ZHEJIANG MASTER INJECTION SYSTEM CO.,LTD

VVT项目介绍

Hydraulic VVT Introduction

量产清单Massproductionlist

主机厂Factory OE.

01

02

03 福特Ford 917-250 征服者、探险者、野马、登山者

04 雪佛兰Chevrolet 917-254 探界者、科沃兹、君越、君威

05

福特Ford、路虎Landrover CJ5E6C524AE 蒙迪欧、致胜、发现

奔驰Benz 2710500800 梅赛德斯 奔驰 Mercedes-BenzC-Class2003-2011款 /C-ClassT-Model2003-2011款 /CLK2003-2010款 /E-

CLC-Class2008-2011款 /CLK2004-2010款 /E-Class2005-2016款 /E-ClassT-Model2005-2011款 /G-Class2008-2020款 /G-Class Cabrio2009-2020款

/2

款 /3GranTurismo2012-2016款 /3Series2011-2018 款 /4Gran2014-2020款 /4Series2013-2020款 /5Series2010-2017款 /5SeriesGranTurismo2013-2017 款 /X12011-2015款 /X32011-2017款 /X42014-2018款 /X5

奔驰Benz 2700506100 梅赛德斯 奔驰 Mercedes-BenzA-Class2012-2018款 /B-Class2011-2018款 /C-Class2015-2018款 /C-ClassTModel2015-2019款 /CLA2013-2019款 /CLAShootingBrake2015-2019款 /GLA-Class2013-2019款

VVTTraditionalVVT

传统铝合金叶片式

Traditional aluminum vane H-VVT

⚫基本功能、性能实现

Achieve basic function, performance

单击此处副标题

粉末冶金叶片式H-VVT

Powder metal vane

⚫更高的可靠性,更好的性能指标

Higher reliability, better performance

E-VVT

⚫更大的可调节角度

Bigger shifting angle

⚫更宽的可标定区间

Wider calibration range

HM-VVT

⚫更好的性能指标 Better performance

⚫更低的发动机综合成本

Lower engine whole cost

HMM-VVT

⚫更大的可调节角度

Bigger shifting angle

⚫阿特金森循环

Atkinson cycle

HIE VVT(High Intelligent Efficiency)

⚫更快的响应 Faster response ⚫更低的发动机油耗

Lower oi l consumption

传统VVT 简介Introduction to HM-VVT

滞后调节

OCVpoweredon,exhaustVCPadjustedtolagdirection

提前调节 advance

Return Valve 1A Valve 0A

OCVpoweroutage,exhaustVCPadjustedtoadvancedirection

Development of VVT product structure

HM-VVT 简介Introduction to HM-VVT

进气 Intake VCP

机油控制阀 Oil Control Valve

电磁铁 Magnet

排气 Exhaust VCP

机油控制阀 Oil Control Valve

电磁铁 Magnet

HM-VVT 简介Introduction to HM-VVT

滞后调节 Return

HM-VVT 简介Introduction to HM-VVT

advance Valve 1A

OCVpoweredon,intakeVCPadjustedtoadvancedirection

中置式VVT 性能表现Performance performance of HM-VVT

➢ 提高系统响应速度,尤其是在低转速、低油压和低温工况;

➢ 减少油耗,降低机油泵负荷;

➢ Increasesystemresponsevelocity,speciallyunderlowspeed,lowoilpressure,andlowtemperature

➢ LowoilconsumptionduringVVTshiftingprocess,reduceloadtooilpump.

转速 (RPM) 90 ℃ -Oil saving simulation

VVT 性能表现Performance performance of HM-VVT

Control Stability (Crank Angle)

结论:控制精度满足<±1°CA.

➢ Conclusion: testresults <±1°CA.

