MayaAngela Simms

B.Arch 2024 Portfolio

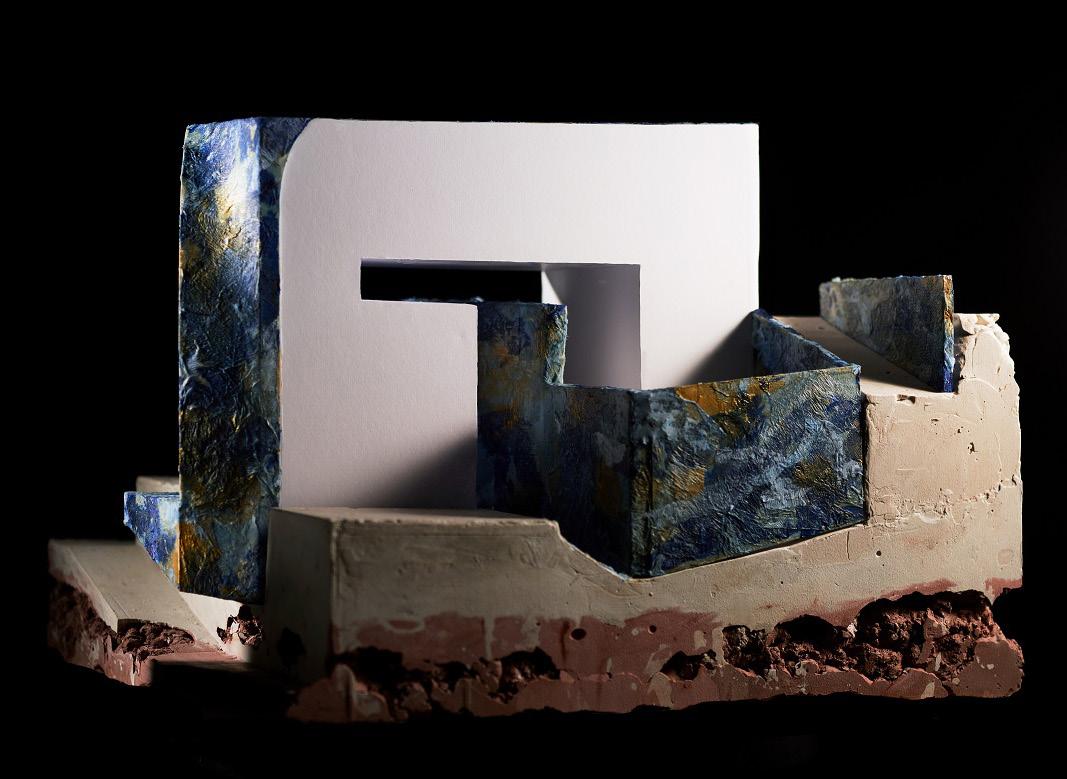

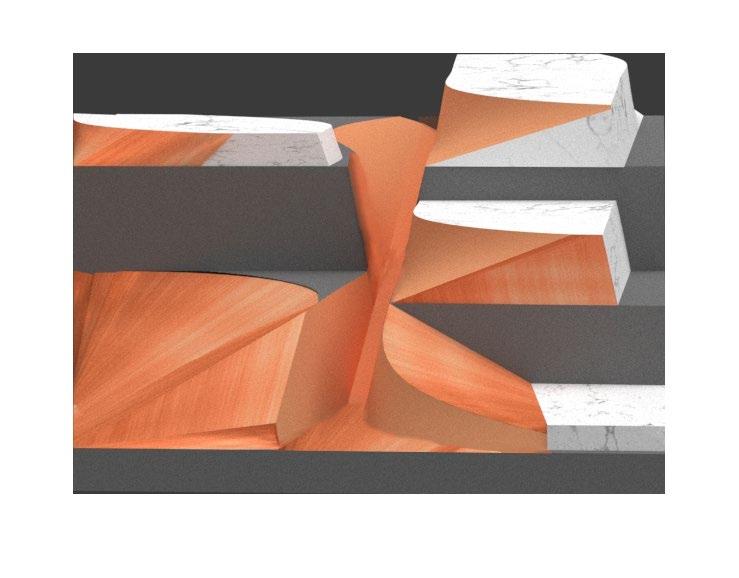

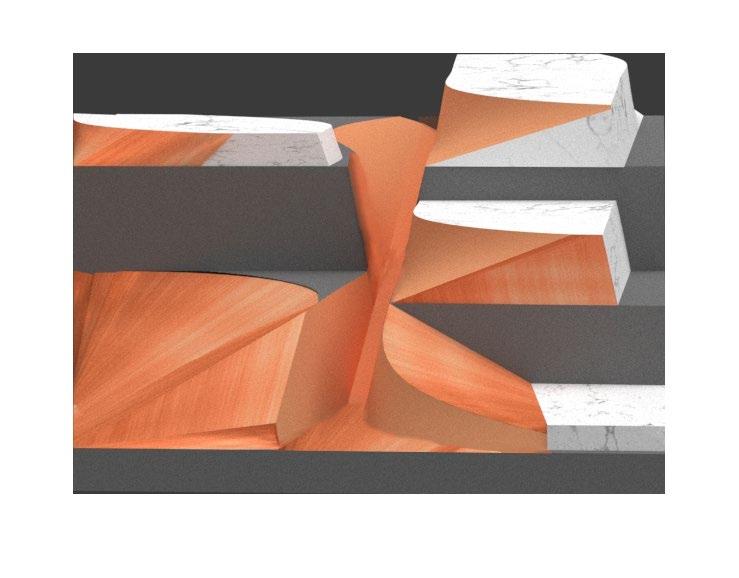

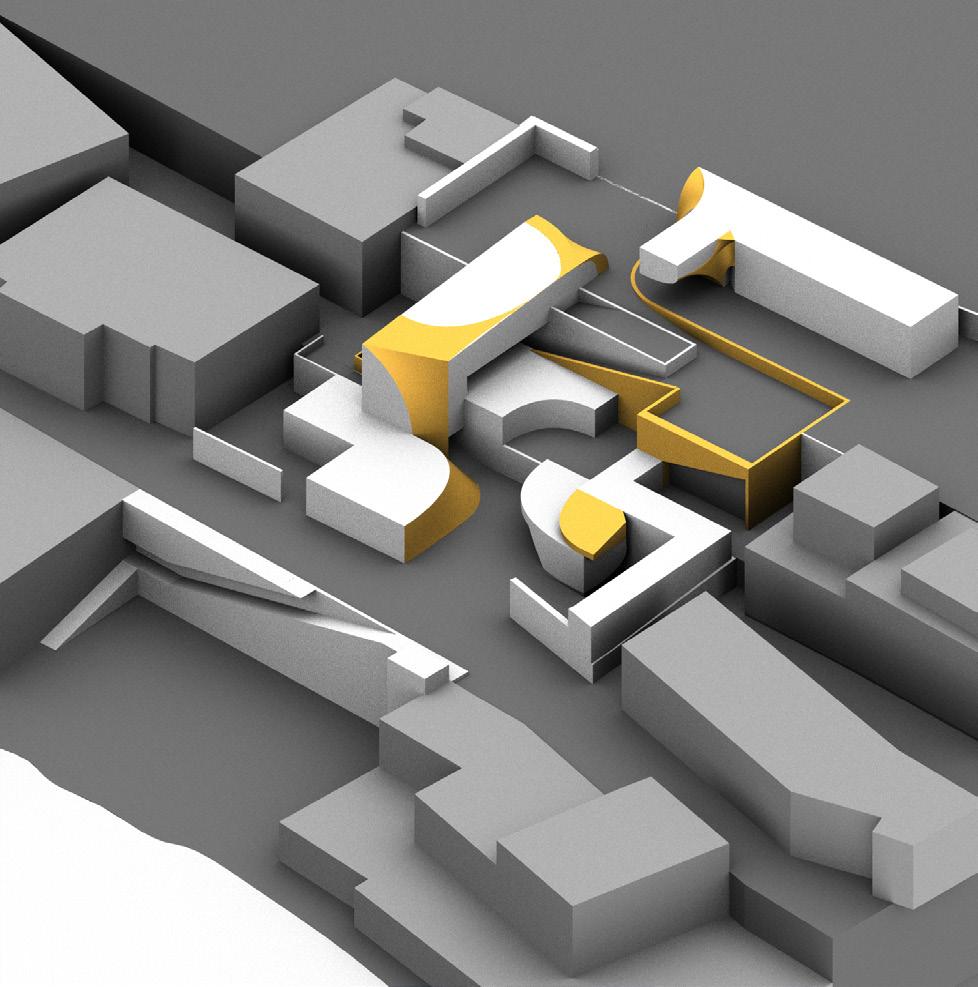

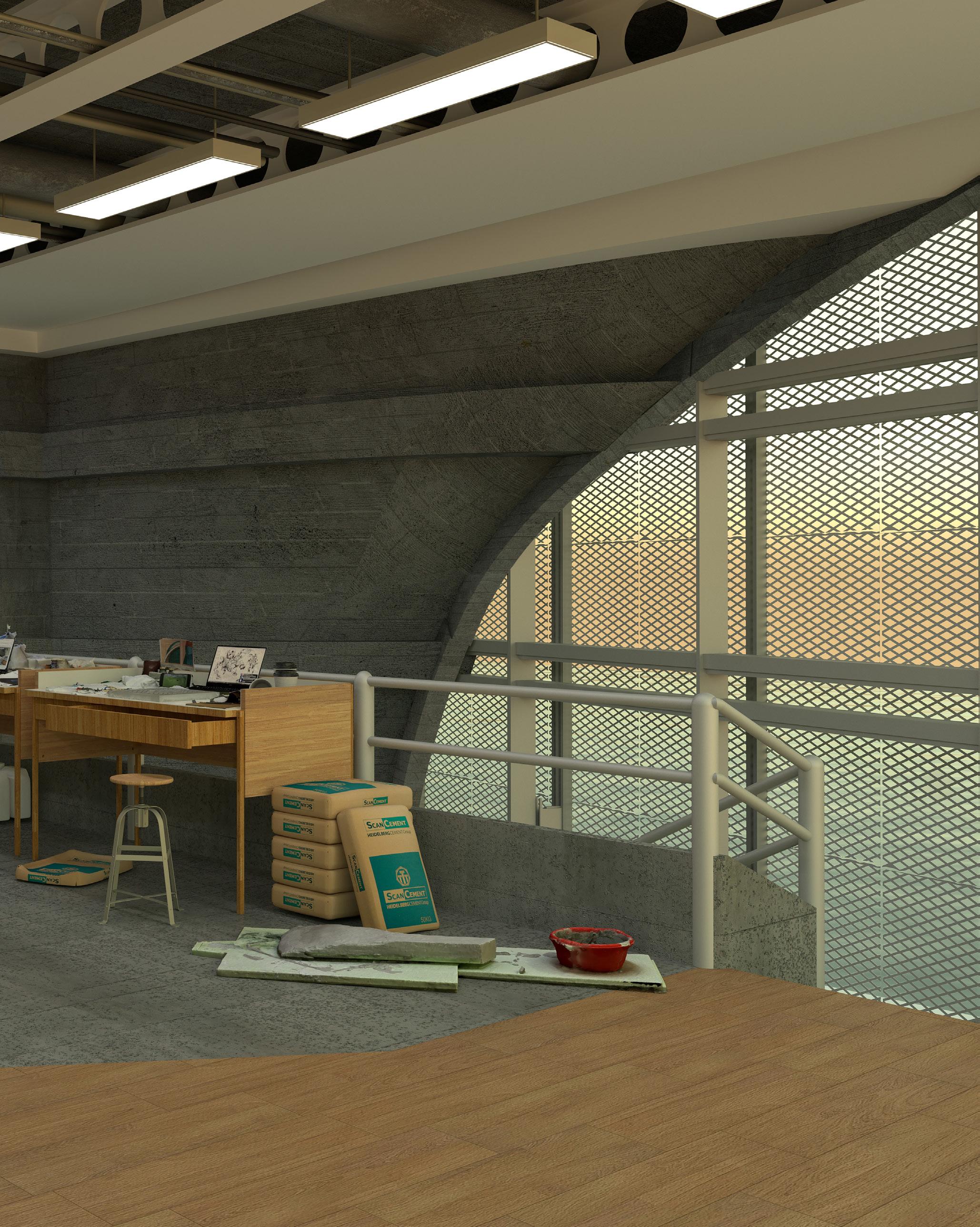

Tesserae Atelier

a visiting artist studio in Selinunte, Sicily

In this working and learning community, artists come to learn the practice of mosaic making to produce their own contemporary art. The program includes exhibition and gallery space, where artists are able to showcase their work as a fusion of ancient and contemporary art with the community.

