Transform your space with our flame retardant and sustainable acoustic panels. Our curated collection cleverly combines sound absorption with digitally printed designs.

This acoustic panelling adds depth, texture and art to commercial, hospitality, healthcare, government and education interior projects.

• Specifications Page 4

• Sustainability Page 5

• The Collection Pages 6-25

• Installation Page 26

• Cleaning Page 27

Acoustic panel key features:

• Global GreenTag GreenRate Level A certified - recognised in the Green Star responsible products program.

• Low VOC.

• Recycled content.

• Mould resistant.

• Pre-trimmed panels for easy installation.

• Recylable

Printer & ink features:

• Printed in Sydney.

• Energy-efficient, direct UV printer.

• Greenguard Gold certified.

• VOC free.

• TPO free.

• Vegan.

• Free of heavy metals.

Application: Acoustic Wall Panels

Composition: 100% recycled PET

Panel Size: V: 270cm x H: 120cm approx. – trimmed

Thickness: 12mm

NRC Rating: 0.4 – 0.85

Flammability : Group 1, AS 5637.1: 2015

Our acoustic panels are manufactured with eco-friendly materials, aligning with the growing demand for sustainable building practices.

• 100% recycled PET (60% recycled post-consumer PET / 40% recycled pre-consumer PET)

• Third party certified by Global GreenTag achieving GreenRate Level A certification.

• The ink used to print onto the panels is Greenguard Gold certified – VOC free and free of heavy metals.

This makes them a great choice for projects aiming to achieve sustainability ratings such as Green Star Buildings and Green Star Fitouts.

Learn more about Green Star Rating tools here

What is rPET

rPET, or recycled polyethylene terephthalate, is a type of plastic widely used in the production of food and beverage containers, textiles, and increasingly in interior design products like acoustic panels and insulation. PET is popular because it’s lightweight, durable, and recyclable, making it a versatile choice across industries.

Being repurposed into non-plastic applications, such as acoustic panels in buildings, not only diverts PET from landfill but also makes it a part of sustainable construction practices.

Recyclability: PET is highly recyclable. It can be melted down and reshaped multiple times without significant loss of quality, allowing for the creation of new products from recycled PET (rPET). With the use of 100% recycled PET, our acoustic panels reduce the demand for new raw materials.

Resource Efficiency: Producing PET requires fewer resources, such as water and energy, than other plastics, which minimises its environmental impact during production. Additionally, as it’s lightweight, transporting PET products consumes less fuel compared to heavier materials.

Long Lifecycle and Versatile Use: PET products are durable and often last a long time, particularly when used in textiles or building materials. This durability means products don’t need frequent replacement, reducing waste and resource consumption.

Materialised recycle our acoustic offcuts and offer a take-back program for any used, uncontaminated panels or samples. Returned products are shredded, recycled back into felt, and reused, prioritising circularity and responsible and of life management.

