www.maxwellslitters.com

StartSlide

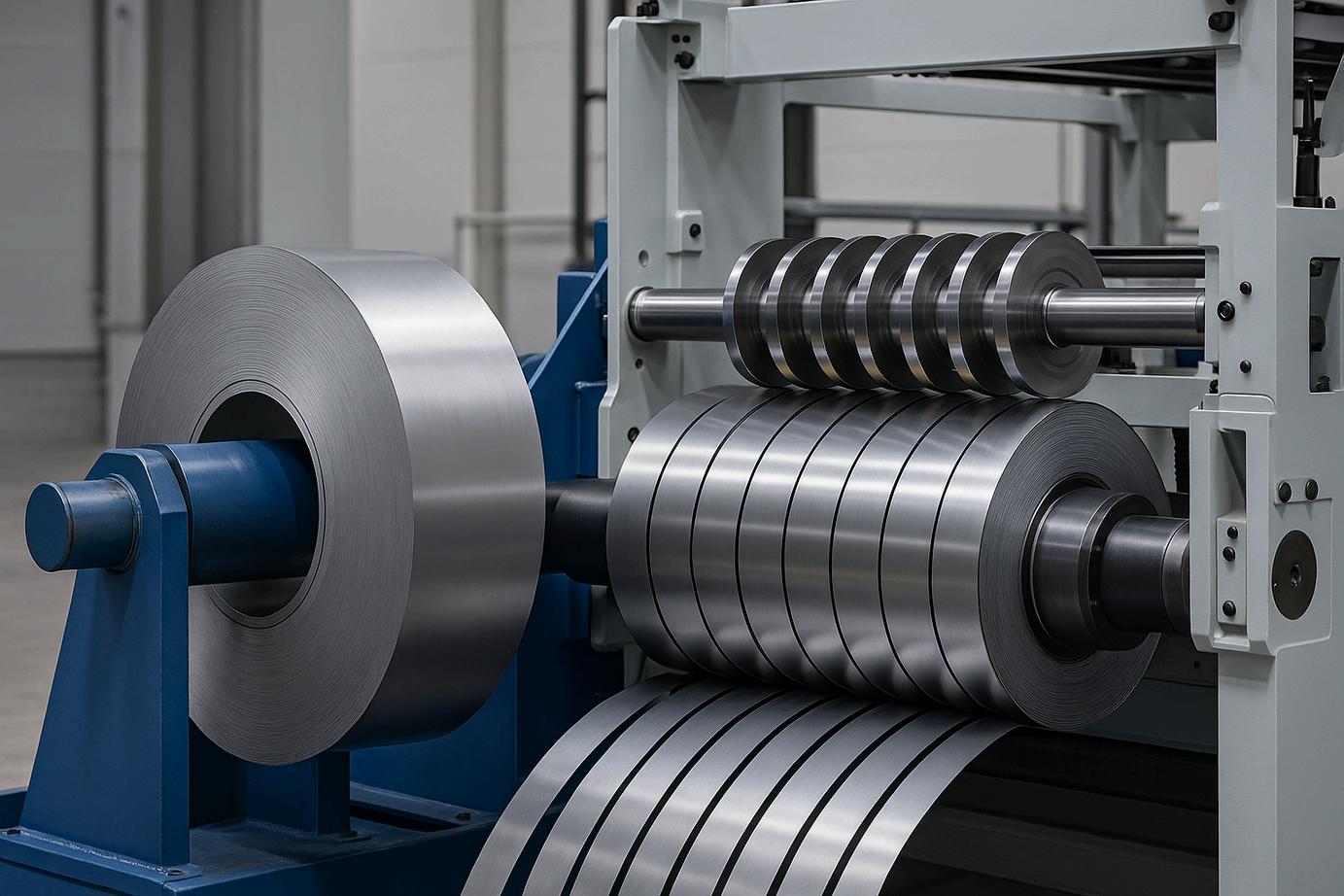

When it comes to manufacturing, precision cutting, or heavy-duty processing, industrial blades play a crucialroleinensuringefficiencyand productivity.Whetheryouareworking in packaging, food processing, metal cutting, or plastic conversion, choosing the right industrial blades can drastically impact your operational success. With numerous manufacturers and a range of blade types available, selecting the right bladerequirescarefulconsideration.

MATERIAL QUALITY: THE BACKBONE OF PERFORMANCE

The material from which a blade is made determines its durability, sharpness retention,andoverallperformance.High-carbonsteel,stainlesssteel,toolsteel, andcarbide-tippedbladesarecommonmaterialsusedinindustrialblades.

High-CarbonSteeloffersexcellenthardnessandwearresistance.

Stainless Steel is ideal for environments where corrosion resistance is essential,likefoodprocessingorhumidconditions.

Tool Steel ensures strength and durability for high-speed and precision operations.

Carbide-Tipped Blades are known for their hardness and resistance to abrasion,idealforcuttingthroughtoughmaterials.

BLADE GEOMETRY AND EDGE

TYPE: MATCH IT TO THE TASK

Not all blades are designed the same. Blade geometry, including length, thickness, edge angle, and tip configuration, must match the application. Straight-edge blades are great for clean, precise cuts.

Toothed or serrated edges are helpful in cutting fibrous or rigid materials. Hook or concave blades are often used in slitting and trimming operations.

TOLERANCE AND PRECISION: KEY FOR CONSISTENT OUTPUT

In precision manufacturing, even the slightest variationcanleadtoproductdefects,machinewear, or downtime. That’s why high-quality industrial bladesaremanufacturedwithstricttolerances. Ask your blade manufacturer about their machining tolerance levels. Look for blades that are precisiongroundandquality-inspectedwithdigitalmeasuring tools. The more accurate the blade, the more consistentandreliableyouroperationswillbe.

BLADE COATINGS: BOOSTING BLADE PERFORMANCE

Bladecoatingscansignificantlyenhance performance,particularlyindemanding environments.Coatingsreducefriction,increase wearresistance,andpreventcorrosion.

Popularcoatingoptionsinclude:

TitaniumNitride(TiN)forincreasedhardness

ChromeCoatingforrustresistance

CeramicCoatingsforhigh-temperature operations

MAINTENANCE AND RESHARPENING SERVICES

Blade maintenance is crucial to performance. Even the best industrial blades will dull over time. Choose a supplier that provides resharpening, honing, or refurbishmentservicestoextendthelifeofyourblades.

Somebenefitsofprofessionalresharpeninginclude:

Costsavingscomparedtobuyingnewblades

Maintainingoriginaltolerancesandedgegeometry

Safebladehandlingandproperdisposaloptions

Industrial blades are more than just cutting tools. They are integral to your operation’s performance, precision, and profitability. When purchasing industrial blades, it is essential to look beyond price and focus on factors like material quality, blade geometry, tolerance, equipment compatibility, and after-sales support.

Opt for a reputable manufacturer with a track record of excellence and the ability tocustomizesolutionsforyourneeds.