal events – we stop them before they become fires,” says Clément. “When we test in labs, neighbouring modules show zero damage – not even a scratch.”

Real battery making

Unlike many of its competitors, Clément says, Leclanché actually manufactures its own cells rather than simply assembling imported components.

“Most of our competitors aren’t true battery makers. They buy cells, usually from Asia, and package them in Europe or North America,” he says. “Our batteries are made in Europe, designed for marine use from the ground up. That gives us performance and safety advantages.”

Their approach extends to sourcing too. Clément is candid about the contentious history of cobalt in battery production but insists the company has addressed these concerns head-on. “We source cobalt from Umicore in Europe. It’s certified, traceable, and 100% free of child labour,” he says. “Ironically, cobalt is now one of the safest materials to source because of all the scrutiny it’s been under for decades.”

In fact, Leclanché is already phasing cobalt out of its new chemistries. Its next-generation NMC-A (nickel-manganesecobalt-aluminium) chemistry, backed by the EU’s Current Direct project, boosts energy density by 15% and slashes cobalt content further.

Initially dominant in the ferry market, where routes and charging patterns are predictable, Leclanché’s marine batteries are now seeing growing demand in more complex vessel types. “We used to say ferries were 100% of our market. Today, it’s everything: offshore support vessels, seismic ships, wind farm installation vessels,” says Clément.

We weren’t just a battery supplier – we were one of the first in the world with a working marine-certified battery system

Guillaume Clément, vice president for Marine Mobility at Leclanché

On these hybrid vessels, batteries don’t typically power propulsion, but support high-demand operations like crane deployment or jack-up operations. They also serve to optimise generator efficiency by storing excess energy and supplying it during peak loads, as spinning reserve. This hybrid functionality can deliver fuel savings of 7% to 15%.

“It’s not enough on its own to justify battery investment,” Clément admits, “but if you already have batteries onboard, why not use them for multiple functions?”

Charging directly from offshore wind farms is on the horizon, especially for Crew Transfer Vessels.

“It depends on the operator’s point of view. If you’re operating the wind farm, recharging at sea saves you port fees,” he says.

Scaling up and recycling

The future is bright – and busy.

“Our biggest challenge isn’t demand,” says Clément. “It’s capacity. We’re investing to expand production in Germany by tenfold.”

Recycling is another critical piece. While most marine batteries haven’t yet reached end-of-life, automotive

batteries have, and whatever you hear from potential battery recyclers, it is not being done on a meaningful scale yet. It simply isn’t cost effective: it is simply cheaper to mine new materials than extract them from used batteries.

Leclanché already includes recycled content in its cells at least, and advises customers on best-practice recycling options.

“We’re selective about who we work with, because not all recycling methods are equal,” he says.

One point that Clément raises is about the use of PFAS (Per- and Polyfluoroalkyl Substances), or ‘forever chemicals’, which have been around since the 1940s because they contain strong carbon bonds that make them extremely resistant to heat, water and oil. They are almost nearly impossible to break down in the environment or indeed the human body.

Leclanché’s batteries avoid using them.

“We want our batteries to be worth something at the end of their life,” he says. “The rare materials we use – like cobalt – give them real recycling value.”

The battery horizon

As new EU regulations on maritime emissions come into force, Clément believes batteries are no longer “nice to have” – they’re a necessity.

“Every ship is now asking whether to have batteries and if not now, at least to be ready to retrofit later,” he says. “And the battery systems themselves keep getting bigger.”

Leclanché’s goal is to stay ahead of that wave. With solidstate and sodium-ion technologies still 10 years away from commercial readiness, Clément believes high-performance lithium batteries like theirs remain essential.

“We’re enabling the energy transition – not just with what we make, but how we make it,” he says.

As the maritime industry accelerates its transition to low- and zero-emission solutions, Wärtsilä is playing a commanding role by engineering fully integrated propulsion systems tailored to specific vessels.

Torsten Büssow, managing director of Wärtsilä’s Electrical and Power Systems division, talks to Maritime Journal about the company’s fast-evolving role in the marine battery market.

“We are electrical integrators,” says Büssow. “We don’t have our own factories for batteries. We work with battery makers to create marinized systems that meet the needs of each ship. That’s how we make our input felt in the product.”

Wärtsilä acts as a bridge between battery OEMs and vessel owners, shaping full-electric or hybrid propulsion solutions using its expertise in marine engineering.

This system-level responsibility means Wärtsilä engineers complete solutions – generators, converters, transformers, and batteries – that are tailored not only for the different demanding marine environments, but the different use cases they can expect.

“The marine market is so small that there are no dedicated factories for marine converters or generators,” he says. “We adapt and engineer existing technologies into robust marinegrade systems.”

