Is the role of a business partner that controllers are aspiring to only a “wishful thinking”, or real support for managerial decisions?

DR INŻ. JERZY SZKWAREK

Companies’ external surrounding

Companies’ internal perspective

Change of competition paradigm

Companies’ strategic goals (company – market)

New approach to operational controlling

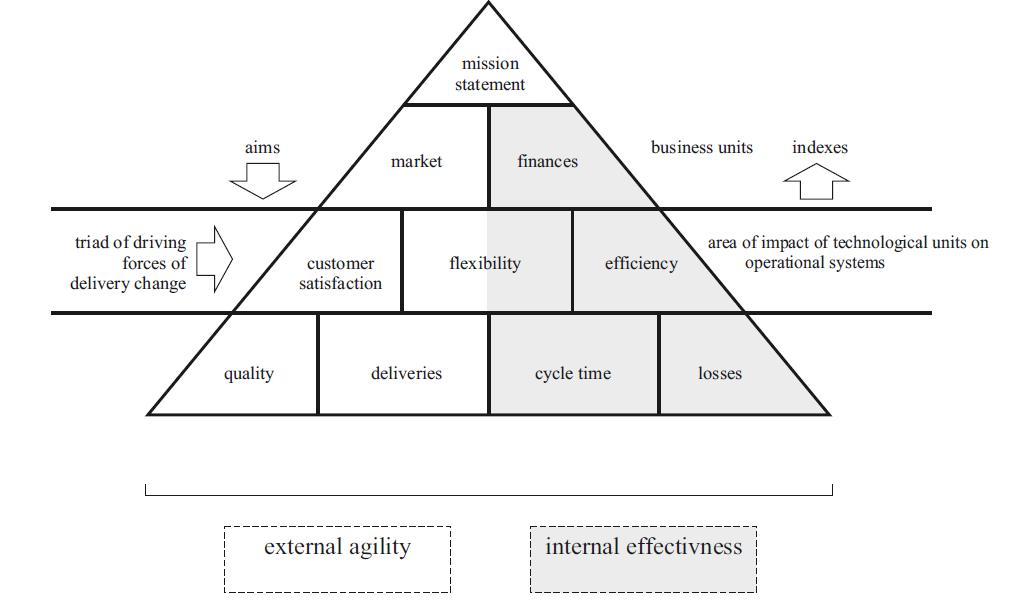

Three-dimentional model of measuring conceptions

Functional and process dimentions Financial dimention

Synchronization of strategy tactics and operations

Integrated model of value chain Conclusion Summary

Economic cycles have been distorted

Emotions govern market participants’ behavior which leads to deflections

Strategies of balancing require companies to be able to quickly adjust to changes (adaptation)

The Internet and new communication technologies radically change reality

Constant pressure to reduce price and increasing „commoditization” have beome reality

Wikinomy supplants economy (Google, Facebook, Amazon, Apple)

Logistic networks support traditional formulas of supply chains

Consumer:

Consumer has transformed into Prosument

Quality and time play a crucial role selling transactions

Customer is expecting still more for less

New relation C2B is emerging – the business is „socialized”

Traditional methods of reducing operational costs have already almost been depleted.That is why enhancing effectivity in the range of whole supply chains may be a considerable source with high potential to gain competitive advantage.

It is necessary to look out for new managerial methods questioning established stereotypes (dynamic process management)

The natural conflict arising among sale, logistics and finances should be tapped into as a source of inspiration to creat innovative and strategic aims

Due to a wide range of application possibilities of the dynamic development of information technologies there is the need to change organization of carried out processes

Knowledge of real parameters concerning logistic processes makes it possible to improve efficiency in functioning whole supply networks

Companies looking for new opportunities for new operations must carry out simultaneously conflicting short and long term aims. (Lean Management and Agile Management)

- Production according to forecast

- Central stock management

- Looking for advantages resulting from the scale effect

- Production to order

- Using quick response to demand (QR)

- constatnt replenishment conception (CR)

Technological advancement triggers the effect of „mass individualization”

We observe two phenomenons in supply chain analysis:

