Modularhousing

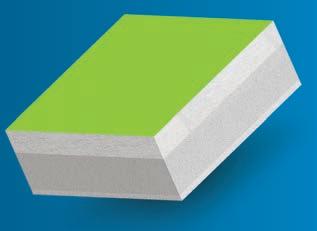

The Better Way To Achieve Higher R-Values

If you are using EPS as exterior insulation in your builds, there is a better way to add R-value. BTRboard delivers higher performance and is easy to install.

Build a Even Better Home

• 30% better R-value than EPS per square inch

• Costs less than XPS panels

• 21% structurally stronger

• Fire & moisture retardant

• Build faster with less labour

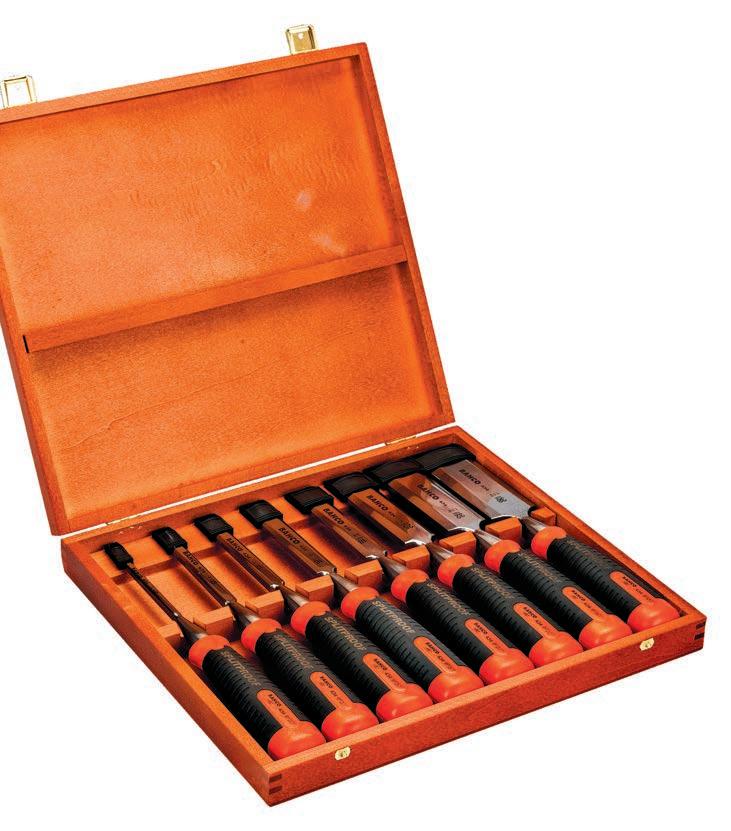

BTRboard OSB

OSB Sheathing

Medium Density

Polyurethane Foam Core

Fibreglass Facer

BTRboard FIRE-X

Gypsum Drywall Sheathing

Medium Density

Polyurethane Foam Core

Fibreglass Facer

7 PRESIDENT’S MESSAGE, CURTIS MERCER

Embracing new ways to build and renovate

8 CEO’S MESSAGE, KEVIN LEE

The potential – and barriers –of factory-built construction

12 MEMBER PROFILE

Grandeur Housing: Building community, one modular home at a time

24 RENOVATORS’ CORNER

Unlocking the potential of accessory dwelling units

EDITOR

Wayne Karl wayne.karl@nexthome.ca

EXECUTIVE MEDIA CONSULTANTS

Jacky Hill

Michael Rosset

SENIOR VP, SALES NEXTHOME Hope McLarnon 416.708.7987 hope.mclarnon@nexthome.ca

SENIOR MEDIA CONSULTANTS

Amanda Bell 1.866.532.2588, amanda.bell@nexthome.ca

Merlyn Minty 204.782.8692 merlyn.minty@nexthome.ca

VOLUME 8, NUMBER 4 WINTER 2025

CEO Kevin Lee

DIRECTOR, MARKETING AND COMMUNICATIONS

Natasha Rombough

MANAGER CUSTOMER SALES/SERVICE

Marilyn Watling

SALES & MARKETING COORDINATOR

Gary Chilvers

POLICY AND COMMUNICATIONS ANALYST

Emily Fielden

HOME SHOW MANAGER & NEWSPAPER CIRCULATION – GTA

Josh Rosset

DISTRIBUTION

distributionteam@nexthome.ca

ACCOUNTING INQUIRIES

accountingteam@nexthome.ca

VP MARKETING — GTA

Leanne Speers

DIRECTOR OF PRINT MEDIA

Lauren Reid–Sachs

VP PRODUCTION — GTA

Lisa Kelly

PRODUCTION MANAGER — GTA Yvonne Poon

GRAPHIC DESIGNER & PRE-PRESS COORDINATOR Hannah Yarkony

COMMUNICATION STRATEGIST

Chloe Perreault

Published 4 times a year by NextHome, on behalf of the Canadian Home Builders’ Association (CHBA), all rights reserved. No part of this publication may be reproduced in any form without written permission. Building Excellence, NextHome, and the Canadian Home Builders’ Association (CHBA) are not responsible for any claims or promises in any advertisement, nor for any unsolicited material sent to the magazine. Canadian Publications Mail Agreement # 40065416

Published by

nexthome.ca

Advertising Call 1.888.761.3313 for rates and information. Fax: 1.888.861.5038

Copyright 2025 All rights reserved. All copyright and other intellectual property rights in the contents hereof are the property of NextHome, and not that of the individual client. The customer has purchased the right of reproduction in NextHome and does not have the right to reproduce the ad or photo in any other place or publication without the previous written consent of NextHome.

Terms and Indemnification Advertisers and contributors: NextHome is not responsible for typographical errors, mistakes, or misprints. By approving your content and/or submitting content for circulation, advertisers and contributors agree to indemnify and hold harmless NextHome and its parent company from any claims, liabilities, losses, and expenses (including legal fees) arising out of or in connection with the content provided, including but not limited to any claims of copyright infringement, unauthorized reproduction, or inaccuracies in the content. Advertisers acknowledge that they have the necessary rights, permissions, and licenses to provide the content for circulation, and they bear full responsibility for the content’s accuracy, legality, and compliance with applicable laws upon approval. Contributors acknowledge NextHome reserves the right to omit and modify their submissions at the publisher’s discretion.

NEW WAYS TO BUILD AND RENOVATE

EMBRACING FACTORY-BUILT CONSTRUCTION

BY CURTIS MERCER, CHBA PRESIDENT

smaller units rather than complete structures, which adds expense and complexity. This limitation has shaped perceptions and slowed adoption in Newfoundland and Labrador.

Conversely, when I recently visited PEI, I noticed modular construction was far more common. Why? They have a bridge. Transportation is simpler and more cost-effective. This is even more true in the Prairies, where adoption increases even more where transportation regulation is more favourable to larger loads.

Factory-built housing construction methods, such as panelized and modular construction, are having their moment in the sun. While not a silver bullet to Canada’s housing affordability and supply challenges, they can certainly be part of the solution.

In my travels to local HBAs across the country, I’m fascinated by how often this subject gets brought up and how different regions are embracing and adopting factory-built methods. Specifically, I’ve learned that geography plays a big role in adoption. This is doubly true in provinces where current conditions have severely hampered sales and construction, making the thought of investment in technology or adopting new approaches very untimely.

But for those regions where sales conditions are okay (and hopefully this will be the case in all regions soon), the opportunity is there. In Newfoundland and Labrador, these approaches are still in their early stages. Unlike other regions where modular homes have gained more traction, most of what we see locally is brought in from out of province. Transportation is the biggest challenge: Everything comes by boat, so homes arrive in

However, for the first time this year in Newfoundland and Labrador, we’ve seen a local company begin to manufacture panels – and another panelization factory is under construction. For my company, this year marked our first steps into panelized construction. The motivation was simple: Labour shortages. Like many CHBA members across Canada, we’re struggling to find enough skilled workers. Panelized construction offers a way to build more with fewer people, and on several of our projects, it has worked remarkably well. Addressing labour shortages is why CHBA formed its Modular Construction Council back in 2017.

But the reality is that adopting panelization requires a complete overhaul of how we do business. It changes our schedules, workflows and planning processes. If we were turning over a house every week, widespread panelization or even full modular methods might make perfect sense. Instead, because we’re smaller volume, we’re adjusting project by project, which adds time and complexity. But once adopted, it could smoothen our delivery process.

CHBA’s Sector Transition Strategy does a great job outlining these challenges, and

others, in moving to factory-built approaches. It offers solutions for governments to help de-risk investments in factory-built methods to get past the high overhead hurdles, because the upside is there. Labour shortages aren’t going away, and factory-built construction reduces the number of people needed on-site while boosting efficiency. The challenge for stick builders is streamlining that process.

