Woodruff Buzz

GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING GEORGIA INSTITUTE OF TECHNOLOGY

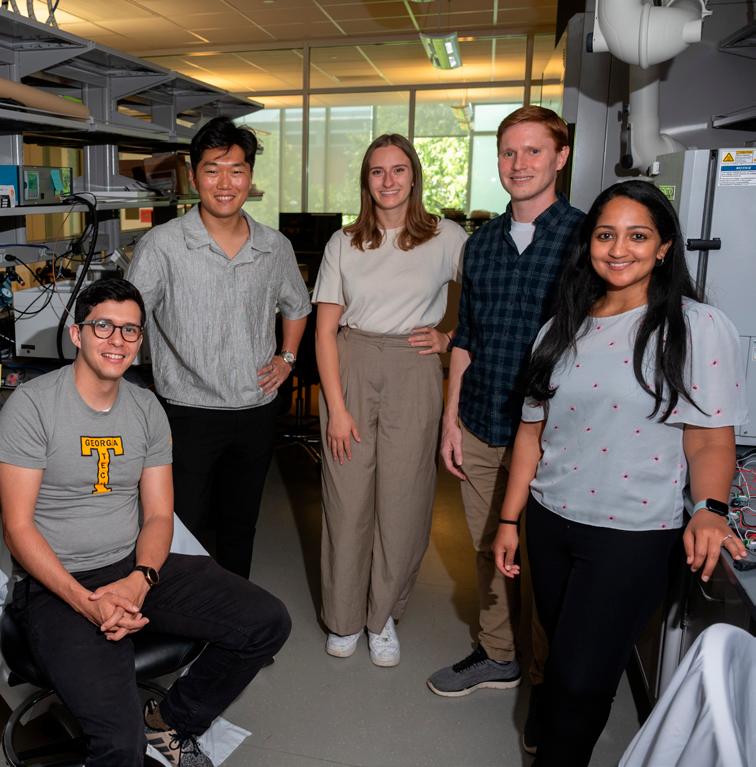

Mikey

Steven

Rachael

Jason

Tess

GEORGE W. WOODRUFF SCHOOL OF MECHANICAL ENGINEERING GEORGIA INSTITUTE OF TECHNOLOGY

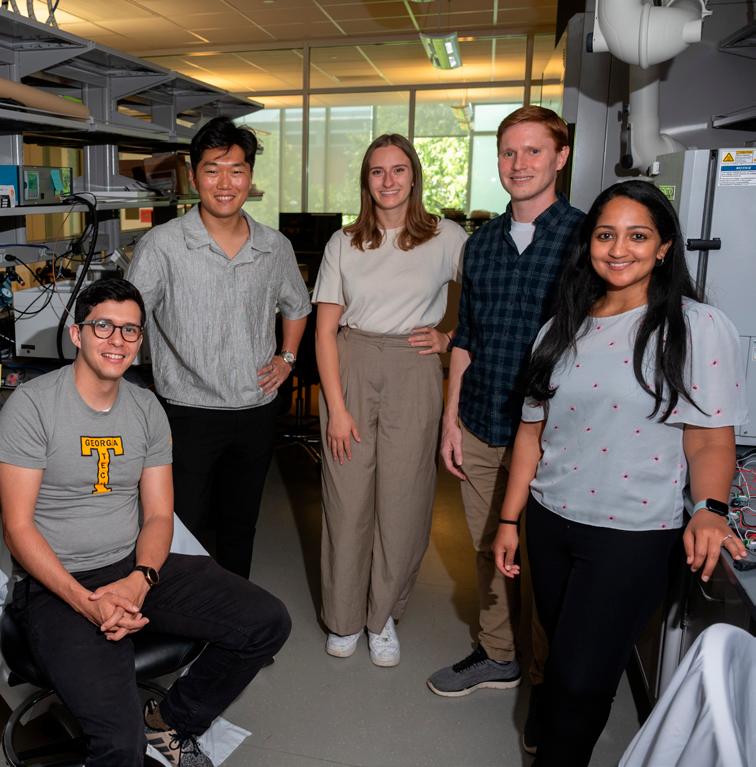

Mikey

Steven

Rachael

Jason

Tess

It’s an honor to introduce myself as the interim chair of the George W. Woodruff School of Mechanical Engineering and to present the latest edition of Woodruff Buzz, produced annually for our students, faculty, staff, alumni, and friends. As many of you know, former chair Devesh Ranjan recently accepted a new role as dean of the College of Engineering at the University of Wisconsin–Madison. We are grateful for his outstanding leadership and lasting impact on the Woodruff School, and I am excited to build on that momentum in the year ahead.

This edition of our magazine captures the energy and excellence that define our School — from student innovation and faculty research to alumni engagement and community celebration. During the last academic year, Woodruff School students once again demonstrated their creativity and impact. Mechanical engineering student Anuj Pandey and his Convexity teammates won the Georgia Tech InVenture Prize with a game-changing electronics 3D printer, revolutionizing how circuit boards are manufactured. Georgia Tech Motorsports secured its first podium finish in more than two decades, showcasing the technical depth, drive, and teamwork that define this student competition center team. Beyond competitions, our curriculum continues to set the standard for preparing workplaceready engineers. The Woodruff School’s Lab Sequence — Experimental Methods and Technical Communication followed by Systems Laboratory — is empowering students to conduct complex system-level investigations and communicate actionable conclusions to both executive and technical audiences, an essential skillset in today’s fast-paced, multidisciplinary engineering landscape.

Our faculty continued to advance research at the highest levels. Researchers like W. Hong Yeo, Carolyn Seepersad, and Bill Singhose pushed the boundaries of innovation — from biomedical sensors and interdisciplinary design education to crane safety research. Several faculty were

named Woodruff Faculty Fellows, and we launched the Woodruff Innovation Nexus (WIN) to fund bold, high-risk research ideas. Our faculty also helped shape national conversations around energy and technology: from a leap forward in AI-powered robotic exoskeletons developed in Aaron Young’s lab to a major new manufacturing testbed led by Tequila Harris, and new NIH- and DOE-funded projects tackling critical societal challenges. And in a historic milestone, NREMP Program Chair Steven Biegalski became the first engineer to receive the George Hevesy Medal — the highest international honor for lifetime achievements in applied nuclear and radiochemistry. He is just the seventh American to receive the award in its 57-year history.

This year, we continued to celebrate the achievements and impact of our community. Six members of the Woodruff School were named to Georgia Tech’s Class of 2024 40 Under 40, and we welcomed five new members to the Woodruff Young Alumni Council. At the 2024 College of Engineering Awards, alumni Emily Woods, Lindsey Thornhill, James R. Borders, and Carl D. Ring were honored — a testament to the excellence and influence of our alumni across industries. We also awarded Women of Woodruff (WoW) fellowships to six students. This initiative, launched and supported by members of our advisory board, continues to grow in its mission to support and retain women students and allies in mechanical and nuclear engineering. Faculty and staff were recognized across 22 categories at our annual Faculty and Staff Honors, Awards, and Promotions Reception, a reflection of the commitment and talent that drive our School forward. We also paused to remember and honor Ward O. Winer, Regents’ Professor Emeritus and the longest-serving chair in Woodruff School history, whose passing in May marked the loss of a deeply respected leader, mentor, and friend. His influence on the field of mechanical engineering and on generations of students and colleagues is both profound and enduring.

At the same time, our graduates continued to shape the School’s future in powerful ways. Our alumni paid it forward through generous gifts that support graduate fellowships, student teams, and programs like WoW. Others left a legacy through their stories: a mother and daughter shaped by their shared Georgia Tech experience; a family whose ties to the School span generations; and a couple whose connection began on Techwood Drive. These stories reflect the lifelong bonds and impact of a Woodruff School education, and they underscore our commitment to fostering a culture of inclusive excellence, where every member of our community feels empowered to thrive.

This past year, your support helped us raise $11.3 million, bringing our Transforming Tomorrow campaign total to more than $93 million — well beyond our original $75 million goal, with two years still to go. This success would not be possible without outstanding members of the Woodruff School community — you are the foundation of the Georgia Tech experience. Thank you for all you do. I am inspired by your continued commitment, and I look forward to working together to strengthen our impact — and to build a future that is bold, inclusive, and transformative.

Best regards, Shreyes N. Melkote Interim School Chair, Morris M. Bryan Jr. Professor

The George W. Woodruff School of Mechanical Engineering is an inclusive, innovative, and thriving educational and research environment committed to fostering the next generation of intellectually curious and globally engaged leaders who are empowered to create solutions to society’s most challenging problems and dedicated to improving the human condition.

