Future of Manufacturing

www.businessnews.ie

“Digital and additive manufacturing are rewriting the rules again.”

Dr Stephen O’Driscoll, Head of Research Centres, Research Ireland Page 02

“AI is now a priority for 52% of businesses, with 97% planning adoption to improve efficiency.”

Sharon Higgins, Executive Director, Membership and Sectors, Ibec Page 10

There is a strong need for companies to identify where robots and automation add the most value – and where they don’t.

~Domhnall Carroll, CEO,

Digital

Manufacturing Ireland

How manufacturers can boost AI adoption — with the help of academia

Manufacturing companies can leverage AI to gain a competitive advantage. However, they also face various AI adoption challenges that must be overcome with careful planning.

Professor Denis Dowling, Director of I-Form, the Research Ireland Centre for Advanced Manufacturing, headquartered at University College Dublin, works with industry partners on bespoke solutions that make their processes more efficient, sustainable and profitable.

Crucial advantages for manufacturers adopting AI

He outlined that AI presents manufacturers with numerous important advantages. “Take predictive maintenance,” he says. “Sensors and data analysis can help identify problems in the manufacturing process at an early stage. Manufacturers can then modify the process or stop the equipment, but either way, they will have enhanced processing efficiency, because they won’t be wasting their materials and energy.”

For example, Prof Dowling recalls how I-Form developed a bespoke machine learning-based Recommender System for one SME partner. This analyses sensor data in real-time to detect manufacturing defects and then sends recommendations to an operator’s mobile in under nine seconds. The SME was able to enhance the yield from its manufacturing process, while reducing both waste and development costs.

AI also offers manufacturers valuable predictive modelling capabilities. For instance, when I-Form developed a set of bespoke AI-based simulation tools for the design and manufacture of engineering components, the company that trialled the tools reported a 90%

@MediaplanetUKIE

Strategic Account Manager: Kate McSwiggan kate.mcswiggan@mediaplanet.com

Media Manager: Jonni Asfaha All images supplied by Getty Images, unless otherwise specified

Director :

reduction in the number of physical experiments needed to develop its new product line.

A careful and strategic approach for successful AI adoption

Nevertheless, manufacturers should be aware that successful AI adoption must be carried out carefully and strategically to overcome the various challenges they will inevitably confront. These include high upfront investment costs, integration difficulties with legacy systems and a lack of skilled talent. Access to goodquality data is also key. “If poor information goes in, then poor information comes out,” says Prof Dowling.

Cultural resistance from employees is another issue.

“There’s a human-centred side to AI adoption — including the upskilling of staff and job changes — which is important to consider,” says Prof Dowling. One way to make AI adoption easier is for manufacturers to engage in collaborative research with academia. They can then access cutting-edge knowledge, specialised expertise and advanced facilities without heavy upfront costs.

Partnerships also support long-term skills development, attract funding opportunities and ensure alignment with ethical, regulatory and sustainability standards, making AI adoption in plants more practical and scalable.

Those that successfully adopt AI have the potential to use it to enhance efficiencies,” says Prof Dowling. “Those that don’t do so are likely to be at a disadvantage.”

McGregor |

Big impact from small-scale precision in advanced manufacturing

Investment in advanced manufacturing has helped develop Ireland’s talent pool, generate enterprise partnerships and drive economic competitiveness.

Over 200 years ago, American inventor Eli Whitney introduced a concept that would change manufacturing forever: interchangeability. Today, swapping out a lightbulb or a car wheel is done without a second thought. In Whitney’s time, the idea that parts could be easily replaced was revolutionary. Interchangeability would make assembly faster and set the stage for mass production lines.

As interchangeable parts became standard, a new challenge emerged: tolerance. In manufacturing, tolerance is the small, allowable difference in a part’s size or shape that ensures even slightly different parts will still fit and work together. This makes it possible to assemble products from parts made at different times or places, ensuring everything fits and functions as intended.

Making smaller things

Today, our drive to master tolerance (and related precision) means we are working at incredibly small scales down to nanometres and molecules. In microelectronics, making devices smaller and more powerful means building parts just a few atoms wide. This requires tight tolerance and high precision (making each part as close as possible to the required size or shape).

Research Ireland’s investment in advanced manufacturing

has helped develop Ireland’s talent pool, generate enterprise partnerships and drive economic competitiveness.

Transformation

At IPIC Research Ireland Centre for Photonics and Tyndall National Institute, researchers are creating advanced devices that underpin everything from fast internet to modern medical tests. The pharmaceutical world is also being transformed, with tailoring medicines to individual patients becoming a reality.

SSPC Research Ireland Centre for Pharmaceutical Research is an international leader in this area, developing manufacturing processes that control molecules and crystals with remarkable precision. By blending chemistry, engineering and data science, SSPC is making precision medicine possible.

Digital and additive manufacturing are rewriting rules again. Modern factories now use 3D printers to build complex components layer by layer, guided by digital models and real-time data. I-Form Research Ireland Centre for Advanced Manufacturing is driving this transformation using AI, advanced sensors and materials science to push boundaries of customisation and efficiency, achieving things that Whitney could never have imagined.

Professor Denis Dowling Director, I-Form

Greenway

Junior Designer: Ellen Cahill Interim Content Manager: Rachelle Ong | Paid

Dr Stephen O’Driscoll Head of Research Centres, Research Ireland

With improved asset health insights and predictive maintenance capabilities, we can better support customers through optimised lifecycle performance.

Global engineering firm increases investment in Ireland, applying Industry 4.0 principles

Modernising manufacturing drives productivity, quality and digitisation, enabling customers to manage critical water infrastructure through advanced technological oversight and reduced lead-times for maximum efficiency.

Across Europe, water companies face ongoing challenges in the supply and treatment of water. They work against a backdrop of population growth, leaking, outdated infrastructure and an evolving regulatory landscape holding them to exacting standards regarding environmental compliance and quality control.

Partnerships that help improve water quality and supply resilience

“Meeting the water demand and legislations for both utilities and industries require a more resilient water system,” explains Veronica Jergelind, Head of Water Treatment Solutions at Sulzer.

Sulzer is a global industrialengineering and manufacturing firm, delivering innovative solutions wherever fluids are treated, pumped, or mixed, through its specialised ‘flow division’. Present in over 160 countries, and with a network of local Tier 1 contractors and supply partners, they’re a market leader in pumping solutions and an ideal partner, not just for water utilities, but for any sector required to move or treat wastewater.

“We can upgrade and modernise assets, making them more efficient and reliable,” continues Jergelind. “By leveraging the global expertise centred around key technologies, we’re committed to working collaboratively with the industry and regulatory bodies to help meet national energy, environmental and water targets.”

Long-established manufacturing presence in Ireland

Deeply rooted in Ireland since 1973, the company’s largest Irish

site (Wexford) employs around 270 people across R&D, engineering, manufacturing, sales and service support. Pulling together a comprehensive water and wastewater treatment solutions portfolio across the entire water cycle, designed to help customers achieve sustainability and operational targets.

