THE MAGAZINE FOR THE PROFESSIONAL BREWING INDUSTRY ROOSTER’S BREWING CO Growing older gracefully BREWERS JOURNAL SPRING 2024 | VOLUME 10, ISSUE 1 ISSN 2059-6669 18 | JOHN KEELING ON CASK: NORTH OR SOUTH? 26 | SMALL PACK EQUIPMENT: INNOVATION AND INVENTION 44 | HOMEBREWING: JACK WALKER SHARES HIS SECRETS

Shaping the future together

It’s important to look beyond the short term, which is why Krones is working on “Solutions beyond tomorrow”. Beverage filling lines, digital services and plastics recycling: Krones’ innovative solutions combine superior performance with sustainability.

krones.com

LOOK TO THE FUTURE

As the dust settles on the latest budget, the last from Chancellor Jeremy Hunt before the General Election, the consensus was there were opportunities to be taken but, unfortunately, missed.

So when SIBA’s Barry Watts kindly invited me to the launch of their new manifesto, hosted by the Rt Hon Alun Cairns MP and SIBA CEO Andy Lee, I gratefully accepted.

At its heart, SIBA is urging the next Government to adopt 11 policies that cover four key areas of market fairness, fair taxation, reforming alcohol taxation and improving the environment. These, they say, will help remove the barriers to growth, ensure that independent breweries remain competitive and help them to make the most of the move to Net Zero.

Commenting, Slee said the manifesto “puts improving fairness for independent brewing at its core” and is full of initiatives that they hope that all political parties will consider as they draw up their plans for the next government ahead of the General Election.

“Independent breweries operate at the heart of our communities, supporting our local pubs and delivering innovative, fresh and tasty beer,” he said.

“However they are constrained by a lack of access to market and a tax system that burdens small businesses. We believe that with government support we

could boost the sector and ensure that independent brewing continues to thrive across the UK.”

And elsewhere in Europe, future planning is also on the agenda. With two months to go until the European Parliament elections, The Brewers of Europe have published their 2024-2029 Manifesto for a sustainable brewing future, a paper urging decision-makers to recognise beer as Europe’s beverage of choice, with its “distinct and positive economic and social contribution to communities across the continent” as well as its value in promoting moderation.

The Brewers of Europe head of operations Simon Spillane said the Manifesto aims to show that brewers are looking ahead and providing answers to some of the challenges facing Europe.

“Beer is a force for good in Europe,” he said. “Brewing provide a distinct economic and social contribution; brewers are innovative and support sustainability, while beer brings people together.

“Policymakers should recognise our role and develop regulation that prioritises partnerships, policies and practices that encourage the adoption of lower alcohol products like beer.”

I hope you enjoy the issue and our sustainability supplement, too.

Tim Sheahan Editor

LEADER

brewersjournal.info SPRING 2024 | 3

CONTENTS

SPRING 2024

News Analysis

In his final budget before the General Election Chancellor Jeremy Hunt unveiled a number of measures. Unfortunately the opportunity to help brewing and wider hospitality was a chance to be taken but a chance missed.

Comment

Ensuring you don’t mislead your brewery’s customers is imperative, especially when it comes to the environment explains Brabners

Comment

Embarking on a net zero journey can be daunting and difficult. But it doesn’t need to be, says Jack Sowler at Net Zero Now.

Comment

When it comes to contract brewing services, it’s hard to put a price on customer service but “excellent” is worth searching for.

Focus | Small Pack

For many breweries, and their customers, bottles are the vessel of choice when it comes to packaging, selling and serving beer. But canning is also impossible to ignore. It’s a good thing then that both of these sectors and their ancillary industries are both rife with innovation, too.

Packaging

Crown caps have become an iconic feature of beer around the world. But where did the crown cap story begin and what is the history behind them. Joshua Webster from Croxsons explains more.

Brewers Intelligence

The latest insight and expertise from the ingredients and sales sectors.

21 Rooster’s Brewing Co 30 years in, Rooster’s Brewing Co of Harrogate remains one of the UK’s most regarded and respected breweries for very good reason.

07 12 14 16 26 38 50 BREWERS JOURNAL 4 | SPRING 2024

40 Branding

United By Design on how effective brand, design, and marketing strategies strengthen a brewery’s connection with its audience.

18

44 Homebrewing

Jack Walker, head brewer at Azvex charts his journey in beer to the Liverpool-based business and also shares a fantastic recipe of his own.

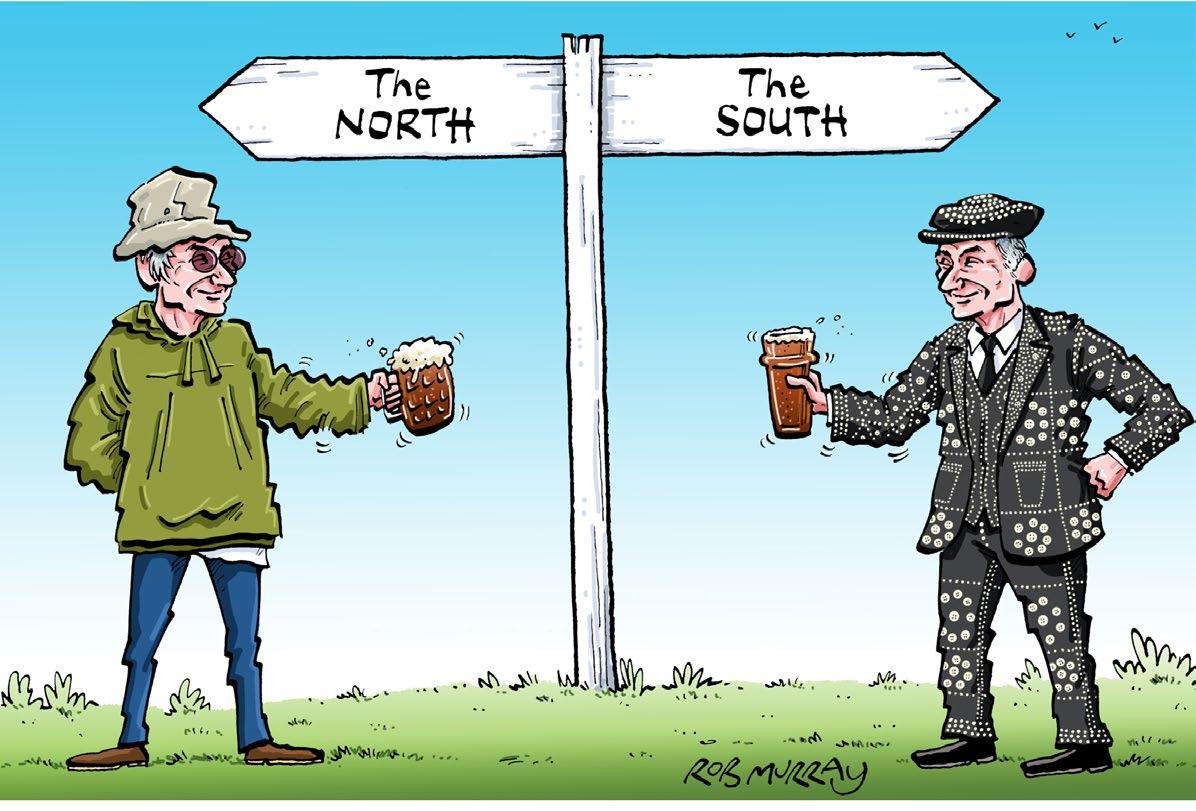

Dear John What are the main differences between cask beer in the North and also in the South?

John Keeling tells all....

SUBSCRIPTIONS The Brewers Journal is a published four times a year and mailed every March, June, September & December. Subscriptions can be purchased for four issues. Prices for single issue subscriptions or back issues can be obtained by emailing: subscribe@ reby.media UK & IRELAND £29 INTERNATIONAL £49 The content of The Brewers Journal is subject to copyright. However, if you would like to obtain copies of an article for marketing purposes high-quality reprints can be supplied to your specification. Please contact the advertising team for full details of this service. The Brewers Journal is printed at Manson Group, St Albans, UK. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording or any information storage or retrieval system, without the express prior written consent of the publisher. The Brewers Journal ISSN 2059-6650 is published bimonthly by Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. Subscription records are maintained at Reby Media, 6 Grove Road, Hemel Hempstead, Hertfordshire, HP1 1NG. The Brewers Journal accepts no responsibility for the accuracy of statements or opinion given within the Journal that is not the expressly designated opinion of the Journal or its publishers. Those opinions expressed in areas other than editorial comment may not be taken as being the opinion of the Journal or its staff, and the aforementioned accept no responsibility or liability for actions that arise therefrom. CONTACTS Tim Sheahan Editor tim@reby.media +44 (0)1442 780 592 Tim O’Rourke Technical Editor John Keeling Contributor Josh Henderson Head of sales josh@reby.media +44 (0)1442 780 594 Jon Young Publisher jon@reby.media Reby Media 42 Crouchfield, Hemel Hempstead, Herts, HP1 1PA

brewersjournal.info SPRING 2024 | 5

AN OPPORTUNITY MISSED

IN

HIS FINAL BUDGET BEFORE THE GENERAL ELECTION CHANCELLOR JEREMY

HUNT UNVEILED A RAFT OF MEASURES.

UNFORTUNATELY THE OPPORTUNITY TO HELP BREWING AND WIDER HOSPITALITY WAS A CHANCE TO BE TAKEN BUT A CHANCE MISSED...