TOP RANKED PROGRAMS

Mechanical Engineering

Undergraduate Program

(U.S. News & World Report, 2025)

Mechanical Engineering

Graduate Program (U.S. News & World Report, 2025-26)

Nuclear Engineering

Graduate Program (U.S. News & World Report, 2025-26)

The Woodruff School will be a student-centered, research-focused, and service-oriented community recognized for its outstanding education, the development of leaders, and the creation of innovative technological solutions that improve society and the human condition. We will embrace the diversity of our collaborative community, the foundational principles of engineering and science, and ethical behavior as we achieve a culture of inclusive excellence.

DEGREES AWARDED, 2024-25

The Woodruff School offers:

2 B.S. Degrees

7 M.S. Degrees

6 Ph.D. Degrees

Acoustics and Dynamics; AI, Informatics for ME (AI2ME); Automation, Robotics and Control; Bioengineering; CAE and Design; Engineering Education; Fluid Mechanics; Heat Transfer, Combustion, and Energy Systems; Manufacturing; Mechanics of Materials; Medical Physics; Micro & Nano Engineering; Nuclear and Radiological Engineering; Tribology

FACULTY AND STAFF

92 Tenure-Track Faculty 89 Staff

Degrees

Degrees

476 299 B.S. Degrees 71

ENGINEERING SCHOLARS

1922 Undergraduate Students Fall 2024

983 Graduate Students Fall 2024

33 Research Faculty

14 Non-Tenure Track Faculty

Alex Aridgides was selected to join the 2025 immersive cohort at South by Southwest in Austin, Texas.

Milad Azizkhani received the Woodruff School Ph.D. Research Excellence Award.

Seunghyeb Ban was selected as a Herbert P. Haley Fellowship recipient.

Erik Barbosa won the 2024 Spark Award.

Saanvi Bethi received the College of Engineering Honors Day Award.

Sara Bitarafan received the Woodruff School Ph.D. Research Excellence Award.

Stephen Britten received the Richard K. Whitehead Jr. Memorial Award.

Aisha Brundan was awarded an NSF Graduate Research Fellowship.

Jiehao Chen received the Woodruff School Ph.D. Research Excellence Award.

Mingeun Choi received the Woodruff School Excellence in Service and Leadership Award.

Katie Ciavola received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Derek Coffsky received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Benjamin Du received the College of Engineering Honors Day Award.

Allannah Duffy was awarded a WoW Fellowship.

Emmeline Evans received the Woodruff School Excellence in Service and Leadership Award.

Colin Gold received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Alexander Gross was awarded an NSF Graduate Research Fellowship.

Zhaoyuan Gu received the Woodruff School Ph.D. Research Excellence Award.

Jungmin Ha received the Woodruff School Best Graduate Teaching Assistant Award.

Abraz Haque received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Dongjing He received the Woodruff School Ph.D. Research Excellence Award.

Nicholas Isaf received the Woodruff School Best Graduate Teaching Assistant Award.

Vibha Ramanathan Iyer was awarded an NSF Graduate Research Fellowship.

Anika Kansky was awarded a WoW Fellowship.

Shaspreet Kaur was awarded a WoW Fellowship.

Jamila Khanfri was awarded a WoW Fellowship.

Alexey Khotimsky was awarded an NSF Graduate Research Fellowship and received the Richard K. Whitehead Jr. Memorial Award.

Keun Hee Kim won the 2024 Spark Award.

Samuel Kirschner was awarded an NSF Graduate Research Fellowship and received the George W. Woodruff School of Mechanical Engineering Outstanding Scholar Award.

Jordan Kocher was awarded the Director’s Postdoctoral Fellowship from NREL and received the Woodruff School Graduate Instructor Award.

Youngjin Kwon received the M.S. Research Excellence Award.

Jeffrey Li was awarded an NSF Graduate Research Fellowship.

Wenjing Li received the Woodruff School Best Graduate Teaching Assistant Award.

Daphne Lin was awarded a WoW Fellowship.

Zihao Lin received the Woodruff School Ph.D. Research Excellence Award.

Zhi Ling received the Woodruff School Ph.D. Research Excellence Award.

Kristian Lockyear was named second runner-up at the 10th annual Georgia Tech 3MT competition.

Matthew Louis received an ANS Scholarship and was awarded a scholarship from the U.S. DOE through the UNLP.

Joshua Mao received the Richard K. Whitehead Jr. Memorial Award.

Harley Martin received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Emmanuel Mate-Kole received the Woodruff School Ph.D. Research Excellence Award.

Madison McKinnon won the George Sherouse Award for Trainee and Early Career Investigators.

Maham Mehmood received the Richard K. Whitehead Jr. Memorial Award.

Lena Moller received the Woodruff School Excellence in Service and Leadership Award.

Madeline Morrell was selected by the U.S. DOE BTO to receive the IBUILD Graduate Research Fellowship.

Asif Rashid received the Woodruff School Ph.D. Research Excellence Award.

Abigail Robb received the 2025 Roy G. Post Foundation Scholarship.

Autumn Routt was awarded a WoW Fellowship.

Dante Santaniello received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Mason Shackelford received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Neel Shah was awarded an NSF Graduate Research Fellowship.

Jacques Singham received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship and the Richard K. Whitehead Jr. Memorial Award.

Gianna Slusher received an ARCS Scholar Award.

Ramón Sosa was selected as a Herbert P. Haley Fellowship recipient.

Shreya Terala was selected for the 2024 Class of the Millennium Fellowship.

Kenneth Thompson III received an ANS Scholarship.

Tianyu Wang received the Woodruff School Ph.D. Research Excellence Award.

Emily Winters received the George W. Woodruff School of Mechanical Engineering School Chair’s Award.

Samuel Woolsey was awarded a scholarship from the U.S. DOE through the UNLP and received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Jatin Yashroy received the inaugural Chair’s Ambassadors in Leadership and Service Fellowship.

Garrett Youngblood received the Outstanding Scholastic Achievement Award in Nuclear and Radiological Engineering.

Ethan and Nathan Morlu have always done things together growing up as identical twins. They played musical instruments, wrestled in middle and high school, became Eagle Scouts, and love Super Smash Bros.

Now, they’re both third-year students in the George W. Woodruff School of Mechanical Engineering, on a Georgia Tech journey together.

But when it came time to pick which college to attend after high school, the twins knew they might have to split up.

“I knew that college would be much more fun going with my twin, but we did have an agreement that we would separate if we ended up liking different colleges,” Ethan said. “I’m really happy that we get to share our college experience.”

Coming from the suburbs of Northern Virginia, they both considered attending an engineering school closer to home. However, when their decision came down to the wire, the twins say a tour of Georgia Tech’s campus sealed the deal.

“I chose Georgia Tech because out of all the colleges that I visited, it felt the most welcoming and had the richest show of tradition and school spirit,” Nathan said.

Ethan was a little more skeptical of going to a school in the middle of a city that’s 10 hours away from home, but he changed his mind after what he saw on the Tech tour.

“I really loved the campus atmosphere and design on our visit,” Ethan said. “Another reason is that Georgia Tech’s program for mechanical engineering can’t be beat. No other school we toured could touch it. I wanted to be challenged academically while also having the prestige of a Georgia Tech degree.”

Georgia Tech was also one of the only schools to give them both a scholarship.

The twins are involved in several groups around campus like the Wrestling Club at Georgia Tech, which Nathan, the club president, and Ethan, treasurer, started together. They have wrestled since middle school but always stayed one weight class apart so they never had to wrestle off for a starting spot. They both say missing the sport after high school pushed them to start the club.

They’re also executive board members for Pi Tau Sigma, the Mechanical Engineering Honor Society, the Residence Hall Association, and members of Tau Beta Pi, the Engineering Honor Society.

Ethan and Nathan both agree that always having a study buddy and being able to compare notes on the same classes is one of the benefits of having your twin go to the same school.

One downside of being a twin, Nathan says, is the confusion it causes their classmates and professors.

“Some of our professors and classmates don’t know there are two of us,” Nathan said. “There have been times when one of Ethan’s professors or classmates will approach and have a full conversation with me. I don’t always realize that they know Ethan, and it becomes awkward for me quickly. I haven’t hurt anyone’s feelings yet, so I think I’ve done a pretty good job navigating those situations.”

The twins hope to use their mechanical engineering degrees after they graduate. Ethan hopes to go into manufacturing and possibly get his master’s degree in mechanical engineering. Nathan plans to explore as many possibilities as he can over the next year to narrow down his choices.

Gone are the days of boring “cookbook” style lab courses—where students mindlessly follow directives to collect data, perform analysis, and parrot back results without meaningful thought. Now the Woodruff School’s Lab Sequence—Experimental Methods and Technical Communication followed by Systems Laboratory—aims to produce workplace-ready engineers, capable of complex system-level investigation and communication of actionable conclusions targeted toward both executive and technical audiences.

