MultiMedical Systems has been trusted for nearly 30 years for skilled BMET staffing – but we can also deliver:

• Cybersecurity solutions for medical devices

• Compliance and regulatory support

• Tailor-Made Field Service Staffing designed for your needs

From the frontlines of patient care to the backend of compliance, MultiMedical Systems delivers the expertise you need, exactly when you need it.

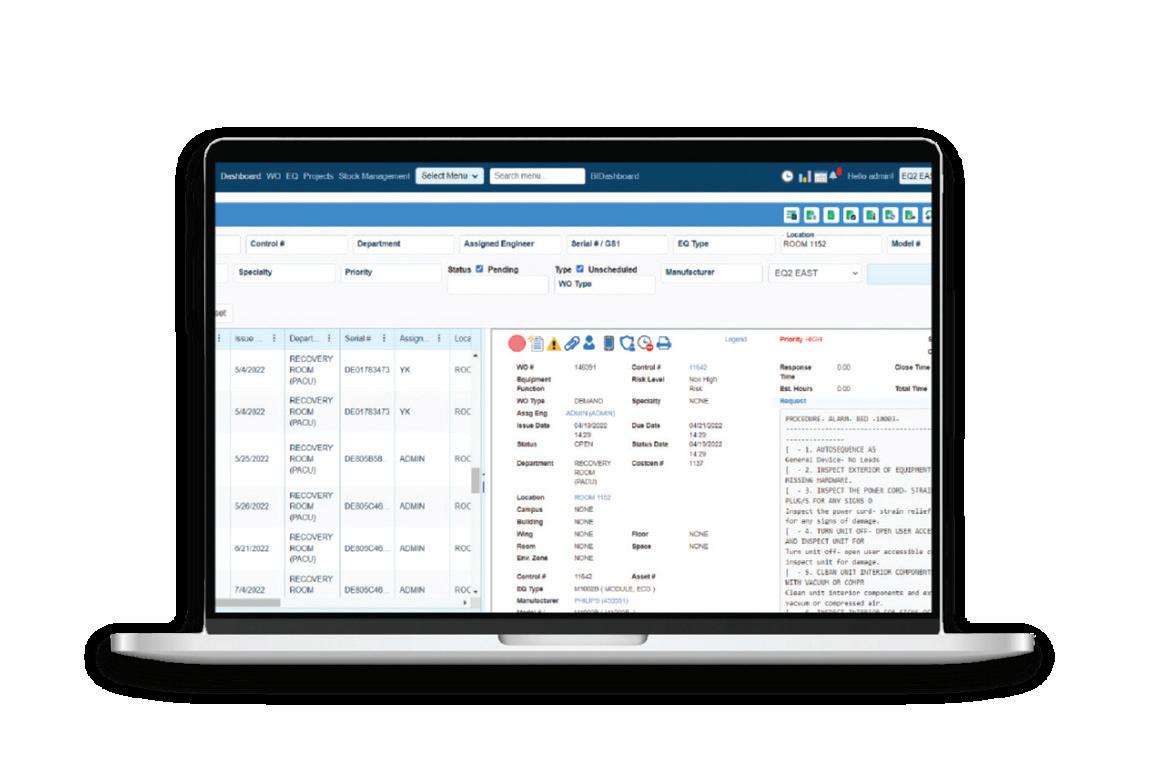

Finally, the features you love most about your favorite ride share app, food delivery app, Angi, UpWork, or TaskRabbit are available for medical imaging equipment maintenance and repair.

Enter a Trace Ticket with one tap to broadcast your repair needs to a network of qualified technicians.

Review Bids to find the best service option for improved repair outcomes with less equipment down time, resulting in a lower overall cost.

Track progress, issue payments and rate services all in a single dashboard.

Speed

Instantly blast your service request to every qualified and vetted service provider

From response times to uptime, you no longer have to rely on service companies to track their own activities and performance

Like your favorite personal apps, get in-app alerts when a service technician is on their way, arrived, waiting for a part, completed a job, etc.

Pay

Competitive bidding among service technicians allows you to get the best price and only pay and track one entity

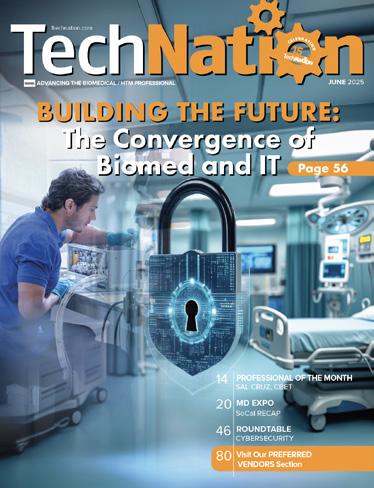

P.12 SPOTLIGHT

p.12 Department of the Month: TRIMEDX Clinical Engineering at UPMC Children’s Hospital of Pittsburgh

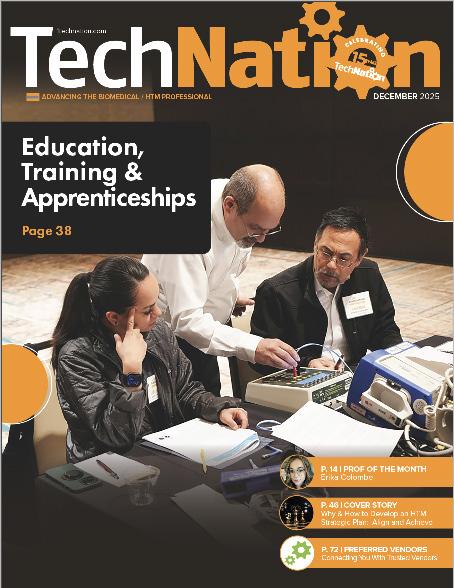

p.14 Professional of the Month: Erika Colombe

p.16 Next Gen: Kyle Koscinski

p.18 Shifting Gears: Andrew Gutierrez, Cool Cars for the Boys

P.20 INDUSTRY UPDATES

p.20 News & Notes

p.26 TechNation Pulse

p.28 Welcome to TechNation

p.29 Ribbon Cutting: MedService Repair

p.30 AAMI Update

p.31 ECRI Update

P.32 THE BENCH

p.32 Biomed 101

p.36 Tools of the Trade

p.69 Webinar Wednesday

P.38 FEATURE ARTICLES

p.38 Roundtable: Education, Training and Apprenticeships

p.46 Cover Story: Why & How to Develop an HTM Strategic Plan: Align and Achieve

P.50 EXPERT ADVICE

p.50 Cybersecurity

p.52 The Future

p.54 Right to Repair

p.56 SPONSORED CONTENT: Renew Biomedical

p.58 The Massey Method

p.60 Networking Notes

p.62 Health-ISAC

PUBLISHER John M. Krieg

VICE PRESIDENT Kristin Leavoy

VICE PRESIDENT Jayme McKelvey BUSINESS DEVELOPMENT

EDITORIAL John Wallace

CONTRIBUTORS

K. Richard Douglas

Joie Marhefka

Steven J. Yelton

Garrett Seeley

Phil Englert

Nathan Proctor

Nadia ElKaissi

ACCOUNT Megan Cabot

EXECUTIVE

ART DEPARTMENT Karlee Gower

Taylor Hayes

Alicia Brown

DIGITAL SERVICES Cindy Galindo

Kennedy Krieg

Haley Harris

EVENTS Kristin Leavoy Sydney Krieg

WEBINARS Linda Hasluem

HTMJOBS.COM Sydney Krieg

ACCOUNTING Diane Costea

CIRCULATION Joanna Manjarrez

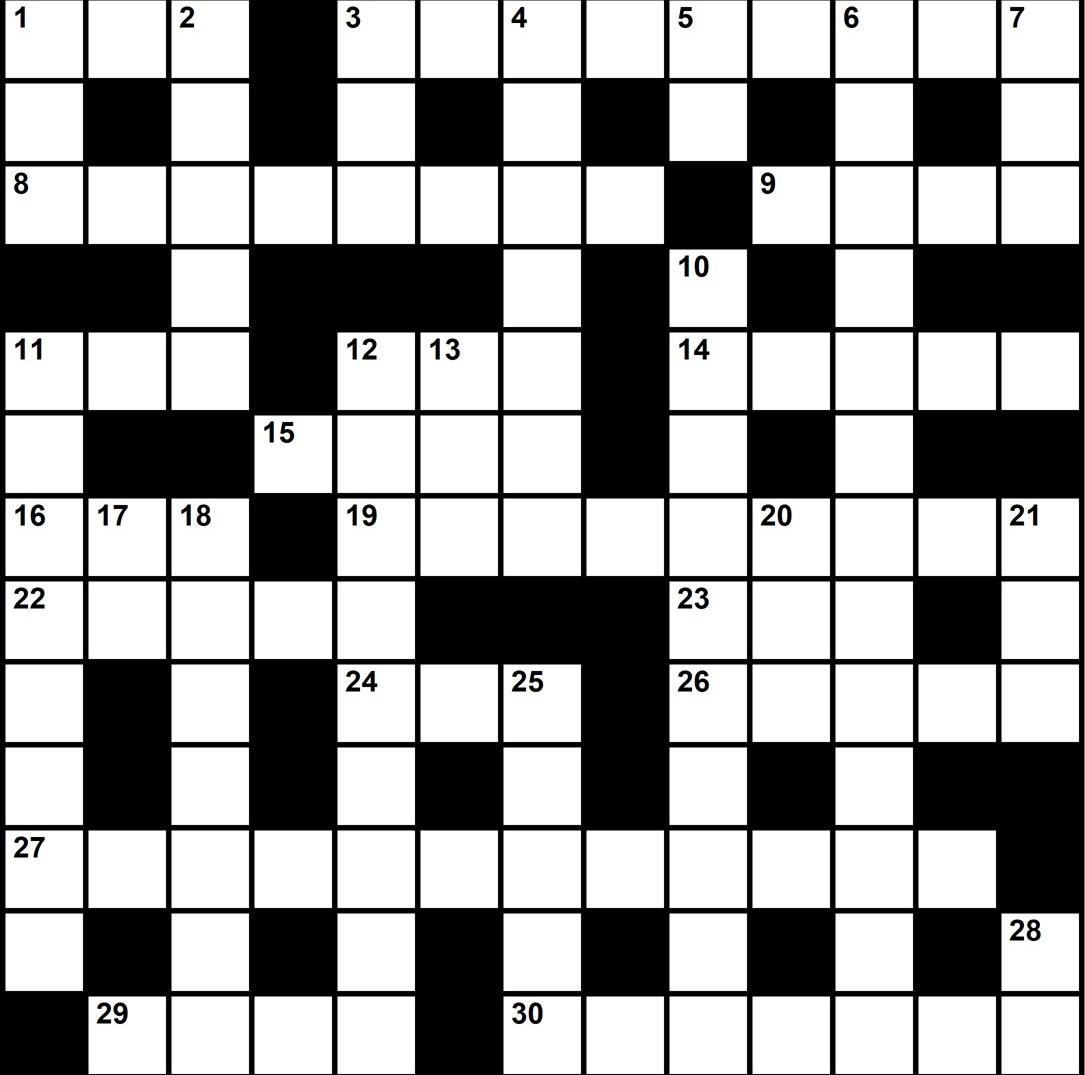

p.66 Biomed Brainbuster

p.67 Word Search

p.67 [Contest] What’s on Your Bench?

p.68 NESCE Scrapbook

p.72 Preferred Vendors

p.76 Service Index

p.79 Alphabetical Index

p.80 Time Capsule

Rob Bundick, Director HTM & Biomedical Engineering, ProHealth Care

Carol Davis-Smith, CCE, FACCE, AAMIF, Owner/ President of Carol Davis-Smith & Associates, LLC

Nadia ElKaissi, CHTM, Biomedical Engineer, HTM, VA Central Office (19HTM)

Bryant Hawkins Sr., Site Manager, Children’s Hospital of New Orleans

Earl Morris Jr., BMET, Director of Clinical Engineering, Harrison County Hospital

Leticia Reynolds, Clinical Engineering Operations Manager at UCHealth Parkview Medical Center

Our nationally recognized programs include Biomedical Equipment Technology (BMET), Biomedical Equipment Support Specialist (BESS), and the Dental Repair Technician (DRT) Certificate. Each is designed to equip you with the advanced skills needed to thrive in today’s evolving healthcare and dental technology landscape.