Described as a ‘Budget for Long Term Growth’, the UK Government said the latest Budget sticks to their plan of delivering lower taxes, better public services and more investment, while increasing size of economy by 0.2% in 2028-29 and meeting fiscal rules – taking the long-term decisions needed to build a brighter future.

With the independent Office for Budget Responsibility (OBR) confirming inflation is set to fall to target a year earlier than previously expected, wages rising consistently and the economy outperforming European neighbours, the Chancellor said he would stick to the plan to improve living standards by rewarding work and growing the economy.

Of, understandably, interest to those in the world of beer, the six-month alcohol duty freeze announced at Autumn Statement will be extended until 1 February 2025.

This, the Government said, would save consumers “2p on a pint of beer, 1p on a pint of cider, 10p on a bottle of wine and 33p on a bottle of spirit compared to if the planned rise had gone ahead. This will benefit 38,000 pubs across the UK, while reducing inflation this year,” they said.

Other points of note were the decision to build on the 2 percentage point cut to Employee National Insurance at Autumn Statement, Hunt announced a second 2p cut from 10% to 8% from April. Taken together with the cut to Employee National Insurance at Autumn Statement, this slashes the main rate of Employee NICs by a third and means, they explained, that the average worker earning £35,400 a year will be over £900 better off this year.

A cut in VAT was always unlikely, that much is probably true, but the positive impact felt by a temporary freeze in duty is unlikely to felt but the hospitality industry – breweries and their customers – it is apparently designed to help.

“Whilst the extension to the freeze in beer duty is welcome, it will do nothing to help pubs, the operators of which are really feeling the pinch in the current market, explains Andy Parker, the award-winning founder of Elusive Brewing.

“High energy costs, supplier price increases, looming business rates increases and the cost of living crisis are sadly creating a perfect storm of challenging trading conditions. Sadly I can see many more pubs closing, which in turn squeezes us as suppliers.”

Luci Clayton-Jones and Mike Clayton-Jones, the founders of Double-Barrelled in nearby Reading, Berkshire, echoed this.

“An extension to the freeze on alcohol duty is obviously welcome over a rise in duty rates, but crucially this is not a cut, when we have one of the highest, if not the highest alcohol duty rates in the world and so will not reflect in a reduction of costs for breweries – as a result no reduction in outgoings for publicans or drinkers either,” they said.

“It is disappointing to not have seen any cut in VAT rates that would have had a far greater positive impact for hospitality-led businesses.”

Darron Anley, the founder of Finchampstead-based Siren Craft Brew, which will open a new venue in Reading this year, said the Budget was “not even touching the margins of anything useful for the country”.

“The definition of insanity is doing the same thing and expecting different results. The government tried a 2p cut in NI in the last budget and got no political capital out of it, why try it again?” he said. “But on an industry-specific point, a hospitality vat reduction is what was required to stave of hundreds of business closures in what is a huge industry sector for the UK. That and business rates. A freeze in alcohol duty won’t help the pubs, bars and restaurants that are our customers.”

Whilst

the extension to the freeze in beer duty is welcome, it will do nothing to help pubs, Andy Parker, Elusive Brewing

And Jordan Childs, the CPO of no-andlow brewery brand Mash Gang says that while a freeze until 2025 will certainly be welcome news for many pubs and taprooms, it does “little to offset the bitter memory of energy gouging which was the final nail in the coffin for many struggling small businesses, and a disgusting windfall for energy giants”.

He says: “Given the last few years, I’ll settle for ‘it’s not getting any worse’. I believe this summer is going to be the best we have seen since 2019 through grit determination and persistence, British pubs keep the dream alive. Drink more cask in 2024!”

brewersjournal.info SPRING 2024 | 7 NEWS ANALYSIS

In Norfolk David Holliday, the co-founder and co-owner of Moon Gazer Ales at The Norfolk Brewhouse, added: “Speaking financially not politically but the Budget did absolutely nothing for hospitality and no by not cutting VAT there was such a missed opportunity for a sector which does and can contribute so much to the economy.

“The hospitality sector is still recovering from the perfect storm of enforced shutdowns during Covid followed by massive increases in energy costs and all input costs from food cost to staff costs including the increase in living wage.

“The resilience of the sector is amazing as against all the odds it battles to keep cost down and customer’s coming in –but that is not sustainable and a recent survey showed that over 50% of hospitality have exhausted all their cash reserves and have less than 3 months reserves.

“This simply isn’t sustainable and the recent increase in closures is only set to continue both for financial reasons and also personal reasons as there is only so much people can take!”

Holliday adds: The duty freeze is welcome but this is not a cut. It’s a real kick in the teeth to see the HMRC show on social media that the freeze will cut our costs as a brewery – it won’t – it will just not put them up. If people are not going to help you then we have to live with that – but at least let you down honestly and don’t lie – that’s the kick in the teeth. We will keep campaigning for the meaningful support the sector needs and deserves.”

From an industry body perspective, SIBA’s chief executive Andy Slee says that the Government’s continued support for independent breweries and community pubs through an extended beer duty freeze is a welcome announcement that will help keep the price of a pint from rising, and that the National Insurance cuts will also put more money into people’s pockets which is essential for encouraging spending in pubs and hospitality.

He adds: “However nothing has been done to address the heavy Covid debt the sector still carries, and despite pubs and independent breweries being vital

We are disappointed that nothing specific has been done to help alleviate the cost tsunami facing our much loved breweries and pubs in the months ahead.

Andy Slee, SIBA

global brewing giants and the likes of supermarket alcohol. CAMRA will continue to campaign for the Treasury and all political parties to back our sensible ask of making tax on pints in pubs 20% lower than the general duty rate.

“The Chancellor’s announcement that the VAT registration threshold for small businesses will be increased will not benefit the majority of pubs, breweries or cider producers.”

Phil Halls, co-founder of Grain Brewery in Norfolk, concludes: “A freeze on beer duty is welcome but does nothing to solve the problems faced by today’s small brewers and the pub and bar industry.

“There have been calls for a cut in VAT for hospitality, which would be welcome but unlikely, and again does not confront the real problems we are facing. Going down the pub is an expensive hobby.

to local communities they have received no direct support in the Spring Budget – with a missed opportunity to increase the Draught Relief to 20% or more which could have boosted our hospitality sector. Between them SIBA members run over 2000 pubs, bars and brewery taprooms, making a significant contribution to the local economy and community well-being. We are disappointed that nothing specific has been done to help alleviate the cost tsunami facing our much loved breweries and pubs in the months ahead.”

And CAMRA Chairman Nik Antona adds: “The Budget was a missed opportunity to show ‘backing for the Great British pub’ by significantly cutting tax on draught beer and cider served in pubs. However, freezing alcohol duty until February 2024 will be welcomed by consumer and breweries, helping mitigate an additional hike in costs to be passed on to pubs and pub-goers.

“Making duty on draught beer and cider significantly lower would promote drinking in the regulated setting of a community local and help small and independent producers who sell mainly into pubs and taprooms to compete against the

“The core problem is that brewers have been massively squeezed on their margins because of high ingredients cost, high energy costs and the knock on effect these have on other materials, at the same time as an increase in minimum wage. Then we sell to pubs whose margins have similarly been squeezed, and neither pubs nor brewers are selling beer at the price it needs to be to earn a fair wage.

“And pub goers have had their household budgets slashed, resulting in less ability to buy a pint. Inflation is down to 4%, but that 4% is still an increase on top of already unaffordable prices. Until the fundamental costs of property, energy, and food are brought under control and become fair and affordable, anything else is spin. Our politicians should start by giving frank and honest information to us.”

BREWERS JOURNAL 8 | SPRING 2024 NEWS ANALYSIS

If you’re talking bottling and canning lines, shouldn’t you be talking to us?

At the Enterprise Group you will find a personal commitment to your project, whether it’s a single machine for integration into your existing line or a turnkey project on a green field site.

At the Enterprise Group we are not just agents, we can offer you a total package. Our experienced project layout engineers working with state-of-the-art CAD facilities, combined with our team of field engineers, allows us to respond quickly and accurately as your project develops.

This commitment continues with machine efficiency trials and performance tests, followed by full aftersales service and backup.

So whatever your requirements, you should be talking to us.

Visit : www.enterprisetondelli.com HEAD

INTERNATIONAL

OFFICE : Enterprise Tondelli Srl. Via La Spezia, 193/A - 43126 Parma – Italia.

+39 - 0521-940068 Fax +39 - 0521-940067

Tel

E-mail : info@enterprisetondelli.com

TECHNICAL SALES OFFICE

7, College Farm, Barton Road, Pulloxhill ,Bedfordshire, MK45 5HP, United Kingdom. Tel. +44 (0)1525 718288

: info@enterprisetondelli.co.uk

Unit

E-mail

CICERONE CERTIFICATION PROGRAM ACQUIRED

The Cicerone Certification Program has been acquired from founder Ray Daniels by two Master Cicerones – Dan Imdieke and Jason Pratt.

“For several years now, I have been looking for a suitable group to take over ownership of the Cicerone Certification Program,” said program founder Ray Daniels. “These two Master Cicerones are well known to me and to the program as the result of having worked with us in a number of capacities over the years.

“Based on their experience both in the industry and with Cicerone, I feel very confident entrusting the future of the program to them.”

