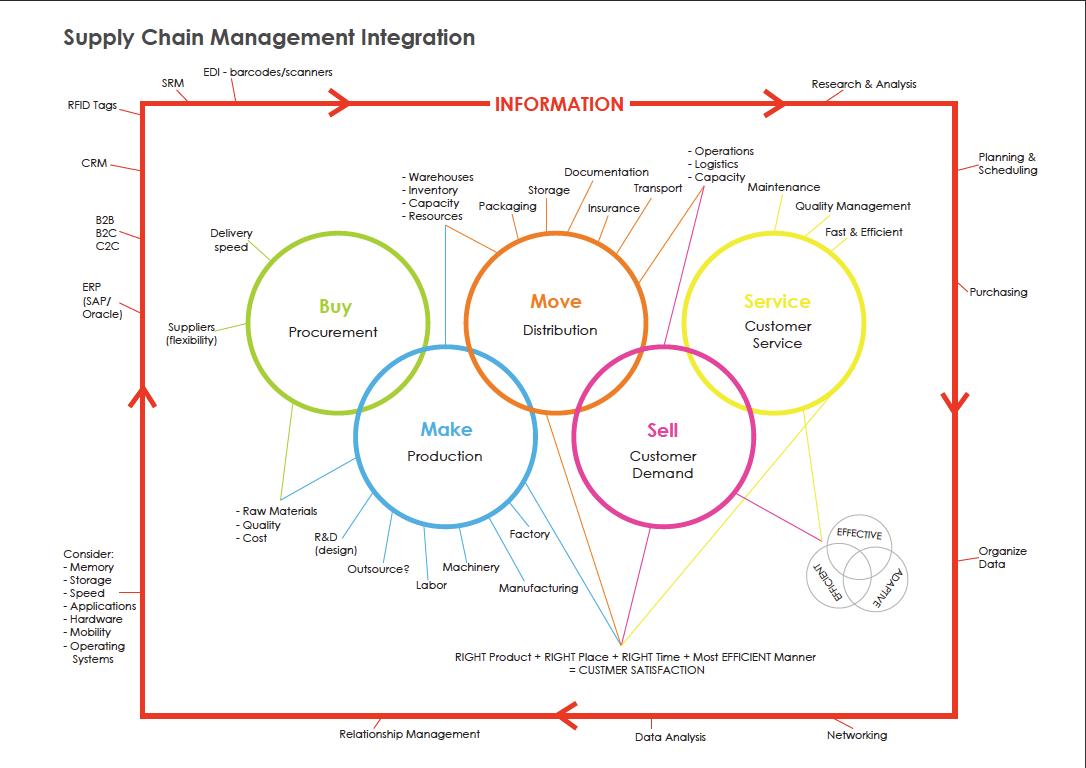

Supply Chain

Lanac snabdevanja

Value, volume ili cost driver

Integralni Lanac Snabdevanja

End to End Supply Chain (E2E)