Wärtsilä’s integration role also means flexibility across vessel types and battery chemistries. “We have approved suppliers for all chemistries to fulfil different ship specifications,” Büssow says. “A ferry is going to have very different requirements than a tug.”

For short-range operations like ferries, the future is already electric.

is providing the battery electric propulsion system and waterjets for South America’s Buquebus ferry operator in what will be the largest battery installation in marine transport, at 40MWh. The batteries are from Corvus Energy and the vessel is being built by Incat. It will have a passenger and crew capacity of 2,100, car capacity of 225 and more than 2,000 square metres on one level.

“Anything below three hours of operation will go batteryelectric,” he says. “We’re delivering those vessels today.”

Hybrid propulsion systems are also in high demand, especially in offshore markets, where vessels can save up to 25% in fuel by using batteries during standby or DP modes. “That’s a short payback time,” he says.

On the infrastructure front, change is coming fast. “In the ferry market, charging comes with the terminal – it’s not a chicken-and-egg problem,” says Büssow. For larger commercial ports, EU regulation is driving progress. “Shore power connections are mandatory by 2030 for passenger and container ships. This infrastructure is what batteries will use.”

Some vessels are being built with batteries specifically for zero emissions in port, in cases where shore power is not yet available. “There’s a clear business case there,” he says.

Retrofits and battery engineering Wärtsilä has completed around 30 battery retrofits, making it the most experienced player in this niche.

■ The new Buquebus ferry will be the world’s largest zero-emissions, lightweight catamaran ferry, and it will be powered by a battery-electric propulsion system and waterjets from Wärtsilä

■ Torsten Büssow, managing director of Wärtsilä’s Electrical and Power Systems division

The marine market is so small that there are no dedicated factories for marine converters or generators. We adapt and engineer existing technologies into robust marine-grade systems

Torsten Büssow, managing director of Wärtsilä’s Electrical and Power Systems division

“It’s not a big part of what we do, but nobody has done as many as we have,” he says. “Four years ago when we started this decarbonisation I would say every vessel will have a battery. It sounded very funny at that time, but now not so.”

According to Büssow, these retrofits have delivered immediate benefits in efficiency and emissions reduction.

“Offshore vessels, for example, are perfect candidates. They often need two engines running in DP mode, even at low loads. Batteries allow the engines to operate more efficiently, closer to 80% load.”

Battery lifespans are engineered with practicality in mind.

“You don’t engineer batteries for the 25-year vessel life. You engineer for 10 years, because the technology advances so fast,” he says.

To ensure a battery will last the full 10 years, the company oversizes it so that it actually has more capacity than is needed. There is no need to use the full capacity on day one, but it means there will be plenty left by year 10.

“It’s pure engineering criteria – oversize it so it lasts 10 years,” he says.

Safety and supply chain concerns

One of the most talked-about challenges in the battery space is thermal runaway, the catastrophic chain reaction that begins in an over-heated cell and spreads to other cells, risking fire outbreak.

According to Büssow, marine batteries are far better protected than their automotive counterparts.

“Marine batteries are protected either on the cell-to-cell level or the module-to-module level,” he says. “It’s forbidden to use inflammable materials between the cells. There’s a huge difference in safety design.”

Even in the rare case of cell failure, systems are designed to prevent escalation.

“There’s always dual or triple temperature sensing. If two sensors report high temperatures, that cell or module is shut off immediately,” he says. Fire suppression systems, including water or coolant flooding, are also in place. The outcome?

“Globally, there have only been two or three marine battery incidents – and those happened years ago. It shows the safety systems work.”

Despite growing concern about the environmental impact of lithium-ion battery production, Büssow is says it does not affect marine because it will be led by the automotive market and the consumer.

“Marine batteries use the same cells as car batteries. We benefit from that market’s push for cleaner supply chains,” he says. “As regulations like the EU battery passport take hold, the consumer market will solve this for us.”

Chemistry choice also plays a role.

“There are lower-cobalt options like LFP (lithium iron

phosphate), which are cheaper and more sustainable. We tailor chemistries to each vessel’s operational profile.”

Although battery-only propulsion is not yet viable for transatlantic container ships, it is increasingly the go-to solution for ferries, offshore wind vessels, and port operations, with the Ropax sector Wärtsilä’s biggest so far.

“We’ll see small merchant ships move to full batteryelectric. For others, hybrid is a fuel-saving device – and it works today,” he says Büssow.

Indeed, Wärtsilä now holds about 25% of all marine battery capacity installed globally. “We have more than 1GWh of marine battery systems installed. That’s a quarter of the total – and it’s growing,” he says.