“Having such a strong local presence enables us to respond quickly to any issues or operational needs in the field,” explains Jamie Longman, Managing Director.

“Having streamlined the supply chain, we have a much higher capacity to supply products next-day, with the added benefit of reduced carbon emissions.”

Wexford produces a range of products, including submersible pumps, mixers, dewatering pumps, grinders, alongside domestic and commercial products aligned with a global network of strategically placed distribution centres to offer same-day shipment across 60% of their product range. “We’re always expanding our services to become an even better and more active partner,” says Stuart Anderson, Factory General Manager.

Smarter factories by design

Sulzer is applying Industry 4.0 principles to drive productivity, quality and space utilisation, supporting an annual output from the Wexford factory of more than €100 million. “We’ve applied smartfactory principles to our XFP pump production cell,” explains Anderson. “The step-change in output and efficiency has been transformative. If we continue improving at this rate, we’ll have freed up around 20% of our production capacity, enabling

expansion into other product ranges, alongside further operational improvements.”

Leveraging technologies to streamline processes, enhance control and monitoring operations and enable asset visibility in the field, they’re transforming how customers manage critical infrastructure,te Jergelind explains. “With improved asset health insights and predictive maintenance capabilities, we can better support customers through forecasting, early intervention and optimised lifecycle performance.”

Investing in Ireland is part of its long-term strategy, with ongoing partnerships and projects across the Irish community. “Wexford has a highly skilled and experienced team, drawn from the local population, with employees spanning several generations of families,” explains Longman.

The Wexford factory recently initiated a full apprenticeship programme with the Waterford & Wexford Education and Training Board. “We’re actively engaged with local schools, colleges and engineering programmes to nurture the next generation of talent,” adds Anderson. “By investing in skills development and providing realworld experience, we aim to give back to the community that has supported us for decades.”

Sulzer’s continued investment in the manufacture of IoT and digitalenabled solutions marks a new era in water management — helping customers anticipate challenges, act proactively and unlock long-term operational resilience.

Jamie Longman Managing Director Water & Industry Business Unit, UK & Ireland

Stuart Anderson Factory General Manager & Managing Director, Ireland

Veronica Jergelind Head of Water Treatment Solutions

Sponsored by Sulzer

Unlocking production flexibility with additive manufacturing

Learn how additive manufacturing (AM) helps strengthen supply-chain resilience, reduce part costs and produce critical components closer to demand.

Customer expectations are shifting faster than ever. Product development cycles are shortening, while demand for more personalised products continues to grow. This requires a greater level of responsiveness across the entire value chain. Traditional manufacturing, with its reliance on tooling and long ramp-up phases, cannot adapt quickly enough to support this pace of change.

Manufacturing is at a turning point AM enables a fundamentally different approach. By moving directly from a digital design to a finished component, AM eliminates the need for tooling and complex scheduling. This allows manufacturers to pivot instantly to new designs or orders, cutting response times from weeks to days and creating a direct line between customer demand and product delivery.

Strengthening supply chain resilience

In recent years, manufacturers have faced repeated disruptions from wars, logistics blockages, pandemics and most feared of all, tariffs. These events have exposed the vulnerability of long, globally dispersed supply chains. AM offers a route to resilience by localising production and reducing dependence on external suppliers. Through design consolidation and reduced part counts, manufacturers can simplify their bills of materials and produce critical components closer to the point of use. The result is a more distributed, agile and secure manufacturing network that can adapt rapidly to global uncertainty.

Maintaining precision and quality

Even as demand cycles accelerate, expectations for quality continue to rise. Today’s AM technologies deliver the precision and reliability required for highperformance applications, commonly rivalling injection moulding. Combined with new material developments, including regulated polymers for food-contact and medical environments, the barriers for industrial adoption of AM are fading.

Competitive advantage through simplification For the right components, AM delivers not just flexibility and precision, but measurable cost benefits. By removing multiple production stages and minimising workin-progress, part costs can fall significantly. This creates a powerful combination of agility, quality and economy, with additive production as a cornerstone of the next generation of Irish manufacturing.

Mark Hartnett Senior Technologist, Additive Manufacturing, Irish Manufacturing Research

Supporting manufacturing engineering apprenticeships to build local engineering talent

Dundalk Institute of Technology (DkIT) has expanded its industry-focused programmes with the launch of the Manufacturing Technician and Manufacturing Engineering Apprenticeships.

Developed by Irish Medtech, the Ibec trade association for the sector, with ATU Galway, these programmes address Ireland’s evolving manufacturing skills needs and have enrolled over 600 apprentices nationwide since 2017. The apprenticeships blend on-the-job learning with academic study, producing graduates who make an immediate workplace impact.

Championing internal talent

Hiab Ireland Ltd, a global leader in load handling with a major Dundalk base, supports the initiative as part of its strategy to develop local engineering talent. President Barry McGrane, a DkIT Mechanical Engineering graduate, says the apprenticeships reflect Hiab’s culture of continuous improvement.

“At Hiab, we’ve initiated a transformation programme called ‘Model Factory’ to bring our global production facilities up to world-class standards. This will bring a whole new level of efficiencies and flexibility,” McGrane explained. “Rather than hiring expertise from outside, which can be costly and short-term, we prefer to develop talent from within. It’s the Hiab way.”

“For most, it’s a route to upskill and progress within the company. They’re our rising stars,” said McGrane. “We value the applied, real-world learning these apprenticeships offer.”

Apprentices share their journey

Two of those rising stars are Ernest Roklicer and Nadjib Heddane. Croatian native Ernest, a longtime forklift driver, says the apprenticeship offers “a great balance between classroom knowledge and practical application. Hiab has really stepped up — giving us mentors who are experts in the field.”

Nadjib, from Dublin, brings over 26 years’ experience in construction and manufacturing. “I put my best foot forward for this opportunity. I’m not the most academic, but I’m committed and wanted a new challenge.”

Both say the experience has opened new doors. Ernest is progressing toward a quality role, while Nadjib aims to move into production operations.

“There’s definitely scope to climb the ladder — even into management,” Nadjib added.

DkIT’s expanded apprenticeships highlight the power of collaboration between academia and industry — nurturing talent, creating career pathways and strengthening Ireland’s worldclass manufacturing ecosystem.

Sponsored by Dundalk Insitute of Technology Find out more at dkit.ie

Barry McGrane President, Truck Mounted Forklifts, Hiab

Ernest Roklicer Manufacturing Engineering Apprentice

How digitalisation and supplier consolidation are changing procurement

Gary Bradley, Country Manager at RS Ireland, discusses why companies are taking a more strategic and technology-enabled approach to procurement amid increasing cost pressures, complexity and supply chain disruptions.