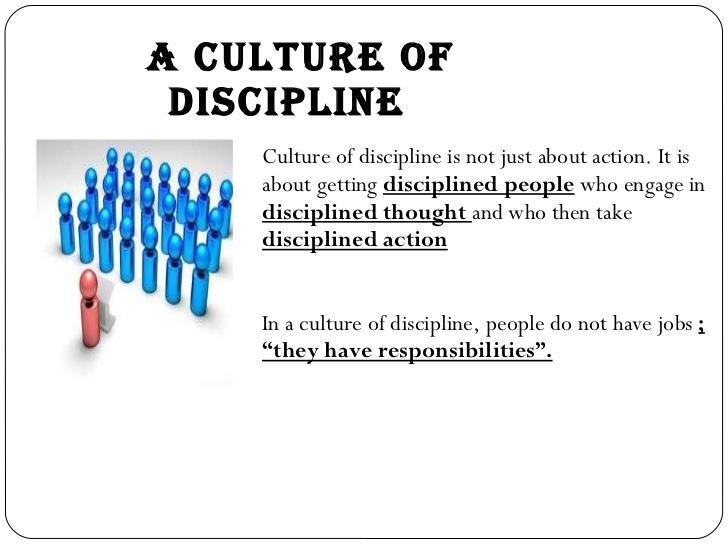

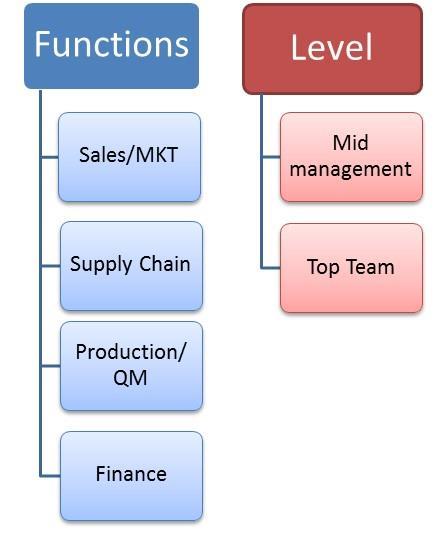

Change management - Get the right people on board and manage the change

• Only 40% of projects met schedule, budget and quality goals

• Biggest barriers to success listed as people factors:

- - Changing mindsets and attitudes – 58%.

- - - Corporate culture – 49%.

- - - Lack of senior management support – 32%.

https://www.youtube.com/watch?v=Yk7bzZjOXaM

8 Kljucnih gubitaka –

No value (Cost)

TRANSPORTATIO

INVENTORY

Unnecessary movements of products & materials

Excess products and materials not being processed

Unnecessary movements by people e.g. walking

WAITING

OVER PROCESSING

Wasted time waiting for the next step in a process

More work or higher quality than is required by the customer

OVER

Production that is more than needed or made before it is needed

Extra work caused by rework, scrap and incorrect information

SKILL UTILISATION

Extra effort due to Poor skills, or lost potential due to people being over qualified for the task

