16 minute read

Pilot performance

PERFORMANCE PARAMOUNT FOR POLISH PILOTS

Finish specialist aluminium shipyard Kewatec, has handed over its latest Pilot 1630, to pilot boat operator Gdańsk Pilot in Poland

The fast pilot boat is self-righting and designed with extraordinary safety performance for both the pilots and boat operators.

This is the second Pilot 1630 that Kewatec has handed over.

Kewatec Pilot 1630 has a large wheelhouse, and it is flexible mounted to the hull for minimum noise. The boat is equipped with two Caterpillar C 18 marine engines and CJR FPP propellers. There is a separate galley and sleeping bunks in the downstairs. The extensive navigation equipment is supplied by Furuno and communication from Cobham Sailor.

The boat is set to join the established fleet of Gdańsk Pilot, which also consists of the sister ship ‘Pilot 23’ that was delivered to the customer last year.

Oy Kewatec AluBoat Ab is a Finnish company with a history dating back to the 1970s. The business is based on strong boat expertise and is today one of the nordic region’s leading manufacturers of professional aluminium boats. A large proportion of the boats are exported.

The company has delivered hundreds of professional boats to meet diverse customer needs. Kewatec’s customer base consists of public actors such as sea rescue and coastguard organisations, fire brigades, police authorities, and defence forces, as well as other companies and associations that need work boats for professional use.

The wide range of products includes professionally designed work boats, passenger boats, Fire Fighting and Oil Recovery boats, pilot boats and patrol vessels, which can be easily modified to meet each customer’s specific needs.

The company also offers professional boat docking services and associated maintenance, repair, and renovation services as well as modifications.

Turnover is approximately EUR 27 million and the business employs approximately 100 peoplein facilities at Kokkola and Porvoo in Finland and Bergen in Norway. The company is headquartered in Kokkola.

8 Kewatec Pilot 24 handover

Double-ended electric ferry

Turkey’s Tersan Shipyard Inc. has successfully delivered the 7th Double-Ended Electric Car and Passenger Ferry to Norwegian ferry operator Fjord1 ASA.

The Multi Maritime designed ferry, named Rødvenfjord is the third in the series of which the first one was delivered in August 2019. She is the seventh ferry delivered to Fjord1 ASA by Tersan Shipyard. 107.47 metres long and 17.7 metres beam, the ferry has a capacity of 299 passengers including crew, 120 cars and 12 trailers.

Rødvenfjord has electric propulsion with fast charging batteries using rapid shore connection during the disembarkation of passengers. In line with the latest environmental demands, she is also arranged with a diesel-electric back up system and can operate in fully electric mode, hybrid mode or diesel-electric mode. She can also navigate autonomously on the most optimum route with an Auto crossing feature to reduce fuel/energy consumption.

Tersan Shipyard has successfully delivered seven 100% electric ferries to Fjord1 ASA from 2017 until today. Two newly designed ferries NB1113 and NB1114; will be the eighth and ninth vessels which Tersan Shipyard will build for Fjord1 ASA as proof of a long-term cooperation. The latest in this long line of ferries are planned to be delivered in the second quarter of 2023.

CYBER SECURITY PLANNING HELP Security focus for new Installation A new interactive infographic summarises the key Standard considerations owners and operators should make when building a cyber security plan. Educational information

The Shipowners’ Club infographic is based about preventing theft and on the IMO’s recommendation of a cyber security improving vessel security risk management framework based in five has been added to the functional elements: Identify, Protect, Detect, next version of a voluntary Respond and Recover. standard that clarifi es

