The Automatic Micro-Hardness/Hardness Testers

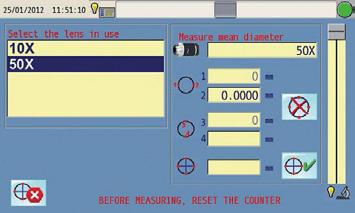

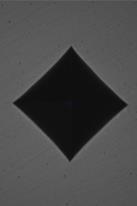

ISOSCAN AC version allows the execution of Vickers microhardness and hardness tests by measuring the diagonals of the indentation, which is generated automatically by the instrument. The system assures a high level of reliability and fast measurement and fully complies with ISO 6507/2 – ASTM E384 Standards.

It is provided with a device for the motorized load application and generation of indentations. The measuring device is composed of an optical group fitted with a LED illuminator and a high resolution digital camera allowing the indentation readout in two modes :

-Automatic reading : the system tracks the indentation and carries out the relevant measurement to determine the hardness values

-Manual reading : the operator moves a line reference onto the four vertices of the indentation and the system measures the two diagonal, calculating the resulting hardness values.

ISOSCAN OD series is the new line of automatic microhardness / hardness testers, allowing Vickers and Knoop microhardness / hardness testing by measuring the diagonals of an indentation automatically generated by the instrument.

The indentation measurement is carried out manually by means of a high precision digital micrometric eyepiece with LCD readout. The complete test cycle, electronically controlled, is in conformity with ISO 6507-2 and ASTM E384 Standards.

Ergotest DIGI Digi 25 R / Digi 25 RS

-Automatic conversion of the values measured in the various hardness scales: Rockwell, Brinell, Knoop, Vickers as well as tensile strength according to either “Galileo conversion tables”, ISO 18265 or ASTM E140 standards.

-“Go-no go” function

-Automatic test cycle with electronic process control

-Load dwelling time 1-99 s selectable by keyboard

-Self diagnosis program

CATALOG CATALOG

-USB port

-LAN connection

-Load selection by knob

E-Computest

Portable light load hardness tester

E-computest is a light load (5 kgf) portable hardness tester using the Rockwell method (preload, full load, and reading back at preload)

It can be used to test the whole range of metals, without changing the indenter

Allows fast wireless data sharing (up to 100 meters distance) through a user-friendly Android application

Cordless design for a great working ergonomy

Can be supplied with international standards certification

Working principle : Rockwell

Loads : 5 kgf (49N)

Preload : 11.2 kgf (11.8 N)

Load application method : Manual

Standard scales : HRC (0-70), HRB (0-120), HB30 (80-700), N/mm2 (260-2300), kg/mm2 (27-235), HV (35-1080), DPTH (0-100)

Reading : on touch-screen tablet 5.9” display

Storage : 16 GB

Minimum meas. dia. : 2 mm with stand N, 3mm with stand T, 35 mm by hand

Output interfaces : tablet with micro usb - micro TF slot

Outputs : wifi, Bluetooth, gps

Power supply : 100- 240 volt

DIN 50157 (ASTM E-18 ISO 6507 ISO 6508 ISO 6506 indirect method)

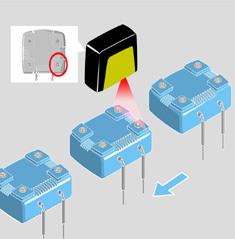

e●Brio²

Standard scales : HB 30 HB 10 HB 5 HB 2.5

Brinell loads : 3000-1000-750-500-250-187.5-125-62.5-31.2-15.6 kgf

Selectable functions : Brinell indentation readings, histogram of the tests, statistics, printout of the test report

Reading : Automatic / Camera resolution 752 X 480 pixel / Reading resolution 0.001 mm

Camera resolution : 752 x 480 Pixel

Minimum meas. dia. : 0.7 - 5.0 mm

Working area : base : 30 mm diameter

Dimensions : H 170 mm , Ø 66 mm

Working conditions : 0 - 50° room temperature

Weight : 0.750 Kg

Norms and certifications : ASTM E10 and ISO 6506

AT130 DR-NX

Working principle

Preload

E-BRIO Price : 275,000.-

E-BRIO With Tablet Price : 299,000.-

> MOD DR : Rockwell > MOD DR : 10 kgf (98.1 N)

Loads

> MOD DR : 60 kgf, 62.5 kgf, 100 kgf, 125 kgf, 150 kgf, 187.5 kgf (N 588, 613, 981, 1226, 1471, 1839)

Standard scales

> MOD DR : HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, Other scales on request.

Load application method : Manual with automatic pre load application

Selectable functions : Scales, Tolerances, Calibration.

Output : RS232

Reading : On display

Power supply : 115VAC o 230VAC

Minimum meas. dia. : 4 mm

Working area : Max. Measurable Height : 210 mm/ Depth: 240 mm

Working conditions : 0°C - 50°C

Dimensions : 30 cm x 60 cm x (h) 73 cm

Weight : 95 kg.

Norms and certifications : Rockwell - ASTM E-18 - ISO6508

Price : 349,000.-

P1 KB 30 S FA basic Fully automatic machine

Micro/Macro hardness testing machines from KB convince by extraordinary precision and reproducibility. The user enters a whole new world of hardness testing by the use hardness testing software KB Hardwin XL. The KB hardness testing machines can superiorly test Brinell, Vickers and Knoop.

New innovative developments allow new possibilities of automation which guide the user fast and quickly to the test results. The product line Load Cell Range bases upon different stages of extension, 10, 30 and 50 kgf. This subdivision combined with numerous additional options suit the KB hardness testing machines optimally to the user‘s individual needs.

- Operation via the hardness testing software KB HardwinXL

- 5 Megapixel USB-camera

- High load step range 0.01 kg – 50 kg

- KB 4x digital zoom (standard)

- KB 7x optical zoom (optional)

- LED lighting

- Export into Excel or text file

- Customer-specific test protocol creation

- Network compatible

- Equipment variants from individual tests to fully automatic machines

- Subsequent upgrade to fully automatic system possible

P1 KB 30 S FA basic

Including : - KB 30 S FA basic.

- Light control, autofocus, auto measurement.

- Desktop PC With 24” monitor.

- Vicker indenter > HV 0.2

- Fixed optic with 20x objective.

- Selectable load range 10 kgf, 30 kgf, 62.5 kgf

- Software option Scanning.

CATALOG

Software to Control Hardness Testing Machines For New Machines and Modernizations.

Configuration Levels and Options Software Hardness testing

YOUTUBE

X = Including, O = Option, - = Not Applicable

Software Hardness testing with KB HardWin XL

Suitable for controlling individual testing machines right up to fully automatic machines

Procedure Rockwell DIN EN ISO 6508, Vickers DIN EN ISO 6507, Brinell DIN EN ISO 6506 Knoop ISO 4545 and DIN ISO 4516 USB video camera can be connected, for manual or automatic measurement of the indentation on the monitor

Correction of curved surfaces according to DIN EN ISO for Vickers and Rockwell

Conversion tables according to EN ISO 18256 incl. extended reassessment table

Warning when exceeding the scale area, Series testing as standard

Optional pattern tests manually or automatic,welding test, multiple sample holder, mapping

Measurement values as table and diagram

Software testing with statistics, data export, (Option control chart)

Operating system Windows XP / Vista / Windows 7/ Windows 8

Language German and English available ex works

Customer-specific coupling and networking to QS systems

Can be extended to semi and fully automatic machines

CATALOG

Advanced Motorized Torque Test Stand

- Mounting holes for bench mounting.

- Base may be removed for alternative mounting.

- Grip / fixture mounting plate with 25 #10-32 threaded holes.

- Integrated angle indication with programmable travel limits.

The TSTM-DC Advanced Motorized Torque Test Stand offers all the mechanical specifications of the TSTM motorized test stand, including standard 11.5 Nm torque capacity, versatile modular design, quick engagement and disengagement of samples, fixture mounting plate, stepper motor design that prevents speed variation with load, and more. A 22 Nm capacity upgrade is available as an option. including full PC control, programmable angle limits, programmable cycling, auto return, password protection, and other features.

Technical

Maximum torque

Speed range:

Speed accuracy

Maximum programmable travel limits

Rotational travel accuracy

Rotational travel repeatability

Rotational travel resolution:

Slider travel rate:

TSTM-DC Price 299,900.

Standard : 11.5 Nm, Optional : 22 Nm

Standard : 0.05 - 90°/s, Optional : 0.2 - 360°/s*

: ±0.2% of setting, ±0% variation with load

travel limits: ±999,999.9° / ±2,777.77 revolutions

: ±0.7° / 0.02 rev.

: 0.1° / 0.01 rev.