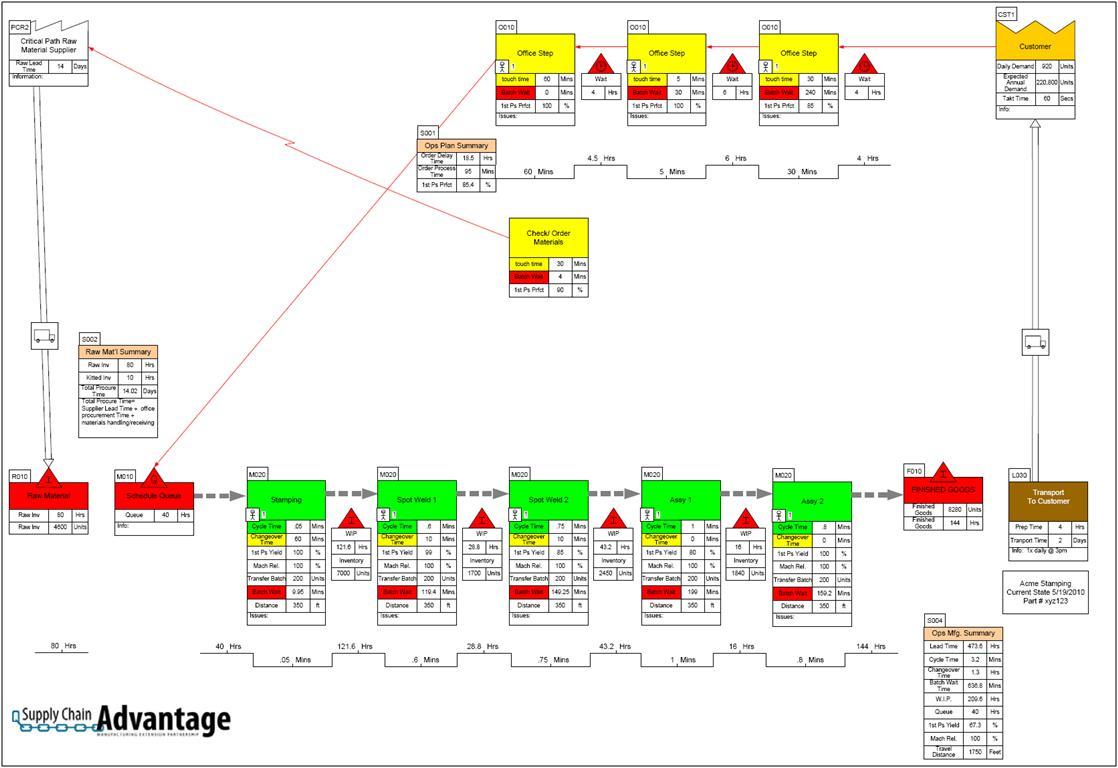

Value stream map

ŠTA I KAKO

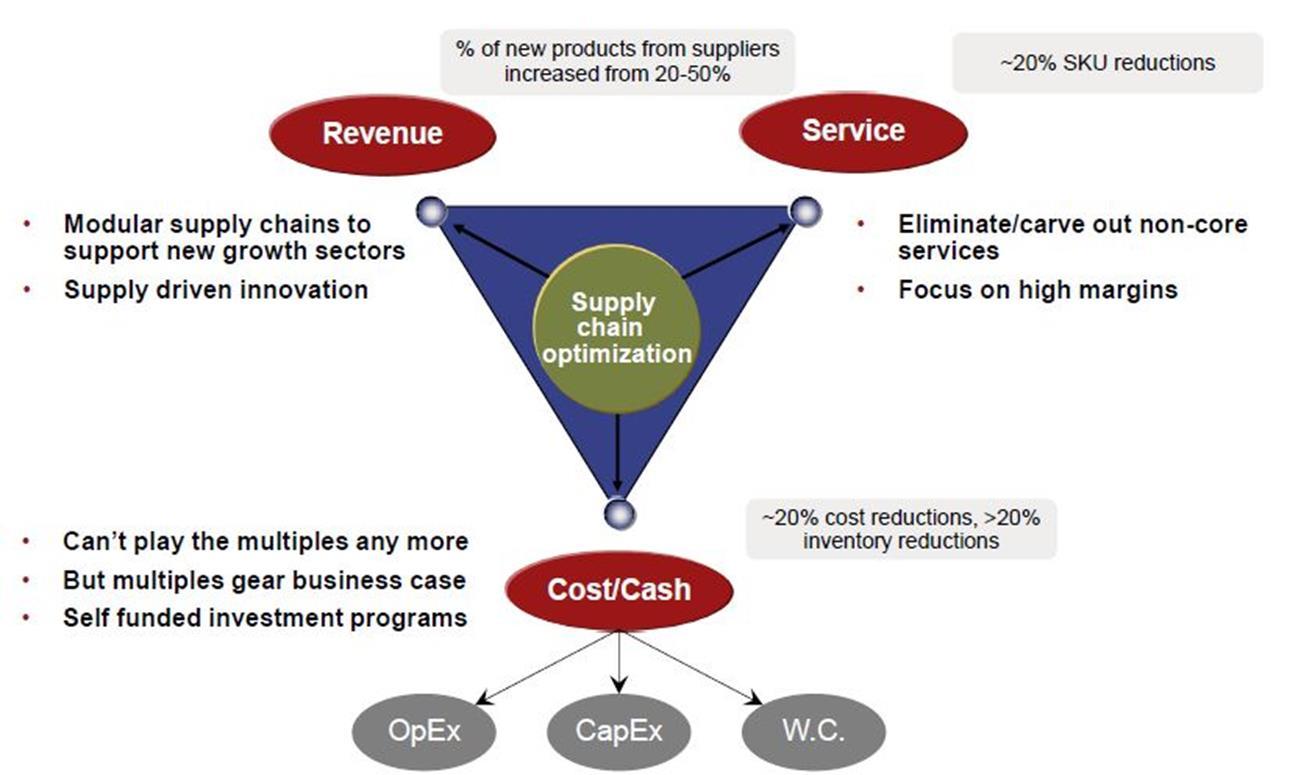

Increase of total market coverage

Increase orders fulfillment - OTIF

Increased forecast accuracy

Increase Customer Responsiveness

Decrease Out Of Stock - OOS

Reduced SC errors

Reduced transportation cost

Reduced warehousing cost

Reduced distribution cost

Reduced Inventory carrying cost

Reduced procurement cost

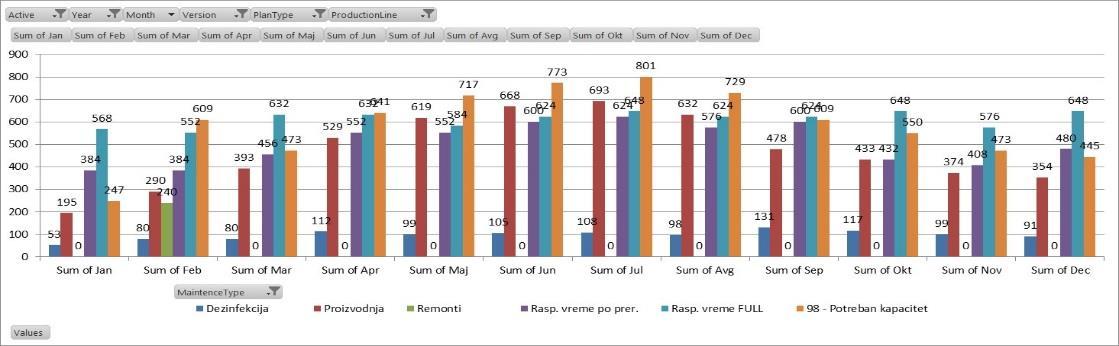

Increase Overall Efficiency of Equipment - OEE

Reduced manufacturing cost

Reduced Head Count- labor cost

Reduced Facility cost

Increase Energy efficiency

Reduced Logistic asset cost

Reduced Inventory

Increase inventory turns

Reduce lead and cycle time

Accelerate Cash to Cash cycle

Reduced Logistic and other assets

Supply Chain Cost Management

Tradicionalni troškovni princip

Prodajna cena = Troškovi + Profit

Supply Chain strategija (E2E)