I’m a firm believer that industry needs to collaborate more closely to truly scale up. Let’s work together – builders and factories, with government collaboration – to make factory-built methods practical and scalable. It’s not just about solving labour shortages; it’s an opportunity to transition to a more efficient, resilient way to build homes in challenging environments. The potential is there. Now it’s time to seize the opportunity.

CHBA’s Modular Construction Council is ahead of the game on this front, and I’ve found their insights invaluable in helping me take the leap to embrace factory-built techniques in my business.

So, if you’re a CHBA member who is considering a move to factory-built methods, there is no better time than now to get involved in the Association. Get involved locally and come to provincial and CHBA National events, join a Committee or Council, and subscribe to CHBA’s Building Modular News (email communications@chba.ca to get on the mailing list). Together, we can stay up to date on the most current information about the opportunities in modular methods, share ideas, tackle challenges and unlock the full potential of factory-built construction to help pursue the doubling of housing starts to help solve Canada’s housing supply challenges.

BRINGING REALITY TO THE OPPORTUNITY

FACTORY-BUILT CONSTRUCTION OFFERS MUCH POTENTIAL, BUT FACES MANY BARRIERS

BY KEVIN LEE, CHBA CEO

Over the last few years, factory-built construction has increasingly been deemed a key part of the solution to Canada’s homebuilding productivity woes. While it has a lot to offer, the reality is that there are many market barriers to broader adoption. CHBA and our Modular Construction Council have been working hard over recent times to bring the realities of the challenges to government, to help make the potential a reality.

While the conversation around modular construction had been percolating for years prior – after all, factory-built methods are not new – it has gained real momentum as governments have latched on to modular construction as a potential solution to the labour and productivity challenge. CHBA recognized the labour challenge and the potential for factory-built to be part of the solution years ago: We started our Modular Construction Council in 2017, bringing together two previous national modular associations under the CHBA umbrella to lead the charge.

Given that the government was interested in modular construction but lacked understanding of its realities, we released our CHBA Sector Transition Strategy (STS) in February 2024. It

garnered expansive media coverage and strong interest from federal officials, leading to the inclusion of many of CHBA’s STS recommendations in the 2024 federal budget. I was subsequently invited to last year’s Liberal Cabinet Retreat and included as an expert on the federal Expert Panel for an Industrial Strategy for Homebuilding. This resulted in government actions not only to support factory-built construction, but also to support more housing construction at large. (CHBA has been explaining that the most important way to get more factory-built construction capacity is to remove the barriers to getting all types of housing built, since getting past barriers to more housing supply in general is critical to making the housing sales that can in turn lead to investment in more factory-built approaches.)

During this spring’s election period and in the 2025 federal budget released in November, factory-built construction was amplified even further with the federal intention to make it a key piece of its new housing entity, Build Canada Homes (BCH). While BCH focuses on non-market affordable/social housing projects, it will focus on factory-built solutions to help create a steadier pipeline for factories. The government has also committed $25 billion in debt financing and $1 billion in equity financing to Canadian prefabricated home builders. Through BCH and other channels, the government is aiming to eliminate duplicative inspections and streamline approvals for factory-built homes. These were direct recommendations from CHBA’s STS, and while they are a great start, CHBA remains adamant that to truly scale up factory-built construction and meet Canada’s housing targets, innovative

solutions and support for modular projects must extend to market-rate housing as well. BCH will focus on government-subsidized housing, so while it can be a catalyst for transition in some ways, it is the broader supports for market-rate housing that are needed to fully execute change.

There is no doubt that factory-built methods can build homes faster. However, as CHBA’s STS outlines, the full potential of factory-built methods can only be unleashed when broader obstacles facing the entire sector are addressed. For example, expanding the GST to all buyers, financial system change that enables Canadians to access homeownership, zoning and development charge reform, addressing building code challenges and working with municipalities to lower development taxes are some key priorities to facilitate more supply and create the conditions for more factory-built investment. Derisking high factory start-up investment costs, ensuring stable demand to keep factories running and improving financial institutions’ understanding of the modular business model to expand access to suitable financing are also critically important.

All in all, there is a real opportunity to seize, but governments need to make regulatory and policy changes for that opportunity to come to fruition. Rest assured, CHBA has our foot on the gas to get more wins for members, including removing barriers preventing a more widespread transition to factory-built methods.

Read CHBA’s full STS at chba.ca/ sector-transition or head to page 16 for more information about CHBA action on factory-built construction.

I adap�ivlltl

Foralloflife'schanges.

tiOm e

Thedemandforhomemodificationsishere. Thereare10million Canadiansage 60+, representingmorethan1/3 ofthepopulation. Thevastmajority arehomeownerswhowant toliveintheirhomefortherestoftheirlives. Theyaresearchingforqualified professionals fortheirhomemodificationneeds.

TheAdaptiv Home Renovation Coursewas developedforrenovators, contractors, architects, designers, andotherprofessionals whowanttolearnabouttheaging-inplacemarketandthegrowingbusiness opportunitiesacrossthecountry.

TheAdaptiv Home RenovationCourse providesparticipantswith:

• Up-to-dateinformationon Canadianbuilding codesandstandardswithanemphasison improvingdesignwithsafety, security, ease ofuse, comfort, accessibility, andoccupant health.

• Specificbuildingknowlege onrampsand slopes, zero-stepthresholds, curbless showers, accessibilityequipment, andhome automationsolutions.

• Traininginclientcommunication, empathy, privacy, insurance, andlegal considerations.

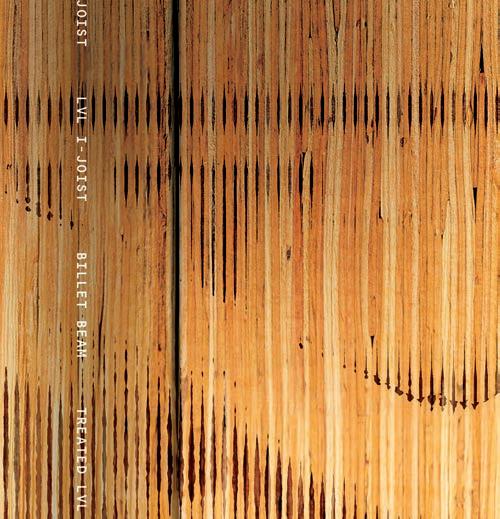

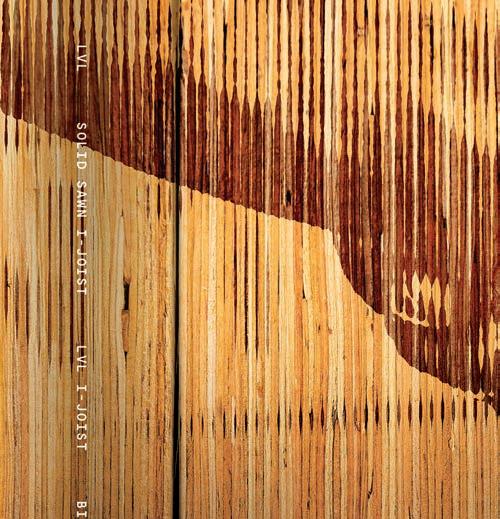

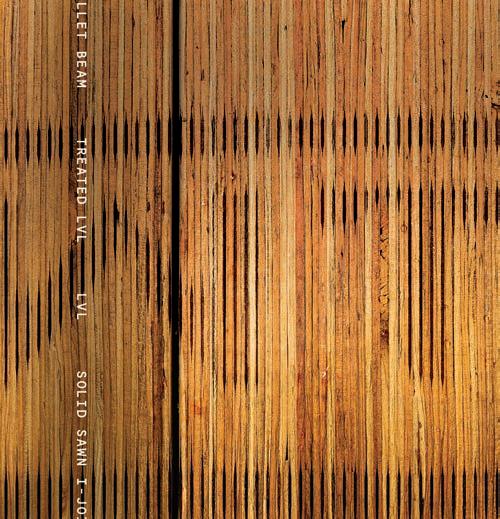

BUILDING PARTNERSHIPS THAT LAST PWTEWP.COM

Ahandshake used to mean everything. It wasn’t just a polite gesture. It was your word. A promise. Today, too often, that’s been replaced by clicks and cold transactions. But in our business, trust still matters. Relationships are still crucial. And nothing is more real than the power of a handshake.

At PWT, we believe engineered wood products are only part of the story. What truly builds stronger projects, stronger businesses and stronger communities is partnership. Real partnership. The kind that happens when you look someone in the eye and commit to standing by them – not just when it’s easy, but when it counts.

