10 minute read

Ocean sciences

Geoquip Marine has successfully completed a highly challenging off shore windfarm geotechnical investigation in harsh environmental conditions off the coast of Japan.

Geoquip and strategic partner Fukada operated the highly capable Poseidon 1 for the project for Influx Offshore Wind Power HD. Poseidon 1 is a DP2 vessel with a twin tower derrick permanently installed over a central moonpool.

The presence of rock below mudline made standard push sampling and CPT testing techniques impractical to complete the boreholes. As a result, Geoquip Marine chose to utilise a wireline core barrel to recover rock cores and progress boreholes. Geoquip was able to perform coring in rock utilising the standard API drill string because the Geoquip system enables the use of wireline core barrels without the need to recover the drill string.

“The fact that sampling, CPT testing and coring was able to be completed with a single drill string when changing mode from sampling and CPT testing to coring meant that the process was completed very rapidly and highly efficiently,” explained Project Manager Torran Purchase.

“Utilising the wireline core barrel in these circumstances provided us with really excellent recoveries – whilst allowing us to change back to sampling and CPT testing if necessary. Ultimately it provided excellent quality rock cores in very difficult conditions with less than one per cent downtime.

“Given the challenging conditions experienced throughout the duration of the work, the time saved by not having to recover the drill string to perform coring, improved safety by reducing the risk exposure of the drill crew whilst allowing operations to be completed in shorter weather windows, which contributed to the contract being completed with no safety concerns whatsoever,” he concluded.

A new laboratory testing facility will off er fast and accurate analysis of all types of geotechnical data.

Offshore geotechnical engineering and drilling company, Geoquip Marine has unveiled an in-house onshore testing laboratory in Bristol, UK that includes eight separate laboratory areas. The analyses undertaken include sample logging, classification/index testing, consolidation, shear, triaxial and effective stress testing.

“This is a highly significant development for our company following a sustained period of remarkable growth,” commented Geoquip Marine chief executive, Stewart Higginson. “Up to now we have been working with external partners for our onshore laboratory testing and there is no secret in the market that the shortage of suitable providers was becoming ever more of a problem as demand has increased.”

By providing this laboratory, Geoquip Marine aims to present customers with a comprehensive end-to-end service, worldwide.

Higginson added: “Our objective was to be able to provide our clients with the accurate and reliable data possible, delivered to meet their project timelines, and I’m delighted that we have succeeded in that.”

Geoquip Marine provides the offshore renewables, nearshore civil infrastructure, scientific research, gas hydrates, offshore mineral exploration, and offshore oil & gas markets with accurate profiles and conditions of the sub-seabed, from the shoreline to depths of 3,500m.

CORE BARREL TECHNOLOGY FOR CHALLENGING WIND POWER SITE INVESTIGATION

8 Poseidon 1 was used for this project

Geotechnical data analysis lab Lidar buoys will fact find for energy islands

Floating wind lidar measurements will be taken for what will be the world’s fi rst off shore artifi cial energy island, which is being constructed for the Danish Government.

Fugro will install and operate four SEAWATCH wind lidar buoys at two locations, Energioe Nordsoen and Energioe Baltic, that will act as hubs connecting several offshore wind farms.

From October, these buoys will record continuous wind measurements for a minimum of 1 year to support wind-resource mapping for the two islands, and the engineering and design of the future wind farms. Fugro is already performing geophysical surveys for the Energy Island project under a separate contract to provide Energinet with a reliable derisked site interpretation.

The SEAWATCH wind lidar buoy can record wind measurements up to 250m above sea level, and wave measurements and current profiles down to the seabed. The buoy also acts as a multipurpose platform for additional metocean sensors and, on this project, will be fitted with sensors to capture Geo-data on environmental impact parameters, including bat monitoring.

CSA and GEO Marine strategic alliance

CSA Ocean Sciences Inc., an international provider of marine environmental and geomatics services, has announced that it is teaming with GEO Marine Survey Systems.

GEO Marine is a global provider of geophysical products, software, and personnel focused on innovative high resolution seismic sparker systems, 24-bit recording, and ultrahigh resolution (UHR) streamers for 2D and 3D operations.