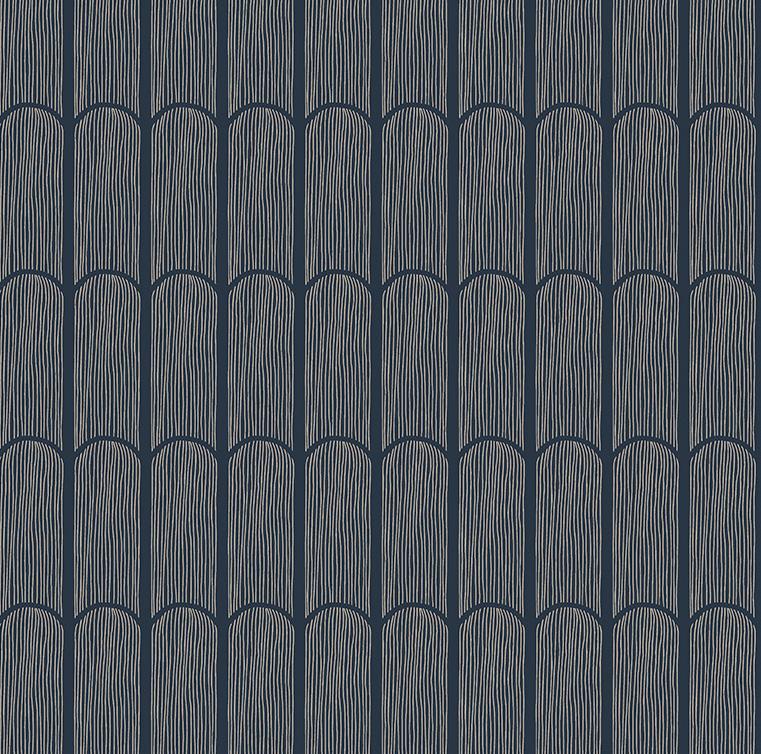

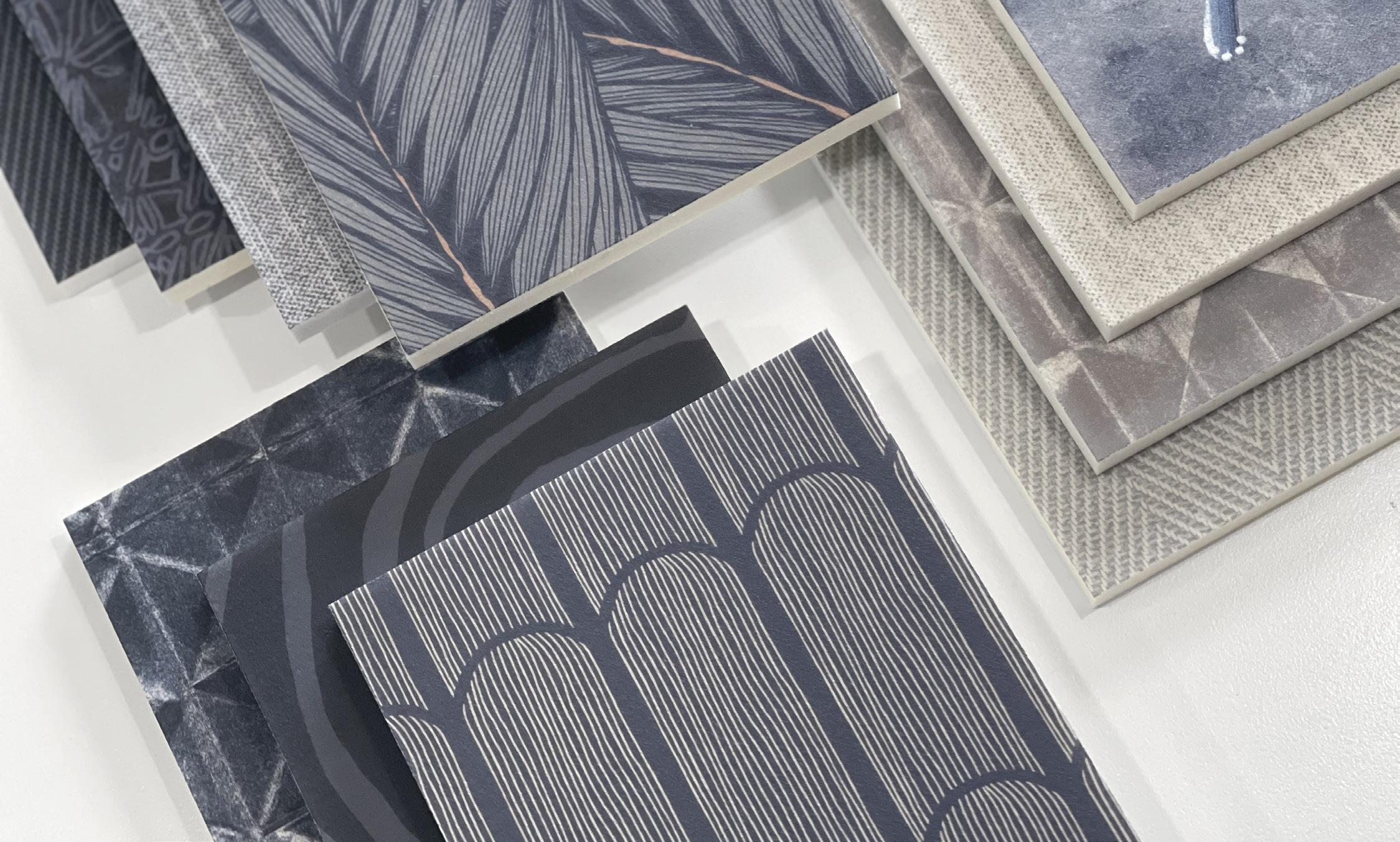

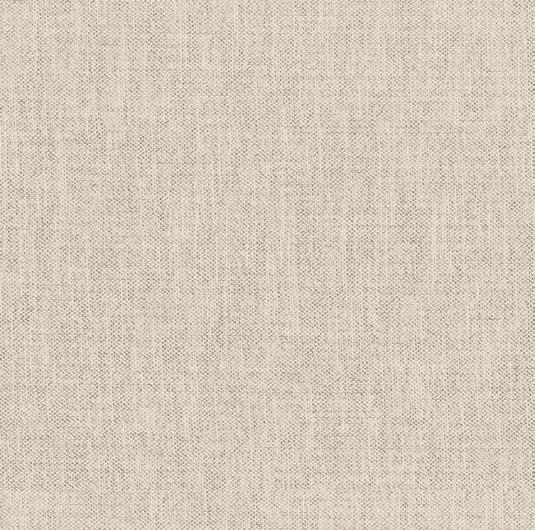

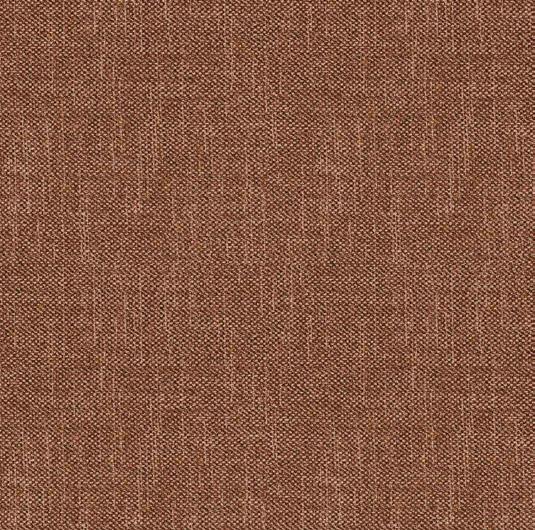

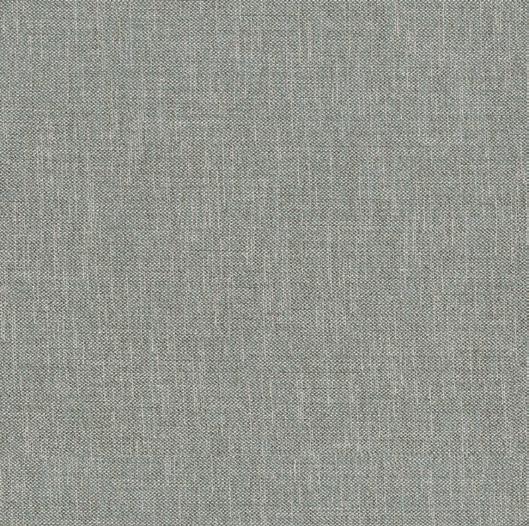

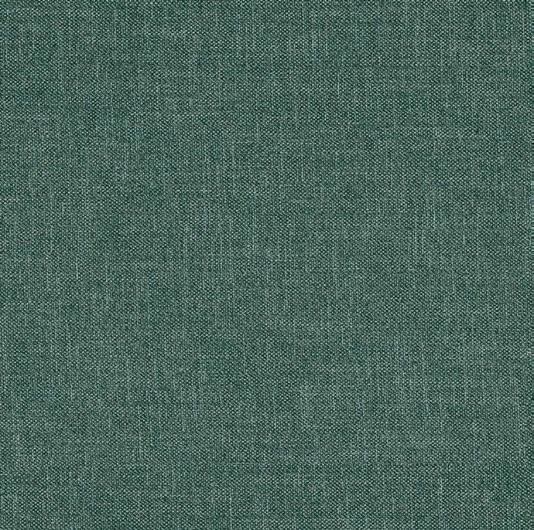

We are renowned for our exceptional collection of stunning prints, and when it comes to digital printing, it’s something we truly excel at. We’ve curated a beautiful collection which includes everything from our in-house textures to designs by Indigenous and local Australian artists. These designs are then directly printed onto 12mm acoustic panels, allowing us to print on demand, minimising waste.

Our designs are optimised to work seamlessly with the panels, and each one comes pre-trimmed for easy installation. All you need to do is choose your design and specify the number of panels required. Simple as that!

For any project enquiries or sample requests please reach out to sales@materialised.com or your local Project Manager.

Pattern Repeat - V: 60.3cm x H: 120cm approx.