Our premium engineered wood products, from LVL beams and headers to I-Joists, are designed for reliability, consistency and performance in the toughest conditions. Our products are third-party certified by APA–The Engineered Wood Association and evaluated for code compliance by ICC Evaluation Service, ensuring every product meets the highest industry standards.

But what really sets us apart isn’t just the wood. It’s the way we do business. Competitive pricing that helps you stay sharp in the market. People who answer the phone, walk the yard and work side by side with you to solve problems. A culture that believes trust isn’t just earned once – it’s honored every day. With seven manufacturing facilities across North America and a strong independent distributor network, we make sure you get what you need when you need it. And we stand behind it all with industry-leading lifetime limited warranties because your peace of mind should be as solid as the structures you’re building.

That’s why for more than 26 years, we’ve put people first. From our dealers to our

“ At PWT, we believe engineered wood products are only part of the story. What truly builds stronger projects, stronger businesses and stronger communities is partnership .”

builders and the crews installing our products, we know that success doesn’t happen in isolation. It happens when we show up for each other. When we keep our word. When we back every beam, joist, header and column with the same strength we put into every handshake.

And while we continue to push the boundaries of what’s possible with engineered wood, we never lose sight of our responsibility

to the future. Innovation and environmental stewardship go hand in hand, ensuring that the forests we rely on today will stand strong for generations to come.

At PWT, we don’t just sell engineered wood. We build partnerships that last. And that begins, as it always has, with a handshake.

Ready to build something stronger together? Connect with us at pwtewp.com

GRANDEUR HOUSING

BUILDING COMMUNITY, ONE MODULAR HOME AT A TIME

BY NATASHA ROMBOUGH, DIRECTOR OF MARKETING AND COMMUNICATIONS, CHBA

For nearly 50 years, Grandeur Housing Ltd. has been focused on reimagining home construction. Based in Winkler, Man., Grandeur specializes in volumetric modular construction, producing a wide range of products, including single-family homes, multi-family residences and apartments, commercial buildings and specialty projects such as supportive housing and shelters for remote communities.

Founded in 1976, Grandeur began with the vision of creating exceptional “mobile homes.” Today, the Grandeur production facility is more than 200,000 square feet, employs 250 staff and produces an average of one home per day. The factory comprises two main production lines, with a third for R&D and special projects. Line one handles larger projects such as townhouses and apartment buildings. Line two focuses on single-family homes, smaller products and some commercial projects, often sold through their retail outlets.

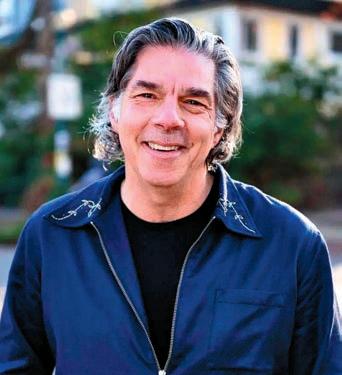

Derek Hiebert, Grandeur’s general manager, has been with the company for 29 years. In that time, he has seen Grandeur grow in scale and capacity, and broaden its range of modular products to adapt to new opportunities and keep the production lines running.

“Historically, we were known as the quality customized modular homebuilder, and the majority of what we did was single-family homes. We’ve maintained that reputation for quality over the years, and we’ve taken on challenges that were outside of what we would traditionally do, like building houseboats during the winter, that could help sustain a factory for a full 12-month cycle,” Hiebert says.

TOURING A FACTORY

I had the opportunity to visit the Grandeur factory in 2024 and was given a small group tour of the facilities by Hiebert. If you’ve never been to a modular factory, I highly recommend going to

one if you get the chance. We entered through huge bay doors and and saw the first stage of a home’s construction: The floor being built. Unlike site-built homes, where the structure is stationary and trades rotate through, factory-built homes efficiently move through stations where different trades work, like a giant assembly line. The modules in the Grandeur factory are moved from station to station using air casters to “float” the homes on a cushion of air.

Hiebert walked us from the front of the factory to the rear, showing us the different stages of construction and highlighting the attention paid to quality construction, including tight building envelopes for superior energy efficiency, which as a Qualified Net Zero/Net Zero Ready Builder is very important.

Derek Hiebert

It was mid-afternoon, and there were many people working at the time, including quite a few women and visible minorities – a testament to the company’s commitment to hiring people from all walks of life.

MODERN METHODS, MODERN OPPORTUNITIES

Grandeur’s approach to hiring and training is rooted in the belief that anyone can succeed with the right support. “Factory construction is able to accommodate a lot of different demographics, skills, and knowledge bases,” says Hiebert. “We have taken people with an

FEB. 10, 2026

CHBA Day on the Hill Ottawa

interest in construction and turned them into great framers, plumbers, electricians, finishers, cabinet installers and more. They’re able to try out those jobs in a safe and controlled environment. We’ll hire a high school student as well as someone who’s nearing retirement, and they all have roles that we can incorporate into our systems.”

Grandeur currently has employees from 18 different countries, which is fairly diverse for a small town in Manitoba. That diversity does present unique language-barrier challenges. To help newcomers feel at home, they’ve designed custom ESL (English as a Second Language)

Coming CHBA Events

MARCH 2026

Finalists Announced for the CHBA National Awards for Housing Excellence

FAST FACTS

Company Name: Grandeur Housing Ltd.

Head Office: Winkler, Man.

Areas Served:

North-Western Ontario, Manitoba, Saskatchewan, Alberta, BC

Full Time Employees:

250 Retailers:

3 Units per year: 230-250

courses, using company standard operating procedures as the foundation. “They not only learn to use English in a more conversational way, but they’re also taught the lingo that we use here at the factory,” Hiebert says.

Regardless of background and experience, employees are able to try different areas of the process if they have an interest. Hiebert says that some people really enjoy learning one skill and doing it well, while others eventually want to explore different kinds of work.

MAY 4-8, 2026

CHBA Home Building Week in Canada Québec City, Que.

The Pikangikum Safe House main entrance

The Pikangikum Safe House site

His own daughter started working at Grandeur after coming out of school. Even though she’d helped with home renovation projects in the past, she didn’t have the confidence to jump into construction right away. Instead, she started with a cleaning job. She soon realized she could do more and worked her way through the system.

Hiebert says providing those types of opportunities is part of Grandeur’s mandate. “Sometimes people don’t think they’re capable of doing this work, but when you give them a little bit of a safer opportunity, they prove to be more than capable, and so if we can get people in the door who think they can do a little, we

can often show them how much more they are capable of.”

SERVING REMOTE LOCATIONS

Tapping into opportunities doesn’t just happen within Grandeur’s workforce; the company is always on the lookout for unique business opportunities. Their flexibility and willingness to serve remote communities has been a lifeline for places where housing and infrastructure are hard to come by. “We really service the remote northern market well from a residential perspective because we become a solution provider for a lot of the communities,” Hiebert says. “It’s not just about cranking out an

apartment building; it’s about really working and understanding the needs within the communities, and meeting them.”

One example that holds a special place for Hiebert is a Safe House the company built in Pikangikum, a remote First Nations community in Northern Ontario. “We were able partner with the community to provide much needed services for the community. I’m always proud of the projects that have a positive impact on people’s lives. We are also currently in the process of completing a Women’s Shelter and will be delivering Second Stage Housing to this same community in February of 2026,” he says.

Transportation is a constant challenge, especially when delivering homes to remote locations. “Some of these communities are restricted to access on winter roads. So, we work with the community, design and build a product, and deliver when the winter road opens,” Hiebert explains. “If needed, we fly in to complete the project and turn over a fully functional home or building.”

CHALLENGES

Factory-built construction is not without its challenges. Securing financing for projects is

Transportation on a winter road

difficult due to industry norms and government policies, such as not financing a project unless it is physically at its final destination. This creates cash flow issues and limits the ability to scale up production.

Grandeur, like other modular factories, faces significant hurdles due to inconsistent building codes and standards across jurisdictions, which Hiebert says makes it difficult to scale up the company’s assembly lines to maximize efficiencies, and therefore increases operational costs due to different requirements in different jurisdictions.

Another major challenge is educating clients, policymakers and industry partners about the unique requirements and benefits of modular construction. Derek describes the need for a “mindset shift” in the construction industry: “If we want modular to be part of the solution, we actually have to leave room to do it in a way that is modular conducive. We can’t leverage all the benefits of what we do if we’re not willing to look at doing it differently.”

As demand for modular construction grows, they must balance the desire to expand with the realities of supporting systems, financing and regulatory compliance.

A VALUES-BASED APPROACH TO INNOVATION AND GROWTH

Despite these challenges, Grandeur is looking to the future. The company currently produces roughly one home a day, and plans to double capacity in the coming years. “There’s some automation equipment that I want to start incorporating into our system along with refining our current processes and systems that will increase efficiency and increase capacity through our factories,” Hiebert says. “It’s not about replacing people, but it’s about reallocating that labour to another area to utilize the automation.”