设计目标

DesignTarget

产品布局

Productlayout 产品设计

QFD、FTA、Benchmark

单击此处副标题

系统分析

CAE,toleranceanalysis

实验设计

DOE

实验计划

Flowchart,benchtest validation

ProductDesign

DFMEA开发

DFMEADevelop

系统组件分析

System&Componentanalysis

DV实验

DVTest

结构尺寸

Boundarydimension

◆System

•TS16949-APQP

◆Standard

•JB/T13289-2017

尺寸、材料、性能

Dimensions,material performance

设计校核、DV清单

Designreview,DVlist

响应、控制、泄漏、强度、应

力Response,accuracy,leakage, strength,stress

功能、耐久性、可靠性

Function,perlorance,reliability

◆CAD

•PRO/E

•UG

•CATIA

•AUTOCAD

◆CAE

•ANSYS

•Maxwell

•Amesim

设计冻结

Designfrozen

◆PLM

Current control and preventive measures

A: Design standards reference table

B:Simulation analysis table

C: Benchmarking table

D: Tolerance analysis table

E: Design calculation sheet

F: Empirical data reference table

Design optimization table

Design frozen 历史失效参考 Historical failure reference

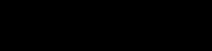

Design record A—Design standard

Design record B Design Simulation

Design record C—Design

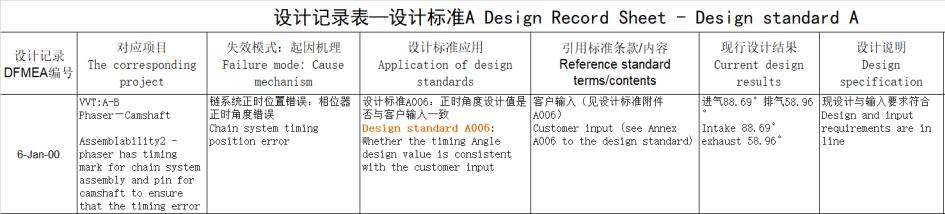

Design record D—Design Tolerance Analysis

Design record E—Design calculation

Design record F—Experience data

VVT开发仿真计算

VVTdevelopsimulation

系统响应速度

Systemresponsespeed

单击此处副标题

系统控制精度

Systemcontrolstability

VCPParts 机械强度仿真

Mechanicalstrength simulation 扭簧模态仿真

SpringModal simulation

OCVParts 机械强度仿

Mechanicalstrenght

Electromagnetic temperaturesimulation

OCVParts 静态电磁特 性仿真

Staticelectromagnetic simulation 瞬态电磁特性仿真

Instantelectromagnetic simulation

OCVParts 流量特性仿

simulation

Pressureloss simulation

OCV单体试验 OCV Test

阀体总成P-A流量测试

P-Aflowtest

阀体总成P-B流量测试

P-Bflowtest

阀体总成B-A流量测试

B-Aflowtest

阀体总成A-B流量测试

A-Bflowtest

P口单向阀开启压力测试

P-portcheckvalveopeningpressuretest

单击此处副标题

P口单向阀反向泄漏测试

P-portcheckvalvereverseleakagetest

循环单向阀开启压力测试