Common price pressure,

Profit concentration in one link of value chain

Development of supply networks requires new paradigm of competition and new understanding of competitiveness. We can apply here, for example:

conception of firm strategies referring to positioning and adjustement

modual approach

theory of value migration

conception of profit model

Number of unprofitable sectors is rising- neither large share in market, nor operations in a rapidly increasing sector guarantee high profitability

Success and reached profitability are the award for creating a new, innovative model of company activity

Ability to optimaly use the resources

Ability to define and realize appropriate goals

Poziom strategiczny

Strategic level

Operational level

Relation of the result to the costs of their achievement > 1

Transition from the seller market to the buyer market means a radical verification of the classical marketing conception 4P. It also introduces the new term „marketing logistics”, which is based on; quick response to needs, reliability of servicing and customer relations leading to the full satisfaction of the customer

Creating demand (marketing) as well as fulfilling its requirements (logistics) cannot be anymore perceived as separate functions, but as integrated by mechanisms tools for operating the supply chain oriented on the market.

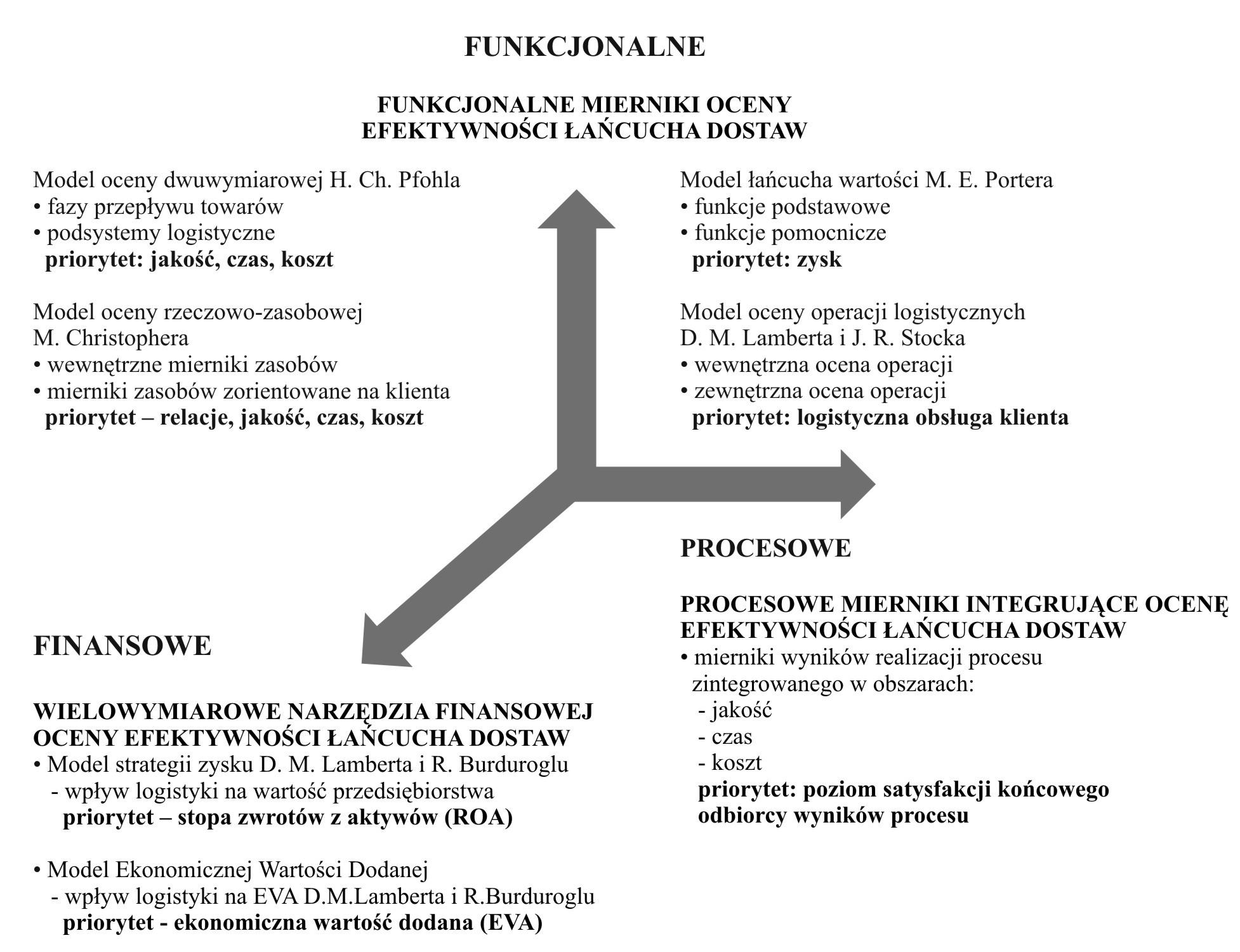

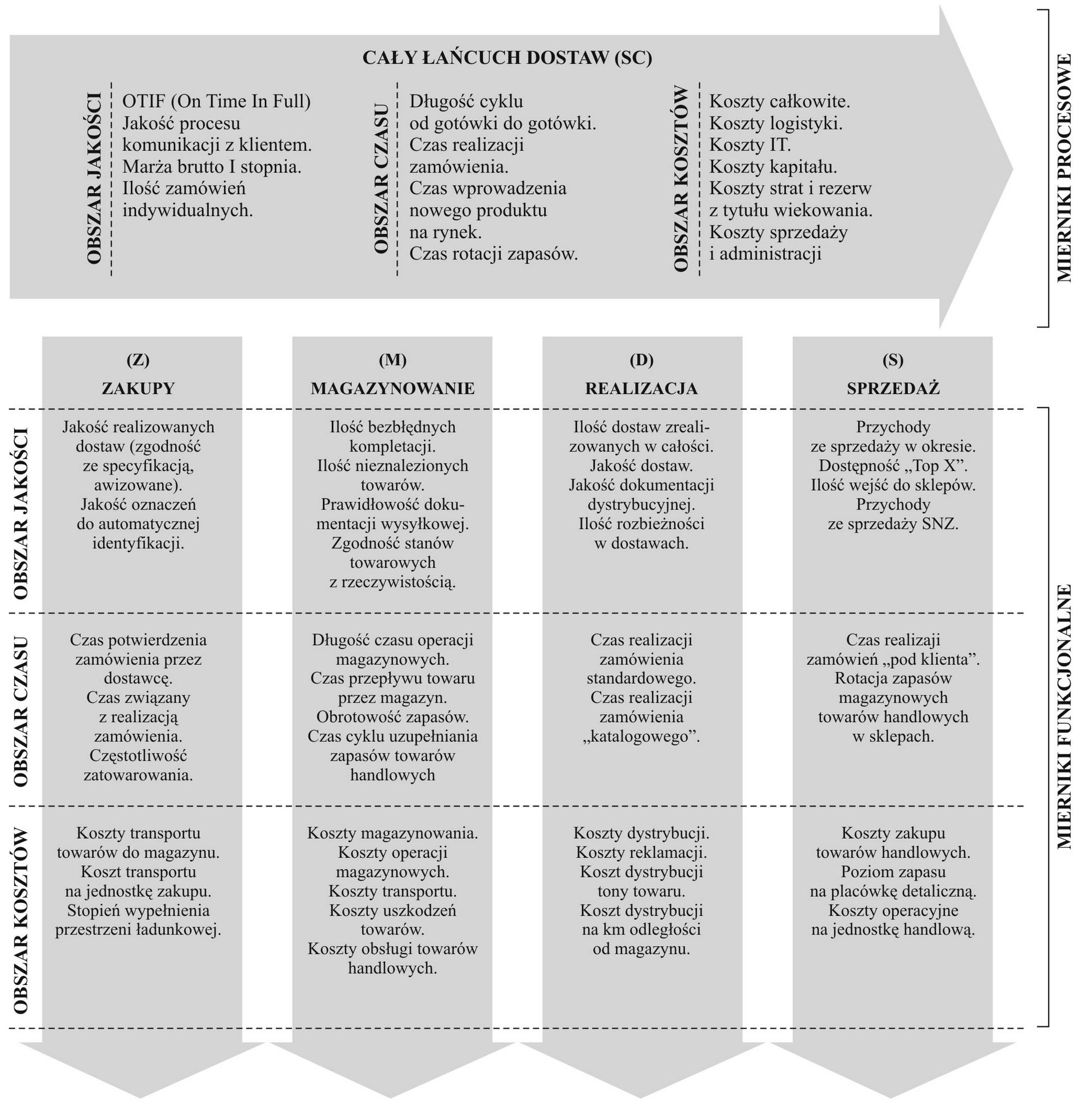

FUNCTIONAL MEASURES OF THE EVALUATION OF VALUE CHAIN EFFECTIVENESS

MULTIDIMENTIONAL TOOLS OF THE EVALUATION OF VALUE CHAIN FINANCIAL EFFECTIVENESS

PROCESS MEASURES INTEGRATING THE EVALUATION OF VALUE CHAIN EFFECTIVENESS

Przychody

Koszty zakupu towarów handlowych

Poziom jakości obsługi klienta

Kapitał obrotowy

Koszty transportu

Koszty wielkości zamówienia Koszty magazynowania

Koszty systemów IT

Koszty zarządzania i sprzedaży

Przychody

Zysk netto Całkowity koszt

Koszty

Poziom jakości obsługi klienta

Kapitał obrotowy

Koszty pozyskania kapitału

Koszty transportu

Koszty wielkości zamówienia Koszty magazynowania

Koszty systemów IT

Koszty zarządzania i sprzedaży

Koszty zakupu towarów handlowych Zapas

Należności

Observations show that ERP systems designed to collect data about companies provide certain insight into the transactional side of company activity. Many users of such systems do not undertake further necessary actions and as a result they come up with plenty of data, but little knowledge.