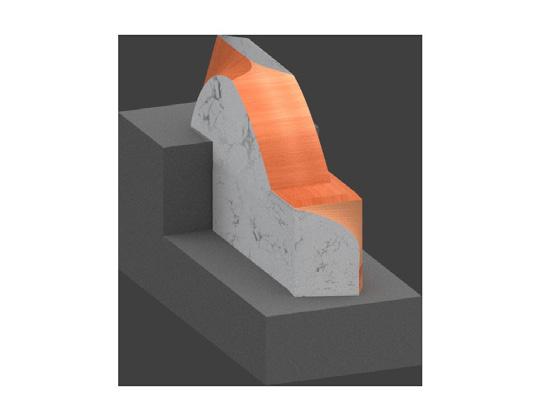

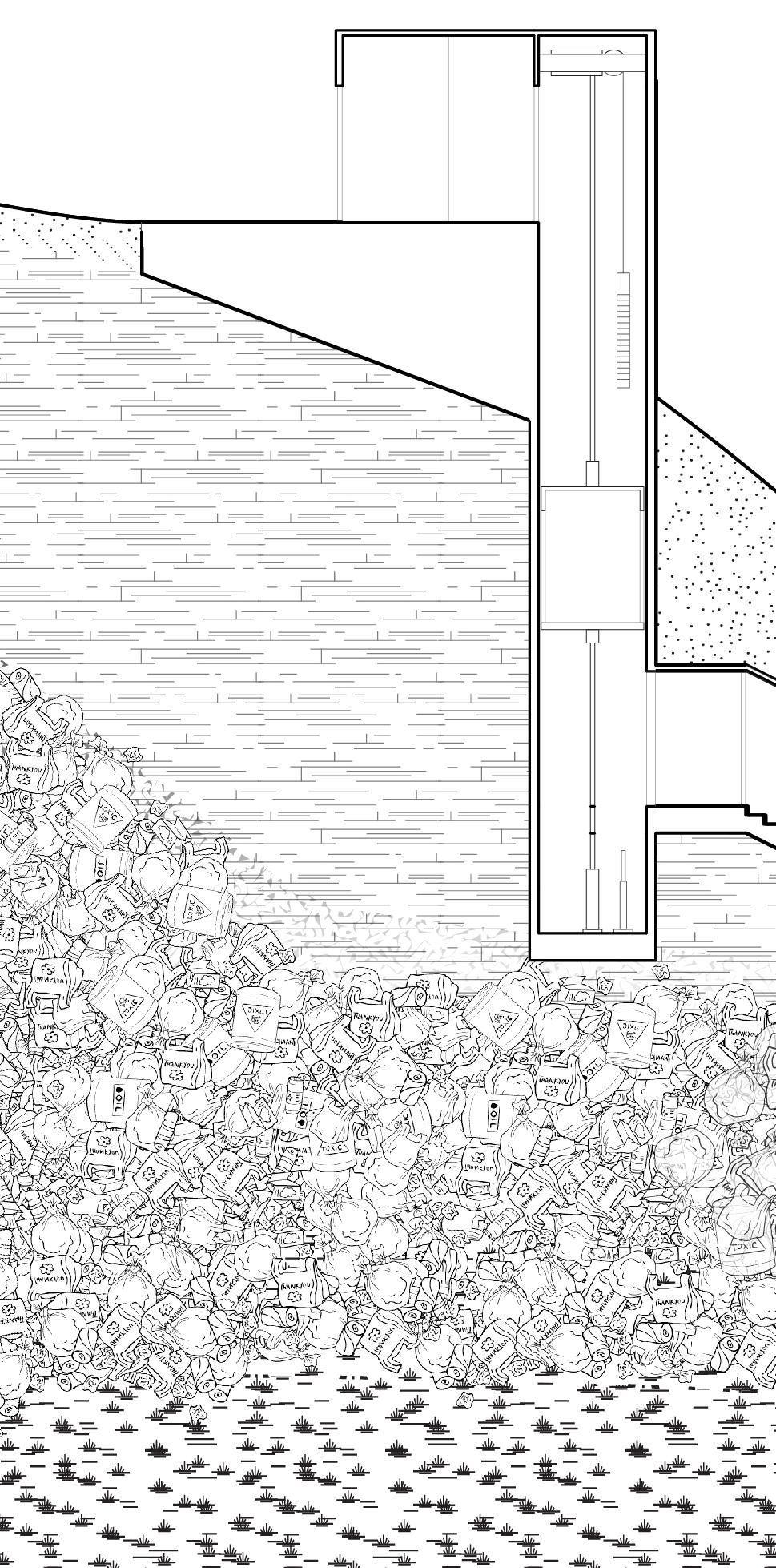

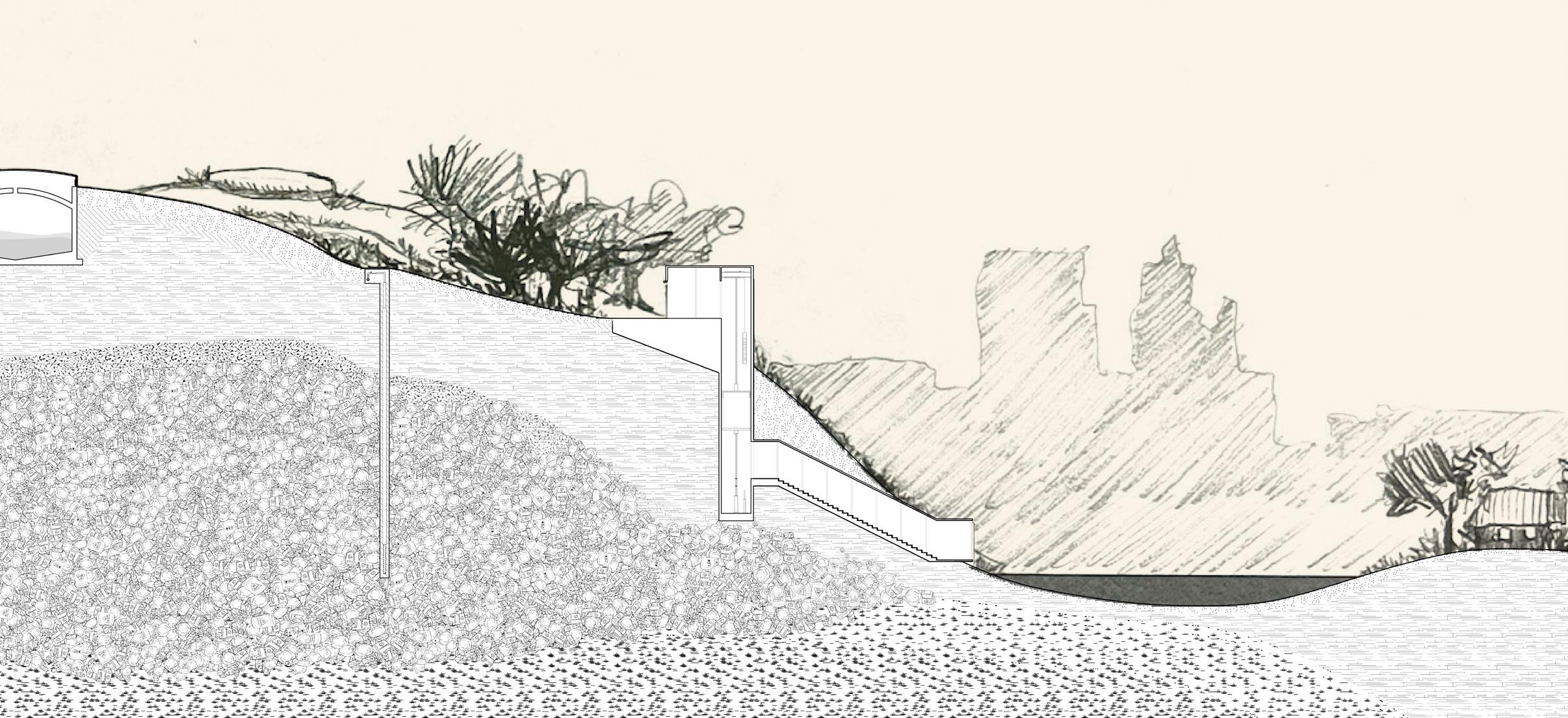

There is a distinction between 3 materials throughout the design process: ground, mosaic surfaces, and non-mosaic surfaces. These distinctions create an opportunity for exploring the interaction between large masses, surface treatment, and ground excavations.

It is intended for the mosaics to evolve and populate the site beyond the idea of the architect’s intervention as artists continue to live in Tesserae Atelier. By putting the true “final” design of the site in the hands of the visiting artists and the community within Selinunte, the hope is that the design becomes a beacon of collaboration and growth that can be expanded upon for decades.

This project was done in collaboration with Jeanelle Cho and Sarah Fellingham.