Circulatingcheckvalveopenpressuretest

循环单向阀反向泄漏测试

Circulatingcheckvalvereverseleakagetest

滤网强度验证试验

Filterstrengthtest

螺栓内孔变形量验证试验

BoldInnerholedeformationvalidationtest

泄漏量测试

Leakagetest

线圈电阻测试

Coilresistancetest

绝缘电阻测试

Absoluteresistancetest

循环单向阀耐久试验

Circulatingcheckvalveendurancetest

共42项 Total42items

气密性测试

Airtighttest

螺栓拉断力验证试验

Boltbreakforcevalidationtest

保持点电流测试

Holdpointcurrenttest

响应时间测试

Responsetimetest

异物动作寿命可靠性试验

相位器单体试验 VCP test

锁销解锁油压测试

Lockingpinunlockingoilpressuretest

相位器泄漏量测试

VCPleakagetest

锁销间隙测试

Lockingpinbacklashtest

可调节角度测试

Adjustableangletest

Foreignmatteractionlifereliabilitytest 摩擦扭矩测试

高温动作寿命可靠性试验

Hightempactionliftreliabilitytest

低温动作寿命可靠性试验

Lowtempactionreliabilitytest

冷热冲击试验

Cold-hotimpacttest

抗振动可靠性试验

Vibrationresistancereliabilitytest

耐水可靠性试验 Waterresistancereliabilitytest

耐盐水喷雾试验

Saultsprayresistancereliabilitytest

100H抗化学腐蚀药品试验

100Hchemicalresistancetest

Frictiontorquetest

锁销机构耐转矩强度测试

Lockingmechanismtorqueresistancetest

500H冷热冲击试验

500Hcoldhotimpacttest

转子打滑试验

Rotorsliptest

壳体打滑试验 Housingsliptest

系统试验 System test

VVT系统执行速度MAP试验

VVTsystemshiftingspeedMAPtest

VVT控制稳定性MAP

VVTcontrolstabilityMAPtest

锁销动作可靠性能试验

Lockingpinactionreliabilitytest

锁销解锁试验

Lockingpinunlockingtest

800H微小动作可靠性能试验

800Hmini-actionreliabilitytest

800H全行程动作可靠性试验

800Hfullstrokereliabilitytest

耐脏油可靠性能试验

Oilcontaminationreliabilitytest

试验项目

Testitem

试验标准

Teststandard

试验目的

单击此处副标题

Testobjective

试验设备

Testequipment

试验台Testbench ◆ 重点试验项目及设备Key experimental projects and equipment

VVT 发动机模拟实验

VVTenginesimulationexperiment

JB/T13289-2017内燃机 可变气门系统

JB/T13289-2017TechnicalConditionsforVariableValveSystemCamPhaseAdjustersinInternalCombustion Engines

用于评估VVT的工作范围内功能和耐久表现(-30-140℃)

UsedtoevaluatethefunctionalanddurabilityperformanceofVVTwithintheworkingrange(-30-140 ℃)