The data provided by transactional systems may be analyzed with the help of analytic information tools and processed into knowledge. Many companies made the costly mistake and took it for granted that an appropriate ERP system will solve all problems.

Many companies struggle with intergration of all functioning „silos” of supply chain and putting them into one reporting and organizational structure – making an effort to find measures which would join all functions into a loosely connected whole. We can see everywhere companies using the same technics – planning, supply, logistics etc. – for all products and channels. However, it must be emphasized that this approach is wrong.

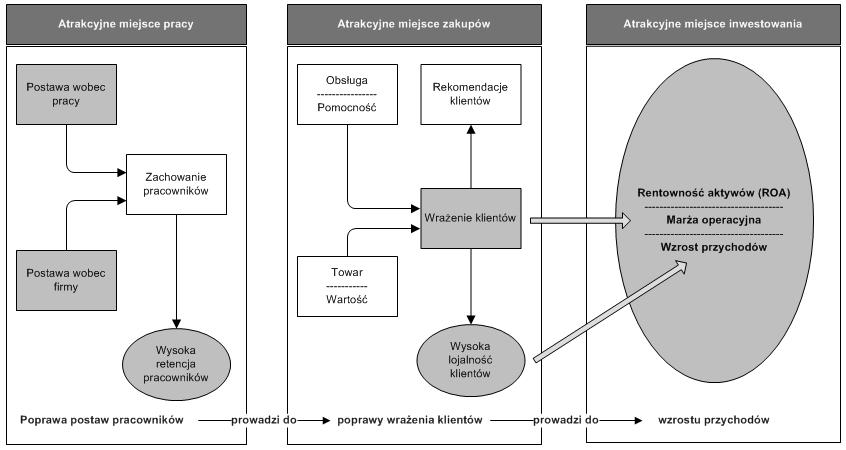

Increasing internal effectivity resulting from costs reduction is not a sufficient method of improving a company’s market position.

Prosument requires the company to constantly fulfil his growing requirements

Modern economic organizations should as a standard carry out the strategy „demand driven”

Market competitive pressure demands concentration on the core of the business (specialization, values migration, innovation - every day new improvement EDNI)

Process approach to operational activity becomes necessary, if we want to eliminate weaknesses of the silos approach

