MICHAEL D. GILCHRIST BSc (Hons), MArch, ARB,

Architect Selected works 2018-2024

Architecture portfolio

MICHAEL D. GILCHRIST BSc (Hons), MArch, ARB,

Architect Selected works 2018-2024

Architecture portfolio

I am a dedicated architect with over three years of postPart 3 experience and more than eight years of professional practice across five architectural firms. I hold both a Master’s and an Honours degree from the University of Strathclyde. As a native English speaker with a passion for languages, I speak Japanese and I am currently studying Spanish with the aim of sitting my first DELE exam.

Architect - Rivington Street Studio, London, UK

• Project architect for a £6m children’s centre and a £650k cricket pavilion.

• Implemented significant changes to Stage 4 packages.

• Led two projects through to completion.

• Performed all contract administration duties as required.

• Produced all BREEAM submissions to achieve a ‘very good’ rating.

Architect - Kerr AT Architects, Inverness, UK

• Project architect for two housing extensions now completed.

• Produced site reports, issued interim certificates and tender packages.

DOB: 17/02/1982

Email : mdg237@gmail.com

Tel: 07703696230

In 2009, I moved to Japan to work as an English teacher, seizing the opportunity to immerse myself in a new language and culture. Upon my return to the UK in 2018, I joined NORR, where I became an integral part of the design team for the £35m Grade B restoration project at Brora Distillery. Primarily working during RIBA Stages 4 and 5, my responsibilities included producing all production drawings, which required an in-depth understanding of both contemporary and traditional construction methods.

In 2020, I joined Kerr AT Architects, a sole practitioner firm, where I completed my Part 3 in 2021. As the project architect for two residential projects, I was also deeply involved in several other residential projects, participating in all stages of the design process alongside the director.

Seeking to expand my professional network and undertake greater career challenges, I relocated to London in 2022. During this period, I served as the project architect for a £6m refurbishment and extension project at the Grade II listed Woodberry Down Children’s Centre, as well as a £650k refurbishment project at Harrow Cricket Pavilion.

In preparation for my Part 3 exam, I was a member of the winning team in the 2020 Part 3 Contract Game, an annual competition among three universities and twenty teams.

I am deeply passionate about architecture and I am driven to create generous, adaptable, and authentic designs.

Outside of my professional life, I am an avid guitarist. I enjoy painting, sketching, and exploring new cities and places. I am also committed to studying Spanish daily.

• Collaborated on a range of housing projects through all work stages.

Part II Architectural Assistant - Kerr AT Architects, Inverness, UK

• Managed planning applications and building warrants for housing projects as well as all further correspondence with building standards.

• Created BIM models and mentored others in the office on software issues.

Part II Architectural Assistant - NORR Consultants Ltd, Inverness, UK

• Produced all 330+ pages of production drawings for the £35m restoration of Brora Whisky Distillery.

• Issued construction drawings and revised packages.

• Implemented a Project Execution Plan to improve performance.

• Liaised with the lead engineer and contractor on an almost daily basis.

English University Tutor + Teacher - NUFS, Interac, Cosmo, ALC, Nagoya, Japan

• Led intensive CPD training seminars for senior management executives.

• Delivered interactive lectures and lessons to university students.

• Designed and implemented course structures.

Part II Architectural Assistant - Duco Architects Ltd, Glasgow, UK

• Submitted planning and building warrant packages for commercial projects.

• Produced SketchUp models and renderings for presentations.

Part II Architectural Assistant - CMCC Architects, Glasgow, UK

• Submitted planning and building warrant applications for commercial and residential projects.

• Provided technical details and 3D renderings for a water treatment plant.

RIBA APEAS Part 3 Examination in Professional Practice and Management

MArch Advanced Architectural Studies

University of Strathclyde, Glasgow, UK

BSc (Hons) Architectural Studies

University of Strathclyde, Glasgow, UK

Software skills

Proficient in: AutoCad, Revit, Vectorworks, SketchUp, Enscape, VRay, Photoshop, Illustrator, InDesign, Procreate, Morpholio and competent in sketching and hand drawing

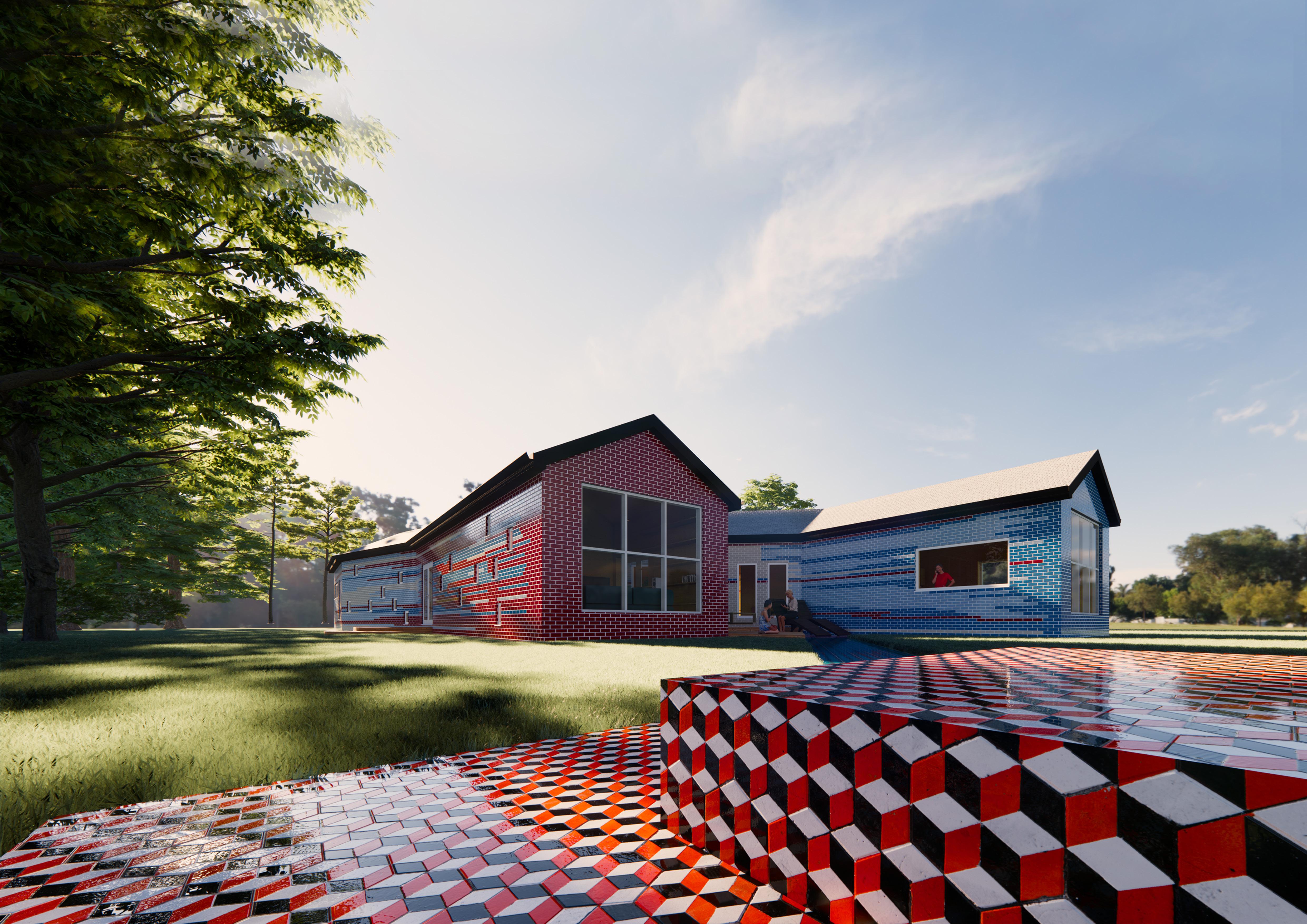

Location London, UK : Budget £6million : Type Education : Current Stage Completed in 2024: Involvement Stage 4 Technical Design + Stage 5 Construction : Software AutoCad, Photoshop, Illustrator : Project Architect Michael Gilchrist