CBET’s Virtual Reality (VR) labs offer a flexible and immersive learning experience that adapts to your busy schedule. our VR labs allow you to practice and perfect your skills in a controlled, risk-free environment.

BY K. RICHARD DOUGLAS

The University of Pittsburgh Medical Center (UPMC) is a large nonprofit with approximately 100,000 employees and 40 affiliated hospitals. One of those hospitals is UPMC Children’s Hospital of Pittsburgh. It provides 1.5 million square feet of space to provide treatment of childhood conditions and diseases and accommodate the families of patients.

The state-of-the-art facility has won national recognition and includes a 10-story, 300,000-square foot research facility.

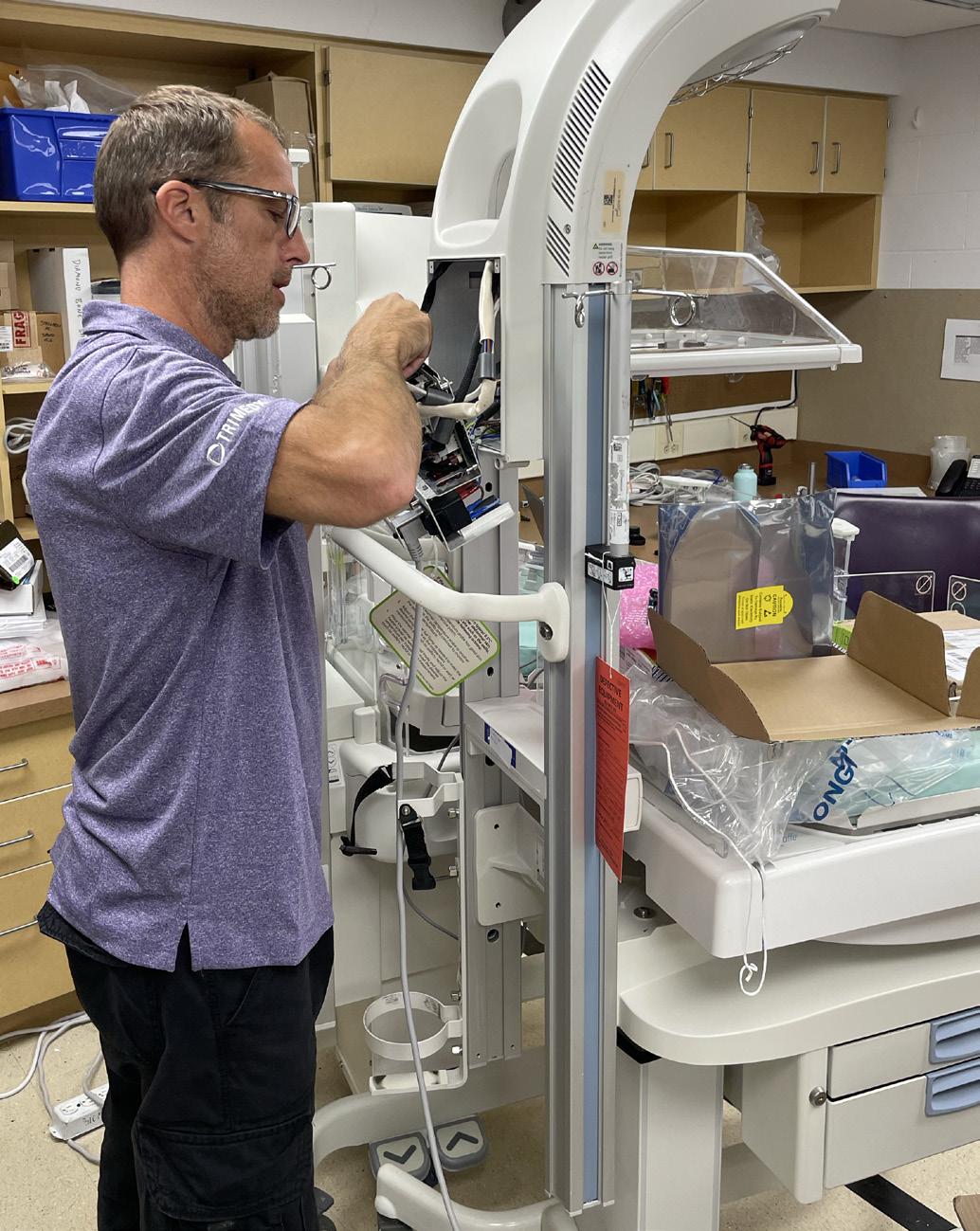

M anaging medical equipment for the Children’s Hospital is the TRIMEDX Clinical Engineering Department at UPMC Children’s Hospital of Pittsburgh. The department is comprised of 10 members. They include Site Manager Ross Scalise, Clinical Engineering Supervisor Alan Knupp, six

BMETs and two imaging technicians.

Knupp says that the group’s technicians have areas of specialty.

“ We have technicians who are specifically trained and assigned to various specialty areas within our department. These include anesthesia, ventilators, dialysis, EEG, imaging modalities and ECMO. Whenever possible, we also ensure there is a backup technician available to provide coverage and maintain continuity of expertise in each area,” he says.

Knupp says that the team supports a children’s hospital with 330 licensed beds, along with three main offsite facilities. These offsite locations vary in function but typically include office spaces, imaging services and, in some cases, operating rooms.

H e says that service contracts are managed through a thoughtful, data-driven process that typically takes place during budget planning.

“ The team reviews the previous years’ service history and associated costs to determine whether it makes

financial and operational sense to continue, modify or initiate new service contracts,” Knupp says.

The team also collaborates closely with its IT counterparts.

The TRIMEDX Clinical Engineering team took on a largescale project that benefited patients and clinicians.

“One of the most impactful special projects the team has taken on was the replacement of approximately 500 patient monitors across the hospital. This initiative required nearly a year of detailed planning, coordination and execution. The team was responsible for configuring each monitor with new IP and MAC addresses, integrating them into the hospital’s system, and managing live swaps in critical care units – often while patients were actively being treated. This meant working closely with clinical staff to ensure seamless transitions,” Knupp says.

H e adds that the project also introduced a new capability to allow real-time monitor viewing from any workstation, significantly enhancing clinical accessibility.

“ This project demanded collaboration across multiple hospital departments, IT, GE and hospital administration. It demonstrated the team’s ability to manage large-scale, high-impact technology upgrades without disrupting patient care,” Knupp adds.

In tackling the large patient monitor project, the group proved that they were up to meeting the many challenges that can be encountered with so many touchpoints and variables.

“ The patient monitor replacement project also serves

as a prime example of the department’s problem-solving capabilities. The team had to navigate a wide range of logistical and technical challenges, from coordinating live equipment swaps to customizing installations for different units. For instance, some ICUs required remote monitors outside patient rooms, which involved sourcing and installing specialized cabling, adapters and power supplies,” Knupp says.

H e adds that in operating rooms and cath labs, the team had to pre-plan for multiple displays and ensure that vital signs could be viewed from various locations within the room. All of this had to be done without interrupting patient care, requiring precise scheduling and strong communication with clinical staff.

“ The success of this project laid the groundwork for another major initiative: the replacement of approximately 2,500 infusion devices, including 770 syringe pumps,” Knupp says.

H e says that this project, which is currently underway, involves tagging, inventorying and coordinating floor-byfloor device swaps.

“ The team has applied lessons learned from the monitor project to streamline this rollout, once again demonstrating their ability to solve complex problems through collaboration, planning and a patient-centered approach,” Knupp adds.

The TRIMEDX Clinical Engineering Department at UPMC Children’s Hospital of Pittsburgh proves that a midsized specialized team can accomplish a lot. For the health of pediatric patients, that value cannot be overstated.

BY K. RICHARD DOUGLAS

Windsor, Ontario sits across the Detroit River from Detroit on the Canadian side. The city features a waterfront park that stretches three miles and is known as the “Automotive Capital of Canada.”

The city also has two campuses of St. Clair College. The college is known for it’s excellent biomedical engineering technology program. One of the program’s graduates is Erika Colombe, biomedical engineer technologist for TRH services in Cambridge, Ontario. Colombe works as a field service technologist with the company.

While Colombe’s interest in the biomed field began in high school, it was piqued while attending St. Clair.

“I learned and got into the HTM field through my professors at St. Clair College. These professors are James Linton and Jim Durocher. They introduced this to my class and encouraged us to integrate any management into any of our assignments with emphasis on our project management course,” she says.

Colombe says that the program she took was biomedical engineering technology, a three-year advanced diploma in Canada.

The biomed job opportunities are not that great in Windsor, but Colombe was prepared for that reality before entering the job market.

“I was pretty lucky to have professors that were pretty straight forward about this topic.

I would’ve never found a job in Windsor, my hometown. I had to move away. Currently, right now, the jobs in Ontario itself are very limited; most of them are located out of province but definitely not as bad as if in the U.S. I see jobs all the time for the U.S. as compared to Canada,” she says.

She says that working for an independent company, her training looked a little bit different.

“I had one-on-one training with the other technicians on job sites for about a month then I was on my own. Since then, I have helped develop a more standardized training program for my company. After that I have received a variety of manufacturing training on various equipment,” Colombe says.

Today, as a senior technologist, she offers support to new members of her team, including job preparations, what questions to ask, etcetera.

“I am not only working with management I directly report to, but management at the sites I work at. St. Clairs’ Project Management course encouraged us and taught us that every single person you work for/with is management and always a customer – whether it is a nurse, physiotherapist, dentist, etcetera,” Columbe says.

Since entering the field, Colombe has worked as a biomedical technologist, senior technologist and team trainer.

With a few years under her belt, the field-tested biomed is used to challenges and knows she is on the job to get the repair completed.

“One of the biggest challenges I have faced in itself comes from working for an independent company. When describing what we do, I call us a ‘fix it company.’ We fix everything. For our customers, we do not send anything back to the manufacturer unless it is our only option. With this, it means a lot of learning and troubleshooting,” Colombe says.