Digitalisation, automation and data analytics can transform procurement functions and decision-making by improving visibility, agility and control.

Companies have long sought to streamline procurement using automated approval workflows and continuous improvement practices. However, geopolitical events, tariffs, shifting demand, sustainability expectations, cybersecurity and supply chain disruptions have transformed procurement into a more complex function. This exposes organisations to significant risk and escalating costs if not addressed with a strategic, valuedriven approach.

Benefits of consolidating suppliers

“These challenges require organisations to take a more strategic approach to procurement, which includes consolidating partner suppliers. This can generate significant savings,” explains Gary. “To facilitate companies on this journey, RS Ireland can support its customers with a wide breadth of product categories and service solutions to customers in the Maintenance, Repair and Operations (MRO) and Original Equipment Manufacturer (OEM) markets.”

Supplier consolidation can simplify the supply chain and improve cost efficiency in the procure-to-pay process. “Overseeing a multitude of suppliers can be complex and lead to challenges, which drive process costs with increased multiple purchase orders and invoices.

“Managing a team generating purchase orders of low value can be expensive and outweigh any costsavings made on the products they’re purchasing,” says Gary.

With a strategic partner, savings can be achieved by consolidating purchase orders, leading to a lower volume of deliveries to manage and a consolidation of invoices.

How consolidation improves relationships

Instead of placing 10 orders with 10 different suppliers, consolidating purchase orders through fewer suppliers dramatically reduces process costs.

Beyond efficiency, consolidation fosters a stronger relationship between customer and supplier, strengthening supply chain resilience and reducing the need for excess inventory. This approach enables organisations to partner with trusted distributors that offer broad product categories, robust inventory levels, reliable delivery and an exceptional customer service proposition.

Naturally, there are pitfalls when streamlining your supplier base. While consolidation can improve efficiency and reduce risk, over-consolidation may limit supply chain flexibility and

increase risk. To mitigate this, many organisations adopt a tiered supplier model anchored by strong strategic partners supported by a smaller network of specialists or backups. This balanced approach ensures resilience, agility, less risk and captures the benefits of consolidation.

The role of technology

Technological enhancements have enabled larger organisations with an enterprise resource planning (ERP) system to adopt a more strategic approach to procurement with the introduction of eProcurement platforms. Digitalisation, automation and data analytics can transform procurement functions and decisionmaking by improving visibility, agility and control.

“Some of our larger customers with an eProcurement platform have a direct digital connection with our online channel and can create and place orders seamlessly,” says Gary. Additionally, the introduction of e-invoicing allows for a fully digital end-to-end purchasing process. eProcurement platforms can also provide clear spending pattern data to help procurement teams identify cost-savings, efficiency opportunities and better manage risk. “That’s the power of this technology. It provides our customers with the rich data that supports their procurement strategy,” adds Gary.

Strategic procurement: unlocking the benefit Larger organisations have been on a digital procurement journey for the last decade or so. However, with advances such as cloud computing, procurement technology has become affordable for, and ultra-accessible to, small and medium-sized businesses as well.

According to a 2024 report by RS and Chartered Institute of Procurement & Supply (CIPS), around 25% of organisations surveyed are actively streamlining their supplier base. Those who leverage digital tools reported significant gains in speed, spend transparency, compliance and reducing the end-to-end process cost of procurement.

Gary sees more businesses taking a more strategic approach to procurement in future. Going forward, the biggest opportunities lie in using AI and data to anticipate demand, strengthen supplier performance and free up time for more strategic work. “All companies are looking to reduce their operating costs and increase their profitability. And the enabling technology is available to help them do it.”

Gary Bradley Country Manager, RS Ireland

Sponsored by RS Group

WRITTEN BY

Tony Greenway

Ireland’s first large-scale biologics CRDMO site reaches commercial milestone

Leading biologics manufacturer’s Dundalk site is the first facility in Ireland capable of large-scale commercial biologics drug substance production for its global partners, operating under an integrated CRDMO model.

Ireland has made itself indispensable to global pharmaceutical manufacturing in recent years, and 2025 brings yet another defining moment. No longer just producing established products, Ireland’s first large-scale contract research, development and manufacturing organisation (CRDMO), WuXi Biologics, has been granted authorisation for commercial biologic manufacturing from the European Medicines Agency (EMA).

Dr Eimear McCarron

Director

Ireland’s entry into global CRDMO commercial supply “The past three years have been transformative,” explains Brendan McGrath, Ireland Site Head & VP of Manufacturing. “We’ve hit every major project milestone, completing construction, qualification, engineering and PPQ batches, and successfully achieving MIA / IMP approval from the HPRA. Achieving EMA approval has allowed us to release the first commercial biologics batches into Europe, a huge inflection point for the company.”

Their Dundalk facility is the first in Ireland with true large-scale commercial biologics capability under this integrated CRDMO model, offering development, manufacturing and regulatory support for global partners of all sizes in line with the company’s mission that every biologic can be made.

The company develops, makes, tests, helps gain approval of and manufactures biologics globally, including monoclonal, bispecific and multispecific antibodies, fusion-proteins, cytokines, enzymes and immunoglobulins.

“We’ve strengthened our CRDMO model, enhanced our quality systems, hired and trained an exceptional workforce and now operate as a full commercial manufacturing hub with the capacity to support clients in Europe, the US and beyond,” continues McGrath.

Different model from traditional biopharma

Ireland is traditionally built on stainless steel biopharmaceutical facilities, but Dundalk is different by design. Operating across two major manufacturing platforms, perfusion and fedbatch, the company utilises large-scale single-use technology to enable tech-transfer agility, digital visibility and rapid, reliable scale-up. For example, the WuXi Biologics MFG7 facility in Ireland houses twelve 4,000L SUBs, meaning it can realise flexible manufacturing at 4,000L, 8,000L, 12,000L and 16,000L, for different stages, scales and products.

“We are a fully single-use, closed-system operation, meaning every batch benefits from faster turnaround, reduced cleaning time and greater flexibility,” explains McGrath. “This allows us to manufacture more frequent batches and adapt quickly to client needs. It’s a competitive advantage for our customers, and a more sustainable approach for Ireland’s biopharmaceutical

landscape.”

With such innovative manufacturing models, Ireland can now boast global CRDMO commercialisation capabilities, strengthening Europe’s unrelenting biopharmaceutical landscape, accelerating the discovery and delivery of breakthrough therapies, while also significantly reducing the environmental impact of pharmaceutical manufacture. By combining SUT with a scale-out strategy, the company has manufactured over 300 batches at scales ranging from 4,000 to 16,000 litres across our global facilities, achieving a 98% success rate since 2022.

Manufacturing excellence and digital execution

Delivering commercial biologics requires precision and excellence in technology transfer, validation, digital visibility and quality culture. Dr Eimear McCarron, Executive Director of Quality, speaks to the harmonised quality assurance systems in place across all sites, developed to enable consistent, compliant and patient-centric global manufacturing throughout all stages of commercial drug supply.