For Hiebert, the future of modular construction is about building relationships. “I see modular being used in various ways and formats to complete projects in partnership with various other organizations and companies. The future is an alignment between utilizing the benefits of factory and off-site construction to complete projects on site using the knowledge and skills that exist in the larger industry.”

As the company approaches its 50th anniversary in 2026, it is planning celebrations for employees, owners and the community. No

matter what the future looks like, Grandeur will stay true to its core values: Family, commitment, quality, faith and integrity. For Hiebert, who has grown along with the company for decades, those values have allowed both him and Grandeur to evolve and thrive, and the future is full of possibilities.

MODULAR homes

CANADA’S

modular landscape

OPPORTUNITIES AND OBSTACLES FOR CANADA’S HOMEBUILDERS AND RENOVATORS

BY NATASHA ROMBOUGH, DIRECTOR, MARKETING AND COMMUNICATIONS, CHBA

If it seems like you’ve been hearing a lot about factory-built construction these days, you’re not imagining things. Modular building techniques have taken the public – and the government – by storm, often touted as the answer to increasing sector productivity and improving Canada’s housing supply gap. And while it’s true that there are certainly huge opportunities to be had, factory-built homes are not a silver bullet for the entire housing crisis. As site-builders, renovators and modular

factories themselves know, the path to widespread adoption is far from straightforward. There are significant barriers that must be overcome if Canada is to use modular construction to its full potential.

WHY CANADA HAS BEEN SLOW TO ADOPT MORE MODULAR CONSTRUCTION

Despite its promise, modular construction faces substantial obstacles that have limited its adoption in Canada and in many other

countries similar to Canada, such as Australia and the United States.

One of the complexities is the ebbs and flows that our housing market typically experiences. Site-built construction business models evolved to be able to expand and contract along with the market, with limited overhead and few employees, using sub-contracting to roll with the turbulent sales cycle. In the current downturn, for example, if Canada’s residential construction industry was

TOP BENEFITS OF FACTORY-BUILT CONSTRUCTION

• Faster construction with fewer delays

• Year-round work with limited weather issues

• More energy efficient and less waste

• Increased output with less labour

• Easier to get labour (fewer barriers to entry, appealing conditions, ideal for immigrant workers)

made up primarily of factories, we would be seeing company bankruptcies rather than just layoffs. High capital investment, high overhead and a dedicated full-time workforce drive the

need for steady throughput, making factories vulnerable to market fluctuations.

Regulatory and policy hurdles are also challenging. Time and resources are wasted when there are duplications of inspections in the factory and on-site – CHBA is working to collect data where it can, to show the inefficiencies. And the benefits of reproduction at scale are lost when the same product must be built in different ways due to jurisdictions interpreting the building code differently or

imposing different by-law requirements. Transportation restrictions can make the logistics of moving modules within provinces and across provincial borders overly complicated, but these problems are not unsolvable if governments come together to recognize the needs. Government and/or regulators also need to step in to work with financial institutions to create better construction financing that recognized the reality of off-site construction. But if steady demand can be secured and more financial investment and de-risking can be rolled out, there is plenty of room for added factories in Canada. Then more builders can take a modular-first approach that allows for repetition and the gains made by production on a large scale.

ADDRESSING LABOUR CHALLENGES

Residential construction has struggled with labour shortages for years, and the problem is projected to get worse. BuildForce Canada estimates that 22 per cent of workers will retire over the next decade. The problem is further compounded by fewer young people entering the trades due to society encouraging university education over vocational training, and Canada’s immigration system not targeting the types of workers actually needed in residential construction.

To give a sense of the magnitude of labour shortages, BuildForce Canada calculated that to attain the Government of Canada’s stated goal of building 5.8 million new homes by 2033, the workforce needs to grow by a staggering 83 per cent above the current status quo. Realistically, that’s not possible. Which means builders and renovators must find ways to create more housing with fewer people. That’s where modular construction can really make an impact.

When modules and panels arrive on site pre-assembled and ready for installation, fewer tradespeople are needed. The accelerated timelines achieved in factory-built construction allow smaller teams to accomplish more in less time, improving overall productivity. There are also gains to be had thanks to the accuracy and consistency that modular construction is known for, which results in less rework.

A Grandeur Housing Ltd. modular home being transported.

CHBA’S MODULAR CONSTRUCTION COUNCIL LEADING THE WAY

The potential to address labour shortages is the main reason why, in 2017, CHBA created its Modular Construction Council, bringing together the Canadian Manufactured Housing Institute and MHICanada to join forces under the CHBA banner. The Council, which is made up of representatives from modular factories across Canada, supports the increasing role of factory-built construction in the building industry. Their familiarity and expertise, combined with the experiences and insights of stick builders, informed CHBA’s Sector Transition Strategy which was released last year and received extensive interest from government and media.

The Strategy provides the government with concrete steps it can take to help to address Canada’s housing crisis and improve housing affordability through the increased productivity of factory-built solutions.

First and foremost, Canada needs a market environment that makes purchasing a home of any kind more attainable. That means changes to our financial systems that enable well-qualified Canadians to buy a home. We need policy changes that stop adding red tape that cause delays and add to construction costs. Governments need to stop making additions to the building codes without considering how they’ll impact affordability, and get development charges under control. And we can’t rely only on modular construction to make up workforce shortfalls alone; we

need changes to better support Canadians and industry to get people into careers in residential construction, and we need to change the immigration system to bring in the right workers to help build homes. Finally, to see real productivity changes, there must be substantial capital investment into factory-built construction, it must be incented and de-risked, and better construction financing products for modular must be created (see more about progress in that area on page 30, Financing Products for Modular Homes.)

Only once we have an environment where housing production can actually increase will we be in a position to allow more adoption of factory-built construction.

MODULAR CONSTRUCTION HAS INTERNATIONAL APPEAL

Many countries around the world are experiencing labour shortages in residential construction. Like Canada, they’re also looking to modular construction as a potential solution, and it’s a topic of great interest for the International Housing Association (IHA), where CHBA is heavily involved. The IHA is comprised of organizations from countries around the world representing the home building industry. It is, essentially, the international association of home builders’ associations, with nations from six continents and including both developed and developing countries.

CHBA was a founding member of the IHA more than 35 years ago, and CHBA’s CEO Kevin Lee is past chair of the IHA. Today, CHBA still plays an important leadership role, including being elected as secretariat in 2025. Through collaboration with other IHA countries, our participation impacts international affairs that affect Canada’s residential construction industry, while also bringing back to Canada lessons learned from abroad to inform CHBA activities to best serve our members, including around factory-built construction.

In September, CHBA hosted the annual IHA meeting in Calgary, where modular construction was on the agenda. Norway has

Modular apartments in Winnipeg supplied by Grandeur Housing Ltd.

Modular unit in the factory of Triple M Housing, Lethbridge, AB

successfully incorporated a lot of factory-built construction, while Japan, considered a world-leader in the space in many ways, and facing major labour shortages due to an aging population, is still predominantly a site-built country. Others have had much slower mass adoptions, including Canada and nations similar to ours in both size and construction processes, such as Australia and the U.S. Meanwhile, some have rushed into factory-built construction, such as Ireland, which is actually now seeing factories closing and/or becoming insolvent in the slowed market.

“Just like we have similar issues in each province, countries around the world also have many challenges in common that they’re working through,” says Kevin Lee, CHBA’s CEO who represents CHBA at the IHA on behalf of Canada. “The IHA brings us together to share strategies and lessons learned. What works in one country may or may not work as well in another for a variety of reasons, and this is what we’re seeing with modular construction. There are many things we can learn from each other.”

As part of information-sharing among nations, while in Calgary, members of the IHA toured Promise Robotics’ new state-of-the-art factory that uses automation and AI-powered robots to produce homes from single-family to

multi-story apartments – a real view into the potential of the future. (Learn more about this exciting topic on page 40).

WHAT’S NEXT

In September, the federal government launched Build Canada Homes (BCH), a new federal agency that will focus on creating more affordable (i.e. non-market) housing to fight homelessness and provide housing for low-income households, by leveraging public lands and placing emphasis on using modular construction. CHBA emphasized that the government should use the private sector to actually develop land and build the housing units, and Prime Minister Mark Carney empha-

sized this partnering with industry in his remarks. The government has also acknowledged the importance of eliminating duplicative inspections and streamline approvals for factory-built homes, which were direct recommendations from CHBA’s Sector Transition Strategy.

But BCH aims to build only less than one per cent of the nearly 500,000 units of all housing types that government says Canada need to build each year, and will focus on government-subsidized housing, so it will not be the answer to improving affordability for the average Canadian. While it may help influence some positive changes to address the challenges to modular construction, CHBA is pushing the government to do much more outside of BCH.