This strategic alliance will provide the US offshore renewables, marine engineering, government, and oil and gas markets with access to UHR seismic equipment and surveyors. The equipment will be housed at CSA’s Rhode Island facility, which offers direct vessel access to the heart of the US renewable market. Commenting on the new partnership, Gordon Stevens, Vice President and General Manager for CSA said: “Having recently completed a successful 90-day campaign for a major offshore renewable energy company, during which this seismic equipment performed flawlessly aboard our newly outfitted R/V Dolphin, it made perfect sense to extend our partnership with GEO Marine to continue offering this bundle of cutting-edge technology to the Northeastern offshore industries.”

The equipment can be rented with an operator direct from GEO Marine and installed onto a vessel of opportunity or chartered with the R/V Dolphin where fit-for-purpose mounting and operational apparatus have been fabricated and are permanently installed for efficient mobilization and operation.

STANDARDISING CLIMATE CHANGE DATA

RTSys and IFREMER have jointly developed a new system that helps standardise data collected during studies into the impact of global warming on the oceans.

The European Multidisciplinary Seafloor and water column Observatory (EMSO) researches deepwater ecosystems, generating data on marine, tectonic, volcanic, hydrothermal and gravity processes as well as monitoring associated natural risks to coastal areas such as earthquakes and tsunamis.

The EMSO Generic Instrument Module (EGIM) aims to standardise these measurements obtained at a variety of locations by using the same equipment, sensor references, methods of qualification and calibration, data formats and maintenance procedures.

At the heart of the EGIM system is COSTOF2, a datalogger than can reach depths of up to 6,000 metres, sourcing data from a wide range of sensors of different make, model and type. It has been designed to continuously measure environmental parameters, providing data on marine changes in Europe, and will soon be deployed by the Portuguese Institute for the Sea and the Atmosphere off the southwest coast of Portugal, at a depth of 4830 metres.

COSTOF2 allows the data for up to 12 sensors to be synchronised via acoustic modem or by WiFi and can be operated on mooring lines, seabed stations and surface buoys.

8 The COSTOF2 8 The EGIM can reach depths of

6,000 metres

Energy harvesting smart buoy prototypes

Nagasaki University and Kyocera Corporation have announced their joint development of an Energy Harvesting Smart Buoy.

The new technology combines Nagasaki University’s tidal current power generation technology with Kyocera’s IoT technology to collect reliable ocean data.

The buoys can collect a wide range of marine data using self-generated energy.

Marine pollution and climate change have become serious societal issues. To solve these issues and help create a more sustainable world, scientists need more reliable ways to monitor and visualize various sea conditions. However, maintaining a stable power supply is a big challenge for continuous data collection at sea. Therefore, Nagasaki University and Kyocera developed the “Energy Harvesting Smart Buoy,” which generates its own electric power for continuous ocean data collection using a tidal-current power generation system in the buoy.

The new Smart Buoy combines tidal-current power generation technology from Nagasaki University and IoT-related technology from Kyocera. In addition, Kyocera has future plans to monitor fisheries and aquaculture, conduct ocean surveys, and more.

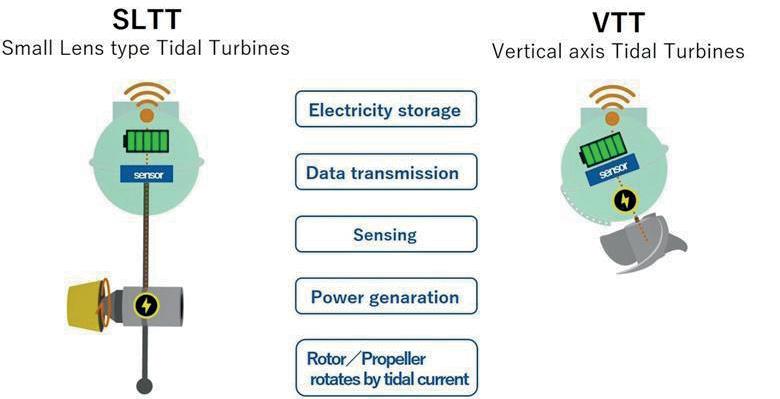

Each prototype is equipped with two different tidal-current power generation systems:

SLTT (Small Lens-type Tidal

Turbines) - The buoy and power generation are separate, and a diffuser is installed around the turbine. In addition to protecting the turbine, the diffuser has the effect of increasing the flow of water for better power generation.