Daniels formally launched the Cicerone Certification Program in January 2008. Its mission has been to improve the quality of beer service for consumers by educating and certifying beer professionals. Over the past 16-plus years, the program has reached servers and other beer professionals in more than 90 countries to become the de facto standard in professional beer certification in the United States and elsewhere.

The program’s offerings include online exams, training programs, and other remote learning resources in seven languages. When circumstances permit, they also conduct in-person, interactive classes that prepare participants for exams. To date, more than 150,000 individuals worldwide have completed at least one level of certification in the program.

BEER52 ENTERS DISTRIBUTION MARKET WITH EEBRIA ACQUISITION

Craft Beer Holdings Limited, a subsidiary of Beer52 Limited, has entered into an agreement to acquire certain trade and assets of distributor EeBria Limited. The deal secures the future of an important route to market for independent brewers across the UK and Europe. It follows the announcement on midnight of 19th March 2024 that EeBria had been placed into administration. Beer52’s acquisition, the terms of which have not been disclosed, allows EeBria to move forward

well-capitalised, with a strong balance sheet and a clear focus to get more craft beer into more pubs, bars, shops and restaurants.

Fraser Doherty, CEO of Beer52, said: “We are acutely aware of how difficult the current trading environment is for breweries, brands, producers, and customers. Now more than ever, the industry we love needs EeBria’s revolutionary platform to thrive, connecting suppliers and customers and getting more people drinking great beer.”

KIRKSTALL TO RENEW “LANDMARK OF YORKSHIRE BEER CULTURE”

Kirkstall Brewery has announced that it is taking on the lease of The Tetley, with plans to make it a hub for great beer from Leeds and renew its status as a “landmark of Yorkshire beer culture”.

‘The Tetley’ building is the former brewing headquarters of Tetley’s Brewery, built in the Art Deco style in 1931. In the 1980s, Tetley’s Brewery became the largest producer of cask ale in the world, and the site has remained an icon of Leeds beer history, even after its closure in 2011. The building, which now sits at the heart of Leeds’s newest mixed-use district, Aire Park, then operated as a contemporary art gallery from 2013 until 2023, when its lease ended.

From May, Kirkstall will be operating The Tetley as a showcase of the very best of brewing in Leeds. It will feature beers from other breweries in the area, alongside brands from Kirkstall Brewery, Leeds Brewery and Holt’s most recent acquisition, North. Kirkstall also plans to host a number of events at the historic building. “It’s a tremendous privilege to bring Leeds’s most iconic brewery building into the Kirkstall fold,” said Steve Holt, Kirkstall Brewery’s owner and founder.

“As a brewery that pays a great deal of respect to the history of brewing in the city, we believe we are the ideal custodians for the next chapter of this legendary building.”

THE INDIAN BREWERY EXPANDS

The Indian Brewery has expanded its presence in Birmingham’s Jewellery Quarter with a new brewery and taproom. The Indian Brewery said it is thrilled to announce its official expansion into a new premises in the heart of the Jewellery Quarter, St Paul’s Square. Situated on the corner of Mary Ann Street and Livery Street within an iconic building, the new location highlights The Indian Brewery’s commitment to becoming an integral part of the local community.

“The Jewellery Quarter, with its rich history and atmosphere, provides the perfect backdrop for the brewery’s growth.”

NEW LABELLING MACHINE AT STAFFORDSHIRE BREWERY

Willis European Limited have supplied and installed a new Sysmec 6 head Fully Automatic labelling machine for Staffordshire Brewery in Cheddleton, Leek. The fully specced machine is fitted with electronic cams which allows it to handle virtually any bottle shape.

As a contract Bottler, Staffordshire Brewery are able to register every bottle and label configuration in the machine menu, and a simple press of the button is all that is required to set the machine for a specific bottle and label dress.

The machine has a maximum output of 6000 bottles/hour, but is available with outputs from 4000 to 50,000 bottles/ hour. A coding device is also fitted to allow printing of Batch Codes and Best Before dates.

NORTHERN MONK BOOSTS CAPACITY 20%

Northern Monk is set to increase their brewing capacity by a fifth following a £500,000 investment in new equipment and the main brewery site. The 20% increase in capacity will be the equivalent to an additional 8,000 hectolitres (HL), or 1.4 million pints, of beer per year. Last year, Northern Monk, who are based in Leeds, brewed around 7 million pints from their two brewing sites, Sydenham Road in Holbeck, and their original home, The Old Flax Store, Leeds.

BREWERS JOURNAL 10 | SPRING 2024 NEWS

Looking to create beers with huge flavour? low c olou r Create super pale beers that allow your hop and fruit flavours to sing. This malt also pairs exceptionally well with crystal malts in making vibrantly coloured ales as the super low colour allows the red, amber and orange hues to shine through. Contact the Muntons sales team to find out more. D ISTRIBUTOR SALES TOTAL BREWING SUPPLIES, offering bespoke services and deliveries for smaller minimum order quantities of Muntons malt in the East Midlands, Lincolnshire, Yorkshire, Bedfordshire and Cambridgeshire area. 01636 823909 | gary@totalbrewingsupplies.co.uk | @totalbrewinguk BARTHHAAS X, offering next day delivery UK wide and order on demand with quantities that suit your brewing needs https://shop.barthhaasx.com/s/ | barthhaasx MUNTONS. MAKE IT HAPPEN. MUNTONS.COM MUNTONS DIRECT SALES DAVID HANNAH Brewing & Distilling Malt Sales Manager Scotland & Northern England 07525 809093 david.hannah@muntons.com @MuntonsDavid ADAM DARNES Brewing & Distilling Malt Sales Manager Midlands, Yorkshire & Lancashire 07795 920922 adam.darnes@muntons.com adam_muntons JOSEPH FIFIELD Brewing & Distilling Malt Sales Manager London, Southern England & Wales 07583 048935 joseph.fifield@muntons.com muntonsJoe Muntons Super Pale Ale Malt is ideal for brewers looking to create low colour, high gravity ales.

GREENWASHING RISKS FOR BREWERIES

ENSURING YOU DON’T MISLEAD YOUR BREWERY’S CUSTOMERS IS IMPERATIVE, ESPECIALLY WHEN IT COMES TO THE ENVIRONMENT EXPLAINS DANIEL FINN, SENIOR ASSOCIATE AT BRABNERS.

Increased public concern about environmental issues (for example, climate change and plastic in the oceans) means that consumers are more likely than ever before to consider the potential impact of a product on the planet when making purchasing decisions.

Some businesses may be tempted to accentuate their environmental credentials to reflect the mood and maintain or increase their market share. Greenwashing is the practice of making false, misleading or unproven claims about the environmental benefits or attributes of a business, service or product.

Greenwashing can lead potentially to significant legal liabilities. The Consumer Protection from Unfair Trading Regulations 2008 prohibit unfair commercial practices aimed at consumers, which is wide enough to include greenwashing.

Similarly, the Business Protection from Misleading Marketing Regulations 2008 prohibit greenwashing claims aimed at businesses.

Breaching either set of regulations constitutes an offence for which the maximum penalty is an unlimited fine and/or two years imprisonment.

In addition, where an offence is committed under either set of regulations by a company or other body corporate with the consent or connivance of a director, manager, secretary or other similar officer (or is attributable to their neglect), that individual will be personally liable as well.

The UK’s Competition and Markets Authority (CMA) has become increasingly active in relation to alleged greenwashing and, in January 2023, announced that it would be reviewing green claims made in the Fast Moving Consumer Goods sector (including beverages). In addition to the regulations, however,

greenwashing could lead to claims for damages brought by customers for misrepresentation.

THE GREEN CLAIMS CODE

To assist businesses in understanding and complying with their obligations under the law when making green claims, the CMA has published the Green Claims Code. At the core of the code lie six principles: Claims must contain correct information and be true. However, claims can also be misleading if what they say is factually correct, but the impression that they give about the environmental impact, cost or benefit of a product, service, process, brand or business is deceptive.

Claims should be worded in a way that is transparent and straightforward so that consumers can easily understand them. They should not be presented in ways that are liable to cause confusion or give the impression that a product, service, brand or business is better for the environment than it actually is.

Claims must not omit or hide important relevant information. These sorts of omissions can occur where claims focus on one environmental aspect of a product, service, brand or business but not another, or where they say nothing at all.

Comparisons must be fair and meaningful. Comparisons should be based on clear, up to date and objective information. They should not benefit one product or brand to the detriment of another if the comparison is inaccurate or false.

Claims must consider the full life cycle of the product or service. All aspects of the environmental impact of a product or service over its life cycle are relevant, including its components, manufacture, production, use, performance and

COMMENT

BREWERS JOURNAL 12 | SPRING 2024

disposal. Claims must be substantiated. This final principle overlaps with that relating to comparisons. Businesses should be able to back up their claims with robust, credible, relevant and up to date evidence.

The Advertising Standards Authority (ASA) regulates broadcast and nonbroadcast advertising through codes of practice that contain specific rules relating to green claims, including that: The basis of claims must be clear –unqualified claims could mislead if they omit significant information; The meaning of all terms used in marketing communications must be clear to consumers; Absolute claims must be supported by a high level of substantiation; Claims must be based on the full life cycle of the advertised product, unless the marketing communication states otherwise, and must make clear the limits of the life cycle; and It must not be suggested that claims are universally accepted if a significant division of informed or

Businesses should be able to back up their claims with robust, credible, relevant and up to date evidence,” Daniel Finn, Brabners scientific opinion exists.

