6 minute read

Product Lifecycle

Shorter Product Lifecycles: The Digital Print Solution

In response to these changing times, brands today must be extremely agile and responsive. Their offerings must be refreshed often, showing not only innovation and creativity, but a desire to engage and connect with consumers.

Above all, the pressure on brands to get to market quickly is stronger than ever before. The product lifecycle has changed dramatically, with speed to market increasing by over 70% over the last several decades. Brands must keep up, or risk being left behind.

A comprehensive solution

Digital printing is becoming increasingly attractive to brand owners because it offers production flexibility, a versatile substrate range, customization and shorter delivery times.

Quality and versatility

Digital printing has the challenge of meeting all the established quality and application expectations of traditional offset and flexo processes, and does so flawlessly, albeit with a very different printing process. Productivity gains can be made from the automated workflows that digital printing boasts and lead times are greatly reduced from those of traditional printing processes.

Though traditionally thought of for lower volumes and/or multiple SKU’s, digital printing can be a great solution for traditional offset users with unique one-off projects or promotional campaigns.

Another way to demonstrate the flexibility of this technology is through the marketing possibilities that customers and brand owners can take advantage of. Digital press platforms can have different designs

Product lifecycles are getting shorter

1980’s

1980’s 1990’s

1990’s 2000’s

1,08 Years 1,67 Years

1,67 Years 2,25 Years

2,25 Years

2000’s Today

Today Tomorrow

0,62 Years

0,62 Years 1,08 Years

Tomorrow 0 100 200 300 400 500 600 700 800 900

0 100 200 300 400 500 600 700 800 900

Digital saves you time and money by optimizing production

Print what Is needed, when it is needed! Product lifecycle:

Analog printing workflow

Design & Prepress

Plate making Make ready registration

Digital printing workflow

Make ready color Printing Converting Finished product

Design & Prepress Printing Converting Finished product Storage Storage

on each sheet, enabling customers to test market a design. Digital allows for changes to colors or design with immediate visibility. This is a great way to decide between concepts before doing a complete run. Today, brands can print countless different designs and test their products live on the shelf. With this real time consumer feedback, brands can then go to production with only the designs they know resonate with their consumers.

For customers who are traditionally printing via flexo or offset, there are many use cases where digital print can be the perfect solution: • Holiday campaigns • Temporary/unique marketing or promotional campaigns • Point-of-sale displays • Private label offerings Print on demand also offers greater flexibility. Label design changes can be made on the fly without having to wait weeks to get a new batch of pre-printed labels or scrap existing printed inventory. Customers also could customize products in bulk in an affordable way; they are never required to order large batches of labels to get a reasonable price.

3 4

1 2

Market testing

Market acceptance needs to be tested - low volume requirements. Digital permits several short runs as pilots in the market. Product launch

Once the product is proved viable, the brand produce the volume needed per reasonable time in the market, 2-3 weeks. Controlled supply

Here the brand enters a phase of fragmented deliveries helping supply chain and reducing inventories / risk Product Refresh

This can last as long as the product remains under one graphics, if there is a need for a refresh, the graphics can be altered at low volume until…

5

Phase Out

The brand wants to discontinue this product and orders decrease up until fade out.

Margot & Tita Chooses Digital Printing to Conquer the World of Fragrances

Margot & Tita is a French fragrance brand which stands for nature and simplicity versus luxury and sophistication. They believe perfume is like clothing, it goes along with your style and mood. Each fragrance expresses something different, and these expressions correspond to different occasions, desires, styles, and activities. The collection was created in a way that allows each and every client to create her/his own fragrance by mixing multiple perfumes. When seeing the fragrance labels, you immediately experience what the fragrance stands for.

New launch

Margot & Tita’s fragrances are available online and in department, duty free, drug and perfume stores. As a fast-growing business, Margot & Tita’s team contacted MCC to create 70,000 labels spread over 7 SKU’s, within 7 days for their launch in one of the largest beauty & drug stores in Poland.

Speed to market

MCC Europe used digital printing to deliver the speed to market and volume of pressure sensitive labels needed for this project. By using digital printing, MCC was not only able to deliver the labels on time, but also had possibility to add embellishments at a decent cost. On the contrary of what’s mostly expected, digital is more cost-effective for smaller volumes.

A premium look

As a result, MCC used a silver material with a shiny lamination to provide a premium look on the body mist bottles. This gave the scented body mist bottles a luxury appearance, setting them up for success to conquer the Poland consumer market!