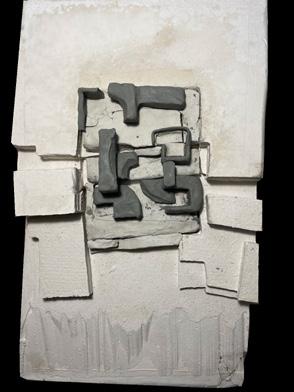

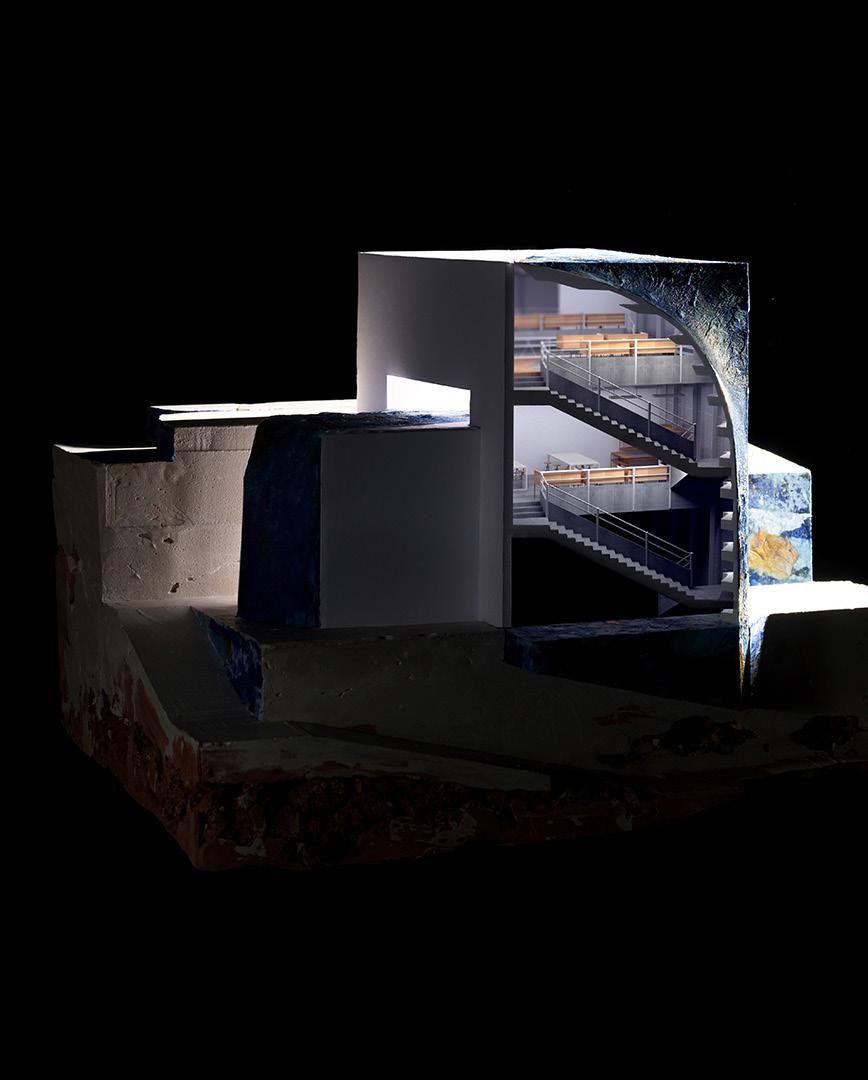

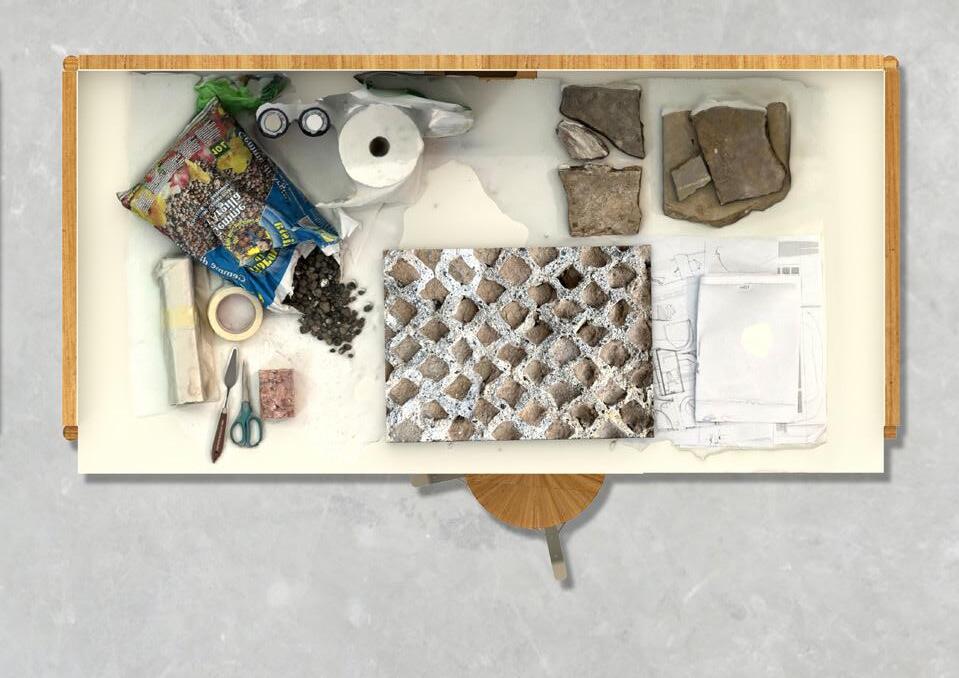

Final Model

plaster cast, paper mache, foam core, 3D print

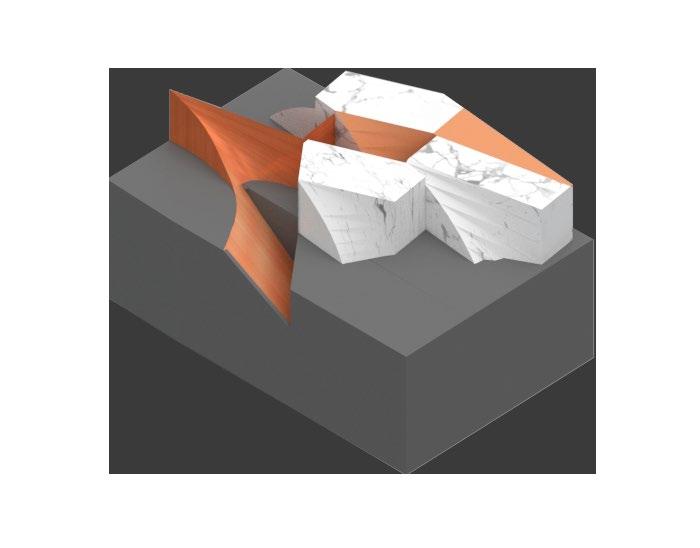

The design process began with a simple object digitally modeled under the prompt “separate vs apart.” This model was our attempt at “apart.”

This concept was applied iterated upon with physical section, and digital modeling.

applied to the site and physical modeling, plan, modeling.

The ideas explored in these iterations were then brought together for a final design of the Tesserae Atelier campus

Site Plan (top left), Plan (top right), Site Section (bottom) Rhino, V-Ray, Adobe Photoshop, Adobe Illustrator, Photogrammetry

Final Model and Rendering Composite (left)

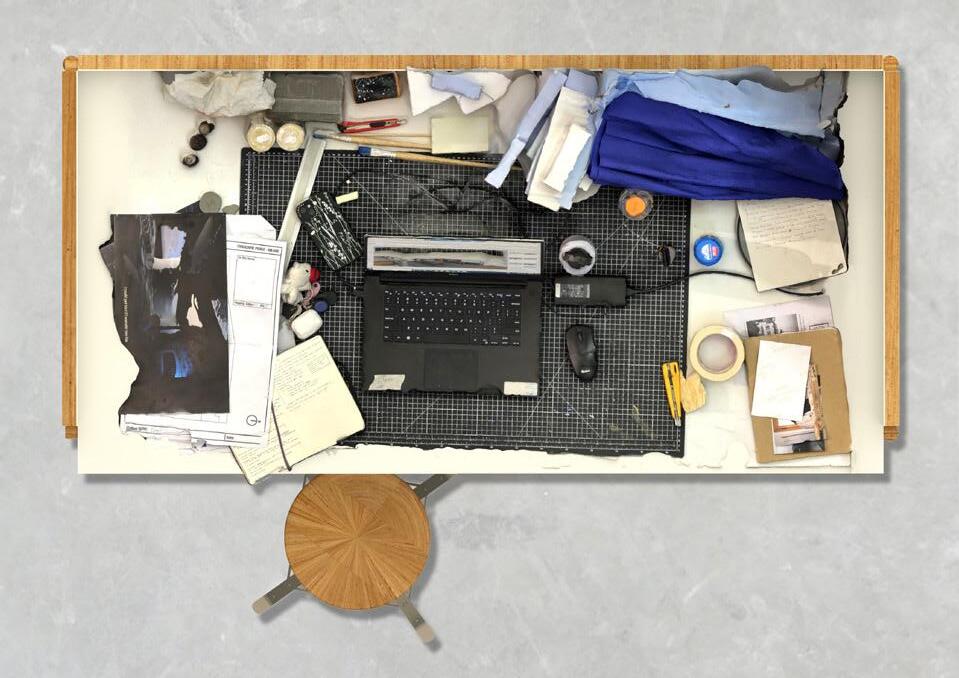

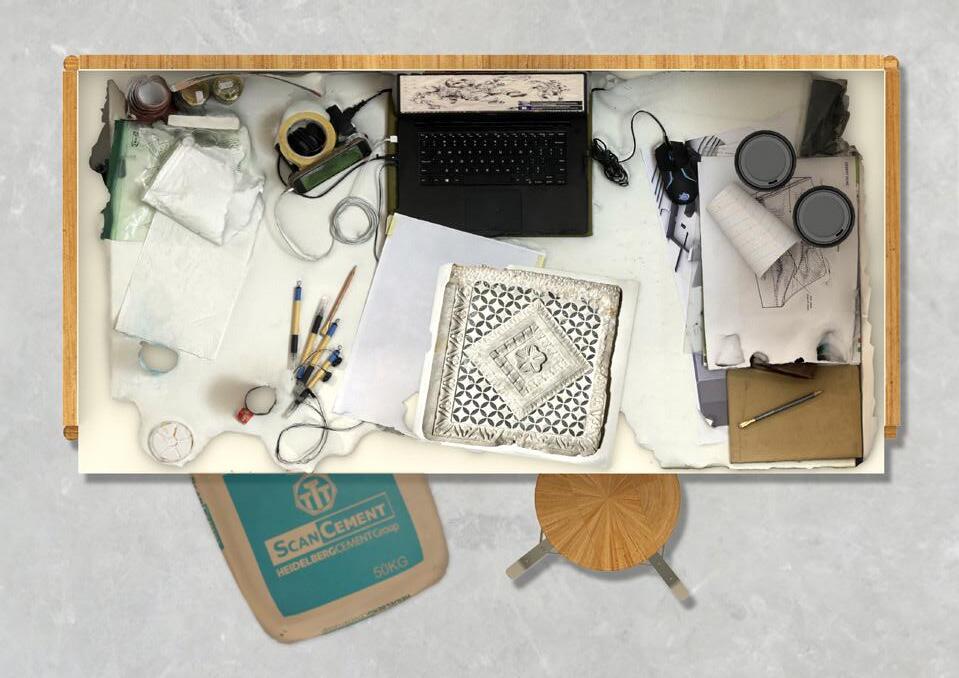

Studio Desk Photogrammetry Scans (above)

The real studio desks of students in Syracuse Architecture were scanned using photogrammetry and imported into the final render in order to better imagine what the studio space could be like in the peak of an artist’s visit.

