AUTUMN 2023 www.greenport.com

Blowing bubbles Novel pollution prevention

GreenPort Congress | Technology | Pollution| Monitoring

22

14 Cruise Antwerp-Bruges is getting greener on multiple fronts, writes Michele Witthaus

17 Australasia Focus

Australia’s Port of Hastings talks to Dave McIntyre

25 Africa Focus

Shem Oirere looks at how Bujumbura port is mitigating flooding

31 Opinion

Isabelle Ryckbost talks about the EU’s aim to unify emissions counting

39 Alternative fuels

Methanol bunkering; Green hydrogen; Renewables hub

For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 3 CONTENTS NEWS FEATURES REGULARS 46 Global briefing Zero landfill; digital port calls; shore based power 11 Product News Smart port data: electric tug; LNG dredger 12 Port Profile A Q&A with this year’s GPC host, the Port of Lisbon 18 Monitoring PortXchange has a vision to harness the power of data 22 Pollution Frog Environmental explains how bubbles are stopping pollution 26 Technology A closer look at the H2Ports project at the Port of Valencia 32 Monitoring Miros tackles the topic of early oil spill detection 34 Technology PD Ports talks achieving zero emissions port operations

18

14 12 26

EDITOR’S DESK

ANNE-MARIE CAUSER | Editor

Technology - make sure you’re in the driving seat

Technology – it really does control most of our everyday lives now and where would we be without it?

No matter which side of the fence you’re on, like it or loathe it, it’s here to stay and in a very big way. So, there is a very real need to embrace it and make it work for your business.

The ports sector has become much more reliant on technology over the last few decades, but in the last five years this has ramped up, expedited by the need to do business during a global pandemic.

Some of the main drivers towards AI, big data and autonomy, have been the race to achieve efficiency, drive down emissions and embrace the energy transition.

In this issue we look at cutting-edge emissions monitoring, pollution mitigation technology and the future of port equipment, to name a few.

Ocean insights company, Miros, has developed an OSD system with the unique ability to interpret, alert and monitor an oil spill simultaneously.

The system equips users with early detection and mobilisation capabilities, limiting the chance of oil spreading over vast areas and ultimately making them easier to combat.

In this issue, we also chat to PortXchange. Its technology was born out of a vision to harness the transformative power of data using collaborative platforms for both ports and shippers.

PortXchange specialises in cutting-edge data monitoring to enhance ocean supply chain efficiencies while prioritising sustainability, thereby increasing productivity and reducing CO2 and NOx emissions.

Another interesting focus of this issue is how bubble technology is revolutionising pollution mitigation.

Bubble curtains can reduce underwater noise pollution to protect fish and other wildlife and help provide silt, abstraction and inlet protection, as well as litter and weed prevention and emergency aeration.

In this issue we also take a look at hydrogen powered equipment, specifically the work that the Port of Valencia has been doing under the auspices of the H2PORTS project.

The technology it is piloting could well change the face of the port equipment market into the future.

The key take home from this issue should be that when it comes to technology, there is something out there for every operation to drive up efficiency and drive down emissions.

On a final note, the upcoming GreenPort Congress is a great opportunity to network and share lessons learnt with others in the sector. Don’t miss the chance to share and learn a new piece of wisdom for your operation. We’ll see you there.

Share your news with us online by searching @greenportbiz on X and Facebook or email editor@greenport.com

EDITORIAL & CONTENT

Editor: Anne-Marie Causer editor@greenport.com

News Reporter: Rebecca Strong rstrong@mercatormedia.com

Correspondents

Dave MacIntyre, Australasia Shem Oirere, Africa Michele Witthaus, Cruise

Contributors

Adriana Belei, PortXchange Frans Calje, PD Ports Richard Haine, Frog Environmental Isabel Moura Ramos, Port of Lisbon Jonas Røstad, Miros Isabelle Ryckbost, ESPO

Production David Blake, Paul Dunnington production@mercatormedia.com

SALES & MARKETING

t +44 1329 825335

f +44 1329 550192

Media Sales Manager: Arrate Landera alandera@greenport.com

Chief Executive: Andrew Webster awebster@mercatormedia.com

Published quarterly by Mercator Media Ltd, Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD

Tel: +44 1329 825335

Fax: +44 1329 550192

E-mail: sales@greenport.com Website: www.greenport.com

Registered in England Company Number 2427909

Registered office address: c/o Spinnaker House, Waterside Gardens, Fareham, Hampshire PO16 8SD

Subscriptions

Subscriptions@mercatormedia.com Register and subscribe at www.portstrategy.com

1 year’s digital subscription with online access £166.00

For Memberships and Corporate/multi-user subscriptions: corporatesubs@mercatormedia.com

©Mercator Media Limited 2023 ISSN: 2045-6085 (print) ISSN: 2633-4488 (online)

Cover image: Frog Environmental

For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 5

Some of the main drivers towards AI, big data and autonomy, have been the race to achieve efficiency, drive down emissions and embrace the energy transition

‘‘

BRIEFS

DP World launches roadto-rail incentive

DP World has launched a new programme in the UK to help cargo owners reduce their carbon emissions by shifting from road to rail.

The Modal Shift Programme is being trialled at the company’s Southampton Logistics Hub and will pay customers who swap road for rail. DP World hopes the scheme will reduce CO2 emissions by as much as 30,000 tonnes per year.

Mawani and Rotterdam ink smart ports deal

Mawani, the Saudi Ports Authority, and the Port of Rotterdam are joining forces on smart ports, HR, knowledge transfer and commercial opportunities.

The deal will see the two work together on port corporatisation, whereby terminal operations are outsourced to the private sector whilst ownership and regulation remains under government control.

The agreement also includes supporting marine eco systems and a ‘green ports initiative’ aimed at creating economic and social values.

Canadian LNG tug fleet gets an electric boost

Sanmar Shipyards has delivered its second electric tug to HaiSea Marine which will be used to service tankers calling at LNG Canada’s new export facility in Kitimat.

The new ElectRA series harbour tug HAISEA WEE’GIT and its previously delivered sister HAISEA WAMIS, will together make up one of the greenest tugboat fleets in the world.

PORTO ITAPOÁ BECOMES ‘ZERO LANDFILL’ TERMINAL

Porto Itapoá in Brazil has become a ‘zero landfill’ terminal with all solid waste generated by the company now sent for recycling and co-processing.

Key to this achievement is a treatment facility that uses an accelerated composting method to turn the material into fertiliser. More than 13 tonnes of organic waste have been saved from landfill so far.

“In 2023 alone, we generated more than five tonnes of this organic compound,” said Sergni Pessoa Rosa Jr., director of operations, environment and technology at Porto Itapoá.

“The material is distributed to the local community of Itapoá, which uses it as fertiliser for plantations and gardening.”

The treatment process has

The Spanish Government has granted APM Terminals Barcelona €3.9 million for a electrification pilot project which aims to reduce CO2 emissions by 821 tonnes per year.

This pilot project will include the acquisition of five zeroemission electric straddle carriers, four recharging stations, a new IT network and the development of the technology required for operations and recharging of machinery.

“At APM Terminals we are committed to reducing CO2 emissions and we will spare no effort in meeting our 2030 goals,” said Carlos Arias, general manager of APM Terminals Spanish Gateways.

”For us it is very important that this is done in a collaborative way with the governments of the countries where we operate. If there is anything that definitely belongs to all of us, it is our planet.”

Optimising operations

The Port of Barcelona acknowledged the project as essential to making progress in achieving the environmental objectives of the port and the city. It will lower noise levels and

been developed by Organa Biotech, winner of the Supplier Day 2022 Award which celebrates initiatives dedicated to ESG.

Non-organic solid waste is sent for recycling, such as the bricks, cement and pavers which are crushed for use as aggregate. Metallic material gains new life in the foundry and wood, paper and cardboard are also recycled. These initiatives, plus others,

have reduced the port’s CO2 emissions by 17 tonnes and avoided the use of more than 1,200 plastic bags.

Another key initiative is the Menos Um Lixo campaign, which sees the company distribute a retractable and reusable silicone cup to its employees, suppliers and partners, saving 60,000 plastic cups per month in the terminal alone.

BARCELONA PUSHES AHEAD WITH ELECTRIFICATION PILOT

improve air quality due to zero emissions in line with APM Terminals’ overall objective to reduce CO2 emissions by 70% by 2030 and achieve CO2 neutrality by 2040.

The project is also expected to bring benefits in terms of equipment availability, improved maintenance processes and the creation of a cleaner and safer working environment, by significantly reducing the use of oil in daily operations and waste generation.