Tržišni Lean princip

Profit= Prodajna (tržišna) cena - Troškovi

Integralno poslovno planiranje i Nabavka

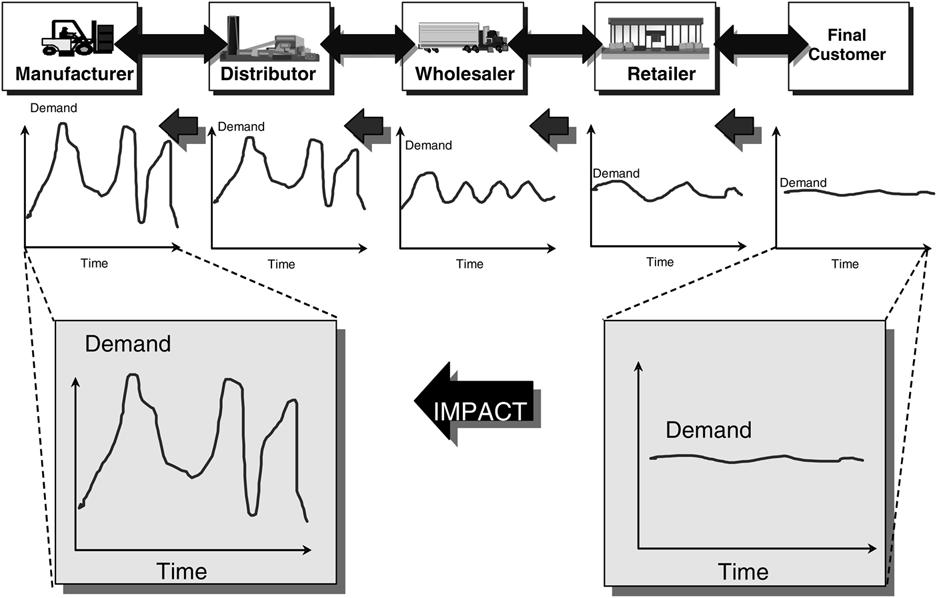

Bullwhip efekat

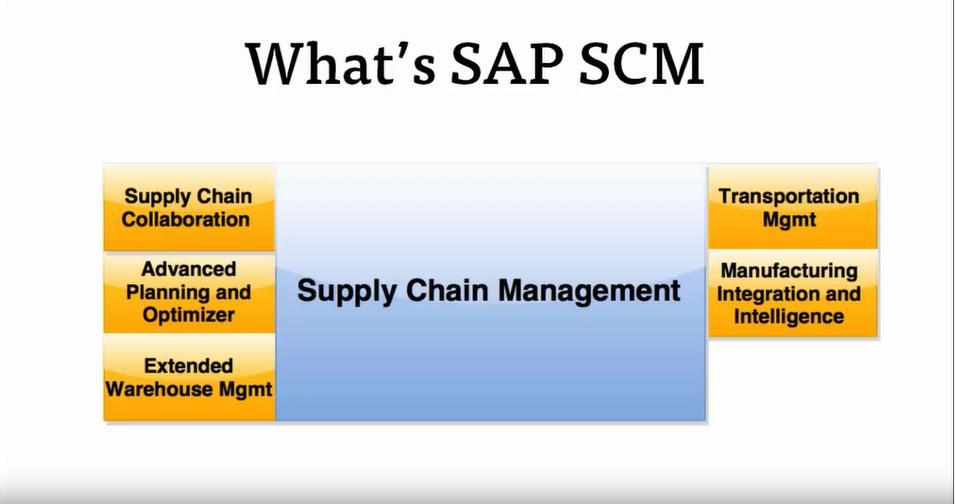

Šta je S&OP ?

