Obtaining The Most effective out of Dewatering Equipment

Has the Dewatering Functionality Declined through the years?

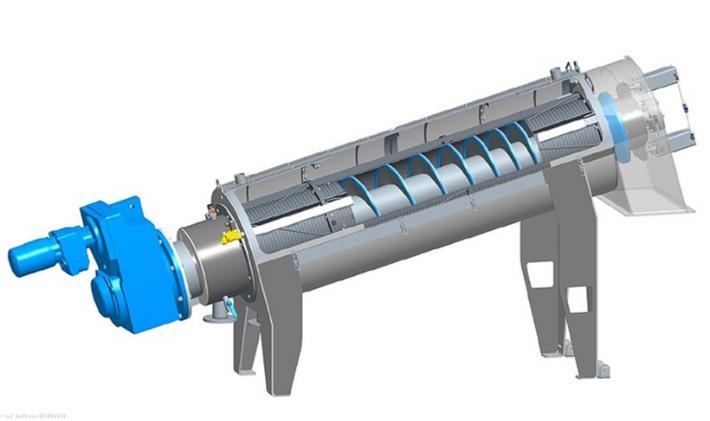

Sludge Dewatering and thickening is The most widespread processes in Water and Wastewater remedy plants. Belt presses, gravity tables and centrifuges are the same old devices goods utilised. In the case of belt presses and gravity tables, the simplicity of your devices can lull operators and servicing workers into a slow strategy of making it possible for the machines and options to deteriorate.

A latest survey of press installations ranging in age from three to 18 several years has proven that many are being operated at ten to 30% below the initial style capacity. There are many good reasons, but normally reduced general performance appears being due to a mix of aspects, including employees turnover, servicing and buying decisions, as well as a want to reduce the period of time invested changing the tools.

A de-tuned method is often more stable, and can tolerate more variability inside the feed ailments. Further out there plant capacity may also stimulate this tactic.

Functionality components

In restoring performance there are two procedure elements to take into account. The first is the fact that sludge dewatering is often a combined Actual physical /chemical means of flocculation, followed by a next procedure, the mechanical stage of the actual dewatering. Efficient Procedure of both of those steps is vital for profitable dewatering.

Flocculation

Flocculation of sludges depends strongly on the nature of your sludge. All through initial commissioning the machines provider plus the flocculant provider will Generally perform jointly to pick out the most beneficial flocculation routine. This involves not simply the alternative of the right flocculant (normally a cationic polymer), but additionally the usually means of dosing and mixing, together with the dosage charge. If, above successive years, the cure course of action, or even the procedure plant influent, alterations, these selections might require to be revisited. The dosing settings, for example final dilution and mixing adjustments also must be altered, and these configurations may be important to good effectiveness.

Flocculant suppliers have an on-going source of earnings through the sale of substances, and so are usually the leading resource of data and repair in this regard. Even so, They could not have an in-depth knowledge of the mechanical tools adjustments necessary to fit The brand new ailments. In addition, they

Use a vested interest in advertising and marketing their individual goods.

The polymer flocculant is the guts and soul of the biosolids dewatering system. While doctorate theses abound concerning the performance and range of the proper polymer for an software, the reality is It's really a demo and error course of action, with luck and ability included.

Business Variables

A typical issue is Water Authorities with multiple treatment method plant employing polymer flocculants contacting for tenders for offer of polymer flocculants to get a quantity applications in a single huge deal. This will work towards selecting the best polymer for every application, as sometimes a person suppliers’ polymer vary will not suit every circumstance.

Due to this solution, It is far from unusual to locate lousy executing polymers being used, with corresponding lowered dewatering performance of your products. This coverage also brings about a flurry of screening activity at tender time, accompanied by a long interval for the duration of which the polymer supplier focuses his awareness elsewhere.

A serious occasional dilemma is a earth –broad shortage of Uncooked resources, that has raises the price, and alternatively encourages polymer makers to lessen the active information for each kilogram of chemical.