As well as the fact that the new electric straddle carriers are zero-emission, the electricity contracted by the terminal comes exclusively from renewable sources. This has been the case since 2018 and will continue to be so until at least 2032, according to the latest agreement reached with the distributor.

The Barcelona project is being funded through the Moves Singular Projects II Programme for Efficient and Sustainable Mobility, launched as part of the

Spanish Government’s Recovery, Transformation and Resilience Plan and is financed by NextGenerationEU funds from the European Union.

The cranes are expected to arrive in Barcelona during the third quarter of 2024, with testing to take place until the second quarter of 2025.

APM Terminals is also investing US$60 million on machinery electrification pilot projects across its other terminals in order to futureproof its facilities

NEWS 6 | SUMMER 2023 For the latest news and analysis go to www.greenport.com/news

n Porto Itapoá has become a ‘zero landfill’ terminal

n The Spanish Government has granted APM Terminals Barcelona €3.9 million for a electrification pilot project

Source: Porto Itapoá

Source: APM Terminals Barcelona

Converting a conventional RTG into an electrical one (E-RTG) means to shut down the diesel generator and to power the RTG with electrical power only – the emission saving, sustainable basis for automation. This is possible with electric power solutions, including E-RTG auto-steering and positioning systems, developed by Conductix-Wampfler: Plug-In Solution, Drive-In Solution, Hybrid Solution, Full-Battery Solution and Motor Driven Cable Reel Solution with CAP - Cable Auto Plug-In.

We move your business! www.conductix.com

We add the “E” to your RTG Electrification of Rubber

Gantries

Tyred

E-RTG with Drive-In L Solution and ProfiDAT® E-RTG with Motor Driven Cable Reel Solution and CAP - Cable Auto Plug-In E-RTG with ECO BatteryPack Hybrid Solution

GOTHENBURG WORKS TO CUT EMISSIONS DIGITALLY

Gothenburg Port Authority has started developing an entirely new digital port call solution in order to to reduce 1000 tonnes of CO2 emissions annually.

Designed in collaboration with other maritime operators, the “Digital Port Call” solution will lead to time and cost savings for vessels calling at the port.

“Today, there are numerous contacts that need to be made for a ship to arrive at berth, to load and unload and then depart. This consumes time and creates uncertainty,” said Fredrik Rauer, manager of port control at the Port of Gothenburg.

”Digital Port Call consolidates all communication points into a smooth and efficient chain where predictability for the entire ship call process becomes evident. This is a digital tool that many of us have been waiting for.”

Efficient planning

Through the Digital Port Call tool, all parties involved in a ship’s arrival, from the onboard captain to the harbour crew, will be able to better plan their daily operations and maximise efficiency.

Portsmouth International Port is to spearhead the UK’s move to greener ports with the roll out of shore-based power at three of its busiest berths.

The SEA CHANGE project has received a GB£19.8 million award from the Zero Emissions Vessels and Infrastructure (ZEVI) competition and brings together the port with Brittany Ferries, the University of Portsmouth, MSE International, B4T, IOTICS and Swanbarton to design, build and operate the system.

“Once delivered this revolutionary multi-user, multi-berth shore power facility will be a UK first,” said Stephen Watkyns, technical director at Portsmouth International Port.

“We’ll be able to provide shore power for ships on thee of our berths,” he continued. “This project is another huge step forward for our ambitions to reach net carbon neutral by 2030

“It encompasses everything from booking pilots and tugs, ensuring cranes are in the right position for the vessel, having the port crew ready to receive ropes, knowing the prevailing wind strength, to identifying the vessels in port. Essentially, it ensures that the right information is available at the right time for effective planning of a smooth arrival,” Mr Rauer added.

Digital Port Call is the result of an extended collaboration between the Gothenburg Port

Authority and the Finnish company Awake.AI, which is responsible for developing the service. In 2021, the parties launched a new digital Berth Planner tool, Allberth, to the market.

Now with this new tool, the collaboration aims to digitalise the whole port call.

From the ship’s departure from the previous port until it arrives, a plethora of information influences the voyage and needs to be communicated. In total, this involves nearly 120 different stakeholders that need to be synchronised in some way.

The tool allows captains to receive a comprehensive overview of the route to the Port of Gothenburg up to 36 hours before departure. Through a digital port call arrival declaration and its confirmation, speed into the port to minimise emissions and avoid anchoring and waiting for an assigned berth.

The Digital Port Call service is a crucial component of the Port of Gothenburg’s vision to lead in digitalising the entire logistics chain from sea to inland via the port.

PORTSMOUTH SPEARHEADS SHORE-BASED POWER

good neighbours to those who live and work around the city as soon as these vessels arrive in 2025,” said Christophe Mathieu, chief executive of Brittany Ferries.

“We are delighted that our forward-thinking partners have pushed to so hard to make this happen and are proud to contribute to wider emissionreduction goals.”

A game changer in electric vessel charging?

Crowley and the Port of San Diego have designed a new shoreside charging station to provide clean energy for the company’s forthcoming zeroemissions tugboat.

The charging station for the first all-electric tugboat in the United States, represents a significant step forward in the industry’s journey to decarbonisation and reduce emissions in the San Diego community.

Spanish port rolls out biofuels for ferries

Biofuels produced from agricultural waste will fuel passenger ships from the Spanish port of Algeciras across the Strait of Gibraltar.

It is the first time that Spanish passenger vessels have used this kind of fuel, which is known as second-generation biofuel, produced by oil and gas firm Cepsa.

“We continue to promote sustainable mobility as one of the pillars of our strategic growth,” said Samir Fernández, director of Marine Fuel Solutions at Cepsa.

Patrick Terminals hybrid straddle carrier order

and eliminate emissions by 2050.”

Shore-based power will save more than 20,000 tonnes of CO2 emissions per year from 2027, says the south coast port, and help realise the potential of two new Brittany Ferries LNG-electric hybrids which will begin sailing from Portsmouth in 2025.

“Shore-side power in Portsmouth means we can be

Funded by the UK government and delivered in partnership with Innovate UK, ZEVI is part of the UK Shipping Office for Reducing Emissions (UK SHORE), a new unit in the Department for Transport focused on scaling up clean maritime technologies. It has a current budget of GB£206 million, of which GB£80 million has been allocated by ZEVI to ten flagship R&D projects.

Kalmar is to supply ten new hybrid straddle carriers to Patrick Terminals in Melbourne, Australia.

The order was booked in Cargotec’s 2023 Q3 order intake, with delivery of the machines scheduled to be completed during Q1 of 2024.

Patrick is the first terminal in Australia to invest in the Kalmar hybrid straddle carriers.

For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 9 BRIEFS NEWS

n Through the Digital Port Call tool, all parties involved in a ship’s arrival will be able to better plan their daily operations

Source: Port of Gothenburg

n A ‘green revolution’ is beginning at Portsmouth International Port

Source: Portsmouth International Port

NEW TECH BRINGS SMART PORT AND SHIP DATA TOGETHER

A new product links sleek shipmanagement operations with a comprehensive data platform, to drive up efficiency and reduce emissions for both ports and ship operators.

Port State Control (PSC)

Submission API is a result of a collaboration between RightShip, NYK and Solverminds, which links NiBiKi, the NYK Group’s common platform for ship-management operations, with RightShip’s data platform.

“The PSC Submissions API is a simple but important innovation, designed to address a significant issue for ship managers: the inefficient system that requires them to manually pass data through separate systems,” said Christopher Saunders, chief product officer at RightShip.

”Our API can drastically improve workflow for ship owners and managers – allowing them to make quicker and better decisions during their pursuit of zero harm operations.”

Damen Group’s zero emissions electric tug Sparky has been nominated for the Ship of the Year Award.

Sparky is the result of six years of collaboration between Damen and Ports of Auckland Limited (POAL) in a quest for a sustainable, zero-emissions tug suitable for New Zealand’s unique environment.

“It has been a long time in the making and many parts of Damen have contributed to its development, alongside POAL,” said Erik van Schaik, product manager tugs at Damen.

“We believe that its introduction heralds a new chapter in harbour towage and a milestone in sustainable shipping.”

Tug milestone

Delivered last summer, Sparky is Damen’s first, fully-electric tug capable of 70 tonnes bollard pull that can undertake two or more assignments at full power before being recharged.This takes just 1.5 to two hours.

The key challenge for Damen

Efficiency benchmark

Initially launched on RightShip’s e-commerce platform RightSTORE, the new technology is designed to share data across both RightShip’s and NYK’s platforms.