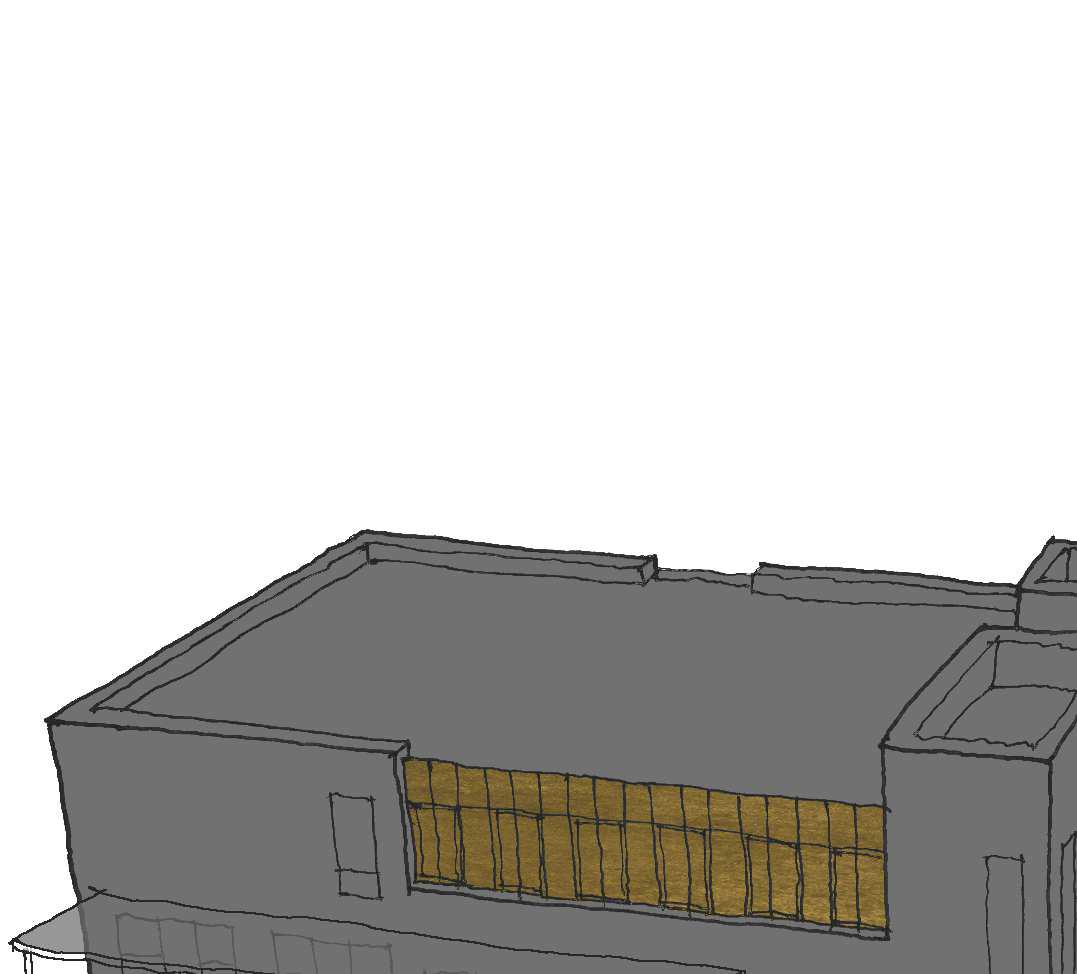

The aim of this project was to consolidate existing children’s centre services into a single building and address crucial renovation needs for the Grade II listed nursery, originally built in 1952. We reorganized the children’s centre services into distinct zones to maximize future flexibility. Our design solution respects the historic context while integrating with the new Woodberry Down master-plan.

Two extensions were added to the east and west of the existing building. One was constructed using timber frame, while the other utilized shear walls and SFS framing. These extensions function as independent structures flanking the existing building. Constructed separately, they allowed various parts of the current centre to remain operational during different phases. They were designed to enhance a courtyard space, which will be enclosed on three sides to provide a safe, high-quality external play area.

During construction of the extensions, it was discovered that the existing structure did not have a concrete soffit as initially assumed, but instead consisted of a concrete beam and block system. These beams had been notched by existing services, compromising their load-bearing capacity. After structural analysis, it was determined that the roof could no longer support any additional weight. Consequently, a completely new strategy for fixing services had to be devised.

• Revising the entire set of drawing packages to correct inconsistencies and errors in the details.

• Conducting regular site visits to monitor progress, ensure quality, and verify compliance with the design intent and specifications.

• Reviewing shop drawings, material standards, and mock-ups submitted by the contractor.

• Resolving on-site issues and addressing contractor queries promptly.

• Redesigning the service routes for the west wing and existing building, detailing their implementation and housing.

• Serving as the primary point of contact for the client, contractors, and consultants.

• Chairing site meetings and preparing minutes to document discussions and decisions.

• Coordinating with the design team to address design clarifications and modifications during construction.

• Administering the construction contract, handling claims and disputes, and ensuring fair and equitable resolutions.

• Ensuring the project achieved a ‘Very Good’ BREEAM rating.

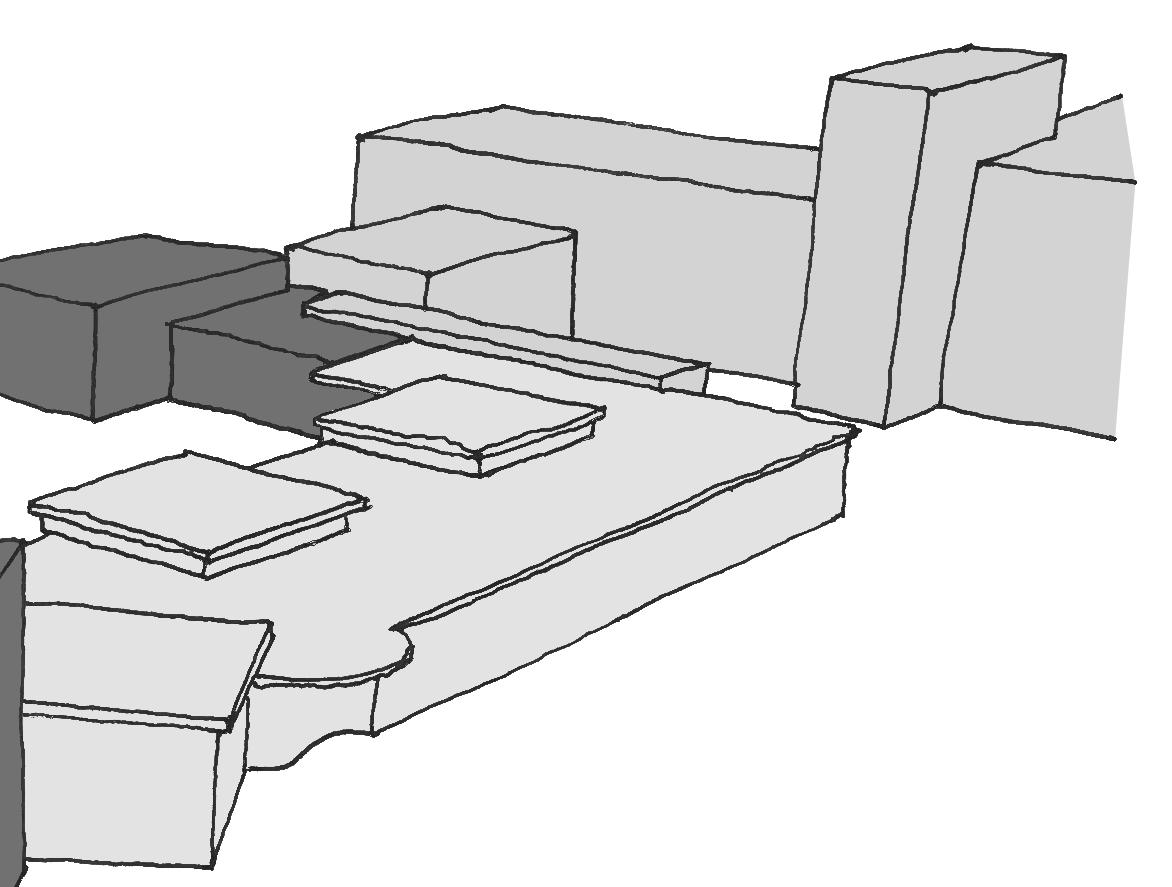

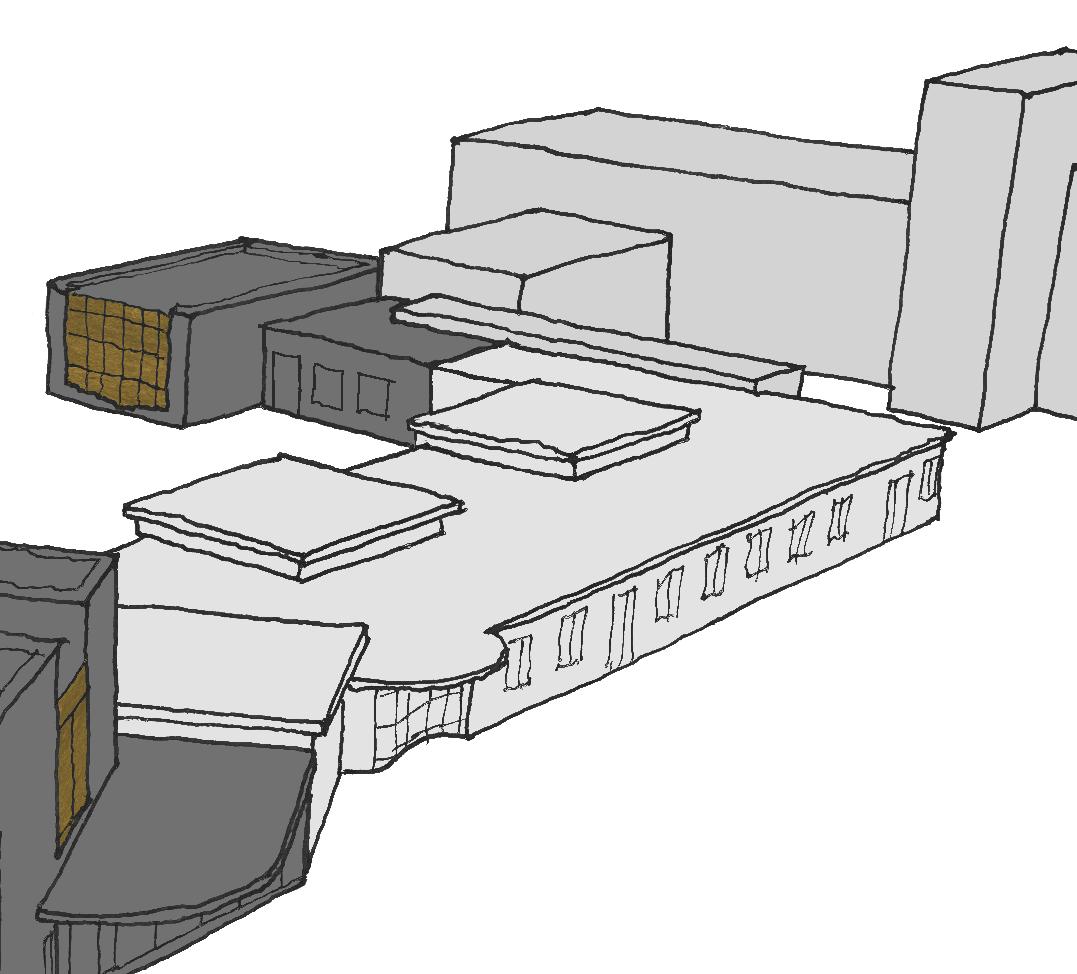

01: Existing massing

Existing nursery is a single storey annex of the health centre with dominant clerestory pop-ups over the principle spaces

02: proposed extensions

The two extensions intend to bookend the existing grounds by creating a private courtyard. the proposed masses pop-up to reinforce the architectural language of the existing complex

03: final composition

significant original entrance with reinstated curved glazing and adjacent external lettering remains central to the proposal

1 Ground floor Vinyl on 75mm screed with ufh on 75mm insulation on dpm on

2 First floor Vinyl on 75mm screed with ufh on 50mm insulation on 500 gauge slip membrane on concrete slab either exposed or with

3 Roof Single ply roofing on tapered kingspan insulation on vlc on

5 parapet coping on dpc on 12mm plywood capping on cavity closer

6 External wall Type 1 facing brick on cavity on wall ties on 50mm rockwool duo slab on breather membrane on 12.5mm sheathing board on

150mm rockwool flexi with 150mm sfs framing on vapour control layer on 12mm plywood on 12.5mm plasterboard.