It’s growing, but there will be no short-term end for diesel.

“Deep-sea ships will still use combustion engines – but they’ll consume less and less,= fuel,” he says. “Batteries are here to stay, and they’re improving fast. This isn’t future technology – it’s being sold while we speak. Dong, dong, dong.”

Are we there yet? Despite so many battery manufacturers hailing the benefit, the risks and problems of onboard and onshore battery systems identified in a recent Bureau Veritas report suggests not.

With 1,500 battery-powered vessels in operation and hundreds more under construction, the integration of lithium-ion (Li-ion) battery systems is accelerating rapidly. These systems offer higher energy efficiency, zero-emission operation in port and improved responsiveness.

However, despite being rolled out on boats and as Onshore Power Supply (OPS) systems, they also introduce new layers of complexity and risk.

A report by Bureau Veritas Marine & Offshore, Maritime Electrification: Maritime Battery Systems and Onshore Power Supply, emphasises that the successful adoption of these systems depends on rigorous safety standards, system integration and regulatory compliance.

The most critical hazard associated with Li-ion batteries is thermal runaway, when a battery cell heats up and causes a reaction as cell after cell is heated until fire can break out. It can be triggered by internal short circuits, overheating, overcharging or mechanical damage.

Once ablaze, battery fires are extremely difficult to put out because of the generation of oxygen from the battery’s internal reactions.

Consultant George Brilmyer, an electrochemist with more than 45 years’ experience in the battery industry and owner of the consultancy Batt-Tek Consulting, is extremely sceptical about lithium batteries.

“Any battery can go into thermal runaway and explode,” he says. “But with lead-acid batteries, for example, they can go into thermal runaway but they won’t explode because the electrolyser is an acid.

“If lithium batteries come into contact with water, chlorine, a noxious gas, is released, and hydrogen comes off the other terminal – which can then explode.

“Lithium iron phosphate (LFP) was originally claimed to be safer but it’s not. It has a lower voltage cell but when one of those goes into thermal runaway, you have more problems, such as the chemistry releases more hydrogen, and the solvents are all flammable.”

“Batteries can also re-ignite after initial suppression of the battery fire,” says the BV report. “Therefore, an after-cooling strategy is needed to prevent re-ignition.”

Fire suppression must be both immediate and sustained, using systems that may include inert gases, aerosols, foam or water-based cooling.

As well as fire there is a risk of hazardous gases such as hydrogen, carbon monoxide, hydrogen fluoride and phosphoric compounds being released, creating explosion hazards.

“The accumulation of flammable off-gases in enclosed spaces represents a risk of explosion,” warns the report. Ventilation systems, it says, can in fact make the risk worse, because they introduce additional oxygen that could ignite the off-gases.

“The exact composition of gases will vary from case to case, and it is recommended that a composition analysis be

performed, so gas detectors can be adapted and optimized to the expected composition,” it says.

System degradation and maintenance issues

Li-ion batteries naturally degrade over time, reducing energy capacity and increasing the chance of internal failure.

Ageing batteries are more susceptible to mechanical stress and may exhibit unpredictable behaviours.

“As the battery ages, the risk of hazards will also increase, alongside a decrease in performance,” says the report. “This is due to unwanted internal reactions and mechanical stresses that can lead to internal component deterioration and a reduced amount of lithium available for energy storage.”

A key safeguard is the Battery Management System (BMS), which monitors cell temperature, voltage and current. It can isolate malfunctioning cells, balance charge across modules, and communicate with the ship’s Power Management System (PMS).

Any malfunction or misconfiguration of the BMS significantly increases the risk of battery failure.

Battery placement also matters. Batteries must be housed in compartments with adequate ingress protection, cooling, gas monitoring and fire suppression. Increasingly, modular systems are favoured because it is possible to isolate them and contain hazards.

Green credentials

Brilmyer is also candid about the recycling reality of lithium batteries, which is in direct conflict with the ‘green’ claims, and the fact that they require rare earths that are only available in meaningful amounts in China.

“Rare earths can only be sourced from China. The world doesn’t like that,” says Brilmyer. “They are very expensive, but they are needed for the electric motors.

“The materials in batteries are single use and they are not green. You have to realise that. If you are doing this just to be green, you have got to think again. They are not recycled, the electricity is not coming from anywhere green unless you’re in Norway, where there’s a lot of hydropower, or Washington, DC, which has 80% hydropower.

“There’s got to be a better solution and I don’t think lithium is the ultimate answer for electric propulsion. Everybody’s working on it – from sodium to flow batteries – and the petrol guys are also working on making their fuels cleaner.”