The product integrates a ship manager’s ERP system directly into the RightShip platform using an API data flow. This can save hundreds of man hours of manual data entry and significantly improve efficiency across ship management groups of all sizes.

PSC API enables users to instantly submit and receive PSC inspection and deficiency data without the need to switch between separate platforms.

It also enhances transparency within a ship manager’s workflow by giving users full visibility over their pending PSC deficiencies. This enables them to make quick, informed decisions.

The new technology will compliment RightShip’s portfolio of tools available to shippers and ports designed to help them

Port of Santos moves to electric cranes

DP World is accelerating its adoption of renewable energy at the Port of Santos in Brazil with electrification of the terminal’s rubber tyred gantry (RTG) cranes.

lower their carbon footprint and meet sustainability goals.

The GHG Rating, for example, gives ports and terminals a quick way to assess the emission profile of a vessel calling at their port and to develop strategies to reduce total emissions produced during daily operations.

Port operators can use the tool to measure a vessel’s relative efficiency and upgrade their sustainability programmes, reduce emissions in and around their ports and help strengthen their market position.

SPARKY ELECTRIFIES THE TOWAGE SECTOR

directly connected to the propulsion system.

A total of 22 dieselfuelled units will be electrified by the end of next year, at a cost of more than US$16.2 million.

Peel Ports welcomes LNG dredger

Peel Ports Group has welcomed its first ever energy-efficient LNG dredger.

Van Oord’s groundbreaking Vox Apolonia will be used for maintenance dredging at the Port of Liverpool and King George V Dock in Glasgow.

It is the first time the LNG trailing suction hopper dredger has been used at any of the group’s ports, and only the second time it has carried out work in the UK.

was how to install all the equipment for the E-Drive into a hull just 24 metres in length, with one of POAL’s requirements being that that the vessel should be operable by two crew. This along with a range of other capabilities was achieved through mutual cooperation and continuous two-way communication between the two parties.

The solution was to have four identical and independent battery packs, each in its own insulated, temperaturecontrolled battery chamber and

The battery packs are designed to have a life equal to or longer that of the tug itself; 30 years or 30,000 cycles. Another advantage of having a dispersed energy source is that the propulsion system can be scaled up or down and it will be used in other Damen tug types, both larger and smaller.

Sparky brings with it all the benefits of Damen’s proven RSD Tug 2513 series. These include always ‘bow first’ operations and its Damen-patented twin fins skegs give it excellent manoeuvrability and stability despite its small length to width ratio.

Other features include having the complete superstructure spring-mounted on the hull. This results in low noise and vibration levels in the accommodation and wheelhouse.

A greener spill management solution?

A new eco-friendly absorbent, which is suitable for both marine and land, is being used at an American port authority.

FlashDry is a spill containment product, manufactured by EarthSafe Chemical Alternatives, which works for all types of spills including chemicals, biohazards and hydrocarbons.

“When developing new products, efficacy and efficiency are always primary objectives but, safety is penultimate,” said Kurt Wong, EarthSafe COO.

For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 11 NEWS BRIEFS

n A new product links sleek shipmanagement operations with a comprehensive data platform, to drive up efficiency and reduce emissions for both ports and ship operators

Source: Damen

n Sparky is the result of six years of collaboration between Damen and Ports of Auckland Limited (POAL)

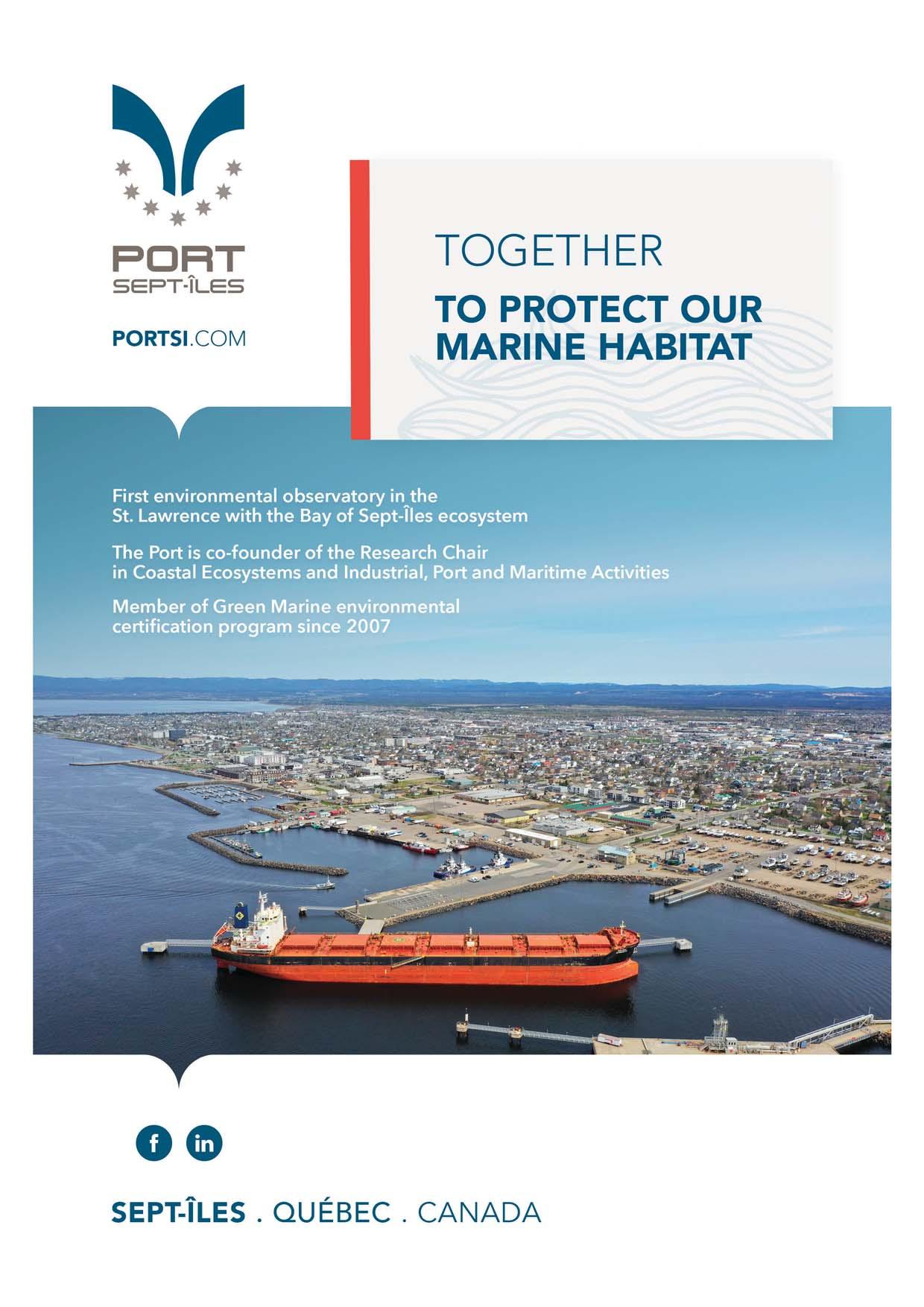

DEVELOPING A GREEN SMART AND RESILIENT PORT

GreenPort sits down for a Q&A with Isabel Moura Ramos, board member, Port of Lisbon, as this host for GreenPort Congress and Cruise

Q As this year’s host port, why do you think Lisbon is the right choice to hold the conference this year?

A The Port of Lisbon is a vast port, located in the Tagus estuary which, not only is the centre of the largest and most densely populated metropolitan area of Portugal, but also holds significant nature conservation values and cultural heritage interests, due to its ancient origins.

Located in the capital and neighboring cities and bordering 11 municipalities, the port must tackle several environmental, social and economic challenges.

More than half of the port area is in the Natura 2000 Network, where we intend to develop inland navigability in the Tagus estuary, one of the most emblematic projects of the port aiming to mitigate carbon emissions.

In addition, large operational port areas are located within urban areas with heritage protection status, which requires increased investment efforts towards reconciling the port with the environmental and municipal and citizen interests. Strong investments are being made in environmental monitoring and actions to give the port a benchmark of high environmental quality.

Moreover, occupying an area of the globe which is very susceptible to the effects of climate change, the port is continuously being forced to invest in adaptation to become a more resilient port.

In 2023, we are developing a significant set of projects beyond the inland navigability of the Tagus estuary, such as Onshore power supply (OPS), the production of electricity from renewables, the accelerator of the blue economy, and so on.