The new course progression, a result of collaboration between Director of Interactive Learning David MacNair and Frank K. Webb Chair in Communication Skills Jill Fennell, places students into roles at an engineering faux consulting firm—playfully named Burdell, Inc.—as they advance through scenarios of increasing complexity that simulate an employment journey: moving from newly hired experimental technicians to system engineers responsible for guiding high-stakes decision-making.

Across the sequence, students are taught the following tools, all while investigating technical topics from across the wide spectrum of mechanical engineering: Engineering Experimentation (“How do I characterize what is going on in the real world?”); Engineering Investigation (“How does theory help me explain real world behavior, and when does it fall short?”); and Engineering Communication (“How do I convince stakeholders of my conclusions in ways that best suit their needs?”).

“Many people imagine labs as demonstration-oriented exercises where a manual tells you, ‘Set knob A to 10, knob B to 5, and then read from dial C. Plug that number into an equation and write a report about the result.’ There is very little learning there,” said MacNair. “It’s more important that students learn an investigation process,

leveraging experimentation and engineering discernment to logically connect a client’s needs to actionable conclusions.”

Students are primarily responsible for designing key details of the lab experience themselves that produce their final deliverable, much like the autonomy they would have when dealing with a client. One project students complete is a stress/strain experiment. In their scenario, they analyze the device performing the experiment (testing high-strain elements like climbing slings and low-strain metal components such as bolts) instead of the items tested by the device. The rig has intentional issues for academic consideration, and students must use their knowledge and exploration to determine the errors occurring for the client. Their findings are presented the way they would be in a workplace, emphasizing the clear communication of the data and results to the hypothetical client.

“We want to develop their engineering judgment,” said Fennell. “We are trying to shift the bar of what it means to create industry-ready engineers by fostering their ability to determine what data is usable and needs communicating.”

Fourth-year mechanical engineering student Marina Godinez has enjoyed the challenge of directly applying her knowledge and the investigative process. “The information we are given is not super straightforward, which is pretty accurate for how it is in real life. It comes with challenges, but we get to use our engineering judgment and problem-solving skills,” she said.

This unique course design is not standard practice in other schools and is regarded by students as a great advantage.

“It was surprising how much the faculty emphasized the client-to-engineer relationship and how important it is to consolidate the technical data and language in an easily consumable way,” said student Nolan Kurtzer about the Experimental Methods and Technical Communication course.

Students taking Systems Laboratory are expected to analyze complete systems through experimentation to determine the system’s capabilities (whether they meet specifications) and when assumptions are appropriate. One project that students are tasked with focuses on an internal combustion engine. In this scenario, students

perform a complex work/energy analysis on an engine to experimentally derive the system’s properties. Students are given basic details in the form of an email from their client and, like working engineers, design and execute any testing that needs to be done and present their findings to the client.

Beyond data collection and analysis, the lab sequence trains students to become effective information designers. In both courses, students are challenged to distill complex technical findings into intuitive and actionable insights that will inform their clients’ decisions via short executive summary reports. This involves prioritizing data, choosing the most effective methods for presentation (such as visualizations), and framing results in ways that align with the client’s decision-making needs.

“In the Webb Program, we tell students that it’s an engineer’s job to communicate

information to their audience with the lowest cognitive load while still remaining trustworthy and actionable,” said Fennell. “This sequence puts the responsibility on students to determine how best to balance these needs within a very short report.”

By embedding students in simulated consulting roles at Burdell, Inc., the lab sequence offers a hands-on approach to mastering engineering judgment and communication, demonstrating that technical skill and communication skill are inextricably intertwined. As students make technical decisions in the lab, they also must plan how they can shape the information for the audience. Graduates leave with more than technical skills—they possess the discernment and adaptability needed to succeed as professional engineers who can not only understand and interpret data but also communicate its value effectively to those who depend on it for critical decisions.

Drilling, threading, or knurling, students can do it all in the Montgomery Machining Mall (MMM) where they’re given the opportunity to build and manufacture prototypes for school projects or gain experience on specific machines.

The machining mall supports academic and research projects for the George W. Woodruff School of Mechanical Engineering, the School of Electrical and Computer Engineering, the School of Materials Science and Engineering, and the College of Sciences at Georgia Tech. MMM employees maintain a professional learning space with a focus on safety.

Anyone who has spent time in the MMM in the past year has probably seen or asked for help from Harley Martin, a fourthyear student in the Woodruff School who recently completed a cooperative education program, also known as a co-op, in the

Wepfer Design Commons space.

Co-ops allow students to use their disciplinary knowledge on the job to not only reinforce and sharpen their classroom learning, but also to make meaningful contributions in the workplace.

Martin said she was determined to work in the MMM after her academic advisor brought her to meet the machine shop manager and take a tour of the facility.

“I felt welcome and had the chance to meet all the staff members,” she said. “The environment was so positive and confirmed my desire to get the experience of working with machines.”

A typical MMM co-op alternates between full-time study and three semesters of full-time work, which involves 8–10-hour shifts depending on the semester. Students can learn hands-on skills with more

than 30 different machines including manual lathes, mills, and computer numerical control (CNC) machines.

Martin said even though she’s a student, she was treated like every other staff member who was expected to fulfill all the same responsibilities. Some of her main job duties included helping students with their questions and guiding them through machine operations. She also fabricated parts for research based on specific job requests.

According to Martin, the support from the MMM staff has made a difference in her life and experience at Georgia Tech.

“The staff has been so welcoming, and everyone

has been willing to help with anything,” Martin said. “I have formed a relationship with every staff member and see them as family. I appreciate them all dearly. Words can’t capture how grateful I am to have had the chance to get to work with such a great team.”

Nathan Mauldin, machine shop supervisor, said Martin became the face of the MMM during her co-op.

“Working with Harley has been a real pleasure,” Mauldin said. “It was great to watch her go from not knowing anything about machining, to becoming so proficient in manual and CNC machines that she was able to teach others. I know Harley will go on to do great things.”

Graduate student Lillian Tso, ME 2023, was selected as an analog astronaut for the Asclepios IV mission, a training exercise that simulated a space crew deployed to the moon.

The Asclepios project is a program of analog missions designed by students for students under the mentorship of trained professionals, which began in 2019. The two-week exercise occurred last year at the Sasso San Gottardo Museum in Switzerland, a decommissioned war fortress near the Gotthard Pass, where the crew remained underground for the entire exercise simulating life at the lunar South Pole.

Tso’s participation was funded partly by a $1,000 Travel Award from the George W. Woodruff School of Mechanical Engineering. She was one of five students who received a travel award for the semester.

The crew prepared by completing nearly 12 months of intense training, including backpacking in the Andorra mountains, firefighting drills, and zero-g parabolic flight training. Tso was selected as Commander of her mission and was the only female analog astronaut in the crew. During the exercise, Tso and crew had the opportunity to control bomb-diffusing robots, go

on simulated extravehicular activities, and conduct various science experiments.

“I am so grateful for the unforgettable memories, incredible experiences, and new

Patrick Villarreal, a fourth-year undergraduate student in the George W. Woodruff School of Mechanical Engineering, took his experience and knowledge to new heights recently after completing a 14-week hands-on internship at Firefly Aerospace, where he saw his own work launched into orbit, contributing to the very projects that will help pave the way for future space exploration.

Villarreal’s journey to Firefly Aerospace began with curiosity and an online application. “I heard about the internship by checking their website for applications, but I had no idea that it would be a bigger opportunity than I initially expected,” he said.

During the three-month internship, Villarreal worked on realtime, meaningful projects that directly supported the company’ s mission. This included a variety of critical tasks, such as designing and assembling flight hardware for Firefly Aerospace’s lander missions.

Villarreal worked on Firefly Aerospace’s first Commercial Lunar Payload Services (CLPS) flight for NASA, Blue Ghost Mission 1, which launched on January 15 at 1:11 a.m. EST aboard a SpaceX Falcon 9 rocket from Launch Complex 39A at the agency’s Kennedy Space Center in Florida.

Villarreal worked directly with the Blue Ghost 1 team and contributed to multiple aspects of the project. He designed a ground support tool to streamline mechanism integration for the LEXI telescope payload, performed final acceptance testing on the final flight units of the four lander legs, worked closely with spacecraft technicians to write work instructions for complex mechanism assembly, and suited up for the cleanroom daily to assist with miscellaneous Mission 1 lander integration tasks. He also assembled the final flight antenna that got mounted to the top of the lander for in-space communications.

Blue Ghost will deliver 10 instruments to the lunar surface as part of NASA’s CLPS initiative. After approximately 45 days in orbit, Blue Ghost successfully landed in Mare Crisium (a large, dark, basaltic plain on the Moon) on March 2. It captured the lunar sunset on

March 16, providing data on how solar activity causes lunar dust to levitate and create the lunar horizon glow, which was first observed during Apollo 17. Following this it will operate several hours into the lunar night.