Rotational travel resolution: 0.1° / 0.01 rev.

26.6 mm / lever revolution

* Maximum torque decreases proportionately with speed.

Examples : Maximum torque at 60 RPM = 2.8 Nm, Maximum torque at 30 RPM = 5.6 Nm

Strength Meter (Pulse Velocity Tester)

IPSM-U+T+D

The pulse velocity tester IPSM-U+T+D allows to measure the strength and homogeneity of the concrete, bricks and other materials under the composition and surface sounding in products and designs for construction projects, inspection of buildings and structures, according to ASTM C597-16 (Standard Test Method for Pulse Velocity Through Concrete). Has the determining of the depth of cracks by the surface sounding probe function and also flaw detection mode (A-scan).

TECHNICAL

CATALOG

Concrete Cover Meter Rebar Dectertor

Concrete Cover Meter Rebar Detector is designed in accordance to EN 12504-4, ASTM C597-02, ISO 19207:2004, IS13311, CECS 21 standards and is intended for operational monitoring of reinforced (searching rebars inside building structures) concrete products and structures for process control in the factories and building sites, surveys buildings and structures.

The main function

- Scan mode products & Deep search for reinforcement.

- Configuration mode for steel.

- Measuring the thickness of the protective layer of concrete with a certain diameter.

- Determination of the diameter of fittings for a known protective layer.

- Measurements of the unknown parameters of reinforcement.

TECHNICAL

The device measures the protective layer of concrete by magnetic method. The range of measurements of the propagation of

Concrete cover meter rebar dectertor Price : 69,900.-

CATALOG CATALOG

protective layer 175 mm

Measurement accuracy (0,03 h + 0.5) mm

AC-4624

Tensile Adhesion Tester AC-4624 is manufactured in compliance with EN13144 and ISO4624, ISO16276-1.

The testing with mechanical tensile adhesion tester AC-4624 is performed in the following way.

On the testing cover is glued dolly and after that, it is pulled-off with the spring-system of the device.

The force which is applied for pulling-off the glued dolly, is displayed in numerical value by the indicator on scale of the device.

This value – is the value of adhesion.

TECHNICAL

Breakout force

200 kg

Diameter of base dolly 15,1 (№ 1) and 19,5 (№ 2) mm

Specific breakout force Dolly №1 up to 10 MPa (100) Dolly №2 up to 6 MPa (60)

Scale 1 (№ 1) and 2 (№ 2) Mpa

KRC-M2

Steel Structure Analyzer is designed for measuring coercive force of metal products in accordance with IEC 60404-7 and is used for non-destructive testing of chemicalthermal, thermal and thermomechanical treatments, evaluation of mechanical properties and residual stresses.

Steel Structure Analyzer allows to determine the mechanical properties and hardness of metals and to test the ferromagnetic products if there are any correlations between tested parameters.

The main area of using the Steel Structure Analyzer is analys the stress-strain state and residual life of pipelines, elevators, cranes and lifts, pressure vessels, steel cables of bridges also it used in engineering and metallurgical industries.

TECHNICAL

: KRC-M2 Price : 139,000.-

- Measurement of coercive force

- Current measurement

- Code measurement (units)

- Additional scale for calibration

Troq-Tronic

Features :

• Accuracy of +/- .5% of Indicated Value from 10% to 100% of rated capacity.

• Tests in both clockwise and counterclockwise directions.

• Four modes of operation - Track, Peak, Initial Peak and Power Tool.

• Units of measure include English, Standard International and metric.

• With only 8 buttons Torq-Tronics 2® is amazingly simple to operate!

• Four line vacuum florescent display (VFD) is easy to read.

• Red/Green LED indicates whether a measurement is within the target torque value.

• Built with Fail Safe Engineering.

• Power Tool mode has ten filters and will accurately test all clutch type and pulse tools.

• Memory stores up to 999 records that can be downloaded to Hyper-Terminal or terminal type program or serial logger program included on the USB stick to create testing reports and data storage.

Applications

The VeriTorq® line of Digital Torque Testers is ideal when :

• Clicker type torque wrenches or torque screwdrivers need to be tested.

• An inexpensive and versatile tester for intermediate checks of torque tools is needed.

• Simplicity of operation is desired.

Features :

• +/- 1% Indicated Value Accuracy from 10% to 100% of capacity.

• Integral “L” bracket for horizontal or vertical mounting.

• Easy programming via our button control panel

• Units of measure include English, Standard International, and metric.

• Three modes of operation - Track, Peak and Clicker - provide excellent versatility.

• Electronics module with large display rotates horizontally and vertically for easy viewing

• Serial port for immediate or batch data transfer with terminal program

Global 400 mp (Part No. 10612)

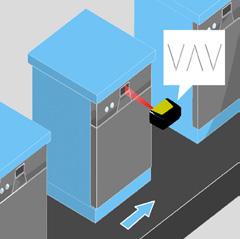

The Global 400mp distributes all the power, flexibility, ease and capabilities of the Global 400 over four (4) individual network interfaces. The result? Up to four (4) operators can work independently and don’t even have to be in the same work cell.

Four separate network interfaces and Global 400mp architecture eliminate the need for groups in order to support simultaneous work.

The operators can use any of the following tools:

• 1250 Series Exacta 2 digital torque and angle wrenches

• 1200 Series Exacta 2 digital torque wrenches

• 1200 Series PST (Pneumatic Sensor Transceiver)

• SLTC FM 2.4 GHz preset wireless click wrenches

Parameters are formed directly into jobs. With 4 network interfaces each operator can work on their own job, independent of the other operators.

The Global 400mp can be applied to assembly, repair, and maintenance operations.

The Global 400mp works with up to 16 torque tools, 8 holding tools and 8 I/O tools divided among the 4 network interfaces.

1200 Series Exacta 2

The 1200 Series Exacta® 2 Digital Torque Wrenches are made specifically to work with the Global 400 and the Global 400mp process monitors. With an accuracy of +/- 1% I.V. and the ability to report both variable and attribute data, you can be sure that all joints are tightened to your specifications.

• Bi-directional +/- 1% Indicated Value from 20% to 100% of tool capacity.

• Access to well over 100 interchangeable heads that all fit on all of our dovetail wrenches

• Choice of ratchet or our traditional pin/spring dovetail or quick change.

• Error Proofing by Guidance with visual and auditory operator feedback.

• Operator can complete active P-Set even if radio communication is severed

• The wrench automatically recalibrates for P-Sets requiring different head lengths

• When radio communication resumes, the wrench automatically uploads all missed P-Set data.

• Our Yellow/Green/Red guidance where the display turns yellow upon torque engagement, turns green when target torque is achieved, and turns red when maximum torque has been exceeded.

• Pairs with our new Holding Wrench for applications where two tools are required to create a compliant fastening.

(Example: Hydraulics)

System Capabilities :

• Six inch diagonal, back-lit, color LCD display

• 2-RJ-45 Ethernet ports allow for chain, or ring network communication.

• USB-A connector for use with bar code scanner, or updating firmware, and saving files.

• RS-232 D-Sub9 connector for use with serial bar code scanner or serial printer.

• Ten pin I/O connector providing discreet I/O capabilities.

• Five pin connector for the additional I/O capabilities of the optional GIM400.

• Power Supply 100-240 VAC at 50-60 Hz.

• Key switch for programming access. 21-function keys for programming.

• Adjustable and programmable beeper for audio communication.

Protocols : EtherNet IP, Open Protocol, ToolsNet, Software : SR Global Manager (Included) optional SR GlobalHost reporting software (Part No. 10622)

SLTC FM 2.4

Announcing the new SLTC 2.4 GHz A3 Preset Clicker-Type Torque Wrench. We kept the flattened case for superior accuracy, reliability, and durability. Customers tell us that this wrench holds calibration better than any other brand.

• Full compatibility with all Global 8, Global 400 and Global 400mp, TCV, TCV-Ethernet, and PTV.

• Access to well over 100 SR interchangeable heads.

• Accuracy of +/- 4% or better of preset value from 20% to 100% of capacity meets or exceeds requirements of ASME B107.300-2010 and ISO 6789.

• Excellent audible/tactile impulse when preset torque is achieved.

• Error Proofing By Guidance: Monitors time in the “clicked” position to provide “OK/NOK” quality attribute data with every use of the tool.

o Too little time in the clicked position means the tool was likely “jerked”, resulting in over-torque.

o Correct time in the clicked position means the tool was used properly to transmit the preset torque correctly to the fastener.

o Too much time in the clicked position means the tool was likely pulled past the click and excess torque was applied to the fastener.

Global 8

GLOBAL 8 process monitors work with up to eight PST 2000 ported torque sensing power tools, 1100-Series Exacta® 2 digital torque wrenches, 2.4 GHz preset torque wrenches — in any combination.