We consider these excellent reasons to host an event like the GreenPort Congress that will allow us to show the work and projects that we have been developing with our partners and help us celebrate the 136th anniversary of the Port of Lisbon Authority.

Q In terms of your own environmental objectives what are you striving for in the short and longer term?

A The European Green Deal and the whole legislative train/package it has been delivering, requires a systematic approach to ESG issues so, in 2022, the Port of Lisbon joined the UN Global Compact, to align the port strategy with the Ten Principles and the UN Sustainable Development Goals

In environmental terms, our main goal is to develop a green, smart and resilient port. Our main focus is nowadays on reducing CO2 emissions and improving air quality

in operational areas.

We have already started the energy and digital transition with our partner Liscont, which is making major investments in the modernisation of the Alcântara Container Terminal, by reorganising the entire container park to improve operational efficiency and retrofitting and installing new electrical equipment.

We’ll also proceed with the installation of OPS at the Lisbon cruise terminal and four more cargo terminals in the eastern area of the port and with the improvement of the conditions for inland navigation of the estuary. This will allow us to reduce the impact of the port on air quality and to transfer cargo from road to barges reducing the number of heavy vehicles with containers crossing urban roads between the terminals in Lisbon and the logistics areas located upstream.

We will maintain and increase the ongoing environmental monitoring effort , especially with regards to the monitoring of dredging and cruise activity and we will start the production of energy from renewable sources.

Our effort to fully integrate the port in the urban surroundings involves the reallocation of port areas, which involves continuous work with the municipalities. We have several redevelopment projects for the areas of Alcântara, Santos and Pedrouços.

The latter, will create a new centrality in Lisbon and Oeiras with a highquality hub for blue economy – the Ocean Campus.

We are in the process of

PORT PROFILE 12 | SUMMER 2023 For the latest news and analysis go to www.greenport.com/news

Source: Juntas/Wikipedia CC BY-SA 3.0

n Mr Carlos Correia, chairman of the board, Port of Lisbon

n Partnerships for energy and digital transition in the port have started with the modernisation of the Alcântara Container Terminal

improving the recreational ships repair park located next to recreational docks in the UNESCO cultural heritage area of Belém. In the eastern port areas, where the municipality of Lisbon is undergoing huge urban interventions, we intend to qualify all terminals (including green clauses in the new concessions) and the access to the port. We will build a new port gate and improve road access and parking contributing to high-standard landscape integration in the city.

Q What green projects are currently underway at the port?

A Right now, we are particularly focused on energy and digital transition.

The main projects under development are the inland navigability of the Tagus estuary, OPS, the Ocean Campus and the production of energy from renewable sources. We are looking to the creation of a community renewable energy hub to which we hope several of our partners will join in the future.

In addition, we are working on future digital monitoring of the port - we aim to start with environmental monitoring, production and consumption of electricity to later develop a port digital twin.

Q What projects are next for the port, including alternative fuels?

A In terms of energy and digital transition we are building a roadmap for future investments. Naturally, this roadmap is based on the above-mentioned projects, but we intend to actively seek partnerships to develop innovative projects in these areas.

We are already starting with the creation of a blue economy innovation accelerator program in the Port of Lisbon in partnership with the Ocean Forum and through which we will host a pilot project of innovative urban wind turbines.

The port has also started a pilot project with Repsol in order that the port authority fleet is operated on greener fuel, we hope that we will see the impact of this pilot in 2024. At the same time, we are constantly seeking partnerships to develop R&D projects that promote the increased resilience of the port.

Q What messages are you looking to deliver to the industry at the GreenPort Congress?

A The main message we want to deliver is that sustainability is the only way forward for ports that want to survive. At the current time, energy and digital transition are among the prime issues to be addressed. And we believe that the establishment of partnerships and innovative collaborations are crucial for the overall sustainability success of Port of Lisbon.

Q Why is it so important in your opinion to attend the event?

A As our chairman of the Board, Mr Carlos Correia, says: “To host the GreenPort Congress & Cruise conference in Lisbon is a unique opportunity to gather the port community together to discuss port sustainability issues and to showcase the Portuguese practice and expertise in the transition to a greener, digitalised and decarbonised port ecosystem.”

Q Can you give us some facts and figures on how these projects have impacted efficiency and emissions at the port?

A The pandemic has introduced a huge distortion in the emissions statistics therefore we have not yet been able to get the true dimension of its impacts.

In Portugal, a lockdown policy was adopted during the pandemic that has drastically reduced travel and transferred part of the energy consumption associated with economic activities.

For example, regarding energy consumption, the resumption of office work in 2022 led to a growth of about 1.5% in total energy consumption, compared to 2020 and 2021. Electricity consumption increased by about 7.5% but this was offset by around a 10% reduction in fossil fuel consumption in fleets and heating. The reasons for these figures may be, not only the increase in office occupancy but also in the number of trips made with the electric vehicles in our fleet, most of them acquired in 2019, just before the lockdown.

In terms of CO2 emissions, the increase in energy consumption has not been accompanied by an increase in emissions. In fact, preliminary data points out a significant reduction of CO2 emissions, mainly due to the supply of greener energy from the current electricity operator.

The conference will cover a wide range of themes and will be an opportunity to bring together the whole port community, working as a platform for exchange of information on the latest in sustainable environmental practice.

We are looking forward to welcoming the port community to Lisbon for the Greenport Congress & Cruise 2023 and we believe it will be a success.

PORT PROFILE For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 13

n A new centre is being created in Lisbon and Oeiras with a high-quality hub for blue economy – the Ocean Campus

Source: Port of

‘‘

Sustainability is the only way forward for ports that want to survive. At the current time, energy and digital transition are among the prime issues to be addressed. And we believe that the establishment of partnerships and innovative collaborations are crucial for the overall success of Port of Lisbon.

FOCUSING ON FUTURE FUELS TO TARGET ZERO EMISSIONS

Located on the coast of Belgium between Northern France and the Netherlands, Zeebrugge is an established port of call in a multitude of Western and Northern European cruise itineraries and is of special interest to travellers wishing to explore the history and culture of Flanders and Brussels.

As well as longer multi-country cruises, the port attracts ships on mini-cruises from the UK. Zeebrugge’s cruise operations are managed by the Port of Antwerp-Bruges, which welcomes around 180 cruise ships and 400,000 passengers each year.

Taking all its emissions into account, from its cargo operations as well as the passenger shipping sector, the Port of Antwerp-Bruges has stated that it plans to reduce CO2 by 35% by 2025 compared with 2005 levels, with the reduction reaching 55% by 2030.

Energy transition

To advance its strategy of reducing ship-related emissions, the port plans to introduce onshore power supply (OPS) at the beginning of 2026.

“By 2028, the planned OPS connection will be reinforced to provide 16 MVA of power capacity,” says Piet Vandenkerkhove, Account Manager Cruises at Port of Antwerp-Bruges.

“We offer LNG and bio-LNG bunkering (ship-to-ship and truck-to-ship), which can already reduce CO2 emissions compared to conventional fuel oils.”

”Besides, we are also focusing on preparing our port for the multifuel future where multiple renewable fuels like methanol or hydrogen will be available and bunkered at our port (for the port as a whole, not only the cruise sector).”

To enable the cruise side of the business to achieve its targets in this context, the port is investing in plans to provide sustainable cruise operations going forward, with a strong focus on future-proof fuels.

“Our goal is to be ready to offer alternative fuels at scale in the future (hydrogen, methanol and e-LNG),” says Mr Vandenkerkhove. “Zero emissions at quay and on the terminal is the ambition. This also involves further electrification of all rolling stock on the terminal.”

Other emission-reducing moves include the planned introduction before the end of 2023 of a battery electric shuttle bus to bring cruise passengers from the gangway to the terminal building (and vice versa).

The port is also taking various actions to streamline cruise calls, with a particular emphasis on efficiency. “The introduction of new (wider) fenders will make calls more efficient,” says Mr Vandenkerkhove. “Up to now, loading and unloading of luggage, waste and stores was very difficult because of lack of space between the ship and the quay wall.”

Changes afoot?

Some established European cruise destinations experienced record high temperatures during the recent summer season, leading cruise lines to change their itineraries in the worst-

affected areas.

This is driving opportunities for ports that can adapt to different patterns of calls, as Mr Vandenkerkhove explains. “We are witnessing a seasonal shift of deployment of cruise ships. The weekly winter calls (October through March) of AIDA Cruises and MSC Cruises ships are a good example.”