CHBA will continue to advocate for builders, renovators, factories and Canadians in terms of housing affordability and supply. And for site builders and renovators: Now is the time to explore how modular construction could be incorporated into your business model – so CHBA is creating a training initiative expressly to support those interested in exploring the transition to working with off-site factories to address their labour shortages and speed up project delivery. Get engaged, attend a CHBA Modular Construction Council meeting, sign up for CHBA’s Modular Construction newsletter, check out CHBA’s Working with Modular webinar series, talk with other builders who have successfully made the change, and consider how your business will look in the years to come.

Norwegian modular supplier Konsmohus (Konsmo House)

Norwegian modular supplier Konsmohus (Konsmo House)

Photos on this page supplied by the Norwegian Home Builders’ Association

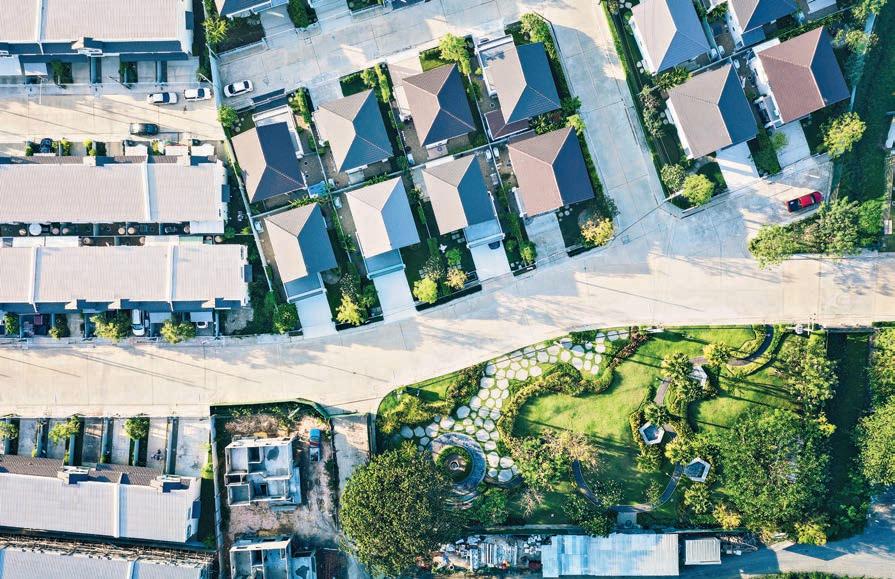

GEOWAREHOUSE

In Ontario’s development environment, having access to accurate property data can make or break a project. From zoning and ownership to market trends and legal encumbrances, the details matter and missing them can lead to costly delays. GeoWarehouse brings Ontario essential property intelligence and title data together in one easy-to-use platform, giving builders and developers the tools they need to evaluate sites, reduce risk and make confident decisions from planning to purchase.

SPOT HIGH-POTENTIAL AREAS FAST

GeoWarehouse’s interactive Heat Maps offer a clear view of key market indicators such as average sales, growth rate, turnover and rental percentage. These visuals help developers quickly identify promising locations and make informed decisions based on current trends.

GET THE FULL PICTURE WITH PROPERTY REPORTS

GeoWarehouse provides a suite of detailed reports to support every stage of site evaluation. The Property Details Report includes ownership, legal descriptions and demographic

data. The refreshed Search Comparables Report offers valuation information. The Title Check Tool and Parcel Register reveal encumbrances and property transfers, critical for avoiding legal issues. The Residential Relocation Report highlights migration patterns, while the Basic Zoning Report outlines permitted uses and restrictions, ideal for early-stage planning.

REDUCE RISK AND STAY AHEAD

Successful developers know that boundary disputes, title complications, and misaligned market choices can derail projects. GeoWarehouse helps uncover these risks early. Whether identifying a title issue before purchase or leveraging demographic data to eliminate

low-growth areas, the platform enables confident, proactive decision-making.

TRUSTWORTHY DATA YOU CAN RELY ON

Powered by POLARIS, Ontario’s official land registration system, GeoWarehouse offers authoritative, up-to-date property data. Every transaction (listed or not) is captured, giving users a reliable foundation for due diligence.

EXPLORE WHAT’S POSSIBLE

GeoWarehouse isn’t just a tool, it’s a competitive edge. Download the free eBook to explore its features, or request a demo to see how it can support your next development. Visit geowarehouse.ca/buildinganddeveloping.

HOW ABOVE-FLOOR PLUMBING IS SHAPING TODAY’S CONSTRUCTION PROJECTS

As renovation and retrofit projects continue to grow in Canada, builders are running into a familiar challenge as they try to add or relocate plumbing in spaces that were not originally designed to support it. In basements, slab-on-grade homes, older buildings or smaller urban spaces, traditional drainage systems can make it hard to change a layout, and often lead to costly or inconvenient compromises.

The issue almost always comes down to drainage. Conventional plumbing relies on gravity and large-diameter pipes, which typically means breaking floors, trenching concrete or reconfiguring existing infrastructure. For many renovation projects, that level of demolition simply isn’t in the budget. It adds time, increases labour requirements, and can introduce structural complications that ripple across the entire build.

This is why above-floor plumbing systems are gaining more attention in the construction industry. By pumping wastewater through small-diameter piping without relying on gravity, these systems allow plumbing fixtures to be installed in locations where conventional

drainage isn’t accessible. For builders facing tight timelines or clients seeking more layout flexibility, this approach can help streamline both planning and execution.

SFA Saniflo Canada’s Sanivite is a prime example of a compact drain pump engineered specifically for grey water applications, making it a practical choice for basement kitchens, laundry rooms and secondary rental suites. Increasingly, systems such as the Sanivite are being incorporated into renovation projects because they enable trades to work within the existing building structure rather than modifying it. Instead of breaking through a basement slab to install new drainage, the unit simply pumps wastewater to the nearest accessible line, reducing disruption, labour and cost.

Above-floor plumbing systems are becoming increasingly common, as homeowners look to turn underused areas into livable, value-adding spaces. Basement suites, in particular, are experiencing renewed interest as Canadians look to create income-generating rental units or flexible multi-generational living spaces for adult children and aging parents.

Similarly, for projects requiring additional bathrooms in tight spaces, compact macerating toilet systems such as the Sanicompact provide an alternative when conventional plumbing isn’t an option. These solutions support powder rooms in locations such as under staircases, loft corners or within small additions, helping builders maximize square footage.

What’s notable is not just the technical capability of above-floor plumbing, but the advantages it creates. By reducing the need for structural changes, crews can complete framing, electrical and finishing work more quickly. That’s a meaningful benefit at a time when labour shortages and scheduling pressures remain an industry reality.

These systems aren’t intended to replace traditional plumbing in new construction, nor should they. But with more complex renovations these products are becoming an essential part of the modern contractor’s toolkit. Rather than being viewed as a workaround, abovefloor plumbing is emerging as a practical, code-compliant solution that supports today’s industry demands without compromising project integrity.

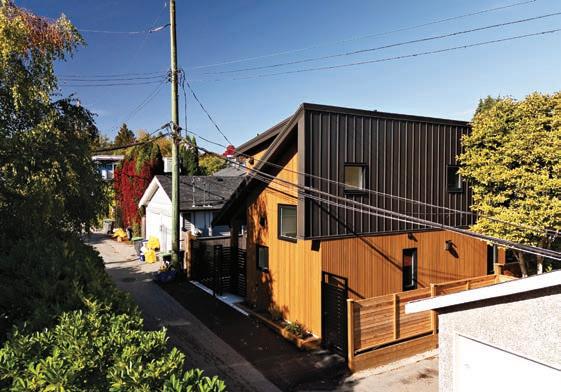

UNLOCKING ADU POTENTIAL

BY SARAH CARON, DIRECTOR, RENOVATION SERVICES, CHBA

Accessory dwelling units (ADUs) are quickly gaining attention as a possible answer to Canada’s housing challenges, offering flexible, compact spaces for families, renters and communities. Cities across the country are wrestling with housing affordability and densification while the housing industry faces acute labour shortages and escalating material costs. CHBA renovators and custom builders are getting approached more and more about building ADUs, and utilizing off-site construction methods to build them can be an efficient, high-quality and timely solution. But what opportunities and challenges await those ready to embrace this evolution?

Industry leaders Jake Fry and Rick Weste offer invaluable insights on the future of off-site ADU construction.

Jake Fry is the founder of Smallworks, a company specializing in panelized prefabrica-

tion and ADU construction, with more than two decades of experience and approximately 500 homes built. He played a leading role in advancing the ADU move ment in Vancouver, helping to make it a citywide initiative, and founded the advocacy organization Small Housing BC. Jake has contributed to policy development at municipal, provincial and federal levels, and continues to promote innovative, scalable housing solutions through both his company and industry advocacy.