‘Identify’ - which systems are vulnerable to and defi nes competent attacks, which systems are vital to operations and installation practices. who is responsible for them. The National Marine 5 Protect - the plan should define measures to 8 The ‘MV Neptune Cyber’ ship allows visitors to go on a Electronics Association prevent attacks from taking place. 5 Detect - if an attack does happen, recognising it virtual exploration of a vessel and understand potential cyber risks (NMEA) aims to help prevent the theft of marine electronic can mitigate damage on a virtual exploration of a vessel and understand displays and systems with its 5 Respond - plan a clear means of getting back up potential cyber risks. NMEA 0400 Installation and running as quickly as possible using a second In June 2017, the IMO laid out its ‘Guidelines on Standard. The Installation system. Maritime Cyber Risk Management’. Shipowners and Standard additions describe 5 Recover - get the primary system back running managers now have until 1 January 2021 to build marine electronic display and analyse the cause. cyber risk management into their ship safety installations using specialty initiatives - or risk having their ships detained. security through-bolts and NEPTUNE CYBER TOOL Gwilym Lewis, CEO of Neptune Cyber, said: “Our nuts along with other best Neptune Cyber has also launched a new online tool quick-start guide includes clear action steps to help practice recommendations to ensure marine operators stay ahead of new cyber you prepare for the new IMO regulations. Depending that make removal of a risk regulations that come into force in January 2021. on the complexity of your vessel more steps may be display from the vessel

The ‘MV Neptune Cyber’ ship allows visitors to go needed to adequately protect against cyber attacks.” more difficult.

Photo: Neptune

Steady at sea

Improve your working days

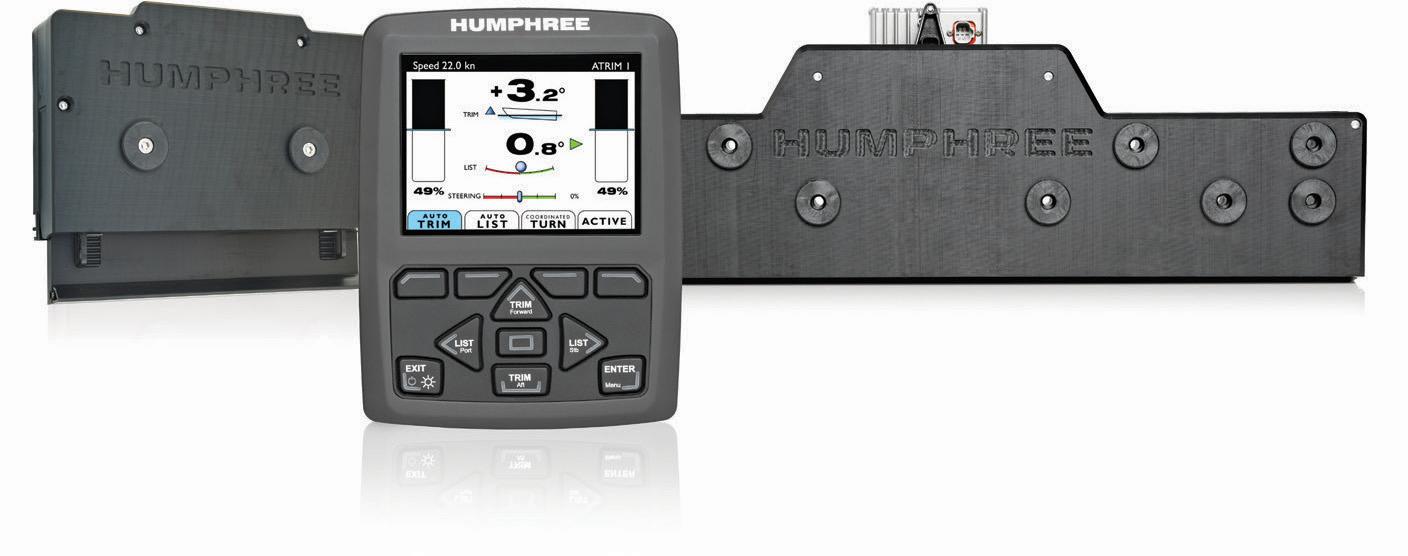

Install a powerful Humphree Stabilization system and working days on the sea will be steadier than ever. Our interceptor system lowers roll and slamming by up to 50%. And it feels like even more. It also reduces resistance. That means lower fuel consumption and less CO² emissions. Easy to install, easy to operate. Premium technology at affordable pricing. Help our planet and ensure a successful mission for you and your crew at humphree.com

For Humphree web page and international dealer network - visit commercial.humphree.com Scan QR code with your phone. We are just one click away.