BUSHLAND

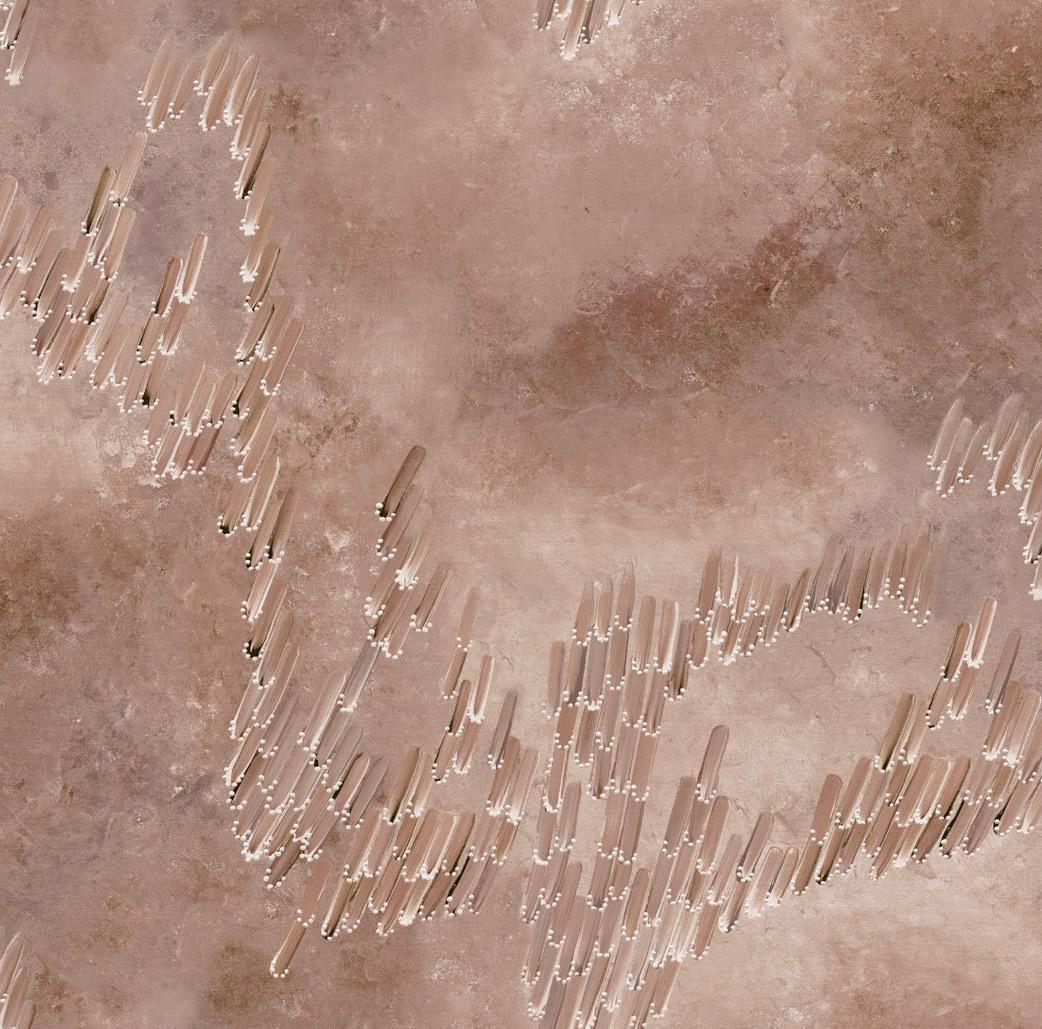

DESERT

Pattern Repeat - V: 50.4cm x H: 60cm approx.