That often requires troubleshooting older equipment. She says that this means understanding the issue and repairing it on the first try.

“In addition, because we work on so much equipment, it has been a challenge simply learning it all. We work anywhere from surgical sites, dental offices, physiotherapy clinics, hospitals;

My favorite part of being a biomed is the challenge. As much as it drives me crazy, I love working on broken equipment and trying to figure out what is wrong with them. The reward when you figure it out is blissful.

basically, anything medical we work on. This went way beyond the scope I was taught in school and three years into my career, I am still learning,” Colombe says.

She says that on a more interpersonal level, time management is one of the hardest challenges and she tells every new member of her team that.

“If I am only given five hours on site to complete a job, I have to finish it and I am not leaving until it’s done. This is because of costs from our end as well as [the] customer’s end. Customers do not want to pay for us to come onsite another day if we don’t need to. They are given a time a frame and we are expected to complete it in that time frame. So, time management is an absolute key part of my job,” Colombe says.

Colombe describes herself as “just a young woman passionate about what she does.”

“I try my best to make light of everything; my job is tough. And it’s not only tough for me but for all the other techs as well. I want to keep the team in a good mood constantly and I try my best to do that – my boss would describe me as a ‘yapper’ when I’m around everyone,” Colombe says.

Family includes a twin sister who is a nurse.

“She’s two minutes older and never lets me forget. I also have an older brother who is a biomedical engineering technologist, although he followed in my footsteps,” Colombe says.

When not working, she enjoys painting, drawing and occasionally even playing video games.

“I was an avid soccer player for most of my life and even to this day, I still love the sport,” she says.

“I do have memberships with MedWrench and I also follow TechNation as a whole. Here in Ontario, I am working towards my OACETT, certified engineer technologist certifications,” she adds.

Biomed customers in Ontario can rest assured that when this biomed is on the job, the goal will be to get things fixed. A passion for the field can only mean good things.

FAVORITE BOOK:

I am currently reading a Court of Thornes and Roses series and loving it!

FAVORITE MOVIE:

I’m not much of a movie watcher but my favorite television show is “Vanderpump Rules.” I’m a sucker for good reality TV.

FAVORITE FOOD:

It’s cliché, but I could eat pizza every day. Specifically, pizza from Windsor, Ontario, my hometown; it’s what Windsor is known for.

HIDDEN TALENT:

I’m not sure yet but I did teach myself to play the guitar.

FAVORITE PART OF BEING A BIOMED?

My favorite part of being a biomed is the challenge. As much as it drives me crazy, I love working on broken equipment and trying to figure out what is wrong with them. The reward when you figure it out is blissful.

WHY DO YOU READ TECHNATION?

I read TechNation because there is so much to learn from everyone in all parts of society. I love reading about people who do the same job I do and see what their days look like compared to mine. I like to read about the new skills that people mention and how I can apply them to my everyday life.

Kaleida Health Imaging Specialist I Kyle Koscinski believes in continuing education. He holds associate and bachelor’s degrees in engineering as well as the following certifications: CBET, A+, Drager Apollo & M300 certification, Siemens Basic & Advanced Service Essentials, and Zoll R-series certification.

TechNation interviewed this New York native to find out more about his path to HTM and his goals for the future.

Q: WHERE DID YOU GROW UP?

A: Depew, NY (Buffalo Metropolitan Area)

Q: HOW DID YOU FIRST DISCOVER HTM?

A: Recommended field from a relative.

Q: WHY (OR HOW) DID YOU CHOOSE TO GET INTO THIS FIELD?

A: It was the first job field that responded to my application to work. After gaining experience, I decided to stay and invest in a future in the field. The main appeal at the time; healthcare was considered one of the more reliable jobs to have for life.

Q: WHAT DO YOU LIKE MOST ABOUT YOUR POSITION?

A: The complexity of the equipment being worked on makes it engaging; more fulfilling.

Q: WHAT INTERESTS YOU THE MOST ABOUT HTM?

A: The direction the field can go in 10, 20, and 50 years from now. How fast technology evolves; it’s exciting to think about what new equipment/techniques will be used and worked on in the future.

Q: WHAT HAS BEEN YOUR GREATEST ACCOMPLISHMENT IN YOUR FIELD THUS FAR?

A: Getting to the position I am in currently (imaging) after starting from the lowest entry position.

Q: WHAT GOALS DO YOU HAVE FOR YOURSELF IN THE NEXT 5 YEARS?

A: The main goal is expanding my knowledge in as many areas of imaging as I can through various means and OEM training.

FAVORITE HOBBY: Cooking

FAVORITE MEAL: Braised beef ribs with asparagus

WHAT WOULD YOUR SUPERPOWER BE? Getting somewhere quickly/teleporting

SOMETHING YOUR CO-WORKERS DON’T KNOW ABOUT YOU: I have an autoimmune disease.

K. RICHARD DOUGLAS

Turning a wrench is a lifestyle choice. It can mean many things, but it always involves hand or power tools, a knowledge of using tools and repair, maintenance or modification techniques and the foresight to complete a project.

Wrenching on a project car or on a medical device both mean that knowledge and tools collide in the hands of a skilled technician or mechanic. Something of value will result because of the effort.

In the world of car enthusiasts, there are projects meant to restore, modify, upgrade or enhance the vehicle. Whether the project is restoring a salvage car to pristine condition, increasing the horsepower of a daily driver or building a car for the track, there are skills, parts, tools and experience that all come into play.

Andrew Gutierrez, MBA, CBET, a clinical engineering technician in Stockton, California, understands the enthusiasm and wrenching skills needed to achieve a transformed and unique project vehicle. He also has the hands-on experience.

Gutierrez has been working recently on two project vehicles, a 1971 Chevelle and a 1951 Chevy classic truck. He has very specific future plans for the two project vehicles.

“My two vehicles are for my two boys, Andrew Jr., who is six and Nikolai, who is five. I have them help me do little things to get their problem-solving gears turning and ask questions,” he explains.

Since the boys will not be able to slide behind the steering wheels for at least nine years, are they excited about their future rides? What if they turn 16 and decide they want a Hellcat instead?

“My sons absolutely love the time we spend on these builds. For them, it’s not just about the car – it’s the bonding, the learning and the lessons about patience and hard work. Even if someday, they want a Hellcat, the

foundation we’ve built together won’t change. They’re learning that these projects are more than machines; they’re quality time and life lessons,” Gutierrez says.

He says that the old truck brings back some childhood memories.

“This truck was chosen because when I was little, my dad had an old one similar to that. I could see through the floorboards, and I remember cruising with him as a kid,” he says.

The Chevelle is a vehicle that Gutierrez wanted since he was young.

“This car was a dream project as a kid. I’ve always loved the aesthetic and performance of muscle cars, and I wanted to create something that embodies speed, power and nostalgia,” he says.

The two project vehicles have already received nicknames from their future owners.

Andrew Jr. named the Chevelle “oralleys” because Gutierrez would take him all the time to the store for parts. Niko named the 1951 Chevy truck “Bubba G.”

Gutierrez embraced the hobby of working on cars many years ago.

“I really got into cars when I was little. My dad worked with me in the garage, and those early moments of wrenching together really stuck with me. That foundation shaped everything that came later,” he says.

These two projects have not been Gutierrez’s first.

“My very first big project was an LS swap into a 1957 Chevy pickup, just like my dad had. That build was special because it connected me back to him,” he says.

Interestingly, it was not working on cars that led to the biomed profession for Gutierrez. It was the other way around; his ability to work on fabricating frames, working on engines and transmissions and brakes all came out of his healthcare career.

“Honestly, I credit my career in biomed for that. Working in healthcare technology management taught me how to diagnose, repair, and fabricate – just in a different setting. Those skills translated directly into cars,” he says.

The vehicles have had a chance to dazzle local car-lovers. Gutierrez says that he took the Chevelle out to participate in the Modesto, California Graffiti Night Parade. He says it was a highlight of owning the car so far.

The vintage pickup truck is a mix of restoration and customization.

“The plan is to maintain the exterior’s classic lines but upgrade the engine to Gen 3 LM7. The suspension is Mustang II in front and rear four-link and the interior is from Range Rover,” Gutierrez says.

With the addition of the more modern engines, Gutierrez used engine-mount kits as well as reinforcing the older frames, not designed for modern torque.

In addition to his ability to wrench and restore classic vehicles, Gutierrez also has created a biomed crossword puzzle book and sells biomed/HTM T-shirts.

HTM field and give professionals something fun, meaningful and stylish.

“Some proceeds from select designs support related causes – i.e., cancer charities when tied to oncology-related themes,” Gutierrez says.

He said inspiration for the design of a new T-shirt comes directly from his day-to-day experiences as a biomed.

“Every work order, every repair, every perspective I see in the hospital sparks ideas. And I think about how it would connect with all healthcare workers; not just biomeds. That’s how I build designs that really resonate,” Gutierrez adds.

His design themes include slogans such as: “Biomed: The Backbone of Healthcare,” “HTM: We Keep It Running So They Can Save Lives,” and “Built for Techs. Powered by Purpose.”

“Each piece is carefully themed – from maternity tech to ESUs, pumps and lab departments – to ensure it resonates with professionals in that area,” Gutierrez says.

While the T-shirts, biomed puzzle book and car projects are

Asahi Kasei has advanced its suite of critical care products through premarket approval by the U.S. Food and Drug Administration (FDA) for ZOLL’s Zenix monitor/ defibrillator. The Zenix device is the culmination of years of user feedback and is ZOLL’s most clinically advanced, user-friendly professional monitor/ defibrillator, according to a press release.

The Zenix monitor/defibrillator is designed for use in EMS and hospital settings. It features a large, durable touchscreen and functionality to automate workflows. Users can dynamically customize the device with real-time adjustments that make it easy to use in critical moments. The device also features ZOLL’s Real BVM Help and exclusive Real CPR Help technology.

“The approval of Zenix reflects our strategic, longterm focus on growth through high-value, solutionbased technologies. This device has been designed with an understanding of customer needs, and we expect it will be well-received by customers and healthcare professionals,” commented Ken Shinomiya, leader of the healthcare sector at Asahi Kasei. “This innovation expands our critical care portfolio and offers healthcare providers an excellent tool to tackle their key challenges. We will stay competitive and reinforce our commitment to long-term profitable growth through these innovations.”

The Zenix monitor/defibrillator is available in the U.S. and Canada.

Renovo Solutions has announced a strategic partnership with Surgical Solutions, a leader in on-site surgical support services. The collaboration is designed to help hospitals and health systems reduce costs, improve efficiency and strengthen outcomes for patients, staff and providers across the United States.

By bringing together Surgical Solutions’ ISO 9001-certified sterile processing and perioperative services with Renovo’s comprehensive HTM programs, biomedical and imaging expertise, and surgical equipment repair capabilities, this partnership creates a more integrated and effective approach to supporting operating rooms (ORs) and sterile processing departments (SPDs), a press release states. Renovo Solutions is ISO 13485 certified, underscoring its commitment to the highest quality management standards for medical devices, patient safety, and compliance.