Studio Render Rhino, V-Ray, Photogrammetry

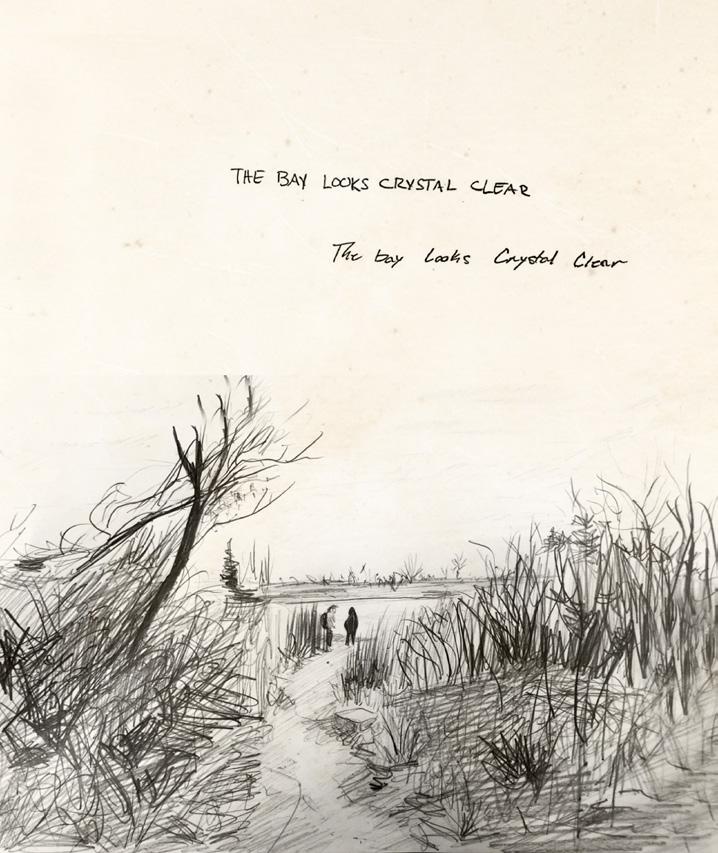

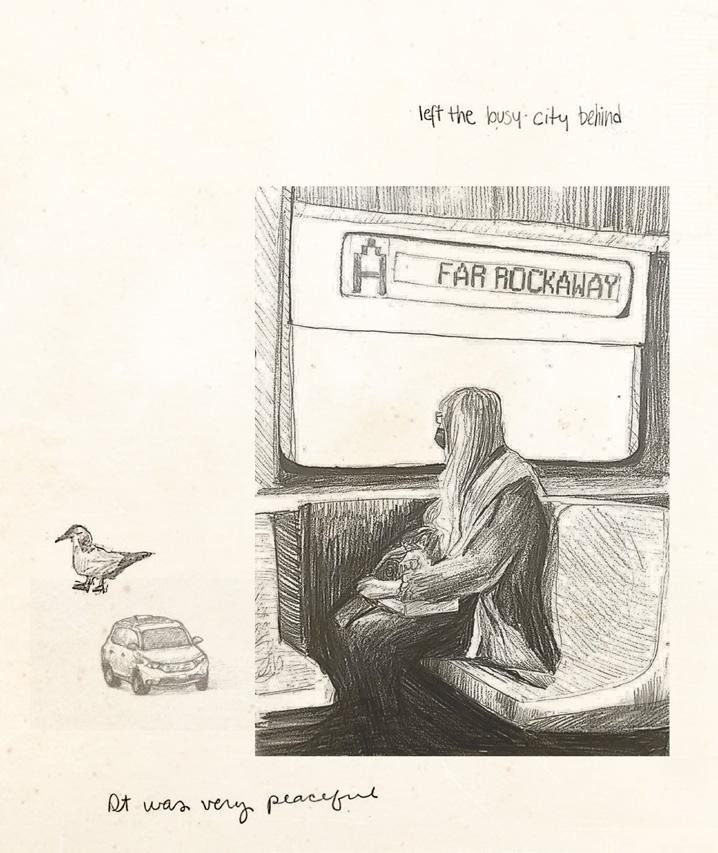

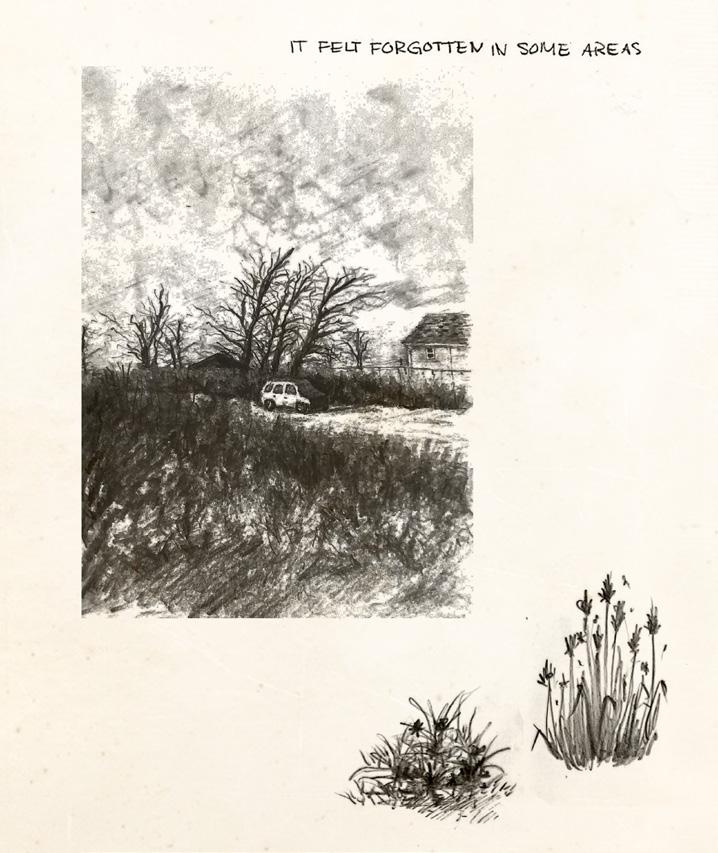

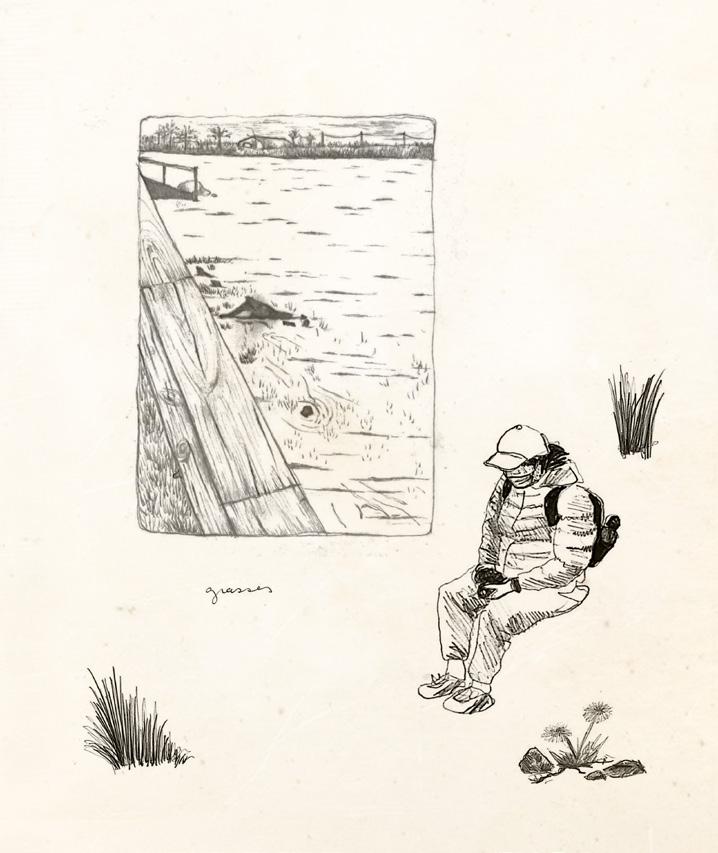

Reconstructing Roots

memorializing a community left behind

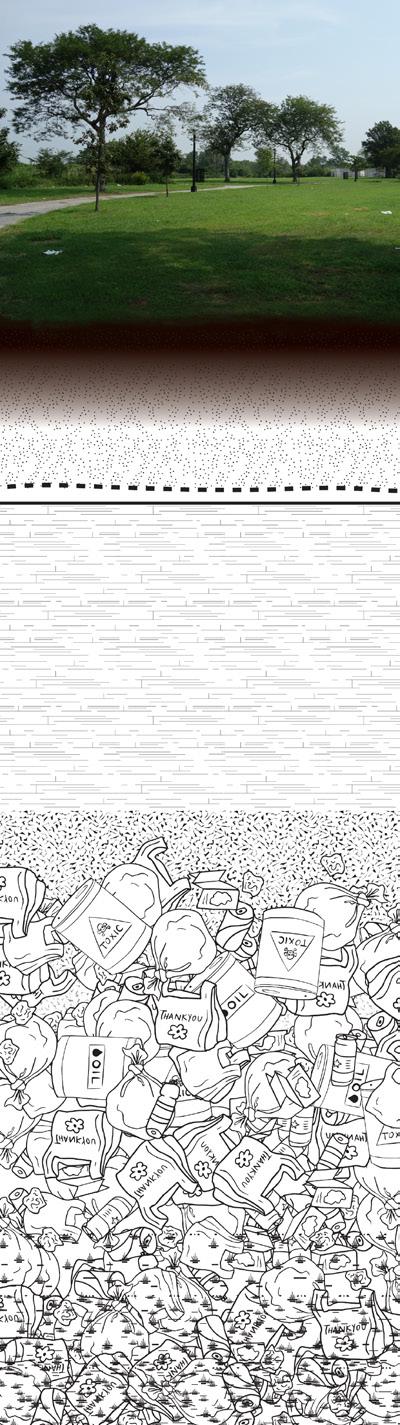

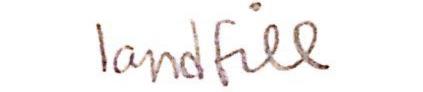

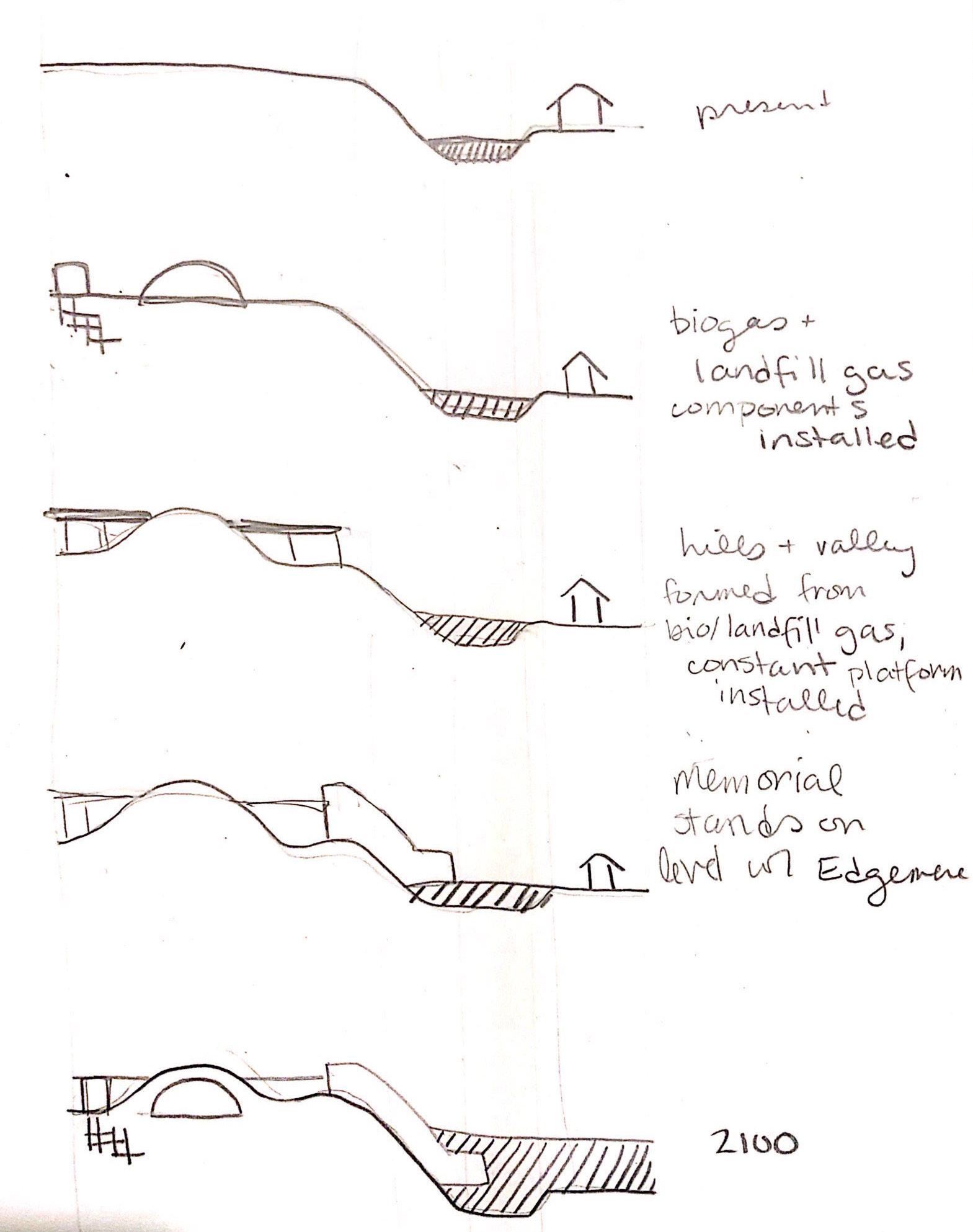

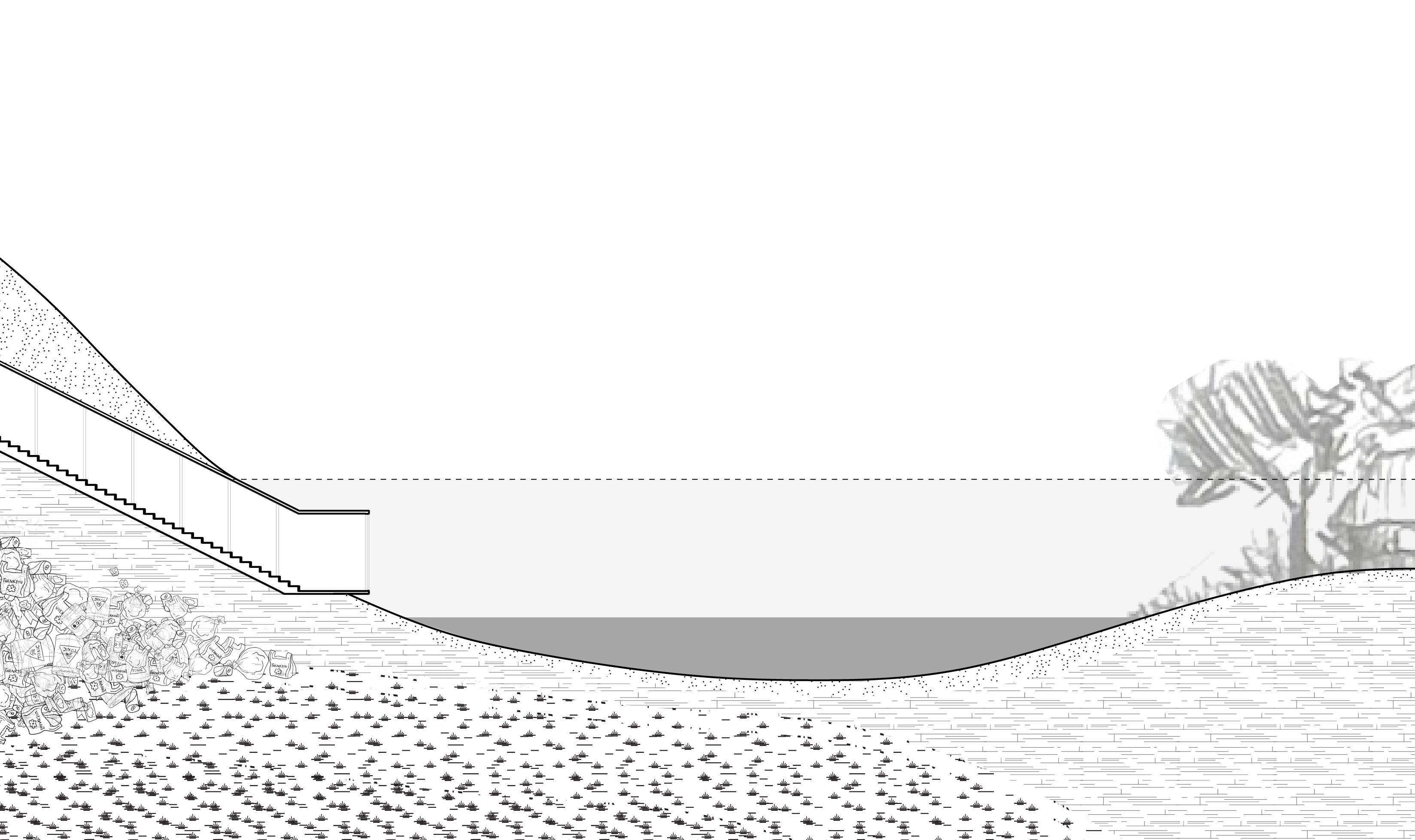

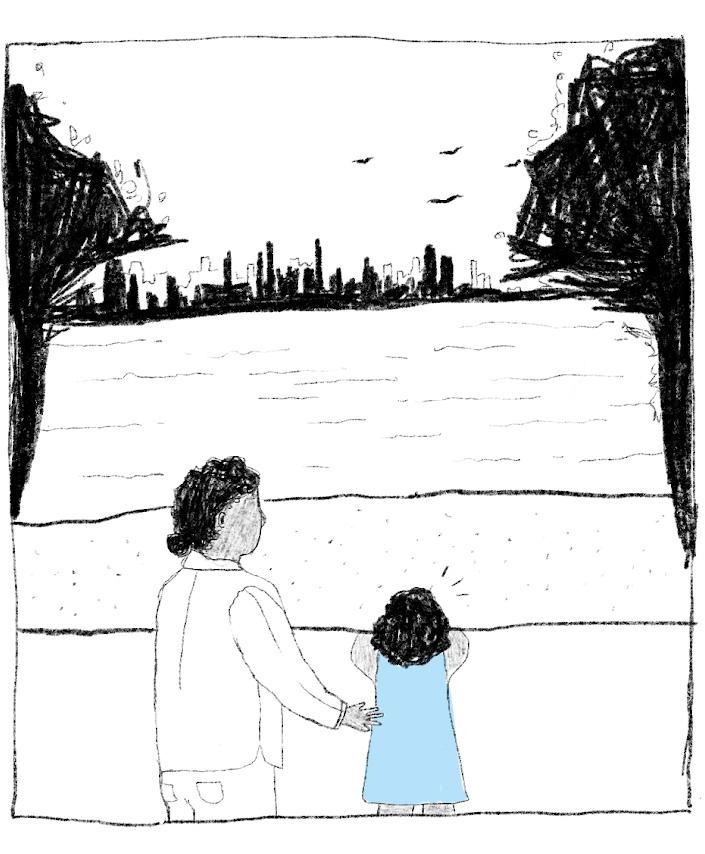

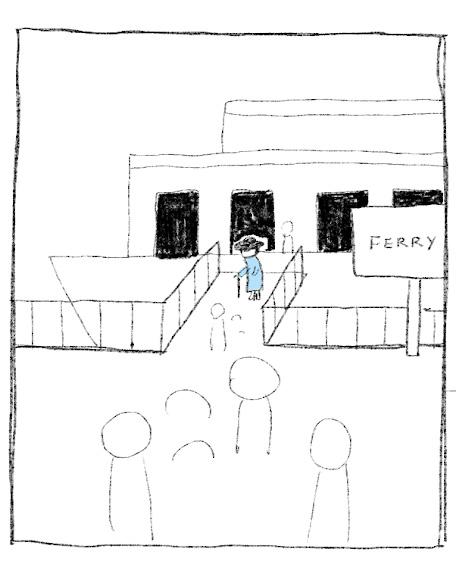

Edgemere is a town on the Rockaway Peninsula at the very edge of New York City. The current projection for rising sea levels means that the landfill in Edgemere will be one of the few pieces of land on the peninsula to survive the effects of climate change in 100 years.

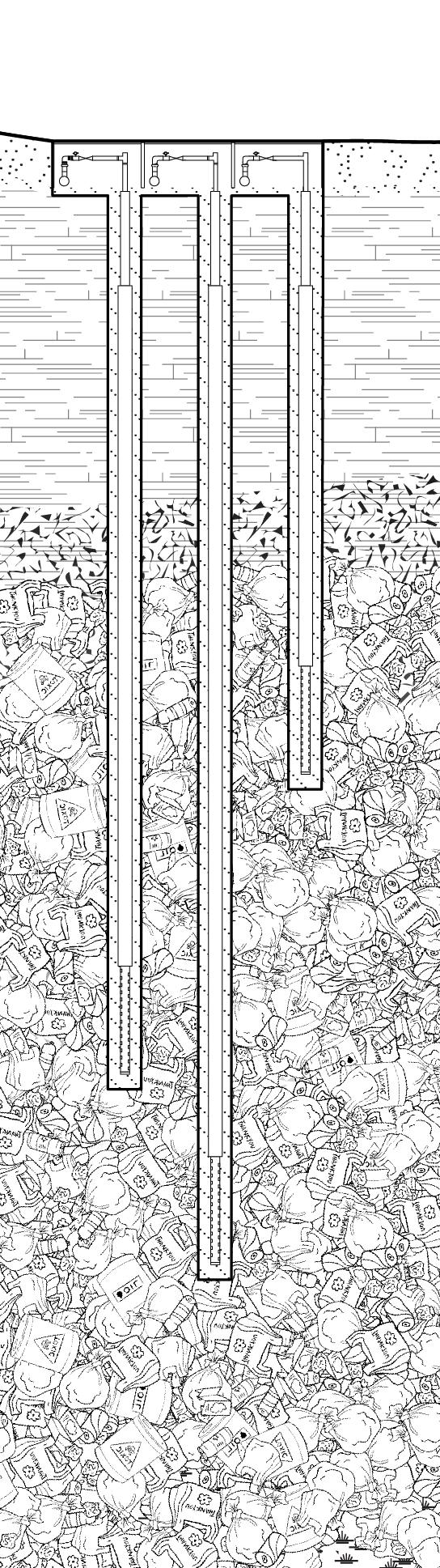

This location offers the opportunity to design for the local population and to utilize renewable energy. Gas retraction systems can create energy in the present from the methane buildup already within the landfill, and biogas