Onshore Power Supply (OPS)

OPS systems have their own challenges.

OPS systems can place significant stress on local power grids. A large cruise ship, for instance, may demand up to 20 MVA while docked.

“These high-power requirements have the potential to strain the electricity grid, necessitating significant investment in grid reinforcement or energy storage solutions," says the report – adding that while Battery Energy Storage Systems (BESS) are sometimes used to buffer this demand, they also add to cost and complexity.

OPS frequency and voltage mismatches are also common, BV says. Ships often operate at 60Hz, while port grids may supply 50Hz. The inclusion of frequency converters and transformers introduces more failure points and complicates maintenance, not to mention increasing costs all round.

OPS systems involve high-voltage electrical equipment, often managed in busy port environments. Dodgy installation or operation increases the risk of electrical shock, fire, or system failure. Better training, protective systems and regular inspections are yet more necessary expenses.

Regulations and lack thereof

The BV report also says that current international regulations for OPS and maritime batteries remain fragmented.

While classification societies like Bureau Veritas provide guidance and standards (eg BV NR467), it says, there is no single, globally adopted framework. This regulatory uncertainty adds to operational risk.

The report says the transition to electrification in the maritime sector is both necessary and inevitable, but cannot be undertaken lightly.

“Safety and standardisation must be upheld as top priorities,” it says, and OPS needs to interface with a variety of connection equipment and different onboard power systems.

“Standards help ensure compatibility and interoperability between various components and systems, enabling seamless integration and operation across different ports and vessels,” it says.

‘‘

The materials in batteries are single use and they are not green. You have to realise that. If you are doing this just to be green, you have got to think again. They are not recycled, the electricity is not coming from anywhere green unless you’re in Norway, where there’s a lot of hydropower, or Washington, DC, which has 80% hydropower

George Brilmyer, consultant

The tide of batteries flowing through the maritime industry is lapping at the hulls of all kinds of vessels, from tiny RIBs to container ships.

It’s very early days: according to Maritime Battery Forum managing director Syb ten cate Hoedemaker, there are only 1,500 battery-powered ships operating around the world at the moment, and 80% of those are hybrids.

Driven by calls and looming regulations to operate with zero emissions, fleet operators all over the world are having to consider them, and he sees few problems that can’t be solved with the ever-improving technology for the vast majority of vessel types.

But when it comes to tugs, not everyone agrees.

Maritime Journal spoke to a senior manager at a wellknown tug company who said battery-powered tugs were not feasible, far too expensive and unworkable in a busy port.

They also didn’t make any sense from an environmental perspective, he said.

Out of respect for this individual’s request to remain anonymous, we will refer to him as ‘Smith’, which is the most common surname in the UK.

Cost and energy

“For one electric tug, we can buy two conventional dieseldriven tugs,” Smith says. “Economically it’s just not feasible.”

And it’s not just the tugs themselves – a piece of shoreside charging kit can cost up to €1.5 million, he says.

If there is no fast charger – and these are a problem in ports where grids are already congested – it can take up to 10 hours to recharge, and having already paid twice as much for the vessel in the first place this is simply unacceptable.

“We can sail with a diesel-powered tug for 30 days and then we need one hour to refuel,” Smith says. “With methanol, we can sail for 14 days then need one to two hours’ refuelling. Go

to hydrogen – that’s one day’s sailing and two hours’ refuelling.

“Go to batteries, and that’s four to six hours’ sailing and if you have fast charging, 45 minutes but slow charging – eight to 10 hours.

“It’s crazy.”

“If you look at the typical operations of a tugboat, they are very suitable for battery power,” says Hoedemaker. “There are quite a few battery-powered tugs sailing across the globe right now. Some are fully electric, some are hybrids, but it is true, they are more expensive, so that is one challenge you have to solve.”

Neither of the two largest tug operators in the world, Svitzer and Boluda, has a single fully electric tug in their fleets, although Svitzer told Maritime Journal that it had one on order, expected for September.

MSC Towage, Rimorchiatori Mediterranei and Fairplay also have no fully electric tugs, and Kotug’s only electric tugs operate on inland waterways.

Most fleets have at least one hybrid tug, whether that is with diesel or one of the newer fuels.

Battery costs and charging infrastructure

Smith believes that batteries have not, as was promised, come down in price – but Hoedemaker disagrees.

“We’re not yet at the automotive battery price range, but in China there is a massive over production, so that will bring prices down. It’s a bit slower in maritime, but we are starting to see it,” he says.

He also says that there is more of a move towards lithium iron phosphate (LFP) batteries, which don’t have the controversial element cobalt (a great deal of which is mined

by children in the Congo) in them, and they are also cheaper.