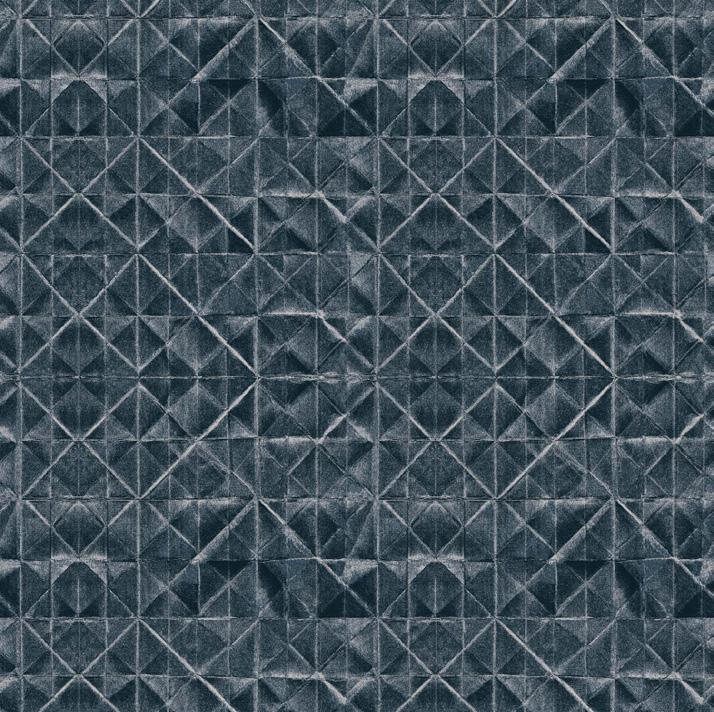

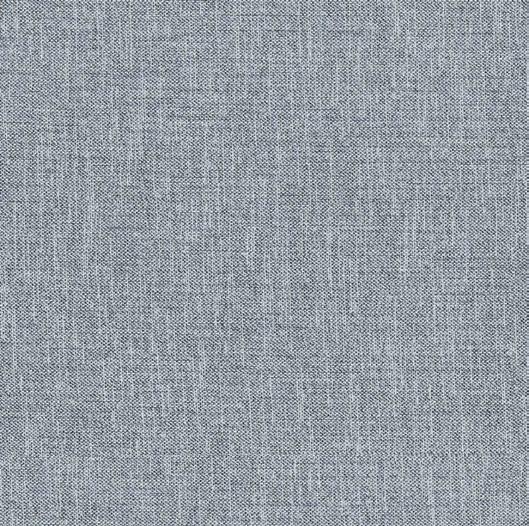

BONDI

DESERT

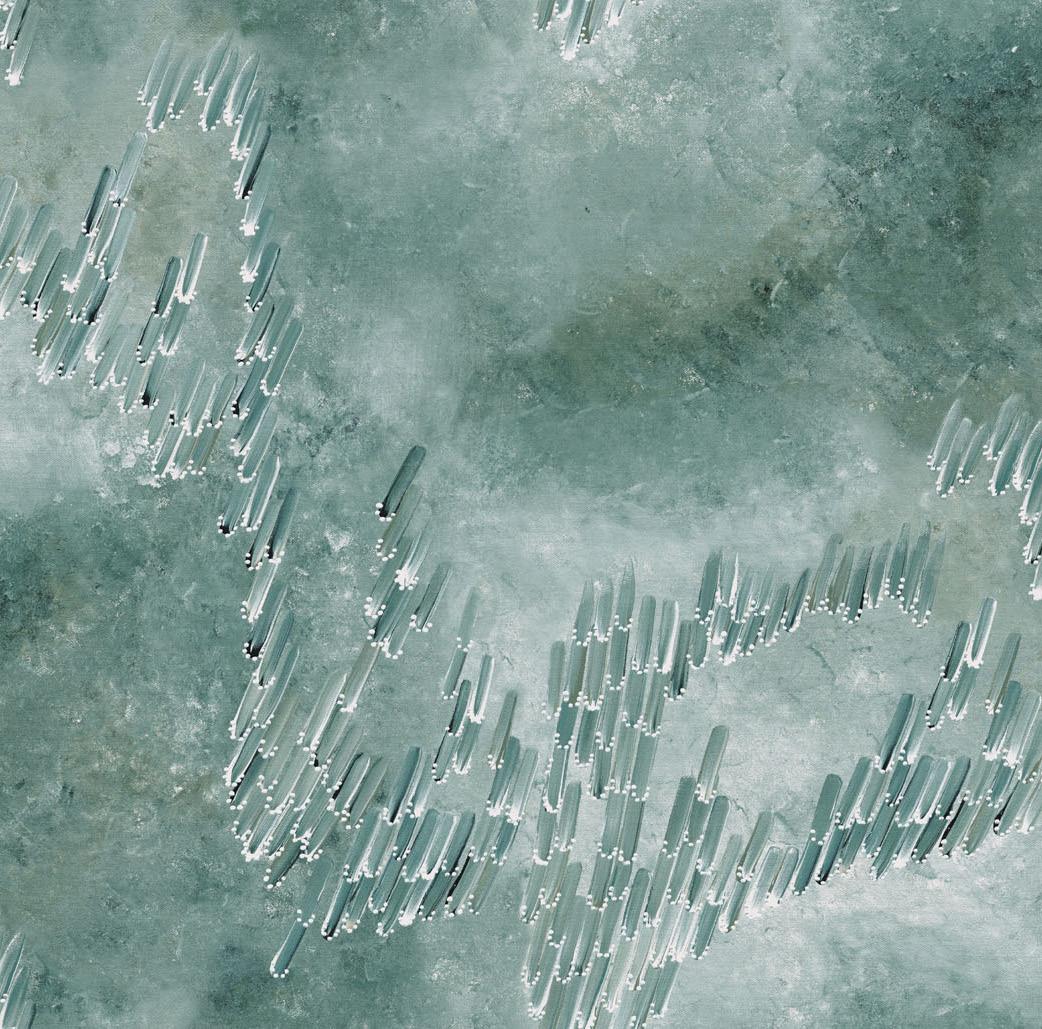

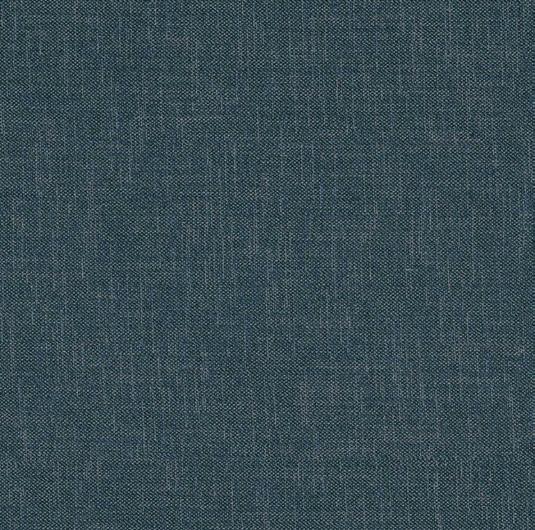