Rick Weste is the President and CEO of Triple M Housing, a leader in the factory-built housing industry with roots dating back to 1981. Operating with approximately 450 employees across two shifts, the company produces about 5,000 sq. ft. of homes daily,

translating to about three completed homes every day. Their extensive reach spans Western Canada, Northern Ontario, the Arctic and the United States, with a robust dealer network facilitating local sales, permitting and logistics.

REGULATORY BARRIERS, STANDARDIZATION AND CUSTOMIZATION

One of the most significant obstacles facing ADU construction is the patchwork of

Jake Fry

Rick Weste

Smallworks

municipal regulations. Fry highlights the difficulty: “It’s tough to achieve repeatable designs when every municipality has its own set of requirements. We’ve tried to standardize construction details, but regulatory differences mean we rarely get to use identical floorplans.” Each project submission, he notes, often triggers new rounds of feedback and unique conditions, stalling progress and complicating workflows.

Rick Weste echoes this sentiment, emphasizing that regulatory inconsistencies not only slow down project timelines but also add to costs and uncertainty. “Every jurisdiction seems

to want something different, which makes it challenging for us to create economies of scale or streamline production.” The absence of harmonized standards means that what works in one city might be rejected in another, diminishing the efficiency gains that off-site construction promises.

While regulatory harmonization is important, the industry must also respond to

shifting consumer demands for customizable, adaptable spaces. “Today’s buyers want options – custom finishes, flexible layouts and smart technology,” Fry says. He cites digital platforms and social media with raising homeowner expectations. A winning solution is one that allows homeowners to personalize their space while maintaining the efficiencies of off-site manufacturing.

Triple M Housing

Smallworks

Smallworks

Smallworks

OPPORTUNITIES IN PRE-APPROVAL, ADVOCACY AND RESOURCE SHARING

Despite the challenges, there is optimism on the horizon. Fry points to the potential for municipal pre-approval of ADU plans. “It would reduce wait times, provide certainty and allow the industry to focus on quality and innovation rather than paperwork.” The approach mirrors successful models in other jurisdictions, where municipality-endorsed designs allow for faster permitting and better resource allocation.

Weste agrees, noting that the factory-built industry is keen to work with regulators to develop standard templates and repeatable solutions. “We want to be partners in modernizing the homebuilding process, not obstacles.”

The creation of a resource for pre-approved ADU designs could unlock significant efficiencies and encourage broader adoption.

The path toward widespread off-site ADU adoption is not one that builders and renovators must walk alone. Industry groups and advocacy organizations, including CHBA, play a crucial role in sharing resources, best

practices and policy updates. Engaging with these networks helps builders stay informed, influence policy and hone their practices.

Weste underscores the value of collaboration, encouraging builders to participate in industry roundtables, pilot projects and advocacy campaigns. “The more we share knowledge and coordinate our efforts, the more likely we are to see real progress – both for our businesses and for the communities we serve.”

THE FUTURE OF OFF-SITE ADU CONSTRUCTION

Despite regulatory obstacles and shifting consumer expectations, the future for off-site ADU construction in Canada is bright. As Fry puts it, “We’re at a turning point – if we can streamline regulations and offer the flexibility buyers want, off-site construction will become a cornerstone of housing innovation.” For those ready to adapt, the opportunity is not just to build more homes, but to build them better, faster and with greater impact for Canadian communities.

Triple M Housing

Triple M Housing

Smallworks

Smallworks

Smallworks

Smallworks

BTRBOARD

Easy Assembly, Better Thermal Resistance (BTR). BTRboard OSB is a structural insulated sheathing panel composed of mechanically bonded layers of OSB, fire-resistant polyiso foam and mould-resistant fibreglass facer. Its unique one-piece composition ensures labour savings combined with superior airtightness, high R-value and structural stability for single-family and multi-family construction.

BTRBOARD btrboard.com

PWT – BUILD SOMETHING STRONGER

At PWT, a handshake isn’t just a greeting – it’s a commitment. A commitment to putting partners, like you, first. It’s an acknowledgement that our brand isn’t just built on engineered wood, but also the partners who push its potential. Because real business isn’t about transactions – it’s about relationships that last.

PWT pwtewp.com

JWC8500 HYBRID WINDOW

JELD-WEN of Canada’s JWC8500 Hybrid Window merges vinyl interiors with aluminum exteriors for durability and style. Its 26% slimmer frame and 22% superior energy efficiency meet 2030 standards, while the Tri-Pane Glass option offers 30% better insulation. Customizable designs, low-maintenance finishes, and advanced hardware elevate modern living, blending innovation with sustainability.

JELD-WEN jeld-wen.ca

SANIACCESS 3

SFA Saniflo provides simple, cost-effective plumbing solutions for upgrading or adding bathrooms, kitchens, laundry rooms and more without major renovations. From macerators to drain pumps, our systems offer flexible, reliable, and innovative solutions for small to large-scale residential and commercial projects.

SFA SANIFLO sfasaniflo.ca

THE PREMIER RESIDENTIAL CONSTRUCTION EVENT

The 2026 NAHB International Builders’ Show (IBS), Feb 17-19 in Orlando, is your best opportunity to meet with top companies, discover the latest trends and hottest new products and learn what’s new and what’s next in the residential construction industry. Learn more and register!

NAHB INTERNATIONAL BUILDERS’SHOW (IBS) buildersshow.com/whyibs

GEOWAREHOUSE

Teranet is Canada’s leader in land and commercial registry solutions, providing essential property intelligence to real estate and development professionals. Its flagship product, GeoWarehouse, equips builders and industry experts with proprietary imagery, property reports, title data, and market insights, streamlining decisionmaking and ensuring project success through accurate, accessible information.

TERANET geowarehouse.ca

MODULAR DEVELOPMENT

A CALGARY-BASED DEVELOPER’S EXPERIENCE USING FACTORY-BUILT HOMES FOR A NEW COMMUNITY

BY NATASHA ROMBOUGH, DIRECTOR OF MARKETING & COMMUNICATIONS, CHBA

There’s a new development in southeast Calgary that’s bringing together high-performance modular construction and energy-efficient design.

Emerge Seton Towns is Avalon Master Builder’s newest purpose-built rental community, ideally situated within walking distance to major amenities, including healthcare,

shopping, the YMCA, transit and an upcoming 6.4-hectare park. It will feature 46 stacked townhomes, with two thoughtfully designed home types: A level-living two-bedroom, one-bath home (566 to 577 sq. ft.), starting at $1,295/month, and a spacious three-bedroom, 2.5-bath, two-storey home (1,232 to 1,239 sq. ft.), starting at $1,895/month (utilities not

included in either). All homes will be qualified through the CHBA Net Zero Home Labelling Program, which means those utilities bills should be very manageable depending on occupants’ usage.

Chris Williams is president of Avalon Master Builder. He’s well-versed in Net Zero construction and was a founding member of CHBA’s

Net Zero Energy Housing Council back in 2014, and still sits on its Management Committee. Emerge Seton is the second townhome project that Avalon has built that utilized volumetric modular construction. “We chose to use modular construction for Emerge Seton as we believe this is the future of construction – the ability to control the variables inside of a factory is the perfect scenario for high performance and durable housing,” Williams says. “We also wanted to hone our modular construction skills close to home (in Calgary), as we prepare our offering for communities that have more challenging site conditions or smaller labour forces.”

DEVELOPING WITH A MODULAR-FIRST APPROACH

Incorporating factory-built construction requires taking a modular-first approach to design. Avalon has been building traditionally for 42 years, and its procedures did not align with the needs of modular, which requires more pre-planning to be successful. “Many other construction solutions allow you to start with architectural design, then pivot to alternative construction practices. It can be very difficult to use modular construction if the architectural design does not plan for modular,” Williams says.

To help Avalon design for modular, the company began the project by partnering with fellow CHBA members Big Block Construction and Gravity Architecture. Avalon also included local building officials early on to ensure the project efficiently navigated the complexities of CSA scope lines and local building authority interpretations.

From that process, the company had its architectural plans, which modular factory builder Grandeur Housing – yet another CHBA member, featured on page 12 – used to create a set of shop drawings.

“Upon release of permitting, it was a race for Avalon to complete the undergrounds,

surface works and foundations installs before the modular units were ready to ship,” says Williams. “Big Block Construction supervised the modular production, and began to prepare the logistics of shipping, staging, craning and completions of the buildings. The final stages by Avalon included further civil surface works and landscaping.”