There are also indications that some cruises will move away from the warmer Southern Europe itineraries that have

CRUISE 14 | SUMMER 2023 For the latest news and analysis go to www.greenport.com/news

The Port of Antwerp-Bruges is working towards greener operations on multiple fronts to tackle the environmental, social and economic impacts of cruise operations, writes Michele Witthaus

n An aerial view of the Port of AntwerpBruges

‘‘

The port is investing in plans to provide sustainable cruise operations going forward, with a strong focus on futureproof fuels.

Source:Port of Antwerp-Bru -

Source:Port of Antwerp-Bru -

n City view from Het Steen terminal in Antwerp City Port

been in place for many years. “If the heating up of the Med area continues, new opportunities may arise from cruises operating further North during the summer months.”

Increasingly, the social impacts of mass tourism and ‘overtourism’ are concerning to cruise ports in or near hightraffic destinations. The Port of Antwerp-Bruges is working to reduce the pressure of tourism in the main destination of Bruges, says Mr Vandenkerkhove.

“We limit the number of simultaneous cruise calls to two ships per day. On a total of 180 calls per year, we only have about 25 days with two ships. We actively promote off-season cruise calls to obtain a better spread of tourists throughout the year.

“A well-considered berthing policy should keep cruise tourist flows within acceptable limits in order not to become a burden for the main destination. Opening up the touristic hinterland to destinations off the beaten track is a challenge but will be beneficial to a better spread of tourists.”

Globally, breaking news about the cruise business is more quickly and widely publicised than ever, thanks to the ubiquity of social media. In this context, Mr Vandenkerkhove says that good data management and communication is crucial.

VIPs

Easy access to amenities is of particular value to an oftenundervalued category of people spending time in port: Ships’ crew.

For the Port of Antwerp-Bruges, crew members are an important and valued visitor category.

“A ship’s crew can be an ambassador for a port,” says Mr Vandenkerkhove. “Every port should consider providing them with free or affordable services based on their needs, including wifi, a crew lounge, specialty food shops and transport arrangements.”

“The importance of providing correct data to (mainly political) stakeholders cannot be over-stressed. Negative news spread by some is often picked up by mainstream media and reaches the general public easily, even though many assumptions are based on perception rather than facts.”

Communication with partners and stakeholders is a major focus for the port.

“Regular concertation with all actors involved in the landside aspects of cruises is a must,” says Mr Vandenkerkhove. “It is also a way of keeping them updated about a continuously changing industry. The port authority plays a crucial role in conveying the concerns between the land side and the cruise lines. Improvements and solutions are only durable if they are supported by the port, the inland destinations and the cruise lines.”

Growing green cruise operations at Antwerp City Port

Antwerp welcomes around eight hundred river cruises and thirty sea cruise ships annually. Antwerp City Port manages the cruise operations at the city’s Scheldt Quays and the new terminal at Het Steen.

Over the entire urban port area of Antwerp, there is maximum capacity for a total of 40 river cruise ships with an overall length of up to 135m and one sea cruise ship with a maximum length of 265m. At the latter berth, vessels are moored on a purpose-built floating pontoon with a connection to the main terminal building.

“River cruise ships can dock at various locations spread throughout the urban port area and the Scheldt Quays in accordance with the ‘City port plan 2020-2030’, the policy vision of the city as far as shipping is concerned,” says City Harbourmaster Werner Weijts. “Reconciling the various functions of urban areas is one of the key tasks in this regard: habitation, tourism, and economic activities.”

Alternative power Sustainability is an important part of the plans for the port and onshore power supply is currently provided at Kattendijkdok, the operating base for river cruise ships in the port. The city of Antwerp has committed to additional locations for the rollout of shore power for river cruise ships, including the Scheldt quays, with full implementation due to take place before 2030.

In addition to offering alternative power sources to as many vessels as possible, the port is keen to attract ships that are cleaner by design. “The new ships are invariably equipped with stage V engines (new standards in Europe),” says Mr Weijts.

“The city can also boast that most of the river cruises that dock in Antwerp hold a gold or silver, Green Award certificate for inland shipping.”

Reconfiguration of facilities at the port in recent years has included the development of a new cruise terminal and visitor centre located at Antwerp’s oldest building, Het Steen.

The City’s Vice Mayor responsible for tourism, Koen Kennis says: “Our brand-new cruise terminal opened in 2020 and allows us to welcome vessels and passengers in the most comfortable, safe and durable ways possible.”

”All major attractions are located within walking distance from the terminal. By offering these advantages we are happy to see the large majority of passengers prefer to spend the day in Antwerp, rather than hop on a bus and visit other destinations.”

Going forward, Antwerp City Port will focus on attracting cruises in the premium and luxury end of the market.

The economic and social sustainability benefits that such ships bring to Antwerp and the higher number of people exploring the city during calls, are important factors in this strategy.

“The average number of passengers aboard a river cruise is one hundred and forty, while for a sea cruise ship it averages six hundred for Antwerp,” says Mr Weijts.

CRUISE For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 15

In addition to offering alternative power sources to as many vessels as possible, the port is keen to attract ships that are cleaner by design

‘‘

Source:Port of Antwerp-Bruges

n The Port of Antwerp-Bruges welcomes large cruise ships such as MSC Cruises Virtuoso

HASTINGS EARMARKED TO SUPPORT OFFSHORE WIND

Australia’s Port of Hastings has been chosen as the ideal location for the Victorian Renewable Energy Terminal to facilitate offshore wind assembly, writes Dave

MacIntyre

The terminal is a key requirement to help achieve the Victorian State Government’s commitment to delivering 9GW of offshore wind energy generation capacity by 2040 and will bring economic benefits and jobs to local communities.

If approved and subject to required approvals, the Renewable Energy Terminal will be capable of supporting offshore wind delivery of up to 1GW per year, placing Hastings at the centre of Australia’s offshore wind construction and deployment.

Offshore wind is deemed as crucial to support Victoria’s energy transition. The state has set ambitious targets of 2GW of offshore generation by 2032, 4GW of offshore wind capacity by 2035 and 9GW by 2040. Developing specialised port infrastructure is critical to achieving these targets.

Good choice

There is no port in Victoria that is currently suitable to support offshore wind construction. The Port of Hastings has been selected for the future establishment of the terminal following an extensive technical review and engagement with key stakeholders including offshore wind developers and ports.

Hastings has attributes that make it an ideal location for offshore wind assembly, including large areas of available land close to deep water channels, proximity to existing port precincts, and to proposed offshore wind farms off the Gippsland and Portland coasts.

Offshore wind components are very large and heavy, placing unique operational requirements on ports, including the need for heavy-duty pavement strength and significant areas of land adjacent to available berths.

Locating offshore wind assembly at the port will also allow easy access to industry and workforces in the surrounding regions.

The area identified for the establishment of the terminal is

the Old Tyabb Reclamation Area (OTRA), located within the port precinct between Esso’s Long Island Point and BlueScope Steel. The OTRA site is located within an existing port zone. The development would see the site transformed into a multi-user facility with new landside infrastructure and berths adjacent to the existing shipping channel.

Next steps

The Port of Hastings Corporation (PoHC) has submitted environmental referrals to the Victorian and Australian governments, an important first step in defining the requirements PoHC will need to meet, to receive state and federal government approvals.

One referral has been submitted to the Victorian Government under the Environment Effects Act 1978 to determine if an Environment Effects Statement is required for the terminal project. It is anticipated that an EES will be required. The PoHC has begun some environmental monitoring which will inform the preparation of the EES. Subsequently, a set of scoping requirements for matters to be investigated and documented for the EES will be issued in draft and made available for the public to comment.

In addition, PoHC has submitted a referral to the Australian Government which will determine whether the project will require formal assessment and approval under the Environment Protection and Biodiversity Conservation Act 1999. This will also be open for public comment.

The port has begun an extensive community and industry consultation process and will continue to engage with traditional (indigenous) owners, local communities and interested stakeholders as the project progresses.

Opportunities for stakeholder input to improve the overall design and ensure it meets community expectations will be available on multiple occasions throughout the planning and design phase.

AUSTRALASIA FOCUS

For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 17

n An aerial image showing the Old Tyabb Reclamation Area (the green field between the two jetties) which is the proposed location of the Victorian Renewable Energy Terminal

Source: Port of Hastings

‘‘

Hastings has attributes that make it an ideal location for offshore wind assembly, including large areas of available land close to deep water

HARNESSING THE TRANSFORMATIVE POWER OF DATA

PortXchange was born from a vision to provide the maritime industry with digital solutions for predictable and sustainable shipping, says Adriana Belei, PortXchange

Its fundamental principles are deeply grounded in leveraging cutting-edge data science to enhance maritime operations, while prioritising sustainability, thereby significantly increasing productivity and reducing emissions.

