ACCURATE TM METERS

Compatibility: C-Series and 1910 Air Carts. 1910s New for 2026

The AccuRateTM meter precision upgrade brings a host of improvement to your existing air cart, significantly boosting seeding accuracy with the integration of individual electric meters for each primary run. By leveraging the power of electric meters, John Deere offers customers unprecedented precision in seeding across the entire tool width.

SectionCommand™ Pro allows for more exact section control on/off by stopping the meter as each section shuts off, and more accurate variable rate application due to the ability to change the speed of the meters by section. This technology also enables curve compensation, which changes the meter speeds across the tool to account for turns and puts down a more consistent amount of product on the inside and outside of the tool.

Easily control product flow with a switch, utilizing a powerful 1500 lb actuator for seamless tank management.

(Optional)

High powered LED offer excellent tank visibility at all times, instantly indicating product levels during nighttime filling.

The EZCal™ system (optional) automates calibration tasks to achieve a 45% faster process than leading competitors. The system only requires users to pour a bucket of product into the hopper, select the correct roller and tank, and initiate calibration, then accept the Meter Displacement Value (MDV) once completed. All of this is done from the ground level using the dedicated calibration station and new G5e display mounted on the side of the cart, which sends your MDV directly to the tractor cab.

The blend of stainless steel and composite materials create a durable and reliable system that withstands diverse and abrasive products.

The newly designed bottom clean-out door now swings fully open and latches securely, providing ample space for easy tank emptying.

EXACTAPPLY TM

Compatibility: All model years of R4030, R4038, R4044, R4045, R4060, 408R, 410R, 412R, 612R, 616R.

Improved Coverage Through Corners

Fertilizers and crop protection products are too expensive to waste, and seed is too valuable to risk over- or under-treating. To help make sure your solution is getting to the crop at exactly the right rate and droplet size across a wider range of speeds, look to ExactApplyTM nozzle control system.

The six-nozzle turret allows for Pulse Width Modulated (PWM) spraying, either with 15-HZ (single nozzle) or 30-HZ (dual nozzle) frequency. This allows for more consistent pressures and droplet sizes over a wider range of ground speeds and application rates. AutoSelect A/B mode also allows for automatic switching between nozzles when conventional spraying to maintain more consistent pressures.

Turn compensation decreases the spray rate on the inside of a turn while increasing the rate on the outside, ensuring consistent application across the entire width of the boom.

Minimized Overlap

Individual nozzle control minimizes overlap by controlling spray application at the individual nozzle level, not in 2.4- to 3.35-m (8- to 11-ft) section widths.

Compatibility: MY08-14 4730/4830 (100’ Boom only). All model years of R4030, R4038, R4044, R4045, R4060, 408R, 410R, 412R, 612R, 616R (100’ or 120’ Boom).

Utilizes Pulse Width Modulation technology in a traditional five nozzle setup to provide the right rate and droplet size across speeds and corners, and reduce duplicate coverage using individual nozzle control.

Consistent Droplet Sizing

Adds pulse width modulated spraying at a 15-HZ frequency through a single nozzle to provide more consistent pressures and droplet sizes over a wider range of ground speeds and application rates.

Improved Coverage Through Corners

Turn compensation decreases the spray rate on the inside of a turn while increasing the rate on the outside, ensuring consistent application across the entire width of the boom.

Minimized Overlap

Individual nozzle control minimizes overlap by controlling spray application at the individual nozzle level, not in 2.4- to 3.35-m (8- to 11-ft) section widths.

* With Individual Nozzle Control Pro and boom pressure recirculation, nozzle turrets located at the end of spray pipes only support two spray tips. Nozzle turrets continue to support up to five spray tips in all other areas.

Compatibility: MY18 and newer John Deere Sprayers.

Quality of application is critical. Avoid settling in the plumbing by keeping solution in motion with pressure recirculation, coupled with product reclaim and boom air purge. These features save precious time, product, and expense when rinsing and priming the boom while switching solutions.

saving 113.6L (30gal) each prime compared to a traditional setup. Product Reclaim transfers chemical from the boom to the solution tank to improve rinse functions and reduce chemical exposure when servicing nozzle bodies.

Recirculation mixes the solution and primes the boom before spraying to provide uniform distribution of product across the boom. Increased chemical agitation of the product in the boom also results in reduced nozzle clogging.

Recirculation when rinsing removes chemical which has settled out of suspension during spraying, resulting in a higher rinse water velocity in the spray pipe. Rinse water can also be utilized multiple times to further clean piping and reduce cleanout times.

BOOMTRACTM PRO 2 HEIGHT SENSING

Compatibility: MY18 and newer John Deere Sprayers.

Thanks to the addition of an inertia-monitoring sensor that helps correct for chassis roll, BoomTracTM Pro 2 offers up to 22% greater spray accuracy (composite score over a variety of terrains) compared to the previous BoomTracTM Pro system, and a five times increase in the amount of time the boom maintains its target height, which is a real plus in rough or hilly conditions.

Along with the improved accuracy and reduced drift, operators will appreciate having one less function to perform and one less thing to worry about.

Compatibility: MY14 & newer John Deere Sprayers.

Capture in-field weather information for on-the-go decision making. Accurate information is critical when making decisions surrounding product application, so it is important to use weather information that is specific to the operator and area being covered.

John Deere Mobile Weather displays five critical values needed when determining the effectiveness of product application.

Compatibility:

n TRUE WIND SPEED

n WIND DIRECTION

• Vehicle Lighting Packages: MY14 to 21 John Deere Sprayers.

• Boom Lighting Packages: MY14 & newer John Deere Sprayers.