From a land development perspective, Williams says modular construction changes things in a big way, especially for nearby residents. “In a perfect world, we would complete all civil works, all basements/ foundations, much of the curvaceous improvements, and then the modules would just start arriving. The neighbouring homes are only disturbed for a couple of months, rather than for a couple of years.”

TIMELINE GAINS DEPEND ON COORDINATED APPROACH

Theoretically, developments using factory-built construction should see significant timeline improvements. The units themselves can be built in a fraction of the time, but other factors outside of the developer’s control are at play, including permitting and servicing. For Emerge Seton, delays in permitting resulted in the factory being held up for many weeks, and when all four buildings were craned in place, they sat without electricity for many months. “Although on this project the overall project timeline was much the same as tradition construction,” Williams says, “the learns on our approach were invaluable.”

CHALLENGES FOR MODULAR DEVELOPMENTS

Williams notes that financing was a hurdle, since traditional financing terms expect product on site prior to funding. For Emerge Seton, that meant large deposits were required for product that may not be installed for months.

Permitting and inspections were also challenging. “We believe that we have navigated the permitting requirements for Calgary, and in fact had a much smoother experience with a more recent project in Calgary, but the assumption that CSA created a clear scope line of authority having jurisdiction is a very unsafe assumption,” Williams warns. The experience with inspections was similar.

MORE MODULAR IN AVALON’S FUTURE

Going modular has been a learning curve for Avalon, and the company is just getting started developing communities with factory-built homes. Avalon has two upcoming modular projects being built in partnership with Big Block Construction: A building in Belmont (Calgary), and a 120-unit Net Zero townhome project in Canmore, Alta. Despite the changes needed to procedures and the challenges encountered, Williams sees the benefits of modular construction and is enthusiastic about applying the lessons Avalon learned: “Our experience in preplanning design, financing and the local authority having jurisdiction partnership have already been applied and are making a difference.”

ECONOMICS

FINANCING PRODUCTS FOR MODULAR HOMES

INNOVATIVE OFFERINGS FOR BUILDERS AND BUYERS THAT HELP UNLOCK MODULAR DELIVERY

BY EVAN ANDRADE, CHBA ECONOMIST

Lack of access to proper construction financing products for factory-built construction is one of the major factors preventing greater industry growth in Canada. The challenge was one of several flagged by CHBA and its Modular Construction Council in CHBA’s Sector Transition Strategy.

There are legal differences between real property and chattels as well as lending practices that developed over time to support traditional site construction – which has become status quo. As a result, modules under construction in the factory or in transport to the installation site have been unable to

secure traditional lending methods, since they aren’t considered real property until affixed to a permanent foundation. This means that funds can only disbursed to the builder when the modules are attached to the foundation and become real property.

The issue with this is that the capital that a modular builder needs during production must come internally before being compensated upon project completion. This is one cashflow risk that reduces the attraction of investing more into modular construction.

However, there are new financial products arriving that can help smooth the cash flow

issues, allowing modular builders access to a steady stream of payments prior to and during the production of the modules. Two of CHBA’s Alliance Network Members, Canada Mortgage and Housing Corp. (CMHC) and RBC Royal Bank, have relatively new products geared specifically to financing residential modular construction.

PERFORMANCE BONDING ALLOWS FOR FINANCING

Still in its pilot stage, the CMHC is attempting to fill an industry gap with a new insurance program for construction loans specific to modular multi-unit rental buildings of five units

“ The capital that a modular builder needs during production must come internally before being compensated upon project completion. This is one cashflow risk that reduces the attraction of investing more into modular construction. ”

or more. Within their mandate, outlined by statutes in the National Housing Act, CMHC is unable to insure non-mortgage loans and can only insure new construction loans up to the amount of costs in place. To overcome this, the pilot program allows modular factories to get a performance bond from a third-party surety. This bonding is insurance that the modules will be completed to specification. The typical cost of the bonding ranges between 0.5 and two per cent of the contract value and depends on the factory’s project history and company financials. CMHC is then able to insure the construction loan, using the bonding as collateral, and work with the lender to make advances based the amount of bonding insurance in place. This means that the factory is able to receive funds prior to the modules being affixed to the ground.

While modular construction is not new, CMHC has little historical precedence that involve this construction method. It’s one reason why the pilot program is narrowly available for modular rental projects of five units or more. CMHC and its partnered lenders, while interested in supporting modular, are using this pilot program to better understand its unique risks. The multiple meetings with lenders and manufacturers throughout the application process will be used to refine CMHC’s internal processes, which have yet to be formalized. Two eligibility requirements have been finalized, though: Modules must be CSA labelled, and must be manufactured in Canada by a Canadian company.

The performance bond does not only allow the manufacturer to access funding but also allows the projects to benefit from the flexibilities of CMHC’s MLI Select. This includes larger leverage, lower overall borrowing costs and longer-term amortizations of up to 50

years. While the benefits will vary from project to project, the uptake for MLI Select is very high. CMHC feels that there is a strong likelihood that the benefits of construction loan insurance outweigh the cost of the performance bond – improving the project’s pro forma.

CMHC presented the product at CHBA’s Modular Construction Council meeting in October, where they were provided feedback on how it could be made more attractive, supportive and more broadly applicable to the sector. We look forward to the evolution of this product.

EARLIER ACCESS TO MORTGAGE FUNDS

As a separate product, RBC has expanded its residential lending suite of products to support retail individuals purchasing a detached or multi-unit (up to six units) modular building. Working with a growing list of pre-approved modular manufacturers, RBC can advance the contract amount to the manufacturer in tranches as stipulated in the purchase agreement. Typically, this gives the manufacturer access to 20 per cent of the mortgage funds before production begins, 20 per cent when all modules make it onto the production line, 40 per cent when the modules are complete, and 20 per cent when the modules are finally affixed to the foundation. These advances illustrate how lenders are willing to assume additional risk to support modular or off-site construction. This advance release of funds gives builders more cashflow to manage their trades, materials and other business costs.

The maximum leverage RBC can extend depends on the type of building being purchased. With insurance, buildings with

two or fewer units can borrow 95 per cent of the property’s value while buildings with three or four units can borrow up to 90 per cent. A 20-per-cent down payment is required for buildings of five or six units. Finally, in line with new refinancing programs, buyers can access 90 per cent of the property value up to $2 million to build a secondary suite for a family member or relative.

For those looking to join RBC’s network of pre-approved modular manufacturers, there are some simple requirements. The details of the down payment structure in the agreement to purchase and sale needs to be accessible by RBC’s underwriters. The manufacturer must have transporters insurance with at least $5 million in liability. Finally, the builder must be in good standing with a provincial new home warranty program. Additionally, builders should be comfortable with RBC appraisers inspecting modules at different stages of production and installation to ensure disbursements are made on schedule. CHBA’s Modular Construction Council was pleased to see the advancements in this product when it was presented at the meetings in October – members have already started to engage RBC to secure funding and to help refine the offering.

STEPS IN THE RIGHT DIRECTION

It is well known that Canada needs to address the systemic problems that prevent building needed housing supply at attainable prices. By alleviating some of the financial challenges that modular manufacturers face and providing greater certainty in business cash flow, these two products are step in the right direction.

BY THE numbers

MODULAR MATH

TAKING STOCK OF FACTORY-BUILT CONSTRUCTION DATA IN CANADA

BY EVAN ANDRADE, CHBA ECONOMIST

One of CHBA’s objectives is to push for improved data collection and publication related to new home construction. With the high-level policy target of doubling housing starts over the next 10 years, much of the data needed to track progress towards this target is simply not available. For example, the number of new housing starts that utilize some form of factory construction product would be helpful in monitoring the government’s effectiveness in promoting and reducing the barriers to modular construction. This article explores several sources of factory-built construction data, and what we can learn from them.

Hard costs of modular construction compared to on-site (stick-built)

Statistics Canada tracks the factory gate price growth of prefabricated buildings. This is measured as a component of their Industrial Product Price Index (IPPI). We see that the annual year-over-year cost growth between 2018 until the third quarter of 2025 is highly correlated between modular buildings and on-site construction. In both instances, the growth rate of costs have slowed, but continue to compound on the doubledigit cost growth seen over 2021 and again in 2022. This strong correlation helps support the view that while modular and other factory-built construction methods offer many benefits over on-site construction, especially speed of construction, hard cost savings is currently not universally true.

Accessory

Dwelling

Units

potential growth area for factory-built construction

In discussions with the data team at CMHC, CHBA continues to stress that the “apartment and other” category (which includes everything from ADUs to stacked townhomes to highrise residential towers) is antiquated and does not allow measurement of important middle density housing. Listening to this feedback, CMHC is now reporting quarterly on accessory dwelling unit (ADU) starts. While more breakdown of the category is needed, getting this data on separate accessory suite options like laneway suites, garden suites and carriage homes is very helpful, as they are a great application for factory-built methods. Clients often hire a renovator to build their ADU. This means that demand for factory-built products will likely increase from both site builders and renovators, who can still do the site-work, but save time and limit disruption for buyers through factory-built solutions.