“We have one quality framework operating to the most stringent principles of compliance in an integrated and proactive way,” she explains. “Our initial focus was on establishing foundational compliance systems, but today, we operate with a proactive quality governance model that integrates digital tools for real-time visibility and predictive analytics.”

This evolution has strengthened data transparency, reduced human error and improved the cost of quality, leading to a 100% global inspection success record across their network. More importantly, it has embedded a culture of continuous improvement while ensuring that quality isn’t just a compliance requirement, but a driver of operational excellence, while ongoing investment into digital solutions continues to support access to personalised medicines.

“We’re continuing to build on these capabilities,” she explains. “Expanding into EU drug product release services and building capabilities for quality testing and importation. These value-added services allow us to offer a more integrated solution

Executive

of Quality, WuXi Biologics

Brendan McGrath Site Head, VP of Manufacturing, WuXi Biologics

WRITTEN BY

Bethany Cooper

Images

to clients, supporting them through every stage of the product lifecycle.”

From stand-alone quality testing to EU importation and release, the company operates as a true EU hub of excellence, layered on top of its commercial manufacturing capabilities.

European supply resilience and innovation

Ireland is becoming a strategic node between the US and EU markets, leveraging the supply chain resilience built during the COVID-19 pandemic. “At a time when pharmaceutical companies are under pressure to minimise carbon impact and reduce the miles their medicines travel, being able to supply Europe from Europe is a real advantage,” explains McGrath. “It means faster pathways to market and the ability to respond rapidly when the world needs it most, as we demonstrated during COVID-19, providing capacity in the global health emergency.”

Such diverse regionalised manufacturing supports emerging biotechs locally, while also delivering on global pharmaceutical programmes, growing Ireland as an EU hub for importation.

“With direct access to the European market and deep EMA-aligned quality expertise, we enable our customers to move with confidence, compliance and speed,” adds McCarron.

Driven by the vision that ‘Every drug can be made’, the layers of commercialisation capability and supply chain resilience continue to accelerate and transform the discovery, development and manufacture of biologics.

Sustainable, flexible drug substance manufacturing

The Dundalk site delivers large-scale commercial manufacturing powered by 100% renewable electricity, with 48,000 litres of fed-batch and 6,000 litres of perfusion capacity, demonstrating that high-performance biologics manufacturing can also be environmentally low-impact and intentionally designed to align with Ireland’s national sustainability goals.

“Our facility has been designed to minimise environmental impact at every level. From air handling units with heat recovery and rainwater harvesting, to sensor-controlled lighting and office design that maximises natural light, we’re reducing

Under pressure to minimise carbon impact and reduce the miles their medicines travel, being able to supply Europe from Europe is a real advantage.

electricity and resource use wherever we can,” says McGrath. “We also support sustainable commuting with 24 electric car chargers, preferential carsharing parking and have designed the facility in a way which encourages people to walk, cycle or run to work. Even small changes, like eliminating single-use cups and implementing ‘follow-me’ printing, contribute to lowering our footprint.”

Dundalk’s fully single-use platform significantly reduces energy and water consumption and changeover time, making it wholly consistent with Ireland’s green-industry vision.

Building the next generation of biomanufacturing talent

Despite ongoing recognition as a key player in biologics commercialisation, McGrath insists that their workforce is its greatest achievement, recognising a culture of determination to bring effective medicines to those who need them.

“Our employees understand the tangible impact their work has on patients who depend on it, and being able to supply therapies globally is driving that sense of purpose, pride and responsibility throughout the company.”

“Successfully receiving EMA approval for a breakthrough therapy was a significant reward, and recognition has been felt throughout the whole workforce, strengthening the culture of pride and commitment to delivering life-changing medicines,” adds McCarron.

Partnering with the Dundalk Institute of Technology (DkIT) and the National Institute for Bioprocessing Research and Training (NIBRT), WuXi Biologics hopes to continue its development from a construction site to a thriving scientific and engineering community, training over 800+ employees of 22 different nationalities to become the next generation of Ireland’s biophamaceutical leaders.

“Our mission in Ireland has always been clear,” concludes McGrath, “to build capability that accelerates the delivery of biologics from idea to patients. And with commercial manufacturing now underway, Ireland plays a central role in the global biologics ecosystem.”

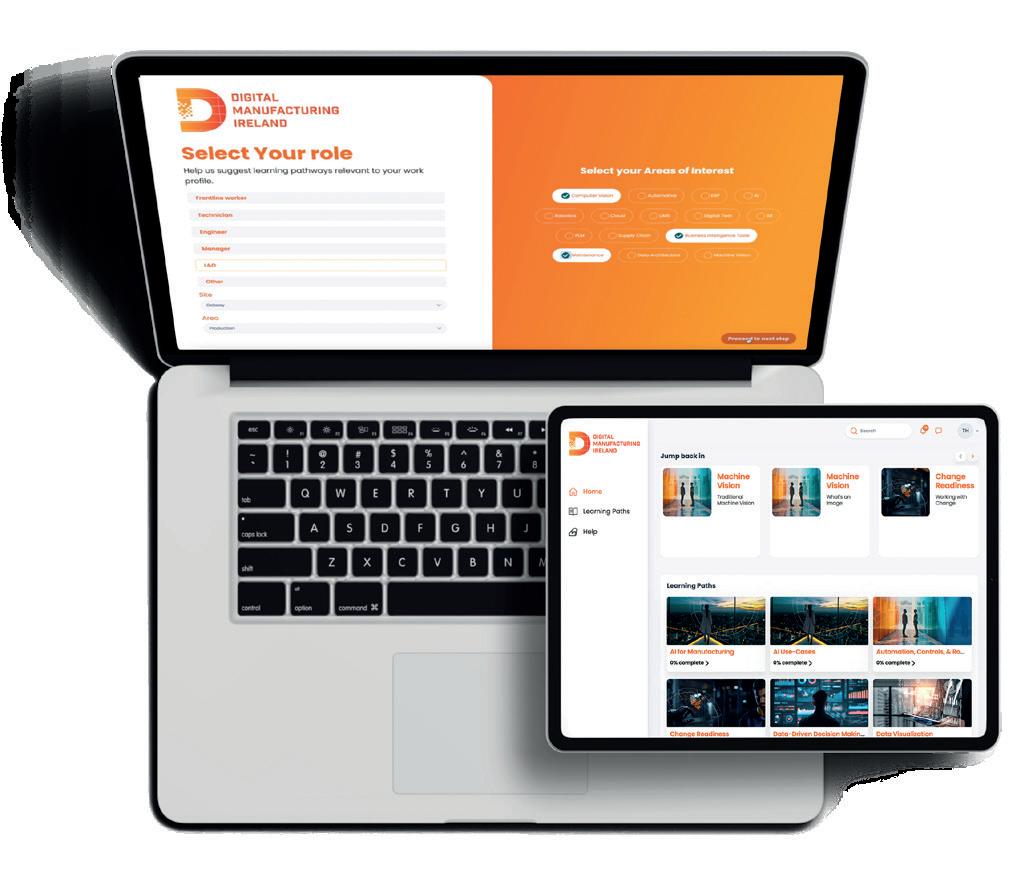

Leverage the full power of digital manufacturing through people

As Ireland deepens its position as a global manufacturing leader, combining emerging technologies with an empowered, agile, futureready workforce is proving to be the key to sustainable growth.