7 External wall type 2 metal rainscreen cladding on secondary support framework on 50mm rockwool duo slab on breather membrane on 12.5mm sheathing board on

150mm rockwool flexi with 150mm sfs framing on vapour control layer on 12mm plywood on 12.5mm plasterboard.

8 acoustic panels & led lights

9 external canopy

1 mf system fixed to partition and ladder framing

2 steel beams For partitions to fix back to cannot fix to ceiling

3 timber joists between existing beam and block roof and fixed into existing steel beams

4 gas pipe services hidden behind acoustic panels and packed out wall

5 radiator encasement gooding aluminium 2mm perforated panels with ver t fix fixings on 50x50mm sw framing on 2 x 22mm copper tubes mounted in aluminium fins on 25mm spacing with 50mm spacing to front and 25mm spacing to back

6 planter refurbished

7 new awnings to replace existing

8 parapet existing redesigned in timber upstands with pressed aluminium coping with new rainwater outlet connecting to existing rwps.

9 refurbished entrance screen

10 proposed services could not be fixed to soffit steel beams fix to existing walls 18mm mdf access panels with 50x75mm sw framing hung from ub with 25mm shadow gaps services fixed to unistrut spanning onto the ub and fixed to the existing wall.

1 roof type 1 single ply roofing on tapered kingspan insulation on vcl on 2x12mm plywood on i joists on 12.5mm plasterboard

2 roof type 2 single ply roofing on tapered kingspan insulation on vcl on 2x12mm plywood on i joists on 12.5mm plasterboard with suspended ceiling

3 external wall type 1 facing brick on cavity on wall ties on 50mm rockwool duo slab on breather membrane on 12.5mm sheathing board on 150mm rockwool flexi with 150mm timber stud with 12mm ply

to either side on vapour control layer on 12.5mm plasterboard.

4 External wall type 2 metal rainscreen cladding on secondary support framework on 50mm rockwool duo slab on breather membrane on 12.5mm sheathing board on 150mm rockwool flexi with 150mm timber stud with 12mm ply to either side on vapour control layer on 12.5mm plasterboard.

5 fixed rooflight

damper

Location London, UK : Budget £6million : Type Education : Current Stage Completed in 2023: Involvement Stage 4 Technical Design + Stage 5 Construction : Software AutoCad, Photoshop, Illustrator : Project Architect Michael Gilchrist

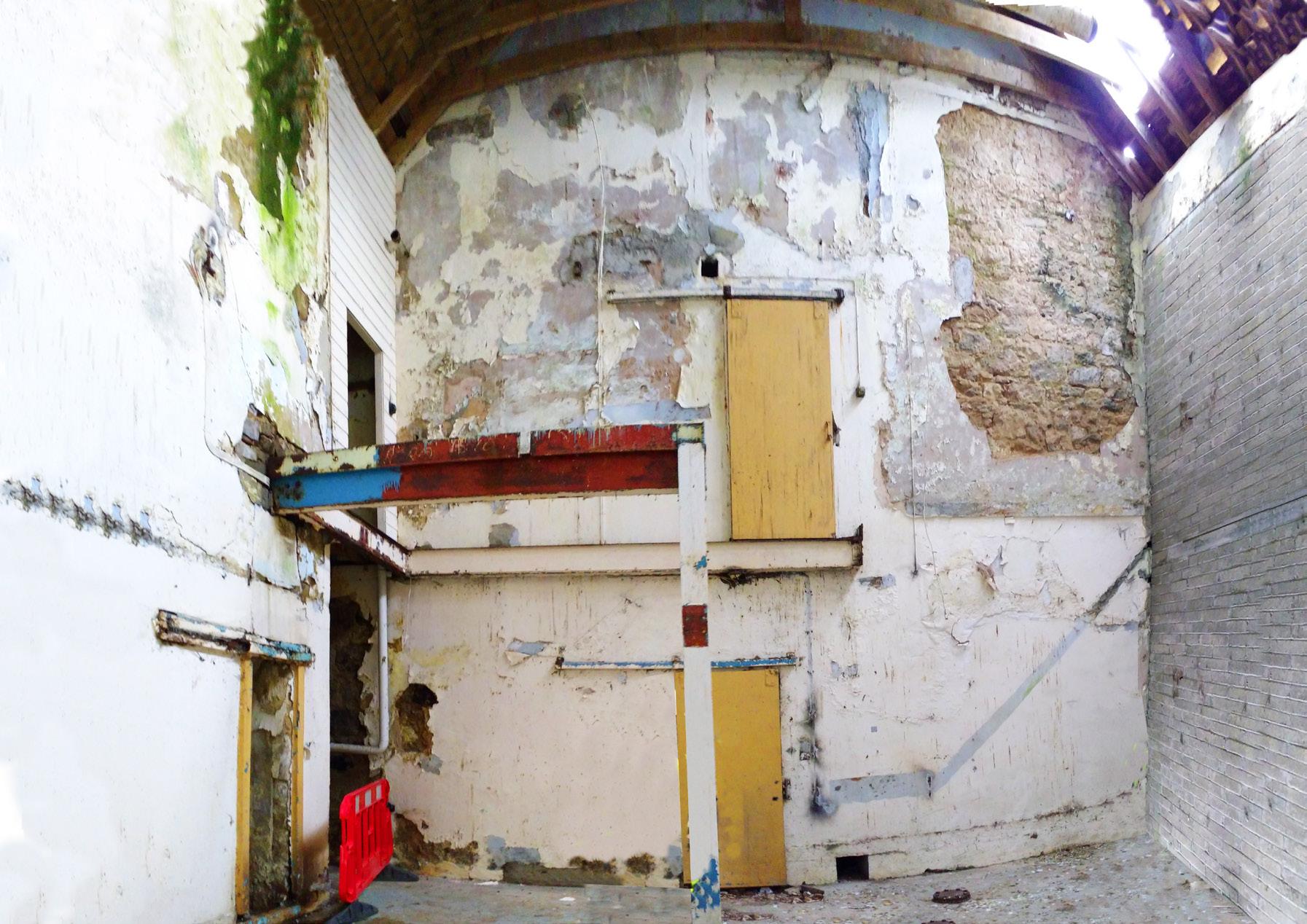

Harrow School entrusted us with the restoration of a historic cricket pavilion dating back to 1853, nestled within a conservation area. The school, renowned for its association with Sir Winston Churchill during his student years, envisioned transforming the pavilion into a clubhouse complete with changing room facilities.

The restoration project encompassed extensive tasks, beginning with the installation of entirely new mechanical and electrical (M&E) services. To enhance functionality, a new timber frame extension was seamlessly integrated at the rear to house modern bathroom facilities.

Significant efforts were focused on restoring the roof and cupola to their original splendour. Inside, the renovation included laying new insulated floorboards, installing timber linings, flooring, and erecting new partitions. Existing steel trusses were carefully refurbished to maintain historical integrity.

Externally, enhancements featured new stairs and handrails at the main entrance, alongside the installation of fresh doors and windows. Extensive repairs and a sympathetic refacing of the existing brick elevations ensured harmonious integration with the pavilion’s original architecture.

• Revising technical Stage 4 details to ensure accuracy and completeness. Conducting regular site visits, resolving on-site issues, and addressing contractor queries.

• Chairing site meetings and preparing minutes to document discussions and decisions.

• Serving as the primary point of contact for the client, contractor, and consultants.

• Leading the project team and coordinating the efforts of engineers and consultants.

• Administering the contractor and issuing necessary certificates. Evaluating and addressing extension of time claims and disputes as they arose.

• Managing the handover process to ensure a smooth transition..