发动机缸盖倒拖试验台

Enginecylinderheadreversetowingtestbench

Camangledecoder

曲轴编码器Crankshaftangle encoder

Pressuresensor

油检性能测试台

Performancetestbench

Key experimental projects and equipment

缸盖实验台 Cylinderheadtestbench

信号轮实验台

Signalwheeltestbench 耐脏油试验台

Dirtyoilresistancetestbench

耐久实验台 endurancetestbench

平衡试验机 Balancingmachines

冷热冲击实验箱 Cold-hotimpacttestchamber

高温耐久试验台 Hightemperaturedurabilitytest bench

单击此处副标题

Chemical composition

Mechanicalproperty

Dimensions

Heattreatspec

Cleanliness

Shifting

Unlocking

Key Process Control -

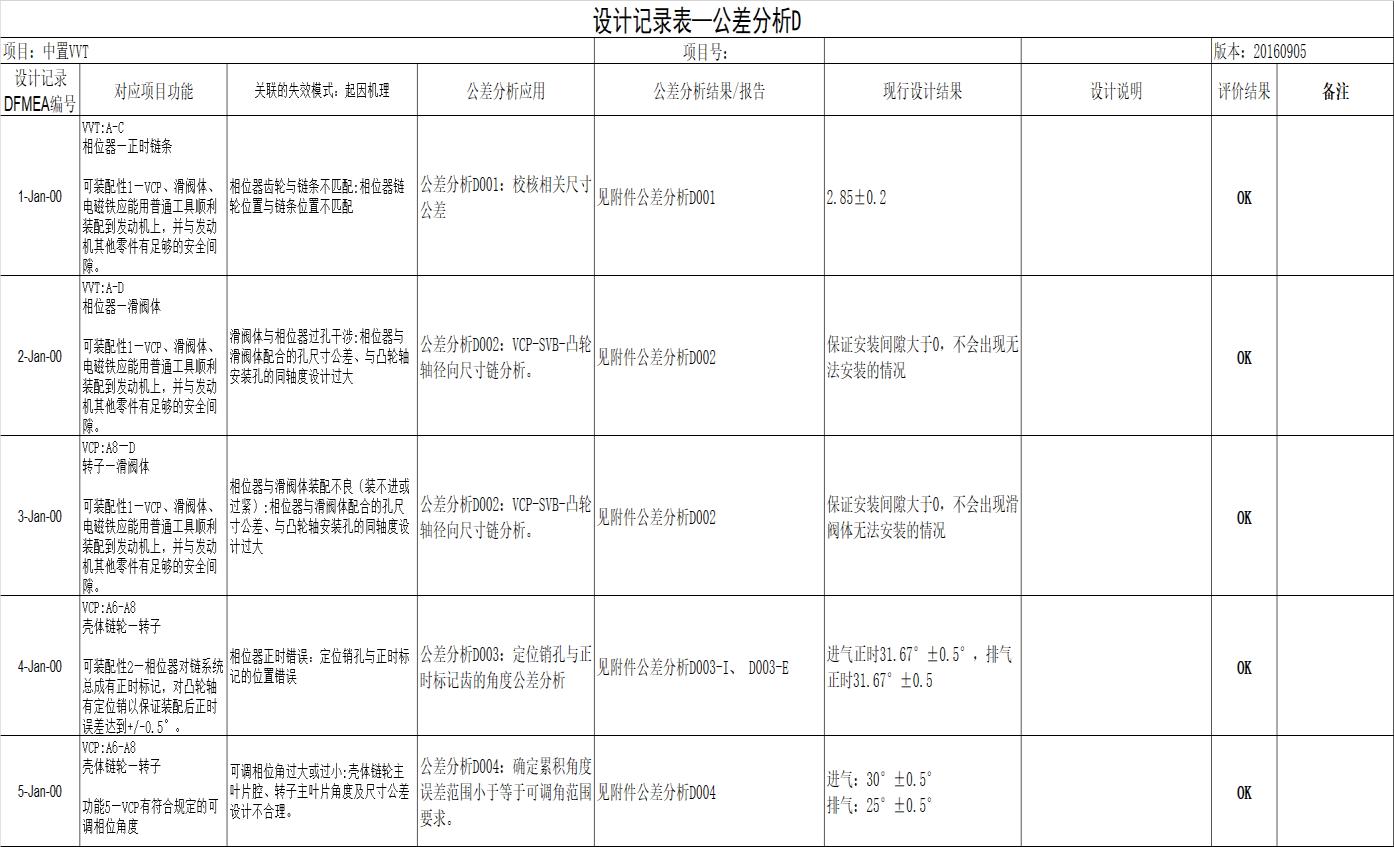

Double End Grinding of Rotors

关键过程控制Key Process Control -VCP性能检测VCP performance test bench

单击此处副标题

测试界面Testinterface

VCP性能测试台 Performancetestingbench

序号No. 要求 Requirement

检测方法 Inspection method

控制方法 Control method 1

解锁压力 Unlockingpressure

压力传感器 Pressuresensor

2

3

可调节角度 Shiftingangle

角度编码器 Angledecoder

4

锁销间隙 Lockingpinbacklash

角度编码器 Angledecoder

•100%在线检测100%continuous inspection

•不合格品隔离NOKpartrejected automatically

•启动设备前标Equipmentselfinspectionwhenstart

•传感器定期标校Sensorcalibratedat regulartime

摩擦力矩 Frictiontorque

扭矩传感器 Toquesensor

5 泄漏量Leakage

流量传感器 Flowsensor

•数据记录储存Datastorage

基本性能测试Performancetest

单击此处副标题

序号 No. 项目 Item

技术要求 Requirement

1

中心点匹配 Centerpoint matching

工艺设定值 Drawing requirement

2 气密性 Airtightness

OCV性能测试台 OCVperformancetestbench

3 单向阀测试 Checkvalvetest

工艺设定值 Drawing requirement

检测方法 Inspection method

流量传感器 Flowsensor

测试界面Testinterface ◆ 关键过程控制Key Process Control – OCV性能测试仪OCV performance test bench