Technology is changing the manufacturing landscape rapidly. The arrival of tools such as artificial intelligence (AI), advanced robots, vision systems and the Internet of Things (IoT) has meant that manufacturers need to adapt quickly and ensure they have the latest cutting-edge innovations at their disposal to avoid falling behind. However, investing in the right talent should go handin-hand with investing in the right technology, explains Domhnall Carroll, CEO of Digital Manufacturing Ireland (DMI), an industry-led organisation that helps drive digital technology adoption across Irish-based manufacturing.

In a demanding environment, maintaining focus on the human element is a key opportunity to unlock the full value of new technologies. This is where the concept of ‘human-in-the-loop’ becomes essential, ensuring that people remain actively involved in decision-making, oversight and continuous improvement. Human-in-the-loop systems allow manufacturers to blend machine efficiency with human judgement, supporting safer, more adaptable and more reliable operations.

When manufacturers develop technology roadmaps to optimise and enhance operations, sometimes, the people aspect is overlooked.

“It’s a challenge we understand,” says Carroll. “Ireland is uniquely positioned to lead in advanced manufacturing, and we’re here to help the continuation of this advancement by creating roadmaps that recognise the importance of people.”

from paper-based systems to

“Manufacturing is, essentially, a physical activity,” says Carroll. “So, any change takes on a different, slower cadence than it would in, for instance, insurance companies or financial services firms. But if your role as a manufacturer is to physically make 100,000 products and get them out the door by the end of the month, there’s a temptation to view upskilling in, say, AI as a distraction from your day job. What we’re saying at DMI is: we understand that. But also, while you might not need those skills right now, you should be ready for when you do because that day will arrive.”

Helping manufacturers understand the skills they need With technology evolving so quickly, there’s a tremendous opportunity to stay ahead of the curve and understand which skills will be essential both now and in the future.

This creates an exciting space for deeper partnerships. DMI works closely with clients to transform existing data into actionable insights, while empowering manufacturing leaders to make informed decisions about their workforce development.

When machines are introduced, they should support people, rather than the other way around.

Enabling workforces to adopt new technologies

“We’re embedding future skills requirements into our technology roadmaps,” explains Carroll. We empower manufacturers to ask the right questions: ‘What capabilities will our workforce need? How can we prepare our teams to maximise the value of new technology?”

Manufacturers are increasingly finding that it’s not only advanced technologies, such as AI, that require workforce upskilling, notes Carroll. Training is equally important when a company makes more foundational technological changes,

Another valuable dimension in adopting new skills is addressing workforce concerns about their evolving roles. Successful upskilling focuses on the enhancement and evolution of roles, not the replacement. The focus is to build digital capability in an accessible and empowering way, linking technology adoption directly to business outcomes and career advancement.

There is a strong need for companies to identify where robots and automation add the most value – and where they don’t. When machines are introduced, they should support people, rather than the other way around. “That may seem like a small detail,” says Carroll, “But it’s an important one because putting people in control of processes and outcomes is key for the culture of any organisation.”

Importance of microlearning in manufacturing

In ultra-busy manufacturing environments, it’s one thing to talk about the importance of upskilling staff to use the latest technology. It’s quite another to find the time to do it successfully.

“It sometimes happens in manufacturing

Domhnall Carroll CEO, Digital Manufacturing Ireland

WRITTEN BY Tony Greenway

such as transitioning

digital ones.

Spread sponsored by Digital Manufacturing Ireland

organisations that workforce training is planned but then has to go by the wayside when a big order comes in,” says Carroll. “As a result, a gap opens between those employees who have the time to step out of their day job for training and those employees who don’t.” This creates a dilemma: manufacturers need to upskill their people while continuing day-today operations. Finding that balance is the challenge, notes Carroll.

“This presents an interesting dynamic: how do we ensure everyone has access to upskilling opportunities, regardless of their role?” says Carroll. “As a manufacturer, the opportunity is to view upskilling as a strategic investment that is woven into your operational rhythm, not separate from it. What we’re doing at DMI is helping manufacturers design flexible training approaches that work for all employees, ensuring everyone can develop new skills while keeping operations running smoothly.”

Modern manufacturing opens exciting possibilities to upskill the workforce in ways that fit seamlessly into operational demands. One approach is DMI’s newly launched Manufacturing Skills Platform, a flexible training platform developed by industry, for industry, addressing real-world manufacturing challenges. The platform delivers role-specific microlearning content online, directly to the workforce. “The great thing about microlearning is that staff don’t have to take a day out to sit in a training room,” says Carroll. “They can do it in multiple 10-minute sessions, at their point of work, whenever it fits into production schedules. It’s a way for everyone to gain new knowledge.”

Maintaining Ireland’s place as a leading manufacturing hub

Various factors have made Ireland a hub for advanced manufacturing over the years. Many site leaders have put digital transformation at the forefront of their strategies, while the country also benefits from a strong, well-established manufacturing supply chain. Additionally, the Irish workforce demonstrates remarkable adaptability and agility. “It’s a culture where people support each other and work well together,” says Carroll. “Geographically, we’re quite small, which helps build a strong ecosystem where networking opportunities are very high. And our manufacturers are very well qualified, with high rates of frontline workers having a third-level education. The skills level here means that people are more open to adopting new technologies, which in turn fosters a culture of continuous improvement and collaboration. It’s a workforce that’s enabled for new technology.”

What steps can manufacturers take in the next six months?

Ireland is poised to seize a significant moment. The world has evolved dramatically with the introduction of AI.

Over the next six months, Irish manufacturers can build foundational digital literacy skills across their organisations. This empowers manufacturers to support AI adoption through accessible digital skills development, and at the same time scale successful data-driven initiatives across their teams, aligning workforce development with the pace of technological change. Manufacturers who embrace change today can unlock new possibilities and position themselves at the forefront of Ireland’s evolving manufacturing landscape.

Concrete actions taken today will open doors for Irish manufacturers leading into the future, presenting them with the space to explore how emerging technologies and the development of new skills can improve their global competitiveness. “While long-term strategic planning remains important, we’re committed to showcasing the incremental changes that will deliver tangible results for companies immediately,” says Carroll.

Images provided by Digital Manufacturing Ireland

Manufacturers turn to AI amid trade pressures

As we close 2025, Ireland’s manufacturing sector remains the economy’s engine, employing over 240,000 people and contributing over €10 billion (36%) in corporation tax. However, economic shifts are increasing financial pressure on companies.