digestors will give future waste the opportunity to be made into energy as well. Reconstructing Roots is an urban design project that redesigns the empty landfill to include a renewable energy plant, a public park with viewing platforms, and a memorial to the lost community.

It must be acknowledged that this project cannot fix the effects of climate change alone; the homes of many will be underwater in 100 years unless greater change is made. Most importantly, Reconstructing Roots tells a story of Edgemere so that people can remember what once was and work for a better future.

This project was done in collaboration with Lauren Li and Lillian Zhao.

+3ft of water

The landfill, having been previously declared a Superfund site, will be safe to build on in 2021

of Edgemere Rhino, Adobe Illustrator, Adobe Photoshop

+6ft of water

+10ft of water

Map

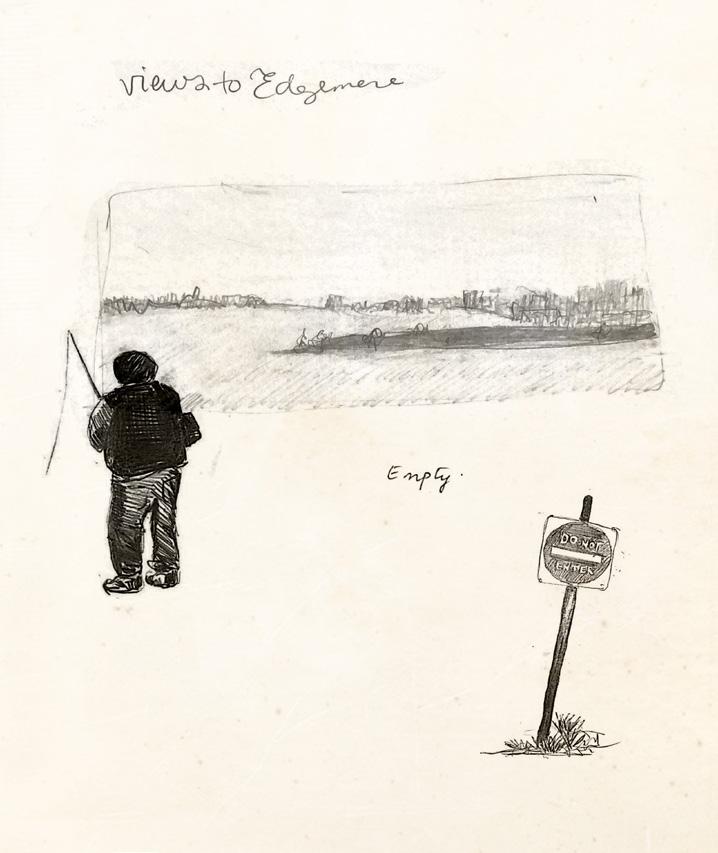

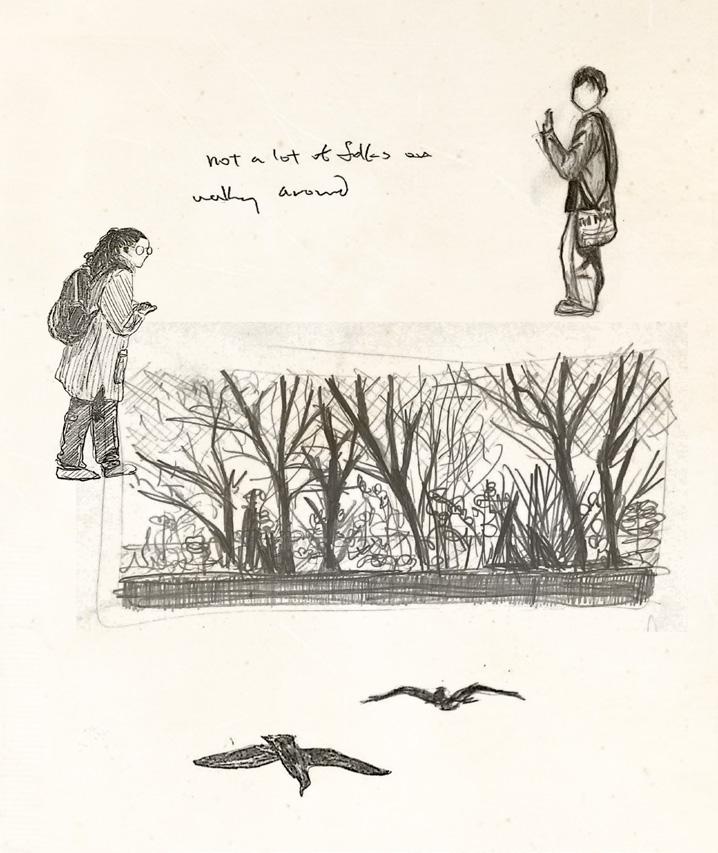

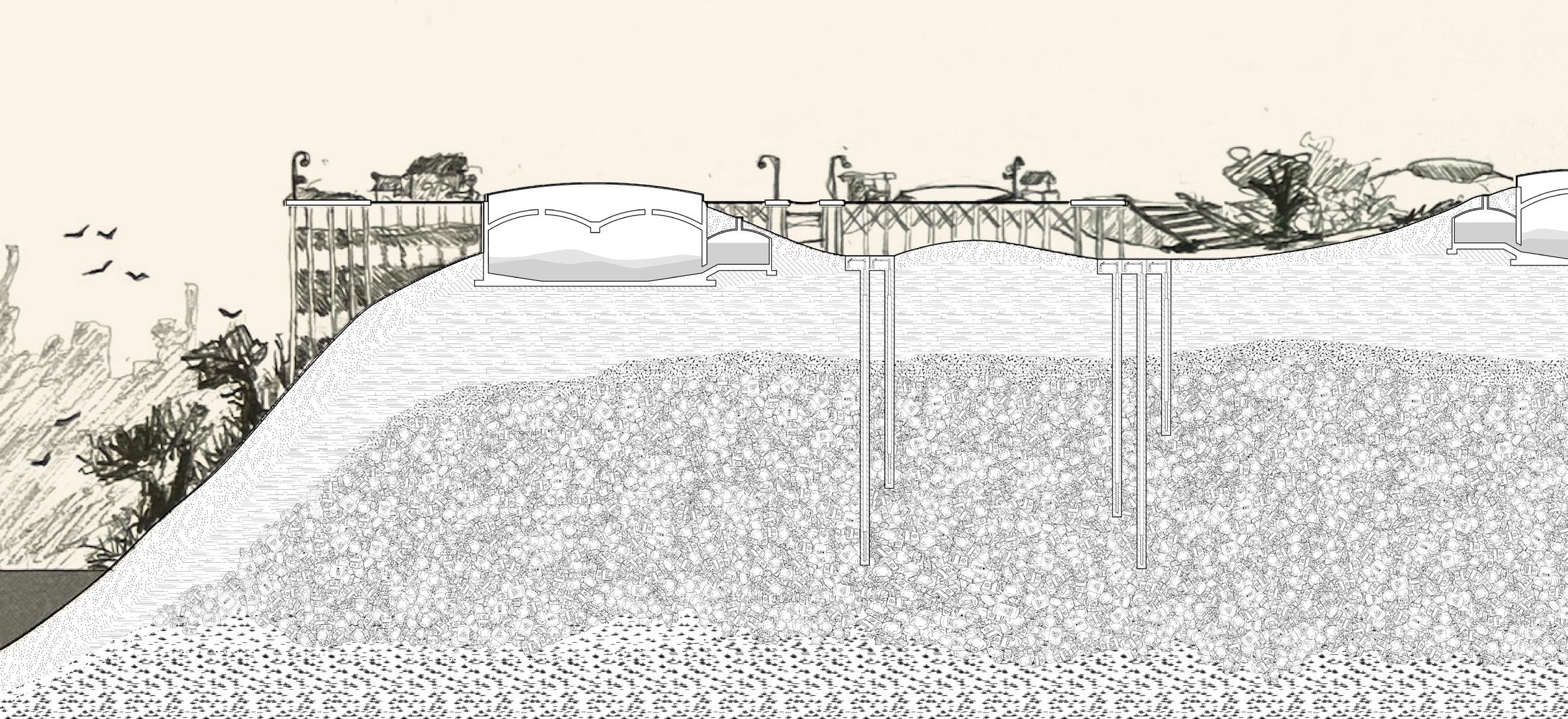

Collaborative collages (above) and section diagrams over time (right)