S&OP – Sales & Operational Planning

Proces za integrisano upravljanje biznisom

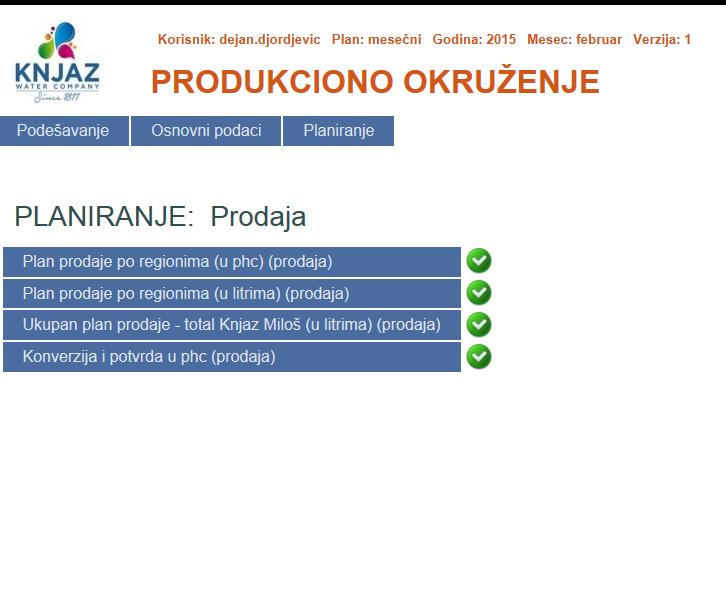

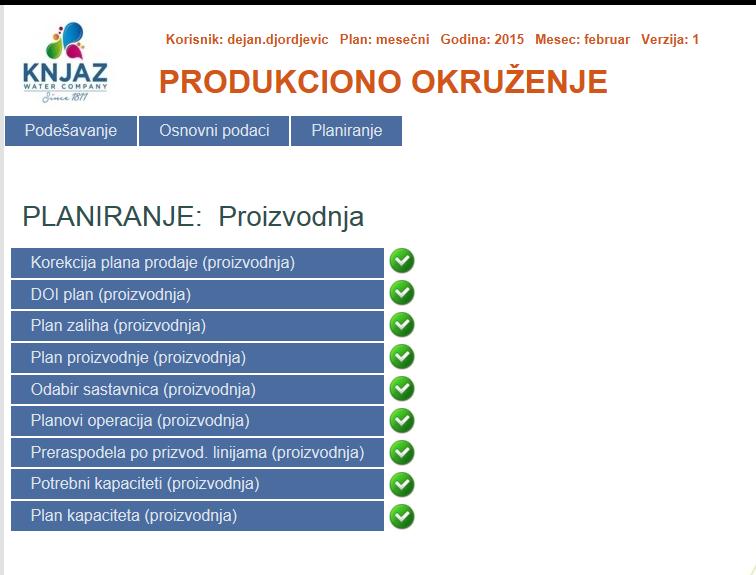

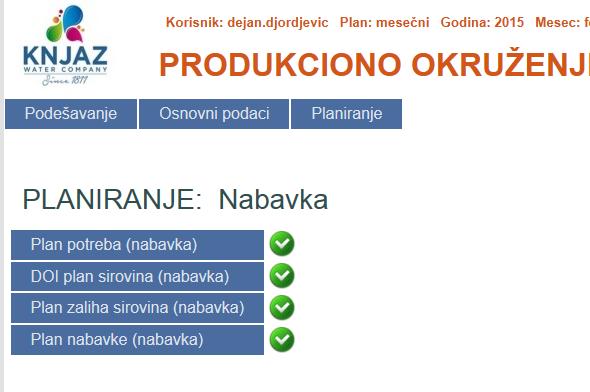

Software za podršku S&OP procesu

Benefiti impelemtacije S&OP

To enable the business to understand installed asset potential, calculation of OEE is as follows