This is particularly crucial for coordinating Just-in-Time arrivals through our Synchronizer platform and offering effective emission monitoring solutions with EmissionInsider. In doing so, we aim to become a vital facilitator in the maritime industry, not just as a solution provider but as a collaborative partner working toward a more efficient and sustainable ocean freight ecosystem.

Global potential

Tracing back to our origins, PortXchange evolved from Pronto, an innovative port call optimisation platform pioneered by the Port of Rotterdam in 2018. Witnessing its tangible impacts and after the success of comprehensive trials, there was a unanimous agreement on the potential this platform could offer globally.

This led to the birth of PortXchange in 2019 as an independent entity, aiming to share this vision with ports worldwide. The traction has been exceptional, with over 50 stakeholders leveraging our platform to optimise more than 100,000 port calls.

One example is historically, ports operated on the ‘firstcome, first-served’ principle, which, while straightforward, often led to operational delays and an inflated carbon footprint. A paradigm shift is possible with meticulous monitoring: Ports can transition to a data-centric model, optimising port calls and minimising unnecessary idling, thus reducing fuel consumption.

Moreover, the value of precise emission monitoring is manifold. It paves the way for a well-documented emissions inventory, giving ports a wealth of insights. By harnessing this data, ports can make decisions that optimise their operations and make themselves decarbonisation hubs, making them more attractive to eco-conscious businesses and supply chain partners looking for clean shipping.

n Beyond just providing insights into the emission level, EmissionInsider serves as a strategic guide assisting ports, especially regarding emissions from ships, trucks and rail.

Monitoring isn’t just a procedure; it’s a cornerstone of ensuring environmental sustainability for ports and terminals around the globe. With the maritime sector standing resolutely to decarbonise and meet or better the International Maritime Organization’s (IMO) rigorous emission reduction targets to undertake the journey toward these ambitious benchmarks, one must first understand where they are starting.

This is where the importance of real-time and accurate monitoring comes to the forefront. By embracing the digital transformation wave, ports are increasingly leveraging innovative platforms like PortXchange’s EmissionInsider and Synchronizer to gain this essential opening benchmark. These platforms centralise data in real-time, providing the starting points and bringing to the fore a host of opportunities for change.

The benefits of such platforms don’t just stop at environmental positives; they present immediate and scalable solutions that strike right at the heart of maritime decarbonisation while ensuring cost-effectiveness.

Beyond operations, ports are intricately woven into the fabric of local communities. Their actions, or the lack thereof, directly affect the health and environment of their and neighboring regions. By actively diminishing emissions, ports ensure a cleaner, healthier atmosphere for all.

Looking into the horizon, the path forward for ports is unmistakably green. A rigorous commitment to monitoring positions them not just as trade hubs but as decarbonisation hubs, the vanguards of sustainable progress. They must do so with an unwavering commitment to the planet and its people.

Practical solution

In the changing dynamics of the maritime industry, EmissionInsider offers a practical approach for ports aiming for zero emissions.

Beyond just providing insights into the emission level, it serves as a strategic guide assisting ports in making both environmentally and economically informed decisions, especially regarding emissions from ships, trucks and rail. Distinguishing itself from other generic solutions, EmissionInsider employs a nuanced three-step method designed to address each port’s individual environmental and financial intricacies.

MONITORING 18 | SUMMER 2023 For the latest news and analysis go to www.greenport.com/news

Source: PortXchange

Looking into the horizon, the path forward for ports is unmistakably green.

‘‘

A rigorous commitment to monitoring positions them not just as trade hubs, but as decarbonisation hubs

At the heart of any effective change strategy is a thorough understanding of the status quo. EmissionInsider immediately undertakes an exhaustive emissions analysis. This process meticulously identifies emission hotspots’ primary contributors, spanning all transport types and activities. In doing so, it lays the bedrock of data that is pivotal for any substantial decarbonisation move.

Stage one is the evaluation stage, or emissions strategising phase.This phase leverages the intelligence accrued from the assessment stage. Here, EmissionInsider creates a precise emissions inventory, the catalysis upon which operational and strategic decarbonisation pathways are identified.

What distinguishes EmissionInsider is its ability to enable ports to simulate their own decarbonisation scenarios. From data points provided by EmissonInsider, ports are able to create their own “what-if” scenarios over time, enabling them to look at each strategy’s environmental, fiscal and logistical implications. For instance, on the operational front, ports are presented with innovations like Just-in-Time (JIT) arrivals induced port fee structures.

Such incentives coax vessels to streamline their timings, effectively minimising idle durations and, by extension, emissions. Further, ports can also dive deep into the potential ripple effects of transitioning to greener fuel options, electrifying operations, or integrating state-of-the-art shore power mechanisms.

Parallel to this, PortXchange is not resting on its laurels with EmissionInsider. The company recognises that as the maritime environment evolves, so must the solutions that serve it. Hence, it is perpetually enhancing the capabilities of EmissionInsider with a vision to ensure that this tool remains the gold standard in aiding ports worldwide as they chart their pathways to strategic decarbonisation.

In the unfolding narrative of emission monitoring, the chapters ahead promise profound technological leaps and methodological refinements. The direction we’re headed in essentially traces back to the proactive commitments made by port authorities to solutions that champion decarbonisation.

n From data points provided by EmissonInsider, ports are able to create their own “what-if” scenarios over time, looking at environmental, fiscal and logistical implications

Secondly, there is the implementation phase - or the journey to zero emissions. Post evaluation, EmissionInsider doesn’t merely hand over a blueprint and recede into the background. Instead, it sits alongside ports in its decarbonisation journey.

A robust sustainability strategy is unfurled, and its efficacy is continually gauged through persistent data monitoring and reporting, all benchmarked against the initial assessment data. This iterative approach ensures that ports remain agile, recalibrating their strategies in real-time, keeping them at the forefront of sustainable maritime operations.

In a marketplace inundated with solutions, EmissionInsider stands out. Its holistic, customised approach and commitment to drive tangible change make it an indispensable ally for ports, fervently charting a course towards a greener, more sustainable maritime future.

Into the future

Standing still is equivalent to moving backwards in the fastpaced realm of maritime operations. PortXchange, fully aware of this adage, is gearing up with fresh endeavours to enhance the operational prowess of shipping conglomerates. Their ambition is clear: to be at the forefront of driving efficiency while reducing the environmental footprint.

A flagship initiative in the pipeline is facilitating operational enhancements, including Just-in-Time (JIT) arrivals. This strategy directly resonates with the maritime world’s larger goal of reducing emissions. The premise is straightforward: If vessels can time their arrivals to dovetail seamlessly with port readiness, the idle time — and consequently, emissions — can be substantially minimised.

Future ports won’t merely be data collectors. Instead, they’ll evolve into analytical powerhouses, capturing nuanced emissions information with a precision hitherto unseen. The depth of this data will illuminate not just the ‘what’ but the ‘why’ and ‘how’ of emission trends, paving the way for more granular insights.

More intriguingly, ports are poised to harness the prowess of predictive analytics. Gone will be the days of mere retrospection. The modern port will forecast and simulate the environmental repercussions of potential actions, giving them a window into the future. This crystal ball, so to speak, will empower them to foresee the consequences of their decisions, allowing for preemptive measures to mitigate negative impacts.

The horizon promises a paradigm shift from passive monitoring to proactive, predictive analysis. This evolution signifies not just a technological transformation but a philosophical one. It underscores the maritime industry’s steadfast commitment to making sustainability not just an aspiration but an informed, actionable reality.

n On the operational front, ports are presented with innovations like Just-in-Time (JIT) arrivals induced port fee structures.

MONITORING For the latest news and analysis go to www.greenport.com/news SUMMER 2023 | 19

‘‘

Future ports won’t merely be data collectors. Instead, they’ll evolve into analytical powerhouses, capturing nuanced emissions information with a precision hitherto unseen

Source: PortXchange

Source: PortXchange

Sustainable and economical power supply for berthed ships

siemens.com/siharbor

OCT 2023 Lisbon Portugal

Port of Lisbon, Lisbon • Portugal

Host Port:

Conference Programme

Balancing environmental challenges with economic demands

Sponsored by:

Supported by:

Balancing Environmental Considerations with Economic Demands. The world’s leading conference on sustainable environmental practice comes to Lisbon.