“This partnership allows us to deliver even more value to our clients by uniting Renovo’s technology-driven HTM programs with Surgical Solutions’ deep expertise in the surgical ecosystem,” said Matt Forrest, vice president of business development at Renovo Solutions. “It’s about ensuring efficiency, compliance and cost savings – while improving care.”

The Hawaii Society for Healthcare Engineering has announced its 7th annual Hawaii Healthcare Technology & Facilities Engineering Expo. The 2026 Expo is set for Thursday, May 14 at Prince Waikiki. The all-day event begins at 7 a.m.

HISHE is a personal membership organization devoted to professionals who design, build, maintain, and operate hospitals and other healthcare facilities. HISHE members include healthcare facility managers, engineers, architects, designers, constructors and others.

HISHE’s objective is to encourage and assist the membership in the development of their professional knowledge and competence in the field of healthcare engineering through pertinent educational seminars,

Through this partnership, Renovo clients will have access to expanded support including enhanced staffing, sterile processing services and procedural expertise. Together, the two companies will help hospitals and health systems:

• Prevent case delays and streamline OR workflows to ensure on-time starts

• Enhance compliance and readiness for Joint Commission and DNV surveys

• Reduce infection risks through improved instrument reprocessing

• Keep equipment reliable and eliminate costly downtime

• Address staffing gaps with CRCST-certified SPD and OR support staff

• Ease financial pressure with cost-efficient, guaranteed savings solutions

“This collaboration represents a powerful opportunity to solve some of the toughest challenges hospitals face today,” said Ben Schraeder, senior vice president of strategy at Surgical Solutions. “By combining our strengths, we are able to support both the clinical and technical sides of the OR and SPD, ultimately improving efficiency, compliance and patient outcomes.”

conferences and to provide a medium for the exchange of personal experience as well as the distribution of relevant reference documents and codes relative to the facilities management field.

Early bird registration at a reduced rate is available through April 10 at HISHEHawaii.org.

Sponsorships remain available. For information about how to support the organization via a sponsorship contact Jessica Onaga at 808-783-6594 or via email at jessica.onaga@palimomi.org.

The HISHE’s 8th annual golf tournament will be held Friday, May 15 at Kapolei Golf Course. For details about the golf tournament visit, hishehawaii.org/ event-6360582.

AdvaMed has submitted formal comments responding to the U.S. Department of Commerce investigation into whether the U.S.’s current level of medtech imports has national security implications. The comments outlined medtech as an American success story and the United States as the global leader in innovating and making the highest quality medtech for the United States and world, an export powerhouse, and much less reliant on medtech imports than sometimes perceived.

“We look forward to working with the Administration to recognize and to reward the unique strength of the U.S. medtech industry and to pursue targeted, America First policies that further bolster our domestic base and export platform,” Scott Whitaker, AdvaMed president and CEO, wrote. “These policies include seeking fair and reciprocal tariff-free trade with our most important allies, aggressively addressing unfair market access barriers in specific countries, and advancing domestic regulatory reforms and procurement incentives to enhance U.S. competitiveness at home and abroad. Appropriately tailored policies can ensure that this critical American industry continues to thrive, innovate, protect and strengthen the economic and healthcare systems of our great nation.”

The extensive comments, submitted by AdvaMed on behalf of its more than 600 member companies, describes the flourishing U.S. medtech industry: Supporting three million well-paying jobs, U.S. medtech manufacturing jobs having grown three times faster than overall U.S.

manufacturing jobs; 70 percent of the medtech sold in the United States is made here, as demonstrated by U.S. Census data on U.S. manufacturing output; by far, the United States is the world leader in medtech exports, enjoying trade surpluses with virtually all trade partners, especially those with large economies.

Tax relief and other pro-growth policies enacted under both Trump administrations have contributed to significant medtech investments in the United States, with billions of dollars in new investments announced this year alone.

The comments outline a series of recommended policies to further support U.S. dominance in medtech production, innovation, exports, and the source of jobs and investment in every state. The response also describes the extensive value of U.S.-dominated medtech to patients, doctors, and hospitals, providing safe, effective medtech for every medical condition at costs that are consistently low relative to other health care spending and often deflationary because of industry competition.

“The American medtech industry is the backbone of our country’s health care system,” Whitaker said.

Through the Commerce Department investigation and tariff deliberations, AdvaMed urges the Administration to consider how lower tariffs combined with supportive policies will promote more medtech manufacturing and job growth in the United States, which means greater access to lifesaving technologies and lower costs to American hospitals and patients and more investment in the United States.

D’Juan James, MBA, CHTM, senior director of clinical engineering for Kaleida Health, recently received Kaleida Health’s Leadership and Influence Award for his ability to influence others, inspire a collective commitment to organizational goals and serve as a role model in promoting the organization’s values.

As voted on by Kaleida Health Employee Resource Groups (ERGs), the Leadership and Influence Award highlights employees’ meaningful impact, visionary leadership, innovative practices, trusted support, cross-functional collaboration and continuous personal and professional growth.

WILLIAMSBURG, Va. | Navy Medicine commands and partners responded to an urgent requirement request from U.S. Naval Hospital, Guantanamo Bay, Cuba, Sept. 19, delivering critical surgical equipment and expertise that bolstered medical readiness across the Fleet and Joint Force.

When GTMO reported a shortage of sterilization equipment and trained personnel, Naval Medical Readiness Logistics Command (NMRLC), Naval Medical Forces Atlantic, Naval Medical Center Portsmouth, Naval Hospital Jacksonville, Defense Health Headquarters, U.S. Naval Hospital Guantanamo Bay, and Defense Logistics Agency, coordinated under a tight 48-hour timeline.

The mission required locating and preparing

Automated Field Steam Sterilizers and Ultrasonic Portable Washers without drawing down prepositioned war reserve materiel already set aside for other operational commitments. Once the equipment was identified, biomedical technicians at NMRLC conducted immediate maintenance and calibration to ensure the systems were fully mission ready.

“An automated field steam sterilizer is a device used to kill or remove all forms of microbial life, including bacteria, viruses, fungi, and spores, to render objects or surfaces completely free of viable microorganisms,” said Jerhmain Jordan, NMRLC’s electronic technician (biomedical) supervisor.

“Sterilization is the highest level of microbial killing, going beyond simply cleaning or disinfecting.”

An ultrasonic portable washer is a military biomedical portable ultrasonic cleaner used for sterilizing surgical instruments and other medical equipment in field hospitals and other austere combat environments.

Transporting the gear posed additional challenges since commercial carriers do not service GTMO. The team secured military airlift, ensuring delivery by the deadline. When one sterilizer malfunctioned after arrival, technicians at NMRLC provided remote troubleshooting to restore full capability within 24 hours.

This rapid, coordinated response ensured GTMO remained fully equipped to deliver surgical care in support of deployed Sailors, Marines, and joint partners. The effort demonstrated Navy Medicine’s ability to move quickly, solve complex logistics challenges and sustain readiness in austere environments.

“This was a perfect example of multiple commands coming together to maintain mission capability,” said Capt. Jared McKendall, chief of staff, Defense Health Network Atlantic. “The teamwork ensured uninterrupted support for

the Fleet and our operational mission overseas.”

Naval Medical Readiness Logistics Command (NMRLC), headquartered in Williamsburg, Va., provides centralized program management and logistics support to ensure Navy Medicine is manned, trained and equipped to support the operational forces. NMRLC delivers expeditionary medical systems, optical fabrication, medical logistics and materiel readiness to sustain Sailors and Marines worldwide. The command plays a vital role in supporting the Navy Surgeon General’s priority of medical force readiness and the Navy’s overall warfighting mission.

Navy Medicine – represented by more than 44,000 highly trained military and civilian healthcare professionals – provides enduring expeditionary medical support to the warfighter on, below, and above the sea, and ashore.

Registration is now open for the 2026 Imaging Conference & Expo (ICE) scheduled for February 20-22 in San Antonio, Texas! Registration is FREE for hospital and imaging center employees as well as active military and students.

ICE is the only conference dedicated to imaging directors, radiology administrators and imaging engineers from hospital imaging departments, freestanding imaging centers and group practices. The conference also delivers valuable CE credits from the ASRT and ACI (pending approval).

This is the imaging conference where all imaging professionals come together for conversations regarding capital projects, imaging practices, service solutions and more.

ICE 2026, like previous years, offers invaluable continuing education, productive networking and an exclusive exhibit hall. Attendees will have the perfect opportunity to enhance their careers and spend time with colleagues. It is the perfect resource to grow and prosper, personally and professionally. Previous attendees and exhibitors have applauded ICE conferences and expect to return.

“I had many takeaways from the conference. The leadership summit was a great platform to share current challenges in healthcare. To me this was a new topic that I have never experienced before at an imaging conference,” Taylor/Chaplin Breast Health Center Associate Director Kathryn Fields ARRT, ARDMS, MBA, said. “It was great to connect prior to the Summit and meet the participants, and then later have an

MD Expo Baltimore invites HTM professionals and thought leaders to submit presentations for the April 2026 conference. MD Expo provides healthcare technology management professionals with a unique and rewarding conference. Clinical engineers, biomedical technicians, directors, managers, procurement/asset managers and others responsible for medical devices and technology will gather in a one-of-a-kind environment to network with peers and learn the latest technologies and advances in HTM.

Benefits of presenting at MD Expo include sharing knowledge and experience with current and future leaders.

open discussion on topics of our choice that are currently affecting us in our work and health care system. It’s always great to see what other facilities are doing and how they handle certain challenges.”

“Overall, it was a great discussion and when I came back to work, I felt motivated and refreshed with new ideas to implement and try out with my team because of the discussion,” she added.

Daniel Adams from Renovo praised ICE after attending in a previous year.

“My favorite part is the general structure of the event. I like the fact that technicians, service managers and clinical managers can share an event and trade stories of their concerns,” Adams said. “I think it helps service people understand what is important to clinicians as well as giving insight to clinicians regarding service challenges/issues.”

MR Imaging Manager Annette Long, R.T.(R), MR, MRSO, from the Ohio State University Wexner Medical Center always enjoys the conference.

“The ICE conference is a fantastic event to attend, offering excellent lectures and highly relevant material,” she said. “While it is a smaller conference, great attention to detail is given to ensuring a top-notch experience, from perfectly curated catering to enjoyable and engaging happy hours.”

Check out the schedule and register today at AttendICE.com.

Speakers are recognized as leaders in the HTM community who take time to enhance the professional development of others. Presenters may also add speaking engagements to their list of achievements on LinkedIn and their resume.

Presenters also benefit from networking with HTM colleagues from across the nation and gaining awareness of available resources.

For more information, visit mdexposhow.com/call-for-presenters.