Although the ASA does not have the power to prosecute or fine, it may, for example, require that adverts are withdrawn or that adverts do not re-

appear in their current form, which can be expensive and embarrassing if a business has invested a significant sum of money on a campaign.

Whilst the Green Claims Code is not law itself, following it may constitute good basic evidence of compliance with regulations.

Whilst there is clearly overlap between them, care should be taken to ensure that any green claims satisfy meet the requirements of the Green Claims Code and the ASA’s rules.

Both of them set high standards and claims, for example, that containers are “100% recyclable” or that ingredients are “sustainably-sourced” may not be justifiable.

Instead, we may start to see more humility and candour in green claims with businesses acknowledging their environmental flaws whilst trying to persuade prospective customers of the steps they are taking to improve.

Scan to see brewing calculators, recipes, best practices and more. CONSISTENT, RELIABLE BREWING YEASTS & BACTERIA We Brew WIth You.™

brewing@lallemand.com

www.lallemandbrewing.com |

brewersjournal.info SPRING 2024 | 13 COMMENT

CREATING A CLEAR PATHWAY TO NET ZERO

EMBARKING ON A NET ZERO JOURNEY CAN BE DAUNTING AND DIFFICULT BUT IT DOESN’T NEED TO BE, SAYS JACK SOWLER FROM NET ZERO NOW.

Since 2022, Net Zero Nowthe climate action platform - has been working with breweries of all shapes and sizes to help them decarbonise.

Breweries follow a dedicated roadmap to net zero, developed by Net Zero Now in partnership with industry sustainability pioneers, Konvoy and Toast, so that climate and industry expertise comes together in the offer of one affordable, easy to navigate package.

Breweries working with Net Zero Now can access all the tools they need to kick-start their sustainability journey and benefit from a standard against which their progress can be measured and certified.

They are supported throughout their process of decarbonisation by Net Zero Now’s friendly and knowledgeable team – from calculating their first accurate carbon footprint, through setting sciencebased reduction targets to implementing a carbon reduction plan and reporting.

Fergus Fitzgerald, Production Director at Adnams Brewery, said: “Net Zero Now provide a solution that makes data collection and analysis manageable for any brewery. The reports helped us identify where we need to focus our efforts as we plan to get to net zero.”

Any brewery that signs up to The Net Zero Brewery Initiative is able to achieve ‘On The Road’ certification – a signal to their stakeholders of their commitment to sustainability.

Many choose to leverage this for competitive advantage - demonstrating to customers, suppliers and peers alike that they are taking action. This certification ensures that a brewery’s

efforts are recognised and can be communicated all the way through to them eventually being fully certified as ‘Net Zero’.

Renegade is among the vanguard of breweries that are already well on the road to net zero. The Berkshire-based outfit may not be long in the tooth, but it is cutting a clear path to net zero, and is keen to do what it considers to be the ‘right thing’ as it continues to expand. Renegade has got to grips with its carbon footprint and has introduced a range of measures – including an array of over 1,000 solar panels that meet approximately 40% of their electrical needs, onsite cultivation of barley and installation of a nitrogen generation plant to cut C02 dependence and output.

They find great value in being able to visualise their carbon usage using the Net Zero Now platform and see, across the business, the impact of the changes they are making.

A recent collaboration with BrewMan also promises to simplify and accelerate the journey to net zero for many breweries. Integration of BrewMan’s operations management software with Net Zero Now’s carbon accounting platform is enabling data to be shared across the two.

In the same way that BrewMan provides an innovative solution to take the heavy lifting out of operations management, Net Zero Now can reduce the burden of sustainability management, and bringing the two platforms together is a massive step forward in catalysing decarbonisation among many breweries.

Sam Williams, Commercial director at BrewMan, said: “Our users care about

the environmental impact of their businesses, and their customers want to be empowered to make environmentally conscious decisions.

“This is why we are delighted to work with Net Zero Now, in offering BrewMan users a simple way to calculate their carbon footprint and find out how they can work to improve it.”

Partnerships across the brewing industry is helping to greatly accelerate its net zero progress according to Jack Sowler, business development executive at Net Zero Now.

“Whether it’s in the development of our bespoke net zero roadmap for breweries or through innovative partnerships that take away some of the burden of moving toward net zero, collaboration between Net Zero Now and key industry players is driving positive change.

“We might be climate experts, but we’re not, perhaps to our dismay, expert brewers. We need to constantly tap into the expertise available in the sector to ensure that we make the journey to net zero as smooth, affordable and accessible as it can possibly be.”

If you’re a brewery considering embarking on a net zero future visit netzeronow.org to take a look at the Net Zero Brewery Initiative or book a walkthrough the Net Zero Now platform with one of our friendly experts.

To quote Martin Kelly, Renegade’s production director, “Every small change that the brewers can make and support through their supply chain will all add up & have a demonstrable effect for the climate, the country and for the world.” Be and brew that change.

BREWERS JOURNAL 14 | SPRING 2024 COMMENT

UNDERSTANDING CONTRACT

BREWING AND PACKAGING

THERE ARE SEVERAL BREWERIES OFFERING CONTRACT SERVICES BUT NOT ALL PROVIDE CUSTOMER SERVICE TO THE LEVELS YOU NEED OR EXPECT. IT’S HARD TO PUT A PRICE ON CUSTOMER SERVICE BUT “EXCELLENT” IS WORTH SEARCHING FOR, EXPLAIN RENEGADE BREWERY.

There are many reasons why businesses selling beer seek out third parties to either brew and pack or simply pack their own beers for them.

Over the last 10 years it has become increasingly common for entrepreneurs with a passion for beer but no brewery of their own to work with established breweries to develop and produce their products for them.

This approach is very sensible if you don’t have a good technical brewing background or lack the investment to establish your own brewery. It also facilitates a faster start into production and is considerably less risky financially.

Several successful brands have started in this way in recent years and, despite the tough economic situation we currently face, many continue to do extremely well.

For brewery owners there are different reasons for considering using a thirdparty brewery to brew and/or pack. Whether it’s a short-term volume increase that cannot be met or a temporary, planned brewery closure, third-party breweries can play a vital role in keeping customers supplied with beer. Another common reason is the proposed launch of a new beer style that cannot, for technical or logistical reasons, be produced in their own brewery.

Possibly the most common reason for established breweries to use third parties relates to packaging.

If a brewery has a customer requiring a packaging format it does not have the

equipment to produce a co-packer can be an excellent solution to delivering the contract.

Whether the new format is cask, keg, bottle, can, minikeg, keykeg or something else if the brewery cannot pack it then finding a capable partner is a godsend.

Transportation of beer via Arlington’s or tankers can be done without any significant deterioration in quality. Clearly, the primary packaging format is key but so too is the secondary packaging. It may be that a brewery has a bottling or canning line but the small pack has to be subsequently packed into flow wrap, tray and shrink or Fully Enclosed Cardboard (FECs - sometimes called “fridge packs”) which cannot be done.

The latter format, FEC, is becoming increasingly popular not only because they look great on a retail shelf but they also guarantee multiple bottle/can sales versus individual bottles/cans, and have the added advantage that they are fully recyclable.

BREWING AND PACKING

When deciding which third-party brewer to use to brew and pack there are some important considerations.

Firstly, if you don’t have a recipe you’ll need assistance either from a brewing consultant or the contract brewery itself. Either way you’re probably going to want to do some pilot brewing before going to full production scale.

It’s usually best to work with a brewery that has a pilot plant which mimics, as closely as possible, their full-scale kit and have brewers who have experience

in taking pilot brews to full scale successfully.

Having a pilot brew you love which isn’t a good match at full scale can be frustrating and expensive if you decide not to pack it, and whilst there are no guarantees with scale-up having an experienced team will get you there quicker.

If you have a recipe and simply want a third-party to produce the same beer on their kit that’s clearly easier but brewing on different kit and potentially different scales can introduce differences in the final product, the key question here is are those differences significant or not? Will your customers be able to tell the difference?

Again, choosing a brewery and brewing team with experience in doing this can save a lot of pain in the long run. In terms of packing the considerations are the same whether the brewery is producing the beer or you are transporting your own for pack-only.

PACK-ONLY

When selecting a partner to pack your own beers clearly the third-party will need the equipment to pack into the primary and secondary packaging formats you require, that’s a given. However, there are a number of questions to ask such as can beer be split into different packaging formats, e.g. can and keg, in the same run, what kinds of loses are typical, what levels of carbonation can be achieved and what are the specification targets for parameters such as dissolved oxygen,

BREWERS JOURNAL 16 | SPRING 2024 COMMENT

clarity and microbiology?

Stabilisation of the beer prior to packing is also an important consideration whether it is achieved via pasteurisation or sterile filtration. With the high energy costs, impact on the environmental footprint of the brewery and potential for off-flavour development, pasteurisation is increasingly being replaced by sterile filtration in breweries.

Once produced most breweries will provide some basic analyses from their own internal laboratory which may or may not be included in the pricing.

Post-packing storage conditions need to be considered if the brewery are holding stock for any extended period.

Ideally they should have a temperature controlled warehouse held at around 12-14 deg C throughout the year to maximise the freshness of the beer. With summer temperatures occasionally hitting over 30 deg C in the UK, a trend that is likely to increase in the future, nobody wants to be drinking cooked beer.

This approach is very sensible if you don’t have a good technical brewing background or lack the investment to establish your own brewery.