Our 2025 Manufacturing Report confirms a fundamental shift. Trade uncertainty is now the #1 challenge (59% of leaders), forcing a move to ‘Cautious Resilience.’

Overall confidence has dropped to 51% from 70% in 2024, driven by tariff threats and domestic costs.

Economic shifts causing manufacturers to rethink strategies

This drop in confidence signals a paradox: sentiment is down, yet corporation tax inflows remain at windfall levels, with ‘excess’ receipts for 2025 projected to be over €11 billion. This is widely seen as a ‘timing effect’ — a sophisticated, shortterm strategy to ‘front-load’ activity into the US to hedge against tariff uncertainty.

The sector is ‘controlling the controllables’: AI is now a priority for 52% of businesses.

This sentiment is deepened by a domestic cost squeeze, with 81% expecting wage growth and 64% expecting energy cost increases. Against an expectation of flat sales, the margin squeeze has seen expected profitability increases drop to just 18% (from 37%).

Financial squeeze halts investment and R&D

This challenging environment has forced a strategic pause on new capital investment (34%) and R&D (19%). Creating the conditions to unpause this vital investment is now a priority. In the interim, the sector is ‘controlling the controllables’: AI is now a priority for 52% of businesses, with 97% planning adoption to improve efficiency. This is the AI Imperative — a deliberate choice to automate and innovate to defend margins.

The sector is proving agile, but it cannot navigate these challenges alone. We commend the Government’s proactive response in Budget 2026, particularly the vital increase of the R&D Tax Credit to 35%. This policy win must be paired with urgent action on energy costs. We urge Government to fund the AI transition through Skillnet and Springboard+, mitigate costs via a PRSI rebate and use the forthcoming R&D Compass to expand qualifying expenditure.

To support our members directly, Ibec’s Tariff Hub provides expert intelligence to mitigate trade risks, while AI Hub delivers practical guidance for this crucial transition under our ‘Work Just Got Smarter’ campaign.

Sharon Higgins Executive Director, Membership and Sectors, Ibec

How lean manufacturing transforms packaging and production efficiency

Using lean methodologies to optimise chemical packaging enables manufacturers to maximise customer value, minimise waste, enhance efficiency and improve quality.

Researching, developing and manufacturing chemical formulations isn’t the only challenge facing companies. Once a new chemistry has been developed — used in the manufacturing process of anything from coronary stents to semiconductor chips — it must be brought to the production line in the most efficient, cost-effective and sustainable way.

Getting this part wrong by using unsuitable and unsustainable packaging isn’t just bad for the environment — it could adversely affect the product integrity and patient safety. Incorrect packaging could malfunction if it’s damaged by the product’s chemistry, or the packaging material could leach into — and contaminate — the product it’s supposed to be protecting.

Holistic approach to Chemical packaging

This is why packaging optimisation — the process of ensuring packaging is the best fit for the products it contains — “should be central to both chemical manufacturers and their customers”, explains Rose O’Doherty, Sales & Marketing Director at Schlötter Ireland, a 50-year-old contract manufacturing firm specialising in bespoke highpurity chemical solutions for the medical device, semiconductor, electronics and surface finishing industries.

To save time and resources in the long run, it’s critical to consider chemistry packaging at the R&D product development stage, with extensive stability studies and stringent testing. “Lean manufacturing methodologies are key to this,” says O’Doherty. “These are principles that maximise customer value while minimising waste, enhancing efficiency and improving product quality.” “And in healthcare, we should never forget that ‘customers’ are, ultimately, patients who need these products to improve their day-to-day lives.”

Schlötter Ireland recently collaborated with a manufacturer of medical devices, using standard UN-approved 25LTR packaging that required multiple changes during a

production shift. But by switching to larger 250LTR packaging with a sterile liner and reusable plastic outer structure, a changeout was only necessary once per shift. This shrank production cycle times, reduced plastic material, water consumption and costs and improved operator safety by eliminating manual handling.

Continuous improvement to ensure competitive advantage To promote continuous improvement, Schlötter ensures all its staff have training in lean methodologies. “After all, some of the best ideas come from the people who are manufacturing our products daily,” says O’Doherty. However, she stresses that, in the highly regulated medical devices industry, change can’t simply be done on a whim. Close collaboration with customers is crucial because all change approvals need crossdepartmental cooperation from sales, quality, engineering, production and regulatory.

In this fast-paced sector, O’Doherty advises firms to constantly review their packaging. “Markets change, and new products are always being developed,” she says. “With that in mind, it’s important to create sustainable packaging solutions that will improve your efficiency, productivity, quality and competitive advantage.”

Three transformations reshaping industry’s sustainable profitability

Many manufacturers are deprioritising sustainability for financial goals, but one doesn’t have to replace the other. Electrification, digital transformation and circularity have the potential to deliver sustainability and financial value.

As industries move to cleaner energy, electrification plays a crucial role, particularly in energy-intensive operations such as boiling or baking. For example, food manufacturers moving from gas to electric ovens must ask: Can my electrical system handle increased loads, what upgrades are needed and will operating procedures need adjustment to maintain product quality and meet demands?

Electrification: powering the future

Effective electrification requires strategic planning, which begins with an electrical audit to assess assets, gaps and risks. In today’s unpredictable energy landscape, manufacturers must also reconsider assumptions about power reliability. On-site generation options such as microgrids and power purchasing agreements (PPAs) can provide greater control and stability.

Digital transformation: the industry’s nervous system If electrification is the backbone of industry, digitalisation is the brain. Smart sensors and real-time data are foundational to this but are just the start. To avoid long-term inefficiencies, top-performing sites also invest in people and process improvements as well as IT/OT equipment to ensure scalable, lasting change. For instance, Hochwald Foods in Germany deployed a system that collects data from across the operation to bridge gaps between shop-floor operations and executives. This enabled seamless monitoring of everything from entry security to product quality. A strong digital foundation also unlocks artificial intelligence to manage repetitive tasks, detect issues early and free employees to focus on high-value work.

Circularity: rethinking sustainability for advantage

Circularity offers clear business and environmental benefits for companies willing to use innovative solutions to tackle three major sources of waste:

• Collecting and processing food waste to create electricity

• Reclaiming water from processes like boiling for non-clean functions

• Committing to sustainable packaging

Reducing food, water and packaging waste is one of the most cost-effective ways to immediately boost revenue and cut carbon footprint. Adopting this mindset enables facilities to unlock future investment opportunities by saving on operational expenses.

Shaping the future of industry

To remain competitive, these modernisation strategies must be embraced now. By adopting circularity, leveraging digitalised systems and prioritising electrification, manufacturers can reduce energy costs, improve operational efficiency and increase profitability – all while driving long-term sustainability.

