- Completed -

Project completed with A D Lab

Photo credits: Khoo Guo Jie

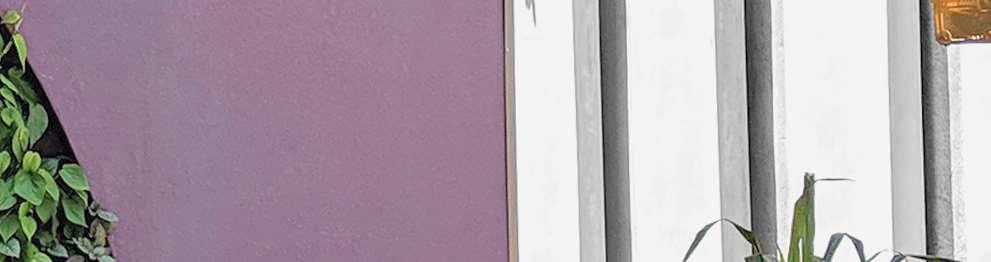

A multi-generational home designed for each household to have their own private spaces in each of the stacked blocks with commmon areas as its central core.

Spanning across 16,000sqft, this house has its own swimming pool at the roof top, leaving a large green lawn available on the ground floor for the kids to run around and play in.

Staying true to the authencity of materials, the use of natural materials like Burmese teak, marble, granite and balinese sukabumi tiles was generous throughout the house. The entire 2nd storey was cladded in Burmese Teak batons & screens along with all the interior rooms in the same timber flooring Swimming pool cladded in turqoise natural sukabmi tiles; Living room in white pearl marble stone and car porch in black granite.

MONOMER HOUSE

-Prefabricated Modular House

FEATURED AT SINGAPORE NIGHT FESTIVAL 2019 | SINGAPORE ARCHIFEST 2019

AWARDED GERMAN DESIGN AWARD 2020

OFF-SITE CONSTRUCTION - 7 DAYS

ON-SITE CONSTRUCTION - 5 DAYS

With the focus on adopting DfMA ((design for manufacturing and assembly) in the design and construction process for small to medium sized projects, the Monomer House is a prototype micro-dwelling house showcasing the possibilities of using pre-finished, pre-fabricated light-gauge steel modules which can be customised to various sites.The Monomer House is made of two 5.2m x 2.6m modules stacked in a L-shaped configuration which can be transported and erected easily. This prototype features vertical green walls, solar panels and smart appliances with the aim of creating self-sufficent and environmentally friendly model.