“I’m very excited to see structures and mechanisms I have designed or assembled fly into space and land on the moon, ” said Villarreal. “I also designed flight hardware that will launch on the Mission 2 lander towards the end of 2026.”

Along with this, Villarreal supported the Mission 2 critical design review with members of NASA and researched conceptual payload deployment designs for future missions.

One of the standout aspects of Villarreal’ s time at Firefly Aerospace was the company’s unique team dynamics. Despite the massive scale of the lander program, the Firefly team consisted of just 50 full-time employees, and Villarreal was the sole intern.

“There’s something special about being part of a small team; I really liked my coworkers’ passion for the project. Being the only intern, I was treated like a full-time employee and had the chance to contribute in multiple ways,” said Villarreal.

This was Villarreal’s second internship, and he has since completed a third. He has very straightforward advice for students seeking internship opportunities.

“Pursue every avenue possible, whether it’s cultivating a relationship with recruiters or applying to every company you may be interested in,” he said. “Keep talking to recruiters and finding applications to fill out because you might find a role to be more interesting than you initially thought!”

As a proud Yellow Jacket, Villarreal credits much of his success to the hands-on learning opportunities Georgia Tech provides.

“I’m happy to say that Georgia Tech prepared me well for this role, especially through our engaging extracurricular engineering teams like GT Off-Road and RoboJackets. Without these experiences, I wouldn’t have had the hands-on exposure needed to be impactful in an important internship like this one,” he said.

A new initiative across the colleges of engineering, business, and design will give Georgia Tech students hands-on exposure to the full sweep of product realization, from design to manufacturing, no matter their major.

Dubbed TechMade, the goal is to unify the widespread design and creation opportunities on campus and add new facets while building a collaborative design community for graduate students and researchers across the Institute.

The initiative kicks off this fall with a new undergraduate course crafted for third-year students in the three colleges. TechMade will also select inaugural fellows, a cohort of four graduate students who will help seed a research community focused on design.

TechMade is the brainchild of the George W. Woodruff School of Mechanical Engineering’s Devesh Ranjan and is being built by Woodruff Professor Carolyn Seepersad, Wayne Li in industrial design, and Karthik Ramachandran in business.

“TechMade will be an opportunity in the long term to give any Georgia Tech student exposure to hands-on designing, building, making, and product realization in a meaningful way,” said Seepersad, who joined the Woodruff School last year to begin realizing the TechMade vision. “We don’t want to create something

that just serves engineers or just serves industrial designers. We want something that serves all students across the Institute.”

TechMade is organized around three pillars: making and manufacturing, human-centered design, and what the team called “digital engineering” — teaching students to use the newest technology, like artificial intelligence, alongside their human skills to design and realize products.

Seepersad said TechMade isn’t about adding on to existing programs and opportunities. The goal is to unify the disparate offerings that already give students design experience, weave them together, and create additional pieces to strengthen students’ backgrounds. Well-known programs like Capstone Expo and the Flowers Invention Studio will be integrated under the TechMade umbrella alongside the new course for undergraduates, the graduate TechMade Fellows, and a research symposium series.

Li said a formalized ecosystem of product realization education responds to students’ desires for even more opportunity in this area.

“There is a hunger to complement theory with practical understanding of engineering concepts applied in real world situations,” said Li, professor of the practice for design and engineering in the School of Industrial Design.

Ranjan said TechMade taps the technological resources available across Georgia Tech to provide a unique, transformative experience for students, no matter their aspirations or degree program.

“Tackling problems of global significance requires creative, interdisciplinary solutions, and TechMade will be a platform for helping our students think outside the box,” said Ranjan, Eugene C. Gwaltney Jr. School Chair of ME. “It will act as a hub for enhancing transdisciplinary activities between different colleges and create a new educational experience in design for our students.”

Georgia Tech engineering students already learn about design in their educational journey. And that’s true for other majors, too. TechMade will expand that design education — deepening it for students in disciplines where it’s a focal point and offering the full picture of product realization for majors where it’s less common.

“An engineering background helps students understand certain aspects of product design and realization, but a business student’s background helps them understand other things better. And someone from the sciences or someone from design will understand other facets better,” Seepersad said. “There’s more opportunity to meet the students where they are and help them have this experience in product realization and what it means to transition an idea into reality.”

One way Seeparsad, Li, and Ramachandran have worked to deepen the experience for students is a new course debuting for the Fall 2024 semester called Product Design and Realization.

Aimed at third-year students, the class of around 30 will mix mechanical engineering, business, and industrial design students, mirroring the way product teams work in the real world. The course will be organized around the three TechMade pillars.

Interdisciplinary teams will work all semester on a big project while, along the way, solo assignments will dive deeper into making and manufacturing, human-centered design, and digital engineering. That will mean tapping low-cost, accessible tools in

makerspaces and perhaps more advanced capabilities in spaces like the Advanced Manufacturing Pilot Facility. Students will learn about AI and machine learning tools to aid in design or mine user data and preferences — marrying human skills with algorithmic power to reach the right process or product.

None of that means business or design students have to understand complex engineering calculations or modeling, for example. The goal is for them to be able to understand those things well enough to work with their engineering teammates to improve the process or product.

“I am a big believer in higher education as an empowerment exercise, rather than just sharing knowhow,” said Ramachandran, Dunn Family Professor in the Scheller College of Business. “Whether our students are talking to a future employer, a potential consumer, or an investor about their creative ideas, it is useful to remember the old mantra: Show, don’t tell. A formal course that introduces design and manufacturing knowhow to our students will be massive in empowering them.”

In these early days, TechMade is a collaboration across engineering, design, and business, but Seepersad said the aim is to involve the other Colleges on campus and expand to the entrepreneurial ecosystem in Atlanta.

Already, the TechMade Fellows span a variety of fields, and the design community they’re seeding will be agnostic of discipline. More sections of the Product Design and Realization course could come online in future years, too, including any School interested in integrating more product realization into its elective offerings.

Seepersad, Li, and Ramachandran are thinking about how to build modules and tools to make it easy for other instructors to pick up the course and teach it.

Philanthropic support will be a critical factor for the growth and sustainability of the TechMade vision, Ranjan said: “The TechMade initiative will have a transformative impact on Georgia Tech students, enabling these future engineers and designers to produce novel ideas and create solutions to the world’s most challenging problems.”

Each year, a small group of graduate students will be TechMade Fellows. They will receive a year of financial support and serve as the nexus of a monthly research symposium series for design-focused research. TechMade Fellows also will be charged with helping to build community across the pockets of design throughout campus.

Mammograms can be an effective resource for detecting breast cancer, but for some women, it can be an invasive and uncomfortable experience.

That’s why Gianna Slusher, Ph.D. student in the George W. Woodruff School of Mechanical Engineering, developed a device that could serve as an effective alternative to traditional early detection methods for breast cancer.

Slusher and her partner, Caitlin Reina, received an official patent for inventing a mounted thermographic imaging system that can be used at home to detect medical issues such as breast cancer.

The device includes a mount that can attach to a wall and a clamp that holds a smartphone or tablet. Through an app programmed by the pair, it uses thermal images as a non-invasive and radiationfree way to capture changes in breast temperature associated with cancerous tumors. The mount can be positioned in multiple discreet and various angles, which can allow for consistent imaging. The user would be instructed on the app to see a doctor if an anomaly is detected.

After months of intense competition, Convexity Electronics has been crowned the 2025 InVenture Prize winner. The team’s groundbreaking invention, an electronics 3D printer for manufacturing 3D-printed circuit boards (PCBs) at scale, promises to improve electronics manufacturing by enabling smaller circuitry, faster lead times, and more compact electronic devices.

Teammates Calla Scotch (materials science and engineering), Anuj Pandey (mechanical engineering), and Atharva Lele (chemical and biomolecular engineering) combined their expertise to develop a technology with the potential to reshape how PCBs are produced. By streamlining the manufacturing process, Convexity Electronics aims to make electronic devices more efficient and accessible across industries.

When asked what winning the InVenture Prize meant to them, the team echoed one another enthusiastically onstage: “We can finally do this!”

For their first-place finish, the team will take home $20,000 and a coveted spot in Georgia Tech’s CREATE-X Startup Launch program, where they will receive mentorship and guidance to help bring their product to market.

“The next step is building more printers,” said Pandey, trophy in hand, “testing out our technology on more boards, and using our connections to start implementing our printers and PCBs. You’ll see us everywhere!”

A love for engineering and a lifelong passion for music led mechanical engineering graduate student Kevin Kamperman to an unusual project: 3D printing a fully functioning acoustic violin.

And what started as a final project in an additive manufacturing class now is a provisionally patented design.