Rhonda Doyle Country President, Ireland, Schneider Electric

Daniel Flynn Sales & Marketing Coordinator, Schlotter Ireland

Rose O’ Doherty Sales & Marketing Director, Schlotter Ireland

Sponsored by Schneider Electric

Sponsored by Schlötter Ireland

WRITTEN BY Tony Greenway

How this Irish company became a powerhouse of high-speed food and pharma packaging automation

Tekpak has been manufacturing complex robot-based packaging machinery for the Food and Pharmaceutical Industries for almost 25 years, becoming Ireland’s leading packaging automation company.

Ireland is a small country with a big pharma industry. It’s the world’s third-largest exporter of pharmaceuticals and serves as a major hub for biopharmaceutical manufacturing. This makes it the ideal headquarters for Tekpak, a Wexford-based high-tech automation company that designs and builds high-speed complex machinery that picks, wraps, packs and stacks food and pharma products into trays, cartons, cases and pallets.

Tekpak has been making world-class packaging automation equipment for almost 25 years, designing and manufacturing full lines with an array of packaging capabilities. These include robotic pick and place, filling, wrapping, labelling, tray loading and unloading, horizontal and top-load cartoning, tray de-nesting and re-nesting, product stacking, case packing and palletising.

Customisable, flexible and compact solutions

“Tekpak is unique in Ireland because we are exclusively focused on Packaging Line Automation, and these world-class machines are designed and manufactured here. We take turn-key responsibility for full packaging lines tailored to the needs of our customers, both at home and internationally,” says John Kehoe, Innovations Director, Tekpak Automation. “Where necessary, we design and manufacture completely new and unique packaging machines. We also have a series of standard modular systems, that are quickly and fully customisable to specific requirements and space constraints.”

WRITTEN BY

Tony Greenway

Tekpak’s technical experts handle every aspect of a project, from design, fabrication, software and commissioning to validation and handover. By utilising the latest digital twin technology, the company can create solutions with shorter leadtimes.

Because Tekpak’s technology is mainly robotbased, it’s extremely flexible. It can run at very high speeds and change format incredibly quickly.

“Traditionally, it would take an hour or two to complete a full changeover on an entire packaging line,” notes Frankie Rose, Technical Sales Manager, Tekpak Automation. “But fully automatic change can be achieved with our machines within two to three minutes.”

Industry 4.0-ready tech for real-time insights

All machines are provided with Industry 4.0-ready options, so they seamlessly integrate with other devices and higher-level SCADA, MES and OEE systems, generating data and communicating with each other to provide pharma manufacturers with real-time insights that improve operational efficiency. For example, AI-enabled cameras, sensors and other Industry 4.0 technologies can be used for quality control purposes and to verify that line clearance operations have been performed correctly. All Tekpak machines are supplied with software tools that provide 21CFR Part 11 compliance and are

built according to Good Automated Manufacturing Practices (GAMP) guidelines. Additionally, control systems can be specified to provide an audit log, time synchronisation, Active Directory for user authentication and user groups and permissions.

This means clients can be reassured they’re receiving not only high-speed, reliable equipment but also the documentation and validation services necessary for full regulatory compliance. “We’ve developed a deep understanding of the needs of our multinational clients, especially those in the pharmaceutical sector,” says Taigh Connor-Watson, Operations Director, Tekpak. “Our project and design teams all receive training regarding constantly changing regulatory requirements.”

Once the machinery is delivered and installed, Tekpak has a dedicated technical support team on standby with guaranteed fast response times. “Our work isn’t just about design, build and implementation,” says Kehoe. “It’s about collaborating closely with our clients to ensure all project deliverables are completed to the highest possible standards.”

PHARMA IN IRELAND — AT A GLANCE

• It’s projected that revenue in the Irish pharmaceuticals market will reach US$2.40bn in 2025. (Statistica)

• Ireland is home to more than 90 pharmaceutical companies and employs around 50,000 people countrywide. (IDA Ireland)

• Nine of the world’s top 10 pharma companies have established significant operations in Ireland. (IDA Ireland)

WHY TEKPAK?

• Full Line Capability - manufactured in Ireland

• In-house packaging and automation expertise, with proven expertise in life sciences and high-volume food manufacturing

• All machines built in compliance with 21 CFR 11/EU annexe 11 regulations

• IOT 4.0 features available on all machines

• Fast turnaround with proven technology, agile project management, and Irish-based service department

• Full project control from design to delivery

Imagespro

Sponsored by Tekpak

John Kehoe Innovations Director, Tekpak Automation

Company founder and now concentrating on R&D and technical innovations as well as M&A activities

Highly experienced engineer with a background in pharma manufacturing, having worked for many years at GSK (GlaxoSmithKline) in their UK manufacturing operations

Recently returned to Tekpak. Frankie has over 10 years’ experience working in Tekpak in areas including design, operations and technical sales.

Taigh Connor-Watson Operations Director, Tekpak Automation

Frankie Rose Technical Sales Manager, Tekpak Automation

Building smarter: how modular manufacturing is shaping Ireland’s industrial future

Ireland’s construction sector is embracing modular manufacturing. Learn how this evolution could reshape the delivery of complex projects.

Manufacturing modules in a controlled environment, teams can reduce waste, improve safety and shorten installation times on site.

Nicholls Group Managing Director, Designer Group

The Irish construction and engineering landscape is changing rapidly, with manufacturing principles increasingly influencing how complex projects are delivered. Modular and factory-based assembly are no longer niche approaches — they are becoming a central part of how large-scale infrastructure, data centres and energy projects are executed.

Investment towards improved delivery models

At Designer Group, we are embracing this transformation and have recently expanded our modular manufacturing capability with a new €10 million facility in Kells, Co. Meath. The investment reflects both our long-term growth strategy and a broader industry shift towards more efficient, sustainable and predictable delivery models.

Rather than seeing modular manufacturing as a replacement for traditional construction, industry leaders are viewing it as an evolution that brings together precision engineering, digital design, higher and more predictable quality and advanced fabrication techniques. By manufacturing modules in a controlled environment, teams can reduce waste, improve safety and shorten installation times on site. For clients, this approach translates into greater cost certainty and reduced risk, two factors that have become essential in capital-intensive sectors.

Growing demand for modular manufacturing

The demand for these methods has grown significantly across the data centre, energy and

pharmaceutical industries, where the scale and complexity of projects continue to rise.

Modular manufacturing offers an effective response: higher repeatable quality, faster delivery and tighter integration between mechanical and electrical systems. It also supports sustainability goals by lowering carbon emissions through reduced transport, material efficiency and fewer site-based activities.

The new Kells facility will allow for the production of large-scale mechanical and electrical modules, pre-assembled plant rooms and specialist components designed for rapid installation. It is expected to create up to 75 skilled roles over the coming years, including positions in engineering, fabrication and logistics. Beyond the technical capabilities, this represents a wider commitment to regional job creation and skills development within the manufacturing and construction ecosystem.