A large and readily visible display ensures the operator is aware of the status of each tightening, the progress through each batch of fastenings, the correct tool for the currently active fastener, and other information required to perform proper fastening.

The Global 8 - Ethernet process monitors all have Ethernet ports, and one of the four available communication protocols pre-installed at the factory. Available protocols include :

Open Protocol, Ethernet IP, PFCS, and ToolsNet. The lower display and keypad provide a Human-Machine Interface for programming elements of the communication.

Further, these units all have relays and a port for connection to your 24 VDC control system, and are capable of fixed or variable sequencing if desired.

Global 8 Process Monitor with No Ethernet card

Part No : 10479 Price : 169,900.-

1100 Series Exacta 2

The 1100 Series Exacta 2 is designed for one tool at a time operation and works with the Global 8.

• Bi-directional +/- 1% Indicated Value Accuracy from 20% to 100% of capacity, both CW and CCW.

“OK/BAD” attribute notification, along with variable data on actual torque and unit of measure on display.

• If you need a basic digital torque wrench for one tool at a time usage, this is the tool for that application.

• Color scheme informs the operator of tightening status.

• The Global 8 Controller works with up to 8 tools in any combination of SLTC FM 2.4 GHz preset click wrenches, 1100 Series Exacta 2 digital torque wrenches, or ported pneumatic tools equipped with the PST 2000.

• Integrates 1100-Series Exacta® 2 Digital Torque Wrenches

• Integrates PST 2000 Pressure Sensor/Transceiver for ported torque sensing power tools.

• Integrates 2.4 GHz Wireless Preset Torque Wrenches

• Manages and communicates variable torque data

• Manages and communicates attribute torque data

• Downloads specifications to tools

• Performs task sequencing

• Accepts task sequencing from external commands

• Display shows current tool and current tightening status

• LED’s for Cycle Accept, Cycle Reject, and Batch Accept

• 10-Pin I/O port for 24 VDC signals and relays

• Beeper augments visual communication

• Soft key programming on front panel or via free Tool Manager software.

• Global 8 models with Ethernet Open Protocol, ToolsNet, and PFCS are equipped with two serial ports for use with barcode scanner and serial printer.

Our Hardwired Preset Clicker-Type Torque Wrenches are based on our industry favorite LTC/LTCR/LTCS line of preset torque wrenches. The SLTC Hardwired wrenches can be connected to a PLC or DC Controller.

• Accuracy of +/- 4% of preset value from 20% to 100% of capacity.

• Excellent audible and tactile impulse when preset torque is achieved.

• Five of seven models use the incredibly strong SR dovetail and can be used with any of over 100 SR Interchangeable Heads.

• Tamper-resistant torque setting mechanism design facilitates setting and discourages unauthorized torque setting changes.

• Light weight and cushion grip provide excellent ergonomics.

- Yellow - the torque specification is being approached

- Green - The current torque is in the specification

- Red - The maximum torque specification has been exceeded

• Wireless bi-directional communication with Global 8 controller

Exacta 2

When the combination of superior accuracy, versatility, and data collection/communication are needed, this is the right tool.

The Exacta® 2 is designed for the tightening of threaded fasteners and is not designed for other applications. This tool is designed to collect, store and transfer up to 999 torque data records.

Since it has a serial port and works with our Exawin software, specification and data handling are quick and easy.

• Bi-directional accuracy of +/- 1% of Indicated Value from 20% to 100% of capacity.

• The Residual mode assists the user in determining retained torque on a joint.

• The actual accuracy percentage is contingent upon the joint condition and user technique.

• The large, bright display can be read at arm’s length, even in shadow.

• Three modes of operation - Track, Peak and Residual - cover almost every application.

• When in a hurry, our tools change from one end of the scale to the other with the fewest number of turns.

• Ball bearing rock-over assembly assures smooth operation enhances repeatability and increases wrench service life.

• The accuracy of +/- 4% of Indicated Value from 20% to 100% of rated capacity.

• Error Proofing By Guidance design provides a strong audible and tactile impulse when the set torque is achieved.

• Error Proofing By Design flattened case provides the mechanism with superior support resulting in a wrench that is easier to calibrate and one that holds calibration longer.

• The flattened case prevents side loading during torque application or testing/calibration.

• Knurled grip offers an ergonomic grip that remains comfortable over long periods of use.

• Changing values with the fewest number of turns save time and energy.

• Ratchet design is very strong and durable.

CATALOG STRUTEVANT RICHMONT CATALOG

ColorLite ColorTube

Benchtop-Spectrophotometer for Refl ection- and Transmission Measurement

The new developed high quality ColorTube is a benchtop spectrophotometer from ColorLite.

The device is made from only highest quality materials like solid aluminium housing and safety glass front. The core of the two-channel system is an integrated sphere with a diameter of 140 mm and two spectrometers for the sample and reference channels.

The measuring range is between 400 and 700 nm with a spectral scanning of 3.5 nm.The integrated gloss trap allows measurements with and without gloss exclusion.

High-performance LED light sources ensure long-term stable measurement results.The type of light and the UV component are variably adjustable.

Depending on the type of sample, the measuring surface area can be infinitely adjusted from 3 to 30mm.

For convenient sample handling, the ColorTube can be placed horizontally or vertically.

Solids are simply positioned in front of the measuring opening and kept stable by the measuring arm.

The measurement of pastes, powders and granules can be easily made with the optional glass cuvette. The device can be easily connected via USB cable with any Windows PC.

Together with the included quality assurance software, the ColorTube offers the perfect complete solution for your application.

Two channel d/8° diffuse illumination; 8° viewing SCI (specular component included), SCE (specular component excluded) switchable

Integrating sphere size 140 mm

Measuring area 3 to 30 mm continuously variable adjustable

Displayed spectral range 400 mm to 700 mm

Spectral resolution Holographic grating spectrometer FWHM**@ 500 nm < 10 nm Scanning in 3,5 nm interval 115 steps per scan

Colour Scales XYZ, Yxy, dE CIE L*a*b*, L*u*v*, L*C*h, Hunter Lab dE, dE94, dE2000, CMC1:1, CMC2:1, dECMCdyn CIE-L*a*b* diagram incl. Tolerance limits

Repeatability dE = 0,01 CIELab

ColorLite sph xs1

State-of-the-Art - Colour measuring instrument Spectrophotometer in pocket format

ColorLite sph XS1 “state of the art“, ultra mobile, 45°/0° geometry, high resolution spectrophotometer in a pocket format. Connect direct to your colour refence database from anywhere in the world, using wireless LAN or tether to your smart phone with Bluetooth V4.0

The small sized instrument, made in Germany from a solid aluminium block, weighs just 270g. It is equipped with the latest high-definition technology allowing a high resolution spectral scan in 3.5nm steps in less than 1 second. The brilliant colour high contrast O-LED display makes a perfect user interface. The menu is simple and clear, so anyone can perform measurements fast and accurate. A further unique feature of the ColorLite XS1 is the integrated data-matrix and bar-code camera. This allows for fast effect sample identification and management.

circular according to DIN 5033

• 100% Internet connectivity via Wireless LAN or Bluetooth 4.0

• Same high resolution as a benchtop spectrophotometer

• Ultra mobile

• Intergrated Data-Matrix scanner

• 60° gloss measurement optional

• Easy to use

• Long-life LED light source

• Unibody aluminium casing

• High quality “Made in Germany“

CATALOG

Yxy, dE CIE L*a*b*, L*u*v*, L*C*h, Hunter Lab Remissions spektrum with cursor displaying wavelength and %, CIE-L*a*b* diagram incl. tolerance limits Quality Control Tolerance Limits and Colour Differences dE CIELab; dL, da, db; dL, du, dv; dL, dC, dh; Min/Max, PASS/FAIL dECMC (1:1 and 1:2), CIE dE94 Metameric-Index for D65/A and D65/F11 according to DIN 6172

ΔE CIELab (ideal conditions)

Spectrophotometer for quality control

The sph870 is a user-friendly, portable spectrophotometer with a 45°/0° geometry, which due to the wide range of accessories available is suitable for a variety of surfaces and materials.

For example, the system can be easily changed from the 45°/0° to a d/8° geometry simply by using our MA35 probe head adapter.

The high-resolution technology enables a spectral scan in 3.5 nm steps in just 0.5 seconds. The menu is simple and well arranged, so that even untrained staff can perform the measurement task fast and accurate.