Join us for two days of conference presentations and learn from the foremost experts in environmental technologies

visit: greenport.com/congress contact: +44 1329 825335

email: congress@greenport.com

Media Partners:

#GPCongress

Tuesday 17th October 2023

18:30 Welcome Reception - Hosted by the Port of Lisbon

08:30 Coffee and registration

09:30 Opening by Chairman/Moderator

Christopher Wooldridge, Science Coordinator EcoPorts EcoSLC, and Visiting Research Fellow, Cardiff University, UK

09:50 João Galamba, Minister of Infrastructure of the Portuguese Republic

Keynote Panel

10:00 Climate Change: Energy efficiency, GHG emissions reduction & adaptation

-11:10 The risks to Ports, Shipping & the Logistics from climate change are increasing. This panel will discuss options available to combat these risks hearing from ports, shippers, and companies across the maritime industry. Confirmed panellists include Isabelle Ryckbost, Secretary General , ESPO; Nicolette van der Jagt, Director General, CLECAT; Isabel Moura Ramos, Executive Board Member, Port of Lisbon Authority; Ms. Lamia Kerdjoudj, Secretary General, FEPORT

11:10

Coffee & Networking

Moderator: Captain Michael McCarthy, Chairman, Cruise Europe

11:30 Going Green: How can a Cruise Terminal be more sustainable

Duarte Morais Cabral, General Manager, Lisbon Cruise Port

11:45 Opportunities, Risks & Threats regarding “Cold Ironing” in Ports - “The case of Heraklion Port”

Minas Papadakis, CEO, Heraklion Port Authority

Cold ironing is the major way that ports can contribute to reducing shipping’s emissions. The administration of Heraklion Port has set the green transition as our top priority. The European program the “Electriport” was the result of our efforts towards a greener and sustainable port.

12:00 Shore-to-Ship Connection at Cruises and Cargo Terminals of the Lisbon Port

Armando Santos, Global Partner - Client Manager - Energy and Industry, Quadrante

Considering the targets for reducing the carbon footprint of the port operation and his impact on Lisbon City, APL desires with that study, the implementation of OPS systems on the Cruise and Cargo Terminals of the Lisbon Port Oriental area.

Moderator: Heidi Neilson, Head of Environment, Port of Oslo

11:30 The Port of Helsinki - A carbon-neutral port Andreas Slotte, Head of Sustainable Development, Port of Helsinki

11.45 How Renewable Energy Communities at Ports can influence cities sustainability

Miguel Matias, CEO, KEME Energy, Lda Ports need a big energy infrastructure and the way they choose to operate it will have a huge influence in the overall city sustainability. By embracing bold decarbonisation targets and energy efficiency goals, engaging and promoting renewable energy communities (REC) in their sites and also in surrounding areas, Ports can become an accelerator for the city sustainability. We will discuss how Ports can implement this RECs inside and outside their area limits and positively impact the cities where they operate.

12.00 Carbon Capture in the green transitionPorts as the entry to make CCUS/CCS & transport feasible

12:15

Transforming Cruise Infrastructure: Global Ports Holding’s Expansion while Developing Future-Ready CruisePorts

Stephen Xuereb, COO, Global Ports Holding

Discover Global Ports Holding’s (GPH)

remarkable expansion in transforming cruise infrastructure and its commitment to developing future-ready ports. Join this session to gain valuable insights into GPH’s expansion and its strategies for developing future-ready cruise ports in shaping the cruise infrastructure of tomorrow.

Ralph Guldberg Bjørndal, Senior Chief Project Manager, Ports, Marine & Coastal, Ramboll Ramboll is conducting a pre-feasibility study, outlining how carbon capture facilities can be implemented, and how port facilities shall be established to support the shipping of CO2 to the final storage destination. Various shipping options are considered, together with an assessment of how the expected CO2 Hub system might evolve.

12:30 Question & Answer Session

12:30

Question & Answer Session

12:45 Lunch & Networking

DAY ONE - Wednesday 18 October 2023

Session 1.1: Cruise Infrastructure Development

Session 1.2: Carbon Neutral Ports

Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

Moderator: Captain Michael McCarthy, Chairman, Cruise Europe

14:10 Port of Toulon - utilizing energy storage

Olivier Teramo, Key Accounts Manager, Head of Projects, ABB Global

The use of renewable energy sources at ports supports the Shore Connection when ships are connecting to it. We believe different shore connection applications will ultimately play a big role in decarbonizing the marine and ports industries. ABB will present to the audience a case example of Port of Toulon, one of ABB’s project deliveries, which is utilizing energy storage as part of shore connection.

14:25 What kind of options do ports have in their carbon neutrality journey?

Laurent Dupuis, VP Global Product Manager

Ports & Maritime, Cavotec

In this presentation, Cavotec will compare the emissions reduction potential of different solutions for several ports and terminal types (cruise, ferries, container) to shed some light on how ports can create the best journey towards carbon neutrality.

14:40 Reliability and availability return of experience, from years of power conversion in Vessel Electrical Conversion systems, and Oil and Gas systems.

Alex Lagarde. Conversion’s Energy Conversion Expert & Business Development Manager, GE Vernova

This presentation will explore reliability aspects of large power converter (range between 5MVA and 20MVA), based on more than 30 years of return of experience on critical electrical systems.

14:55 OPS and the strategic challenges

Jacob Bjarkam, Head of Sales, PowerCon

15:10 Questions & Answers

Session 2.2 – Infrastructure Development for Ports

Moderator: Christopher Wooldridge, Science Coordinator, EcoPorts EcoSLC

14:10 Bruno Vale, General Manager, YILPORT LISCONT

14:25 Energy Recovery & Storage for Ports –Where Energy Supply Meets Demand

Justin Hollingsworth, Business Development Manager, TMEIC

Energy storage systems (ESS) are a great asset when transitioning to renewable energy sources, and they also play a role in strengthening and managing demand on a local grid. This presentation will consider the benefits of ESS within a port and the use cases of distributed energy recovery and centralized energy storage.

14:40 H2PORTS Project: A First Operational Experience Using Hydrogen Powered Machinery at A Port Terminal

Aurelio Lazaro, R&D Engineer, Environmental Sustainability and Energy Transition, Fundación Valenciaport

This work will present the outcomes of the project that will include not only the feedback from this real operation experience but also the lessons learned during it development phase and the analysis of crosscutting aspects of the project such as legislation, replicability, market uptake and human awareness related with the use of hydrogen at ports.

14:55 Decarbonising terminal operations: Reaching a tipping point in battery-electric container handling equipment

Sahar Rashidbeigi, Head of Decarbonisation, APM Terminals

The global shipping industry needs to decarbonise container handling equipment (CHE) to meet emission reduction targets, address demand from customers, and deliver social benefits. Battery-electric CHE is the preferred option, but is still an early-stage market and needs action to reach a tipping point on affordability, attractiveness, and accessibility. This presentation will share which actions are needed for large-scale roll-out of decarbonised CHE.

15:10 - Question & Answers 15:30

Session 2.1

– Shore Power

Coffee & Networking

Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

Session

15:50 Faciliator: Antonis Michail, Technical Director, International Association of Ports and Harbors (IAPH)

Port Endeavor draws on real life examples from the 200+ strong IAPH World Ports Sustainability Program (WPSP) database of projects and best practices on how ports integrate the UN Sustainable Development Goals (UN SDGs) into their business models and operations. The aim of the game is to increase awareness among port management, staff and professionals working in port communities on how ports are already applying the UN Sustainable Development Goals to their business, to ultimately accelerate adoption of these measures in the port sector.

17:20- Day 1 Round up - Christopher Wooldridge

17:30 Conference Close

Session 3.2 ESG - Environmental, Social and Corporate Governance Workshop

15:50 Workshop facilitator: Christopher Wooldridge (Cardiff University - UK)

The workshop will investigate: What are the benefits and value of ESG approach, How do you initiate ESG into your port’s management framework, How do you identify key components, how does it enhance decision-making and what are the links with sustainability?