Hand Drawings, Photoshop

Gas Retraction

Biogas Converters

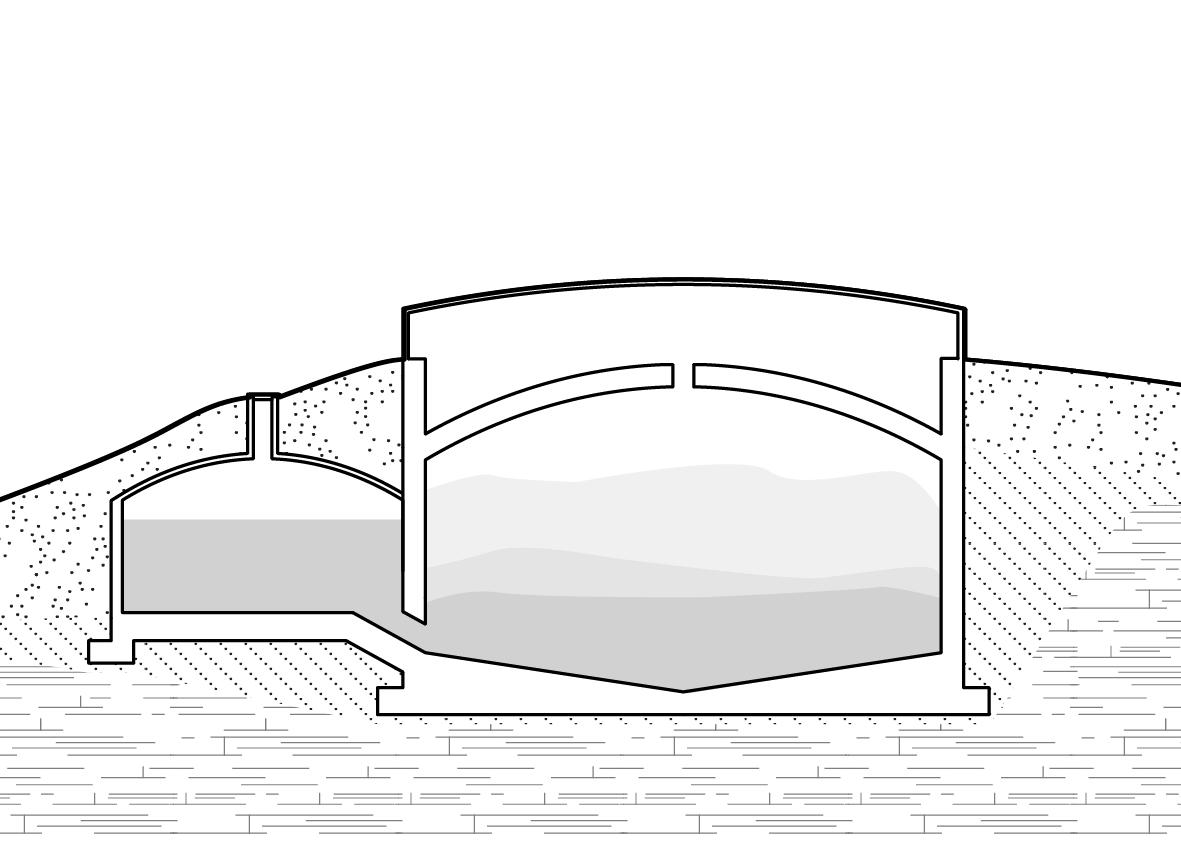

The Memorial Edgemere +10 feet of water

Site Section (top) and close-ups (bottom) Rhino, Adobe Illustrator, Hand Drawings

Site Plan (left) and Key Views (right)

Rhino, Adobe Illustrator, Hand Drawings

3.

2. a view of New York City

the park built up 4. the park on the ground

5. the future ferry entrance

6. the memorial for Edgemere is transformed in a lifetime

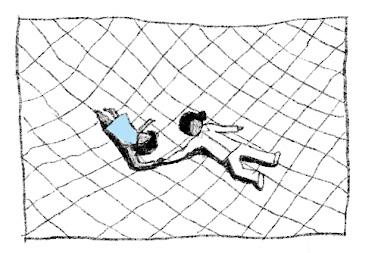

What is this thing?

a book about a found object

Thisoddlyshapedbookwrapsaroundastrange,unnaturalform.Unwrappingthebook proves an additional challenge due to the mysterious 10 pound weight in the center. Throughoutthebook,thereaderlearnswhatthiscentral“thing”wasmadefor,howitwas made, and the larger implications of said making process.

What is this thing? answers the titular question in two ways that, hopefully, forces the reader to reconsider the literally heavy burden that comes with opening this book in a new way.

What is this thing?

chipbaord, canvas, laser cutting, Rhino

What is this thing?

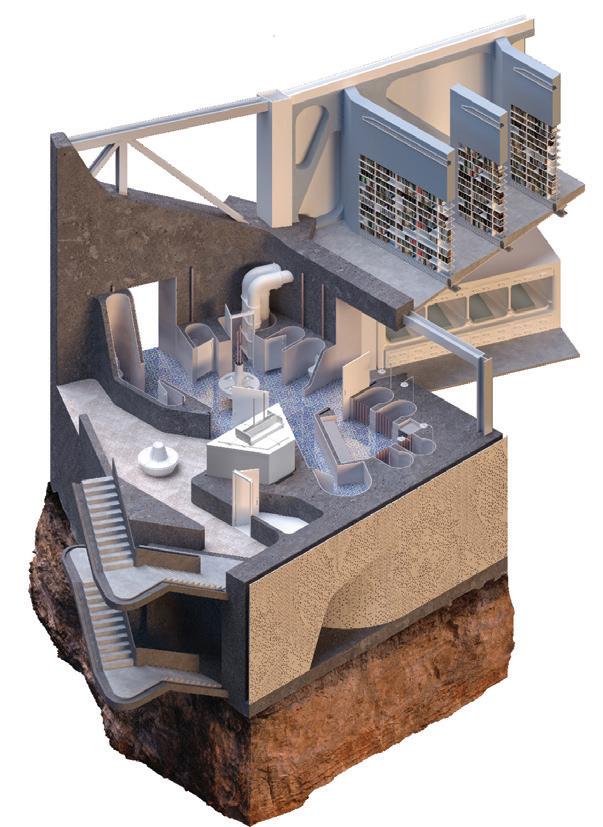

This was one part of a final architecture model done by two fourth years at Syracuse Architecture in Spring 2023.

Theoveralldesignisfora mediathequeinIstanbul, Turkey.Scholars,professors, andstudentsliveandworkfor dayswithinthisbuilding,soliving spacesweredesignedalongside workingspacesandarchives.“Weusedtheprogressionofideasin program,form,andmaterialitytodevelop projectsthatdealwiththeideaof estrangementindifferentscalesand contextswiththegoalof re-interptetingthefamiliar”

thiswhatISthing? But, WHATYOUWILLNEED

ThisisPLASTER Specifically, 10poundsof thisplaster:

However,therearemanyotherbrands thatwillwork.Alloftheseproducts comeinpowderformandarecast samebasicprocess.

Makeamoldoutoffoam; thiscastneededapiece thatwas24”x24”x3”big Getadisposablecontainer andutensiltomixthecast Laydownnewsprintor otherscrappaperto protectyourworkspace

thisprocessgetsmessy,and itcanbeeasierwithafriend

What is this thing?

Estrangementofforminchallengingconventional volumes

This model isof the bathroomof thisproject.Onehas towalk throughthebathroomto move between spacesof sleep andworkandin doingsois forcedto defamiliarize oneself with our preconceptionsof“the bathroom.”

Estrangementin materialth roughtheadaptation of traditionaltiles Estrangementof programbycombininga mediatheque with anaphotel

Adobe Photoshop, Adobe Illustrator,

Adobe InDesign

LIST OF THINGS TO DO

1. sizing of page after paper

2. destroyed foam drawing in final step

3. layout arrangement in black

4. mask images of process

4a. fix layout

5. reorder colophon and instructions

6. print to pdf and check lineweights

1. fix background color

2. 200 pages of content

3. delete readmore

4. cultivate first 10 pages

5. colophon and additional breather layout

6. cover laser layout

7. email Greenberg about book cloth

1. get photos from Karl

2. finalize layout

3. finalize text and cover

4. figure out how to make cover

5. print layout prep

1. redo first test

2. redo second test

SULFATECALCIUMCONTAINSWARNING: SILICA.CRYSTALLINEANDHEMIHYDRATE withcontactrepeatedorprolonged,Direct, createdDustirritation.causemayskinthe nose,skin,eye,causemayproductfrom Avoidirritation.respiratoryupperorthroat, Usecontact.eyeanddustofinhalation NIOSHausingareawell-ventilatedinproduct respirator.approved causesmaterialstheseofmanufactureThe theofstagesallatimpactsenvironmental process.woulditcountry,awereindustrycementtheIf inemitterdioxidecarbonlargestthirdthebe surpassedtonnes,2.8bntoupwithworldthe landfilled,WhenUS.theandChinabyonly todownbreaksanaerobicallywastegypsum smelling,rotten-eggcharacteristicallyproduce mostThegas.sulfidehydrogentoxichighly respiratorythearegasthisoftargetssensitive healthpublicposingsystem,nervousandtract gypsumincinerated,Iflarge.andbyriskat thatgastoxicadioxide,sulfurreleases alike.waterandairland,thepollutes

Luckilythismaterialcanberecycledoncefinalsareover,itjustneedstobe brands castinthe

Mix3partsplasterpowder and1partwateruntilwell combined.

Pourplasterintomold-be suretotapoutanyair bubbles!

Afterthecasthasset, removeitfromthe moldanduseitinyour finalmodel! *thefoammoldwillbedestroyedin theprocessofremovingthecast

Letsitforuptoanhour

PULVERIZED INTO D

UST

an not, it all just

Just like this object, there is a lot of waste that is either difficult to recycle or not recyclable at all.

doneandthisisn’tcountingthemodelsthatare fornon-studio architecturalclasses,andthisisn’tcountingalloftheiterationsof modelsthathadtobedonebeforethefinal, andthisisn’tcountingalloftheeasilyrecycledstuff thatjustgetstossedoutwitheverythingelse,

butifeverymodel

Leftovercastwillgetstuckonthemixing throwncontainersandutensils,sothesemustget outaftertheprocess

All in all, between the foam mold, the mixing materials, and the cast itself, nearly 2 cubic feet of waste was produced to make this object.

Now, let’s do the math.

(50+100+150+400+600)x2 andthereare 600final models madeinfirstyearstudio,

If every final model produces 2 cubic feet of non recycled waste and there are 50 final models made in fifth year studio, andthereare100finalmodelsmadeinfourthyearstudio, andthereare150finalmodelsmadeinthirdyearstudio, andthereare 400finalmodels madeinsecondyearstudio,

isimperativetoevery student’seducation,

thenisthereanythingthatcanreallybe

Rigid insulation foam

The papers you use to

adhesives,

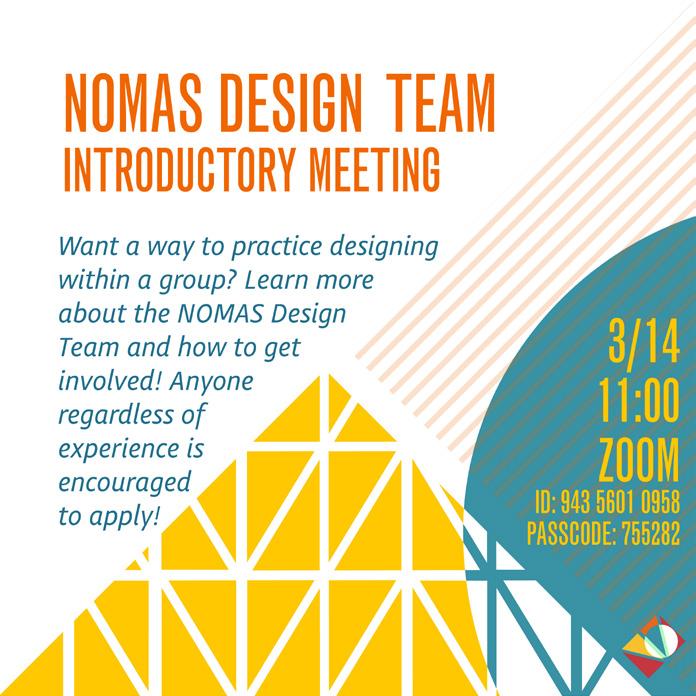

Promotional Material

work from my time as NOMAS Communications Chair

For two years, I was one of the Communications Chairs of Syracuse University’s chapter of the National Organization of Minority Architecture Students. I created several promotional posters for NOMAS events and opportunities to be posted digitally on Instagram and physically throughout the school. The designs had to follow some design guidelines to fit within the Syracuse NOMAS brand, but the elements and geometries could be reorganized however I wished.