DAINTREE

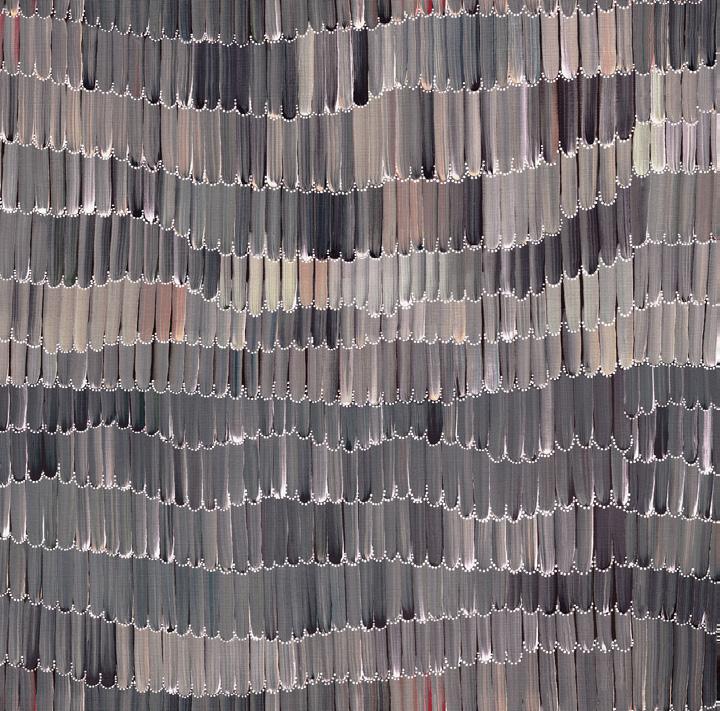

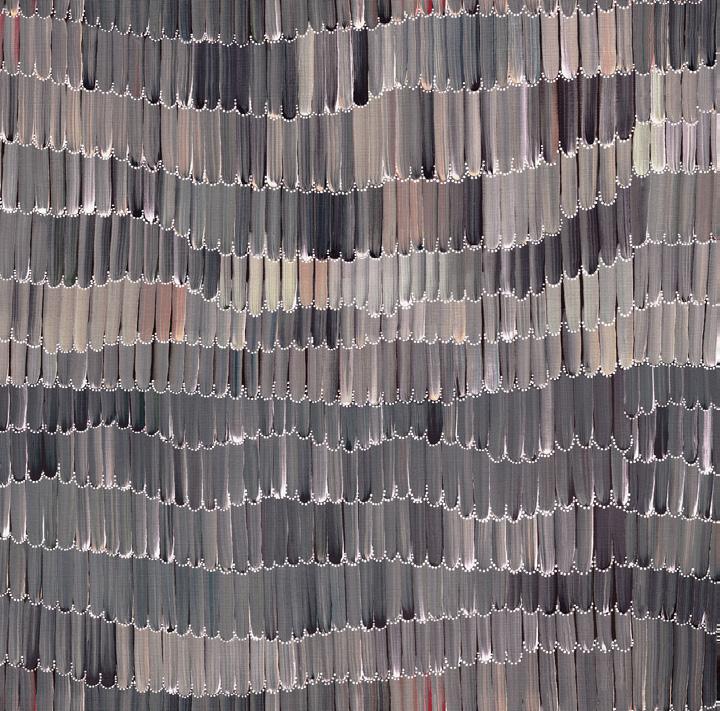

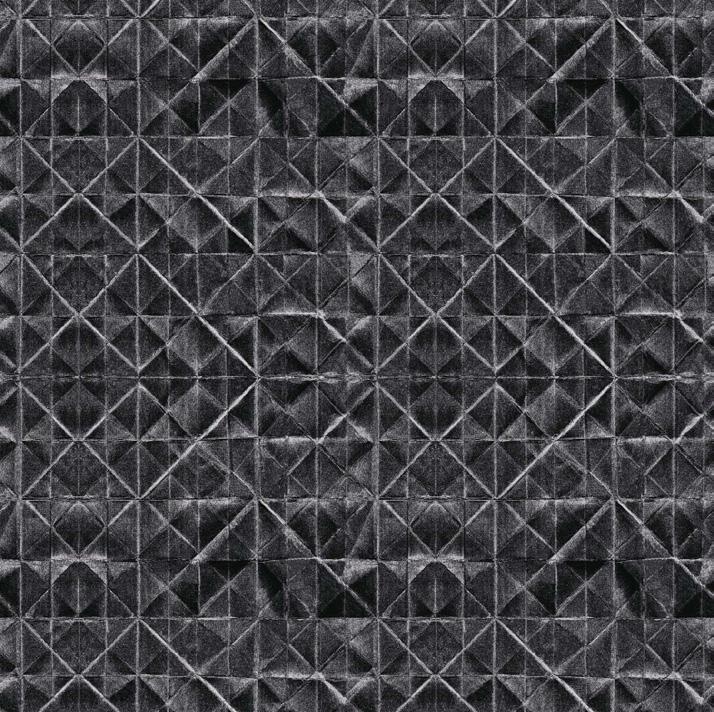

CHARCOAL