“Seeing this dream become a reality is deeply fulfilling,” said Kamperman, a multiinstrumentalist himself. “This invention has the potential not only to be practical but also to bring joy to those who might one day use it to create music. Knowing that something I contributed to could inspire creativity in others is incredibly rewarding.”

The intent of the violin design was to replicate both the sound and feel of a traditional wooden instrument using only additive manufacturing materials and methods. Kamperman and his teammates worked with Endeavor 3D in Douglasville, Georgia, to fabricate their design using the company’s advanced, powder-based 3D-printing equipment.

Once the group made a prototype, they collected performance data in an anechoic chamber at the Georgia Tech Research Institute, comparing their violin to a midpriced and a high-priced wooden instrument.

In their tests, the sound from the polymer violin ranked highest for warmth, natality, and brilliance. Test violinists praised the warmth of the D and G strings but described the A and upper E strings as slightly nasal and less brilliant. A loudness test revealed the polymer violin produced slightly quieter sound than its wooden counterparts.

Kamperman said he’s excited about making music and arts more accessible, affordable, and inclusive. He hopes combining the precision of 3D printing with the artistry of instrument-making can break down barriers for musicians and revolutionize traditional craftsmanship.

Georgia Tech Motorsports (GTMS), one of the oldest competition teams operating at Georgia Tech, sped into a historic third-place overall finish at the 2025 Formula Society of Automotive Engineers (FSAE) Michigan, marking the first podium placement in over two decades and tying the program’s bestever result.

The FSAE competition challenges university undergraduate and graduate student teams to conceive, design, fabricate, develop, and compete with formula racing-style vehicles. Teams are required to participate in a series of events, both on and off track, and have the chance to demonstrate their creativity and engineering skills against groups from other universities around the world. This year, a staggering 108 teams entered the competition.

Entries are tested in endurance, acceleration, design, cost, and sales presentation. GTMS performed well in all events, and their composite scores led to their place on the podium.

“This year marked several historic firsts for us,” said team lead and neuroscience and business administration major Alexander Merryman. “We won the Endurance event for the first time, a 22-kilometer test of vehicle reliability and efficiency that many teams don’t even complete.”

The result is GTMS’ first top-three finish since 2002. This year’s performance represents a breakthrough for the studentrun organization that operates out of Georgia Tech’s Student Competition Center (SCC).

“GTMS could not have done this without the support the Woodruff School provides the SCC,” said Jacob Tompkins, mechanical engineer III in the Woodruff School, and staff support in the SCC.

GTMS has 123 active members, affectionately known as “membos,” from various majors, including several mechanical engineering students in leadership positions and other roles. Thirty members traveled to Michigan for the competition, representing current leadership and the next generation of team leaders.

However, the road to the competition wasn’t smooth. Early in the academic year, GTMS faced a significant financial setback when its Student Government Association funding was slashed by nearly 70 percent, part of a broader reduction affecting registered student organizations across campus.

“Our business team sprang into action, securing new sponsors and grants,” said Merryman. “Leadership worked to reduce costs by 30 percent and integrated costconsciousness into our design philosophy.”

Technical challenges then followed. In January, after a successful day of testing, the

team left the car off-campus overnight. A rare Georgia freeze caused the engine block to crack due to coolant expansion. GTMS runs pure water as the coolant, a decision that ultimately backfired in the cold.

Weeks later, a wheel hub was sheared off during another test, sending the front-right wheel 500 feet into a stream. Fortunately, the driver was unharmed, and the car sustained minimal damage. However, the incident set the team back by six weeks.

“These challenges underscored the importance of our biggest strategic shift this year, finishing the car early,” said Merryman. “Because we completed the vehicle in December, we had time to test thoroughly and recover from unexpected issues.”

By the time the team arrived in Michigan, the car had logged over 230 miles of testing, another first for GTMS. That preparation paid off. The team passed static tech inspection on the first attempt, a comprehensive safety and compliance review that often takes teams multiple tries. The goal was to have a boring competition, meaning everything went according to plan, and for the first time in years, it did.

The HyTech Racing team, a student group that designs and develops Formula SAE electric vehicles, finished third overall at the recent FSAE-EV competition in Michigan. The team placed first in acceleration and was a design finalist for the first time.

HyTech’s mission is to provide students with hands-on experience in vehicle design and development, building skills in mechanical and electrical engineering, machining, testing, project management, and more.

GTMS builds a new car each year, as required by FSAE rules, but its two-year design cycle sets the team apart. The 2025 car was designed in the fall of 2023, and the 2026 vehicle is already in production. This extended timeline allows for deeper testing, refinement, and innovation.

The team’s performance has also earned them an invitation to a new international invitational in Rome, Italy. The event will feature the top 100 teams worldwide and be hosted by FSAE in partnership with the Fédération Internationale de l’Automobile, the global motorsport body behind Formula 1 and Formula E.

“We’re actively seeking funding to make the trip. It’s a huge opportunity to represent Georgia Tech and showcase what it truly means to be a helluva engineer on a global stage,” said Merryman.

With the celebration, the team remains focused on the future. With their sights set on gold next season, GTMS is already back in the shop, designing, building, and preparing to push the limits again.

Three years ago, the Georgia Tech EcoCAR team was given a 2023 Cadillac LYRIQ and two objectives: turn it into an all-wheel drive vehicle and implement autonomous capabilities.

After hard work from students across the Georgia Tech campus, including from the College of Engineering, College of Computing, and the Ivan Allen College of Liberal Arts, the team’s car now has two electric motors and autonomous driving capability.

But, how would the new features hold up at the Year Three Competition?

After a second-place finish at last year’s competition, the car needed to perform even better under much tougher scrutiny this year.

When the nearly two-week-long competition came to an end, the Yellow Jacket team once again proved to be among the best in EcoCAR, finishing second overall.

The EcoCAR EV Challenge is a collegiate competition sponsored by the U.S. Department of Energy, General Motors, and MathWorks, and managed by Argonne National Laboratory. The four-year program spans 2022-2026 and features annual competitions.

The Georgia Tech team is one of the Institute’s largest Vertically Integrated Projects, under the guidance of School of Electrical and Computer Engineering (ECE) Professor David Taylor, along with George W. Woodruff School of Mechanical Engineering (ME) Professors Antonia Antoniou and Michael Leamy.

The team is now moving ahead with preparations for the final year of the EV design cycle. Their goals are even loftier next year with plans to build a market-ready vehicle.

The team will spend the final year shoring up weaknesses exposed at this year’s competition and diving deeper into the autonomous functions, with an aim to complete every dynamic event at the final competition next year.

“We have big hopes for next year, and we have a really great team returning,” EcoCAR project manager and ME graduate student Eric Gustafson said. “Our entire team is super proud of what we’ve accomplished this year, and we really believe that we’re in a really great spot going into next year.”

Students enrolled in the course Electric Vehicles (EV) & the Grid strapped on helmets and raced their custom-modified scooters in the EV & the Grid Grand Challenge, a high-voltage, high-fun competition that tested speed, innovation, and creativity.

Electric Vehicles & the Grid teaches engineering principles of electric transportation and the energy infrastructure. The class also covers the emerging technologies of batteries, renewables, and connectivity that will allow further optimization of the products with the grid.

As part of their final grade, students modify Segway scooters to include a custom circuit board with microprocessor and display capabilities, energy monitoring circuits, solar charging circuitry, a battery spacer, and custom racks to secure these to the vehicle.

The challenge is the culmination of a semester-long project. Throughout the course, students complete a series of technical tasks that prepare them for race day. Early on, each student is assigned a U.S. city and writes a simple Python algorithm that determines when the scooter should charge based on factors such as green energy availability, cost savings, or grid load shedding specific to that location.

Students can work through 10 modules to earn points leading up to the EV & the Grid Grand Challenge, where they compete in a relaystyle race for the fastest lap time with the lowest energy use.

Electric Vehicles & the Grid is offered through a collaboration between the George W. Woodruff School of Mechanical Engineering and Siemens. Alumnus Barry Powell, M.S. ME 1991, head of Siemens Electrical Products for North America, and John DeBoer, Head of Siemens Future Grid and eMobility Solutions, have sponsored the course since its launch in Spring 2023.

Students appreciate the interactive learning aspect of the course and the perspective it gives to the full scope of EVs.

Mechanical engineering master’s student Aaryan Bhiwandkar enjoyed the hands-on experience of working on the karts and benefiting from Tinskey’s automotive expertise.

“I thought it would be great working with Professor Tinskey, knowing his background with Ford,” he said. “I liked learning about the grid, how electric energy impacts the environment, and, of course, the race!”

The EV & the Grid Grand Challenge provides a dynamic element to the course, empowering students to apply their engineering knowledge in a practical, active setting that reflects the future of electric mobility.