HTM professionals are encouraged to vote for the 2026 Tech Choice Awards! Five finalists for each of the 14 categories were determined by nominations. Voting is open until January 9, 2026. The 14 award categories are:

• Association of the Year sponsored by MMS

• ISO Professional of the Year sponsored by MedWrench

• Director/Manager of the Year sponsored by MW Imaging

• Professional of the Year sponsored by Innovative Radiology

• Young Professional of the Year sponsored by Prescott’s

• Military BMET of the Year sponsored by College of Biomedical Equipment Technology (CBET)

• Outstanding Vendor of the Year

• Industry Influencer of the Year sponsored by SOMA Tech Intl

• Icon Award sponsored by Renovo Solutions

• Women in Leadership Award sponsored by Avante Health Solutions

• Humanitarian of the Year Award sponsored by Pronk Technologies

• Educator of the Year sponsored by Maull Biomedical

• Large Department of the Year sponsored by USOC BioMedical Services

• Small/Midsize Department of the Year sponsored by USOC BioMedical Services

The Tech Choice Awards (also known as the Wrenchies) are the people’s choice award for the HTM community. The winners are based 100 percent on the number of votes each finalist receives during the voting period. A special thank you goes out to the sponsors who help make the Tech Choice Awards possible. The sponsors do not have any input when it comes to selecting winners.

Wrenchie winners will be announced in an upcoming issue of TechNation with an award ceremony planned for the MD Expo Baltimore in April 2026.

Visit 1technation.com/techchoiceawards to vote for your favorites.

Enter the contest and help TechNation celebrate. Fill out the short form at 1technation.com/contest for a chance to win one of 12 prizes, each valued at $150 or more!

Additional entries to win can be acquired by sharing on LinkedIn or submitting a photo. Each month, a winner will be selected and featured in TechNation magazine! October winner is Corey Weeden.

Find out more information on Page 80.

Q: WHAT PRODUCT, SERVICE OR SOLUTIONS DOES YOUR COMPANY PROVIDE TO THE INDUSTRY?

Rytex Industries is your trusted source for replacement parts for X-ray, CT, MRI, Cath Lab, and RF systems. We proudly support trusted brands including GE, Philips, Siemens, Toshiba, Carestream, Del Medical, Canon, and Shimadzu.

With over 20,000+ OEM imaging parts in stock, we supply boards, DR panels, X-ray tubes, CT tubes, collimators, transformers, MRI coils, and more, all backed by a 90-day warranty and worldwide shipping.

In addition to our extensive parts inventory, Rytex offers complete installation and de-installation services for imaging systems and now provides X-ray equipment rentals, giving facilities flexible options to stay up and running without interruption.

Our mission is to keep imaging departments operating efficiently through dependable parts, expert support, and professional service, every time.

Q: TELL US WHAT DIFFERENTIATES YOUR COMPANY FROM THE COMPETITION?

What sets Rytex Industries apart is our commitment to reliability, transparency, and personal service. We’re not just a parts provider, we’re a partner to our customers.

Our team understands the urgency of medical imaging service needs, so we maintain a large in-stock inventory for same-day shipping and back every sale with a 90-day warranty.

At Rytex, we take a hands-on approach, offering tech support, testing all of our parts before shipment and responsive communication. Every order (large or small) receives the same level of care and attention that has built long-term trust with our clients across the U.S. and around the world.

Q: WHY DID YOU CHOOSE TECHNATION FOR ADVERTISING?

We chose TechNation because it connects us directly with the professionals we serve; biomedical engineers, imaging specialists, and healthcare technology management (HTM) leaders who rely on trusted partners to keep their systems performing at their best. TechNation’s readership reflects the same values we hold at Rytex: integrity, quality, and collaboration. Advertising through this platform helps us share our message with a community that values dependable service, proven solutions, and lasting relationships.

For more information, visit rytexindustries.com

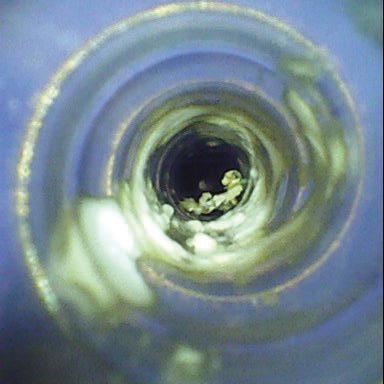

or 30 years, MedService Repair has been a trusted and independent service partner to endoscopy practices across North America. TechNation recently interviewed MedService Repair President Michael Goy to find out more about the company.

Goy: MedService Repair offers full-service repair and maintenance capabilities, parts and PM kits, and certified refurbished Medivators’ reprocessors. We also provide service and support for acquiring a broad range of necessary equipment and consumables including Scope Buddy flushing pumps, leak testers, flexible and rigid endoscopes, power tools, light sources, pigtails, filters and more. If it is used in endoscopy, we have a solution!

We are very excited about our enhanced ability to provide preventative maintenance kits used by biomedical engineers across the U.S.! When we started selling kits and break/fix parts, our customers asked us about enhanced training for their teams. We listened and developed two unique programs under the umbrella of MedService Repair University.

• Biomed training: At our corporate location, we have a program to provide hands-on training to certify biomedical engineers to perform preventative maintenance service and troubleshoot and address break/fix service needs on all Medivators Reprocessor models.

• Clinical training: At a customer location, a MedService repair clinical trainer will work with facility personnel to review scope handling procedures and offer an unbiased review of processes to enhance patient safety.

Goy: Facilities choose MedService Repair for our commitment to exceptional customer service and unmatched expertise in providing service and support on Medivators reprocessors. MedService Repair is led by multiple award-winning, Medivators-trained field service engineers who drive successful service outcomes and a team of account managers who anticipate customer needs and provide consultative solutions to support facilities. The quality of scope

reprocessing and handling practices leads directly to the quality of patient outcomes. Good health for your patients.

In addition to providing all of the above, we also offer significant cost savings compared to working with the OEMs. It is our goal to use our knowledge and experience to provide customers with the right advice in choosing the highest quality and most economical products. We believe in long-term relationships and will never pressure a customer to purchase new equipment when current equipment is operational and meets the needs of their practice. Good health for your practice.

Goy: MedService Repair is very excited to offer two enhanced enzymatic detergents to customers! Endocept and Medizyme represent the future of data driven enzymatic detergents for precleaning endoscopes prior to reprocessing. Our new products are developed for endoscopy while also being more cost efficient compared to current products in the marketplace. We offer free trials of these enzymatics to show customers the value in their own facility! We have another new product line launching in the start of 2026. This will be a very powerful solution to our market! More info to come …

Goy: When you work with MedService Repair, you can expect to receive exceptional service that meets the highest industry standards, using parts sourced exclusively from OEM-caliber providers – delivering top-quality performance at a fraction of the cost. MedService Repair is focused on providing the service a facility needs at the highest level possible. We are focused on being a partner to your facility and keeping your current equipment running at OEM specifications. Our focus is not on selling you replacement equipment that you do not need.

We are focused on listening to customers to design service programs that best meet their needs. The secret sauce is our ability to support a customer. The extra benefit is that they save significant spend working with us compared to the OEM. We are committed to our core values: Good health for your patients. Good health for your practice.

Dental equipment is healthcare equipment, but until now, the professionals who repair these devices are often unaware of the resources and support available to the healthcare technology management (HTM) field. Taking a crucial step to change this, the Association for the Advancement of Medical Instrumentation (AAMI) is bringing the popular “Dental Fix Summit” to the annual AAMI eXchange HTM conference.

“For a long time, dental equipment repair technicians have operated in a silo, similar to how our healthcare model has mentally separated dental care from medical care. UptimeHealth and AAMI wanted to change this narrative,” announced Jinesh Patel, CEO and co-founder of UptimeHealth after meeting with AAMI CEO Pamela Arora and AAMI HTM leadership.

UptimeHealth, a software and services company for outpatient healthcare, has built a strong presence in dental equipment management through its annual Dental Fix Summit. In a bid to bring that resource to the wider HTM community, AAMI has acquired the annual summit, with plans to make it a key feature of the association’s next annual HTM conference in Denver

Colorado, May 29 to June 1, 2026.

“We say dental care is part of healthcare. That means dental equipment is part of HTM,” added Danielle McGeary, vice president of HTM, AAMI. “Much like with hospitalbased HTM, dental instrument servicing is having pipeline issues, but the situation is made worse because folks aren’t as aware of the field or its challenges. By welcoming this community, we’re raising awareness, broadening personnel pipelines, and helping to ensure patients everywhere benefit from safe and effectively serviced devices.”

AAMI’s initial five-year plan for the acquisition includes continued collaboration between AAMI and UptimeHealth, with the co-creation of a dental pavilion on the expansive AAMI eXchange expo hall floor. There, HTM professionals will be able to meet with dental equipment vendors and specialized service providers. The pavilion, sponsored by UptimeHealth, will host 30 vendors and service providers supporting the dental industry.

Additionally, the 2026 eXchange will host hands-on demonstrations and educational presentations intended for dental equipment technicians. A plan to create a dental track of educational sessions at future eXchange conferences is in progress. According to AAMI, the track will see overlap into the conference’s popular sterilization track for device reprocessing – another significant area of interest for dental device service technicians.

“This is going to be a natural, wonderful synergy,” said Patel. “We’ll bring dental vendors and service technicians right to the center of the expo floor, making them feel included in the HTM world.”

The FDA’s Center for Devices and Radiological Health announced a pilot program last year called the Communications Pilot to Enhance the Medical Device Recall Program, designed to shorten the delay between FDA’s initial awareness of a potentially high-risk medical device issue and public communication to health care providers, patients and the public.

The “Early Alert” is distinct from a formal recall announcement. The FDA can issue an early alert when they deem the risk to be significant, even if they haven’t yet completed the full evaluation or determined if the issue warrants a recall.

Initially, the pilot was limited to devices in five categories (cardiovascular, gastrorenal, general hospital, obstetrics & gynecology, and urology) but on September 29, 2025, FDA announced the program has expanded to cover all medical devices for potentially high-risk removals or corrections.

“ECRI strongly supports the FDA Early Alert Pilot Program as an important step toward improving responsiveness and speed in our nation’s medical device safety infrastructure. It’s good for the industry and good for patient safety,” said Scott Lucas, vice president of device safety at ECRI. “By sharing alerts faster, the FDA can better equip healthcare professionals and patients to make informed decisions faster, helping to prevent harm and support timely corrective action.”

“At ECRI, we have long advocated for the need to improve the timeliness of communication surrounding unsafe medical devices. The problematic gaps in our nation’s recall process for at-home medical devices made the #1 spot in our annual research report in 2023, the Top Ten Health Technology Hazards,” Lucas added. “We commend the FDA for its commitment to continuous improvement. Initiatives like this strengthen public trust and demonstrate how clear, rapid communication can protect patients.”

“The quicker that FDA and manufacturers can notify healthcare providers of safety issues, we’re fully supportive of that,” agreed Tom Toczylowski, associate director of ECRI Alerts. “We’ve engaged with the FDA on this topic numerous times over the last several years, including before they launched this pilot program. The program’s expansion is a positive step forward.”

Now, when a device manufacturer initiates corrective actions for a potentially serious issue, the FDA may issue an Early Alert even before confirming whether a full recall is required. The FDA still retains its usual recall processes, but Early Alerts are an additional layer of more proactive communication that’s faster than the FDA’s previous process.