Key Features

• Flexible external probe head and a small spot size (3.5 mm

Ø) for reliable scans on curved surfaces and small samples

• A comprehensive range of accessories and probe head adapters enables the use for a wide range of applications

• Two main geometries (45°/0° and d/8°) avaliable in one device, with the optional accessory MA35-UK

• The automatic accessory detection changes internal settings depending on what accessory is attached

• Very easy 4-button operation and high resolution graphic display

• High quality „Made in Germany“

CATALOG

- or

- according to DIN5033(Optional 45°/0° AND d/8° with MA35-UK Adapter)

CIE-L*a*b* Diagram incl. tolerance limits

CATALOG

Series 3 digital force gauges are designed for tension and compression force testing in numerous applications from 0.5 N to 2500 N.

The gauges feature a sampling rate of 2,000 Hz, producing accurate results under a wide range of test conditions. A backlit graphic LCD displays large characters, and a menu is available to access the gauges’ features and configurable parameters. USB output is provided for data collection purposes.

Series 5 advanced digital force gauges are designed for tension and compression force testing in numerous applications across virtually every industry, with capacities from 0.5 N to 10 kN.

The gauges feature an industry-leading sampling rate of 7,000 Hz, producing accurate results even for quick-action tests. Accuracy is ±0.1% of full scale, and resolution is 1/5000. A large, backlit graphics LCD displays large, legible characters, while the simple menu navigation allows for quick access to the gauges’ many features and configurable parameters. Data can be transferred to a PC or other data collector via USB, RS-232.

Series 7 professional digital force gauges are designed with a number of sophisticated features for the most demanding tension and compression measurement applications, up to 2500 N.

The gauges feature ±0.1% accuracy and a blazingly fast sampling rate of 14,000 Hz, producing reliable results for extremely quick-action tests.

Standard Features

- Moveable 31 mm length posts accommodate a wide range of sample shapes and sizes

-Available extended post lengths and other gripping options

- USB, RS-232, Mitutoyo, and analog outputs

-Automatic output, data storage, and zeroing upon bottle cap removal helps automate testing processes

- First / second peak detection for slip and breakaway torques in tamper evident closures

- 1,000-point data memory with statistics and outputs

- Password protection prevents unauthorized changes

- Programmable set point indicators and outputs for pass/ fail determination

-High-speed 7,000 Hz sampling rate accurately captures peak torque values

- Configurable audio alarms and key tones

- 5 selectable units of measurement

- MESUR™ Lite data collection software included

Cap torque tester, 28 kgFcm / 290 Ncm / 2.9 Nm, 220V EUR Code : MTT01-25 E Price 59,500.-

Standard Features

CATALOG

- Measures real-time and peak force values

- Ergonomic lever operation produces 1,000 N

-USB, RS-232, Mitutoyo (Digimatic), and analog outputs

- Automatic output / data storage / zeroing upon sample break helps automate testing processes

- Configurable audio alarms and key tones

- Mounting holes for bench mounting

-1,000-point data memory with statistics and outputs

- Password protection prevents unauthorized changes

- Programmable set point indicators and outputs for pass/ fail determination

- High-speed 7,000 Hz sampling rate accurately captures peak force values

CATALOG

Force Capacity 100 x 0.05 kgF, 1,000 x 0.5 N, 1 x 0.0005 kN

Accuracy ±0.2% of full scale

Accuracy ±0.2% of full scale

Manual wire crimp pull tester, 100 kgF / 1000 N / 1 kN, 220V Code : WT3-201 E >> 89,900.-

The Kits Consist of :

Series 3 digital force gauge

- ± 0.3% accuracy

- USB output

- Compact design, easy to hold

- Measures in lbF, ozF, kgF, or N

- Peak force capture for push and pull forces

- Durable construction ensures longevity

MESUR™ Lite software

Tabulates continuous or individual data points from the gauge. One-click export to Excel easily allows for further data manipulation.

Digital Force Gauge

Padded attachments : Flat, curved, and square padded attachments mount directly to the force gauge for conducting musculoskeletal strength analysis. Double- and single-handles : Non-slip rubber handles for good grip and consistent test results.

Snap hook : Features a snap clasp, for added safety. Swiveling action ensures proper alignment.

Flat attachment : Round attachment for compression tests

USB cable : For data output to a PC

Basic ergonomics testing kit w/Series 3 force gauge, 1000 N Code : EK3-200

MOBILE HIGH-PRECISION CALIBRATOR AND TESTING DEVICE FOR MECHANICAL AND ELECTRICAL MEASUREMENTS

9250/9251

Universal Instrumentation Amplifier for strain gage, potentiometric, DC/DC and incremental sensors

The future world of automation presents challenges such as networking, speed, accuracy, integration and cost effectiveness.

Highlight

Ultra-fast pushbutton configuration

Non-linearity < 0,005 % F.S.

Features

Supported sensors : Strain gauge/normalized signal ± 5V, ± 10 V, potentiometric sensors

Device test: Strain gauge simulator up to ± 50 mV/V

Easy adjustment through burster TEDS

Excellent linearity with non-linearity < ± 0.001 %

Storage of up to 16 measurement programs

Data logger for up to 30.000 measurements

•

Factory calibration certificate and / or German accredited - DKD / DakkS calibration certificate optionally available for the instrument/entire measurement chain

Order Information

High-precision calibrator for mechanical measurements TRANS CAL - reference measurement device

Model 7281-V0000 Price : 63,000.-

High-precision calibrator and testing device for mechanical and electrical measurements TRANS CAL - reference measurement device-sensor testdevice test/DMS simulator

Model 7281-V0001 Price : 79,900.-

For monitoring press-fit, joining, rivet and caulking operations

Digital I/O to the PLC

Outputs ±10 V, ±5V and 0 (4) - 20 mA

6 wire technique

Automatic sensor recognition due to burster

TEDS

Adjustable cut-off frequencies

Versatile configuration using DigiVision PC software via USB port

Applications

All areas of mechanical engineering

Assembly and joining equipment

Hydraulic presses

Measurement of cable strengths

Increased sampling rate up to 14.4 kHz

Interface for the connection to bus controller 9251

TTL input for incremental sensors

Low-Cost Monitoring for Manual Presses

DIGIFORCE® 9311 is the new standard for economic quality control from the measurement technology specialists at burster. The pioneering force and displacement controller delivers rapid evaluation results when strict quality demands are coupled with high production rates.

Features

Flexible Fieldbus integration by PROFIBUS, PROFINET or EtherNet/IP

Automatic sensor recognition from burster TEDS

3.5” colour touchscreen display

16 measurement programs

Rapid data logging on USB flash drive

New evaluation elements (trapezoid window and thresholds)

User-configurable I/Os and 6 real-time switching signals

Smart autosetup for evaluation elements

Handles worker, admin and identification data

Up to 50 most recent measurements available for display and analysis

Records and evaluates a forward and return curve

Live sensor values provided at the Fieldbus interface

Synchronous logging of measurement data using DigiControl PC software for multichannel applications

ForceMaster 9110 was developed to monitor hand lever presses. One button operation and data for different processes on PLC-slotcards allow every user quick changes of press fitting procedures. Attractive low cost device for precise quality monitoring.

Excellent value “Plug & Work” complete system

Easy auto-configuration with automatic setting of the evaluation tools

Smart Card system for manipulation free configuration and storage of settings

Acoustic and optic error indication

Data logging on USB stick (optional)

PLC sequence control function (optional)

Analysis and configuration software included

Automatic sensor identification

Hub and other component counters

● High IP rate: IP 65

● Light weight: 4kg only including battery.

● 8.4” LCD with resolution 800×600 pixels.

● Working temperature: -10°C - 45°C Faster scan speed(Approximately 3 meters/minute).

● Removable electric fan: cool down the system when it works in high temperature.

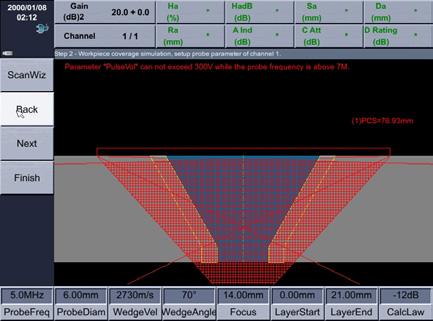

● Support PA/TOFD/UT, suitable for weld, forging and plate inspection.

● 32-channel PA is more suitable for inspection on extra-thick wall and high-attenuation material.

● 32-channel PA and 2-channel TOFD work simultaneously, focusing on pressure vessel inspection.

● Support PR mode, focusing on pipe corrosion inspection when with high-end dual-crystal PA probe.

● System ports: encoder, VGA, standard SD card, USB 2.0/3.0.

● Probe ports: 4 ports for UT/TOFD probe, 1 port for phased array probe.

Manual PA Crawler

Superior Features

PES-02

Mini Phased Array Crawler

Phased Array crawler PES-02 is compact, flexible and easy to operate.