Along with the Siemens partnership, support from the School and the Institute has helped bolster the success of the course. Tinskey looks forward to the course continuing, giving future students the opportunity to be on the cutting edge of EV technology.

Undergraduate and graduate students in the George W. Woodruff School of Mechanical Engineering had the chance to compete in communication-based tasks that pushed them to demonstrate that engineers can communicate beyond equations in the second annual Webb-Donnell Communication Competitions.

Created in honor of Frank K. Webb, ME 1938, and Jeffrey Donnell, former principal academic professional in the Woodruff School, the competitions aim to highlight the critical need for engineers to communicate their work in a way that is understandable and incites action and change.

In 1999, Webb bestowed an endowment upon the Woodruff School that ensured the continued support of students’ communication skills. Donnell was named the first Frank K. Webb Academic Professional Chair in Communication Skills and held this position until his passing in 2022.

With this generous gift from the Frank K. Webb Trust, the Woodruff School continues its mission of providing students with this critical resource to help them succeed in the classroom and on their career paths.

Jill Fennell, the current Frank K. Webb Academic Professional Chair in Communication Skills, is dedicated to continuing this mission, and these competitions are one initiative she has undertaken to do so.

“These competitions aren’t just about prizes—they’re about preparing engineers to solve society’s toughest problems by

communicating solutions in ways that inspire action. Because what good is a breakthrough if no one understands it?” said Fennell.

Undergraduate students could participate in two competitions. They could create a written PSA for a general audience on daily activity safety, emergency preparedness, or ergonomic awareness, or they could design a safety poster for one of several Georgia Tech facilities. Graduate students could participate in a Ted Talk-style presentation that showcased how their original research addresses pressing challenges or contributes to advancements that impact daily life, public safety, or societal well-being.

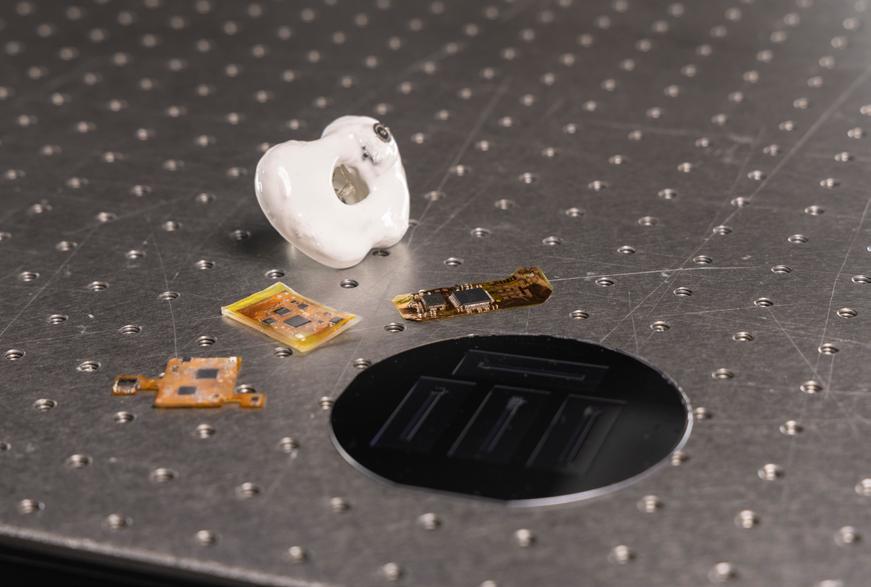

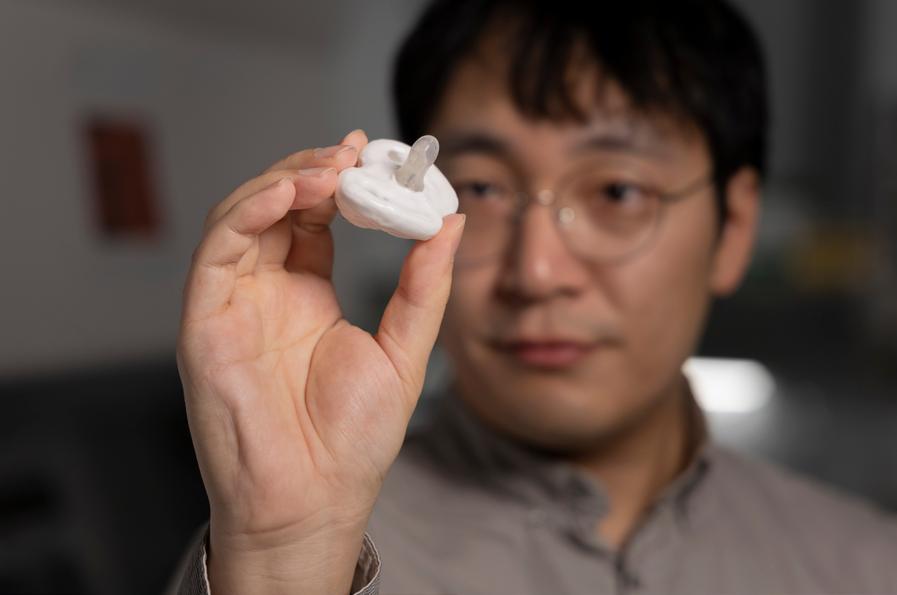

Chinaza Ogbonna, winner of the Quick Talks Graduate Communication Competition for her presentation “A Smart Implant for Safer Surgeries,” was honored to receive such a distinction, as she has only recently begun presenting her research.

“This is the second time I have talked about my research publicly, and it feels amazing that people see the value in my work. It makes me feel more motivated to continue my work efficiently and safely, and hopefully save lives,” said Ogbonna.

Hannah Shin, awarded first place in the Safety PSA competition, was inspired by her health challenges for her entry, “The Silent Strain: How Your Desk Setup is Ruining Your Body.” Shin was experiencing vision issues and back pain, and realized she was guilty of several poor workspace practices.

“Now that I am trying to fix it within myself, I am noticing it in others, so it was perfect for the PSA,” said Shin.

Jacob Stancil was inspired by Fennell to enter the competition after one of her presentations. His winning entry in the Safety Poster Competition is aimed at lab space users and the risk of wearing gloves when they are inappropriate.

Fennell was extremely grateful for the support the competitions once again received.

“I want to thank all the volunteer judges— alumni, faculty, staff, and friends—for supporting these students and believing, as Webb and Donnell did, that communication turns ideas into impact. The competition was tough, and I am grateful to have had other discerning judges to collaborate with,” she said.

The winners were presented with the awards during a ceremony attended by members of the Woodruff School community and honored guests: Martha Webb, the Frank K. Webb Trust co-executor; her husband, neuropathologist Dr. Dana Copeland, who also served as a final judge; and Susan Liebeskind, wife of the late Jeffrey Donnell.

“These competitions aren’t just about prizes—they’re about preparing engineers to solve society’s toughest problems by communicating solutions in ways that inspire action.”

—Jill Fennell

Theme parks have always felt like home to Dennis Velez. He wants to recreate that feeling for people around the world.

As a member of a military family, Dennis Velez moved a lot throughout his childhood, but no matter where they lived, whether it was Jacksonville, Florida, or Yokosuka, Japan, the nearest theme park always felt like home.

Velez never tired of the thrill of a roller coaster and other attractions, but the more parks he visited, the more interested he became in their design and operation — most memorably as an elementary school student during a trip to Tokyo Disneyland.

“The more I learned, the more I realized that it’s one of the craziest engineering problems you can have. Sending people on these attractions that go for hours on end every single day of the year, they have to be perfectly safe and perfectly designed to make sure they can run efficiently and give the same experience to every guest every day,” he said.

Velez arrived at Georgia Tech in 2021 as a mechanical engineering student. He quickly earned the nickname “safety guy ” in the Theme Park Engineering Design Club, as he continued to narrow his focus and determine how to use his major in the industry.

“There are insane ideas for rides and how they are supposed to make you feel — like you’re flying on a broomstick or traveling through space,” he said. “So, how can we leverage technology that exists to reflect that idea, make sure it works as intended, and run it safely?”

Velez became Georgia Tech’s first student representative on the ASTM Committee F24 on Amusement Rides and Devices — a global organization that develops standards and best practices for theme park attractions. Completing internships with Oceaneering’s entertainment systems division and Universal Studios, he learned the project management skills to see an

idea come to fruition and better understand the teamwork required to execute its delivery.

“When you’re an engineer, you’re never working on your own. You’re always working with a lot of people, and you have to make sure that you can work well with others and integrate your skills with your team,” he said.

Velez sees that same principle of interconnectedness in his role as a trumpet player in the Yellow Jacket Marching Band.