流量传感器 Flowsensor

工艺设定值 Drawing requirement

4 流量特性 Flowcharacteristics

工艺设定值 Drawing requirement

流量传感器 Flowsensor

控制方法 Control method

•100%在线检测 100%continuous inspection

•不合格品隔离NOK partrejected automatically

•启动设备前标 Equipmentselfinspectionwhen start

•传感器定期标校 Sensorcalibratedat regulartime

•数据记录储存Data storage

流量传感器 Flowsensor

基本性能测试Performancetest

VVT key point process control

电磁阀防卡滞工艺控制Electromagnetic valve anti jamming process control

OP30: ● 精车内孔

OP40:

OP20:

车削外圆 余量:0.024

:

:

• 换向杆毛刺控制工序Controlprocessforburrsonthereversingrod:

OP50/OP60/OP80/OP100

• 换向杆高点/碰伤控制工序Controlprocessforhighpoints/bumpson thereversinglever:OP100

• 换向杆清洁度Cleanlinessofthereversinglever :内部清洁度控制

Internalcleanlinesscontrolprogram

Key processes for burr control

OP120:

OP110:

2-7μm

Process control for anti jamming of phase

Key processes for burr control

OP40:

• 转子毛刺控制工序Rotorburrcontrolprocess: OP80/OP90/OP100

• 去除倒角毛刺Removeburrsfromchamfers

• 转子清洁度Cleanlinessoftherotor:内部清洁度控制 Internal

cleanlinesscontrolprogram

清洁度控制程序Cleanliness control program

➢需清洗件

Cleaning required

➢外购不清洗件

Purchased non cleaning parts

检清洁度

Cleanliness testing

清洗工序 Cleaning

•多频超声 Multifrequency ultrasound

•分槽分段Dividing slots andsegments

•循环过滤Circular filtration

•专用工装Special tooling

➢包装盒 packing box

•防运输过程中与产品摩

检清洁度 Cleanliness testing

除尘除静电 Dust removal&static electricity

•除静电Removing staticelectricity

•吹吸尘Blowingand vacuuming

•专用通道Dedicated channel

•针对包装For packaging

装配工序 Assembly 包装工序 package

•封闭车间Closed workshop

•气源过滤Airsource filtration

•线体吸尘Vacuum cleaning

•专用器具Special equipment

•封闭车间Closed workshop

•包装吸尘packaging vacuumcleaning

•封闭后出车间Exit theworkshopafter closure

封闭环境 enclosed environment

检清洁度 Cleanliness testing

repair

•·Designtoprevent impuritiesgeneratedby frictionwithproducts duringtransportation

privatechannel

Changing shoesand clothes

airshower

Packaging and shipping

VVT key point process control

相位器防卡滞工艺控制Process control of phase shifter anti jamming

转子超声波清洗过程控制rotor ultrasonic cleaning process control

● 手工清洗

Manualcleaning

单击此处副标题

产品独立放置,手工粗洗The productisplacedindependently andhandwashedroughly

● 摆放整齐 Arrangeneatly

产品独立放置 Productindependentplacement

● 粗洗 Roughwashing

180S大杂质粗洗180Scoarse cleaningwithlargeimpurities

● 浸防锈油 Immersionin rustproofoil

进行浸泡防锈油处理 Soakinantirustoiltreatment

● 再粗洗 Furtherrough washing

180S二次粗洗残留较大杂质180S secondaryroughwashingresidual largeimpurities

● 高温烘烤 Hightemperature baking

600S去除产品水分 600Storemoveproductmoisture

● 漂洗 Rinsing

180S漂洗

180Srinse

● 发泡精洗 Foamwashing

180S精洗 180sfinewashing

Provide

Collect

Provide

Provide

Provide