It is suitable for phased-array single probe (with wedge) to perform ultrasonic phased-array testing on girth weld or longitudinal weld of flat butt welds, pressure vessels or pipes (diameter > 60mm).

Phased Array crawler PES-02 is compatible with different wedges to inspect butt weld and plates.

Manual PA and TOFD Crawler

PTS-P05

Compact Phased Array & TOFD Crawler

The Phased Array and TOFD crawler PTS-P05 is compatible with PA or TOFD ultrasonic flaw detector. It is suitable for phased array or TOFD testing on plates and pipe workpieces.

Superior Features

The Phased Array and TOFD crawler PTS-P05 has up to three combinations to meet different application requirements.

The Phased Array low profile crawler LPS-01 and LPS-02 are compatible with Phased Array ultrasonic flaw detector which is used to perform circumferential weld inspection on small diameter pipes.

The Phased Array and TOFD crawler UHTS-X02 is compatible with PA or TOFD ultrasonic flaw detector. It can be folded in the center for longitudinal weld and unfolded for girth weld enabling the crawler have better coupling stability to work on smaller pipes suitable for phased array or TOFD testing on plates and pipe workpieces (with diameter larger than 500 mm).

The TOFD crawler TSB-1-P05 and TSB-2-P05 are compatible with TOFD ultrasonic flaw detector as well as TOFD wedges. They are suitable for TOFD testing onplate-type work pieces.

SyncScan is designed to increase productivity in less demanding applications. It is suitable for inspection flaw position and size, which can be widely used for various detection demands, such as PA weld inspection, TOFD weld inspection, corrosion mapping, composite inspection, gas pressure welding on rail, pressure vessel inspection, stainless steel and PE pipe inspection.

● High IP rate: IP 65

● 5.7” LCD with high resolution 640×480 pixels

● Adjustable pulse width negative square wave transmission is up to 350V.

● Operating frequency range: 0.5~20MHz, multiple steps of wide broadband and narrow-band for selection.

● Multiple conventional UT functions

- Weld, plate and forging test wizards are available, which can guide users to perform setup easily and improve inspection speed.

- Peak memory, DAC curve, AGC (auto gain control), video record makes convenient and efficient flaw inspection.

- Optional functions such as B-scan, TCG, probe spectral analysis, CSC (curved surface correction), weld simulation, crack height measurement are available.

- Featured with AWS D1.1/D1.5 and API 5UE evaluation standards.

● Multiple thickness measurement functions

- Standard A-scan thickness measurement

- Auto-search, velocity measurement, alarm and dataset management are available.

- Optional functions: through coating measurement, echo to echo mode, B-scan, multi-layer measurement, V-PATH, TDG and temperature compensation are available.

With NABL accredited certificate.

Free Iron Stand

* Accuracy as per IS-7327-1991 Grade ‘0’

Light duty granite Dial gauge stand easy for inspection of small components accurately

Clamping stem diameter : 8 mm

working height : 180 mm

Code No. 1210

Price: 11,000.-

* Not included Dial Gauge

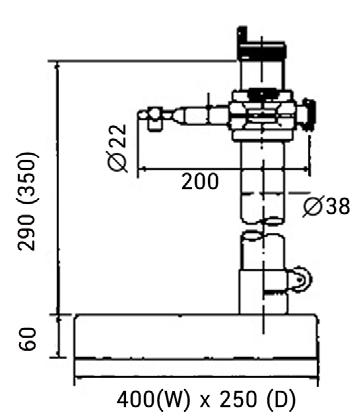

METALLOGRAPHIC SPECIMEN GRINDING & POLISHING MACHINE MP-1B, MP-2B

MP-1B

MP-2B

The base is made from precisely lapped black granite stone and most ideal and economical stand for checking surface finish.

Top end of the vertical column is provided with fine adjusting knob to facilitate easy height

Base Size : 400 x 250 mm Vertical column height : 220 mm

Code No. STS 1810

Price: 24,900.-

The serrated column has a knurled thumb nut which permits rapid up and down movement of indicator bracket assembly and acts as a safety device, preventing accidental dropping of the indicator bracket assembly.

Fine indicator setting is made by turning a fine adjustment knob on the indicator bracket.

Clamping stem diameter : 8 mm

Maximum working height : 200 mm Fine adjusting range : 1 mm

Flatness : 3 µm

Mass Kg : 10

METALLOGRAPHIC SPECIMEN CUTTING MACHINE SQ-80A, Q100B

SQ-80A

Q-100B

Code No. 1230

Price: 14,900.-

* Not included Dial Gauge

METALLOGRAPHIC SPECIMEN MOUNTING PRESS XQ-2B

Model MP-1BMP-2B

Grinding disc diameter Ф230mm

Polishing disc diameter Ф200mm

Speed 50-1000 rpm

Operating voltage Single phase, AC220V 50Hz

Motor 370W 550W

Dimention (mm) 480 x 390 x 370700 x 600 x 280

Price 69,900.-89,900.-

Model SQ-80AQ-100B

Max. cutting diameter Ø80 mmØ100 mm

Cutting disc speed 2800 RPM2100 RPM

Cutting disc specification Ø250 x (1.5-2) x 32 mm Ø350 x 2.5 x 32 mm

Worktable size 230 x 240 mm320 x 300 mm

Power supply 380V, 50Hz, three phases

Dimensions 760 x 640 x 650 mm 930 x 700 x 610 mm

Price 129,900.-229,000.-

Option accessories

• Vertical clamp

• Transverse workbench

The machine may work stably under the following working condition:

• The temperature of surrounding medium can not be less than 10 °C and more than 40 °C

• The relative humidity of air should be no more than 85% (20 °C)

• The voltage fluctuation should be no more than 15%

• There should be no obvious vibration source around

• There should be no current conducting dust, explosive and corrosive air.

Model XQ-2B

Mould Dia Ф22mm Ф30mmФ45mm

Temperature adjusting 100 - 180 °C

Heater 650 W

Power SupplySingle phase, 220V 50 Hz

Dimension 340x270x400 mm

Price39,900.-45,000.-55,000.-

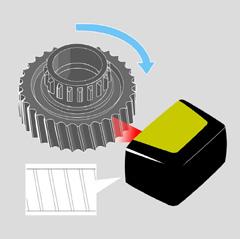

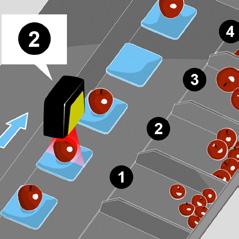

ROBOT - BASED 100 % measuring of bores, chamfers, thread depths and plain depths. Measurement can either be integrated into production process or carried out separately. The extremely fast measuring cycle measures twenty-four-seven and provides 100 % measured values.

Different measuring tasks :

- Autonomous measuring of bores, chamfers, thread depths and plain depths with just one single measuringcell

Reliable data connection and back-up :

- Any time precise and complete measured data by means of automatic wireless transfer

Big Data :

- Improvement of manufacturing processes by automated or manual data evaluation

Controlling of 2 worlds :

- The DIA-Gauge Software controls all measuring processes and robots

Many measuring processes :

- Standardized and storable measuring processes for different applications

Further benefits:

- Automatic storage system for measuring instruments

- Calibration bar for automatic calibration

- Easy changeover

- Scalability

- Quick integration into processes

- The fast measuring cycle saves valuable time in a process

- Safety through 100 % measurement of all features

- Establishment of a DIAWIRELESS real radio network: Comprehensive data evaluation by transfer of 100% measured values

- 100 % measured values ensure best production control

TD-Guage motorize

Resolution 0.001 mm

- “Plug & Play“: Easy handling

- Low wear and therefore low maintenance

- Motor: Made in Germany

- Speed: approx. 300 rpm (5 rpm/sec.)

- Automatic switch-off utomatic switch-off

- Longer life of the lithium-ion battery(s)

- Easy battery change for display and engine

- LCD display switchable from 0.01 mm to 0.001 mm resolution

- Preset

- Display remains visible during measurement

- Integrate into DIAWIRELESS Real radio networks

- No NoGo pin possible

- Threads: M6 to M18, other sizes on request

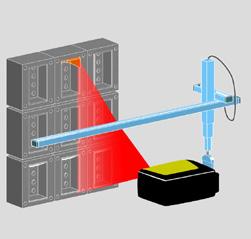

Gauge-2Dimensions

Free choice for digital display of the diameter, e.g. with small dial gauge MDU-S125. Optional transfer of measured data via cable or wireless

Gauge-2Dimensions DYNAMIC WIRELESS

Diameter Measurement: Measured data are automatically sent wireless to DIATRON6060-µNetwork or comparable PC with DIA-Gauge Base Software

Diameter and Depth measurement at the same time

Gauge-2 Dimeter

Through the combination of two measuring solutions, different measuring tasks can be done with just one measuring operation: Measurement of an I.D. and a depth. The best of two worlds have merged: the ergonomics of a TD-Gauge+ DIGITAL with the absolute precision of a BMD plug gauge.