Pattern Repeat - V: 179.2cm x H: 240cm approx.

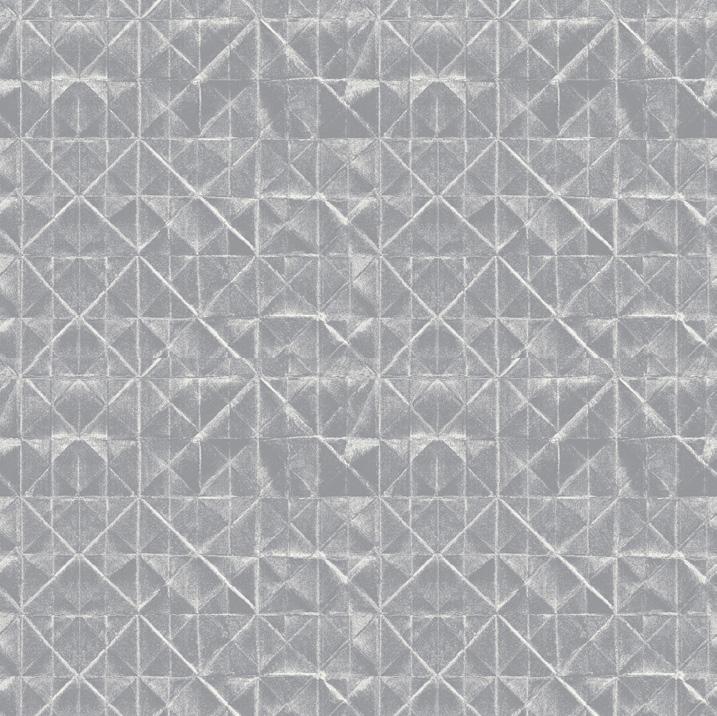

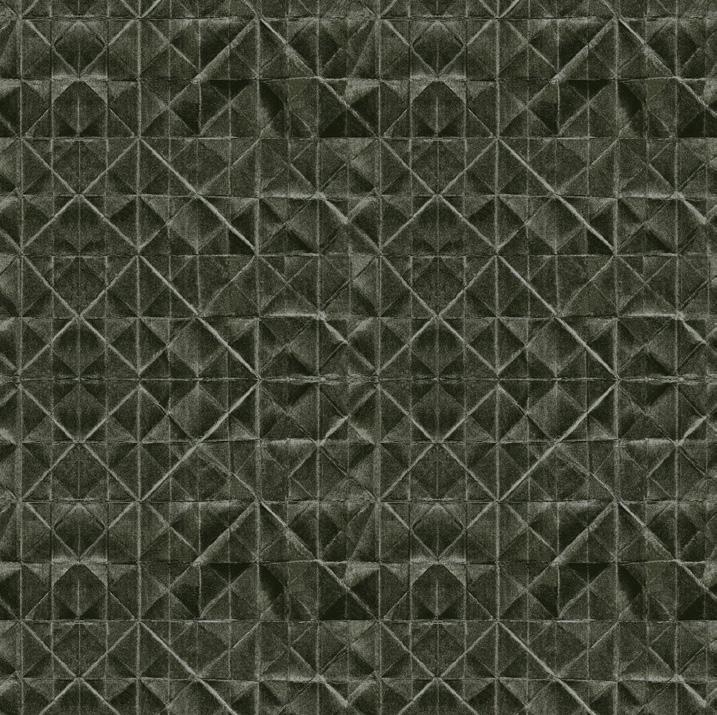

Pattern Repeat - V: 43cm x H: 30cm approx.