ECRI publishes exclusive hazard alerts which sound the alarm about potential threats in devices and pharmaceuticals long before they turn into potential recalls. ECRI remains the fastest and most comprehensive source for coverage of medical device safety issues, often sharing hazard alerts weeks or months before the FDA. Learn more about ECRI.org.

BY BOYD S. CAMPBELL CBET, CRES, CHTM

s biomedical professionals, we often work behind the scenes – ensuring equipment is safe, calibrated, and reliable before it ever reaches a patient. It’s easy to think of what we do as purely technical work, but every now and then, something happens that reminds us of the human side of our profession.

While in biomedical school, there was one lesson that always stood out: “Never walk away from a device unless you would be comfortable having it used on a loved one.”

That principle really hit home for me about a month ago. My fiancée was diagnosed with a rare form of breast cancer that accounts for only about 1% of all breast cancer cases. It was discovered in one of the most unlikely places – the dermatologist’s office.

Fortunately, the dermatologist had seen one similar case before in his career and immediately performed a biopsy. Unfortunately, the results came back positive for Paget’s Disease of the breast.

As our journey continued, the next stop was the surgeon’s office to prepare for surgery – only the third such case he had ever treated. The surgery went well, requiring a partial mastectomy. From there, we visited the oncologist and then the radiation oncologist. It’s a path many others have walked before, but for me, the biomed side of my brain couldn’t help but pay attention to something else along the way.

At every stop, I found myself checking the inspection stickers on the medical equipment being used. At the dermatologist’s office – where the biopsy was performed – the equipment had been inspected by Southeastern Biomedical. At the surgeon’s office, the same. The oncologist’s office? Once again, Southeastern Biomedical.

But the story doesn’t end there. As my fiancée continues her journey, she is now preparing for radiation

therapy. Knowing the facility where she will receive treatment, I have the utmost confidence in the care she will get. Why? Because I know that the devices the radiation physicist will use are of the highest quality. How do I know this? I’ve supplied that facility with Fluke Biomedical and Raysafe products for many years. And there’s one more reason for my confidence — Southeastern Biomedical provides the on-site calibration services for all their biomedical test equipment.

As a biomedical technician and co-owner of Southeastern Biomedical, that realization struck me deeply. What we were taught in school wasn’t just a professional standard or a safety protocol – it was a life lesson. It reminded me that the work we do every day truly touches people’s lives, sometimes in the most personal way imaginable.

Every inspection, every calibration, and every record we document represents a promise – that someone’s loved one can trust the device being used to diagnose or treat them. That’s why we can never forget that early lesson: “Never walk away from a device unless you’d want it used on someone you love.”

Boyd Campbell, CBET, CRES, CHTM is the co-owner of Southeastern Biomedical Association.

TechNation’s recent Webinar Wednesday presentation “Bridging the Gaps in Healthcare Operations: How Digital Procurement Drives Standardization, Savings & Uptime” was popular among HTM professionals. Sponsored by PartsSource, the webinar is eligible for 1 CE credit from the ACI.

In today’s complex healthcare environment, health systems are under increasing pressure to reduce costs, maintain equipment uptime, and overcome staffing shortages – all while advancing digital transformation goals. Yet many organizations still rely on outdated, manual processes to manage critical parts and service procurement.

In the webinar, PartsSource Chief Commercial Officer Jeff Evans shared how leading health systems are modernizing their operations by leveraging data-driven, tech-enabled solutions that deliver immediate ROI, drive standardization and unlock clinical capacity.

Evans discussed how automation and digital procurement platforms are transforming healthcare technology management and supply chain workflows. He shared the operational impact of shifting from transactional sourcing to strategic vendor management. He also discussed ways to reduce clinical equipment downtime through predictive analytics and network optimization. In addition, Evans talked about how to identify and eliminate hidden cost variability across a system.

Attendees were also able to ask questions during the session.

Martin O’Brien, a biomedical technician instructor with RTS Medical in Wisconsin won a Swiss Force Meister Multi-Tool during the webinar.

Attendees shared feedback via a post-webinar survey that included the question, “What does Webinar Wednesday provide the industry?”

“Insight into what is trending,” said Chad Rivers, BMET II, Children’s Health.

“Webinar Wednesday provides free, high-quality educational sessions that help healthcare professionals stay informed about innovations, best practices and operational strategies in the industry,” said Hia Al Saleh, a biomedical engineer with St. Clair College.

“An opportunity to gain insight and knowledge of current industry status, changes and the future of HTM,” Franciscan Health East BMET III Brian Snyder, CBET, said.

Watch these webinars on-demand

TechNation’s Webinar Wednesday series featured “Reactive Mode to Leader Mode” by Eric Massey on October 1. The webinar, which is available for on-demand viewing at WebinarWednesday.live, is eligible for 1 credit from the ACI.

This webinar shared the ongoing shift from Reactive Mode – a state of constant firefighting and reactivity – to Leader Mode – where leaders intentionally focus on high-impact priorities.

Participants were able to join Massey as he explored the Core Day framework and the 60/40 Rule as practical tools for structuring time and energy more effectively. Through guided reflection and a practical exercise, attendees were able to identify one leadership habit to implement immediately and receive a sample Core Day planner page to reinforce learning.

Massey delivered several takeaways for attendees including how to:

• Identify where you’re stuck in Reactive Mode and discover why it keeps even the best leaders from performing at their peak.

• Learn the Core Day Framework – a proven structure to protect your time, focus and energy for what truly matters.

• Experience the 60/40 Rule in action and see how elite leaders prioritize their day for maximum impact.

• Create one immediate leadership shift by replacing a reactive habit with an intentional one.

Massey also emphasized the message, “Your job should support your life, not be your life.”

This was a popular webinar with 83 tuned in for the live presentation. The on-demand recording has been accessed by several people. A video link to watch the webinar is 1technation. com/reactive-mode-to-leader-mode-massey/

Gerald McNeil, a BMET III, GE HealthCare in Maine won a Swiss Force Meister Multi-Tool during the session. McNeil and other attendees provided insightful feedback regarding the webinar via a survey that included the question: “What does Webinar Wednesday provide the industry?”

“Continued growth and educational opportunities especially when training dollars are scarce,” said Paul Neher, a supervisor of biomedical service at Parkview Health.

“An excellent way to get CE credits and useful information,” said Dan Harper, CE manager, with Intermountain Health-St. Mary’s Regional Hospital.

“A variety of topics that are pertinent to the biomed world,” said David Taylor, a Senior BMET III with Baylor Scott & White.

“Practical tools/helps for the HTM community,” said David Banister with Clinical Engineering Services.

“Learning and professional development opportunities,” said Samantha Edmonds, an imaging service engineer with Intelas.

The recent Webinar Wednesday Tools of the Trade presentation “Downtime Trace+SkillNet: The Future of HTM Workforce Readiness” explored a new frontier in healthcare technology management (HTM). The trio of presenters shared a new high-tech way for HTM professionals to add gig work and track their skills and capabilities.

SkillNet Founder and CEO Mike Kritzman provided detailed insights regarding the SkillNet app and how its many features provide a quick and easy avenue to record repair work, education, training and more.

Downtime Trace Chief Products Officer and Co-Founder Jason Mobley along with advisor Dave Francoeur discussed how the Downtime Trace app delivers an on-demand marketplace that connects hospitals with skilled technicians in moments of urgent downtime. Health systems can immediately locate skilled professionals to keep equipment online without patient care being interrupted.

Together, Downtime Trace and SkillNet solve one of the industry’s biggest challenges: matching the right talent to the right need, at the right time.

SkillNet provides the Downtime Trace marketplace with accurate, validated and standardized transcripts that capture a service technician’s training, certifications and on-the-job experience in one portable record. By creating a common language of skills, SkillNet ensures hospitals know exactly what work each technician is capable of performing.

The combined value includes:

• Speed: Hospitals engage qualified service companies and technicians within minutes

• Trust: Skills are transparent, validated and consistent across the industry

• Efficiency: Less time spent on paperwork, more time solving other downtime challenges

• Opportunity: Professionals gain visibility and recognition for their expertise

The presenters also fielded questions during the webinar.

The webinar is eligible for 1 CE credit from the ACI and a recording of the presentation is available for on-demand viewing at WebinarWednesday.live. HTM professionals everywhere can join the 42 attendees present for the live webinar in expanding their knowledge while also earning CE credit.

Michael Lucas, an imaging biomedical technician with Columbus Regional Health in Indiana, won a Swiss Force Meister Multi-Tool during the webinar. He and others participated in a post-webinar survey that included the question, “What was your single biggest takeaway from today’s product demo?”

“Using tools to track time,” said Dat Ha, a biomedical technician with Children’s Health.

“Just seeing how technology is evolving in our field,” said Todd Walker, a biomed with Oregon Health & Science University.

“No more spreadsheets to track techs’ abilities and training,” said Casey Celver, a biomed with Legacy Emanuel.

“Importance of training tracking,” said Joseph Manning, BESS, ICVAHCS.

DEMO: DECEMBER 10 at 2PM ET

Registration on WebinarWebnesday.live

Eligible for 1 CE credit from the ACI.

This educational webinar highlights the importance of training and certifying biomedical engineers to serve as Medical Laser Safety Officers (MLSO) in a healthcare facility. Biomedical engineers should be Laser Safety Officers (LSOs) because their technical expertise with medical devices, understanding of safety protocols and familiarity with equipment maintenance and calibration make them ideal for managing complex laser systems and ensuring patient, staff and public safety in healthcare environments. Their technical background directly aligns with the need for precise risk assessment, implementation of control measures and adherence to strict ANSI standards.

The course objectives include the duties of the MLSO, a specially trained professional responsible for ensuring the safe use of lasers in medical settings such as hospitals, surgical centers, vision clinics and dermatology offices. This webinar will review the MLSO role as defined and guided by ANSI Z136.3, the American National Standards Institute (ANSI) standard for the Safe Use of Lasers in Healthcare. In addition, the webinar will discuss the benefits of having biomedical engineers assume this regulatory role within the facility-based laser program.

For more information, visit medicallasersafety.com

TechNation invited HTM experts to participate in this roundtable article focused on education, training, and apprenticeships in order to share their opinions with readers. The goal is to highlight challenges, successes and insights related to workforce development – how technicians are trained, how programs are evolving, and what the future holds for education in this vital profession.