1 Existing roof roof tiling

2. redecorate existing steel trusses

3. New external wall type to existing

4. suspended lighting

5. existing floor new floorboards to existing joists with mineral wool insulation between

6. Access to undercroft retained refurbished and redecorated

7. new stone steps and handrails

8. resin bound gravel pathway with kerb edging

9. extension roof

Single ply membrane on pir insulation on a 1:9 fall on breather membrane on plywood deck on timber joists with insulation between joists with plasterboard ceiling

10. extension floor

Vinyl on 75mm screed on 60mm rigid insulation on dpm on concrete slab and strip footings on polythene sheet

11. extension external walls

25mm vertical timber cladding on 38x50mm sw timber framing on breather membrane on Rigid insulation on 12mm osb on timber structure with rigid insulation on vcl on 2 x 12.5mm plasterboard

1 Roof

Single ply membrane on pir insulation on a 1:9 fall on breather membrane on plywood deck on timber joists with insulation between joists with plasterboard ceiling

2. Parapet

PPC aluminium coping on timber upstand with waterproofing membranes over upstand

300mm wide gutter with hot air weld with min. 40mm overlaps. edge restraint mechanically fixed at 200mm centres

3. Drainage

Parapet rainwater outlet and hopper connected to rwp rebated into cladding

4. Wall build up

25mm vertical timber cladding on 38x50mm sw timber framing on breather membrane on Rigid insulation on 12mm osb on timber structure with rigid insulation on vcl on 2 x 12.5mm plasterboard

Management Contracting Restoration

Distillery + Hospitality

Location UK, Highlands : Budget £35million : Type Distillery : Current Stage Completed in 2021: Involvement Stage 4 Technical Design + Stage 5 Construction : Software AutoCad, Photoshop, Illustrator : Project Architect Mark Fresson

Description

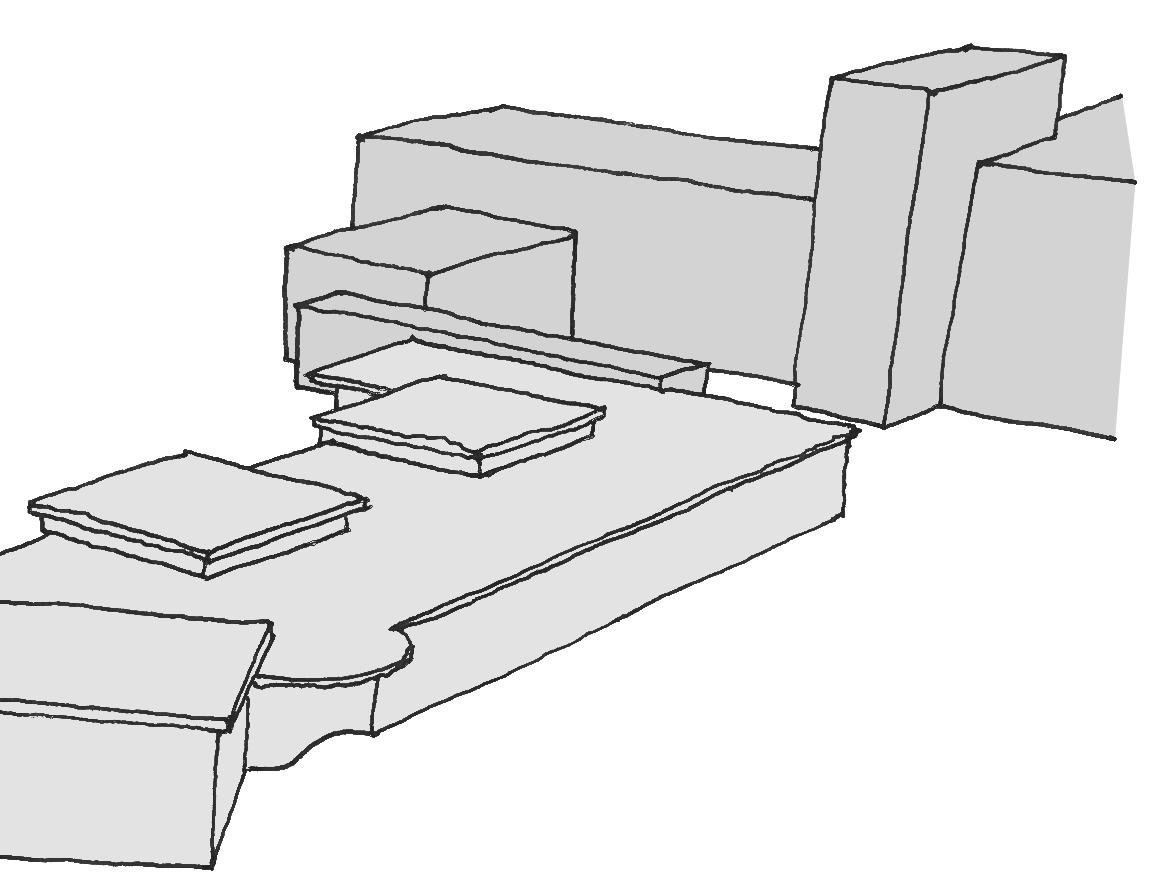

Brora Distillery, a Category B listed building dating back to 1820 and 1896, had been closed since 1983 and was considered one of Scotland’s few ‘ghost’ whisky distilleries until its reopening in 2021. The project utilized a management contracting procurement method, where the management contractor was permitted to bid on tenders. An engineering company served as the Contract Administrator, with the architects acting as sub-consultants.

The design aimed to balance the requirements of a modern distillery with the preservation and enhancement of the original distillery’s character and fabric. This involved a comprehensive and detailed renovation of each space, necessitating close collaboration within the design team to address the project’s challenges effectively.

The Still House was completely reconstructed using salvaged stone, and new additions included a Tun Room, Plant Room, luxurious Visitor Centre, and VIP Blacksmith Suite. The distillery is designed to achieve a maximum production capacity of 800,000 litres per year.

• Independently produced over 330 pages of architectural production drawings.

• Designed and coordinated the rooflights, cupolas, porch, and towers, ensuring their precise placement.

• Created detailed designs for the entrance stair, stairwell, and stillhouse stairs.

• Developed a comprehensive Project Execution Plan, including client requirements, final project brief, change control, project roles table, DRM, and project & design programmes.

• Maintained daily communication with the lead engineer to ensure project alignment.

• Actively participated in both on-site and online design team meetings.

• Made necessary revisions to drawings as the project progressed.

• Frequently corresponded with on-site contractors and participated in inspections.

• Organized project folders, Xrefs, superseded drawings, and schedules to maintain project documentation.

Demolished + restored

Demolished + removed

malt barn - No longer required

malt handling - no longer required

kiln - No longer required

malt storage - no longer required

milling - restored

grist - demolished + Relocated

mash house - Relocated

tun room - demolished + rebuilt

still house - demolished + rebuilt

storage - Demolished + Restored

boiler house - demolished > new

demolished

New dormers, porch & towers

1 roof

39 degree pitch

Salvaged slate on 60x145mm c24 rafters @600mm crs on 295mm deep flitch beams as purlins spanning timber room trusses @1.5m crs on

2 no 225mm deep 100mm wide timber king trusses

2 removable roof

Sinusoidal ks100 srw insulated roof panel (40mm core) on Galvanised steel top-hats on Proctor roofshield on 10mm sarking on 295mm deep flitch beams as demountable timber purlins on 2 no 225mm deep 100mm wide timber frame on timber king trusses

3 Wall type 1

Accord 14/3 sinusoidal corrugated galvanised steel cladding finished in plastisol anthracite grey ral 7016 0.7mm gauge on Cladding rails on Steel frame on 140mm blockwork on 20mm smooth internal cement render

4 wall type 2

150mm stonework on 140mm blockwork on 140mm cavity on 140mm blockwork on 20mm : 2 coats smooth internal Cement render with visqueen zedex cpt high performance dpc 150mm above ffl

5 stills - wash and spirit

6 mezzanine floor

Diamond Pattern Durbar Plate Flooring with Paint Finish Fixed to 25mm Steelway Square Mesh

7 cupula

38 degree to match existing Salvaged slates on Proctor roofshield on 22mm timber sarking on 150mm timber rafters with Aluminium fascia on plywood

8 worm tubs

1 roof

Accord 14/3 sinusoidal corrugated

galvanised steel cladding finished in plastisol anthracite grey ral

7016 0.7mm gauge on

Galvanised steel top-hat rails with 10mm space between sarking on Proctor roofshield roof membrane on 22mm timber sarking on 47x175 c24 timber rafters @600crs on 175mm deep flitch beams as purlins spanning timber room trusses @2.5m crs on

2 no 225mm deep 100mm wide timber king trusses

2 Wall

Accord 14/3 sinusoidal corrugated galvanised steel cladding finished in plastisol anthracite grey ral 7016 0.7mm gauge on Cladding rails on Steel frame on 140mm blockwork on 20mm smooth internal cement render

3 washbacks New timber washbacks

4 mezzanine floor

Diamond Pattern Durbar Plate Flooring with Paint Finish Fixed to 25mm Steelway Square Mesh

5 cupula

Accord 14/3 sinusoidal corrugated galvanised steel cladding finished in plastisol anthracite grey ral 7016 0.7mm gauge on Galvanised steel top-hat rails with 10mm space between sarking on Proctor roofshield roof membrane on 22mm timber sarking on 150mm timber rafters with Aluminium fascia on plywood with mackenzie martin louvres aluminium finish with bird and insect mesh to inner face

1 Handrail

42.4mm Tubular handrail and midrail with 15mm mild steel rods with tubular sticks on 60x15x200mm baseplates

1100mm @ landing

1000mm @ stair

2 Treads, Risers + landings

Diamond pattern durbar plate with gloss paint finish profiled to form nosing fixed to 25mm steelway square mesh treads

Risers to be exposed 25mm steelway diamond mesh

Support steelwork + stringers, durbar plate to landings and treads, balustrades, handrails finished in black gloss paint

3 floor finish

riven slate dovedale grey with mattstone sealer with larson mid grey flexible grout bedded on 5mm larson grey flexible tile adhesive on 85mm floor screed on floor slab on treadguard on visqueen high performance dpm in Conjunction with visqueen double and single sided joining tape minimum 150mm lap on blinding sand on hardcore

7

1

44.5

Accord 14 / 3 Sinusoidal Corrugated Galvanised Steel Cladding Finished in Plastisol Black RAL 9005 0.7mm Gauge on Timber Battens on Timber Counter battens on Proctor Roofshield on 22mm Timber Sarking on 200mm Timber Rafters on 200mm Kingspan Kooltherm K107 Between Rafters on 32.5mm Insulated Plasterboard U-value 0.11W/m2k

2 WALL

Board and Batten : 22mm Timber Batten on 147mm x 22mm on Thick Vertical Treated Timber Boarding on 50mm Counter Battens on 50mm Vertical Battens on Breather Membrane on 9mm OSB on 150mm Timber Framing with 150mm Kingspan Kooltherm K112 Between Framing on 9mm OSB on Vapour Barrier on 38mm Service Area / Timber Framing on 12.5mm Plasterboard U-value 0.19W/m2k