7.30-10PM CONFERENCE DINNER – HOSTED BY THE PORT OF LISBON

DAY TWO - Thursday 19th October 2023

08:30 Coffee and registration

09:20 Opening by Chairman/Moderator

Christopher Wooldridge, Science Coordinator EcoPorts EcoSLC, and Visiting Research Fellow, Cardiff University, UK

09:30 EXCLUSIVE LAUNCH - ESPO Environmental Report

Anaëlle Boudry, Senior Policy Advisor for Sustainable Development, Energy and Blue Growth, EcoPorts Coordinator, ESPO

09:50 EXCLUSIVE LAUNCH - ECO SLC Environmental Report

Christopher Wooldridge, Science Coordinator EcoPorts EcoSLC, and Visiting Research Fellow, Cardiff University, UK 10:20 Question & Answers 10:30 Coffee & Networking

3.1 Port Endeavour

Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

10:50 Faciliator: Antonis Michail, Technical Director, International Association of Ports and Harbors (IAPH)

Port Endeavor draws on real life examples from the 200+ strong IAPH World Ports Sustainability Program (WPSP database of projects and best practices on how ports integrate the UN Sustainable Development Goals (UN SDGs) into their business models and operations. The aim of the exercise is to increase awareness among port management, staff and professionals working in port communities on how ports are already applying the UN Sustainable Development Goals to their business, to ultimately accelerate adoption of these measures in the port sector

Moderator: Christopher Wooldridge, Science Coordinator, EcoPorts EcoSLC

10.50 Sustainable future: overcoming the challenges of large-scale deployment of offshore wind energy

Marco Alves, Chief Executive Officer, WavEC Offshore Renewables

The presentation addresses the current main challenges of large-scale floating offshore wind projects, including aspects such as technology development, site selection, infrastructure adaptation,grid integration, stakeholder engagement, international collaboration, and support policies and regulations.

11.05 Methanol as a Marine Fuel?

NABU study by Öko-Institut (Institute for Applied Ecology)

Malte Siegert, Head of Environmental Policy, Naturschutzbund Deutschland (NABU / Nature and Biodiversity Conservation Union)

NABU will present the major findings of the study “Methanol as a Marine Fuel” highlighting especially the environmental benefits of e-methanol.

11.20 EALING (European Flagship Action for Cold Ironing in Ports) Project

Rocío García Molina, Innovation & Port Cluster Development, Fundación Valenciaport

EALING (European Flagship Action for Cold Ironing in Ports) is a 42-month project, co-funded by the Connecting Europe Facility (CEF), which, in addition to carrying out all the technical, environmental, socio economic and financial studies necessary to prepare the works for the installation of shore-side electricity in 16 ports from 8 EU Member States, aims to work towards a harmonised and interoperable framework in the EU.

11.35 Ports of Bremen in the energy transition–fulfilling social obligations, seizing opportunities

Dr. Janna Köhler, Advisor for hydrogen and decarbonization, Free Hanseatic City of Bremen, Ministry of Science and Ports

Ports of Bremen have formulated the goal of achieving climate neutrality by 2035, together with the relevant port stakeholders. While this poses great challenges on different levels, the energy transition also opens up new opportunities.

11:50

Question & Answer Session

Lunch & Networking Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

Session 4.1 Port Endeavour Session 4.2 Offshore Renewables & Alternative Energies

12:20

Moderator: Heidi Neilson, Head of Environment, Port of Oslo

13:40 Waste Management on a Technical Level

Brian Elliot, Senior Project Officer in Unit Sustainability, Department Sustainability and Technical Assistance, European Maritime Safety Agency

13:55 Generating hydrocarbon products from maritime waste: Ecoslops’ experience on profitable circular economy within ports

Vincent Favier, CEO, Ecoslops

Ecoslops is an innovative cleantech that brings oil into circular economy. The solutions have been developed to help ports manage their waste in a more efficient and environmentally friendly way. The technology allows the recycling of oil residues from ships, as well as land-based hydrocarbon residues (yc used lub oil) that are often considered hazardous and difficult to dispose of.

14:10 Target Zero: Zero Waste to Landfill at the Port of Dover

Ben Crake, Environment Advisor, Port of Dover

Moderator: Christopher Wooldridge, Science Coordinator, EcoPorts EcoSLC

13:40 Ports: hubs of the new blue economy

Ruben Eiras, Secretary-General, Fórum OceanoPortugal Blue Economy Cluster

13:55 Port of Lisbon – HUB2BLUE

Tiago Fernandes, Head of Logistics, Port of Lisbon Authority

The Port of Lisbon, as one of the main logistical infrastructures in the country, being a city port, in a historic city, has energy and digital transition as one of its major challenges. This Positioning will create the opportunity for the Port of Lisbon to develop its innovation hub and be a relevant player for investors and entrepreneurs in the areas of the Blue Economy.

14:10 Clean Ports, Clean Oceans: Improving Port Waste Management in the Philippines

Martine Gripp Bay, Business Development, Grieg Maritime Group

14:25

Port Reception Facilities

Sophie Delair, Secretary General, Euroshore Port Reception Facilities play a key role together for supporting the maritime industry to reduce its carbon footprint, greening ports and preventing marine pollution. The presentation proposes a plead for the installation of adequate port reception facilities where necessary as there are some gaps. What a port reception facility is and their constraints are not always understood as they face maritime and land legislations which are not the same and even vary from one country to another

WWF will present the solutions conducted with the port and city authorities, such as the development of a materials recovery facility in the port of Cagayan de Oro, the collection and recycling of plastic waste in the ports of Manila North Port and Batangas, and will share how activities with other stakeholders in the port area have been developed collaboratively to ensure their sustainability.

14:25 Update on the Silk Alliance green corridor, a Singapore bunkering cluster

Ahila Karan, Senior Decarbonisation Analyst, Llyod’s Register

14:40 Question & Answer Session

14:40

Question & Answer Session

15:00

Session 5.1: Waste Management and Circular Economy Session 5.2: Blue Growth

Coffee & Networking Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

Session 6: Digitalization and Technology

Moderator: Christopher Wooldridge, Science Coordinator, EcoPorts EcoSLC

15:30 Delivering resilient supply chains

Steffen Siebert- Head of Sales Europe, Middle East & Africa at S5 Agency World

For complex supply chains to work, digital solutions are needed to facilitate transparent and clear lines of communication. Steffen will delve into how these softwares can optimise port operations; increasing productivity and reducing emissions.

15:45 Moving on the Mersey – a localised approach for technology deployment to deliver emission reductions in leisure, freight, and passenger transport.

Richard Willis,Technical Director Port Operations & Technology, RoyalHaskoningDHV

Working together with local stakeholders across the maritime sector in the Liverpool City Region we studied where the use of river-centric transport modes blended with low-carbon technologies could transform both the under-used waterways in the city and reduce impact of air quality upon the residents.

16:00 Concrete use cases and experiences in utilising data analytics, AI and simulation to increase productivity, sustainability and safety

Miika Murremäki, Head of Digital Solutions, Kalmar

By leveraging analytics, AI, and simulation, cargo handling equipment experts can help ports to increase productivity, sustainability and safety. This can ultimately help ports to remain competitive in a rapidly changing industry. Kalmar will present on the main use cases

16:15 LSYM Port Simulators developed by the University of Valencia

Pablo Galán, Head of Business Development, e-nquest

Our mission is to accelerate the port industry’s transition to digitalized training. We develop training systems with simulators, capable of reproducing the working environment of real machinery used at the terminals like quay cranes, mobile harbor cranes and vehicles like heavy forklifts or reach stackers among others

16:30 Question & Answer Session

16:50 Conference Wrap up by Conference Chairman/Moderator – Christopher Wooldridge

17:00 Conference Close

DAY THREE - Friday 20th October 2023

PORT TOUR OF LISBON

Book Online at https://www.portstrategy.com/greenport-cruise-and-congress or fax form to +44 1329 550192 For further information please call +44 1329 825335 or email congress@greenport.com

Conference Fee

Cost per delegate (standard rate)

• Cruise – One Day event €1,100

• Cruise & Congress – €2,160

Booking Online greenport.com/congress or complete and fax the booking form below to +44 1329 550192. On receipt of your registration, you will be sent confirmation of your delegate place

Cruise Fee Includes

Attendance of Cruise conference streams on day 1, full documentation in electronic format, lunch and refreshments, place at the Welcome Reception and place at the Conference Dinner.

Cruise and Congress combined Fee Includes Choice of conference streams for GreenPort Cruise on day 1, two day conference attendance at GreenPort Congress, full documentation in electronic format, lunch and refreshments throughout, place at the Welcome Reception, place at the Conference Dinner, place at the Port Tour.

CONTACT US

For further information on exhibiting, sponsoring, or attending the conference, contact the Events team on: +44 1329 825335 or congress@greenport.com

BOOKING FORM

OCT 2023 Lisbon Portugal

BOOK ONLINE OR COMPLETE THIS FORM AND FAX TO +44 1329 550192

(Please copy this form for additional delegates)

Please tick all that apply :