VTT (Vertical-axis Tidal

Turbines) - The power generation element is directly connected to the buoy. Its AI-guided design incorporates a tilted axis to optimize turbine rotation amid heavy ocean swells and waves.

BIDS READY FOR FIRST OFFSHORE ENERGY ISLAND

Belgium’s DEME Group and Royal Boskalis Westminster of the Netherlands have joined a consortium to develop an energy island in the Danish North Sea

They join contractors ACCIONA and MT Hojgaard International to form the NJORD Group, which has signed a partnership agreement with Denmark’s Copenhagen Infrastructure Partners (CIP), a global fund manager focused on renewable energy investments. The Danish Energy Agency is currently in dialogue with potential bidders for the energy island tender, which is expected to be launched by Q3 of this year

The energy island will be located some 80-100km off the Danish west coast, where conditions for green energy production based on offshore wind are optimal. The island will be able to connect 10GW of offshore wind to Denmark and other neighbouring markets, host an innovation zone with potential for large scale energy storage and Power-to-X technologies, and provide accommodation and operation and maintenance services from onsite harbour facilities.

The signing of this agreement marks a significant step towards realising the world’s first energy island, a project conceptualised by CIP. CIP acts as project developer on behalf of an investor consortium composed of PensionDenmark and PFA, two of Denmark’s largest pension funds, and Denmark’s largest utility company, Andel. The grouping is collectively known as the Vindo consortium.

The realisation of offshore energy islands could herald an era of symbiosis and new opportunity for the four major global dredging contractors (DEME, Bosklais, Van Oord and Jan De Nul), all of whom have diversified heavily into marine offshore energy.

Luc Vandenbulcke, CEO of the DEME Group said: “We are proud to join CIP and the Vindo consortium, which gathers a core group of global leaders in maritime engineering solutions for offshore renewable energy production, storage and transmission. DEME Group has been pioneering the concept of energy islands off the coast and is currently involved in designing, planning and executing similar projects in different parts of the world.”

Royal Boskalis Westminster CEO Peter Berdowski added: “We look forward to taking the development of renewables further offshore to create a sustainable new horizon for millions of European households.”

8 The island

will be able to connect 10GW of off shore wind to Denmark and other neighbouring markets

Sustainable biofuel for Boskalis dredgers

Dutch dredging major Royal Boskalis Westminster has taken delivery of its largest ever consignment of drop-in biofuel which will be used to power two trailing suction hopper dredgers on upcoming projects in northwestern Europe.

The use of biofuel will result in a CO2 reduction of approximately 90% for the 12,000 m3 capacity Willem van Oranje and approximately 45% for the 4,500 m3 capacity Strandway.

The delivery of some 1,000 m3 of Hydrotreated Vegetable Oil (HVO), a sustainable biofuel derived from used cooking oil, was in collaboration with Boskalis’ long term partner and fuel supplier, Goodfuels.

Boskalis’ own testing programme with GoodFuels and engine manufacturer Wartsila that began in 2015 has demonstrated that

8 Biofuel use in the Boskalis dredger

Willem van Oranje will result in a CO2 reduction of approximately 90%

drop-in marine biofuels can reduce CO2 emissions by up to 90% compared to fossil fuels. In 2019, as part of the ‘Boskalis on Bio’ programme, the Willem van Oranje became the world’s first dredging vessel to operate on 100% biofuel oil. Since then, Boskalis has successfully used various biofuel blends as an alternative to fossil fuels on both dredging and offshore installation vessels as well as for dry earth moving equipment, resulting in considerable emissions reductions.

Through its agreement with GoodFuels, Boskalis enables clients to opt for biofuel powered vessels to reduce their carbon emissions on projects. In 2020, 80% of Boskalis’ project tenders in the Netherlands included sustainabilty measures, including options to use biofuels.

Willem van Oranje has recently been deployed for dredging works on the Fehmarn Belt Fixed Link, an immersed tunnel crossing the 18km wide Fehmarn Belt in the Baltic Sea. The works are being undertaken under the auspices of Fehmarn Belt Contractors (FBC), a joint venture between Boskalis and fellow Dutch dredging contractor Van Oord.