3 TIMBER GLAZED SCREENS SHS 150X150X16 WITH 50MM RIGID INSULATION BETWEEN VERTICAL COUNTER BATTENS AT SHS

4 RHS 200X100X10

5 CEILING

32.5mm Insulated Plasterboard on 150mm Kingspan Kooltherm K107 Between Ceiling Joists

6 FLOOR

150mm Concrete Slab ON 120mm Kingspan GreenGuard GG300 Below the Slab Visqueen High Performance DPM Min 150mm Lap on 50mm Blinding Sand on Hardcore U-value 0.18W/m2k

ABOVE Existing Cupulas removed

OPPOSITE New timber Cupulas lined with aluminium and infilled with metal louvres

1 roof

38 degree pitch

Salvaged slates with Zinc ridge cap on Proctor roofshield on 22mm timber sarking on 150mm timber rafters

2 louvres mackenzie martin louvres ral 7016 powder painted with Bird and insect mesh to inner face

3 aluminium lining on plywood

4 lead flashing code 5

5 Structure

60x145mm c24 rafters @600mm crs on 295mm deep flitch beams as purlins spanning timber room trusses @1.5m crs on

2 no 225mm deep 100mm wide timber king trusses

1 roof

42 degree pitch Salvaged slates on proctor roofshield on 22mm timber sarking on 150mm timber rafters

2 walls board and batten on 20mm horizontal + vertical battens on 9mm osb board sheathing on 100mm timber framing

3 Code 5 lead dressed up behind cladding, minimum 150mm upstand roofshield dressed up behind and over top

4 cast iron gutter

5 structure

1 roof

40 degree pitch salvaged slates on proctor roofshield on 22mm timber sarking on 50x150mm timber rafters

2 timber rafters nom 50mm x 150mm

3 Timber ties nom 50mm x 150mm

4 timber edge beam 75 x 200mm

5 beaded timber lining on plywood arranged in a square pattern emanating from centre point fixed to soffit

6 timber braces socket jointed into the centre of column and bolted to edge beam

7 timber edge beam 75 x 200mm bolted into wall on dpc on stone wall

8 lead valley between two roofs

9 200mm timber column

10 steel flitch plate. fixings fully recessed and pelleted with timber plugs

ABOVE Existing Malt Handling no longer required

OPPOSITE New Entrance Stair

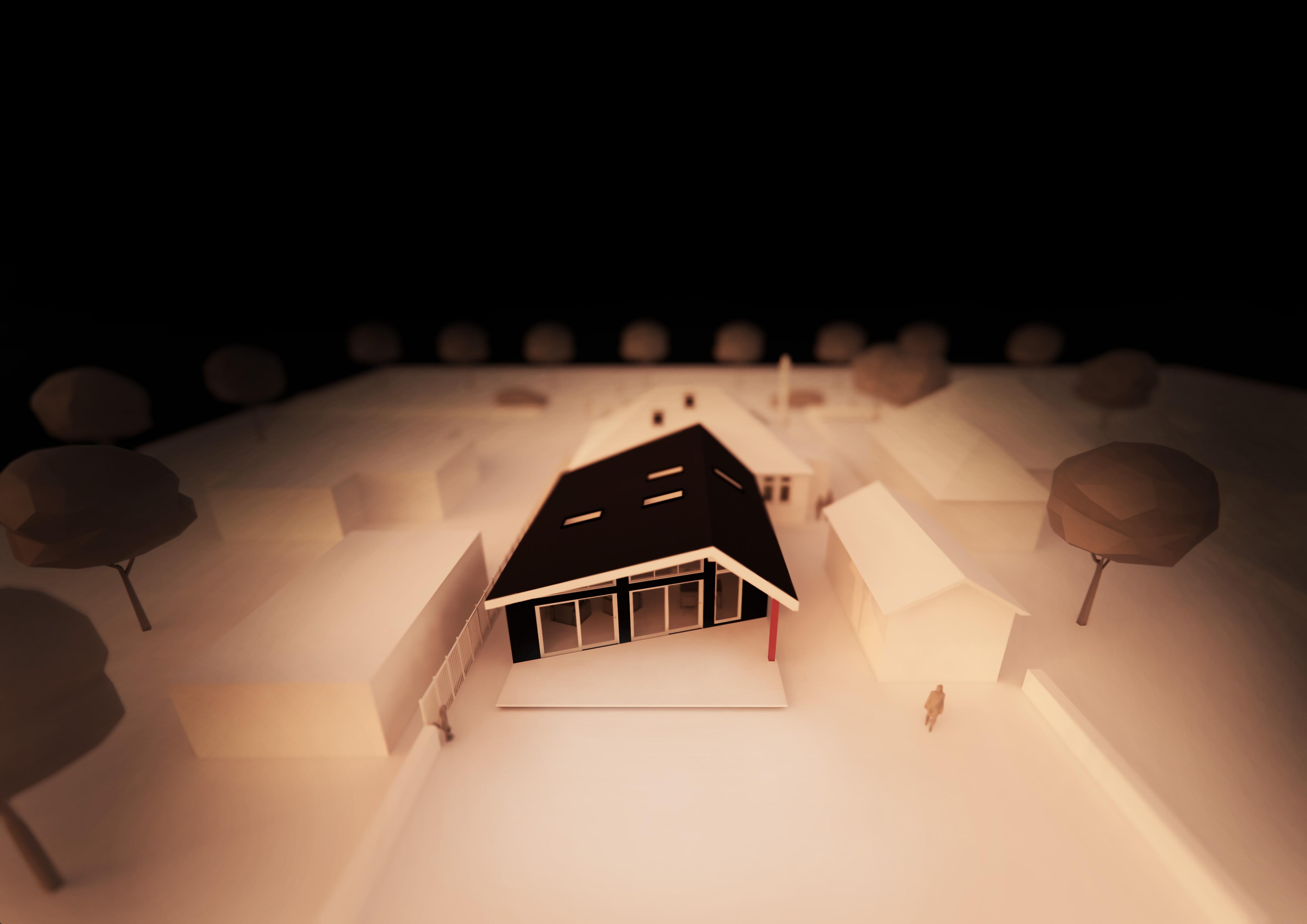

Location Japan, Shikoku : Budget Low cost : Type Housing : Current Stage Developed Design: Involvement Stage 0 Strategic Definition - Stage 3 Developed Design : Software Revit, Enscape, Illustrator, Procreate, Morpholio : Project Architect Michael Gilchrist

Description

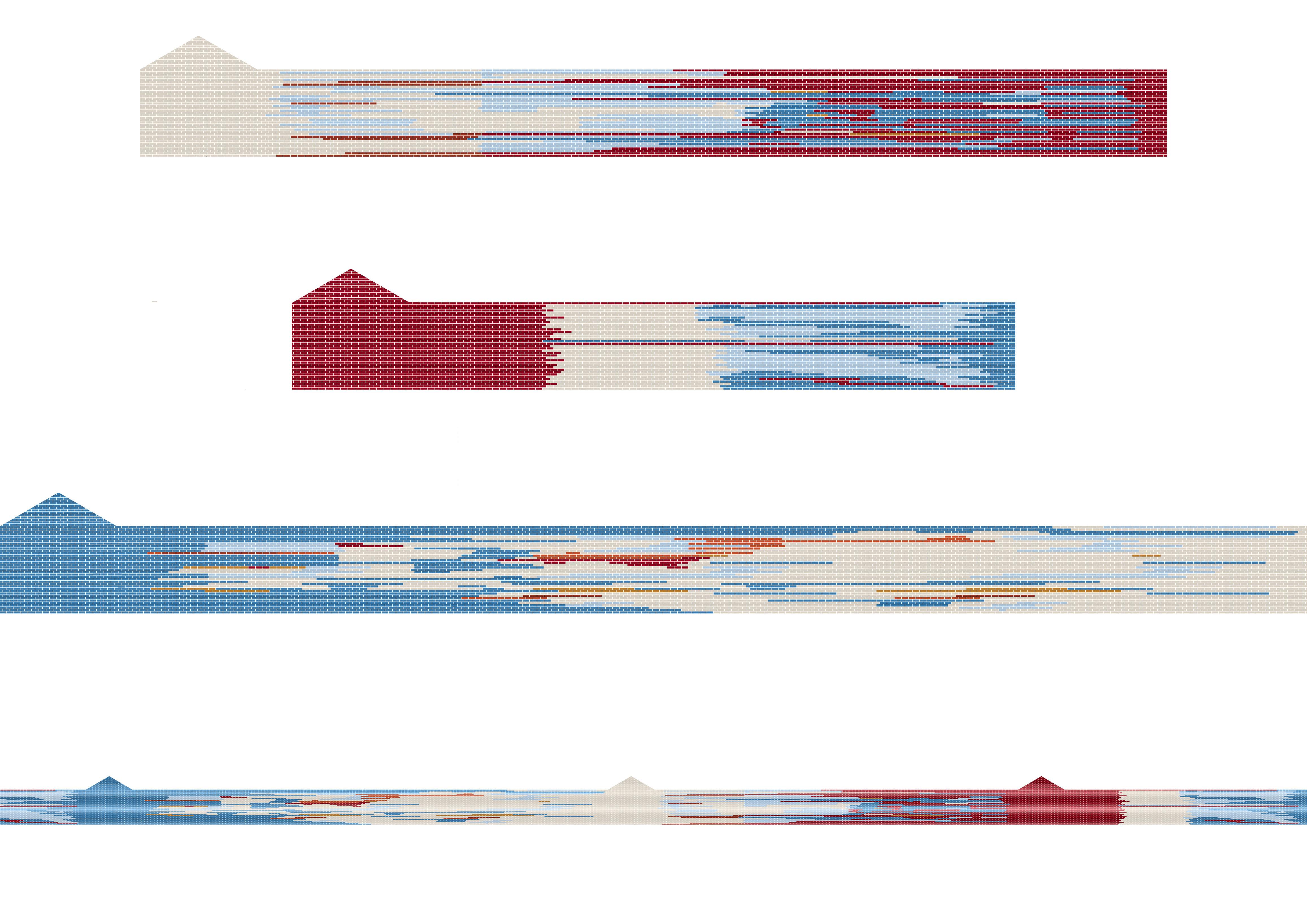

During my nine years in Japan, I had the opportunity to travel extensively, exploring various cities and rural areas. On a visit to the island of Shikoku, I encountered disused railway lines and carriages, which piqued my longstanding interest in abandoned infrastructure and architecture. This discovery inspired us to follow the tracks and delve deeper into the area’s history.