Operators now work longer hours, starting early and finishing late. Clear visibility is essential for spraying and maneuvering. Various LED light packages can be added to the machine and boom to improve clarity and vision.

For sprayers with hood light modules, the Vehicle Lighting package adds 20 LED lights. The Boom Lighting Package includes four LED lights, two for spray pattern illumination and two to the the boom tip.

Compatibility: MY18 & newer John Deere Sprayers

When margins are tight and application windows are narrow, every dollar and every droplet need to work as hard as they can.

See & SprayTM Select uses a combination of cameras and processors to identify the colour green on fallow ground before activating only the nozzles necessary to apply a burst of herbicide, achieving a hit rate comparable to traditional broadcast spray. It also produces weed pressure maps to understand where weeds are occurring more frequently to inform field management decisions.

Efficiency

Reduce herbicide costs where it isn’t required, make fewer tendering stops, and cover more acres in a day.

You may save enough to justify applying a different chemistry while improving your ability to manage herbicide-resistant weeds. Research has shown that weeds sprayed with complex tank mixes and more than two modes of action are 83 times less likely to develop herbicide resistance.

See & SprayTM Variable Rate

* Annual license required for this feature.

Apply products where you need it to protect your crop and unlock yield potential*. This system works by detecting increases or decreases in green biomass and adjusts rates according to operator parameters. No need to enter a prescription, just enter your field, set your parameters, and go!

By avoiding inefficient traditional broadcast applications and spraying only when weeds are detected, you can reduce the applied volume of herbicide in fallow applications.

* Based on John Deere trials during the 2024 growing season in wheat in Kansas for nutrients and in canola in Canada for desiccation. Trial results reflected similar or improved yields compared to broadcast application. Individual results will vary.

Compatibility: MY20+ S700, & all X9 Combines.

Auto Unload takes Machine Sync one step further when unloading on the go. Utilizing a stereo camera on the auger and controller in addition to the Machine Sync software, it senses the grain levels inside the cart and automatically adjusts the grain cart’s position to distribute grain evenly. This allows the operator to focus on the operation of the combine. The system begins unloading at the operator's defined starting homepoint, recommended around the center of the cart or directly above the cart axle(s), then fills forward, followed by backward in the cart. The operator is required to turn off the auger when the cart is full.

Compatibility: All X9 Combines.

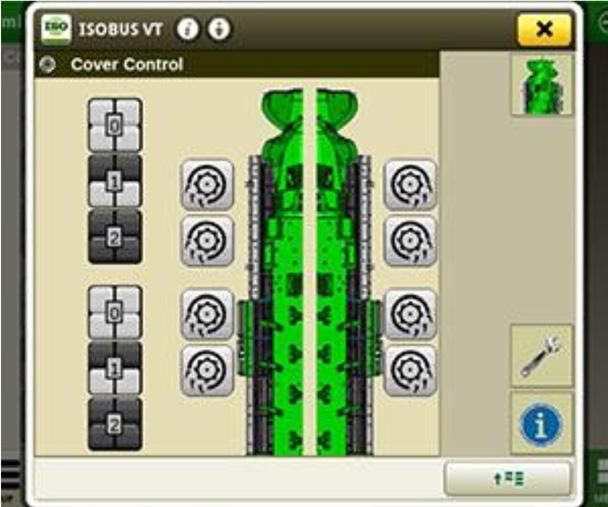

The remote separator grate covers allows an operator to close separator grates in dry small grain conditions remotely from the cab through the display. While harvesting, this establishes a more balanced machine capacity between the separator and cleaning shoe, resulting in an overall higher capacity combine. Changes can be made without manually installing or removing covers, which reduces downtime and allows for easier optimization.

Compatibility: All X9 Combines.

The John Deere concave with remote concave covers kit allows an operator to close off sections of the concaves on up to two sections remotely from the cab through the CommandCenter™ display. On the Gen 4 or G5 display, you can select different buttons to change the covers position depending on the crop conditions, removing the need to stop and add/remove covers or store them on the machine.

In addition to the remote covers, this kit includes a full set of new concaves in one of two configurations: all small wire, or a small/small/large mix.

Compatibility: S700 Combines.

The cross-auger shutoff Precision Upgrade on the S700 Series Combines fully unloads all grain out of the unloading auger anytime it is shut off from the cab. This makes sure all grain leaves the unloading auger, reducing weight in the auger and reducing wear and tear when turning the unloading auger on and off. The advantages of this system are reduced wear and tear on the auger, lower engagement loads, and reduced grain dribble loss in the field.

Compatibility: S700 Combines.

The S700 adjustable auger spout makes it easier to unload into grain carts and trailers by changing the pitch of the spout. The technology is integrated into the 4600 CommandCenter™ system and adjustable from the multi-function lever. A field transport position prevents grain from falling out when the auger is not in use.

Compatibility: MY12 & newer S-series Combines.

Operators are working into dark evening hours and the shorter the days get, the longer harvest goes on. Having better visibility keeps the machine productive and allows you to see the conditions in the field.

n The kit provides improved sight in low-visibility conditions.

n Outer cab work LED lights, rear discharge LED lights, and unloading auger LED light have brighter illumination for better visibility.

n Updated row finder LED light can be pointed directionally where the operator wants the light to shine.

This Precision Upgrade offers 18 LED lights in total that enhance your ability to see an expanded envelope around your combine, especially in the most challenging visual conditions. The kit is focused on the lights used while harvesting. Interested in learning more about the Precision Upgrades

587.713.4427 I precision@horizonagturf.com horizonagturf.com