Ouroboric Matter

exhibiting the material properties of a flax-chitosan composite

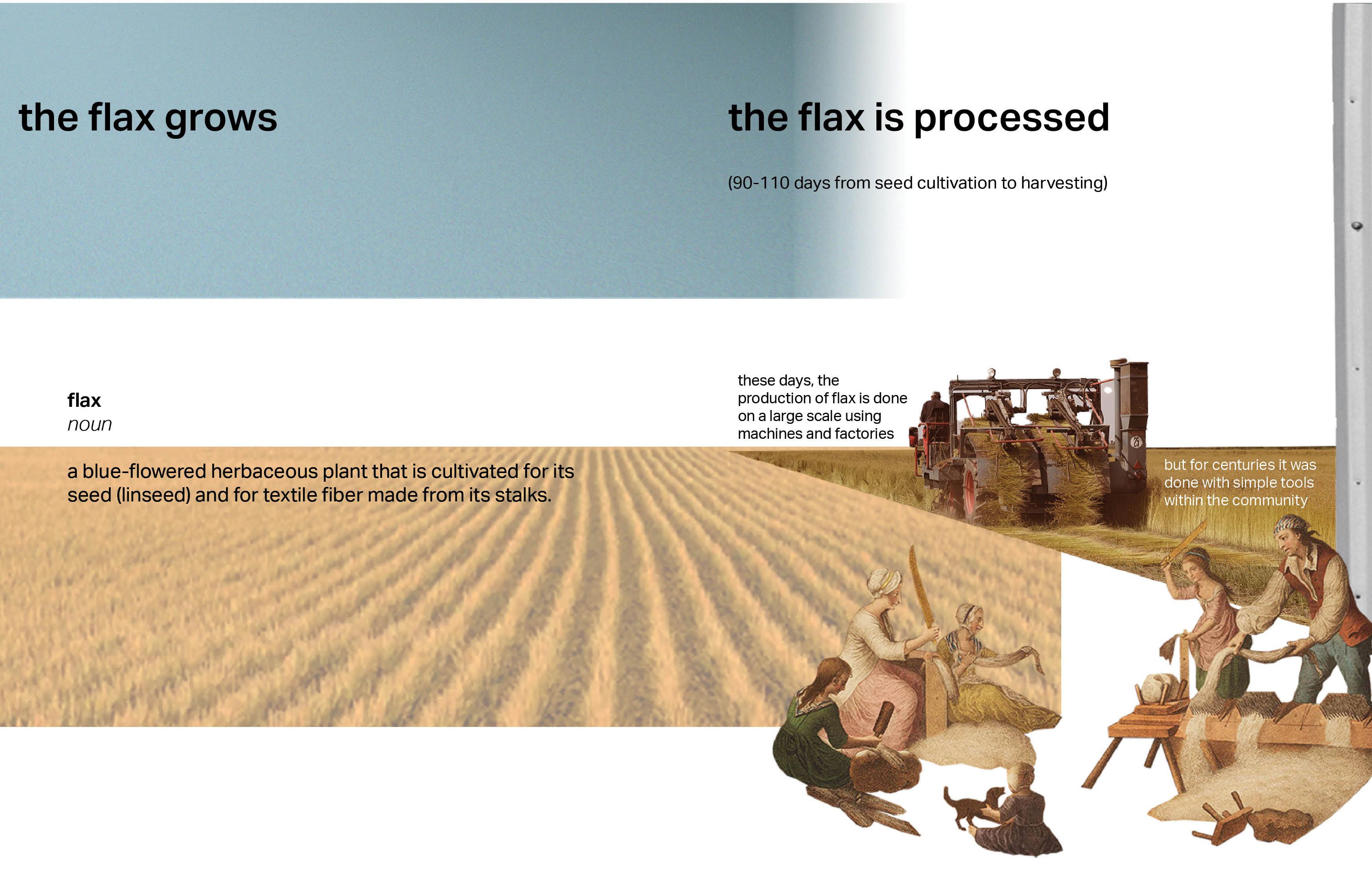

The project started with a question: How can flax become architecture?

We aimed to create a flax system that highlighted the properties of the material using raw flaxfibersofdifferentlengthsasourstartingpoint.Weoptedtomakeflaxpaperbyhandas thevehicleforform.Thevisualqualitiesoftheflaxpaperwereespeciallyintriguing,andthe display of such qualities informed our trajectory in design.

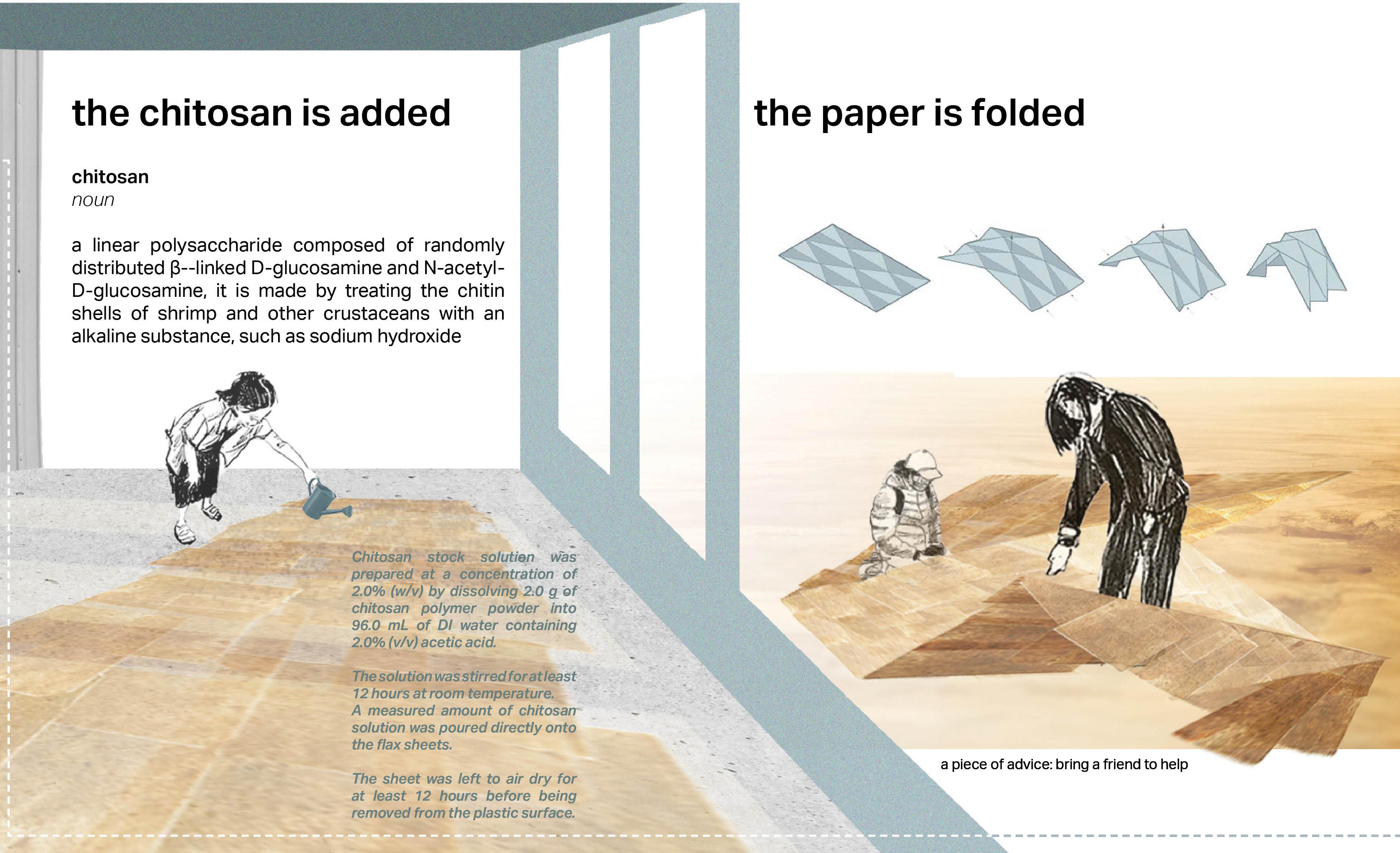

Usingchitosan,achemicalsubstancederivedfromtheshellsofshellfish,achitosansolution wasmadebydissolvingchitosanpowderinalow-concentrationacidicsolution.Thissolution waspouredontothepaperanddried.Asthesolutionevaporated,thechitosanwasleftbehind andcreatedatransparentplastic-likefilmoverthefibers,strengtheningthesheetofpaper.

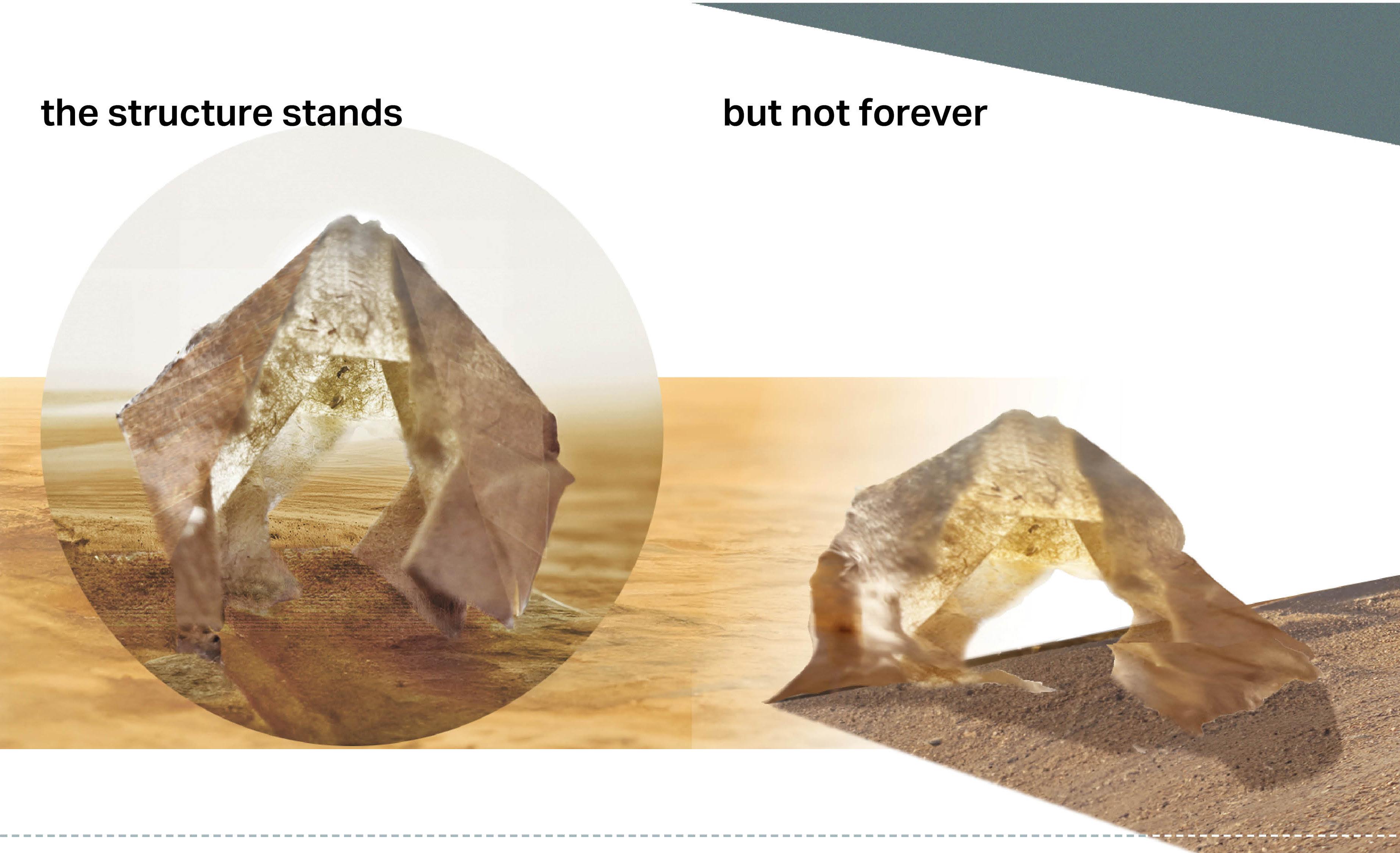

This strengthening was then used to fold and form the 2D sheet into a 3D arch.