- Combination of several standardized DIATEST products

- Basic instrument with standard clamping 8h7 (3/8’’)

- Use of BMD plug gauges from Ø 4,2 on

- Simple change of the BMD plug gauges via individual stop sleeves

- Modular construction system allows a quick change of BMD plug gauges, according to measuring task

- Measured data is displayed separately

- Digital display of measured data, including free choice for the indicator for the I.D., e.g. small digital indicator MDU-S125

- Optional transfer of measured data via cable or wireless

- Easy integration with the DIAWIRELESS real radio solution

- Use with already available accessories for BMD plug gauges

- Easy set up and handling

Diameter and Depth measurement at the same time

Gauge-2 Dimensions DYNAMIC WIRELESS

Through the combination of two measuring solutions, different measuring tasks can be done with just one measuring operation: Measurement of an I.D. and a depth.

- Use of BMD plug gauges from Ø 4,2 mm and above

- Simple and quick change of BMD plug gauges

- Easy set up and handling

- Easy integration into DIAWIRELESS real radio networks

- Measured data is displayed separately

- Digital display of depth measurement switchable between 0.01 mm and 0.001 mm

Range of 50 mm and with lifting device

*Models with order Code B have shortened measuring spindles

*Models with order Code B have shortened measuring spindles

- made from steel - with carbide or ceramic insert - with balls from steel, carbide, ruby, sapphire, plastic or ceramic

***Special contact points to customers’ drawings are available on request.

NEW : Measuring standardized parts

Long angular head 90 degrees with 4 mm stroke ( Article-no.: 69001 )

Long angular head 45 degrees with 4 mm stroke ( Article-no.: 69002 )

Long angular head 0 degrees with 4 mm stroke ( Article-no.: 69003 )

Modular internal micrometer 0626 with digital display, defined measuring force and expandable measuring range of up to 5000 mm.

Techinical

Internal measuring gauge 561, modular, with gauge block extensions up to 6100 mm.

Gauge block extensions for expanding the measuring range of internal measuring gauges to 6100 mm, also available in CFK.

Extension 15 mm is not compatible with micrometer head 100-125 mm. Special extension length 35 mm upon request.

*Special diameter 16.5 mm

Digital micrometer 0800 with non-rotating spindle, 30 mm direct measuring range and protection class IP 65.

Snap gauge with lifting lever, ideally suited to measuring cylindrical parts such as shafts, bolts and spindles as well as for measuring thicknesses and lengths in the 0-25 mm to 275-300 mm ranges.

*Delivery without dial gauge/Digital dial gauge.

Special versions: 0,5 / 1,0 mm pitch, CBN measuring face, protection phase, modified measuring surface like taper, disk, neadle, knife, ball, rollers etc. CATALOG

CATALOG CATALOG

*Available with steel tube frame upon request. **Special versions upon request.

The digital Passameter 3903 for measuring delicate precision components withs low gauging force

The digital passameter 3903 has a lightweight measuring body with a novel inductive measuring system with 4 mm completely fine measuring range.

Measuring body and display unit can be operated separately thanks to the modular structure. This simplifies series measuring at the workstation and does not add any disruptive moments into the measurement.

The digital Passameter 3902 for the inspection of narrow manufacturing tolerances is featured by very high accuracy and a big, direct measuring range of 4 mm.

Passameters can be described as adjustable snap gauges, which can also be used for measuring rotation-symmetric parts, as well as for measuring thicknesses and lengths.

Precision

Interchangeable inserts 55° / 60°, hardened (carbide available upon request)

Precision

Ball diameter 1.0 - 24.0 mm

Measuring rolls (upon request)

BENEFITS

Measuring spheres

- Can be turned in holder/mount

- Hardened special steel

TECHINICAL DATA

Accuracy ± 1 μm ≤ 12,7 mm

± 2 μm ≥ 12,7 mm

Also available as single pair.

Measuring wire diameter 0.170 - 8.358 mm.

BENEFITS

- Durable design, short measuring wires made from special steel, hardened, ground and lapped

- Holders are completely metal

- Safe fit of the short measuring wires in the thread pitch thanks to side clearance in the holder

- Fixing bores available in various diameters

- Fixing bores with clamping spring prevents sliding of the wire holderr

The UMP3 is especially suitable for quick and reliable calibration of analogue and digital dial gauges. By its motorized 30 mm precision transducer a dial gauge can be calibrated simple and safe in a trice.

Testing of :

› Analogue and digital dial gauges

› Test indicators

› Precision indicators

› Inductive probes

The universal dial gauge testing instrument is especially suitable for quick and reliable calibration of analogue and digital dial gauges. By its motorized 30 mm precision transducer, which positions µ exactly with an ergonomic placed hand wheel, a dial gauge can be calibrated simple and safe in a trice. Separated high-speed buttons on the separate control casing guarantee an easy pre-positioning.

- Application range 30 mm

- Resolution 0,1 µm

- Smallest positioning steps 0,1 µm

- Reversal range < 0,15 µm

- Repeatability < 0,1 µm

- Measuring uncertainty 0,08 µm + 1 * 10-6 * L

- System accuracy < 0,5 µm

- Positioning Speed 2,2 mm/sec.

- Positioning force 15 N

- Weight 18 kg

BENEFITS

- Easy to use, due to motorized transducer with included measuring system

- Flexible positioning of system parts due to separate parts

- Very sensitive operation due to rapid-fine adjuster

- Highest repeatability due to adherence the Abbe principle

- Easy to use, right hand or left hand choose able

- Flexible due to wide range of accessories

IKF 100D

TECHNICAL DATA

- Application range / path : 103 mm; 0-4 inch

- Resolution : 0.01 µm

- Clamping shaft : 28H6

- Protection degree : IP40

- Measuring force : 1.8 N

- System accuracy 0.3 µm

- Permissible shear force : 2 N

- Power supply : 5 V DC, Mini USB

- Operating position : vertical

- Weight : 2,600 g

FOR CHECKING AND CALIBRATING OF :

- Production normals

- Pin gauges

- Plug gauges

- Workpieces

- Threaded plug gauges

- High-precision measuring results by resolution 0.01 µm

- High repeatability, operator independent by constant measuring force

- Measuring objects up to 100 mm can be measured

- Compact vertical measuring system with integrated display unit PU26

- Ideal for use in production hall

- Measuring data can be processed with interface on the PU26

- Exchangeable measuring tips with M2.5

The first electronic quicktest with μm resolution and induction charging technology! New design and optimized ergonomics.

Wireless charging

Benzing rack and pinion presses have been specially developed for fine mechanical work. The direct, constant transmission of the applied force enables work to be carried out sensitively and accurately.

Run-out Tester

Height of centres 50 mm, Height of centres 75 mm

Accesories Run out testers Height of centres 100 mm, 150 mm

V-block inserts PE 004-52 For checking non-centred parts and long parts.

Tailstock pair

Vertically adjustable Roller blocks or V-blocks

CMM Arms A5

Standard configuration and accessories:

- Carbon fibre tubes.

- Aluminium mount base.

- 1 mechanical probe with ruby stylus sphere 4 mm.

- High repeatability probe mount with standard joint. (ready for touch probe and laser forks)

- Electromagnetic brake.

- Temperature sensor.

- Power supply and Cables, User manual, USB connection.

- Case with mounting screws, key, tools.

- 20 mm dia. calibrated sphere with magnet.

- Hard case for transport.

- Software T-Core for probe calibration.

*Computer: Not included

• Measuring ranges 1800 to 4000 mm.

• Arm exist in 6 axes.

• Extremely easy to use.

• Protection with electromagnetic.