“If you mess up as one of 40 trumpets, people may not notice because other members are there to hold you up. It’ s another aspect of uniformity and connectedness in a group, and it starts with having a strong connection. For the band, that comes from doing something we love for our school and getting in the heads of the opposing teams at the same time,” he said.

His extracurricular activities and internships took him to new places during his undergraduate degree program, but Velez calls the trip to Ireland to kick off the 2024 college football season his “ magnum opus ” and an experience he’ll remember for a lifetime.

Velez will return to campus in the fall to pursue a master’ s in mechanical engineering before entering the industry. While he admits there were stressful days along the way, he never viewed his time as an undergraduate as a roller coaster, but rather a day at the park.

“Theme parks were always our happy place because we were together as a family, and I’m just excited to one day see the reactions of kids and their families experiencing a ride that I worked on, and giving them that same sense of wonder, ” he said. “This industry is all about bringing joy to others, and I want to do my part in creating this outlet for all to enjoy.”

From a young age, Rijul Patel, fourth-year undergraduate student in the George W. Woodruff School of Mechanical Engineering, knew he wanted to attend Georgia Tech. Not just to follow in his brother’s footsteps, but because he knew the Tech reputation was more than just a name.

As one of the nation’s top public research universities, Patel always saw Georgia Tech as an institution meant for those who challenge the norms, go beyond practical response, and seek the ultimate solution.

Not only did he accept that challenge, but this semester, Patel will be achieving his goal of walking across the stage at Georgia Tech’s graduation ceremony and living up to those expectations he set for himself.

As a Douglasville, Georgia native, Patel began his journey at Tech in Fall 2021. He knew coming in that the Institute was known as one of the best universities in the country, but he learned early on that that title is not something that’s just given—it’s earned through the dedication and hard work of its students completing the coursework while also becoming a well-balanced person.

“At the end of the day, you are the one who makes or breaks that title,” Patel said. “The motto Progress and Service is something I truly understand now that I have completed my degree.”

Between all of the lectures, projects, and meetings he went through in the Woodruff School, it’s the community that Patel built for himself that he says he will miss the most when he moves on to the next stage.

Part of that community for Patel is being the president of the American Society of Mechanical Engineers (ASME). ASME is a student-led organization committed to fostering professional growth and creating opportunities for career development for mechanical engineering students through events, weekly meetings, career fairs, and networking events. These events serve as opportunities for students to establish connections with industry partners and explore potential career paths.

“It’s been incredible to see the growth of the club that helped me grow both professionally and academically,” Patel said.

After graduation, Patel plans to join GE Vernova for its Edison Engineering Development Program (EEDP), a career development program that exposes its members to industry-leading innovators in the power sector. Members work to solve one of the biggest climate crisis problems, providing electricity while at the same time reducing greenhouse gases. At the same time, he plans to pursue his master’s degree in mechanical engineering at Georgia Tech.

Looking back on how he got to this moment, Patel has one piece of advice for students who may follow in his path—enjoy the progress.

“These years will be some of the most demanding moments of your life, so make sure to find enjoyment in what you do,” Patel said.

Greeshma Agasthya joined as assistant professor. She was elected to serve a threeyear term in the southeast chapter of AAPM.

Alexander Alexeev received the Woodruff School Outstanding Achievement in Commercialization and Entrepreneurship Award.

Steve Biegalski was awarded the Radiation Science and Technology Award by ANS.

Yifeng Che joined as assistant professor.

F. Levent Degertekin was named Regents’ Entrepreneur.

Shaheen Dewji was named Woodruff Faculty Fellow.

Bachir El Fil joined as assistant professor.

Andrei Fedorov received two R01 grants from NIH. The funding, a combined $4.81 million, will be used to develop new instrumentation for biomedical research. He was also selected to represent Georgia Tech in a new international research initiative. The program will receive $3.2 million in funding to explore the intersection of AI and informatics, and energy.

Jill Fennell received the Woodruff School Chair’s Appreciation Award.

Aldo Ferri received the Woodruff School Sustained Exceptional Performance Award.

Craig Forest, associate director for MAKE at CREATE-X, played a pivotal role in the program’s Capstone Design course — one of the elements that helped earn CREATE-X the 2025 ABET Innovation Award.

Andrés J. García received the 2025 Biomaterials Global Impact Award from Elsevier’s Biomaterials.

Srinivas Garimella received the 2024 ASME Heat Transfer Memorial Award and the Georg Alefeld Memorial Award.

Abbe Gilmore joined as research associate II-NE.

Rudolph Gleason was promoted to professor.

Ari Glezer received the 2025 AIAA Fluid Dynamics Award.

François Guillot received the CoE Outstanding Faculty Achievement in Research Award (Research Faculty) and the Woodruff School Research Faculty Excellence Award.

Marta Hatzell was appointed interim deputy director of the Georgia Tech Strategic Energy Institute.

Nolan E. Hertel received the Randall S. Caswell Award from CIRMS.

Suhas Jain received the 2025 DNI Award from the American Chemical Society PRF and the 2025 DOE ALCC Award.

Kristen Jakubowski joined as lecturer.

Amit Jariwala was promoted to principal academic professional.

Kyriaki Kalaitzidou was reappointed associate chair for faculty development.

Dooroo Kim joined as research engineer II-NE.

Hojoong Kim joined as research engineer II.

Satish Kumar received the Woodruff School Mentor of the Year Award. He is part of a collaborative team that was awarded a combined $7.3 million from ONR as part of the MURI program. He and his collaborators received the five-year award for their project, Machine learning Enabled Two-pHase flow metrologies, models, and Optimized DesignS (METHODS).

Seung Woo Lee was promoted to professor.

YongWon Lee and his Georgia Tech collaborators were awarded $2 million to advance research in next-generation semiconductor packaging technologies. Georgia Tech was selected as a key partner institution by South Korea’s Ministry of Trade, Industry and Energy (MOTIE) for this major international initiative.

Maegan Lenertz joined as research engineer I.

Steven Liang was named Regents’ Professor.

Zhantao Liu received the Woodruff School Postdoctoral Excellence Award.

Peter Loutzenhiser was promoted to professor.

Anirban Mazumdar was named Woodruff Faculty Fellow.

Ellen Yi Chen Mazumdar was named Woodruff Faculty Fellow. She received the CoE Outstanding Teacher Award (Early Career).

Matthew McDowell was selected as associate chair for research. He was chosen to participate in Georgia Tech’s Emerging Leaders Program.

Kristi Mehaffey received the Woodruff School Outstanding Non-Tenure Track Faculty Award.

Shreyes Melkote was named interim school chair. He received a Distinguished Alumnus Award from the Indian Institute of Technology Kharagpur.

Akanksha Menon received the Early Career Researcher Award from ASTFE. She was named to ASME’s 2025 Mechanical Engineering magazine Watch List.

Karthik Menon joined as assistant professor.

Joseph Mooney joined as research engineer II-LT.

Zhanna Nepiyushchikh was promoted to senior research scientist.

Lokanath Patra joined as research engineer II.

Samuel Petter received the Woodruff School Teaching Excellence Award for NonTenure Track Faculty.

Devesh Ranjan was named dean of the College of Engineering at the University of Wisconsin-Madison. He received the 2024 Distinguished Alumni Award from the National Institute of Technology Tiruchirappalli.

Sourabh Saha was named Woodruff Faculty Fellow. He received the Woodruff School Outstanding Junior Faculty Award.

Christopher J. Saldaña was promoted to professor.

Gregory Sawicki was promoted to professor. He was selected to serve as interim executive director of the Georgia Tech Institute for Robotics and Intelligent Machines.

Ankur Singh was awarded $7.5 million from NIH for his pioneering research in creating functional models of the human immune system in the lab.

Suresh Sitaraman was selected to serve as the director of the steering committee for the new SMART Packaging Program. He will be a key contributor to Georgia Tech’s efforts on the project funded by DARPA to develop the next generation of highperforming semiconductor microsystems for the DoD.

Aaron Stebner was promoted to professor. He was selected by ASM International to receive the 2025 ASM Silver Medal.

Prasoon Suchandra joined as research engineer II.

Todd Sulchek received the Woodruff School Outstanding Achievement in Commercialization and Entrepreneurship Award.

Susan Napier Thomas received the Woodruff School Mentor of the Year Award.

Mike Tinskey was appointed inaugural interim associate chair for innovation and entrepreneurship. He was awarded the inaugural Siemens Corporation Termed Professorship.

Shannon Yee was promoted to professor.

W. Hong Yeo received a Peterson Professorship with the Children’s Healthcare of Atlanta PTC at Georgia Tech. He was awarded a $3 million grant from the NSF Research Training program to help develop a new generation of engineers and scientists in the field of sustainable medical devices. He won the Med-X Young Investigator Award, the Woodruff School Culture Champion Award, and the Woodruff School Research Award.