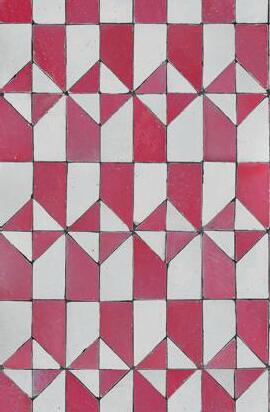

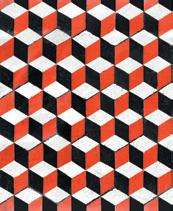

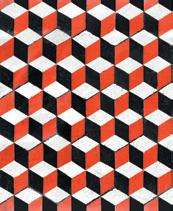

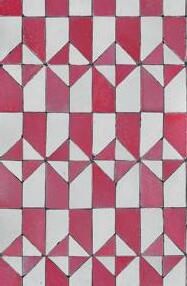

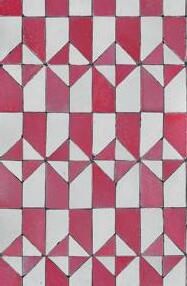

Branch House is a conceptual project inspired by this site. The design emphasizes movement, reflected in both the branch-like form and the dynamic glazed brick cladding, contrasted with the static plywood interiors and sweeping walls and ceilings. Informal meeting areas, distinguished by different ceramic designs, are strategically placed around the building.

The structure consists of three interconnected carriages in white, red, and blue, merging seamlessly to evoke the blur of a speeding train.

This project also provided an opportunity to explore Revit and Enscape, enhancing my skills in these tools.

Responsibilities

• Conducted comprehensive site investigations and managed all aspects of graphics, design, and concept development.

• Advanced my Revit skills to an intermediate level through self-study, tutorials, and classes taken during downtime.

• Created all necessary families for the project from scratch.

• Produced high-quality renderings using Enscape.

• Composed all diagrams and drawings exclusively in Revit.