ACCESSORIES

Labconcept 500J Package

CALIBRATION AND/OR CHECKING OF GAUGES

- Ring gauges from dia. 20 mm to 250 mm

- Ring gauges from dia. >1 mm up to 180 mm

- Plain plug and pin gauges up to dia 100 mm

- Plug gauges from dia. 30 mm to 250 mm

- Snap gauges from 12 mm to 150 mm

- Snap gauges from 1mm to 150 mm

- Thread ring gauges M5 to M180 /pitch 0.9 to 6 mm

- Thread plug gauges up to dia. 100 mm

Specifications

Measuring range : from 0 to 500 mm

Accuracy : 0.19 μm +L/1500 from 0-100 mm, 0.3 μm +L/1500 from 100-500 mm

Repeatability (2s) : < 0.05 μm

Resolution (switchable) : from 0.00001 mm to 0.01 mm (from 0.000001” to 0.0001”)

Measuring Force (adjustable) : 0 – 12 N

- Thread plug gauges from dia. M30 to M250

- External micrometers from 12mm to 100 mm

- 2 point Internal micrometers

- Dial indicator up to 50 mm

SOFTWARE

Height Gauges V8 with Fine Adjust

• Specific handle for fine adjustment

• Larger than 300 mm probes as standard

• Vast range of accessories

- Starter Module for inspection of thread gauges CATALOG

• Electronically adjustable measuring force

• Programmable keys on handle

• All adjustments possible without tools

: 2,XXX,XXX.-ราคาเริ่มต้นที่ : 1,2XX,XXX.- Fastening Bases Magnetic base Touch Trigger Probe Floating Probes Hard Probe

The sensor display unit SD1 was especially developed for industrial use. The robust aluminium case with rubber shock protection as well as a high protection class allow usage in rough manufacturing environment.

The display is rotatable, a numeric display shows the measuring values with high resolution and an analogue display with coloured LEDs presents clearly the tolerance status of the component.

The sensor display SD1 features a large scope of operation and can be configured freely for the particular application as required by a windows software. Thereby functions can be removed or activated and settings can be initialisized.

Unit/Measuring direction mm., inch / positive, negative

Case Aluminium, rubber shock protection

Front plane Acryl glass (scratch-proof)

Dimension 60 x 59.5 x 21.7 mm (95 g.)

Power Battery (CR2032)

Measuring rate adjustable , 2 ... 20 values/sec

Diaplay type Liquid crystal diaplay, reflective

Numeric display 7 digits (10.5 mm.)

Analogue diaplay 53 segments

Tolerance display 3 LEDs

Buzzer Piezo

iSi interface Bus connectoion for sensors, hand/foot swich, tolerance adapter, ...

Triple-interface Connection for IBR radio module or cable with USB/RS232 interface

Protection class IP65

Static measurement Yes / Optiona Hold modw

Dynamic measurement Min, Max, TIR, Mean, Bore

SD1 Applications :

With UKAS accredited certificate.

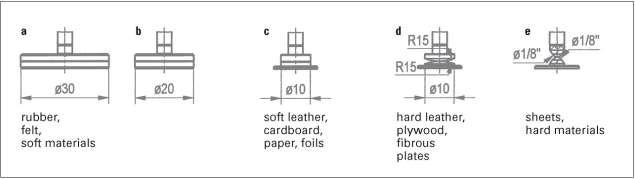

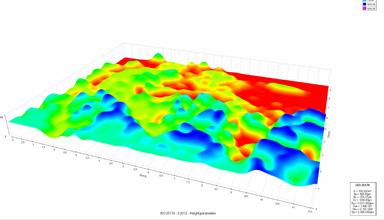

Modus 6ZS - 3D

The DeltaPix Modus 6ZS is a complete digital microscope system that is designed for inspection, documentation, and analyses such as measurements in 2D ,3D topographies as well as roughness measurement according to guidelines of ISO 25178-2:2012.

The 3D Microscope is a versatile system suitable for a wide range of applications. Typical applications:

-Documentation and Archiving- Set of aperture stops

-PCB

-3D

-Roughness

-2D measurement

With

accredited certificate.

They are ideal for inspecting holes or slots (pass/fail). They are also used as Master for setting Micrometers,Vernier Calipers etc.

Features of Plain Plug Gauges

•High Durability

•High Tensile Strength

Ring Gauges are ideal for measuring outside diameter of work pieces. A ring gauge is also effective to check out of roundness on the higher side.

A master setting ring is used as a standard to set bore gauges, which can then be used to determine deviation from the master size.

Product Information

Product Information

•Provides Plain Plug Gauges with GO member in carbide and NOGO in steel (NOGO member can be provided in carbide)

•Both GO & NOGO in steel is also available.

• Also supplied as per customer requirement for special length

•Possess all the required characteristic properties of KCP Class.

•Ring Gauges with GO member in carbide and NOGO in steel (NOGO member can be provided in carbide)

•Both GO & NOGO in steel is also available.

•Manufactured range of Ring gauges -carbide : 6-60 mm and steel : 6-100 mm.

•Ring Gauges with special length and diameter are also available.

The right partner at the right place

- The right partner at the right place

- High precision solutions

- Contact and non-contact metrology technologies

- Lean metrology

- Standard or tailored-made solutions

- Automation - Turnkey projects

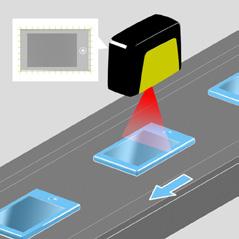

The pneumatic measurement or air gauging units and systems are mostly used for measuring cylindrical workpiece features such as bores and shafts diameters. It is a non-contact measuring technique that performs dimensional and geometric checks of the part. It offers the following advantages:

- Measurements are taken with high reliability, accuracy and repeatability.

- Non-contact measurement eliminates the risk of damaging the workpiece

- Pneumatic measurement system can be operated in harsh environment

- Air pressure acts as a powerful cleaner at the measuring points, thus enabling the user to inspect even dirty, oiled and greased surfaces .

- Inexperienced users and qualified staff are usually promptly convinced of the safety use and fast and stable results, as tolerances are more and more tighter on the shop floor

Typical applications are measurements.of.diameters or multi diameters, distances of axes tapers, and forms checks.

Our Features

The Pneumatic measurement or air gaging units and systems from PFL combine numerous advantages :

- Automatic cleaning of the parts to be measured

- High measuring accuracy

- Repeatability up to 0.1 micron

- Fast and stable results

- Contactless measurement

- Ideal for sensitive parts and surfaces

- Robust measuring elements

- Easy to use and to maintain and features

- Internal external measurement capabilities

- Low sensitivity to thermal variations

In the field of the pneumatic measurement products and systems, PFL Group works in full synergy and partnership with the sister companies. PFL has been manufacturing and supplying air gauges for more than 50 years and this long experience is the insurance that you get the optimal solution in term of applicability and suitability. All the units and systems shown here will be supplied under the PFL Swiss brand name. We can supply:

- Air plugs and rings

- Air plugs and rings for ISO taper

- Air forks

- Air converters

- Air to electronic converters

- Various accessories

- Masters and certificates

- Turnkey solutions

ISO METRIC THREAD PROFILE

Practice : JIS B 0251-1998*

*See foot note for JIS Standard, JIS B 0251-1975 & JIS B0252 -1996

ANSI standard : Basic Dimensions : ANSI / ASME B 1.13 M

Gauge Dimensions : ANSI / ASME B 1.16 M - 1984. BS standard : Basic Dimensions : B.S. 3643 Part I & II - 2007

Gauging Practice : B.S 919 Part III - 2007.

>> ANSI & BS standards use unilateral Tolerances for gauges. These gauges are manufactured only against specific customer order. We require Minimum Ordering quantity for these.

***Others range for thread gauges On Request.

Special Thread Gauge On Request. Exsample. : Mark on Gauge or long neck plug Gauges , etc.

REMARK

PRICES for single ended GO or NOGO thread plug gauges up to 65 mm nominal diameter will be at 60% of Double ended Thread plug gauges

PRICIES of LEFT HAND Plugs & Class of fit Other Than 6H.

1.Prices for Thread Plug other than “6H” class : Add 25% on the price of “6H’’ thread plug.

2.Prices for LEFT HAND Thread Plugs : Add 50% on the price of Right Hand Thread Plug.

PRICIES of LEFT HAND Rings & Class of fit Other Than 6g.

1. For any class of fit other than ‘6g’ class : Add 50% on these prices for Thread Rings up to 25 mm Nominal Diameter and add 25% above 25 mm Nominal Diameter.

2.Prices of LEFT HAND Ring Gauges : Add 50% for rings up to 25 mm Nominal Diameter and add 25% for rings above 25 mm Nominal Diameter.

THREAD PLUG GO and NOGO Gauges.

THREAD RING GO or NOGO Gauges.

399,900.-

X/Y-axis Accuracy ≤ (3 + L/200) µm Video system

Camera Color 1/3” CCD camara

Optical Magnification 0.7~4.5X

Digital Magnification 10~300X

Object view-field 10.6~1.6mm

Contour and surface illumination Ring LED and brightness can be setup

High Accuract Vision Measuring Machine

iMS-3020 : Manual Focus

iMS-3020F : Auto Focus iMS-3020P : Manual Focus & Touch Probe

iVision Series iFocus Series iTouch Series

399,900.-

Price: 489,900.- Price: 449,900.-

Specification

X/Y-axis Travel 400 x 300 mm

Z-axis Travel 200 mm

Load Capacity 25 kg.