As clients seek greater certainty in both programme and performance, the industry’s move towards manufacturing-led construction appears set to accelerate. The combination of digital design, data-driven project planning and modular delivery is helping companies manage complexity while improving environmental performance.

Designer Group’s investment is part of a growing trend across Ireland, one where engineering expertise, sustainability and innovation converge. For the country’s manufacturing and construction sectors, this evolution points to a future defined not by where projects are built, but by how intelligently they are delivered.

Paul

Sponsored by Designer Group

Images

AI: the strategic imperative to defend margins in Ireland’s biopharma sector

Rising costs are forcing biopharma manufacturers to change strategies to meet financial targets, with AI at the forefront.

The Irish life sciences sector is the indispensable engine of our economy, generating €116 billion in exports and cementing Ireland’s reputation as a global leader. We’re the second largest exporter of complex pharmaceutical goods and vaccines in Europe. However, the current financial environment means that mastering generative AI is not an option; it’s a core defensive strategy.

The current financial environment means that mastering generative AI is not an option; it’s a core defensive strategy.

Financial pressures forcing strategic recalibration

Our BioPharmaChem Manufacturing Report 2025 shows that expected profitability increases have dropped sharply to just 14% (down from 33% in 2024). This margin squeeze is driven by rising costs, as 86% of leaders expect wage growth and 71% anticipate energy cost increases.

Faced with this, our members are moving decisively. Latest data reveals AI is now a top priority for 64% of businesses (up from 54% last year), with 86% planning to adopt or extend AI initiatives in the next year or two. Crucially, 100% of those investing do it to improve efficiency and productivity, with 75% to improve

innovation. This pivot to technology is the AI Imperative in action.

Playbook provides roadmap for AI adoption BPCI, with lead authors Brightbeam and Connected Health Skillnet, developed the ‘GenAI in Lifesciences Manufacturing Playbook.’ This is a living roadmap containing over 100 practical use cases, from foundational applications to high-stakes GxP environments like accelerating deviations management. Majority of companies in Ireland are currently at this foundational stage, and scaling AI rapidly through ‘Human in the Loop’ principles is a priority. The Playbook was developed through a collaborative process with our industry partners, a core advantage for scaling innovation and maintaining our global reputation for quality.

To win, we must industrialise our talent pipeline by increasing matched funding for Skillnet Business Networks to deliver the AI fluency our workforce urgently needs. Furthermore, we strongly advocate for sectoral AI regulatory sandboxes and urge the Government to revise the National Digital and AI Strategy to strongly reflect competitiveness needs. Finally, we must utilise the forthcoming R&D Compass to expand qualifying expenditure definitions and reform outsourcing rules, ensuring it fully supports this innovation-led future.

Sinead Keogh, Director, BioPharmaChem Ireland, Head of Sectors, Ibec

Where innovation meets industry: introducing Ireland’s new National AI Studio for Manufacturing

New National AI Studio for Manufacturing’s launch will provide companies with a purpose-built environment to see, test and learn how AI works in real operations.

Ireland’s manufacturing sector has entered a new phase as Artificial Intelligence (AI) accelerates. The AIM (Advancing Innovation in Manufacturing) Centre supports manufacturers to build capability, accelerate innovation and prepare for a digital future, while also delivering practical, CPD-certified AI and digital skills training.

Based in Sligo, the national centre recently won a European Commission award for its leadership in supporting Europe’s digital transition. It’s also an associated partner in Ireland’s national AI Antenna program (led by ICHEC), a €10m initiative linking industry, research and high-performance computing.

AI Studio opening in January

The National AI Studio is an exciting addition to the AIM Centre. Opening in January 2026, this unique space will feature a smart assembly line that connects supplychain data with robotics, vision systems and automation. Demonstrations include real-time defect detection, predictive maintenance, AI-enabled packaging and live dashboards linking production to performance insights.

Julie Dowling, AIM Centre CEO, describes it as “a landmark moment” for Irish manufacturing and Ireland’s broader innovation ecosystem. “This is the first

A new AI learning space for leaders, engineers and operators alike

Artificial intelligence (AI) is reshaping industry at a pace most manufacturers have never seen before, and the only way to keep up is to invest in learning.

Ttime companies will have a resource focused entirely on practical AI adoption. The Studio demystifies the technology while supporting businesses in taking confident steps towards the future,” she says.

Showcasing AI’s organisation-wide impact

The Studio goes beyond the factory floor. Finance teams can explore AI-driven forecasting; HR teams can dive into workforce analytics; L&D teams can access personalised skills-mapping tools; and R&D teams can trial AI for design simulation and optimisation.

David Bermingham, AIM Centre’s Director of AI, says: “Manufacturing companies don’t need complexity — they need clarity. The AI Studio gives them a place to explore and learn, and the Accelerator Programme turns that learning into real results.”

The National AI Studio is co-funded by the Government of Ireland and the European Union through the ERDF Northern and Western Regional Programme 2021–27. Through support from Enterprise Ireland, Sligo County Council, Leitrim County Council, Atlantic Technological University and Western Development Commission, AIM Centre has created an accessible and direct route for manufacturers to embrace the future.

he National AI Studio will create a community for manufacturers allowing them to explore how AI can be applied on the factory floor.

Flexible membership

While the Studio will open in January, it has already delivered programmes for various roles, including business leaders, engineers, technicians and operators. It’s an inclusive space for whole teams to build capability and take a holistic view of their organisation.

Membership options now are available for multinationals, SMEs, local enterprises, start-ups and academia, with significant funding

available.

Member benefits include exclusive access to the AI Studio’s working demonstration place, POV development and sandbox testing, one-to-one mentorship, heavily subsidised CPD-aligned training, and access to a vibrant national community.

Members can access a range of programmes, including first access to the structured 8-week AI Accelerator Programme, which provides a pathway for identifying high-value use cases, assessing data readiness and testing early concepts. It progresses them into proof-ofvalue projects and provides onward supports. This programme has already

“Participating in the AI Accelerator has been invaluable for clarifying how AI can solve real-world problems on our manufacturing floor. We entered with a complex challenge around forecast accuracy, and the programme helped us break it down into a clear, actionable roadmap. We now see a direct path to not just automate tasks but actively improve our agility and service levels for our customers.”

– Avery Dennison

supported 20 technical teams, identified over 60 high-value use cases and delivered multiple demonstrators. It has up to 80% funding support and is CPDaccredited by Engineers Ireland.

How to become a member

Memberships are intentionally affordable, starting at €1,000 per year. Enterprise Ireland clients can get up to 80% funded through the Smart Regions Programme.

The Studio, based in Sligo, will soon have a Galway presence, having just announced its role as anchor tenant in CREW Digital, Galway.

Imageprovidedby AIMCentre

Julie Dowling CEO, AIM Centre

David Bermingham Director of AI, AIM Centre