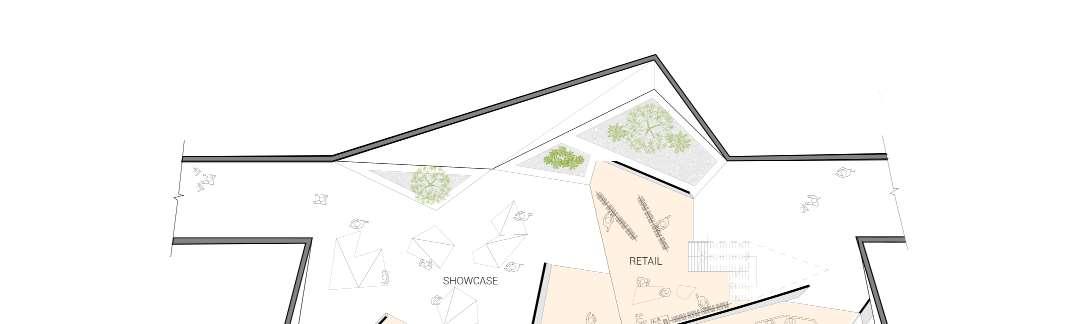

- Concept DesignStart-up lab

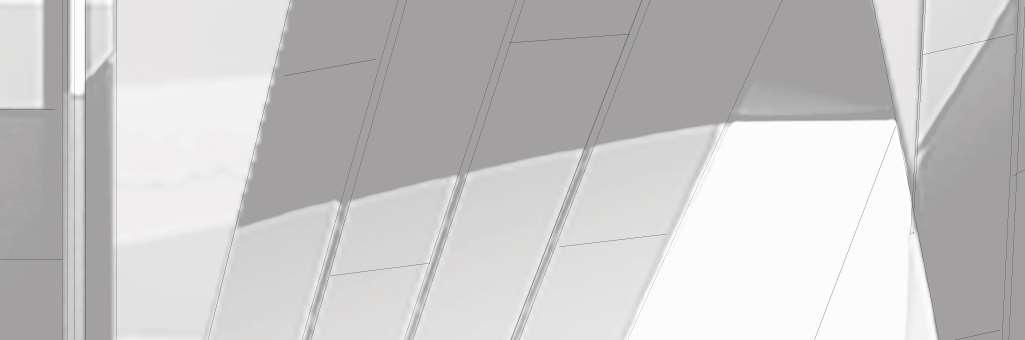

Traditional architectural thresholds such walls, floors, ceilings and doors are coalesced into a physical manifestation of a continuous ribbon which forms the basis of the experience journey of the entrepreneurial culture.

Thefolding ofthiscontinuousribboncreatesavarietyofspacesfromopenspacestoenclosed privatespaceswhile suggesting the building’s structure without the need to introduce additional columns

At the same time, the continuous flow of spaces allows for the product creation journey to be showcased through various key touch points. Visitors can experience and understand the insights of the product lifeline through the various exhibitions and demonstrations to appreciate the creation process. Finally, as the visitor is brought through the sequence of spaces, the entrepreneur would be able to share his ideas in depth in the intimate pitch area.

ELEVATION

SECTION A-A

SECTION B-B

SITE INVESTIGATION NATURAL LIGHTING

Entrance point was placed at the corner of the cross junction to maximise view angle from all directions.

The continuous ribbon was folded in from the Ground level to the Basement with large openings facing the North-East and SouthEast Direction to ensure cross-ventilation across the entire building and even natural ventilation into the Basement level

Creating an avenue for local entrepreneurs to share their stories, the building was designed to bring visitors through a curated flow of spaces for visitors to learn about their entrepreneurial journey

As visitors first enter the building, they will be greeted by back stories of featured entrepreneurs of the month and are guided to see to a snippet of the products on display.

Inspired to find out more about their entrepreneurial journey. visitors subsequently can take a route down to the basement where they get to see a full demonstration of their products and even see live pitches in action as the entrepreneurs attempt to convince their futre investors.