Julie Schoell,

Founder at Margot & Tita

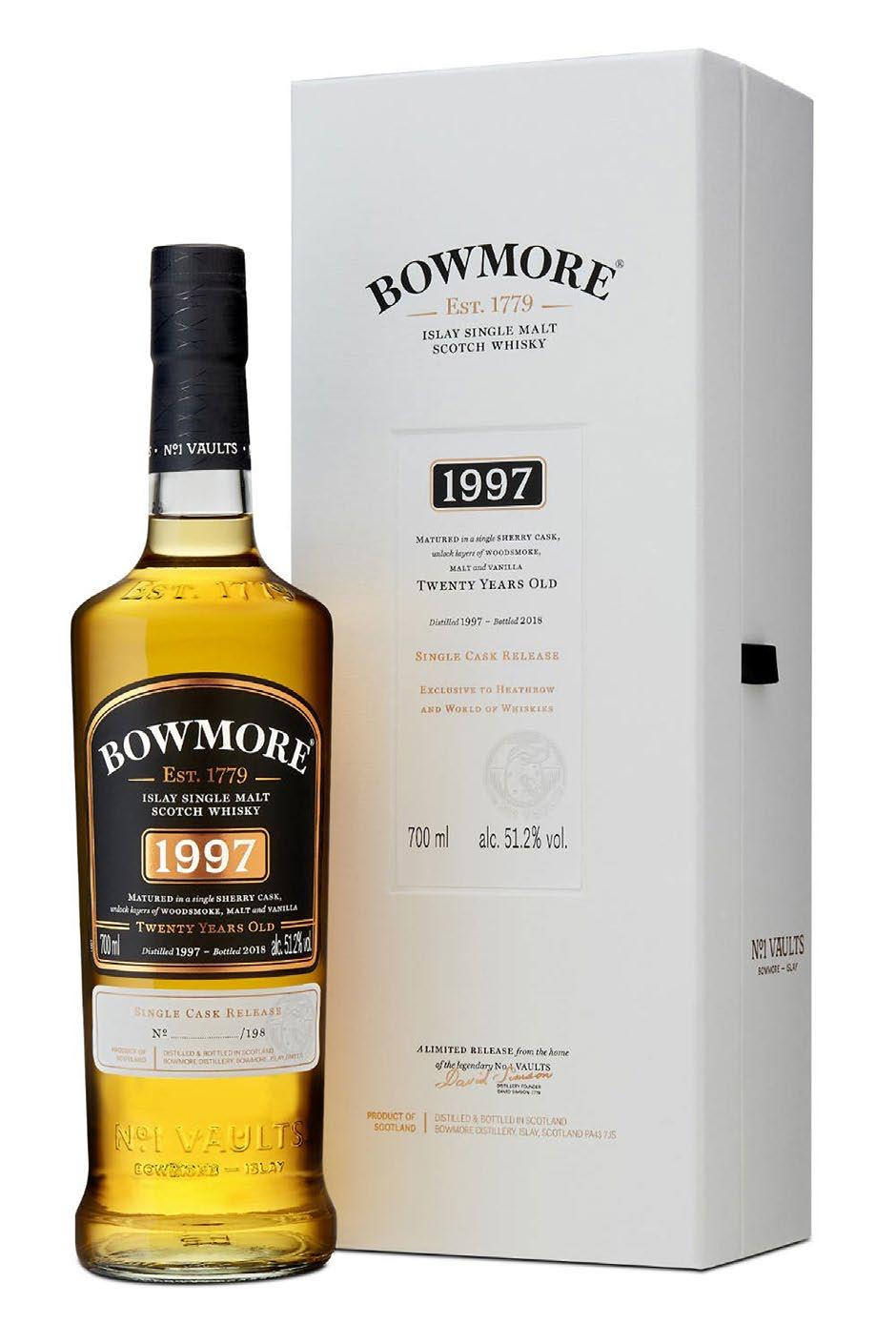

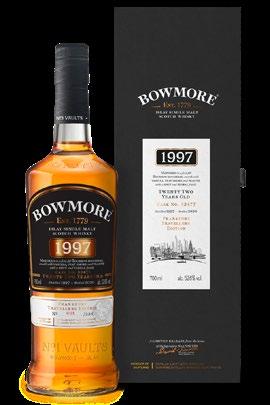

Limited Edition Bowmore® 1997 Single Cask Release

Beam Suntory | MCC Glasgow

Beam Suntory’s Bowmore is a pioneering distillery, home to one of the world’s oldest Scotch maturation warehouses. Bowmore single malt whiskys have been meticulously matured and transformed there for over 240 years.

Whisky definitively shaped by time

Matured for 24 years, the Bowmore 1997 single cask whisky is a limited edition that required a one-of-a-kind promotion. Beam Suntory chose to exclusively launch the product for global travel retail. The select packs were available at Frankfurt and Heathrow Airport in small quantities (less than 600 per cask).

Ed Stening, Global Marketing Director of Beam Suntory Global Travel Retail, says: “Bowmore is a Single Malt with an incredibly rich history rooted in our legendary No.1 Vaults, which has shaped the distinctive character of whiskies made here for over 200 years. As a brand, Bowmore is growing fast in Travel Retail and is very popular with travellers looking to take home a slice of this history and character.”

The traveller’s edition

Due to their collectible nature, each bottle required a unique label. The label needed to reflect the cask information in which it matured as well as being individually numbered. The variable nature of digital print coupled with the short run requirements made it the perfect printing solution for this project. MCC Scotland employed its HP Indigo 6800 press to print the variable elements of the label. To follow, they moved to the digicon press to finish with copper and white foils and complete embossing on the brand name. The bottles were presented in rigid boxes which reflected the same cask information. The box wrap can also be produced on MCC’s digital presses before being sheeted prior to conversion onto the box casings.