FOR ALL BOATS, FAST FERRY, PILOT, POLICE, RESCUE, COAST GUARD, NAVY, MONOHULLS AND CATAMARANS.

HYDROGEN ENGINE RETROFIT PAYOFF

One off shore wind crew transfer operator has benefi tted from reduced fuel usage and emissions with catalytic hydrogen technology

Tidal Transit’s off shore wind energy crew transfer vessel Kitty Petra was fi tted with the Ecomotus EcoPro catalytic hydrogen system in 2020 and Leo Hambro, commercial director, believes that the reductions in vessel fuel consumption and CO2 and NOx emissions have been tangible.

“We are very excited to have another ‘industry first’ on the road to decarbonising the marine industry. Ecomotus’s intelligent system has shown that it reduces fuel usage and resultant CO2 emissions by 20% while also slicing 67% of our NOx emissions. It is phenomenal and I only wish we had invented it!,” he said.

CLEVER TECH

Ecomotus is a UK research and development company and its EcoPro system is designed to inject pure hydrogen into the vessel’s engines through the air filter, thereby ensuring a 100% fuel burn in the combustion chamber and a quicker combustion cycle.

Adrian Bartlett from Ecomotus explained that retrofitting the system to Kitty Petra’s MAN engines and its Kohler generator has enabled the company to work closely with Tidal Transit helping its skippers to use the data provided by the system to achieve the best balance of vessel performance and fuel economy.

“Using Kitty Petra’s wi-fi we can monitor the EcoPro system in real time and, if necessary, adjust it to ensure the efficiency of the vessel’s engines.”

“A dashboard is also provided to enable vessel owners or fleet managers to monitor the system’s operation at any time,” he said.

With over 400 CTVs currently operating in the offshore energy marine sector, Mr Hambro has calculated that if each vessel uses approximately 1,500 litres of fuel per day for 250 days per year, a 20% reduction in fuel would save a staggering 30 million litres of diesel (78,000 tonnes of CO2) annually, with over 60% reduction in NOx emissions.

He said: “I believe the Ecomotus system is now ready for mass adoption by the offshore energy crew transfer vessel sector to reduce Scope 1 and Scope 3 emissions and save fuel costs.”

Source: Tidal Transit 8 Kitty Petra was

fi tted with the Ecomotus EcoPro catalytic hydrogen system in 2020

Autonomous ferry charging solution

Two Nowegian ferry connections are being kitted out with autonomous charging solutions.

The electrification of another two Norway ferry connections will be realised thanks to Zinus’ autonomous charging solution selected by the automation group, SEAM.

“Together with Zinus, SEAM has previously delivered charging systems to several ferries. In our opinion, Zinus offers efficient technology with good charging capacity. The Zinus system is also very elegant in appearance and the charging tower’s footprint makes it both easy to place and space-saving on the quay,” said Karl Norheim, project manager at SEAM.

“Furthermore, the solution is very flexible in relation to installation height, which is an advantage in ferry connections with large tidal differences.”

This latest order adds to the company’s order history of supplying electrical charging infrastructure to the ferry traffic along the Norwegian coast. Supply includes four telescopic charging towers of the Charging Telescopic Autonomous type to be installed on the ferry quays, as well as four charging connections to be installed on board the two ferries that operate the fjord crossings.

When combined, the charging tower and connection form an autonomous system that charges electric ferries fully automatically at call. Connecting the ferries to the power supply only takes around 20 seconds and the system can transmit a current of as much as 4,400 amperes. In total, Zinus now has delivered or to order Charging Telescopic Autonomous systems for 24 ferry connections, spread across several nations.

Zinus specialises in the supply and fabrication of handling systems for shore power and charging to a wide on and offshore market.