Disused tracks

Architects

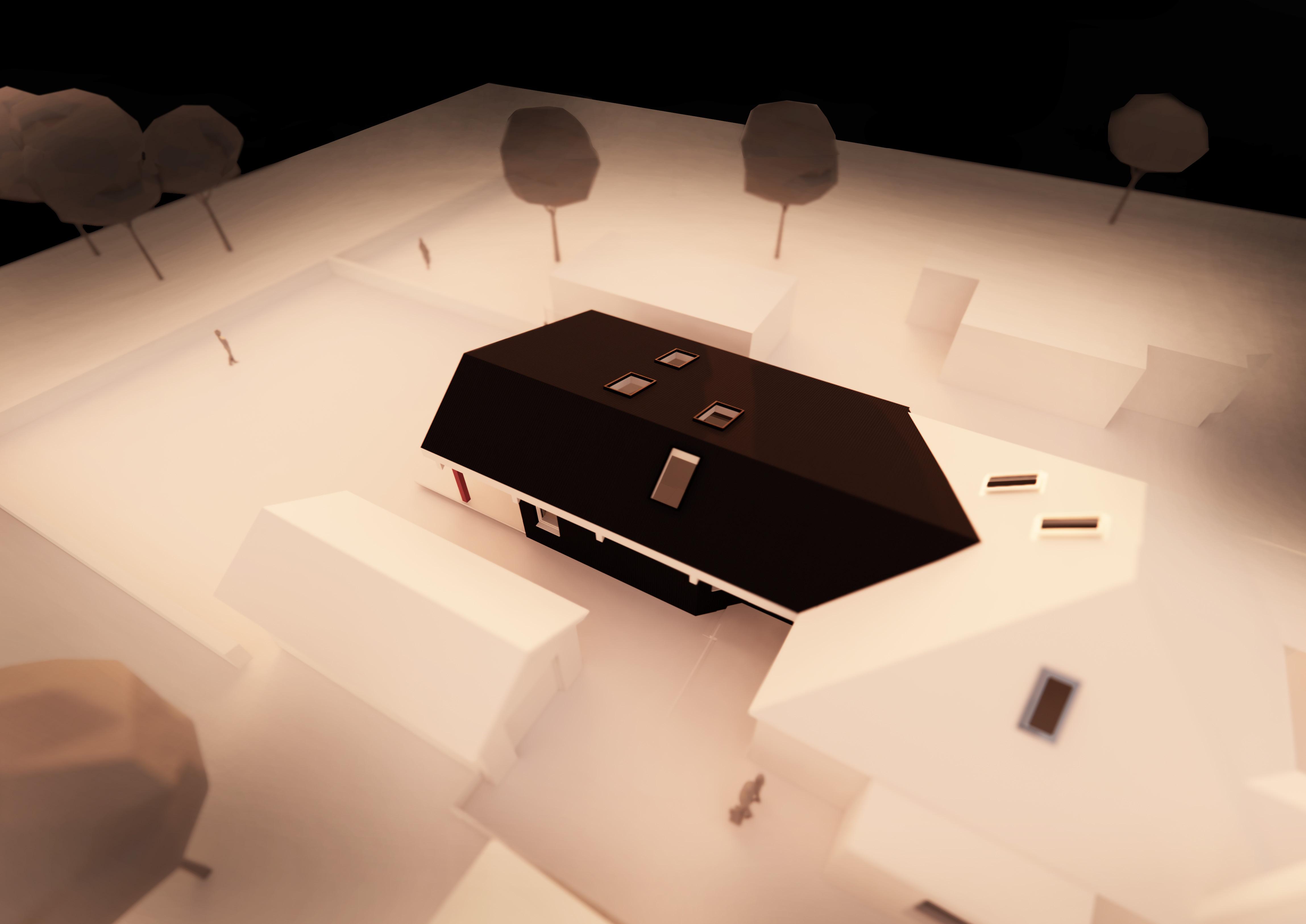

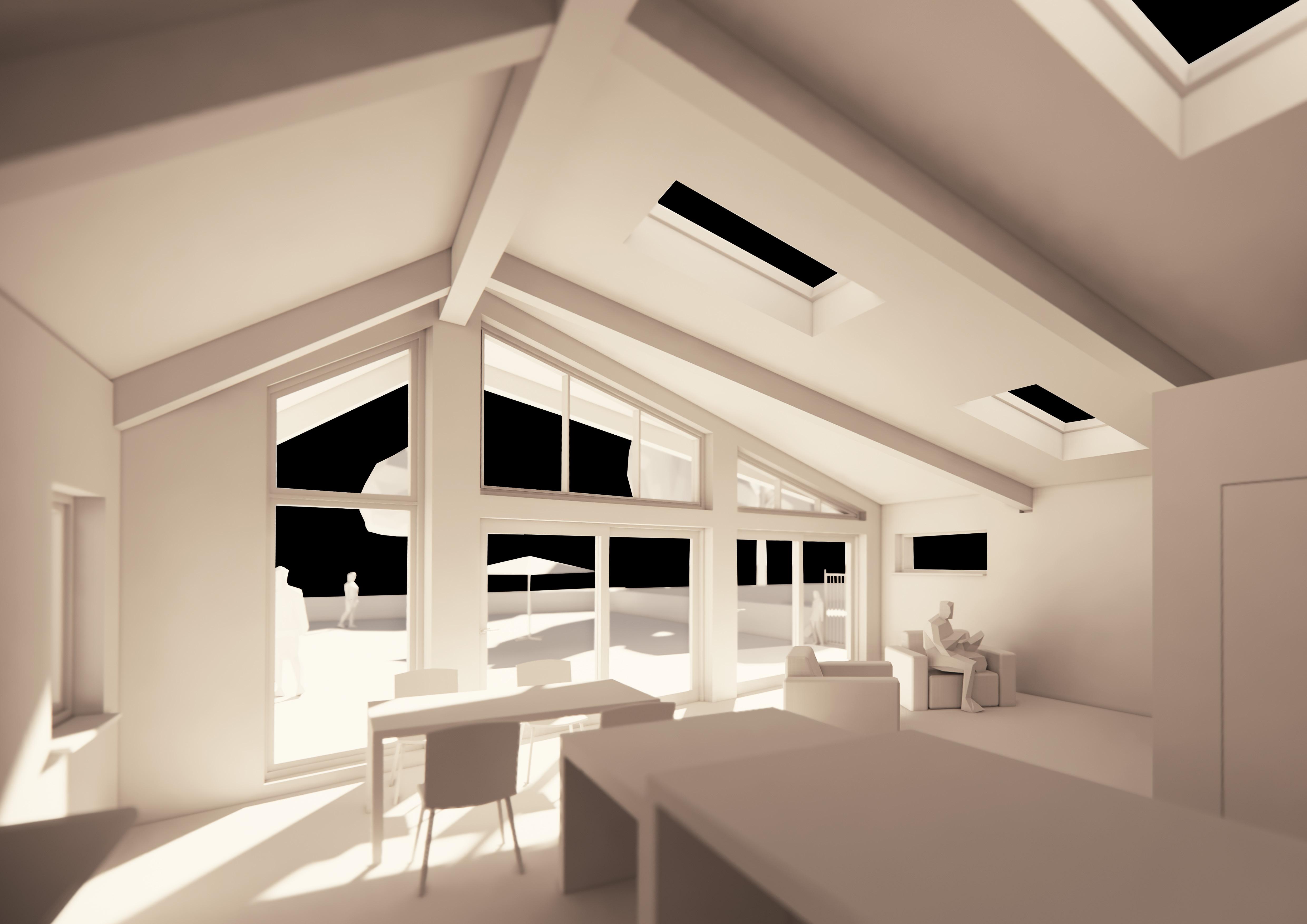

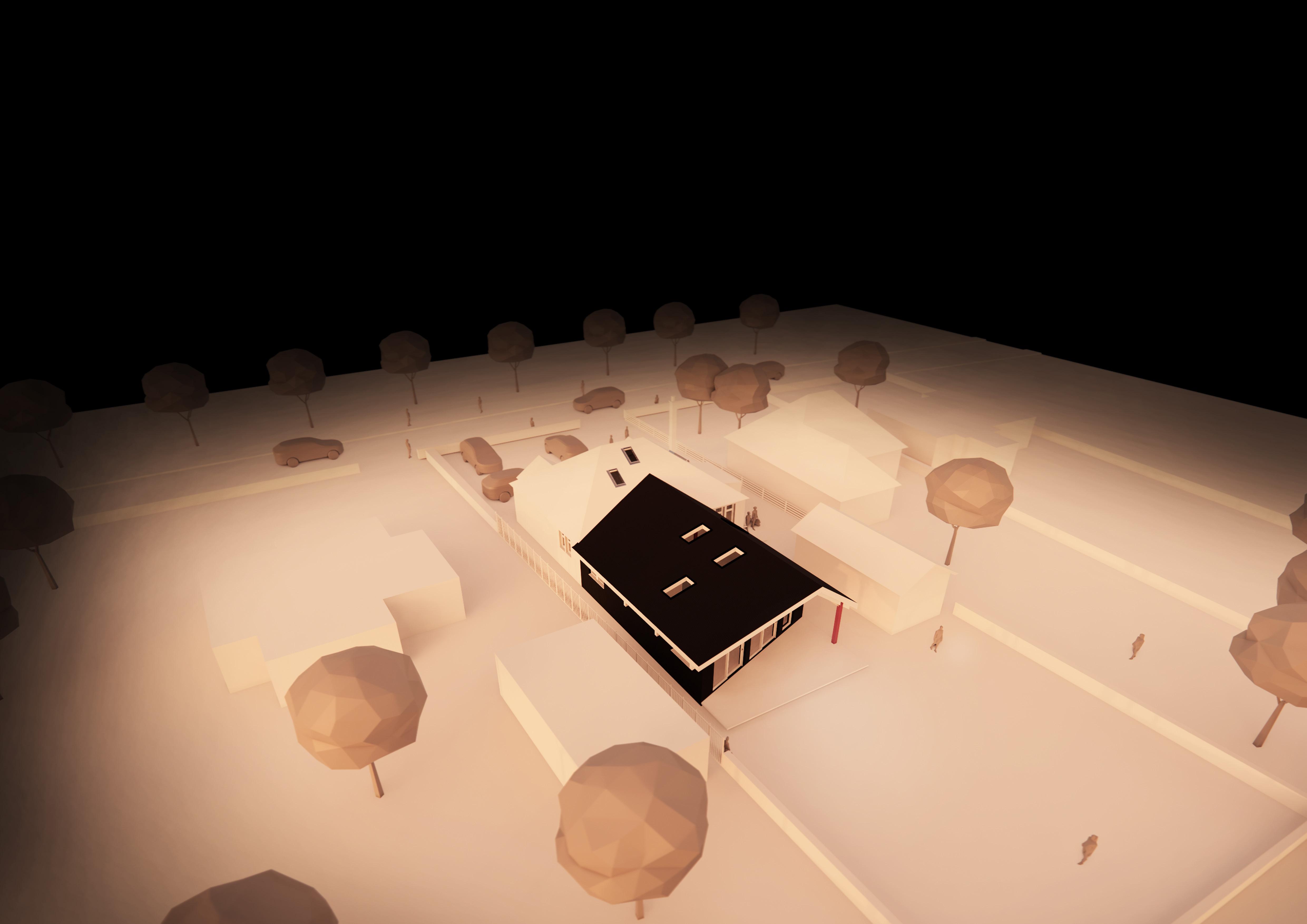

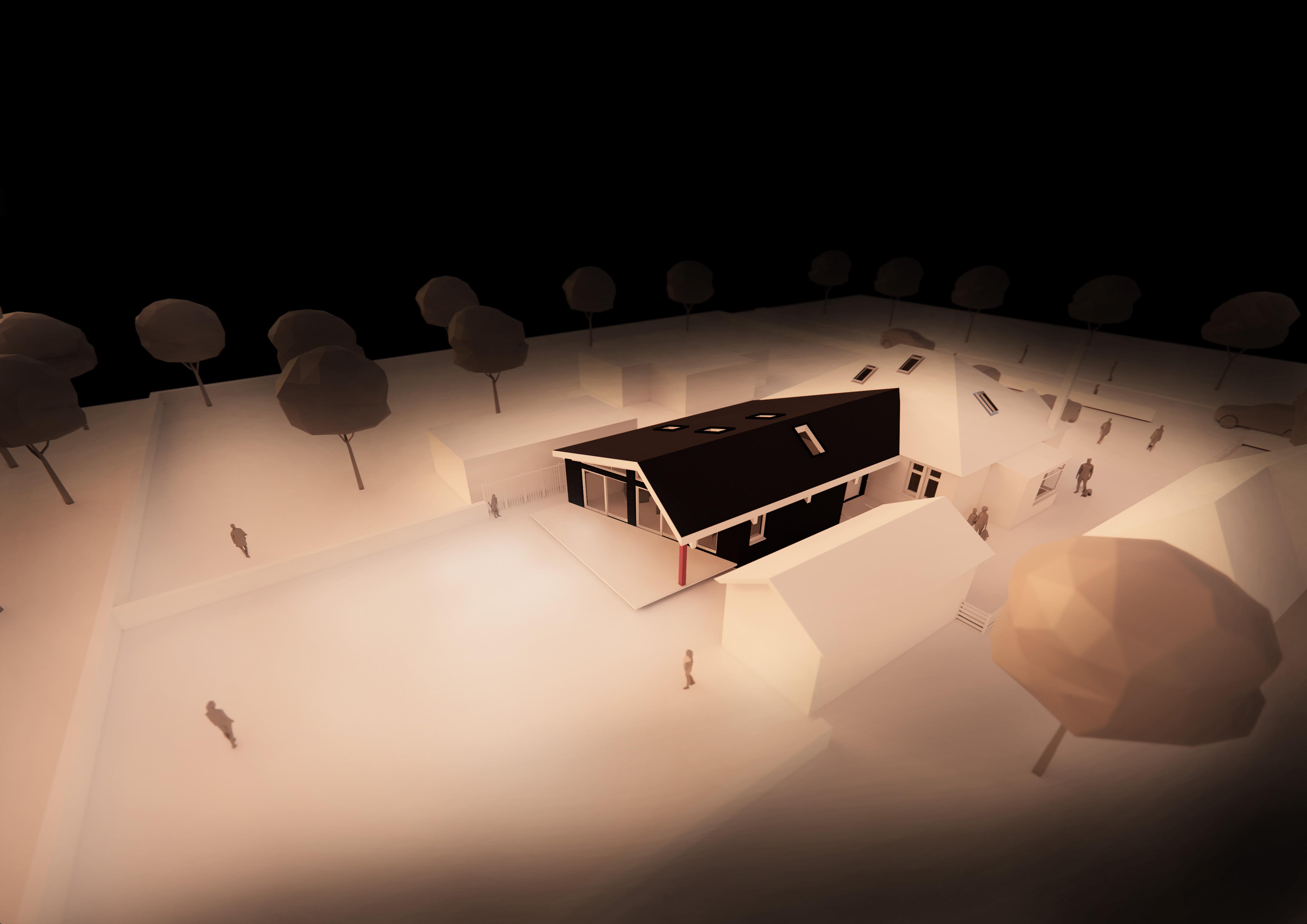

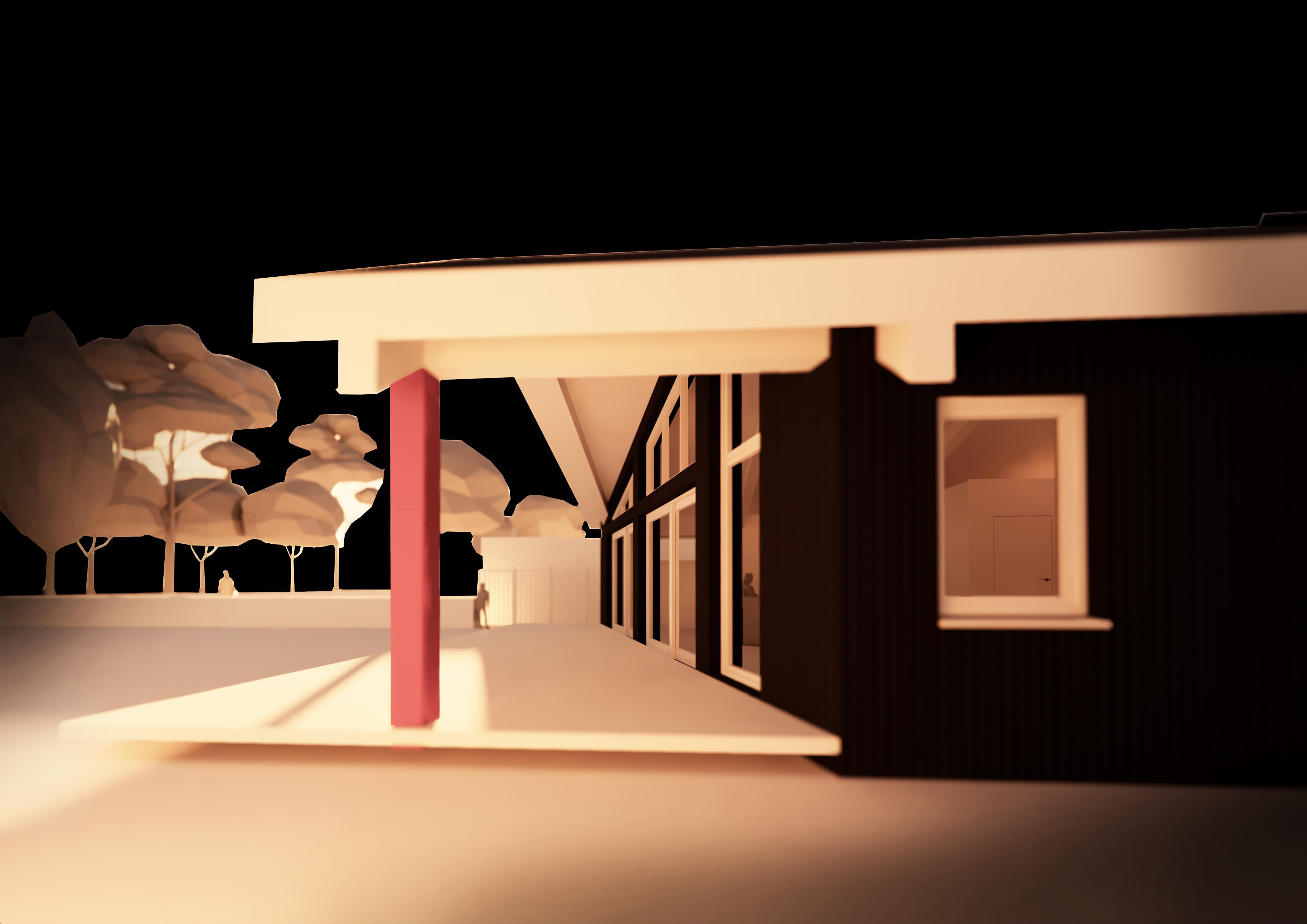

Location UK, Highlands : Budget £203k : Type Housing : Current Stage On-site: Involvement Stage 0 Strategic Definition - Stage 5 Construction : Software Vectorworks, SketchUp, Photoshop, Illustrator : Project Architect Michael Gilchrist

Description

The objective of this project was to design an extension and make internal alterations to accommodate the needs of the family’s two daughters, who both have a degenerative illness that will eventually require wheelchair use.

The design needed to be adaptable to the family’s evolving needs, providing flexible and welcoming spaces. We created an open-plan area with lowered kitchen islands and a wet room equipped with a gantry to ensure accessibility and inclusivity.

The design features a cantilevered glulam ridge beam with glulam feature rafters and timber rafters in between, allowing for a large uninterrupted span. The end gable incorporates a steel portal frame with expansive glazing overlooking the terrace and garden. Two bi-fold doors with flush thresholds seamlessly connect the indoors with the outdoors and are sheltered by a large canopy. The central focus of the design is on promoting family unity

Responsibilities

• Developed a Vectorworks BIM model, a first for the office.

• Collaborated with the Director to progress the design from Stage 0 through Stage 5.

• Produced all production drawings, 3D visuals, and renders.

• Liased with the Client to finalise the Client Requirements and Final Project Brief

• Managed the planning application and building warrant processes, maintaining correspondence with building standards.

• Created all technical details and wrote detailed Specification.

• Collaborated with the structural engineer to solve arising issues. No other consultants were used since this was a small buldings design.

• Participated in design team meetings, conducted on-site inspections, and composed Site Meeting Reports.

• Issued Interim Certificates

1 Glulam ridge beam

300x560mm gl28h glulam ridge beam

2 glulam feature rafters