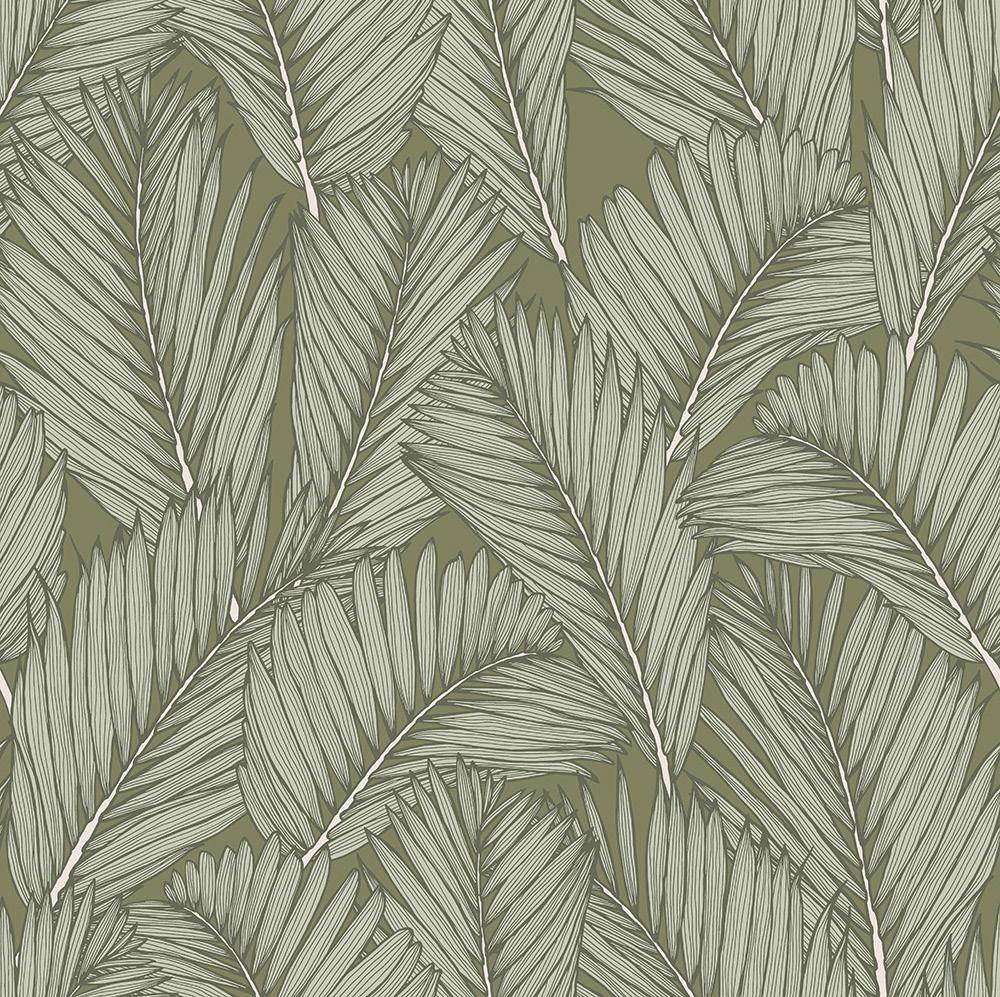

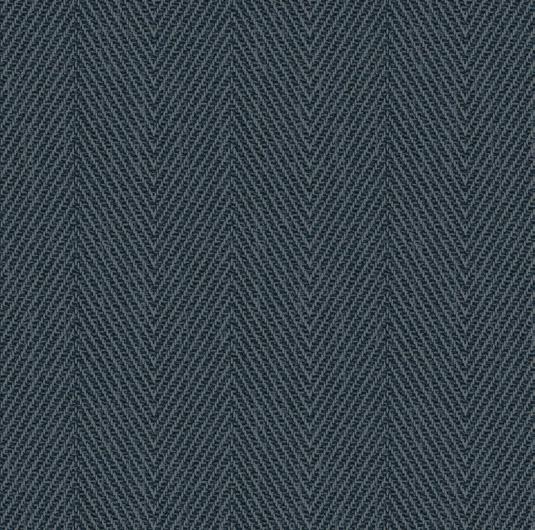

DAINTREE

Pattern Repeat - V: 60cm x H: 60cm approx.

