5 minute read

Largest convertor

SOLAR PAVING HELPING PORT’S CARBON FOOTPRINT

Spain’s Port of Valencia is trialling new solar panels installed on the ground, claimed to be walkable by pedestrians and vehicles

This initiative opens the door to taking advantage of large port spaces to generate solar energy and positions Valenciaport as a benchmark in SmartPorts.

A total of 24 passable solar tiles have been installed on the north dock of the Port of Valencia with a power of more than 1 kWp in just six square metres of surface area, with an energy production equivalent to half the annual consumption of a three-person household, which will avoid emitting 5.7 tonnes of CO2 per year. “It is one more of the bets that we are developing in Valenciaport in cutting-edge technological proposals that provide the site with green and clean energy in our commitment to decarbonisation, while we support entrepreneurship to act as a catalyst for innovation that generates new businesses and opportunities for young talent,” explained Federico Torres, head of Ecological Transition of the Port Authority of Valencia.

The solar paving has been developed by SOLUM, one of the start-ups selected by the Port Authority of Valencia (PAV) and the Valenciaport Foundation within the framework of the EIT Climate-KIC Accelerator, which responded to the challenge launched by Valenciaport on innovation in photovoltaic installations in ports and which, on reaching phase 3 of the accelerator, has received financial support of 30,000 euros.

SOLUM’s Director of Product and Innovation, Luis Muñoz, indicated that “this solar floor is 100% walkable with a design integrated into the urban architecture that guarantees antislip, with regenerative properties and a greater resistance than concrete that makes it resistant to loads, impacts and scratches. The system generates clean energy thanks to the high-efficiency photovoltaic cells integrated in its interior”.

This innovative photovoltaic solution can be installed both in pedestrian areas and in areas with occasional traffic. These solar panels are much more resistant to erosion and easy maintenance and, in a place like the Port of Valencia, they also have the advantage of being able to produce energy in areas where a panel could not be installed.

8 The solar paving

has been developed by SOLUM

Crane rail extension

DP World has completed its crane rail extension in the Port of Southampton which will allow the world’s largest cranes to service the full length of the quay.

Part of DP World’s £40m investment this year in Britain’s second largest container terminal, the 120m crane rail extension has foundations reaching 26 metres below the ground and took 16 weeks to build. It will facilitate the movement along the quay of some of the terminal’s 12 Liebherr cranes which stand up to 130m high, with flexibility being the highest priority for the equipment. The new configuration is designed to maximise utilisation and will save customers’ time by speeding up quayside loading and unloading.

Together with the granting of permission for a third berth to be dredged down to a depth of more than 15 metres, and the addition of a second empty containers park scheduled for September, the investment will take Southampton up to the next level as a smart logistics hub.

8 The new confi guration is designed to maximise

utilisation and will save customers’ time

GERMANS DEVELOP SMART COMMERCIAL UV SYSTEMS

Two research projects involving the development of autonomous underwater vehicles for commercial maritime applications have drawn attention and offi cial funding in Germany, writes Tom Todd

In Kiel, Thyssenkrupp Marine Systems (TMS) and partners in industry and science have been awarded Government funding totalling €13.2 million for the second phase of the Modifi able Underwater Mothership (MUM) project to develop an unmanned, underwater workboat for commercial use. Total project costs are put at some €35 million with Berlin putting up €22 million.

Handing over the latest funding German Maritime Coordinator Norbert Brackmann said “... Pipelines and cables run on the seabed. Maritime infrastructure needs to be built and maintained. With the MUM vehicles ... this work is safer, faster and also more cost-effective”.

The MUM concept has been under study since 2017 and is seen as setting a new standard for future unmanned underwater work.

It is planned to build and test a modular demonstrator vehicle of about 25m length from 2023. Planned is a system for a variety of civil maritime applications including payload transport and deployment, the exploration of hard-to-reach sea areas like the Arctic, as well as offshore applications.

The planned underwater systems will have electrical main energy and be powered by emission-free hydrogen fuel cells. Where needed, power supply can be supported by a Lithium-ion battery module. Regardless of wind and weather, MUMs will work around the clock and 365 days a year. They will, reportedly, also be tailor-made.

In Wilhelmshaven, scientists at that port city’s Jade University of Applied Sciences have meanwhile unveiled an autonomous underwater vehicle system for commercial use. It has been developed during a four year research project called EITAMS funded with €1.5 million by the Volkswagen Foundation.

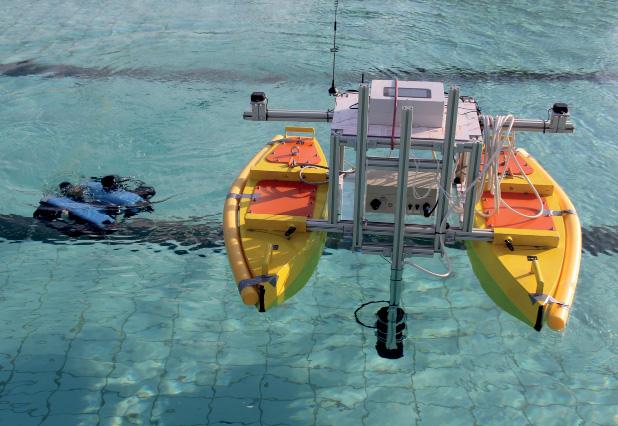

The university said hydraulic structures like port and offshore facilities placed complex demands on maintenance and monitoring which could often be solved with remotecontrolled or autonomous underwater vehicles. It unveiled a test platform based on an autonomously operating surface vehicle which controls a ‘swarm’ of self-drive, interlinked underwater vehicles.

In further research, university departments with differing specialities worked on sub-areas of the main project. One looked at vehicle operation in unknown or hard to reach underwater areas while another developed intelligent strategies for UVs to react to unexpected situations.

8 EITAMS: an

autonomous surface vehicle controls a ‘swarm’ of self-drive, interlinked UVs

Bridge inspection ROV choice

French dams and bridges inspection specialist, IDCBTP, has chosen a Saab Seaeye Falcon ROV for detailed infrastructure examination.

For a clear and accurate analysis of the condition of the structures, IDCBTP’s Falcon is fitted with a range of systems including lasers, multibeam sonar, profiler sonar and navigation and positioning systems.

Precision data collected in this way can identify repairs needed, help maintenance planning and spot trends in structure condition.

Two structures under inspection are the bridge supports for the Pont de la Pyle at Lake Vouglans and the upstream face of the dam structure of the Barrage de Thurins at Rhône.

The Falcon is a small, metre-sized, intelligent, powerful, five-thruster-strong,

8 Falcon inspecting bridge supports at

Lake Vouglans

highly manoeuvrable, multi-tasking and easy to use vehicle, depth rated to 1000 metres.

Enhanced with Saab Seaeye’s revolutionary iCON™ intelligent control system, the Falcon is a future-flexible package designed to adopt evolving technologies.

Saab Seaeye says that with a reliability record covering thousands of hours of operations globally, working in the most challenging environments, including long tunnel excursions, it can remain stable in turbulent waters and strong currents whilst recording and undertaking delicate tasks.