However you decide to work with a thirdparty to brew and/or pack your beers make sure you have a contract in place which is fair and works for both sides. Pricing is important but so are the terms and conditions in which the two organisations agree to work together. The contract covers the codified aspects of the relationship, and most third parties will have a standard contract to use, but you also need to find a partner who you feel comfortable working with and trust. You need to feel confident that they will care about your products as much as you do, that communication is likely to be good and the team are responsive to your questions and needs.

There are several breweries offering contract services but not all provide customer service to the levels you need or expect. It’s hard to put a price on customer service but “excellent” is worth searching for. Happy hunting!

We’re launching our popular, high quality beer yeast in 100 g pouches (so packs, under inert atmosphere), bridging the gap between our 11.5 g sachets (so packs under inert atmosphere) and 500 g bricks (hard packs, under vacuum). So now, whatever your brewer’s profile, you get extra convenience and flexibility.

NEW SIZE! SAME GREAT YEASTS. For details and to purchase, visit fermentis.com or get our app

g

100

Launch_Pub_Range_100G_Beer_190x125mm_RS.indd 1 07/01/2022 10:30:35 brewersjournal.info SPRING 2024 | 17 COMMENT

THE UK IS BLESSED WITH GREAT BEERS. BUT WHAT ARE THE DIFFERENT CHARACTERISTICS AND WHICH DO YOU PREFER? HERE’S JOHN KEELING TO SHARE HIS OPINION.

JOHN NORTH VERSUS SOUTH

Now, I have long maintained that despite the myriad of beer styles judged in competitions there are only two types of beer. These are beers I like and beers I don’t.

As a brewer, I only wanted to make beers I liked and for most of my career this was the case. I reasoned that if a brewer did this, they would make the beer as good as they could and be proud of what they had achieved.

They would recognise unwanted changes in the beer flavour and would be quicker to correct them.

If you care about something you make it better, rather like the difference between a brewery and a factory.

However where did my taste come from? I was born and bred in Manchester but spent most of my brewing career in the south.

I was proud of being a Mancunian (I still am) and a typical Northerner. I supported Manchester United and Lancashire and started my drinking on Boddingtons, Robinsons, Lees, Hydes and Holts. Unfortunately, none of them wanted me as a brewer – however Fuller’s did. I had

only ever drunk Fuller’s once before, so it was a leap into the unknown for me. On arriving at Fuller’s, I leapt into the unknown with a certain amount of gusto quickly developing a taste for their beers.

The brewer’s favourite was Chiswick Bitter, and we always tended to drink that, especially as it was only 3.5% ABV. And in those days we would have a couple at lunchtime.

Chiswick was dry-hopped in cask with Goldings and therefore had a lovely hop character. London Pride was malty and fruitier, much different to the beers of Manchester which were dryer, and with a pronounced bitterness.

So, the Fuller’s beers were very different to the beers in Manchester but then Robbies was much different from Boddies.

In fact, one of the great delights of the beer world in those days was to try each brewery’s version of bitter. None were the same and this provided great interest to the beer drinkers of that era.

However, there was one major difference between the north and south and that was one of presentation.

DEAR

BREWERS JOURNAL 18 | SPRING 2024

It still provides arguments today and that is the use of the sparkler. So, I am going to weigh in on this debate with my customary diplomacy. Northern beers use them to produce a massive head which certainly makes the beer look good and appetising but southern beers have a looser fluffy head.

If you pour beer from a cask into a glass, you will get a very small head indeed and this was the way beer was dispensed before the invention of the beer engine. This produced a bigger head, but it needed the invention of the sparkler to produce the tight creamy heads much loved by Northern drinkers. However, it might look good, but does it taste better?

Firstly, with such an agitated pour the beer must lose some condition, I cannot think that this would be a good thing.

Secondly, we know that certain flavour compounds such as bitterness dissolve into the head which makes the beer less

bitter. However, that foam redissolves into the beer as you drink it making the last few drinks very bitter indeed. Again, I cannot believe this is a good thing and makes the beer inconsistent to the drinker.

So, which do I prefer and to answer that I have to say that the best-tasting beer I have ever tasted was poured directly from the cask. The best-looking beers are the ones poured through a sparkler.

When I was working for Wilsons in Manchester as a young laboratory technician, I was asked to sample beer from a pub which complained about head retention particularly at lunch time.

Turns out they served the best pork pies in Manchester, and everybody had one for lunch. The fat from the pies dissolved the foam very quickly. This helps explain the old adage that you drink with your eyes…

There was one major difference between the north and south and that was one of presentation.

brewersjournal.info SPRING 2024 | 19 DEAR JOHN

Scan to see brewing calculators, recipes, best practices and more. CONSISTENT, RELIABLE BREWING YEASTS & BACTERIA We Brew WIth You.™ www.lallemandbrewing.com | brewing@lallemand.com

AGEING GRACEFULLY

BEING ABLE TO MARK YOUR THIRD ANNIVERSARY IN THE WORLD OF BREWING DOESN’T HAPPEN BY ACCIDENT AND ROOSTER’S BREWING CO OF HARROGATE REMAIN ONE OF THE UK ’S MOST REGARDED AND RESPECTED BREWERIES FOR VERY GOOD REASON.

PHOTOGRAPHY: MARK NEWTON

Where were you a little over 30 years ago? England had failed to qualify for the World Cup, 2 Unlimited were Top of the Pops, Shane Warne had bowled the ‘Ball of the Century’ and Rooster’s Brewing Co has just hatched. And in doing so, forever changing the shape of beer in the UK. Though they’d be too modest to admit, they were originators and innovators of quality and new world pale ales. Rooster’s beers, then brewed by original founder Sean Franklin, were starting to stand out and turn heads amongst a sea of brown beer, with flagship pale ale Yankee leading the way. And a little more than 30 years on, Rooster’s Brewing Co of Harrogate are still going strong.

A brewery known for quality, consistency and approachability, their beers are reaching a new generation of drinkers. Be

that in the wild, their fantastic taproom space in North Yorkshire, or anywhere in-between. And thankfully in 2024, cliché or not, they are showing no signs of slowing down, either. To welcome in the new year, Rooster’s announced that it was ramping up its limited release offering, with close to 50 different beers scheduled for production in addition to their year-round core range.

The Harrogate brewery mapped out their brewing schedule for the twelve months ahead, which includes several new recipes, the return of a few old favourites from the archives and a series of collaborations with some of the UK’s most highly-regarded breweries. So what better time then to catch-up with Tom Fozard, the brewery’s commercial director, to discuss the plans for this year. We look back on the impact and influence that Rooster’s founder Sean Franklin has had on the UK brewing

brewersjournal.info SPRING 2024 | 21

Rooster’s has built its name on quality and consistent beers

industry, and also the way that Tom and his family have helped Rooster’s evolve since taking on the business back in 2011. But sticking with the modern day, and to kick-start the year, Rooster’s released no fewer than six limited-edition beers for January to tie in with #Tryanuay, the online, social campaign that promotes and supports smaller, independent beer business during what is typically a tough trading period in January.

Among them was Sleep Is For The Week (a 5.8% breakfast stout), Volstead (a 4.4%, gluten free pre-prohibition American lager) and Democracy Manifest (a 3.6%, cask-only U.S. pale ale), brewed in collaboration with Lakes Brew Co. Other collaborations taking place this year include those with SALT, Fyne Ales, Thornbridge, Brew York and Siren.

And this Spring marks the start of another year in the story of a brewing staple. Not just in Yorkshire but the UK as a whole. And a new chapter for a beer business some 30+ years young can be no accident. But for Fozard and his family, they will always respect and acknowledge the formative work of founder Sean Franklin.

“If you go back to day one, when the brewery was founded by Sean, the real magic ingredient he had was his background in winemaking. And once

Sean Franklin really broke the mould with Yankee” Tom Fozard

he realised he wasn’t going to be a winemaker for a living, he wanted a way of expressing what he’d learned and understood about grapes, and recognised that that similarity exists with hops,” explains Tom.

Before Rooster’s came to be, Sean was already experimenting with hops at his first brewery - Franklin’s. Located in Bilton, North Yorkshire, brewing commenced at the start of 1980 with Sean hearing about the emergence of beers such as Sierra Nevada Pale Ale in California around the same time.

“Sean tried to have some with fun with these beers in the 1980s but to be pretty direct, the market wasn’t really there. So a good few years later he would give it

another go and set up Rooster’s,” recalls Tom. Being a mere 11 years old when Rooster’s came to be in 1993, Tom wasn’t au fait with the liquid itself but looking back, and being local to the brewery he would recall a sea of brown beer with Sean instead leading the way with that focus on American hops and in particular, Cascade. A hop that features in the brewery’s flagship Pale Ale - Yankee.

Coming in at 4.3%, It was one of the original, new-style, pale ales to be brewed in the UK - Yankee is a modern classic. Light and easy-drinking, it’s a beer that showcases the floral and citrus fruit aromas of the Cascade hop, grown in the Yakima Valley in Washington State, USA, projected against a back drop of soft Yorkshire water and Golden Promise pale malt.

“Sean really broke the mould with Yankee,” says Tom. “He worked directly with farmers in the US because there simply wasn’t the availability over here. Hop merchants were, understandably, focused on English varieties in particular. “It took him considerable time to convince people of what this beer was and why it tasted the way it did. Sean and Yankee were the definition of experimentation. He stripped back that beer to really allow the hops to express themselves.”