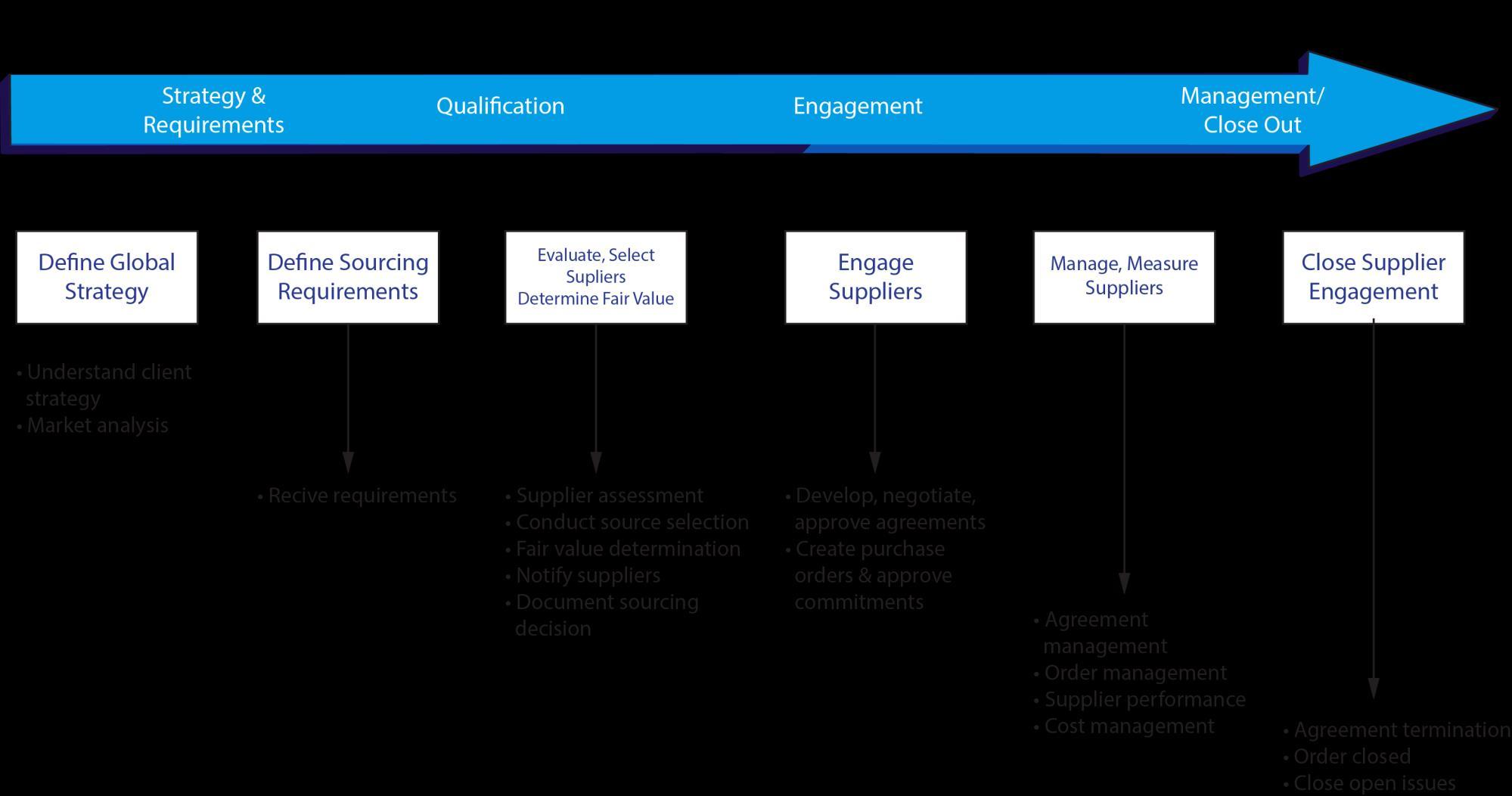

Strategija Nabavke

* Segmentation, focus and sourcing/audit+develop,

*High expenditure area

*Many existing alternate products/services

*Many qualified supply sources

*Goods/services readily available

*Commercial involvement can significantly

*Strategic to operations

*Few qualified supply sources

*Large expenditures

*Design to quality critical

*Complex specifications impact price

*Many existing alternate products/services

*Many sources

*Low value

*Small individual transactions

*Very complex specifications

*Few alternate products available

*Few qualified sources of supply

*May have big impact on ongoing operations

*"Anyone" could buy it or maintenance

*Unspecified items for everyday use

*New technology or untested processes involved in the provision of the product or service

Supply Market Challenge

(i.e. how complex is the product, how difficult is it to find suppliers)

Modeli pregovaranja komercijalnih uslova

• Leveridž materijali – eAukcija

• Strateški materijali – direktni pregovori i auditi/razvoj

• Rutine – tenderi

• Uska grla – tenderi / direktni pregovori

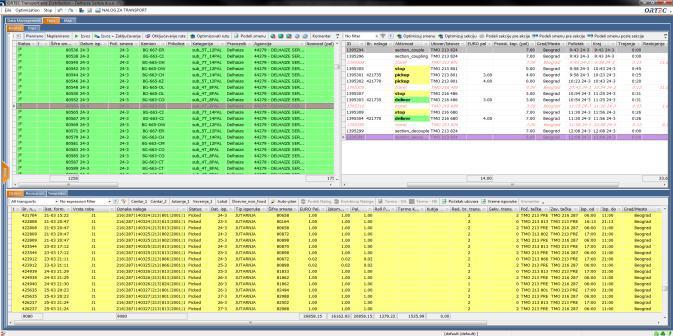

Logistika

KONTINUALNA OPTIMIZACIJA LOGISTICKIH RESURSA I

SKLADISTA

UPRAVLJANJE ZALIHAMA

Efikasna distribucija

• Fleksibilan plan snabdevanja:

• Dodatne investicije u distributivnu flotu

• Moderna tehnoloska resenja (TMS, GPS, WebPortal,...)

• Potpuna sledljivost i kontrola ključnih parametara

• Optimizacija ruta I kontrola troskova

TRADICIONALNI LOGISTICKI MODEL

Future Logistics

Kljucni parametri uspeha

• Kontrola I transparentnost

• Stalna optimizacija I unapredjenje celokupnog Lanca snabdevanja I Logistike

• Pravilno koriscenje modernih tehnologija

• Fleksibilnost I brzo prilagodjavanje zahtevima trzista

SERVIS SA KLIJENTIMA

What is ERP?