Participants in the 2025 Roundtable article on education, training, and apprenticeships are:

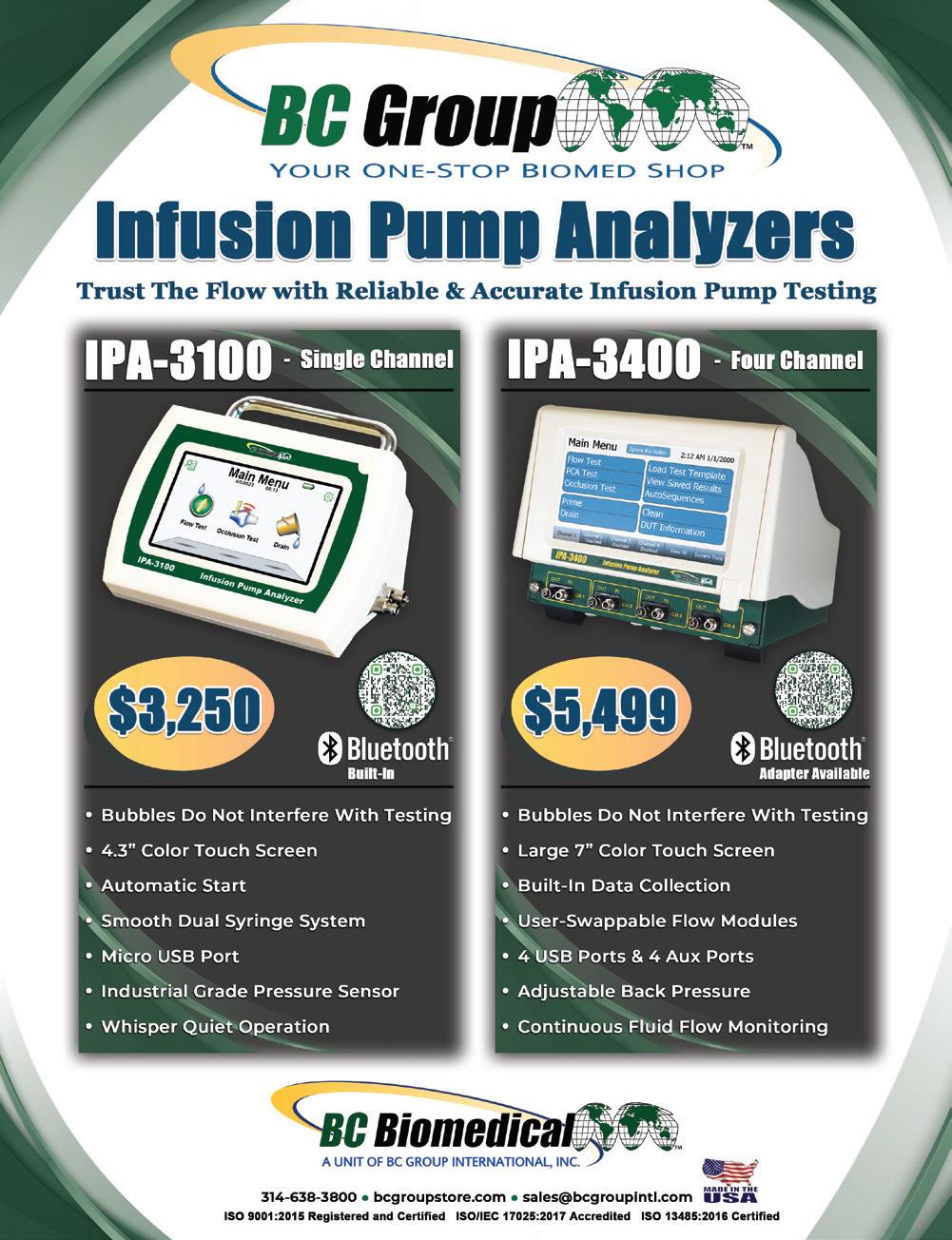

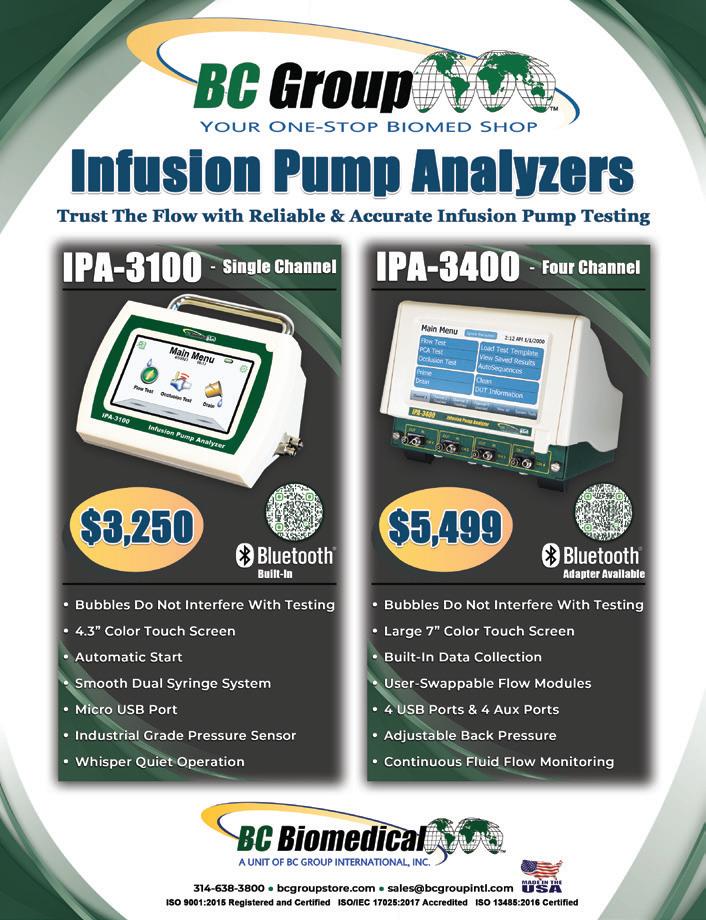

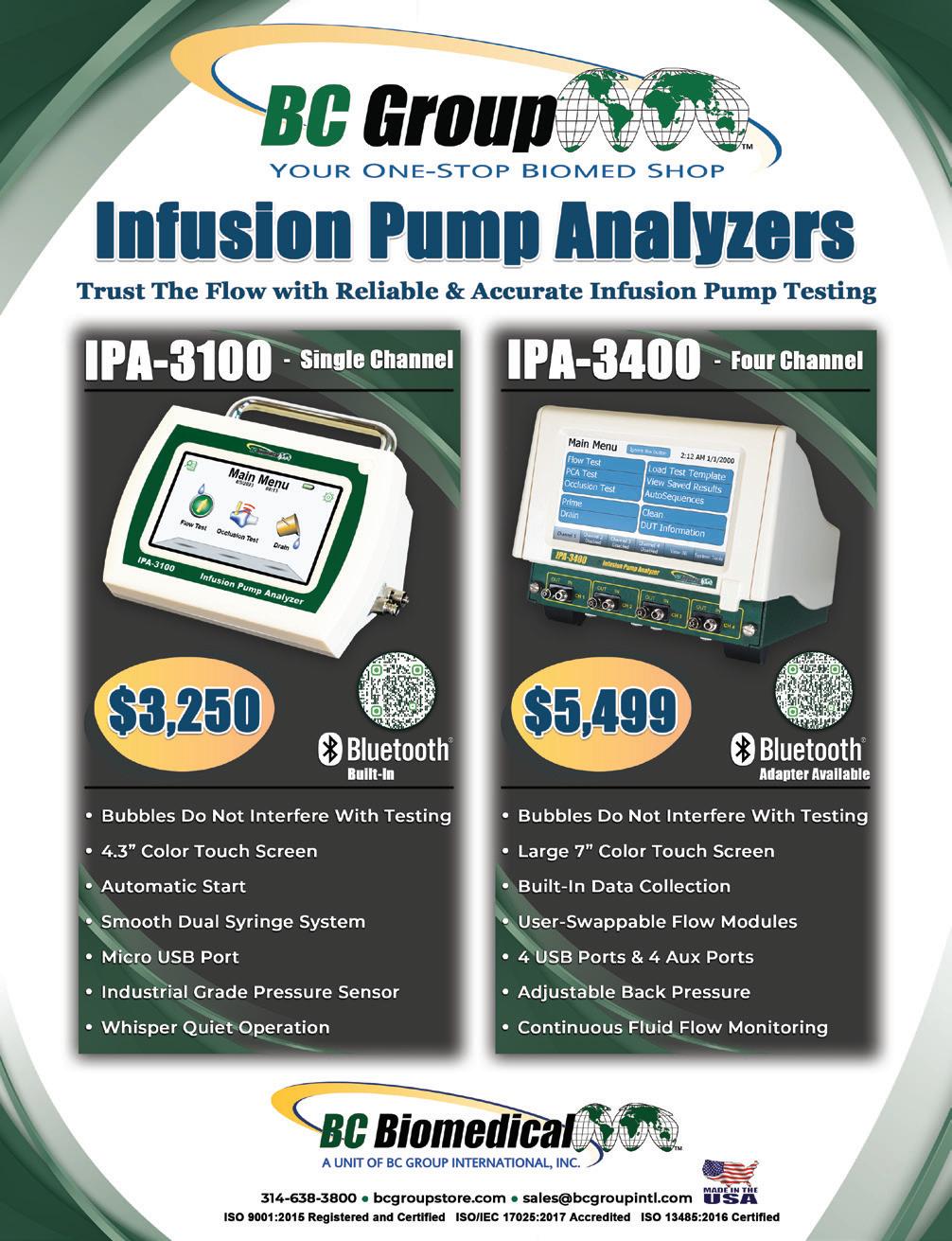

• BC Group International Director of Business Development Justin Barbour;

• College of Biomedical Equipment Technology President Richard L. “Monty” Gonzales;

• Innovatus Imaging Director of Commercial Operations and instructor in Penn State’s Biomedical Engineering Technology Program Ted Lucidi;

• Maull Biomedical Training LLC Owner Stephen Maull;

• Radiological Service Training Institute (RSTI) CEO Todd

Boyland, CRES, CPSM;

• Renovo Solutions Technical Training Manager Donald Armstrong, CBET, CHTM, CABT, CRES; and

• Webinar Wednesday Marketing Manager Linda Hasluem.

Q: WHAT DO YOU BELIEVE ARE THE MOST CRITICAL SKILLS OR AREAS OF KNOWLEDGE THAT TODAY’S HTM PROFESSIONALS NEED?

BARBOUR: The most powerful skill we possess is also the one we often overlook: communication. It’s the foundation of every successful technician. Technical mastery means little if you can’t clearly connect with people. Each day, we engage with medical staff, administrators, vendors, contractors, patients and, yes, even the machines themselves.

GONZALES: In the rapidly transforming field of healthcare, the most critical skills for today’s professionals revolve around a fusion of technical mastery and adaptive expertise to address megatrends like AI proliferation, cybersecurity imperatives, and the demands of an increasingly varied field of necessary expertise. Foremost are proficiencies in emerging technologies – such as AI supporting predictive

equipment maintenance, secure HIoT architectures for connected medical devices, and a nuanced understanding of advanced data analytics for life cycle optimization –which are indispensable for safeguarding patient safety. Complementing these are essential soft skills, including problem-solving, cross-disciplinary communication to align technical and clinical teams, and ethical acumen to empower HTM professionals. To cultivate a truly future-proof HTM workforce, three paramount training requirements must take center stage. First, blending curricula across biomedical, dental and veterinary device maintenance to foster versatile professionals who seamlessly service interconnected ecosystems, thereby reducing silos and enhancing crosssector efficiencies. Second, expanding technicians’ roles via advanced certifications in diagnostic imaging, linear accelerator operations and other domains to enable proactive interventions beyond conventional pathways. Third, conditioning and equipping technicians for on-demand, justin-time training through digital platforms, AR/VR and other innovative methods – prioritizing adaptive upskilling to align with fiscal realities and emergent demands, empowering lean teams to achieve more while transforming constraints into catalysts for innovation.