BREWERS JOURNAL 22 | SPRING 2024 ROOSTER’S BREWING

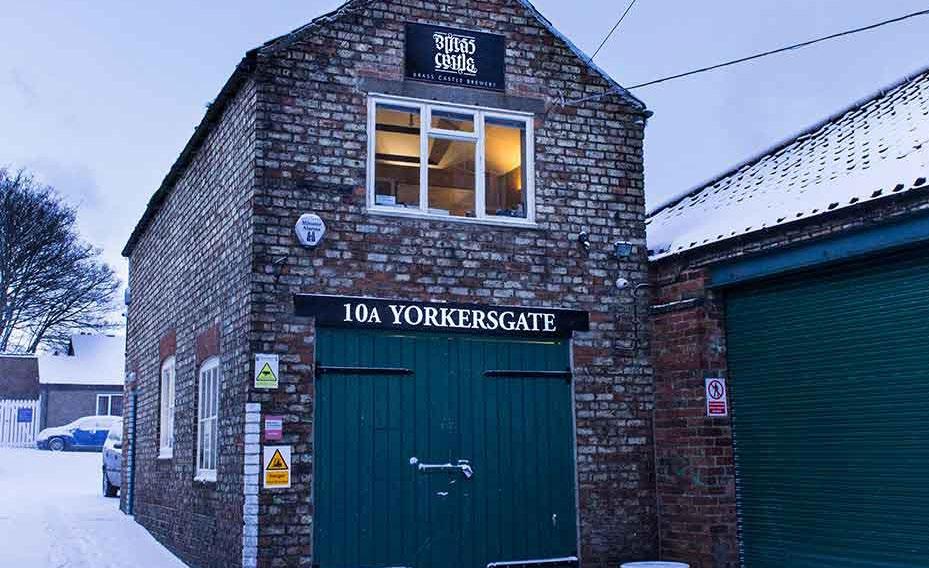

Rooster’s Brewing Co is based in Harrogate, North Yorkshire

Rooster’s celebrated its 30th anniversary in 2023

While Sean Franklin admired and was inspired by the early stages of the US craft beer movement, his creations have gone on to inspire others, too. But while beers like Yankee are something of a household name for many beer fans, Tom feels that Rooster’s remains something of a well-kept secret.

“This is a lovely, friendly industry to be involved with, and we do get quite a lot of people come up to us and express their respect for the brewery and how it made them want to start brewing themselves,” he says. “And obviously my brother and I can’t take credit for that! But it shows that we have a solid reputation. I think people respect that we’ve remained committed to creating consistent, drinkable beers.

“But I think, you know, on a commercial level, despite the success we’ve had and the progress we’ve made, it definitely feels like we’re still a little bit too much of a well-kept secret. Maybe we need to push ourselves out there a little more. I guess that comes with being an established brewery within a fast-paced, challenging market. There are always shiny new beer styles coming out left, right and centre. People want to explore new things, and that’s understandable.

But we’ll continue doing what we do best, too.”

Lots has, predictably, changed, in the three decades Rooster’s has been in business. A business now owned and run by Tom, his brother Oliver and their father Ian. Before the opportunity to take on Rooster’s arose, Tom would pursue a career in journalism while Oliver worked at breweries such as Daleside of Harrogate, a brewery that Rooster’s recently acquired earlier this year. “The financial crash of 2009 meant I lost my job in publishing and I found myself working at a local bar. And before long, I discovered homebrewing. A good brewer is often described as being something of an artist and a scientist combined. I was definitely neither of those. To be honest, I don’t know what I was. But I enjoyed it and got carried away with it.”

Tom’s love of beers, especially US numbers such as those from Odell, Dogfish Head and Stone Brewing, would develop further when working at a local bottleshop and he would soon hatch a plan with a close friend to open up a brewery of their own. “We started working on a business plan but soon decided this wasn’t going to go anywhere. So I put the

business plan to my dad and basically said, ‘What do you think of this?’”.

Fozard adds: “I was looking for a steer in the right direction. He looked at it, laughed and effectively said it was rubbish! But what I didn’t realise at the time was that, even though my brother and I were close, he was getting bored working where he was and that he had also approached our dad for some careers advice.

“Neither of us knew that our dad was ready to sell a small group of pubs that he had built up with a consortium. We found ourselves in a position where Oliver and I wanted to do more work in the industry with a dad who wasn’t ready to just sit back and be bored.

“So we started working on a plan to open our own brewery and about six months into that process Sean Franklin got in touch and said he was ready to retire and if we’d be interested in taking Rooster’s on - and that was it!”

And since taking on the business with their father Ian, Tom and Oliver have successfully built on Rooster’s foundations with the beers they’ve brewed. But in the very early days, they were very firm on their desire to act

brewersjournal.info SPRING 2024 | 23 ROOSTER’S BREWING

as caretakers for such a beloved local business.

“The first thing that we did was spend seven months working side-by-side with Sean, while due diligence was going on. It served as a really good handover period. While Oliver had been brewing for some 10 years at that point, he was still able to learn a great deal with Sean,” he explains.

“We also knew that beer such as Yankee were so highly regarded. There was no way we were going to come in and drastically change things and turn things into ‘The Fozard Brewing Company’ or whatever. We were there to build on the great work Sean had already carried out. “And because Sean had won three backto-back medals at the World Beer Cup in the US, he and the brewery had a great

We aim to create consistent, drinkable beers”

Tom Fozard

reputation overseas. So we’d often have calls from Americans who were visiting and wanted to visit us. But on the flipside, there were people living in a three-mile radius of the brewery that didn’t know we existed....”

Central in those early days, and something that has continued in the years since, was building upon the Rooster’s Brewing Co reputation while also putting the team’s own stamp, their own identity on things.

“When it comes to Rooster’s and the way my brother and I approach things, I feel that we are somewhat of a mix. And that’s a good thing,” he says. “His passion is consistency in the beers we brew and we meet in the middle with how we honour and respect the history of this brewery.

BREWERS JOURNAL 24 | SPRING 2024 ROOSTER’S BREWING

While Yankee remains its flagship, Rooster’s creates a raft of beers across the year.

I’m probably a little bit more out there, always throwing ideas around. “But at the end of the day, he’s the one to actually turn this ideas into beers that people enjoy and want to drink.”

While the last 12 or so years have no doubt flown by, that time has seen the team grow and evolve Rooster’s into a completely different proposition. And that has included moving facility, updating its kit and opening a taproom that can welcome an ever-increasing number of visitors. Much has changed since the team that inherited that cask-only business in nearby Knaresborough.

“When Sean found the land the brewery would start out on, his landlord told him he had a prefab building available lying in a nearby field. It was also something he could put up for him. And I’ll be honest, when we first saw how the flooring was laid, I felt it had to be someone’s first attempt or they were p*ssed when they did it!” laughs Fozard.

“I suppose ramshackle is the best way to describe it. But it was also home to the brewery during Sean’s greatest successes in terms of the beers he was producing, too.”

A few years after really “getting their feet under the table” Rooster’s would invest in their own canning line at the start of 2014. “Breweries such as Fourpure, Camden and Beavertown all installed theirs a few months earlier but outside of London we were really the first of our scale to do so. “The decision to do that in such a premises really stretched us. It was like working with a giant puzzle where you have to move one piece to make space for another. You’d often spend an hour moving stuff out of the brewery just to make space. It was manageable but it was painful.”

Rooster’s would soon reach a point where the team felt it was unable to capitalise on certain opportunities coming their way, and unable to concentrate on growing. So they set about looking at new premises for the business. In searching Harrogate for their new forever home, a lack of suitable industrial properties threatened to hinder this pursuit.

“Harrogate is a lovely area but not one built on industry of that kind,” says Tom.

However, one ideal spot did exist. Hornbeam Park, located several miles south of Harrogate Town centre, simply “screamed perfect location” but it was financially out of their reach. That was until the landlord informed the trio that its break clause had been activated and subsequently was available. Despite some hesitations from father Ian, with the premises been three times larger than their original site, a deal was struck and they had the keys at the start of 2019.

In the years since, not only has it become home for the brewery but also for its ever-popular taproom. This has been an integral part of the Rooster’s offering, seating up to 160 indoors and more than 100 outside. There’s also a private events space, too.

“Before we found this building, I drew up plans for three types of taprooms with option C being a temporary bar and us moving some malt pallets out of the way on a Friday night,” says Tom. “But instead we now have somewhere with quite a large proportion of the premises is dedicated to the taproom and we couldn’t be happier.

“The private events space has also been really important for us. I recall Rich (Burhouse) when he was still at Magic Rock explaining how he wished they had somewhere they could hire out. “Often they’d be approached by people wanting to spend a lot of money to have the space exclusively but he would always decline because he didn’t want to upset the regulars. It was never worth the risk.”

But for Tom, Oliver and the rest of the team at Rooster’s, that ability to entertain and delight is very much high on the agenda for 2024 and beyond. And a busy beer release schedule, and events to enjoy those at, is key to that. In addition to a raft of new beers, its popular Suds With Buds invitational beer festival returns in 2024, too.

“It’s something we wanted to do ever since we moved to this site. We’re really pleased with how it went last year and we’re looking forward to going again,” says Tom. “Being able to welcome people here, to see and hear people enjoying our beers and to have a good time while doing so is massively important to us. We always want that to be the case and really hope it will be.”

brewersjournal.info SPRING 2024 | 25 ROOSTER’S BREWING

SPECIALISE IN SMALL PACK

FOR MANY BREWERIES, AND THEIR CUSTOMERS, BOTTLES ARE THE VESSEL OF CHOICE WHEN IT COMES TO PACKAGING, SELLING AND SERVING BEER. BUT CANNING IS ALSO IMPOSSIBLE TO IGNORE. IT’S A GOOD THING THEN THAT BOTH OF THESE SECTORS AND THEIR ANCILLARY INDUSTRIES ARE BOTH RIFE WITH INNOVATION, TOO.