45x225mm c24 timber rafters @600mm crs fixed to 200x44omm gl28h glulam feature rafter

3 Timber rafters

225x45mm c24 rafters @600crs fixed to glulam feature rafters with Simpson sae 380/45 hangers

4 foundations

Minimum 450mm, 750x200mm deep grade strip footing with 1no. layer a393 mesh to bottom face

5 Canopy

150x150mm douglas fir canopy beam fixed to 3no 47x225mm c24 timbers spiked and 150x150mm douglas fir canopy post

1 roof

Profile 3 eternit fibre cement on 25x30mm Timber battens on 12x38mm timber counter battens on proctor roofshield on 18mm timber sarking on 225x45mm c24 rafters @600crs Fixed between 200x440mm gl28h glulam feature rafters with 300x560mm gl28h glulam ridge beam with 225mm rigid insulation on 35mm foil faced rigid insulation on 12.7mm plasterboard

2 roof canopy

Profile 3 eternit fibre cement on 25x30mm Timber battens on 12x38mm timber counter battens on 225x45mm c24 rafters @600crs fixed to 3no. 47x225mm c24 timbers spiked fixed to cantilever 300x560 glulam ridge beam

3 walls

Profile 3 eternit fibre cement cladding on 50x50mm treated sw counter battens on12x50mm vertical sw straps on breather membrane on 9mm osb on 150x50mm timber studs with foil faced phenolic foam rigid insulation on 35mm rigid insulation on 25mm service void using 25x50mm sw battens on 12.7mm foil back plasterboard

4 Floor

22mm t&g timber flooring on Separating membrane on 75mm latex screed with under floor heating on 125mm rigid insulation on 125mm concrete slab on DPM on 50mm blinding on 150mm hardcore

5 steel frame

203x133x30 ub frame fixed to glulam ridge beam with 2no. m16 bolts fixed to fin plate welded to top of column

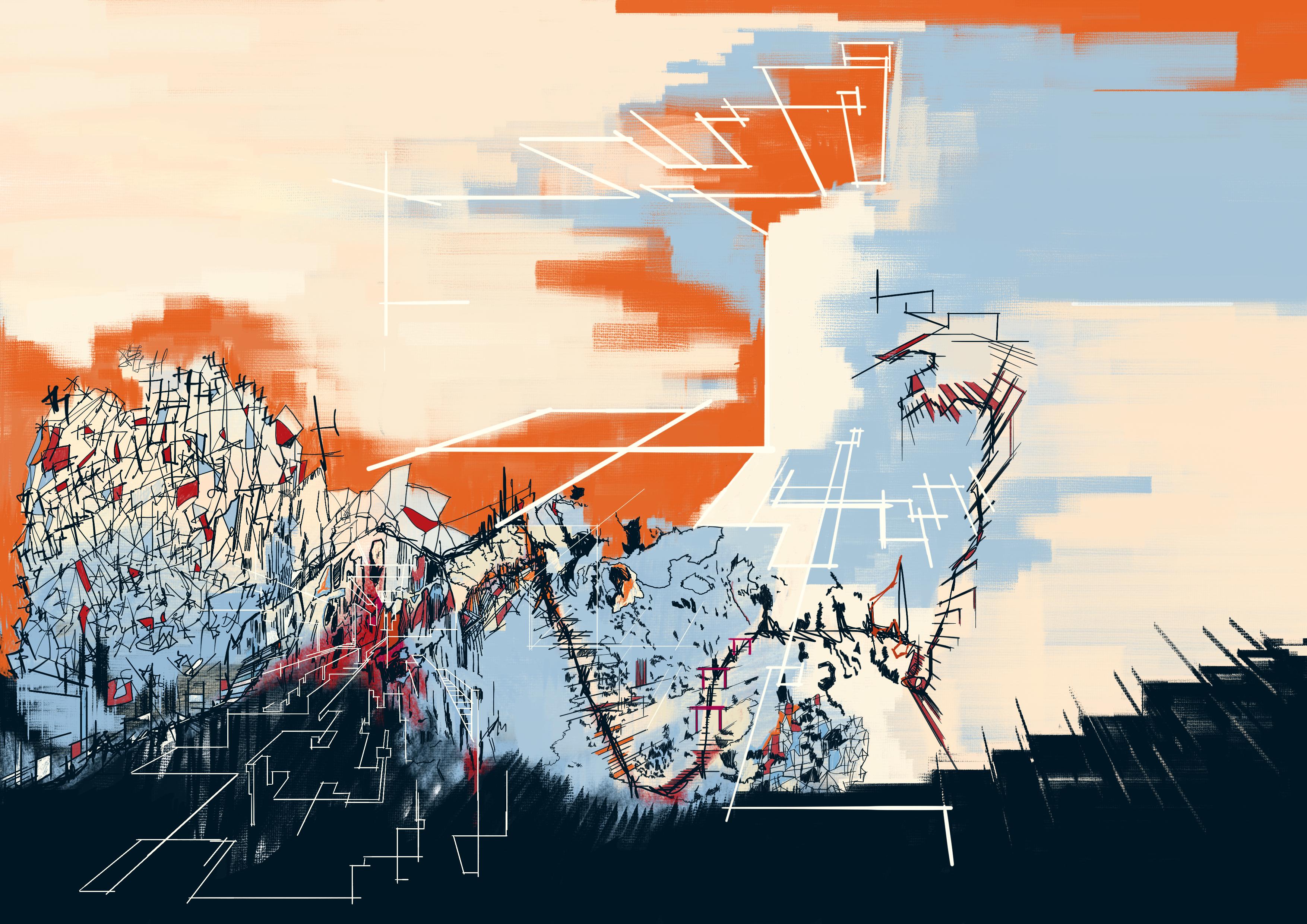

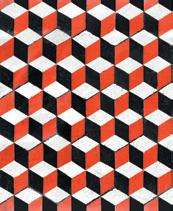

Acrylic, Ink + Pastels

Description

I have a deep passion for art, graphics, and drawing. In my free time, I extensively use Procreate and Morpholio on my iPad, which allows me to think creatively and provides inspiration when producing initial concept schemes for projects in practice.

My artistic endeavors extend to traditional mediums as well. I work with oil sticks and oil paints on large canvases, and I enjoy experimenting with pastels, black ink, and etching at my local art studio.

My primary focus is on abstract art, and I love sketching as a form of expression.