Mechanical Problems

Besides the procedure factors there are actually mechanical maintenance troubles. Belt presses, similar to a car or truck, have wear elements which should be replaced, together with necessitating occasional adjustment. The leading wear components are classified as the filter belts, cake scraper “physician’ blades, as well as the seals for that belt spray clean bins and facet skirts, and the spray nozzles.

Filter Belts

The filter belts Possess a direct effect on the method functionality, and in many cases the aspect skirt seals can have an impact on system general performance. However a lot of businesses go away the purchasing of such spares to procurement departments or mechanical routine maintenance team, who might buy purely on evident value, and the method efficiency can endure as a consequence.

The choice of the greatest filter belt is a compromise concerning an open up weave to stimulate drainage, the need to aid the cake and cut down losses from the fabric, and the chance to wash the belt thoroughly clean. Belt washing can be significant, and also a worn drinking water tension booster pump, or worn nozzles, together with the incorrect decision of belt, is a normal recipe for inadequate approach overall performance.

An extra issue will be the mechanical energy needed, notably the resistance of a filter belt to creasing and distortion on the seam (Which leads to a curved seam, which some call a “smiley deal with” but Individuals during the know connect with a “sad encounter”). A top quality belt push provides minimum stresses from the belt, whereas some compromise presses create far more worry. The incorrect choice of belt can drastically minimize throughput and seize.

Seals

Simple things for instance clean spray seals and enclosures are frequently neglected, leading to aerosol emissions. Even though some operators have reported that they've got tolerated these aerosols For a lot of many years with none sick outcomes on their own team, it is much greater to hold out the minimum amount routine maintenance required, and the advantages will contain a happier workforce. A happy operator will get a lot more care of his tools and have a tendency to generate a better process result.

Spray WashboxSeals need to have standard inspection and alternative the place required. It is necessary they be set up accurately in an effort to seal proficiently. A common installation oversight is to offer insufficient adaptability from the piping towards the spray headers to ensure that suitable adjustment is difficult.

Health practitioner Blades

Other slight mechanical parts in which mistakes are created, are cake release “health care provider” blades and gravity drainage zone skirt seals. You will find a notion that When the thickness of fabric is elevated, it will eventually operate better. Having said that, in engineering, at times more substantial is not generally far better, and the extra stiffness of doctor blades and aspect skirt sealing rubbers may end up in mechanical complications including weak belt monitoring, and increased motor power usage, and shorter belt lifetime.

Tuning

Similar to a motor vehicle, sludge dewatering programs need to be tuned by specialist personnel at normal intervals. A plant with tiny improvements in functioning employees and approach disorders may only need re-tuning each and every 3 or 4 several years, While yearly tuning and reschooling might be appropriate for wastewater plants in high development places and with speedy employees turnover.

Modifications to sludge age can alter the qualities in the sludge, and require a different polymer and push configurations.

In tuning, the expert will assessment the program from your biosolids conditioning chemical substances through the mixing and flocculation routine, and correlate this With all the belt speeds, sort of filter belt weave, belt pressures, and traits of The actual belt press. Some presses for instance are very tough on the shaped floccs, Whilst Some others might have a more Light action. The expert may also location mechanically designed system troubles, including poor belt washing or collection.

Centrifuges

The majority of these elements are true regarding centrifuge dewatering devices, but created extra challenging by The reality that the visual clues supplied by the belt push usually are not out there with the centrifuge. It is also easier to dismiss weak efficiency of the centrifuge procedure, as the process are all occurring inside the equipment, under a cover. Off-tune centrifuges will eat lots additional polymer, or may deliver Significantly deteriorated capture costs, and decreased throughput.

A correctly modified dewatering method will provide Charge financial savings by decreased polymer intake, manpower for operation, and electric power usage. An extra profit can be decreased disposal fees from a drier cake. As being a large proportion in the working price of a remedy plant might be attributed on the sludge dewatering and dealing with, a small financial commitment in protecting and tuning this gear can lead to considerable price savings.

To know more details visit here: sludge dewatering equipments manufacturer