Annual permitted ADU starts make up a small number of overall housing starts right now. However, starts over the past five years show how they are gaining popularity – particularly in Alberta and British Columbia. Starts in 2025 are expected to reach more than 8,000 units. However, the chart below reinforces the reality that if people are not buying new homes, the industry is not producing them. As sales conditions in BC slowed, as measured by the HMI, the number of ADU starts slowed. Alberta’s healthier market has allowed them to produce more than 4,000 units in back-to-back years. This helps illustrate the challenges of managing overhead in producing a product that is subject to large swings in demand.

Trade data shows Canadian prefabricated housing sector making gains

Looking at annual trade data also shows progress for Canada’s prefabricated housing sector. Over the past decade, Canada gradually reduced its annual prefabricated building trade deficit with the United States of more than $300 million in 2014 to a small trade surplus of $32 million last year. This pattern is consistent with prefabricated construction in Canada growing in terms of competitiveness with the U.S. While high transportation costs may prevent greater Canadian competitiveness in overseas markets, it is important to see that Canada’s capabilities in prefabricated construction are comparable to our neighbours to the south.

Builders using or considering factory-built construction methods

Each year since 2023, CHBA’s Housing Market Index survey asks builders a series of questions related to their use of factory-built construction. The intent is to get data on how, why and how fast builders are incorporating modular into their businesses.

In 2023 and 2024, builders were asked if their business currently makes use of modular housing, manufactured homes, panelized components or pre-engineered packages. Both years, use of panelized components came out on top as the most prevalent factory construction method among builders, with 26 per cent of builders using them. Just seven per cent said they use pre-engineered packages and five per cent of builders reported using modular construction.

In 2025, CHBA asked builders who do not currently utilize factory construction products which they would be most likely to consider over the next three years. The result: 59 per cent are giving some level of consideration to using panelized components, 55 per cent would consider pre-engineered packages, and 13 per cent are open to using either modular or manufactured homes. This level of consideration has not changed much since we began collecting data, which indicates that while there is room for broader adoption of modular construction, there are clearly barriers to doing so.

Like builders that are currently using some form of factory construction, these prospective builders are far more likely to partner with an existing third-party factory than investing in an in-house factory as their first foray into factory construction.

IN CONVERSATION WITH…

Lesa Lacey

BUSINESS MANAGER | LACEY CONSTRUCTION LTD. | FRASER VALLEY, BC

BY WAYNE KARL, EDITOR, BUILDING EXCELLENCE

For Lacey Construction Ltd. in Fraser Valley, BC, building award-winning residences – often in remote areas – over the course of its almost 30 years in business, might be enough of a calling card to be proud of. But for this established custom homebuilder and renovator, such success is only part of its story.

Add in an increasing focus on modular construction, with an emphasis on an appreciation for the First Nations and women among its crew members, and you have a company taking a leadership position on a number of fronts.

For insight into Lacey Construction, the challenges and opportunities of modular housing – and some advice for likeminded builders – we sat down with Business Manager Lesa Lacey.

LET’S

START WITH AN EASY TOPIC… A BRIEF INTRODUCTION TO LACEY CONSTRUCTION…

Lacey Construction is a full-service construction firm – renovations, custom homes and commercial work. Founded in 1999 by Erik Lacey, we are a proud five-time CHBA Fraser Valley Custom Home Builder of the Year and three-time CHBA FV Renovator of the Year. Our success is grounded in our amazing team. In 2026, six of our team members will be celebrating their 10-year anniversaries and another seven have been with us more than 10 years. Our team includes past clients and

family members of clients, and we are so fortunate to have such a crew. More than 25 per cent of our field team are women and more than 10 per cent are First Nations. We have all ages from 18 to 72 on our crew.

HOW MUCH OF YOUR BUSINESS IS MODULAR HOUSING, AND HOW FAST IS IT GROWING?

All our current custom home projects, and new builds in First Nations communities, include prefabricated or modular components. From insulated concrete form (ICF) to pre-framed wall panels, to full structural insulated panels (SIP) wall systems, we find modular components to allow us to increase the quality of the final build. We find success in partnering with other CHBA members that produce modular components to share best practices and learn from leaders in our industry.

WHAT ENCOURAGED YOU TO GET INTO THIS PART OF THE BUSINESS?

We met the team at Winton Homes and Cottages in Prince George, BC, another CHBA member, years ago, and hearing about their process, we saw that we could use better framing materials from their plant in Prince George than we could get in the lower mainland at that time. This partnership allowed us to expand our understanding of

what it meant to work with modular, allowing us to expand what modular looked like in our custom homes and builds. We had the privilege of working with Sandpiper Resort in Harrison Mills, BC to build their new cabins – on an extremely tight timeline. To meet their deadline, we worked with full SIP panels and timber framing to deliver gorgeous cabins that came in on time and on budget.

Around that time, we put together a high-performance build with BASF technology from inside a medium security institution in Canada. This opened our eyes to the flexibility of working with modular components to achieve better energy efficiency and higher quality. I continue this work with supporting individuals who are justice-impacted to look at careers in construction post-release. Modular factories are a good spot to start a career in trades – regardless of your background.

HOW WELL HAVE YOUR SUPPLIERS KEPT PACE WITH THE DEMANDS OF MODULAR HOUSING?

With more than 27 years in business, our suppliers are part of our team’s success. We work with them to stay on top of emerging technologies and more. We see more and more of our supplier partners looking to

Photo: Brice Ferre Studio

incorporate some form of prefabrication in their business models. Our truss supplier is now framing full wall panels and becoming more of a one-stop shop. They are responding to the same themes in the industry we are responding to – more efficient construction at a higher quality.

WHAT DIFFERENTIATES YOUR COMPANY FROM OTHERS THAT ARE INVOLVED IN MODULAR HOUSING?

Not sure this makes us different – but we do consider modular and prefab on each of our projects. Does this fit the project? Does this work for our client? Will this help us achieve our clients’ goals?

WHAT ADVICE WOULD YOU HAVE FOR BUILDERS CONSIDERING GETTING INTO THE BUSINESS?

One challenge of working with more prefabricated components is that you must be ready to talk to your clients about being firm on approving their plans. It is more difficult to make changes when you order the walls or components in advance, and those last-minute changes can make a big difference to your budget. We suggest getting your clients to physically or electronically sign off on each page of their plans – and review together in detail before ordering your package from your modular or prefab partner. Therefore, it is key to ensure you have strong language around

“ One challenge of working with more prefabricated components is that you must be ready to talk to your clients about being firm on approving their plans. ”

WHY DO YOU THINK MORE COMPANIES AREN’T INVOLVED IN MODULAR HOUSING?

Some builders are unaware they are using modular components – and part of this is a mind shift. From trusses to floor assemblies, custom builders are used to working with some prefabricated components for construction. We regularly use modules from our supplier partners to meet engineering requirements.

By moving the bulk of the building process into a controlled environment, even custom builders can eliminate many of the delays and headaches associated with traditional builds. Homes can be built with factory precision, ensuring higher quality control and quicker delivery to sites – no matter how remote it may be.

change orders and the impacts of making changes onsite when using modular components. Once you get to a job site, those changes are much more difficult to make. Check out the CHBA National resources on contracts and looking at draft contract language – including highlighting change orders.

As a custom builder, there are multiple benefits to working with a prefab or modular partner. Timelines are shorter, we use less framing labour, the sites are safer and we benefit from factory precision. The materials are higher quality, we meet our goals of reducing waste and we work on future forward building.

laceydevelopments.com

And on a personal note…

WHAT OR WHO IS YOUR GREATEST INSPIRATION FOR WHAT YOU DO?

I dropped out of university in spectacular fashion six months after starting – it was not the space for me. My aunt gave me a job with her event planning company, and I worked with many different industries in that capacity. I saw how business worked in different industries, worked with leaders on their volunteer boards and saw first-hand the power of association work. At CHBA, Past President Nathan Stone inspired me to get more involved with our industry.

WHEN YOU’RE NOT CREATING MODULAR HOUSING SOLUTIONS, AWAY FROM THE OFFICE, YOU… I love cooking and sharing recipes, and I love volunteering in prison. December will be my 13th visit to a U.S. prison with Defy Ventures, assisting individuals with entrepreneurship training and support. Volunteering in prison inspires me to continually work to improve my life and the life of those around me – the Defy Ventures men work so hard to get through the program under trying circumstances, and their commitment to a better life for them, their families and their community inspires me daily.

WHAT’S ON YOUR TV BINGE WATCH, READING OR PODCAST LISTS THESE DAYS?