Dimension 1350 x 880 x 1650 mm

X/Y/Z3-axis Linear Scale High precision linear scale, resolution, 0.0005 mm

Guidance Mode Precision linear guide, double-track double slider guide

Operation Mode Joystick controller, Mouse operation, automatic detection program

Accuracy XY-axis : ≤3+L/200(μm), Z-axis : ≤5+L/200(μm)

Repeatability ±2 μm

Video System High definition 1/3” Color CCD Camera, 6.5X continue click zoom lens, Optical Magnification: 0.7X - 4.5X

Video Magnification : 26X~172X (21.5”monitor)

Illumination Contour : LED Parallel Contour Illumination

999,000.-

Surface : 5-ring 8-division 0~255 grade continue adjustable

Then you will definitely like our optacom VC-10-UL-RDY. Consisting of 6 measuring axes it does contour measurements automatically or in combination with an integrated swivel table, which is placed on an installed rotary axis. This leads to the fact that even complicated measuring tasks of complex formed objects become very easy. At the stylus tip it reaches a true, not only simply calculated resolution of less than 3 nm, and can do this over the entire measuring range.

-The most powerful all-round system for the entire variety of contour measuring tasks

-Contour and roughness in one measurement with the integrated roughness module

-Roundness measurements and gear measurements with the integrated rotary table

-Y-table with 530 mm traveling distance

-Rotary axis with a rotation angle of 210°

-High-precision linear axis with an integrated drive

-Contact-free, linear incremental measuring systems, absolutely wear free

-Various chucks available

-Machine calibration (including stylus tips calibration) in less than 3 minutes

-Body made out of high-strength aircraft aluminium

The DIAVITE DH-10 TOUCH you can work with tracers without and with skid. The entire DIAVITE tracer range is available to you with just one device On the 10.1” Full HD Touch Display you will find all controls for a quick and easy You define the measu- measurement rement (measuring length, filter, speed, etc.) and save it with an image and corresponding protocol. Via the menu or a barcode scanner you select the program and execute it. The protocol is then printed via LAN (WLAN/ Bluetooth) server, USB stick on the previously defined or stored on the path. You have the choice whether to save in PDF CSV or TXT format. A statistical evaluation of several measurements can also be recorded.

-High-precision roughness measuring instrument for universal use in workshops and measuring rooms

-Automatic calibration

-5 measuring sections all adjustable 0.5 to 15.0 mm

-Adjustable measuring speeds

-Calibration of up to 8 tracers measurement conditions with image

-Saving measurement conditions with image

-Many tracers for almost all measuring tasks, including customer-specific solutions

-Simple menu navigation, multilingual

-Tolerance display

-Accessories for many applications, indispensable when working with tracers without skid

Parameter roughness

Parameter profile

Measurement ranges

Display

-ISO/DIN: Ra, Rz (DIN), Rmax, R3Z, Rt, Rq (RMS), Rk, Rv, Rpk, Rvk, MR1, MR2, RPc, C1, C2, Contact Ratio Rmr, C0, Cz, V0, Rdg, RL0

-JIS: Ra (JIS), Rz (JIS)

-ISO 12085 : R, AR, Rx

-ISO/DIN : Pa, Pz, Pt, Pq, Pmr, PPc, Pmax

- Ra, Rq : 0 -20.00 µm | 0-800 µin

- All other measurement values: 0 - 350.0 µm | 0-1400 µin

- Ra, Rq: 0.001 µm

- All other measurement values: 0.01 µm

Connections 2x USB-3.0 / 1x mini HDMI / 1 x LAN/RJ45

Humidity max. 80%, non-condensing

Languages German, English, French, Italian, Spanish, Polish, Chinese

Tracing system Analog Hall effect technology with high linear output signal

Cutoff 0.08 mm / 0.25 mm / 0.8 mm / 2.5 mm / "OFF" for profile parameters

Tracer tip Diamond tip: 5 µm, 90° (Standard) or 2 µm, 60° (option)

Measurement range in Z approx. 450 µm

Static measuring force Tip < 0.5 mN

Static tracking force Skid < 0.15 N

Tracing speed 0.25, 0.5 and 1.0 mm/s

Reverse speed approx. 1.0 mm/s

Motor unit VHF , measuring length 0.48 to 16 mm

Device Dimensions

(LxWxH) approx. 265 x 175 x 175 mm

Motor unit dimensions approx. 20 x 33x 136 mm (with supporting shoe)

VERSION TRACER WITHOUT SKID

- DIAVITE DH-10 TOUCH

- Motor unit VHF

- Tracer without skid NFH

- Calibration specimen metal Ra= 3.00 µm

- Charger

- Connecting cable

- Delivery report

- Carrying case

- Measuring support with aluminium base plate and column 250 mm

*Extendible with all tracers without and with skid

VERSION TRACER WITH SKID

- DIAVITE DH-10 TOUCH

- Motor unit VHF

- Standard tracer SH

- Calibration specimen metal Ra = 3.00 µm

- Charger

- Connecting cable

- Delivery report

- Carrying case

*Extendible with all tracers without and with skid

State-of-the-art Video Measuring Machine : Fast, Easy, Accurate, Compact and Powerful!

All-In-One touchscreen PC

• Powerful All-In-One touch screen HD PC

• Intuitive touch screen measurements software

• Easy programs recording with finger gesture

• Automatic feature recognition

• Up to 16.000 features per item

• Automatic data report •

● Specifically suited for massive (production) quality inspection, in-line control, incoming inspection.

● Eliminates subjectivity and errors of operator-based gauging.

● Increases number of quotas and quality check rate, up to 16000 checking features in a few seconds.

● Performs full automatic reporting and SPC. (Min, Max, Range, Average, Std Dev, 6 Sigma)

● Designed for in-production massive use.

● Plug-and-play, it is ready to use.

● Suitable for unskilled operators use.

● Flexible investment with a fast Return on Investment.

● Reduces time and costs of controls.

Automatic and Productive

The innovative Smart_Rotating_Robot is designed to extend the Smart_Projector’s range of application, allowing control quality check to cylindrical parts and any other item that needs to be examined on different projection planes at defined angles.

It is made of a special automated stage inserted in the Smart_Projector’s measuring chamber and connected to the supplied AIO PC through a dedicated Control Station. The pieces are fixed to a robotic rotation chuck system controlled by software and a dedicated control box, which allows viewing instant results.

The easy integration of the Smart_Rotating_Robot in the Smart_Projector System grants maximum flexibility and reduces the time needed to control parts from different angles of views thanks to the automatic load of different programs for different views.

Smarter than Ever

YOUTUBE

Smart_Automation_Suite is a Hardware-Software combination that includes an integrated I/O Module and a dedicated software. It allows to manage the Automatic Measuring System functions through the automation of the production process.

Features & Benefits

- Integration with other industrial machines

- Automatic measurements integrated with production lines throught I/O module

- In-Line Quality Control

- Immediate adjustment of production quality level

- Reduced production scraps

- No need of skilled operators

- Pass/Fail I/O

- Time and Cost savings

- Advanced data export

3D GOES HIGH DEFINISITION IN HIGH SPEED

The latest ECCO TM range is revolutionising the 3D sensor market, combining high performance and great value in a family of economic compact industrial products.

SmartRay Sensors combine laser triangulation with innovative image formation technology to create detailed 3D images that can be processed by any 3rd party vision software. ELECTRONIC

The latest ECCO family brings a new design philosophy to the 3D Sensor market that delivers high performance, small size and lightweight construction CATALOG

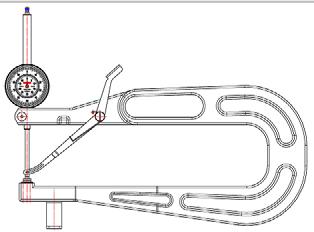

Portable, Laser-assisted and Profilometer for the tire industry

Price : On Request.

Specification

-Measurement Technology: TriangulationPoint Laser technology

-Laser : CCD / Visible / Red

-Datatransmission : Digital

-Measurement range Z (depth) : 150 mm

-Laserclass : IIM

-Distance from laser : 275 mm

-Measurement range X (width) : 300 mm

-Tire typs : Bycicle / cars / trucks / agricultural machinery

Software features

- Smart Scan App Software

- TriScan Software

- ACRONIS Backup & Recovery Software

- Team Viewer Software for remote maintenance

- PDF Creator for export and print-out of data

ให้ตรงกับค่ำแรงโน้มถ่วง/แรงดึงดูด

Hardware features

- Contactless measurement method

- Wireless datatransfer via WIFI or Bluetooth

- Battery- operated

- Smartphone removable

- External Smartphone charger

CATALOG