In recent years, there has been an undeniable rise in popularity of packaging beer into can. There are a number of factors behind this, of course, but for countless breweries beer in bottle is still the go-to option and for good reason.

Craig Wilson, is the managing director of Enterprise Tondelli UK. The company has been working in the beverage industry for more than 45 years and in that time they’ve seen many changes from returnable bottle washers in the late 70’s (now possibly coming back…) to PET bottles rising and now falling in popularity. Also, as he says canning rising, falling and now rising and rising.

“We are seeing a surge of interest in stouts and porters with widget in cans. Widget cans require very particular processing during the filling process and we our filling partner Matrix have recently completed a complete line for this,” he explains. “A conventional filler is not able to effectively handle the widget can which needs nitrogen flushing of the can instead of CO2 to purge the widget of oxygen at high pressure. “This is done with a particular sequence and recipe, then filling with nitrogen at lower pressure followed by Nitrogen injection. A traditional filling valve is also not well suited to the application so the electropneumatic filling valve with adjustable vent tube is ideal for this. These products are then tunnel pasteurised which is also seeing a resurgence in popularity due to the product stability it can provide.”

While canning’s rise continues, that is simply only part of the packaging equation. When it comes to premium

packaging, consumer safety and a low impact on the environment, glass is still the number one choice for breweries, argues Dawn Pugh, sales and marketing director at Beatson Clark, the only independently owned glass works in the UK.

The company has served the brewing sector for many years and the list of familiar brands using Beatson Clark bottles for their beers is growing, from craft brewers like Mount St Bernard and Hurns Brewing Company to bigger brands like BrewDog and Halewood. They offer a flexible approach and can supply standard beer bottles, customised bottles and completely bespoke designs. This means they can cater to a wide range of breweries, and their standard bottles are offered in lower production quantities, perfect for smaller breweries. Currently Beatson Clark is placing particular emphasis on amber beer bottles, which are ideal for breweries as they offer over 90% protection from UV rays which could harm the beer inside the bottle. The company currently has capacity in amber glass, which is visually appealing for the consumer and which has the added benefit of protecting the contents of the bottle from harmful ultraviolet light.

Amber bottles contain more recycled glass or cullet – over 60% recycled content – so they’re more environmentally friendly than white flint or clear bottles.

“Our standard amber beer bottles are very popular, and for a small extra cost we can customise these to reflect the brewery’s branding,” she tells us. “We offer embossing options on our standard bottles, perfect for ordering in smaller

volumes, as well as more tailored services including bespoke bottle design, labelling and crowns.”

Glass bottles can be manufactured in any number of shapes, sizes and designs, and they can achieve stunning decorative effects too, from embossing and debossing to textured surfaces, spray coatings, sleeving and screen printing. The option of embossing words, logos and patterns onto glass containers can elevate a brand and achieve better shelf presence. Recent advances in technology have revolutionised what the company’s in-house design team can now achieve with embossing, and using the latest sculpting software means that the results are better defined and easier to manufacture.

“Nine out of every ten bespoke designs we produce for our customers includes unique embossing – names, straplines, logos or patterns embossed on the glass to enhance its appeal and make the container truly unique,” said Dawn.

We are seeing a surge of interest in stouts and porters with

in

Craig Wilson, Enterprise Tondelli.

widget

cans,”

BREWERS JOURNAL 26 | SPRING 2024 SMALL PACK

Pharmaceutical bottle designs continue to be popular with food and beverage brands seeking to achieve a retro vintage look for their brand. For breweries looking for a cost-effective yet distinctive container, Beatson Clark recently launched a 330ml amber drinks bottle for general sale. Its design is based on an Alpha Sirop medicine bottle, it can be manufactured with a standard crown neck finish, and unlike the original pharmaceutical design it’s tested to 3.0 bar which makes it suitable for carbonated drinks.

“It’s a completely new design and can be supplied as a standard bottle from our general sale range,” said Dawn. “Or for a small initial outlay customers can add their own embossing to the bottle with a minimum order of just 150,000 units in either neck finish.”

With the craft beer revolution in the UK has come an increase in the use of aluminium cans for beer. However, Pugh says there are many good reasons why glass should still be the first choice for breweries.

“Not only are our amber bottles made with over 60% recycled content, but glass is the only primary packaging

material that doesn’t require a plastic layer between the product and the packaging,” she explains. “Many people are surprised to discover that most mainstream beverage containers –including aluminium cans – are lined with plastic which is in constant contact with your beer.

“Glass meanwhile is completely inert. This means it’s safe to be in contact with the beer inside the bottle as the glass will not contaminate the product inside.”

For Craig Wilson at Enterprise Tondelli, another trend they are seeing in the market place is the desire for greater flexibility in the secondary packaging area of the line. For many years the company and its partner Baumer have been supplying wraparound cartoners and shrink wrappers as well as a combined packer for trays with film and also able to handle corrugated wrapround cartons all on the same machine.

“However we find that now the market is looking for the smaller kraft board packs; as well as capability to handle larger

corrugated cartons too,” he says. “Baumer have therefore developed and Enterprise have supplied machines that can handle wraparound cartons for 24 and 12 cans in a wraparound carton with corrugated board.

“In addition we can now handle kraft board material to produce an FEC or fully enclosed fridge pack carton. This can be 4, 6;s, 8’s or 12’s too and means the marketing department or budding entrepreneur has almost no limits! Even in a limited space. Machines speeds start at 20 packs per minute and can be up to 65-70 packs per minute.”

Wilson concludes: “Of course once you have produced your 4 or 6 pack the issue becomes how to palletise and distribute. So Enterprise and Baumer can also supply a special 90 degree infeed tray erector loader that packs the 4 packs into a high sided tray. The system is modular so this can be added in a second stage thus reducing capital investment and allowing upgrades to be made as cash flow is generated.”

Tynt Meadow is mahogany-coloured, with a subtle, warm red hue, and a lasting beige head

Beatson Clark says there are many good reasons why glass should still be the first choice for breweries

brewersjournal.info SPRING 2024 | 27 SMALL PACK

BUYERS GUIDE BOTTLING

WHEN IT COMES TO BOTTLING LINES, THERE ARE OUTPUT OPTIONS FROM THE MODEST TO THE MIND-BLOWING. HERE ARE SOME OF THE BOTTLING LINES ON THE MARKET THAT CAN CATER FOR EVERY NEED.

The Galaxy Monobloc (right) from Costral is a standalone machine handling bottle rinsing (as well as sterilising), filling and capping: T-Corks, Vinoseal (all closures). This 3-in-1 machine combines everything you need to bottle your wines, juices, beers or spirits in one single frame. Described as a comprehensive, versatile bottling unit. According to the business, the major advantages of the rinser/steriliser are that it’s a rinser/steriliser with 24, 36 or 48 stations, it has entirely stainless-steel construction, rinsing time of up to 3 seconds, sterilising by injecting a chemical solution followed by rinsing with filtered water, very long draining time (up to 40 seconds), fast bottle format changeover, possibility of injecting a neutral gas for inerting prior to filling, a small footprint and low noise pollution.

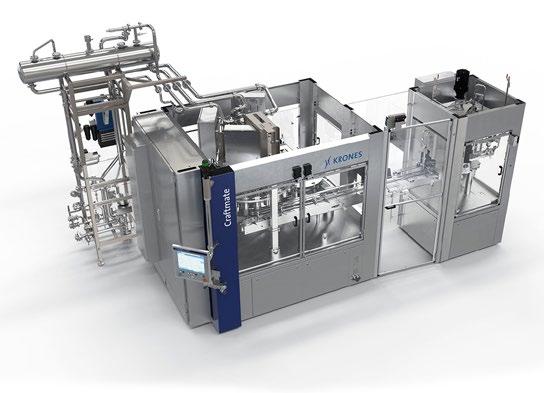

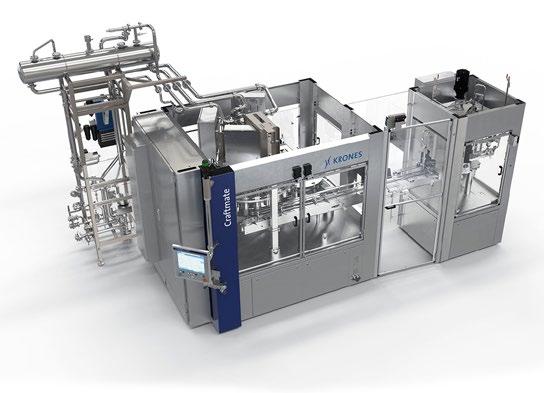

Whether for glass bottles, PET containers or cans, for filling, labelling or packing, for water, beer or soft drinks – Krones offers a customised system solution for every process step, every container type and every beverage category. The wide portfolio comprises all machines required for beverage production: From stretch blow moulders for PET containers and rinsers for glass bottles and cans, through to fillers suitable for every container type and labellers for all conventional labelling and decoration variants, as well as all dry-end systems. When it comes to glass, Krones says that it’s the container type of choice for alcoholic beverages. For water, soft drinks or juices, they often underline the premium character of the brand: glass bottles. Their material properties offer two significant advantages for their use in the beverage industry: Thanks to their good gas barrier, glass containers guarantee a high standard of hygiene and a long shelf life for the end product. And their optical appearance can also be a highlight: A range of different labelling methods, including the use of direct print allow for a myriad of design options, which draw the consumer’s eye to the product. The image shows an installation at Schlossbrauerei Maxlrain which features a new returnable-glass line from Krones rated at 20,000 bottles per hour.