Source: Zinus

8 The electrifi cation of another two ferry

connections in Norway will be realised with Zinus’ autonomous charging solution

The Fastwater project aims to build on Methanol’s numerous references as a simple to adopt sustainable marine fuel.

The Fastwater Consortium and the Swedish Maritime Administration (SMA) recently successfully demonstrated a pilot boat which has been converted to operate on Methanol fuel.

The demonstration in Stockholm Harbour follows the successful bunkering of the vessel at the SMA pilot station in Oxelösund, Sweden, where the pilot boat will be based.

The event was addressed by Members of the Swedish National Parliament Johan Büser and Anders Hansson who spoke to the importance of alternative fuels like Methanol in reducing carbon and pollution emissions on a local and national basis. Low carbon energy available to shoreside facilities using renewable electricity are hard to replicate onboard ship so for the myriad of small craft - tugs, enforcement vessels, dredgers and pilot boats - other sustainable solutions are needed.

Faced with the problem of needing to cut emissions quickly, port and harbour authorities are examining and investing in methanol as an option that can virtually eliminate air pollution and contribute towards lower carbon.

Methanol single or dual fuel engines are very similar in design to conventional diesel engines with the Methanol fuel supply system designed to meet prevailing safety standards.

The GreenPilot project run by SSPA has demonstrated that it is feasible to convert a pilot boat to methanol operation using available technology. Spark ignited engines with port injected methanol were found to have engine efficiency similar to diesel engines. Emissions reductions were substantial compared to conventional fuel oil.

With funding from the European Commission, Fastwater focuses on high impact outcomes, designing retrofit solutions for existing ships and designs for newbuildings, employing Methanol as a future-proof alternative marine fuel to create a fast track to carbon neutral shipping.

The project aims to commercialize medium and high-speed Methanol-fuelled engines for shipping. Consortium members, including OEMs, shipyards, naval architects, ship owners/ operators, port and maritime authorities, classification, fuel producers, and research institutes, will demonstrate feasibility on three vessels running on methanol fuel: a harbour tug, a pilot boat, and a coast guard vessel.

In addition, Fastwater will provide training programs for vessel crew and portside staff, develop rules and regulations for Methanol marine fuel use and demonstrate the complete value chain for bunkering methanol.

PILOT BOAT SUCCESSFULLY RUNNING ON METHANOL

8 The Fastwater Consortium and the Swedish

Maritime Administration (SMA) recently successfully demonstrated a pilot boat

HYDROGEN PROPULSION SYSTEM LAUNCH

A full scale hydrogen based propulsion system has been launched by Kongsberg

The HySeas III is a tested and verifi ed full-scale, zeroemissions ship drivetrain powered by hydrogen fuel cells.

“With a verified and tested hydrogen-based propulsion system, we take the next step in zero-emission solutions at sea. This project is another example of our world-leading Norwegian maritime cluster succeeding when we face the most demanding technological challenges,” said Geir Håøy, president of Kongsberg.

EU PROJECT

The project is the third and final part of the EU funded project “HySeas” which has been running since 2013 to prepare and demonstrate a scalable hydrogen system for ships and ferries.

In this final stage, Kongsberg has built a full-scale electric propulsion system based on hydrogen-powered fuel cells at Ågotnes outside Bergen. The system will now undertake a four-month testing program for validation purposes with the aim of verifying the final design for an H2-powered RoPax ferry. Testing is intended to demonstrate the ease with which H2 fuel cells can be successfully integrated with a proven marine hybrid electric drive system.

The testing mirrors the operational loads which would be experienced by a vessel on a route between Kirkwall and Shapinsay in Orkney. It will confirm safe operation and power and fuel capacity requirements, together with other valuable information to feed back to the vessel design team at Caledonian Maritime Assets Ltd (CMAL) in Scotland. CMAL plans to complete the design in March 2022. Hydrogen fuel will be generated through wind power at the ferry port.