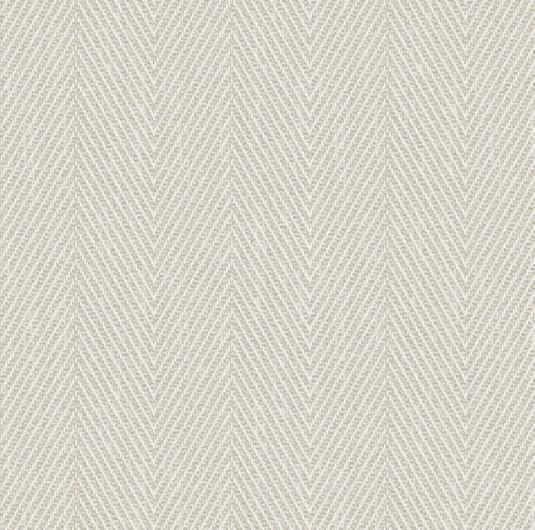

EUCALYPTUS

Pattern Repeat - V: 60cm x H: 60cm approx.

Pattern

Pattern Repeat - V: 18.2cm x H: 15cm approx.

Pattern Repeat - V: 30cm x H: 30cm approx.

IMPORTANT – If at any time before or during installation you do not understand these instructions, or if a discrepancy is discovered in pattern, colour or quality, STOP. Contact Materialised Pty Ltd before proceeding. Any deviation from these instructions will void the manufacturer’s warranty.

Carefully examine all material to ensure correct pattern, colour and quantity.

Materialised acoustic panels must be transported, stored and handled with care. Keep the panels dry and store them indoors. Avoid dropping or storing panels on their corners or edges, as this can cause damage..

Prepare the wall by cleaning it thoroughly to remove dust, dirt and grease. Repair any cracks or holes and sand the surface smooth. If the wall has a glossy finish, lightly sand it to improve adhesion. For coated surfaces, perform an adhesion test to ensure compatibility. Ensure the wall is dry, dust-free and ready for panel installation.

Our panels come pre-trimmed and ready for easy butt installation. However, if you need to cut the panels, please follow these instructions:

- Trial on a piece of scrap prior to cutting the panel. Ensuring highest possible finish

- Use sharp clean blades. Do not cut with dull blade or cutter

- Always use slow, consistent feed rate

- Hold/clamp down sheet firmly while cutting to minimise/prevent vibration and movement. Careful to not apply excessive clamping pressure (have something soft between clamp and board) to avoid dents or damages.

- Avoid overheating causing panels to melt of fuse at heated contact points.

- Make several passes rather than one cut

- Cut from the back to the front

- Mark cuts with masking tape

1) Apply the adhesive to the backside of the panel, following the manufacturer’s instructions carefully. We recommend using:

- Selleys Liquid Nails Instant Hold

- TensorGrip X40 Acoustic Panel Adhesive

It is the installer’s responsibility to ensure that the adhesive is suitable for the intended application and that the wall is appropriate for both the adhesive and the acoustic panels.

2) Apply additional adhesive along the wall at butt joints to ensure sufficient adhesion and a tight join. Take care not to use too much adhesive at the joints, as it may seep through the seams when pressure is applied.

3) Allow the adhesive to tack off correctly before fitting the panel to the wall.

Continue this process for all panels until the installation is complete.

Protect from direct sunlight.

Vacuum using low suction and smooth attachment if needed to reduce dust build up.

- All spills and stains are best to be addressed as soon as possible.

- Before carrying out a proposed cleaning method, patch test on a concealed section to ensure it will not affect the adhesive or product.

- Avoid concentrated rubbing and use minimal pressure when cleaning only.

- Gently scrape or mop liquid from the surface of the fabric, do not scrub with soft application.

- Apply proprietary cleaning agents strictly according to instructions to remove the residue of the spill.

- Do not saturate fibre with water or other cleaning liquids. Avoid excessive amounts of liquid.

- Ensure adequate ventilation if the product is likely to be subject to excessive moisture.

- May be spot cleaned with dry cleaning solvent.

Before carrying out a proposed cleaning method, patch test on a concealed section to ensure it will not affect the adhesive or product.

- Do not use dishwashing or laundry detergents.

- Use only upholstery detergent.

- Do not saturate fibre.

- Allow to dry away from direct heat thoroughly before re-use

Sydney

Head Office: 19 Heath Rd, Blakehurst, NSW Australia 2221

Show Room: Ground Floor, 51-53 Bourke Rd, Alexandria, NSW Australia 2015

P +61 2 8558 3500 F +61 2 9546 5402 sales@materialised.com

Adelaide / Darwin

55A George Street, Parkside, SA Australia 5063 P +61 8 8271 9185 F +61 8 8271 9321 sasales@materialised.com

Brisbane

26 Balaclava St, Woolloongabba QLD Australia 4102 P +61 7 3393 2188 F +61 7 3393 2177 qldsales@materialised.com

Melbourne / Hobart

Suite 2/1 Bromham Pl, Richmond VIC Australia 3121 P +61 3 9815 3033 F +61 3 9815 3077 vicsales@materialised.com

Perth

189 Colin Pl, West Perth WA Australia 6005 P +61 8 9381 2802 F +61 8 9388 1532 wasales@materialised.com

New Zealand

10 Dock St, Freemans Bay, Auckland New Zealand 1010 P +64 9 302 7733 F +64 9 302 7779 nzsales@materialised.com

Malaysia / Singapore

P +65 6635 3377 info@bode.com.sg

Costa Rica

P +50647043189 info@designbox.net