Aaron Young received the Woodruff School Outstanding Mid-Career Faculty Award.

Fan Zhang received the 2025 Landis Young Member Engineering Achievement Award from ANS, the CoE Outstanding Faculty Achievement in Research Award (Early Career), and the Woodruff School Outstanding Junior Faculty Award. She was named a 2025 Jim Pope Fellow and Class of 1969 Teaching Fellow.

Zhuomin Zhang received the 2025 Elsevier/JQSRT Poynting Award on Radiative Transfer and the Woodruff School Distinguished Faculty Achievement Award.

Ye Zhao was named Woodruff Faculty Fellow.

The Georgia Tech community mourns the passing of Ward O. Winer, a distinguished Regents’ Professor Emeritus in the George W. Woodruff School of Mechanical Engineering, who passed away on May 25, 2025, at the age of 88. Winer’s contributions to mechanical engineering and his unwavering dedication to Georgia Tech have left an indelible mark on the Institute and its people.

Winer began his academic career at the University of Michigan. In 1969, he came to Georgia Tech, where he spent nearly 40 years until his retirement in 2008. From 1989 to 2008, Winer was the longest-serving chair of the Woodruff School. After retirement, he was asked to return as the interim chair of the School of Civil and Environmental Engineering for a year, and he continued part-time at Tech until 2019. He maintained his involvement on national and international boards until 2023.

“Ward was instrumental in elevating the School’s academic and research programs. His tenure was marked by a commitment to excellence and a vision that strengthened the School’s standing within Georgia Tech and the broader engineering community,” said Devesh Ranjan, Eugene C. Gwaltney, Jr. School Chair and professor.

Winer’s research spanned tribology, fluid mechanics, highpressure rheology, lubrication, thermomechanics, and machinery diagnostics. Notably, he led a Department of Defense (DoD) MultiUniversity Research Initiative focused on integrated diagnostics of machinery, a testament to his innovative approach to engineering challenges. Other research projects under Winer’s direction were funded by companies from the petrochemical industry, the National Science Foundation, the National Aeronautics and Space Administration, the Office of Naval Research, and the DoD.

Winer’s distinguished academic career was marked by numerous honors and awards, including election to the National Academy of Engineering in 1988 and as a Fellow of the American Society of Mechanical Engineers and the American Association for the Advancement of Science, underscoring his profound impact on his field. He also received the Georgia Tech Distinguished Professor Award and the Sigma Xi Monie A. Ferst Memorial Award for Sustained Research.

Beyond his professional achievements, Winer was a devoted husband, father, and grandfather. He and his wife, Mary Jo, shared a life rich in experiences, including raising four children and welcoming 13 grandchildren and seven great-grandchildren. Their partnership was a cornerstone of his personal life, reflecting the same dedication and care he brought to his professional endeavors.

Winer’s legacy is one of mentorship, integrity, and a relentless pursuit of knowledge. His influence will continue to inspire future generations of engineers and educators, and his impact on Georgia Tech and the field of mechanical engineering will be felt for many years to come.

Cranes are common features in urban skylines. Because construction projects are constantly beginning and ending, the exact number of cranes in use globally is unknown. What is known, however, is that cranes have caused hundreds of deaths and catastrophic injuries. In the U.S. alone, dozens of deaths occur annually, and the construction industry loses billions of dollars.

“Crane usage is not well regulated or well measured. A lot of accidents are not reported or cataloged — and for those that are, there’s often not a proper investigation,” noted William Singhose, professor in Georgia Tech’s George W. Woodruff School of Mechanical Engineering and director of the Crane Safety Research Center.

The center includes researchers from Georgia Tech, the University of Washington, Utah State University, construction equipment suppliers, and industrial automation specialists. Together, they hope to bridge the gap between engineering curricula, practical applications, and legislation.

“We have a six- to eight-year timeline of funding. Our directive is to improve crane safety,” Singhose said.

With the infusion of support, researchers don’t have to apply for funding, which will allow the researchers freedom to focus on pursuing innovative, meaningful ideas.

To mark the center’s one-year anniversary, Georgia Tech hosted a one-day symposium in April to share the center’s latest research findings and priorities. Industry speakers presented information on crane operations and safety.

Attendees included university and industry collaborators, including a contingent from American Crane of Philadelphia. Also in attendance were the center’s funders, Andrea Wang and Henry Wong. They established the research center after losing their daughter, Sarah Pantip Wong, in 2019 in a Washington state crane accident.

A major thrust of their efforts involved championing crane safety legislation to protect the public, focused first in Washington. The state’s legislators unanimously passed this legislation in March 2024, and it will be implemented over the next three years. Part of the family’s efforts include supporting a certification process for crane assembly and disassembly directors, who are required by federal and state Occupational Safety and Health Administration laws to be onsite supervising the crane operations.

Georgia Tech’s College of Design, under Dean and John Portman Chair Ellen Bassett, is working with the Crane Safety Research Center to draft model legislation state and federal lawmakers can use. Wong said that research coming out of academia could inform policymakers to help drive safer rules and procedures for protecting the public near tower cranes.

“The idea is to start a process where we can get information and research out there to enable better safety,” he said.

Wang emphasized that every time a crane-related tragedy occurs, it gets covered by the news and then vanishes until another accident happens. “People don’t realize that there is not a concerted effort to look at these incidents from a public safety perspective,” she said, adding that the way these accidents are categorized is not consistent.

Singhose, whose research focuses on the dynamics and control of flexible machines, says, “I’ve been working on cranes for more than 30 years. I’ve always known cranes are dangerous and challenging, and that it is important to control them better.”

Though the Bureau of Labor Statistics reports that in the U.S., an average of 44 people die in crane-related accidents; Singhose estimates the number is much closer to 200, when all crane-related machines are taken into consideration.

When Singhose was a toddler, his father was involved in a crane accident that hurt a close family friend. And in 2001, Singhose was at work in the Georgia Tech Manufacturing Institute when a crane accident destroyed a $750,000 machine inside the building. He later used that crane, stabilized by advanced technology, as a laboratory to test crane safety technologies.

Key innovations developed include anti-sway and anti-snag technologies to ensure cranes operate smoothly and avoid entanglement with building materials or supplies. According to Singhose, cranes move sideways when they are out of position, increasing the risk of these incidents. The risks are exacerbated on large cranes, where the operation is performed with joysticks or buttons, often from hundreds of feet away. Georgia Tech’s research has focused on advances including cable angle sensing for safe crane control, wind load modeling, and crane section lift-off modeling.

“Cranes are designed for their payload to hang straight down. They are not very strong sideways — that’s why wind tips them over,” said Singhose, adding, “Misalignment before the crane payload lifts off creates a double-swing problem, and that’s killed a number of people over the years.”

Georgia Tech has developed lift-off control technology and inputshaping techniques to address these issues. Christopher Adams, a mechanical engineering research engineer and assistant director of the center, said his interest in crane safety grew out of his research looking at how to stabilize helicopters carrying suspended loads; helicopters are, in essence, flying cranes.

“Because there are so many kinds of cranes and ways to make them safer, our projects are pretty broad. They range from studying existing standards and regulations to technologies to make cranes safer, and that keeps it interesting,” said Adams.

Wind and electrical lines play major roles in crane accidents. One of the most notorious wind-induced crane accidents occurred in 2015 at Mecca’s Grand Mosque, Islam’s holiest site. Extreme weather conditions, including high winds, caused a crane collapse that killed more than 100 people.

And operating cranes near power lines often increases the severity of accidents. “A fairly large percentage of deaths and injury are caused by electrocution,” said Adams.

The researchers stressed that crane accidents are rarely caused by a single factor. Instead, they are often the result of human error, compounded by additional contributing elements.

“I’ve investigated a number of crane accidents, and it usually takes three things to go wrong,” explained Singhose, observing that cranes are robust enough to handle one thing going wrong — but not the cumulative effect of multiple issues.

Both Singhose and Adams reiterated the importance of moving a crane without swinging the payload. As cranes have gotten taller and taller, industry standards on how to reinforce these cranes and prevent accidents haven’t kept up.

Adams contributed to a recent Georgia Tech paper examining how industry standards intended to prevent tip-overs of mobile boom cranes provide a decreasing stability margin as mobile cranes have gotten taller. A smaller stability margin means a crane more easily tips over.

Another big challenge is that crane safety standards are not mandatory but voluntary.

“The way they really get enforced is through lawsuits after a tip-over kills somebody,” Singhose said.

For Andrea Wang, the real indication of positive change will be when the construction industry stops assigning blame for crane accidents and instead embraces education and prevention. As a pharmacist, she has seen this transformation in healthcare with how the industry handles medication errors.

“It’s all about safety. Not until you start changing the culture will mindsets change,” she said. “That’s what needs to happen.”