• ERP is a high-end sophisticated software solution that reduces the pressure and workload off the managers and provides accurate, timely information for taking appropriate business decisions. Managers with knowledge of ERP will be able to achieve their targets and goals by proper implementation of ERP system in their organization.

• In fact managers are expected to translate the business rules and requirements for mapping them into ERP software.

• Implementation of ERP solutions is one of the largest drivers of growth in the consultancy business.

ERP history

Architecture

• Central relational database (e.g., Oracle and many others)

• Client/Server—three-tiered

• ERP Component—Oriented towards common identifiable business modules (PP, MM, SD, FI, CO, HR)

– PP: Production Planning (“Make”)

– MM: Material Management (“Buy”)

– SD: Sales & Distribution (“Sell”)

– FI: Financial Accounting and CO: Controlling (“Track”)

– HR: Human Resources

• Add-ons:

– Customer Relationship Management (CRM)

– Supply Chain Management (SCM)

– Product Lifecycle Management (PLM) –

ERP Industry Solution

• Aerospace/Defense

• Automotive

• Banking

• Chemicals

• Consumer Products

• Engineering/Construction

• Financial Svc Provider

• Healthcare • High Tech

• Higher Education/Research

• Insurance

Media

Mill Products

Mining

Oil & Gas

Pharmaceuticals

Public Sector

Retail

Service Providers

Telecommunications

Utilities

so on

ERP Vendors

World vendors:

SAP

MICROSOFT

ORACLE

Serbian vendors:

UPIS

MIS

AB Soft

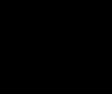

ERP and SCM

SCM applications

You have the following application types in SCM:

• Advanced Planning and Optimization

• Extended Warehouse

• Transportation Management

• Supply Network Collaboration

• Forecasting and Replenishment

ERP today and future

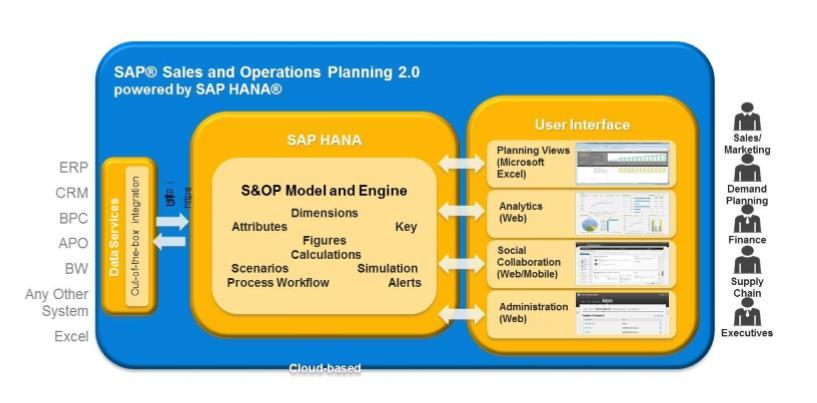

Upravljanje povratnom ambalazom - palete

CILJEVI

•Poboljsati kvalitet

•Pojednostaviti proces

•Povecati fleksibilnost

Konverzijafiksnih u varijabilne troskove

Kvalitet u EURstandardu I pouzdano snabdevanje

•Povecati efikasnost ?

Kompanija

WHY ?

Why become a member of Serbian Supply Chain Professionals Association, one of the fastest growing professional associations in the region?

Here are just some of the reasons:

•Strengthen your professional knowledge by liaising with some of the top professionals in the field of Supply Chain

•Stay up-to-date with the latest industry trends

•Broaden your network of contacts

•Give and receive mentorship

•Contribute to improvement of the business environment in Serbia through participating in Association's activities (e.g. projects, round tables, meetings with Government bodies and other professional associations...)

•Step into a rich new field of business opportunities

•Gain access to members-only materials (e.g. Best practise, books, research and "white paper" reports, templates...)

•Be the first in line to participate at the events organized by the Association (forums, member meetings, workshops...) and receive discounts, free entry and more.

•Enjoy benefits offered by Association's partner bodies

•Synergy: share passion, inspiration and motivation