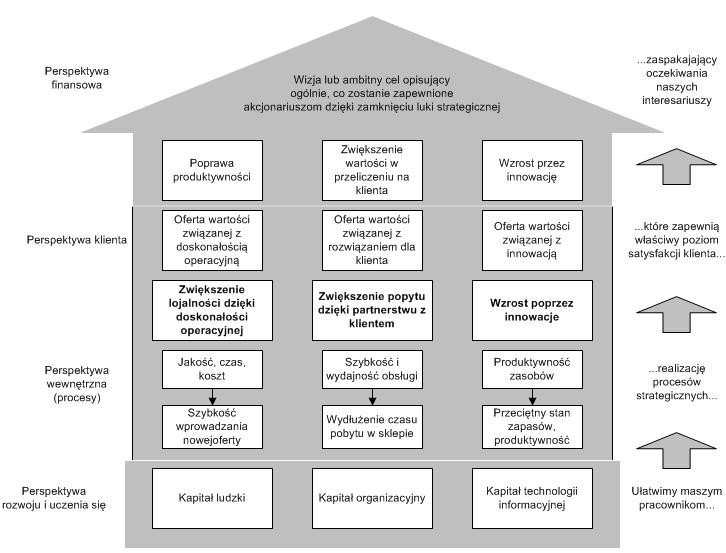

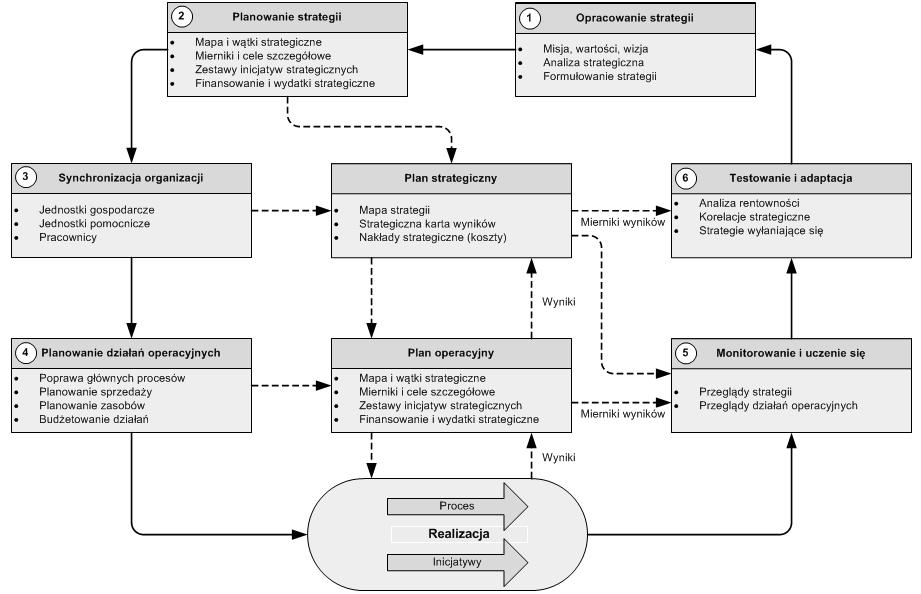

Key to success is synchronization of strategy with tactical and operational actions (integration of internal and external aims)

Lean Management i Agile Management determine the necessity to modify previous approach to management (carrying out conflicting aims)

Modern managers must look beyond the perspective of their own company in order to find opportunities for synergy – even in the competition’s systems.

Creating networks with environment surrounding the company is prerequisite for proper (optimal) management of information and goods flow.

Integration increases also the organizational level of companies as well as supply networks

Using modern information technologies for integrating companies as a part of dynamic, logistical networks is one of the conditions necessary to improve effectivness in leading a company.

Information technologies should be seen as one of the factor stimulating organizational changes, though an important one.

The role of a properly aggregated managerial information is crucial for right interpretation of tasks’ results in the context of reaching aims by companies.

The role of a business partner that controllers are aspiring to cannot remain just a „wishful thinking” – there is a real and justified need to support managerial decisions with competent and integrated analytic approach to executed business model

In such a way constructed function of aims determines the need to engage controllers into the process of strategic, tactical and operational planning so that proper construction of integrated indexes and ratios will singnalize deviations of parameters from conditions requiring some action.

Controllers are required to be proactive instead of previous being reactive because „… controlling is a function of co-creating strategic aims, planning as well as guaranteeing transparent results and at the same time being responsible for their implementation”