-Masters Thesis

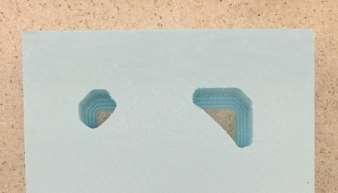

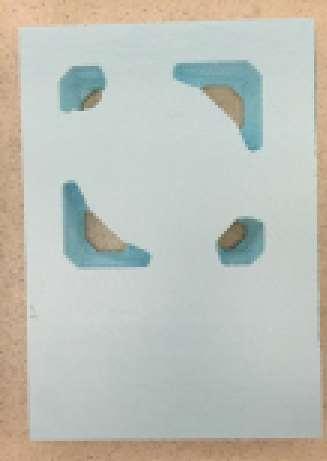

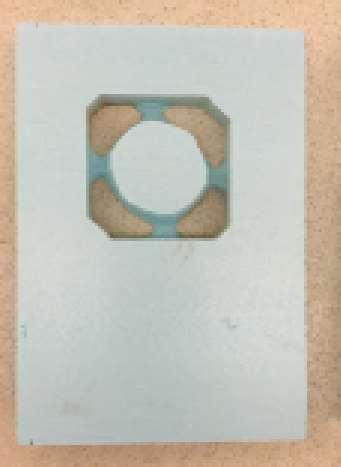

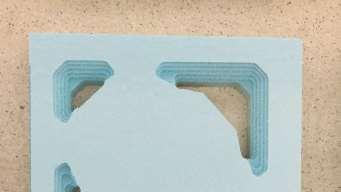

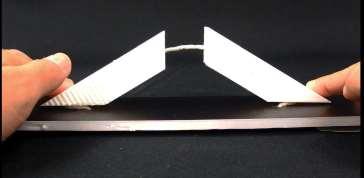

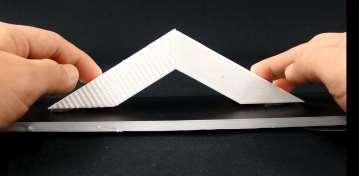

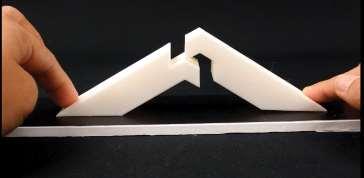

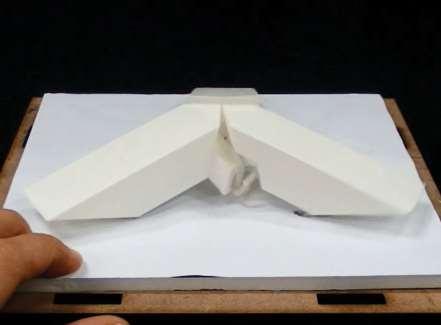

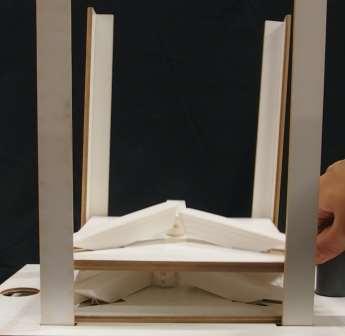

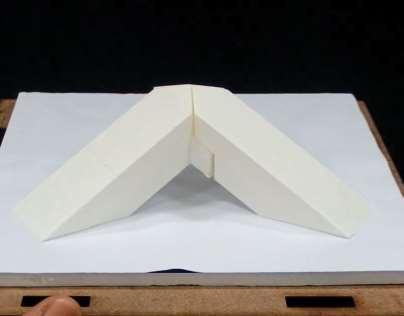

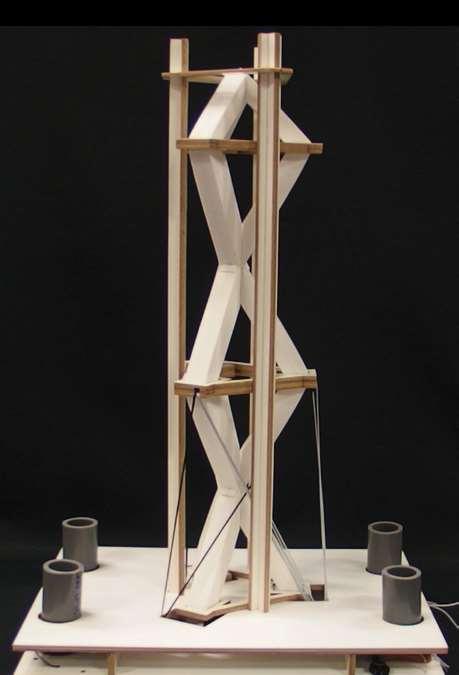

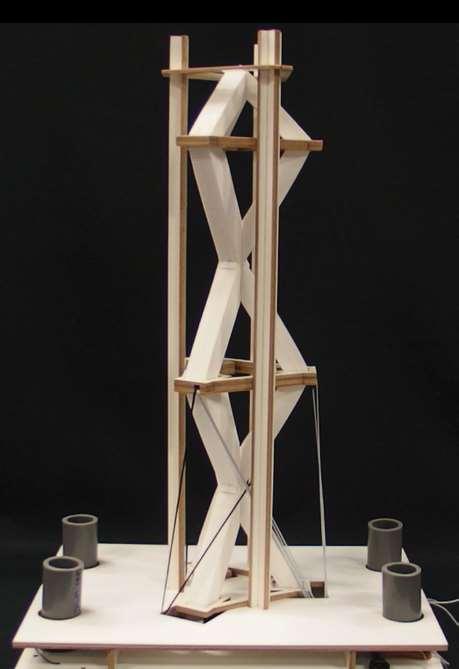

ASSEMBLY

Masters Thesis -

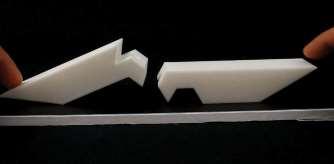

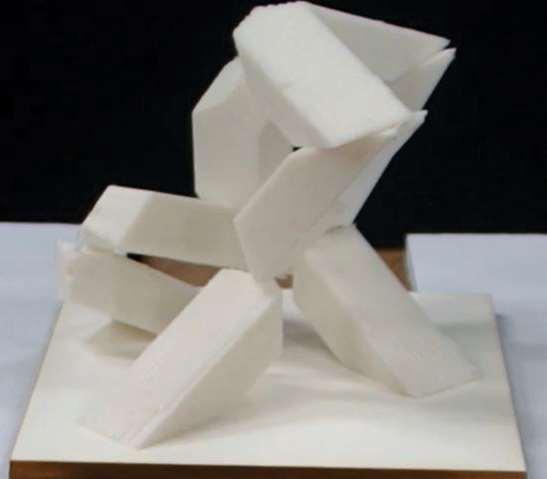

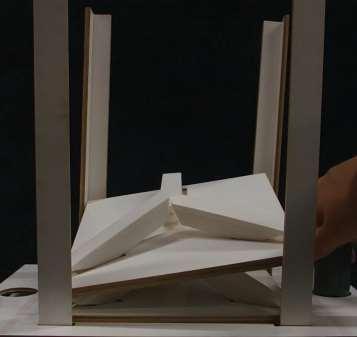

FINAL PROTOTYPE

After several experiments on joint geometry and tension strings along with many failed attempts , the geometry of the joints allowed the modules to move into place and eventually lock into place with the help of tension strings.

The final prototype illustrates the main idea of creating smart modules to create a more efficient construction method.

GROUND LEVEL PLANUPPER LEVEL PLAN

A series of modules were designed and prototyped including specific joint details to allow the smart modules to connect and lock in place by itself by just pulling the tension cables.

