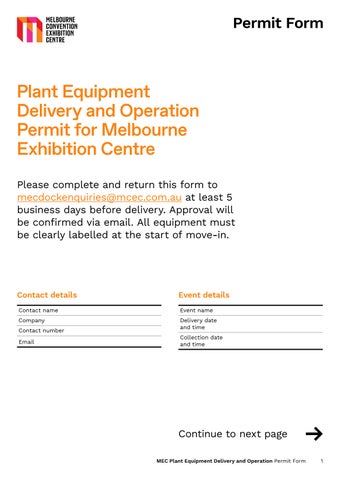

Equipment details

Type of equipment

Forklift

Crane

Scissor Lift

Boom Lift

Other

Number of Gas Bottles

On-site contact details

Name of Contractor/ Company using equipment

On-site contact name

Contact number

I/We declare that I/We

Will undertake work in accordance with Victorian OH&S Act 2004 and OH&S Regulations 2017

∙ Currently have and maintain public liability insurance during any work performed at the venue and will formally notify MCEC regarding any changes to insurances

∙ Agree to comply with reasonable requests from relevant venue and event organisers

Will operate with licensed operators and competent spotters

∙ Will ensure all operators complete the MCEC LinkSafe induction process

Will read and abide by the procedures put in place by MCEC located on the following page

∙ Understand that approved equipment deliveries may be made up to two business days prior to an event, but must be taken off-site prior to 5 pm the next business day after the event has moved out

∙ Understand that any equipment left on the loading dock will incur a $90 per day charge

Understand that failure to comply with any of the above may result in the removal of the permit to operate equipment at the venue

I agree to MCEC’s Operating Procedures and Terms and Conditions

Plant operating procedures

While on-site at MCEC the operating company must ensure that :

∙ If requested, provide appropriate licences and equipment inspections, as required under legislation

Report any incidents, injuries, near misses, property damage, hazard, leak or spills to event security or loading dock staff immediately

Operators observe road rules, operate at a maximum speed of 5km/h and give way to pedestrians on the loading dock

∙ All equipment is maintained in good working condition

Daily pre-operation inspections are carried out and recorded in the logbook

∙ Only approved attachments are used on the equipment and must be securely fitted

Operators do not wear hooded tops and must wear a high-vis safety vest at all times

∙ Operators do not smoke or vape while operating equipment

Operators do not use mobile phones or handheld radios while operating equipment

Operators do not lift or carry passengers

Operators to reverse when vision is slightly blocked by their load and sound horn at intersections and blind corners

Operators to reverse when overhead loads are necessary, ensuring loads are not lifted over pedestrians

Operators do not place items that impede access to emergency exits, fire safety equipment or restrict access in clear aisles

∙ All equipment must have signage attached in a prominent location to identify who it belongs to

All spare gas cylinders have company identification attached and are stored in the gas cage at the loading dock

All equipment must be removed from the Exhibition Centre bays overnight and during event operational period

∙ Operators and spotters must not be under the influence of alcohol or drugs while working at MCEC and must carry out their duties in a safe manner

∙ Plant equipment is not shared with other companies or exhibitors without approval from MCEC Loading Dock

The above list of obligations reflects the minimum requirements for operating at MCEC and is not intended to be an exhaustive list of safety measures that may be relevant to this type of activity.

Spotter responsibilities

While on-site at MCEC the operating company must ensure that a trained spotter is always used, excluding on the loading docks. They must:

Remain a safe distance from the equipment and its load while in motion or if the load is raised

∙ Always be in constant view of the operator

∙ Walk to the left or right-hand side and three metres in front of the equipment. Do NOT walk directly in the pathway of the equipment

∙ Ensure they do NOT direct the driver to enter a designated pedestrian walkway

Warn pedestrians to stand clear of the equipment and load. If the pedestrian does not clear the pathway, the spotter must direct the driver to stop the equipment until the pedestrian moves or uses an alternative route

∙ If the operator must raise a load/overhead lift, the spotter must ensure pedestrians are not located under or near the raised load and that the operator drives the overhead load in reverse

∙ If the spotter is unable to maintain a clear area around the equipment, they will need to direct the operator to stop, with the load on the ground, until they can find someone to assist

∙ Carry a copy of the Exhibition Centre floor plan and direct drivers to travel down the clearway aisles shown on the floor plan

Report any incidents or issues to event security and MCEC loading dock representatives immediately

The above list of obligations reflects the minimum requirements for operating at MCEC and is not intended to be an exhaustive list of safety measures that may be relevant to this type of activity.