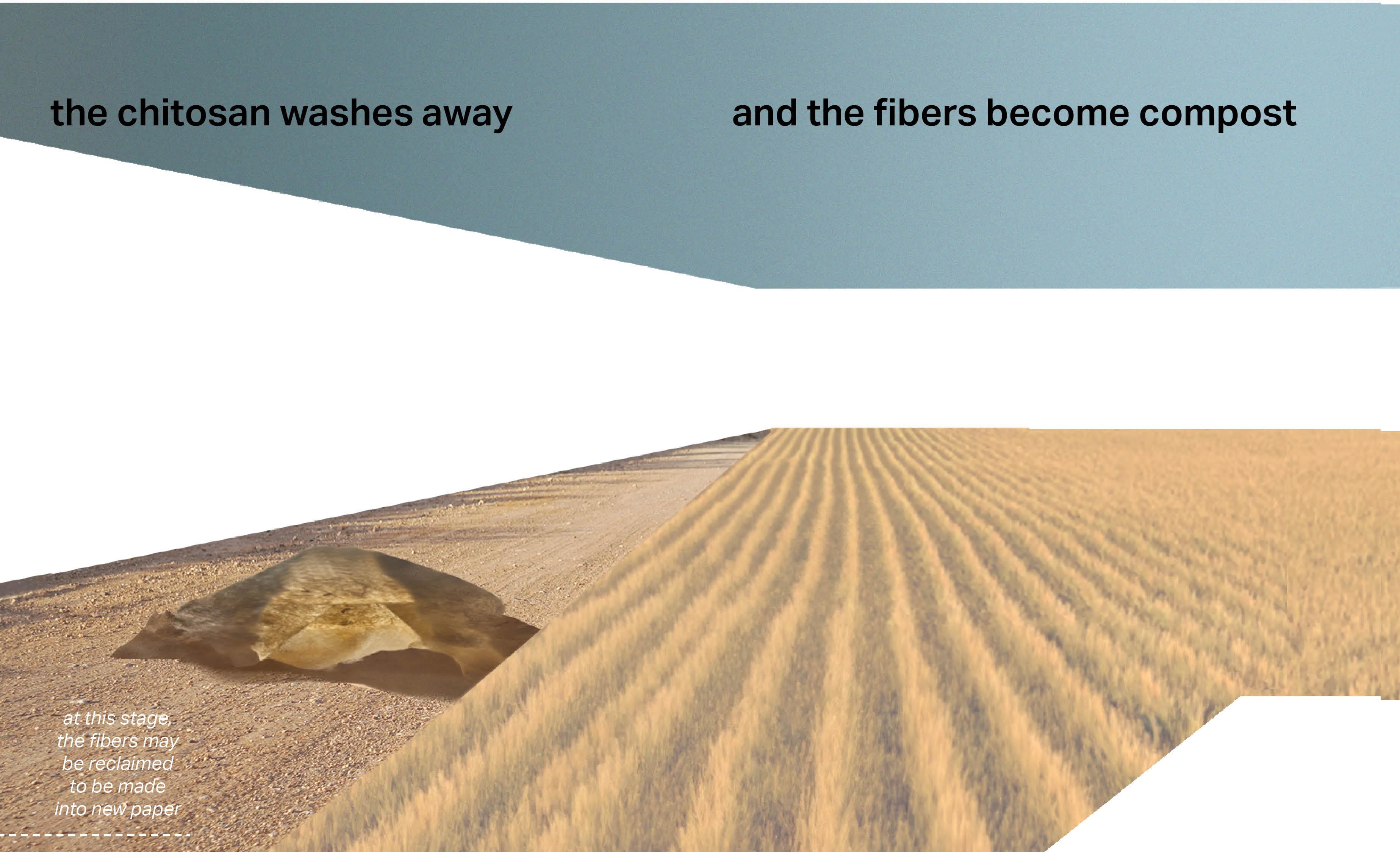

Priorresearchhasestablishedthatthechitosansolutioncanbewashedoffoftheflaxfibers. Oncethisprocessoccurs,theflaxcanberepurposedintomakinganewpaperstructure,orit can be used as compost to grow new flax. Either way, the materialin the next cyclerelies on the destruction of the old one.

ThisprojectwasdoneincollaborationwithSebastianSchwarz,buttheworkdisplayedhere is my own.

Study

Handmade Flax Paper, Chitosan Solution

Models Folding the Flax Paper without Chitosan (top) and with Chitosan (bottom)

Process and Life-Cycle

Adobe Photoshop, Adobe Illustrator, Hand Drawings, Adobe InDesign

Selected Prints

Medium: Screenprint, 12”x12”

Design: Adobe Photoshop, Adobe Illustrator

Design: Hand sketch,

Shrubris (Shrimp Hubris)

Medium: Linocut Print,

Sardines Remember

Print, 7”x10” Adobe Illustrator

Interrupted

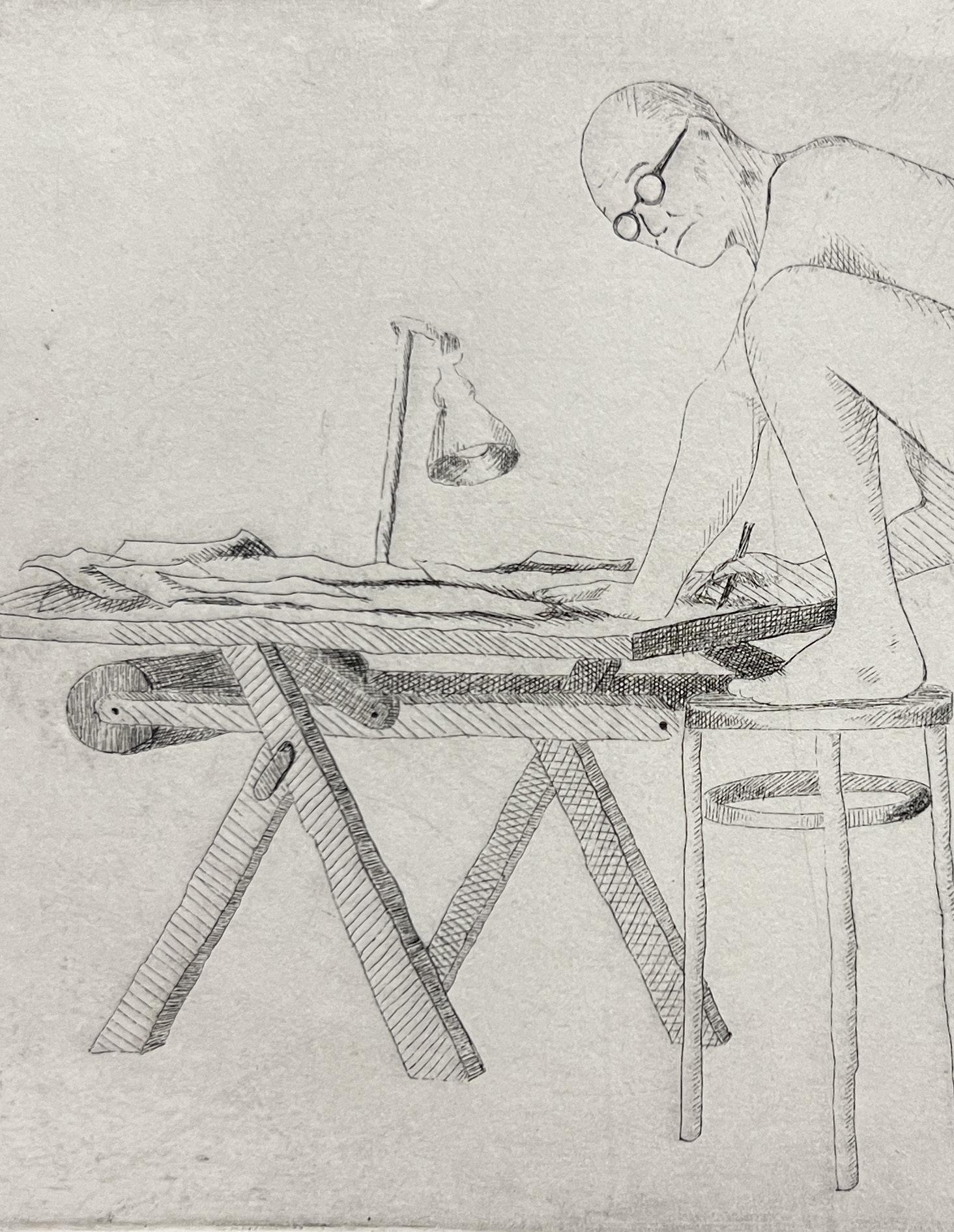

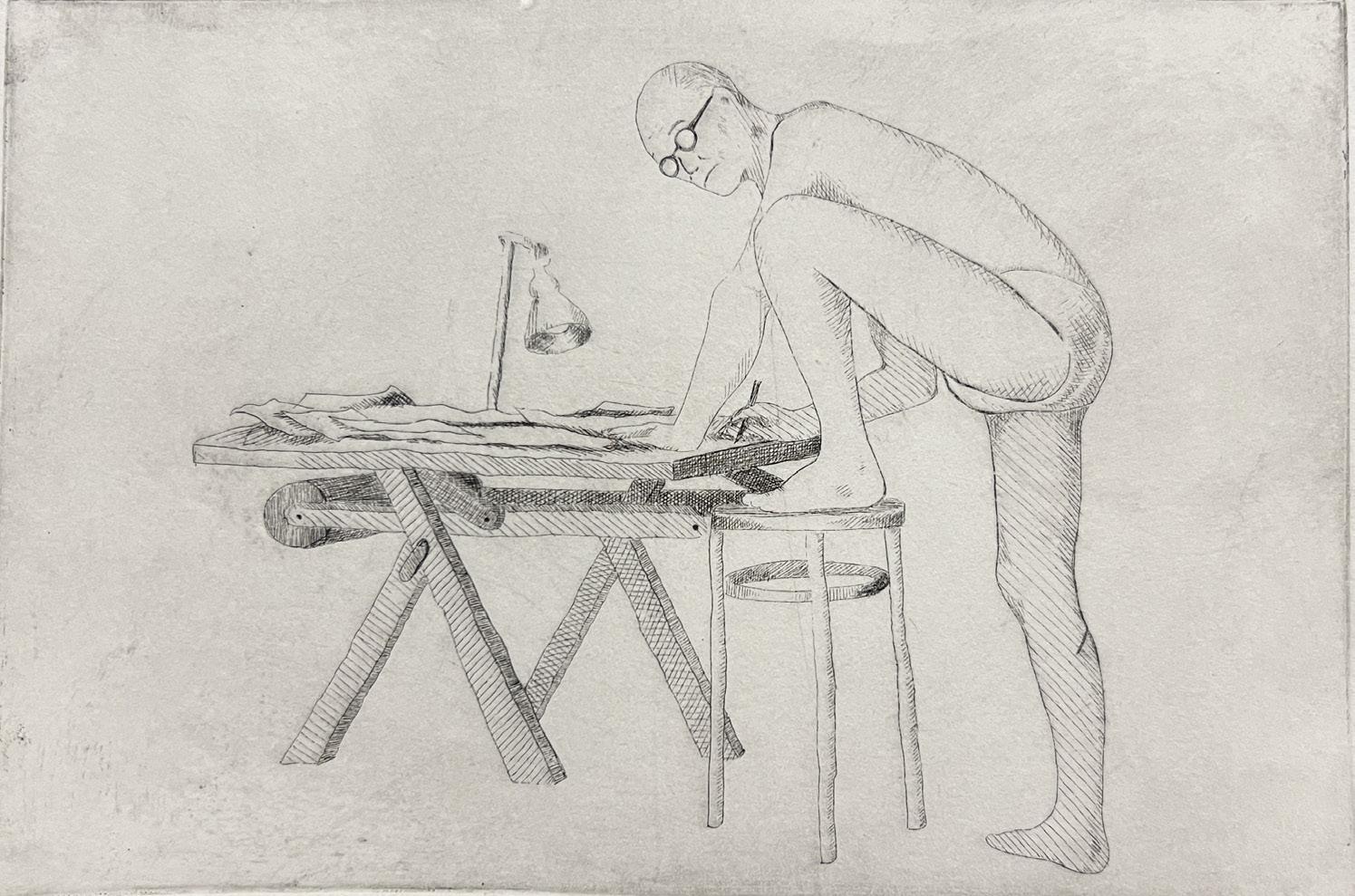

Medium: Copper Plate Engraving, 6”x9”

Design: Adobe Photoshop, Hand sketch

Hubris)

Maya Angela Simms mayaangela2052@gmail.com

610 858 8996