- Concept Master Plan

- Concept Master Plan -

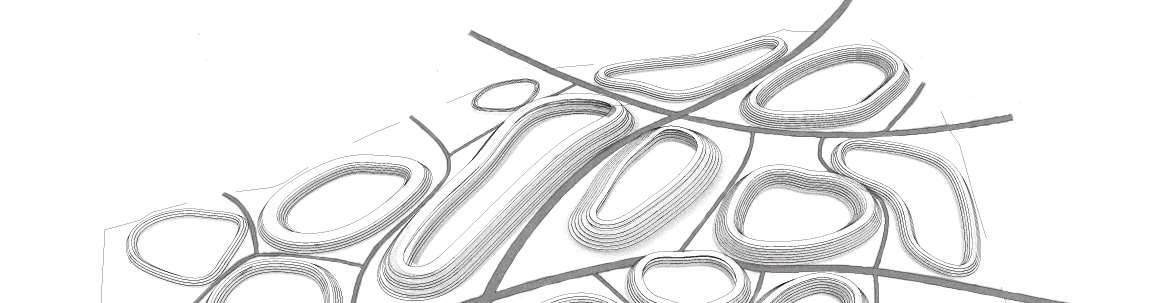

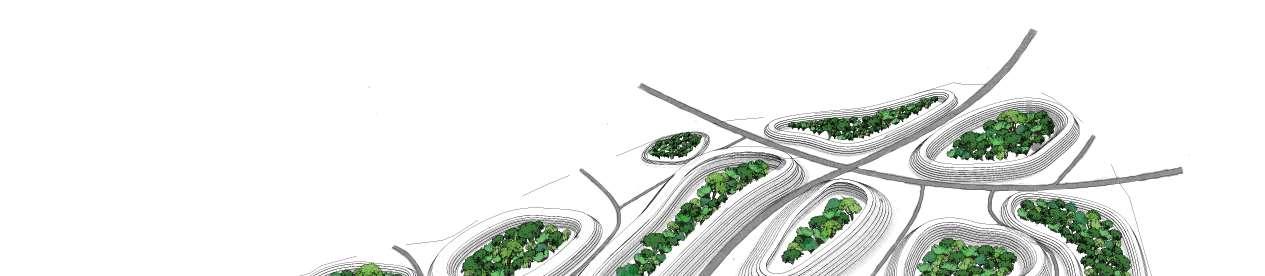

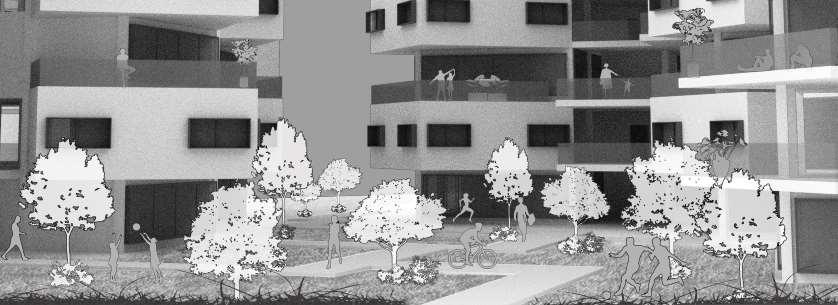

Existing Turf City landscape in Singapore is made up of recreational spaces & commercial areas nestled within numerous clusters of lush green forests. The driving force of this master plan is to retain the main attractive characteristic of the site by creating a terrrain of functional spaces with hills & valleys around the existing forests. At the same time, this concept master plan strives to create communities around each of the forest clusters for people live, work and play with recreational spaces which the current Turf city provides.

PART GROUND FLOOR PLAN

- Concept

- Concept -

STUDIO SHOP APARTMENT

DUPLEX 2 BEDROOM SHOP APARMENT 1st Storey FloorPlan plan1st Storey Plan 2nd Storey Plan2nd Storey Plan

DUPLEX 1 BEDROOM SHOP APARMENT

Stacked Shophouses seeks to create a new form of high density mixed commerical + residential typology by taking queue from existing old shop houses. The old shophouse landscape comprises of a lower 1st Storey commercial space where owners run their businesses while the upper 2nd Storey residential space provides them a more private spaces for their rest. This intent of this project is to retain the same idea of entrepreneurs having their own work space and residential area in the same unit by stacking the shophouses vertically to create a new typology. 8m x 8m modules (64m2 - studio) were used as the basic module to be aggregated throughout the entire site. In addition, the modules were not only stacked but also rotated to give rise to open terraces for users to have their own personal garden despite living in a high rise building