LUCIDI: As an instructor in Penn State’s biomedical engineering technology program, I believe that some of the most important skills for someone entering HTM are related to soft skills and customer service. We can educate most individuals on the how-to’s of troubleshooting, servicing and performing preventive maintenance. It’s more challenging to develop excellent customer service skills. Oftentimes in HTM, we have to fix the people, not the device. Many of today’s, and more of tomorrow’s, medical devices are and will be integrated into PC architecture. From a content perspective, students will benefit from programs that include content on PCs, networking and cybersecurity.

MAULL: The most important skill a BMET needs to have is ‘people’ skills. That is a skill that you kind of either have it or you don’t. Anybody can be taught how to maintain medical equipment, but it’s more difficult to make someone more of a people person than they currently are. You want the department to be glad to see you when you arrive, not be like, “Oh man, they sent Steve! I can’t stand Steve.”

BOYLAND: Today’s HTM professionals need a balance of technical proficiency, critical thinking and communication skills. As equipment becomes more integrated with networks and data systems, understanding connectivity, cybersecurity and interoperability is just as important as understanding the imaging hardware itself. At RSTI, we emphasize hands-on experience and root-cause troubleshooting because the ability to think through complex problems – not just follow a service manual – is what sets great engineers apart.

ARMSTRONG: While our field is highly technical, I believe the most critical skills for today’s HTM professionals are life skills – often called soft skills. Throughout my career, these have not received enough focus in training. If we can prioritize and empower our teams to develop and use skills such

as communication, ethics, teamwork, openness, humility, willingness and a positive attitude, then technical training becomes much easier by comparison. Strong life skills create stronger, more adaptable technicians.

HASLUEM: Definitely communication – it should be the number 1 critical skill! Strong communication is vital for teamwork with hospital/clinical colleagues and vendors. Being a good problem solver is a good skill to have too. With the rapid advancements in healthcare technology, HTM professionals definitely need a varied blend of technical expertise. The HTM field has expanded far beyond traditional equipment repair to cybersecurity, data analytics, etc. so they need to stay current with the latest technologies transforming the industry. Here at TechNation, our Webinar Wednesday series has seen a big shift in webinar subjects over the past couple of years. Our traditional equipment webinars are still popular, especially our Tools of the Trade live demos, but the interest in our technical and IT skills webinars, especially cybersecurity, have generated a lot of interest and are always well received and attended.

Q: HOW EFFECTIVE DO YOU THINK CURRENT HTM EDUCATION AND TRAINING PROGRAMS ARE IN PREPARING NEW TECHNICIANS FOR THE FIELD? ARE THERE SPECIFIC GAPS OR STRENGTHS YOU’VE OBSERVED?

BARBOUR: In many ways, modern technician training has become more effective than ever before. Students and instructors now have access to an incredible range of resources that deliver the latest information in highly engaging and accessible formats (videos, whitepapers, safety recalls, social media and even AI-driven tools). Training materials and supplies are also more readily available than in the past. A thriving market for used medical equipment, along with affordable electronics components from platforms like Amazon and AliExpress, allows technicians to practice and refine their skills.

GONZALES: Key gaps include insufficient emphasis on core skills for emerging technologies, such as AI-driven predictive maintenance and HIoT integration, which hinders technicians’ proactive innovation; a lack of foundational training in ethics within healthcare technology management; underdeveloped skills in effective communication and customer service, essential for clinical collaboration and the adoption of a patient-centered approach; inadequate coverage of compliance and the evolving regulatory environment; pronounced deficiencies in cybersecurity and medical device integration, exposing graduates to risks in networked, datavulnerable systems; and other shortfalls, such as limited focus on developing the next generation of HTM leaders. Bridging these gaps through industry-informed education and training programs is essential to equip technicians for resilient, forward-thinking contributions.

LUCIDI: I believe that the current content provided by most HTM programs is meeting the needs of the field. Today’s technology moves at an outstanding pace. It’s challenging for today’s institutions to “show” the latest technology. It’s

important to focus on fundamentals, not the latest tech. Whether techs are testing the latest, flashy, new physiological monitor, or one that’s 10-15 years old, the same parameters need to be verified. Simulators change and monitors change, but the parameters being verified are the same. If an institution focuses on the fundamentals, it’s preparing students for any level of technology.

MAULL: I know that there is more help than ever before. Several companies are making training more accessible by doing the training remotely or bringing the training on-site, which is getting more and more common.

BOYLAND: HTM programs are doing a commendable job introducing the fundamentals, but there’s a noticeable gap between classroom theory and field-ready confidence –especially in advanced imaging. Many new technicians have the desire and baseline knowledge but need applied, real-equipment exposure to transition effectively into a service role. That’s where RSTI’s model excels – our training center houses more than 70 fully functional imaging systems and offers a 4:1 student-to-equipment ratio so every learner develops real-world proficiency.

ARMSTRONG: We believe that current HTM education and training programs are strong in developing technical knowledge, but there is a significant gap when it comes to preparing new technicians with essential personal and professional skills. Our Renovo internal training courses do an excellent job of covering the technical aspects of the role, which are both important and necessary. However, once new technicians enter the field, they often face challenges communicating effectively with clinical staff and hospital leadership – skills that require deliberate development. In addition, a strong understanding of safety and regulatory requirements is critical. We place great emphasis on ensuring our new technicians are well-rounded, combining both the technical competence and interpersonal skills needed to succeed in any environment.

HASLUEM: Here at TechNation, I hope that our Webinar Wednesday series helps prepare new technicians by providing more than foundational knowledge. Our webinars offer a wide range of topics which cater to all levels of abilities. I have noticed an increase in student attendees over the past couple of years, especially for our Tools of the Trade live demos, which have grown in popularity, so I hope that we are doing our bit to help prepare a new generation of biomeds for the field!

Q: DOES YOUR ORGANIZATION PARTICIPATE IN OR SUPPORT APPRENTICESHIP OR INTERNSHIP PROGRAMS?

BARBOUR: While BC Group International does not offer a formal internship program due to the sensitivity of our laboratory and manufacturing environments, we have a long-standing tradition of identifying exceptional individuals and developing them into outstanding professionals. Our company maintains strong relationships with many of the leading industry schools, and we actively support internships

through training, mentorship and placement assistance.

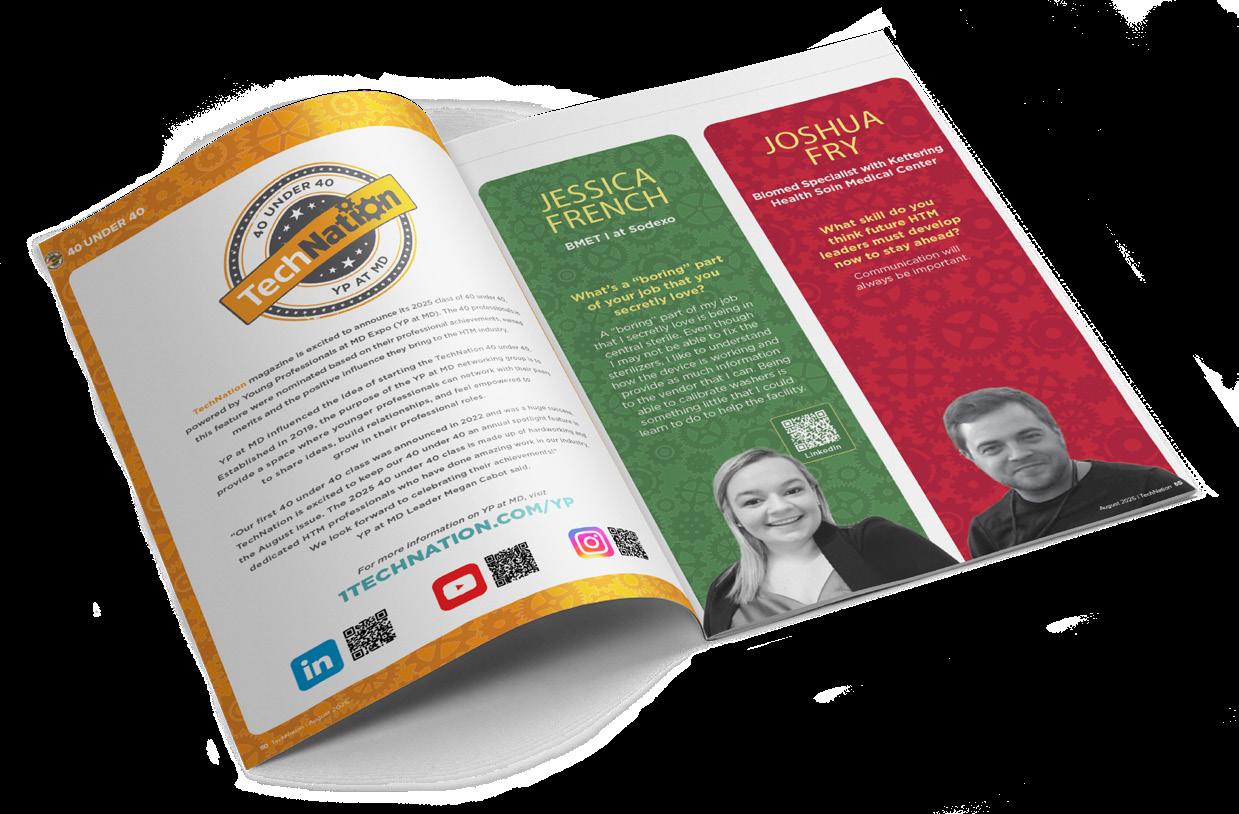

GONZALES: Yes, the College of Biomedical Equipment Technology is deeply committed to apprenticeship, internship, and on-the-job (OJT) training programs, viewing them as vital bridges between students and our employer partners. Apprenticeships have ebbed and flowed in popularity over recent decades – once a cornerstone of skilled trades that declined with the rise of formal academia – they are now resurging as an attractive option for healthcare organizations seeking to build pipelines of trained technicians while managing budgets, with apprenticeships, pre-apprenticeships and hybrid OJT initiatives providing an effective means to achieve both. We have long championed the Association for the Advancement of Medical Instrumentation (AAMI) Apprenticeship Program. Our recent collaboration with American Healthcare Apprenticeships (AHA) has further enabled the college to expand its national reach, introducing students to HTM education and career pathways. Last year, we formed a partnership comprising AAMI, AHA, the college and HOSA-Future Health Professionals. This year, HOSA-Future Health Professionals formally introduced and launched a biomedical equipment technician competitive track for talented high school STEM students nationwide. We take great pride in this partnership and the opportunity to engage with the talented students participating at state and national levels and feel strongly that this initiative will fuel interest in apprenticeship opportunities.

LUCIDI: Innovatus, because of our specialized focus, is rather limited on the content that could be shared during a full apprenticeship or internship program. We are open to students shadowing our techs, but apprenticeship programs are best hosted by healthcare facilities and independent service providers with a wide scope of support. Students are best served by selecting an internship or apprentice program (or site) which offers exposure across the widest variety of devices and environments.