BREWERS JOURNAL 28 | SPRING 2024 SMALL PACK

The Sraml Bottling Monoblock System (above), available through V-Brew, is a set of automated high quality machines combined in one unit to perform rinsing, filling and capping whether you are handling glass, plastic bottles or aluminium cans. The Monoblock System has many advantages over an invidual stand-alone machine. It is designed to perform different tasks during the bottling process while being part of the same block. It requires less space and personnel, optimises energy consumption and enables perfect synchronization between units The system features quick and easy bottle format changeover and high flexibility, even when working with different bottle shapes or closure types. The integral CIP system is fully automatic, which allows fast and thorough cleaning while complying with the highest food-safety standards. Remote access can be optionally included for easy remote control, troubleshooting, or updates.

Comac Group offers a range of beer bottling lines and machines scaled to fit to any production size. From compact machines to industrial-size plants, they have the right solution for any kind of brewery. If you are a small brewery or a microbrewery, you can add to your production line a compact machine for bottling and capping. Their machines require minimum space and yet they guarantee professional results, time savings and reduction of product waste. They are manufactured with high quality materials such as AISI 304 stainless steel, an alloy that prevents rust, corrosion and contamination, and lasts for years. Plus, their bottling machines are equipped with a system for the oxygen pick up, an important process in beer production as it guarantees the excellence of flavour over time. For smaller breweries, the Sagitta 12-12-1 P bottling machine offers production capacity up to 6,000 bottles per hour. For medium-size outfits there are the Sagitta 12-16-3 P (above) and the Sagitta 20-20-3 P lines, while for industrial breweries it offers the Master G Tech model designed to process from 3,000 up to 80,000 beer bottles per hour.

The ModulBlock (right) from Framax boasts rinsing, filling and closing technologies in one machine The virtually-unlimited combinations allows the possibility to deliver to our customers a solution that will cater specifically for their bottling needs, enabling to process various types of containers and closures under one roof.

Perfect synchronism is obtained from one single machine drive having gear transmission or as an option through the use of brushless servo drives controlled electronically by the machine’s PLC.

The ModulBlock is available to suit the packaging of a wide range of products such as mineral water, carbonated soft drinks, wine, beer, edible oils, mixed alcoholic beverages, liqueurs, fruit juices, sauces etc, into traditional or modern packaging such as bottles made of Glass, Aluminium, and PET, among others.

brewersjournal.info SPRING 2024 | 29 SMALL PACK

TO CAN OR NOT TO CAN?

THERE ARE MANY FACTORS TO CONSIDER WHEN IT COMES TO THE QUESTION OF CANNING YOUR BEER. HERE, GIGI LORENCE, GLOBAL MARKETING DIRECTOR FOR PSA, EXPLAINS ALL.

If anyone had told us in the Fall of 2019 what the early Spring of 2020 would bring, we probably would have thought it had the makings of a blockbuster Science Fiction film. But for craft brewers with a lot of beer on hand and no way to get it to a quarantined public, those challenges were all too real. For many brewers, this meant considering a new business model that included bringing canning in-house. For others, it accelerated what was already a goal for their growing business.

Stepping back for a moment, what’s the real motivation behind taking charge of your own canning operation?

Fundamentally, if you’re considering heading down that path, you’re looking to preserve quality and taste, to maximize your product stability and extend its shelf life, and ultimately, to protect your most valuable asset: Your Brand.

All of this means you need a filling machine that enables you to customize your production parameters to suit your unique product. You want to be assured of your ability to achieve consistent fill volumes, limit dissolved oxygen levels, and maintain desired carbonation levels while minimizing product loss and maximizing throughput. You need a hygienic system to eliminate the risk of product contamination and, above all, you don’t want to compromise when it comes to delivering fresh, great-tasting beer to your customers.

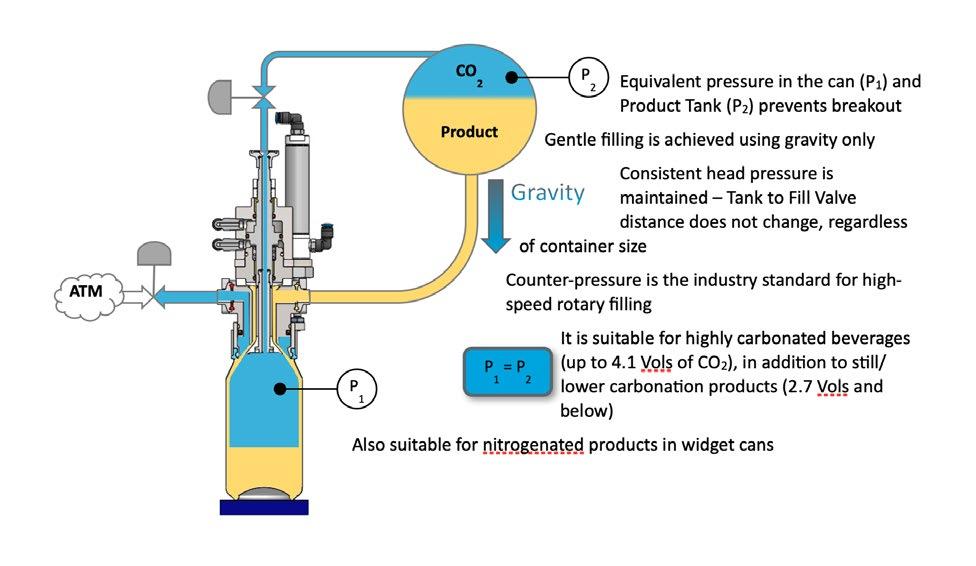

COUNTER PRESSURE FILLING

There are two primary filling technologies to consider –Atmospheric (i.e., Open Air) and Counter-Pressure (i.e., Isobarometric, in its purest sense) – but how do you know which one is right for you? The first step is to find a supplier with experience who is willing to spend the time to understand your needs for today AND tomorrow. Not just where you are now with your packaging experience, but where you want your business to grow for the future. One place to start is with this quick primer on these technologies. Table 1 gives a useful side-by-side comparison. One critical element to consider is the temperature/pressure relationship, as carbonation levels are a direct result of this relationship. To maintain a given carbonation level, pressure must be met or exceeded through the entire packaging process. Higher pressures allow for higher temperatures, which means you can enjoy great flexibility in your product mix with a counter-pressure system.

HOW DOES IT WORK?

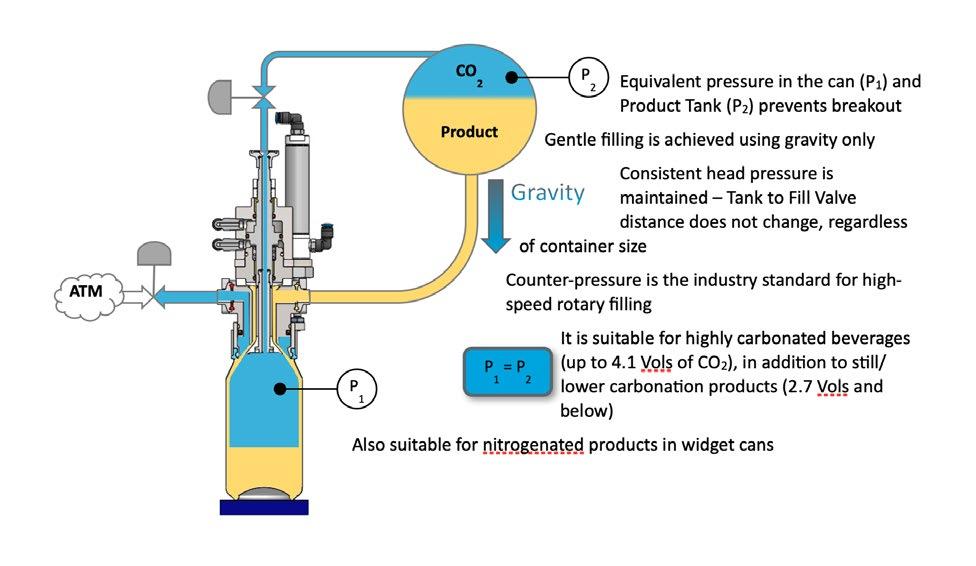

All counter-pressure systems are not created equal. Isobarometric counter-pressure technology requires

ATMOSPHERIC FILLING AND COUNTER-PRESSURE FILLING

Atmospheric (Open Air) Filling

Product flows from a filler manifold into an open can

System is simple to operate and maintain

Foam is created as a natural part of the filling process; undercover gassing limits DO pickup

Production variables, (batch temperature, pressure, etc.) can be challenging to maintain

Technology is well-suited to low speed, linear production, but can be impacted by environmental variables such as temperature

Offers a cost-effective solution for lower carbonation products, but imposes limitations related to carbonation level, temperature, and pressure

Counter-Pressure (Isobarometric) Filling

Product flows from a pressurized tank into a pressurized can

System requires a slightly higher investment in filling technology and packaging savvy

The closed system design minimizes CO2 loss and DO pickup