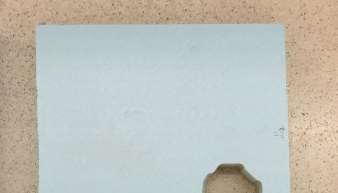

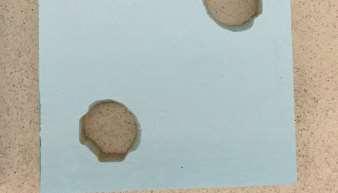

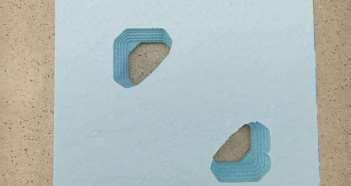

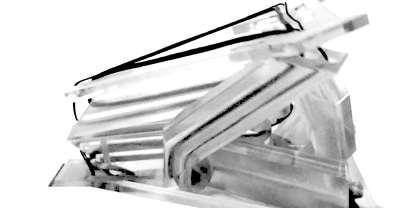

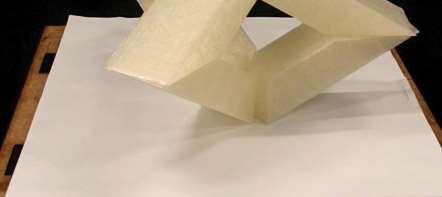

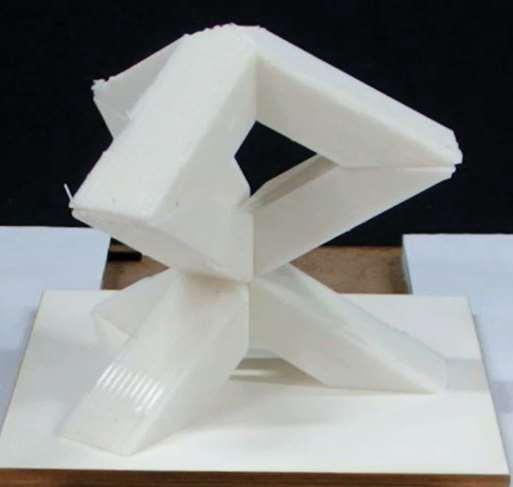

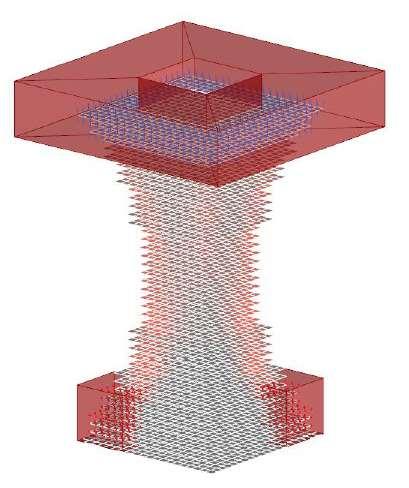

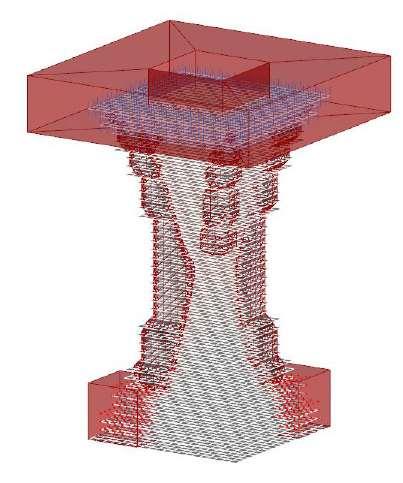

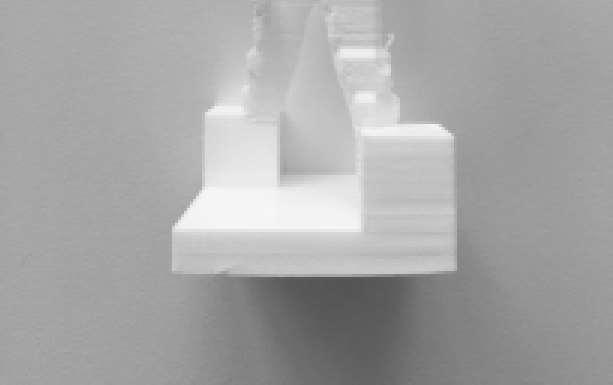

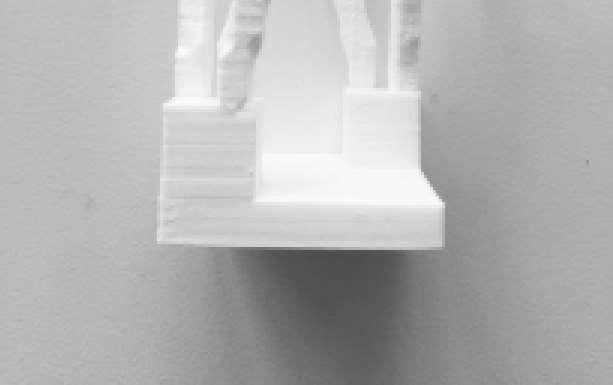

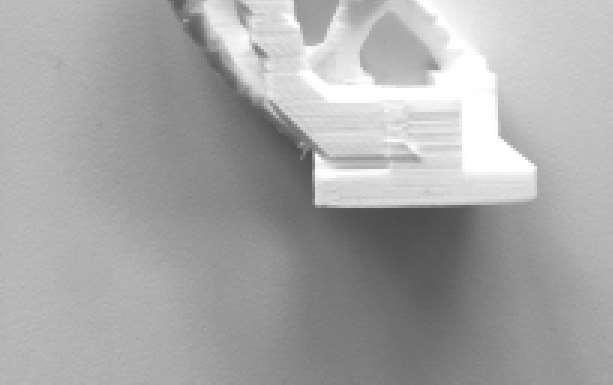

MATERIAL TOPOLOGY STUDY

- Digital Fabrication

- Digital Fabrication -

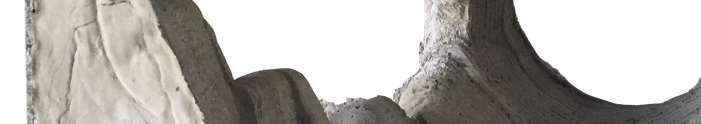

This project seeks to create a more organic and efficient structure driven by Material Topology. By observing how forces are distributed with load and support parameters, material topology creates a form which distributes and insensifies materials at where it is required.

With a form driven by material topology, small prototypes were 3D-printed to test out the physical forms before selecting 1 of them to be fabricated in concrete.