“If we are to succeed with hydrogen investment in Norway, both to reduce national emissions and create new, green and sustainable jobs, we are dependent on being able to show complete pilots on a full scale,” said Egil Haugsdal, CEO of Kongsberg Maritime. ”This means that the next step will be to show the technology in operation, and then quickly put in place the surrounding infrastructure. Orkney will be the first practical usage of this technology while the Norwegian maritime cluster has the opportunity develop our own pilots and projects here in Norway.”

This project is the third and final part of the EU funded project “HySeas” which has been running since 2013 to prepare and demonstrate a scalable hydrogen system for ships and ferries.

8 HySeas III is

dedicated to the design and manufacture of hydrogen powered drivetrains

Waterjet variant off ered for diesel outboard

8 The OXE Jet-Tech waterjet performance

is claimed to be equal to or better than propeller version Jet-Tech Propulsion LLC has partnered with Diesel Outboards LLC to introduce a highperformance waterjet option for the OXE diesel outboard.

The Jet-Tech unit is manufactured as a direct bolt-on replacement to the standard lower unit on OXE Diesel models by OXE.

It is a single stage compact high performance waterjet which combines mixed-flow properties within an axial design build, with a hybrid stator for high torque diesel outboard engines and others. One jet fits every OXE Diesel model manufactured. This approach is claimed to combine the key benefits of excellent high-speed efficiency with superior cavitation margins at lower speeds and high load conditions.

The Jet-Tech waterjet’s performance is claimed to be equal to or better than propeller versions and is matched 1:1 to the unit horsepower-driven prop outboard. “By using advanced proven waterjet engineering and design capabilities, augmenting the innovative OXE Diesel design, we completely redefined outboard motor propulsion and performance. The Jet-Tech unit is designed to grow with our expanding product line as it is a fully scalable product. The patented design will expand into the vertical shaft diesel/gas outboard waterjet applications and inboard waterjets” said Douglas Natoce, President Jet-Tech Propulsion LLC, and Diesel Outboards LLC

SILENT SAILING THROUGH ANTARCTIC ICE

The new Antarctic Supply & Research Vessel (ASRV) Nuyina for the Australian government has arrived at its home port of Hobart in Tasmania

Bakker Sliedrecht supplied the fl exible electric propulsion

for the special (Damen built) vessel, enabling the Nuyina

to sail both electrically and in hybrid modus and break through the Antarctic ice at full power.

The Nuyina can sail in temperatures of forty degrees below zero and break through 1.65 meters thick ice at a speed of three knots. The name Nuyina is the Tasmanian Aboriginal word for southern lights.

The hybrid propulsion enables the Nuyina to sail in different modes. It can sail entirely on diesel to get from A to B as quickly as possible. Fully electric for quiet and economical sailing or on a diesel engine and an electric motor, where the other diesel engine generates energy. In the icebreaker mode, the diesel engines as well as the electric motors and thrusters can be used at full power. In DP mode, those thrusters hold the ship in position.

Bakker Sliedrecht supplied four water-cooled frequency drives that can be deployed multifunctionally, for the two propulsion motors 3700kW each or for the three thrusters with 1300kW electric motors at the stern, three thrusters with 1300kW electric motors for the bow and two transformers for the Power Take Off/Power Take In system. (PTO/PTI). This generates power for propulsion as well as for other purposes, such as on-board voltage. The thrusters are used for both propulsion and the Dynamic Positioning (DP) system that keeps the ship in position. Bakker Sliedrecht provided training for the Australian crew to help them get to know the installation and to operate all the modes of electric propulsion. Due to the corona measures, the training was given online.

“From the first application in 2013 to completion in 2021, Bakker Sliedrecht was directly involved in every phase of this complex project. The vessel had to be able to sail under very difficult circumstances and heavy weather conditions. It also needed a hybrid propulsion. That made it technically very complex and the project very challenging,” says project manager Arie de Jong of Bakker Sliedrecht. “That is reflected in the construction time. We received the first order in 2016 and it was delivered in the summer of 2021. However, the Nuyina has become a state-of-the-art ship with unique features. We as Bakker Sliedrecht and its project team are proud of that.”

8 Antarctic Supply